Mercury 5, 6, 4 Service Manual

Service Manual Outline

Section 1 - Important Information

A - Specifications

B - Maintenance

C - General Information

D - Outboard Installation

Section 2 - Electrical

A - Ignition

B - Charging & Starting System

C - Timing, Synchronizing & Adjusting

D - Wiring Diagrams

Section 3 - Fuel System

A - Fuel Pump

B - Carburetor

C - Emissions

Section 4 - Powerhead

A - Cylinder Head

B - Cylinder Block/Crankcase

Section 5 - Mid-Section

A - Clamp/Swivel Brackets & Drive Shaft Housing

Section 6 - Lower Unit

Important Information

1

Electrical

2

Fuel System

3

Powerhead

4

Mid-Section

5

Lower Unit

6

Section 7 - Attachments/Control Linkage

A - Shift Linkage

B - Tiller Handle

Section 8 - Manual Starter

Section 9 - Color Diagrams

Attachment/Control Linkage

Manual Starter

Color Diagrams

7

8

9

9

90-857138R1 MAY 2000 Page iii

Notice

Throughout this publication, “Dangers”, “Warnings” and “Cautions” (accompanied by the International HAZARD Symbol

cerning a particular service or operation that may be hazardous if performed incorrectly or

carelessly. OBSERVE THEM CAREFULLY!

These “Safe t y A l e rts” alone cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus “Common Sense” operation,

are major accident prevention measures.

) are used to alert the mechanic to special instructions con-

DANGER

DANGER - Immediate hazards which WILL result in severe personal injury or death.

WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

Notice to Users of This Manual

This service manual has been written and published by the Service Department of Mercury

Marine to aid our dealers’ mechanics and company service personnel when servicing the

products described herein.

It is assumed that these personnel are familiar with the servicing procedures of these products, or like or similar products manufactured and marketed by Mercury Marine, that they

have been trained in the recommended servicing procedures of these products which includes the use of mechanics’ common hand tools and the special Mercury Marine or recommended tools from other suppliers.

We could not possibly know of and advise the service trade of all conceivable procedures

by which a service might be performed and of the possible hazards and/or results of each

method. We have not undertaken any such wide evaluation. Therefore, anyone who uses

a service procedure and/or tool, which is not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the products safety will be endangered by the

service procedure selected.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this

manual will be sent to all dealers contracted by us to sell and/or service these products.

It should be kept in mind, while working on the product, that the electrical system and ignition

system are capable of violent and damaging short circuits or severe electrical shocks. When

performing any work where electrical terminals could possibly be grounded or touched by

the mechanic, the battery cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed during service they should be covered

to protect against accidental entrance of foreign material which could enter the cylinders and

cause extensive internal damage when the engine is started.

90-857138R1 MAY 2000 Page i

It is important to note, during any maintenance procedure replacement fasteners must have

the same measurements and strength as those removed. Numbers on the heads of the metric bolts and on the surfaces of metric nuts indicate their strength. American bolts use radial

lines for this purpose, while most American nuts do not have strength markings. Mismatched or incorrect fasteners can result in damage or malfunction, or possibly personal

injury. Therefore, fasteners removed should be saved for reuse in the same locations whenever possible. Where the fasteners are not satisfactory for re-use, care should be taken to

select a replacement that matches the original.

Cleanliness and Care of Outboard Motor

A marine power product is a combination of many machined, honed, polished and lapped

surfaces with tolerances that are measured in the ten thousands of an inch/mm. When any

product component is serviced, care and cleanliness are important. Throughout this manual, it should be understood that proper cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is considered standard shop practice

even if not specifically stated.

Whenever components are removed for service, they should be retained in order. At the

time of installation, they should be installed in the same locations and with the same mating

surfaces as when removed.

Personnel should not work on or under an outboard which is suspended. Outboards should

be attached to work stands, or lowered to ground as soon as possible.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products de-

scribed in this manual.

Page Numbering

Two number groups appear at the bottom of each page. The example below is self-explanatory.

90-826883 R1 JANUARY 1998

Revision No. 1

EXAMPLE:

Page - 6A-7

Section Number

Month of Printing

Year of Printing

Page ii 90-857138R1 MAY 2000

Part of Section Letter

Page Number

SPECIFICATIONS

IMPORTANT INFORMATION

Section 1A - Specifications

Table of Contents

Specifications 1A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . Propeller Information Charts 1A-8. . . . . . . . . . . . . .

Specifications

Model 4/5/6 (4-Stroke)

HORSEPOWER

(kW)

OUTBOARD

WEIGHT

FUEL

Model 4

Model 5

Model 6

Short Shaft

Long Shaft

RECOMMENDED GASOLINE Automotive Unleaded

with a Minimum Pump Posted

4 hp (2.9 kW)

5 hp (3.7 kW)

6 hp (4.4 kW)

55 lbs. (25.0 kg)

57 lbs. (26.0 kg)

Octane Rating of 87

1

A

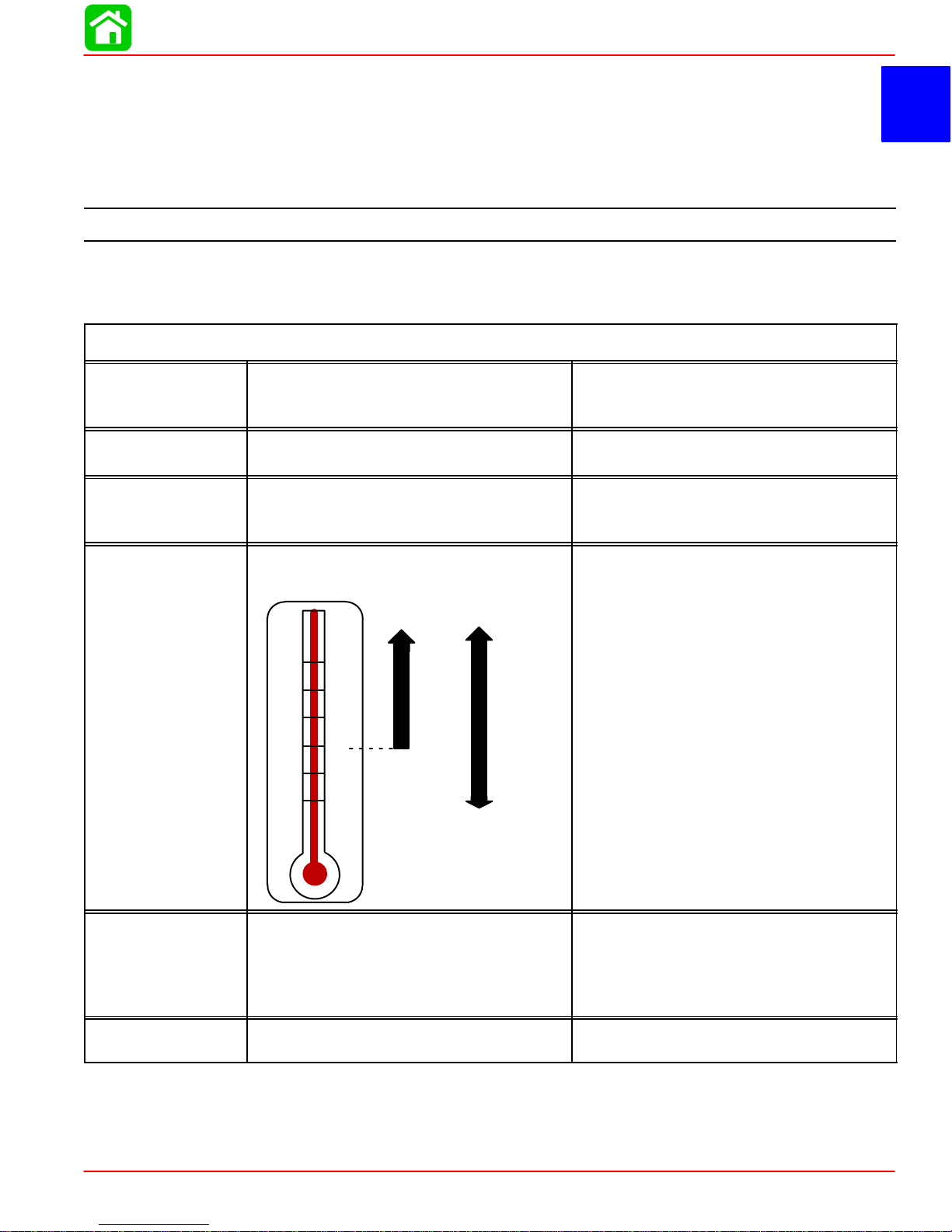

OIL

CHARGING

SYSTEM

Readings taken @

68°F (20°C).

ENGINE OIL CAPACITY

ENGINE OIL

SAE

25W-40

F°

+100

+80

+60

+40

+20

0

Alternator (Optional) Type:

Lighting Coil

Lighting Coil Resistance

Battery Charging Rectifier (Optional)

C°

+38

+27

+16

+4

–7

–18

SAE

10W-30

Either 15 fl oz. or 450 ml.

SAE 10W-30 viscosity oil is recom-

mended for use in all temperatures.

SAE 25W-40 viscosity oil may be used at

temperatures above 40° F (4° C).

Use Quicksilver 4-Cycle Marine Oil with

the proper viscosity for the expected

temperature in your area (see range

thermometer on left). If not available, use

a premium quality 4-cycle engine oil, cer-

tified to meet or exceed anyone of the

following American Petroleum Institute

(API) service classifications SH, SG, SF,

CF-4, CE, CD, CDll.

12 Volt 60 Watt

(Non Regulated Lighting Coil)

0.31 - 0.47 Ω (YEL/RED - YEL/RED)

2 Amperes (Rectified)

STARTING

SYSTEM

90-857138R1 MAY 2000 Page 1A-1

Manual Start Recoil Starter

SPECIFICATIONS

IGNITION

SYSTEM

Readings taken @

68°F (20°C).

CARBURETOR

Type

Spark Plug:

Type

Gap

Hex Size

Torque

Firing Order

Ignition Timing: (Fixed)

Capacitor Charge Coil Resistance

Trigger Coil Resistance

Ignition Coil Resistance:

Primary

Secondary (W/o Boots)

Spark Plug Boot

Engine Speed Limiter

Oil Pressure Switch (Red Light)

Idle rpm (Out Of Gear)

Idle rpm (In Forward Gear)

Wide Open Throttle rpm (WOT)

4/5 (1999 & 2000)

4/5/6 (2001 & Newer)

Pilot (Idle Mixture) Screw

4/5/6 (1999 & 2000)

European Models Only

2001 & Newer

4

5

6

All Other Models Non-Adjustable

Venturi Bore Diameter

4/5

6

Main Jet Size

4/5 (1999 & 2000)

4 (2001 & Newer)

5 (2001 & Newer)

6 (2000 & Newer)

4 (Bodensee)

5 (Bodensee)

6 (Bodensee)

Pilot Jet

4 (1999 & 2000)

5 (1999 & 2000)

4/5 (2001 & Newer)

6 (2000 & Newer)

4/5 (Bodensee)

6 (Bodensee)

Capacitor Discharge Ignition

NGK DCPR6E

0.035 in. (0.9 mm)

5/8 in. (16 mm)

13 lb-ft. (17.5 Nm)

1

25° ± 1° B.T.D.C.

95 - 134 Ω (WHT - BLK/RED)

149 - 243 Ω (RED/WHT - BLK)

0.02 - 0.38 Ω

3000 - 4400 Ω

3500 - 5200 Ω

6300 ± 200 RPM

Continuity Below 3.5 psi ± 0.7 psi

(24.5 ± 5 kPa)

1300 ± 50 rpm

1100 ± 50 rpm

4500 -5500

5000 - 6000

3 ± 1/2 Turns Out

2-1/8 ± 1/2 Turns Out

1-1/2 ± 1/2 Turns Out

2-3/4 ± 1/2 Turns Out

13.5 mm

15 mm

#70

#58

#65

#75

#55

#62

#68

#40

#42

#38

#45

#38

#42

Float Height

Page 1A-2 90-857138R1 MAY 2000

0.35 - 0.39 in. (9 - 10 mm)

SPECIFICATIONS

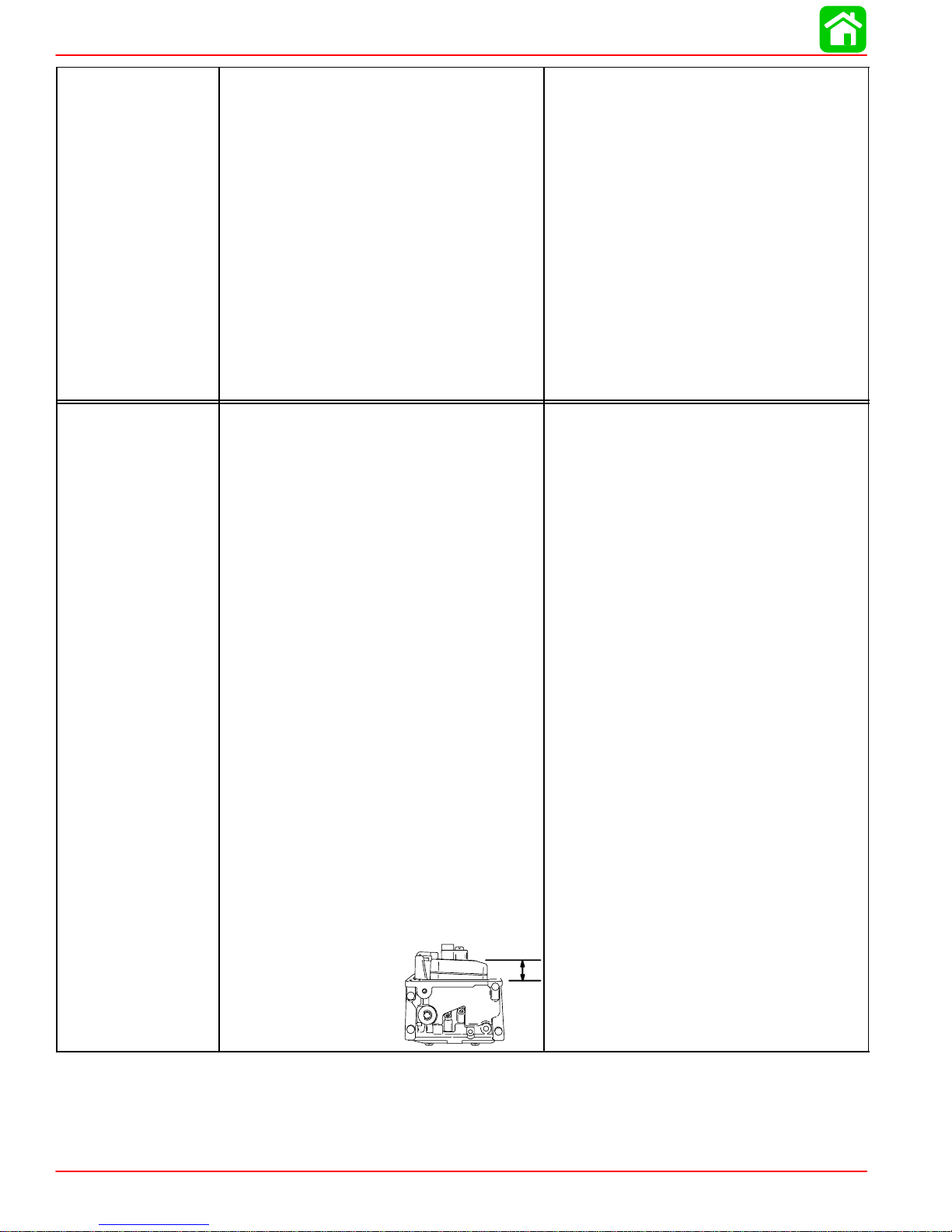

Fuel Pump Type

External (Plunger/Diaphragm)

Fuel Pump:

FUEL

SYSTEM

CYLINDER

BLOCK

Pressure

Plunger Stroke

Diaphragm Stroke

Fuel Tank Capacity

Type

Displacement

Number of Cylinders

2.5 - 5.0 psi (17 - 35 kPa)

0.059 in. (1.5 mm)

0.059 in. (1.5 mm)

3.2 US Gallons

4 Stroke Cycle – Over Head Valve

7.5 cu. in. (123 cc)

1

STROKE Length 1.77 in. (45 mm)

Diameter

CYLINDER

BORE

PISTON

PISTON

CLEARANCE

Standard

Oversize-0.020 in. (0.50 mm)

Taper/Out of Round Maximum

Bore Type

Piston Type

O.D. at Skirt

Standard

Oversize-0.020 in. (0.50 mm)

Piston to Cylinder Clearance

Piston Clearance Limit

2.323 in. (59.00 mm)

2.343 in. (59.50 mm)

0.003 in. (0.076 mm)

Steel

Aluminum

2.321 in. (58.960 mm)

2.341 in. (59.460 mm)

0.001 - 0.002 in.

(0.020 - 0.055 mm)

0.006 in. (0.15 mm)

RINGS

COMPRESSION

RATIO

PISTON PIN

CONNECTING

ROD

Ring End Gap (Installed)

Top

Middle

Bottom (Oil Ring)

Side Clearance:

Top

Middle

Bottom (Oil Ring)

Compression Ratio

With Decompression

4/5 (1999 & 2000)

4/5 (2001 & Newer)

6 (2000 & Newer)

Outer Diameter

Diameter of Piston Pin Hole

Clearance between Piston Pin and

Piston Pin Hole

Oil Clearance (Big End)

Side Clearance (Big End)

Small End Inside Diameter

0.006 - 0.014 in. (0.15 - 0.35 mm)

0.012 - 0.020 in. (0.30 - 0.50 mm)

0.008 - 0.016 in. (0.20 - 0.40 mm)

0.0015 - 0.003 in. (0.04 - 0.08 mm)

0.0012 - 0.003 in. (0.03 - 0.07 mm)

0.0004 - 0.007 in. (0.01 - 0.18 mm)

8.5:1

42 psi ± 14 psi (0.29 ± 0.1 MPa)

9.5:1

42 psi ± 14 psi (0.29 ± 0.1 MPa)

0.6299 in. (16.00 mm)

0.6300 in. (16.002 mm)

0.0001 - 0.0005 in.

(0.002 mm - 0.012 mm)

0.002 - 0.003 in. (0.053 - 0.079 mm)

0.008 - 0.016 in.

(0.20 - 0.40 mm)

0.6303 in. (16.01 mm)

90-857138R1 MAY 2000 Page 1A-3

SPECIFICATIONS

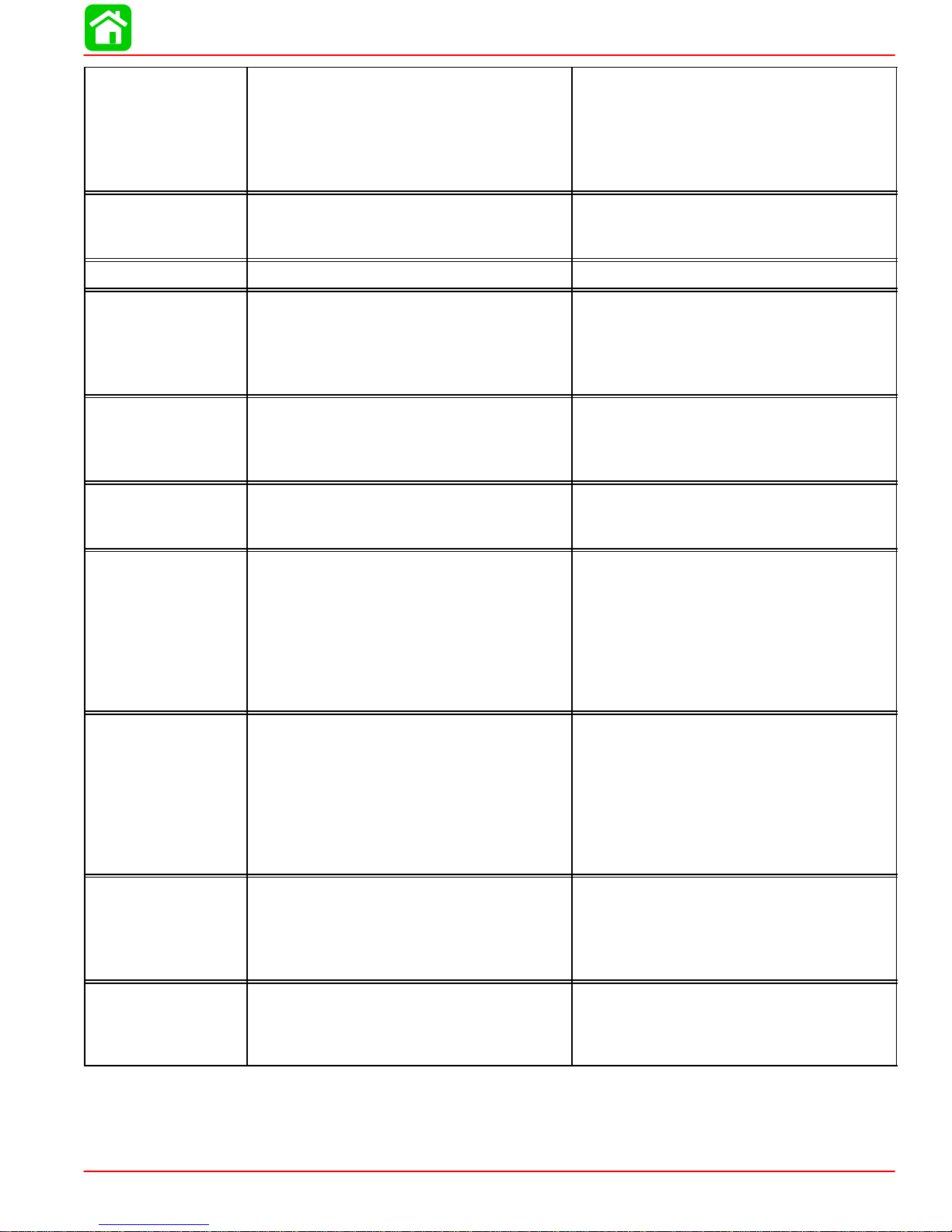

CRANKSHAFT

CAMSHAFT

Crankshaft Runout

Diameter of Crank Pin (A)

Outer Diameter of Crankshaft in Oil

Pan Bearing (B)

A

Camshaft Dimensions

Intake/Exhaust “A”

4 (1999 & 2000)

5 (1999 & 2000)

6 (2000)

4/5/6 (2001 & Newer)

Bearing Diameter “B”

B

B

Less than 0.002 in. (0.05 mm)

1.179 - 1.177 in.

(29.94 - 29.91 mm)

0.983 - 0.982 in.

(24.98 - 24.96 mm)

A

0.993 in. (25.24 mm)

1.047 in. (26.59 mm)

1.115 in. (28.33 mm)

1.115 in. (28.33 mm)

0.550 in. (13.98 mm)

OIL PAN

Inside Diameter of Oil Pan Bearing:

Crankshaft “A”

Camshaft “B”

B

A

Crankshaft to Oil Pan Bearing

Clearance

Camshaft to Oil Pan Bearing

Clearance

0.985 in. (25.01 mm)

0.5515 in. (14.01 mm)

0.0006 - 0.0015 in. (0.015 - 0.040 mm)

0.0008 - 0.002 in. (0.02 - 0.05 mm)

Page 1A-4 90-857138R1 MAY 2000

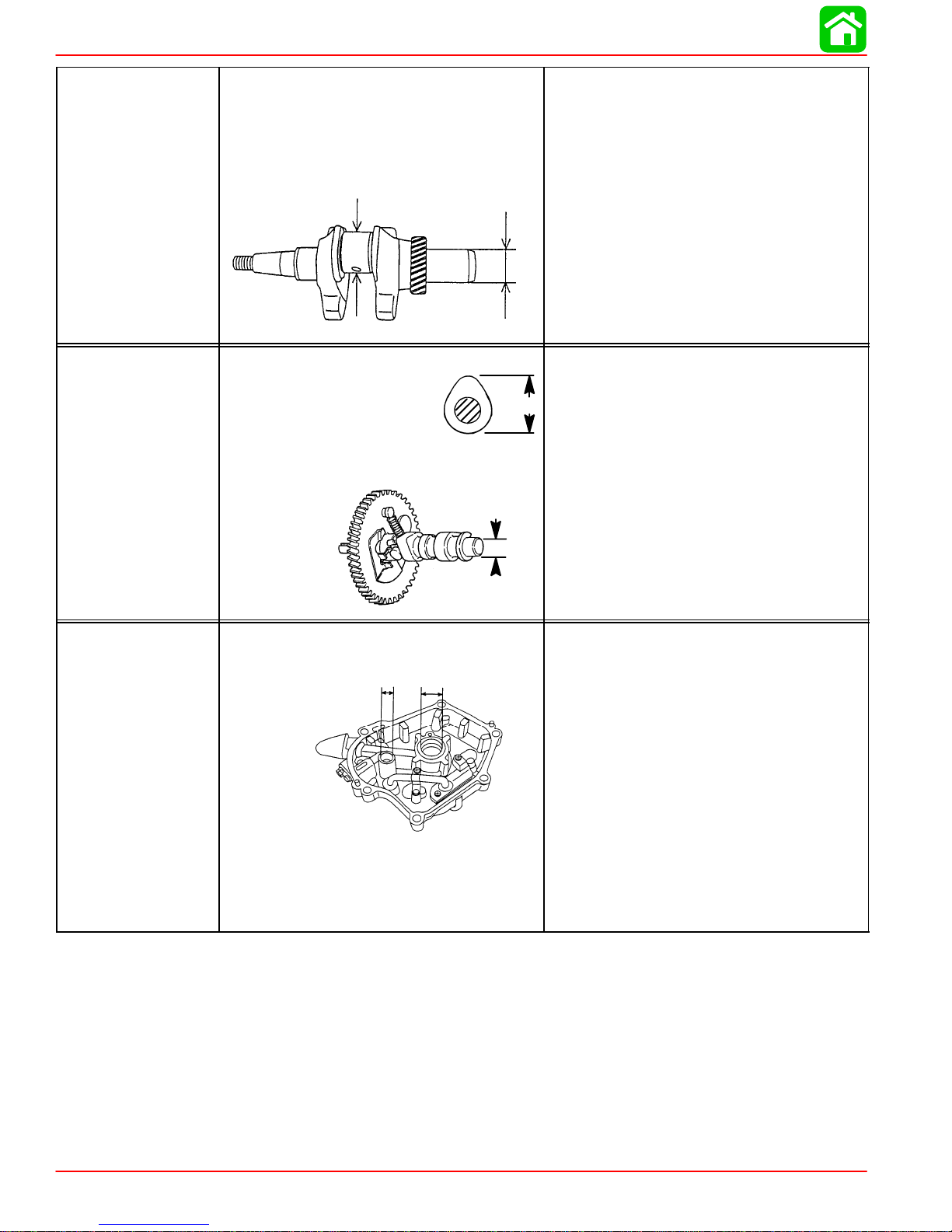

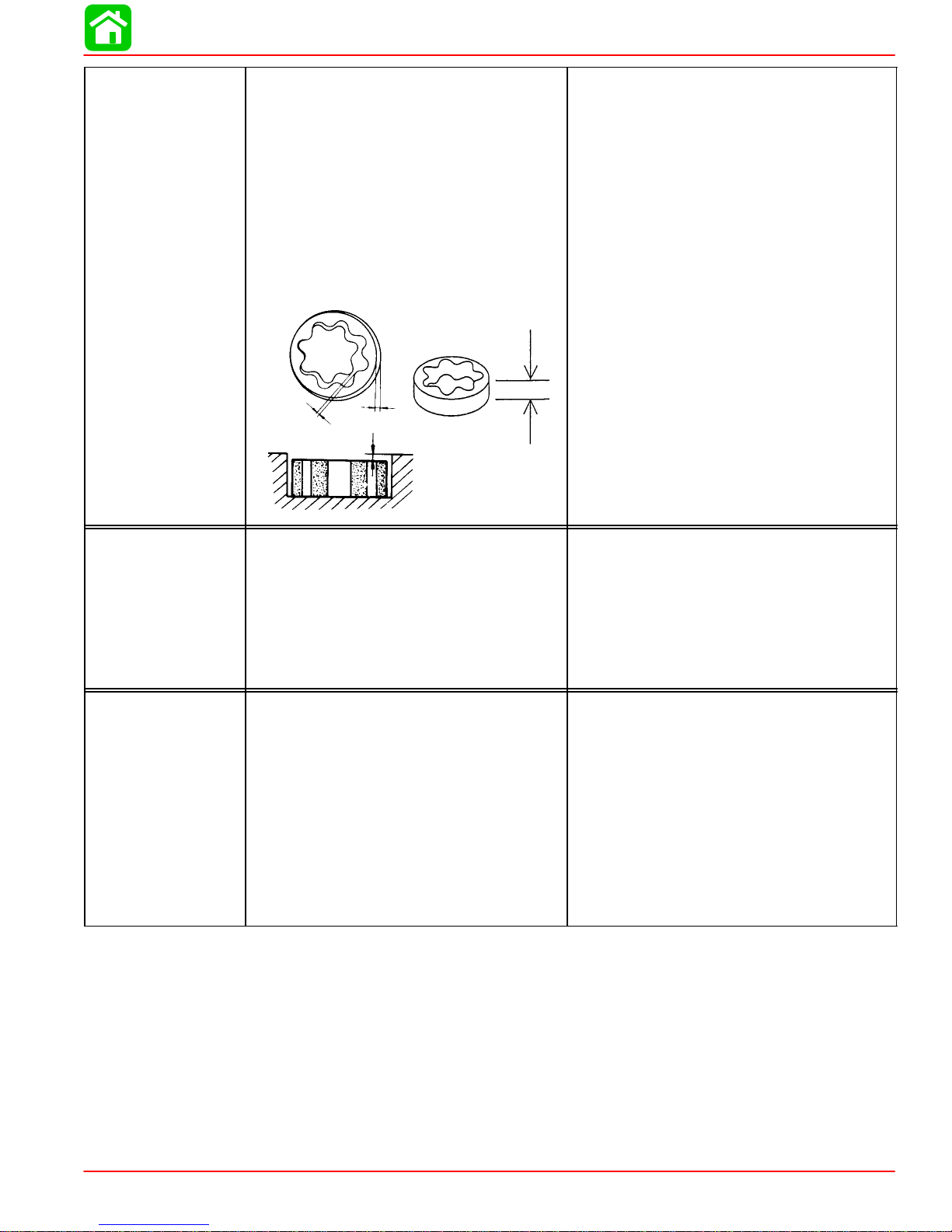

VALVE SPRING

Free Length (Intake/Exhaust) “a”

Tilt Limit “b” (Intake/Exhaust)

4/5 (1999)

4/5/6 (2000 & Newer)

b

a

Compressed Pressure (Installed)

Intake/Exhaust:

Closed Height 0.965 in. (24.4 mm)

4/5 (1999 & 2000)

6 (2000)

4/5/6 (2001 & Newer)

Open Height 0.709 in. (17.4 mm)

4/5 (1999 & 2000)

6 (2000)

4/5/6 (2001 & Newer)

Direction of Winding (Intake/Exhaust)

SPECIFICATIONS

a = 1.260 in. (32.0 mm)

b = 0.044 in. (1.12 mm)

a = 1.378 in. (35.0 mm)

b = 0.044 in. (1.12 mm)

17 lbf. (7.7 kgf)

24 lbf. (10.8 kgf)

24 lbf. (10.8 kgf)

31 lbf. (14.0 kgf)

39.4 lbf. (17.9 kgf)

39.4 lbf. (17.9 kgf)

Right Hand

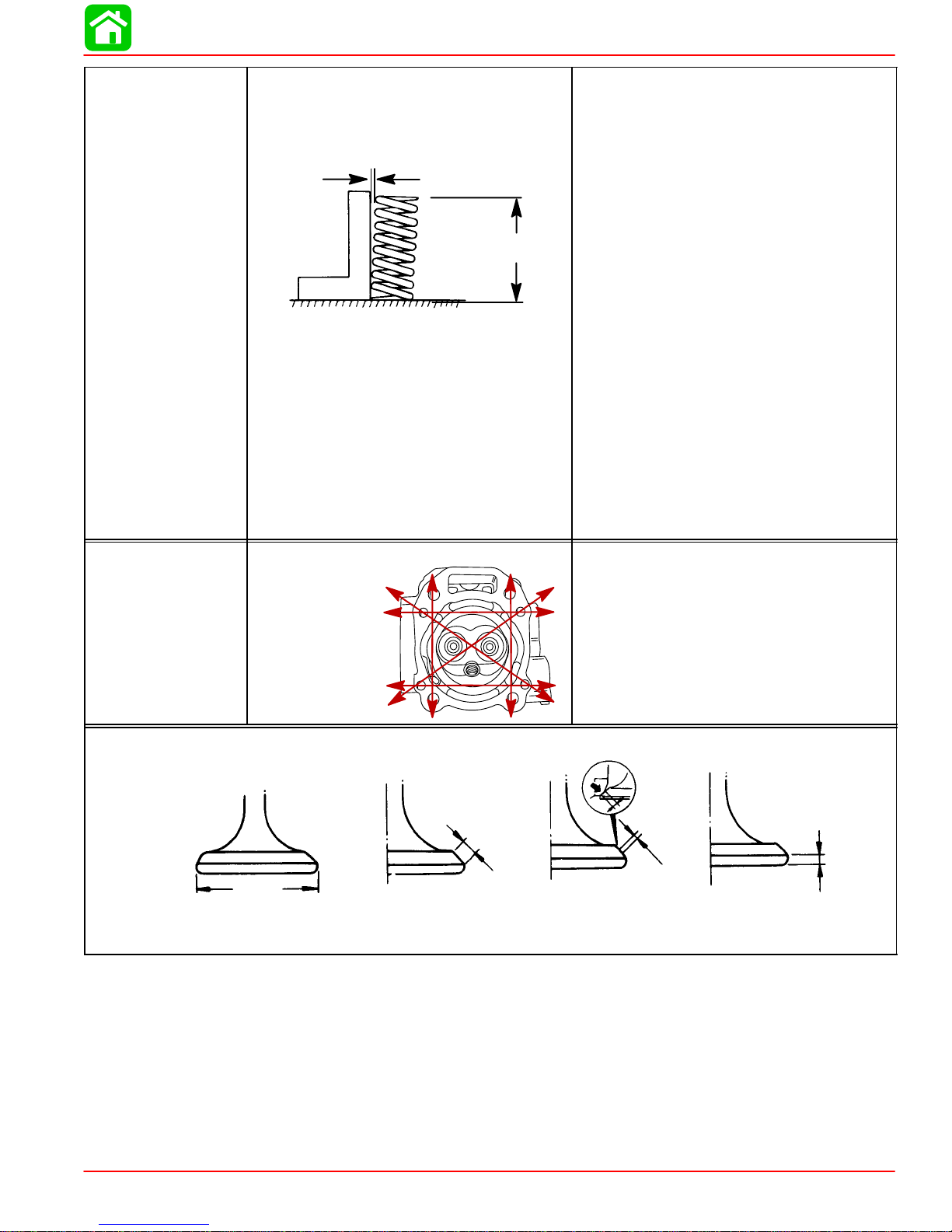

CYLINDER HEAD

Head Diameter Face Width

Warp Limit *

* Lines indicate

straight edge

measurement

“A”

Valve Dimensions

“B”

Seat Width

0.0012 in. (0.03 mm)

“C”

“D”

Margin Thickness

90-857138R1 MAY 2000 Page 1A-5

SPECIFICATIONS

VALVES

Valve/Valve Seat/Valve Guides:

Valve Clearance (cold)

Intake

Exhaust

Valve Dimensions:

“A” Head Diameter

Intake

Exhaust

“B” Face Width

Intake

Exhaust

“C” Seat Width

Intake

Exhaust

“D” Margin Thickness

Intake

Exhaust

Stem Outside Diameter

Intake

Exhaust

Guide Inside Diameter

Intake

Exhaust

Stem To Guide Clearance

Intake

Exhaust

Stem Run-out Limit (max.)

0.002 - 0.005 in. (0.06 - 0.14 mm)

0.004 - 0.007 in. (0.11 - 0.19 mm)

0.980 - 0.988 in. (24.9 - 25.1 mm)

0.941 - 0.949 in. (23.9 - 24.1 mm)

0.102 in. (2.6 mm)

0.102 in. (2.6 mm)

0.031 in. (0.8 mm)

0.031 in. (0.8 mm)

0.028 in. (0.7 mm)

0.047 in. (1.2 mm)

0.216 in. (5.48 mm)

0.214 in. (5.44 mm)

0.2165 in. (5.5 mm)

0.2165 in. (5.5 mm)

0.0008 - 0.0017 in. (0.020 - 0.044 mm)

0.0018 - 0.0028 in. (0.045 - 0.072 mm)

0.0006 in. (0.016 mm)

THERMOSTAT

Valve Opening Temperature

Full Open Temperature

Valve Lift (Minimum)

122°F - 129°F (50°C - 54°C)

145°F - 153°F (63°C - 67°C)

0.12 in. (3 mm)

Page 1A-6 90-857138R1 MAY 2000

SPECIFICATIONS

LUBRICATION

SYSTEM

Pump Type

Engine Oil Pressure* (Warm Engine):

@ 1300 rpm

@ 5000 rpm

Engine Oil Pan Capacity

Oil Pump Clearance:

Inner Rotor to Outer Rotor “A”

Outer Rotor to Body “B”

Rotor to Body (Side) “C”

Height of Outer Rotor “D”

Relief Valve Operating Pressure*

D

A

B

C

Trochoid

4.0 psi (0.03 MPa) Minimum

21.0 psi (0.15 MPa) Minimum

0.95 pt (450 ml)

0.006 in. (0.15 mm) or Less

0.005 - 0.008 in. (0.12 - 0.20 mm)

0.0008 - 0.0028 in. (0.02 - 0.07 mm)

0.236 in. (5.99 mm)

31 - 40 psi (2.2 - 2.8 kg/cm

2

)

216 - 275 kPa

Transom Height - Short Shaft

- Long Shaft

Steering Pivot Range

MID-SECTION

Tilt Pin Positions

Total Tilt Angle

Tilt Angle

Shallow Water Tilt Angle

Allowable Transom Thickness

Gear Ratio

Gearcase Capacity

Lubricant Type

Quicksilver Gear Lube-Premium Blend

Forward Gear

Number of Teeth

GEAR HOUSING

(2.15:1)

Pinion Gear

Number of Teeth

Pinion Height

Forward Gear Backlash

Water Pressure:

@ 1300 rpm (Idle) Neutral

@ 5000 rpm

* Oil pressure specifications listed were obtained with oil at 165°F (75°C)

Water pressure readings will vary with thermostat operation.

17 in. (38 cm)

22 in. (51 cm)

78°

6

75°

4° - 24°

32.5°

2.2 in. (55 mm)

2.15:1

6.5 fl oz (195 mL)

28 Spiral/Bevel

13 Spiral/Bevel

Floating

No Adjustment

2.3 - 3.6 psi (16 - 25 kPa)

8 - 15 psi (55 - 103.5 kPa)

90-857138R1 MAY 2000 Page 1A-7

SPECIFICATIONS

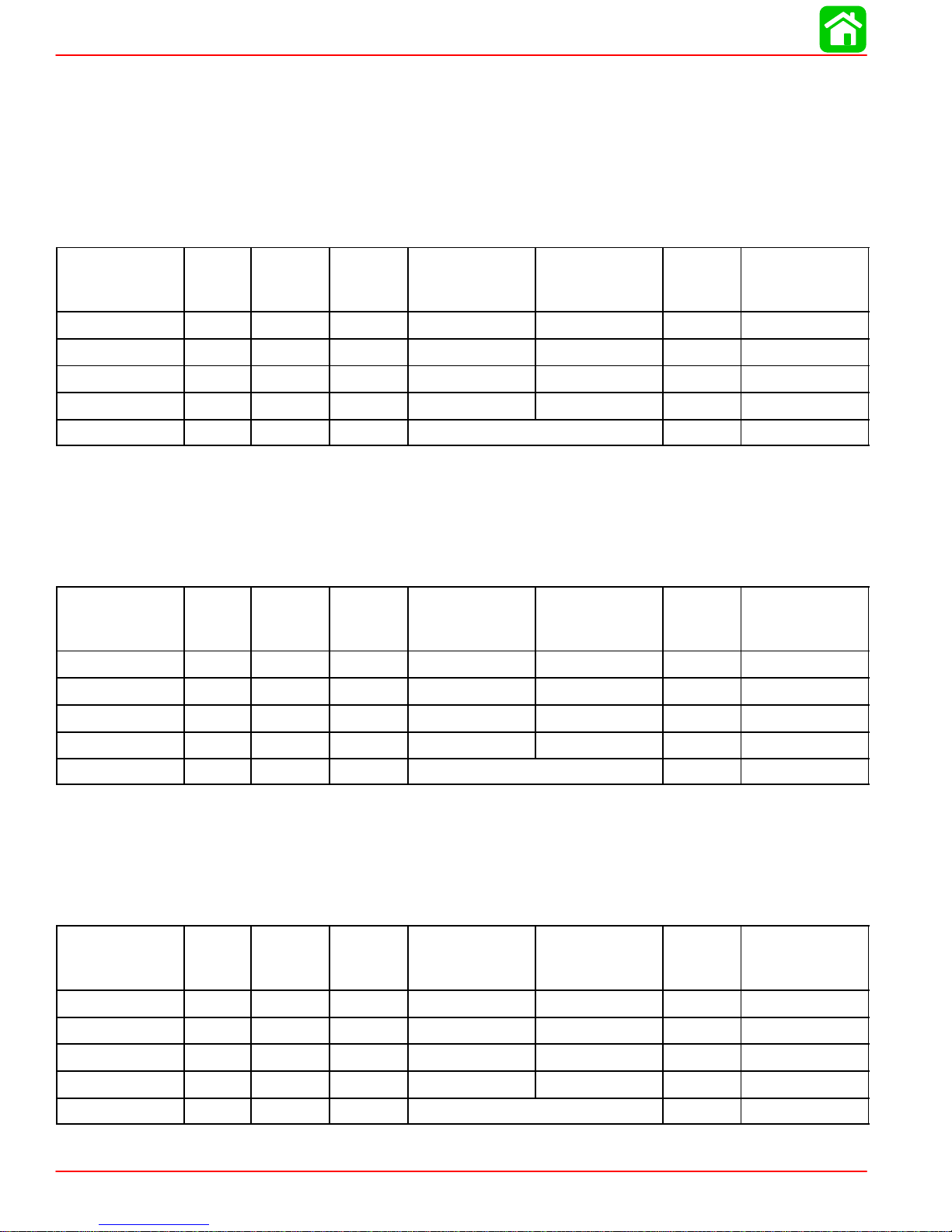

Propeller Information Charts

Mercury/Mariner 4 (4-Stroke)

Wide Open Throttle RPM : 5000-6000

Recommended Transom Heights : 15”, 20”

Right Hand Rotation Standard

Gear Reduction : 2.15:1

Approx.

No. of

Diameter

8-3/8” 9” 3 Alum Up to 400 Up to 14’ 12-18 48-812950T1

8-3/8” 8” 3 Alum 300-500 13-15’ 10-16 48-812950

8-3/8” 7” 3 Alum 400-700 14-16’ 8-13 48-812949*

8-3/8” 6” 3 Alum 600+ 15’+ 1-11 48-16144

8-3/8” 6” 3 Alum Sailboat 1-8 48-812951A1

Pitch

Blades

Material

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Part Number

Mercury/Mariner 5 (4-Stroke)

Wide Open Throttle RPM : 5000-6000

Recommended Transom Heights : 15”, 20”

Right Hand Rotation Standard

Gear Reduction : 2.15:1

Approx.

No. of

Diameter

8-3/8” 9” 3 Alum Up to 500 Up to 14’ 12-18 48-812950T1

8-3/8” 8” 3 Alum 400-700 13-15’ 10-16 48-812950*

Pitch

Blades

Material

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Part Number

Propeller

Propeller

8-3/8” 7” 3 Alum 500-900 14-16’ 8-13 48-812949

8-3/8” 6” 3 Alum 600+ 15’+ 1-11 48-16144

8-3/8” 6” 3 Alum Sailboat 1-8 48-812951A1

Mercury/Mariner 6 (4-Stroke)

Wide Open Throttle RPM : 5000-6000

Recommended Transom Heights : 15”, 20”

Right Hand Rotation Standard

Gear Reduction : 2.15:1

Approx.

No. of

Diameter

8-3/8” 9” 3 Alum Up to 500 Up to 14’ 14-21 48-812950T1

8-3/8” 8” 3 Alum 500-800 13-15’ 12-18 48-812950*

8-3/8” 7” 3 Alum 600-1100 14-16’ 10-14 48-812949

8-3/8” 6” 3 Alum 800+ 15’+ 1-12 48-16144

8-3/8” 6” 3 Alum Sailboat 1-9 48-812951A1

*Standard propeller shipped with outboard.

Pitch

Blades

Material

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Part Number

Propeller

Page 1A-8 90-857138R1 MAY 2000

MAINTENANCE

IMPORTANT INFORMATION

Section 1B - Maintenance

Table of Contents

Table of Contents 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubricant Capacity 1B-1. . . . . . . . . . . . . . .

Special Tools 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quicksilver Lubricant/Sealant 1B-2. . . . . . . . . . . . . . . .

Inspection and Maintenance Schedule 1B-3. . . . . . . . . . .

Before Each Use 1B-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

After Each Use 1B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Every 100 Hours of Use or Once Yearly,

Whichever Occurs First 1B-3. . . . . . . . . . . . . . . . . . . . .

Flushing The Cooling System 1B-4. . . . . . . . . . . . . . . . . . .

Fuel System 1B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Line Inspection 1B-4. . . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel Filter 1B-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Corrosion Control Anode 1B-5. . . . . . . . . . . . . . . . . . . . . . .

Spark Plug Inspection 1B-5. . . . . . . . . . . . . . . . . . . . . . . . . .

1

B

Lubrication Points 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Engine Oil 1B-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Capacity 1B-8. . . . . . . . . . . . . . . . . . . . . . . . .

Oil Changing Procedure 1B-8. . . . . . . . . . . . . . . . . . . . .

Oil Filling 1B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubrication 1B-9. . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubricant Capacity 1B-9. . . . . . . . . . . . . . .

Draining Gear Case 1B-9. . . . . . . . . . . . . . . . . . . . . . . .

Checking Lubricant Level and Refilling

Gear Case 1B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage Preparations 1B-10. . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System 1B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protecting External Engine Components 1B-10. . . . .

Protecting Internal Engine Components 1B-11. . . . . .

Gear Case 1B-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Outboard for Storage 1B-11. . . . . . . . . . . .

Specifications

Gear Case Lubricant Capacity

Gear Case Ratio Capacity

2.15:1 6.6 fl oz. (195.0 ml)

Special Tools

1. Grease Gun 91-37299A1

90-857138R1 MAY 2000 Page 1B-1

MAINTENANCE

Quicksilver Lubricant/Sealant

1. Quicksilver Anti-Corrosion Grease P/N 92-850735A1

2. 2-4-C Marine Lubricant with Teflon P/N 92-850736A1

3. SAE 10-30W Motor Oil P/N 92-802833A1

4. Quicksilver Gear Lubricant P/N 92-19007A24

Page 1B-2 90-857138R1 MAY 2000

Inspection and Maintenance Schedule

Before Each Use

1. Check engine oil level.

2. Visually inspect the fuel system for deterioration or leaks.

3. Check outboard for tightness on transom.

4. Check propeller blades for damage.

After Each Use

1. Flush out the outboard cooling system if operating in salt or polluted water.

2. Wash off all salt deposits and flush out the exhaust outlet of the propeller and gear case

with fresh water if operating in salt water.

Every 100 Hours of Use or Once Yearly, Whichever Occurs First

1. Lubricate all lubrication points. Lubricate more frequently when used in salt water.

2. Change engine oil. The oil should be changed more often when the engine is operated

under adverse conditions such as extended trolling.

MAINTENANCE

3. Inspect and clean spark plugs.

4. Check fuel line filter for contaminants.

5. Check corrosion control anode. Check more frequently when used in salt water.

6. Drain and replace gear case lubricant.

7. Lubricate splines on the drive shaft.

8. Check tightness of bolts, nuts, and other fasteners.

9. Replace water pump impeller.

These items should be serviced by an authorized dealer.

∗

∗

∗

90-857138R1 MAY 2000 Page 1B-3

MAINTENANCE

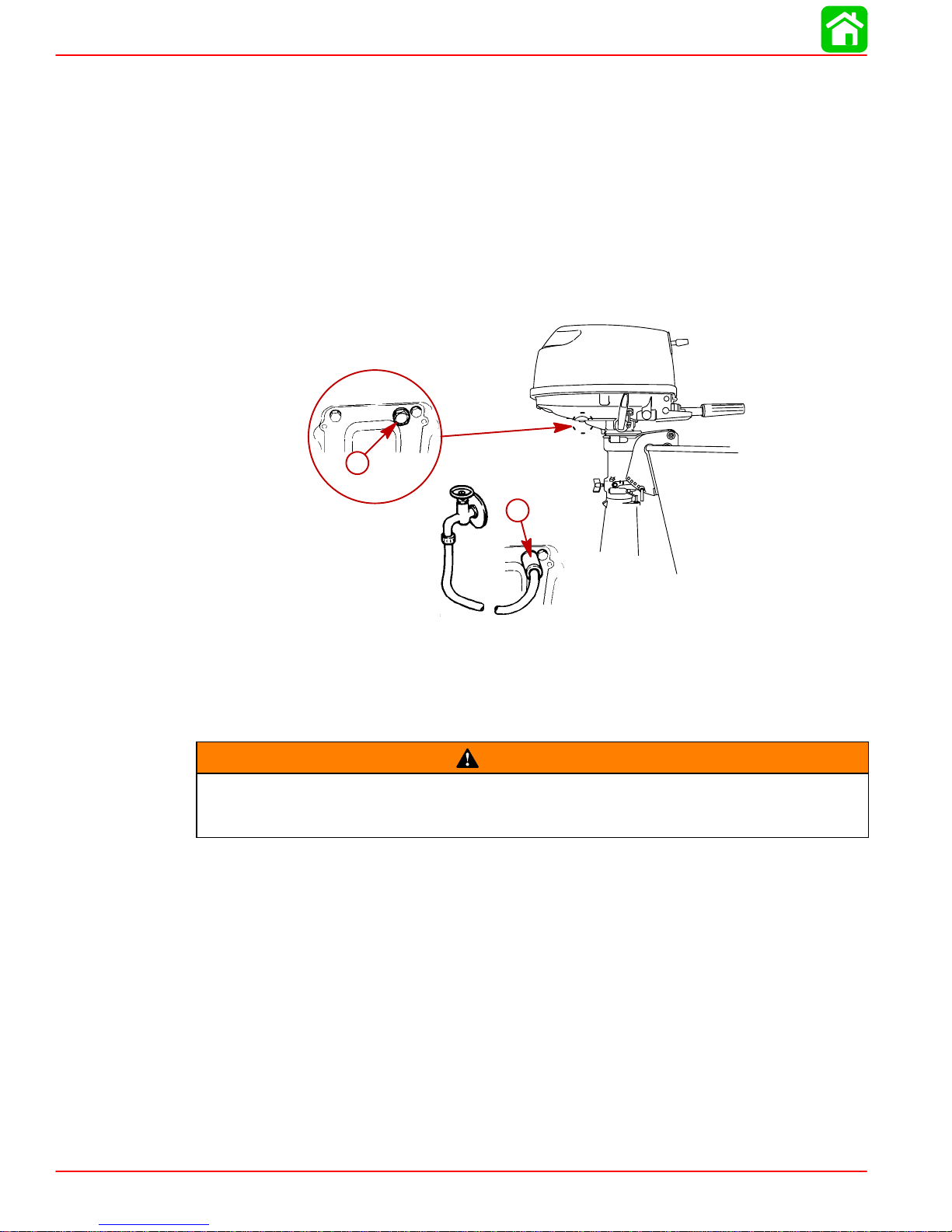

Flushing The Cooling System

Flush the internal water passages of the outboard with fresh water after each use in salt,

polluted, or muddy water. This will help prevent a buildup of deposits from clogging the internal water passages.

NOTE: Do not run the engine while flushing the cooling system.

1. Remove plug and gasket and thread-in hose coupling.

2. Attach a wate r hose to the hose coupling. T urn on the water gently and flush the cooling

system for 3 to 5 minutes.

3. Remove the thread-in hose coupling and reinstall plug and gasket.

a

Fuel System

Avoid serious injury or death from gasoline fire or explosion. Carefully follow all

fuel system service instructions. Always stop the engine and DO NOT smoke or allow open flames or sparks in the area while servicing any part of the fuel system.

Before servicing any part of the fuel system, stop engine and disconnect the battery . Drain

the fuel system completely. Use an approved container to collect and store fuel. Wipe up

any spillage immediately. Material used to contain spillage must be disposed of in an approved receptacle. Any fuel system service must be performed in a well ventilated area. Inspect any completed service work for sign of fuel leakage.

b

a- Plug and Gasket

b- Hose Coupling

WARNING

Fuel Line Inspection

Visually inspect the fuel line and primer bulb for cracks, swelling, leaks, hardness or other

signs of deterioration or damage. If any of these conditions is found, the fuel line or primer

bulb must be replaced.

Engine Fuel Filter

Inspect the fuel line filter. If the filter appears to be contaminated, remove and replace.

Page 1B-4 90-857138R1 MAY 2000

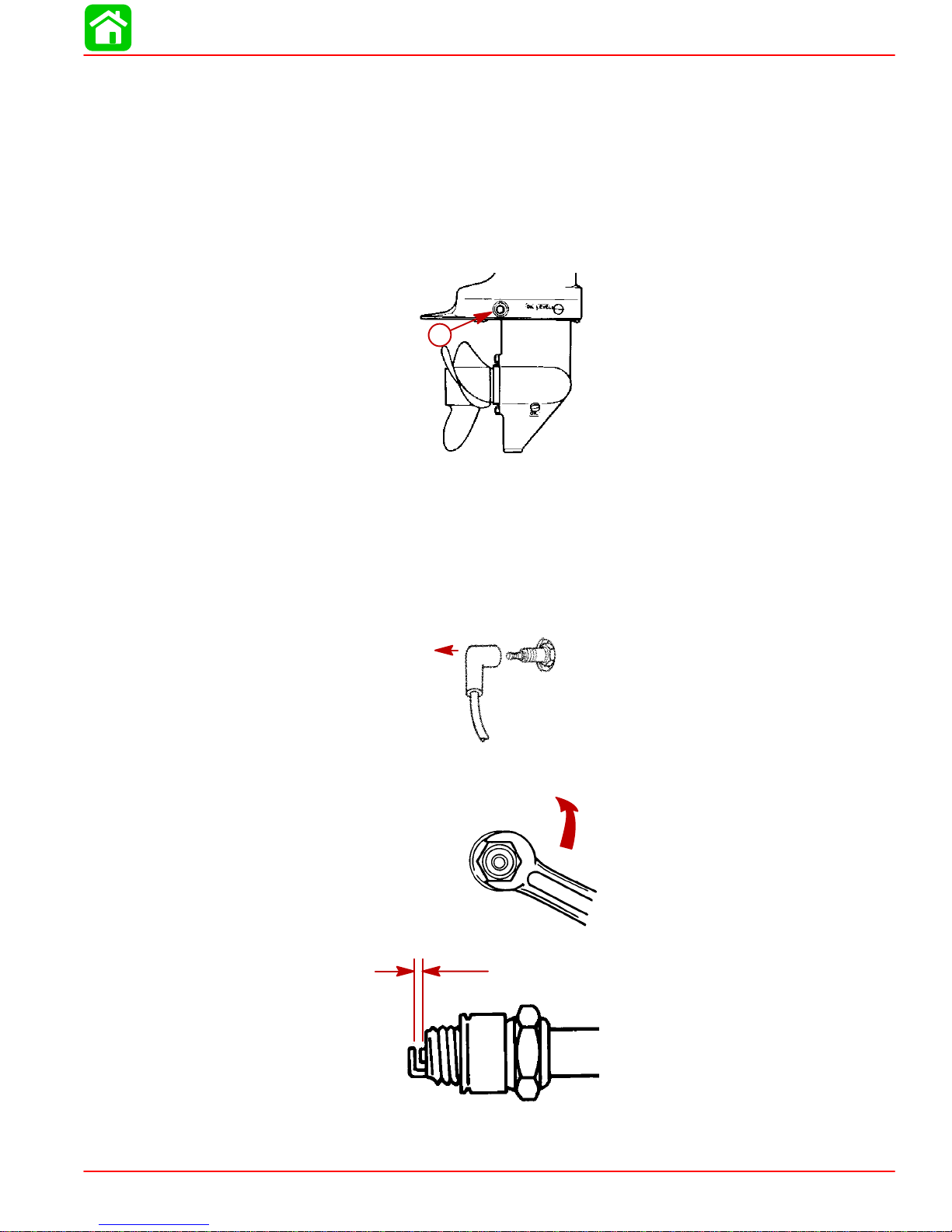

Corrosion Control Anode

Your outboard has a corrosion control anode installed to the gear case. An anode helps protect the outboard against galvanic corrosion by sacrificing its metal to be slowly eroded instead of the outboard metals.

The anode requires periodic inspection especially in salt water which will accelerate the erosion. To m a i ntain this corr o s i o n p r o t e c t i o n , a l ways replace the anode before it is completely

eroded. Never paint or apply a protective coating on the anode as this will reduce effectiveness of the anode.

a- Anode

MAINTENANCE

a

Spark Plug Inspection

Inspect spark plugs at the recommended intervals.

1. Remove the spark plug leads by twisting the rubber boots slightly and pull off.

2. Remove the spark plugs to inspect and clean. Replace spark plug if electrode is worn

or the insulator is rough, cracked, broken, blistered or fouled.

3. Set the spark plug gap. See Specification Chart in General Information Section.

4. Before reinstalling spark plugs, clean away dirt on the spark plug seats. Install plugs fin-

ger tight, and tighten 1/4 turn or torque to 13 lb-ft (17.5 Nm).

90-857138R1 MAY 2000 Page 1B-5

MAINTENANCE

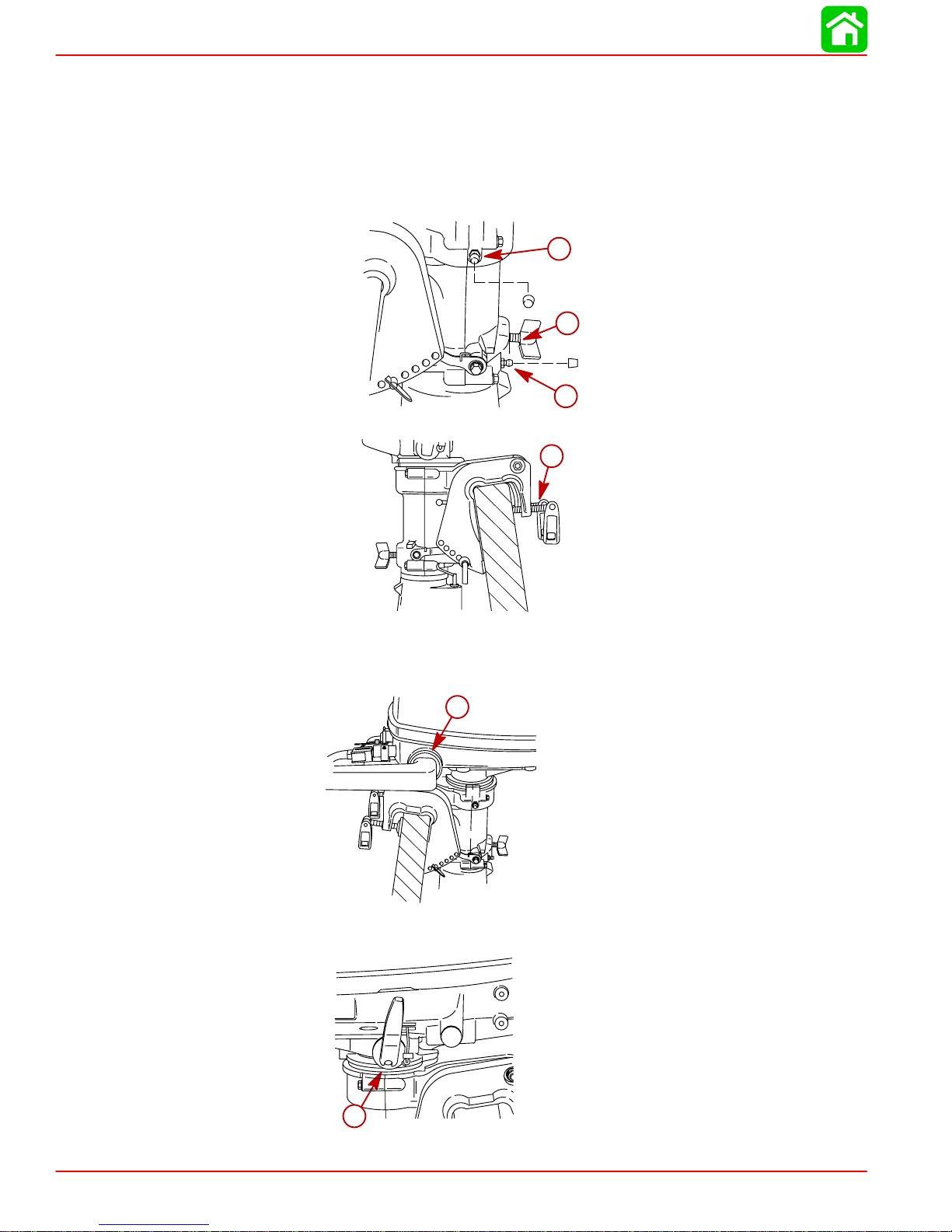

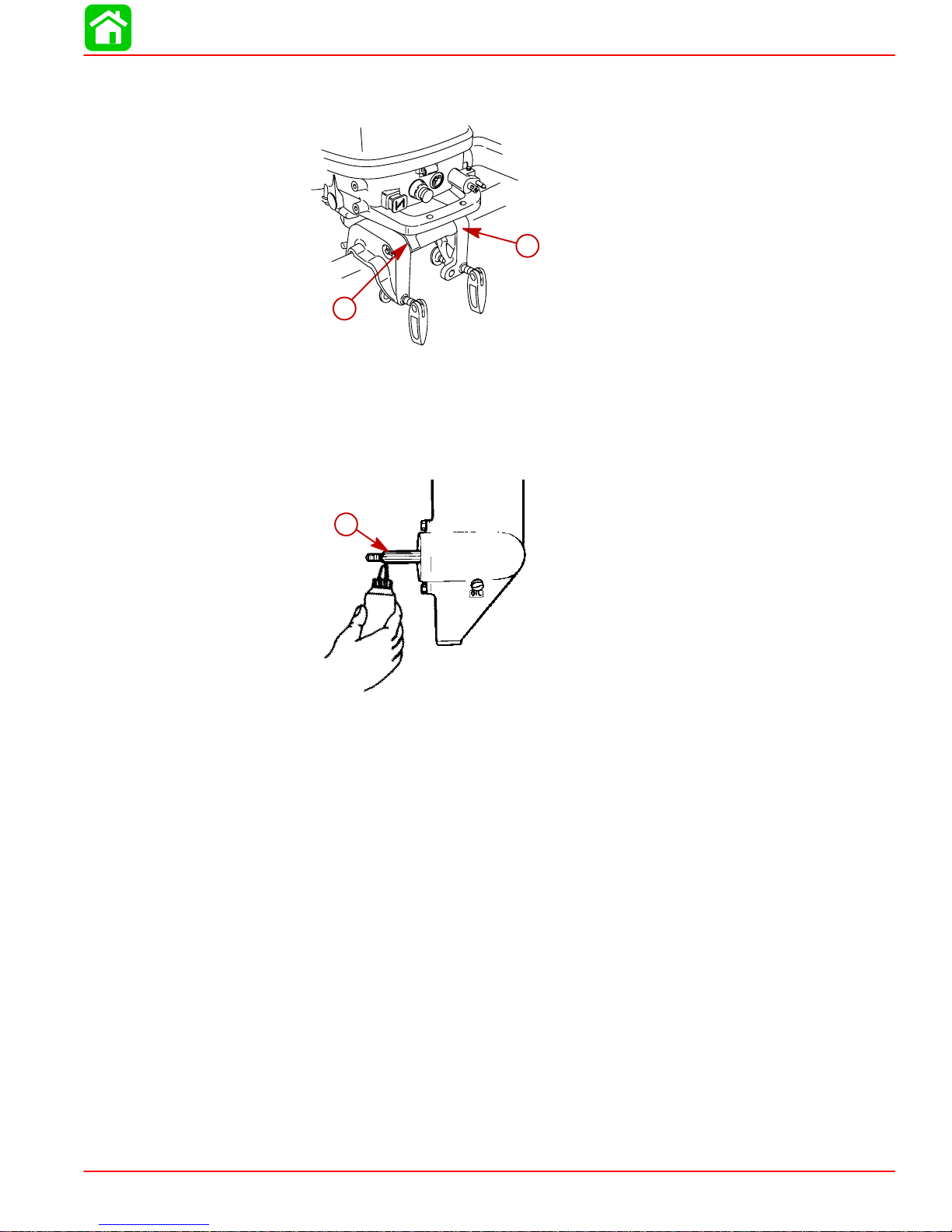

Lubrication Points

Lubricate Points 1 thru 5 with Quicksilver 2-4-C with Teflon Marine Lubricant or Special Lubricant 101.

1. Co-Pilot – Lubricate threads.

2. Swivel Bracket – Lubricate fitting.

3. Transom Clamp Screws – Lubricate threads.

2

1

2

3

NOTE: Lubricating points 4 and 5 require disassembly of the product. These points should

be lubricated at least once a year by an authorized dealer.

4. Tiller Handle Rubber Bushing – Lubricate internal diameter.

4

5. Shift Handle Detent – Lubricate detent.

Page 1B-6 90-857138R1 MAY 2000

5

MAINTENANCE

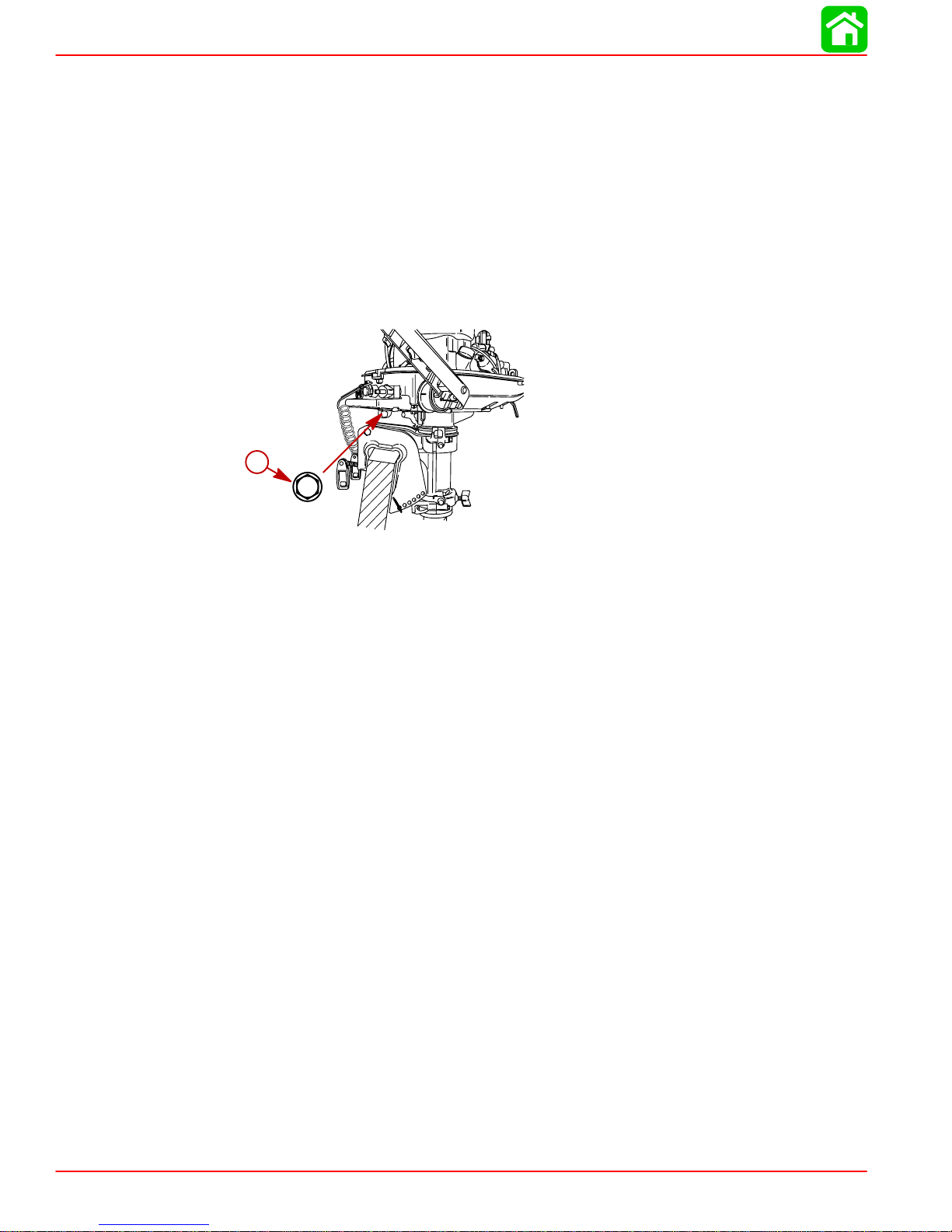

Lubricate Point 6 with Light Weight Oil

6. Tilt Pivot.

6

6

Lubricate Point 7 with Quicksilver Anti-Corrosion Grease or 2-4 - C with Teflon Marine

Lubricant.

7. Propeller Shaft – Refer to Propeller Replacement for removal and installation of the pro-

peller. Coat the entire propeller shaft with lubricant to prevent the propeller hub from corroding to the shaft.

7

90-857138R1 MAY 2000 Page 1B-7

MAINTENANCE

Changing Engine Oil

ENGINE OIL CAPACITY

15 fl oz. (450 mL)

OIL CHANGING PROCEDURE

1. Place outboard in an upright slightly tilted position.

2. Turn the steering on the outboard to gain access to the drain plug. Remove drain plug

and drain engine oil into an appropriate container. Lubricate the seal on the drain plug

with oil and reinstall.

a

OIL FILLING

a- Drain Plug

IMPORT ANT: Inspect oil for signs of contamination. Oil contaminated with water will

have a milky color to it; oil contaminated with fuel will smell strongly of fuel. If contaminated oil is noticed, have the engine checked by your dealer.

IMPORTANT: Do not overfill. Be sure that the outboard is upright (not tilted) when

checking oil.

Remove the oil fill cap and refill with 15 fl oz. (450 mL) of oil. Reinstall the oil fill cap.

Idle engine for five minutes and check for leaks. Stop engine and check oil level on dipstick.

Add oil if necessary.

Page 1B-8 90-857138R1 MAY 2000

Gear Case Lubrication

Gear Case Lubricant Capacity

Gear Case Ratio Capacity

2.15:1 6.6 fl oz. (195 mL)

When adding or changing gear case lubricant, visually check for the presence of water in

the lubricant. If water is present, it may have settled to the bottom and will drain out prior

to the lubricant, or it may be mixed with the lubricant, giving it a milky colored appearance.

If water is noticed, have the gear case checked by your dealer. Water in the lubricant may

result in premature bearing failure or, in freezing temperatures, will turn to ice and damage

the gear case.

Also examine the gear case lubricant for metal particles. A small amount of metal filings or

fine metal particles indicates normal gear wear. An excessive amount of metal filings or

larger particles (chips) may indicate abnormal gear wear and should be checked by an

authorized dealer.

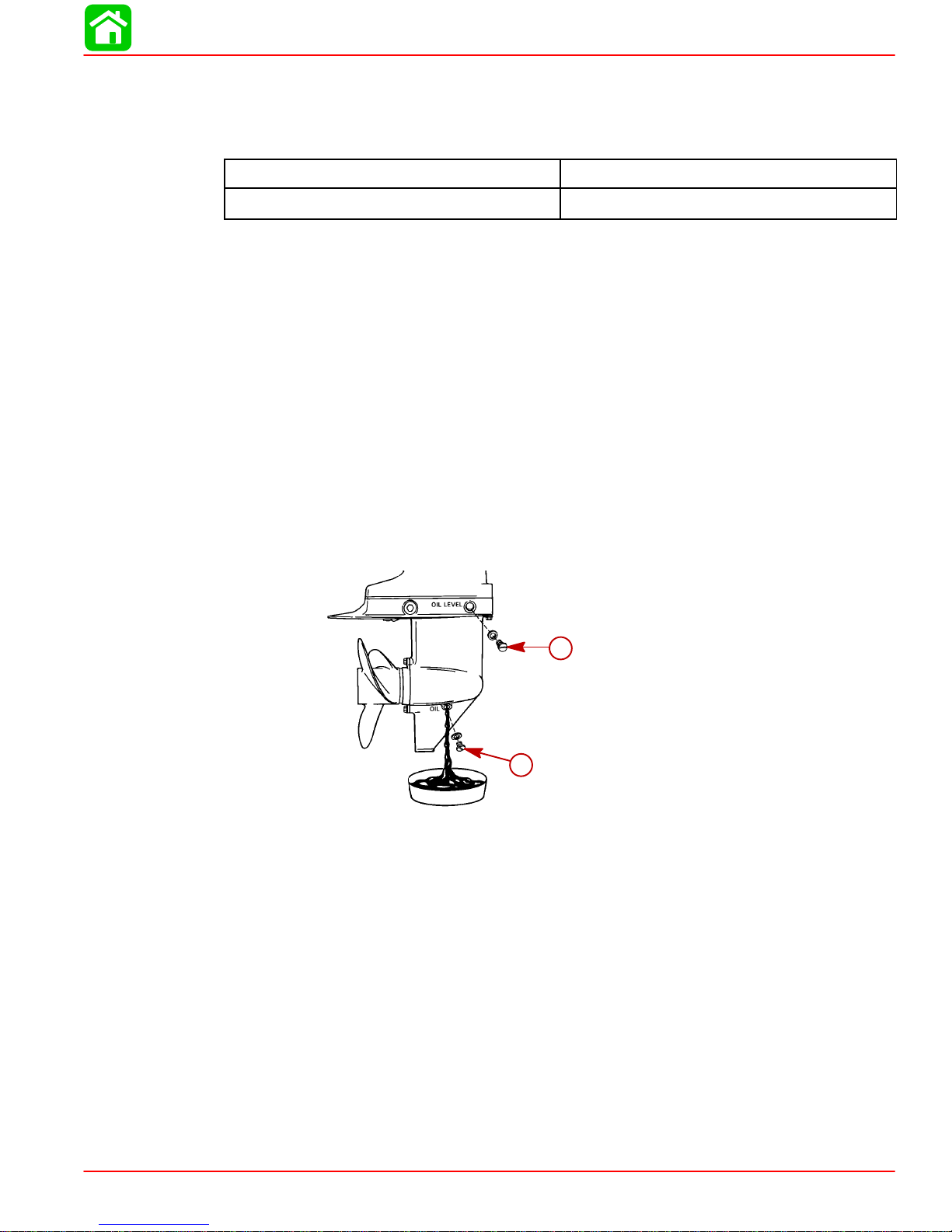

Draining Gear Case

1. Place outboard in a vertical operating position.

MAINTENANCE

2. Place drain pan below outboard.

3. Remove fill/drain plug and vent plug and drain lubricant.

b

a

a- Fill/Drain Plug

b- Vent Plug

90-857138R1 MAY 2000 Page 1B-9

MAINTENANCE

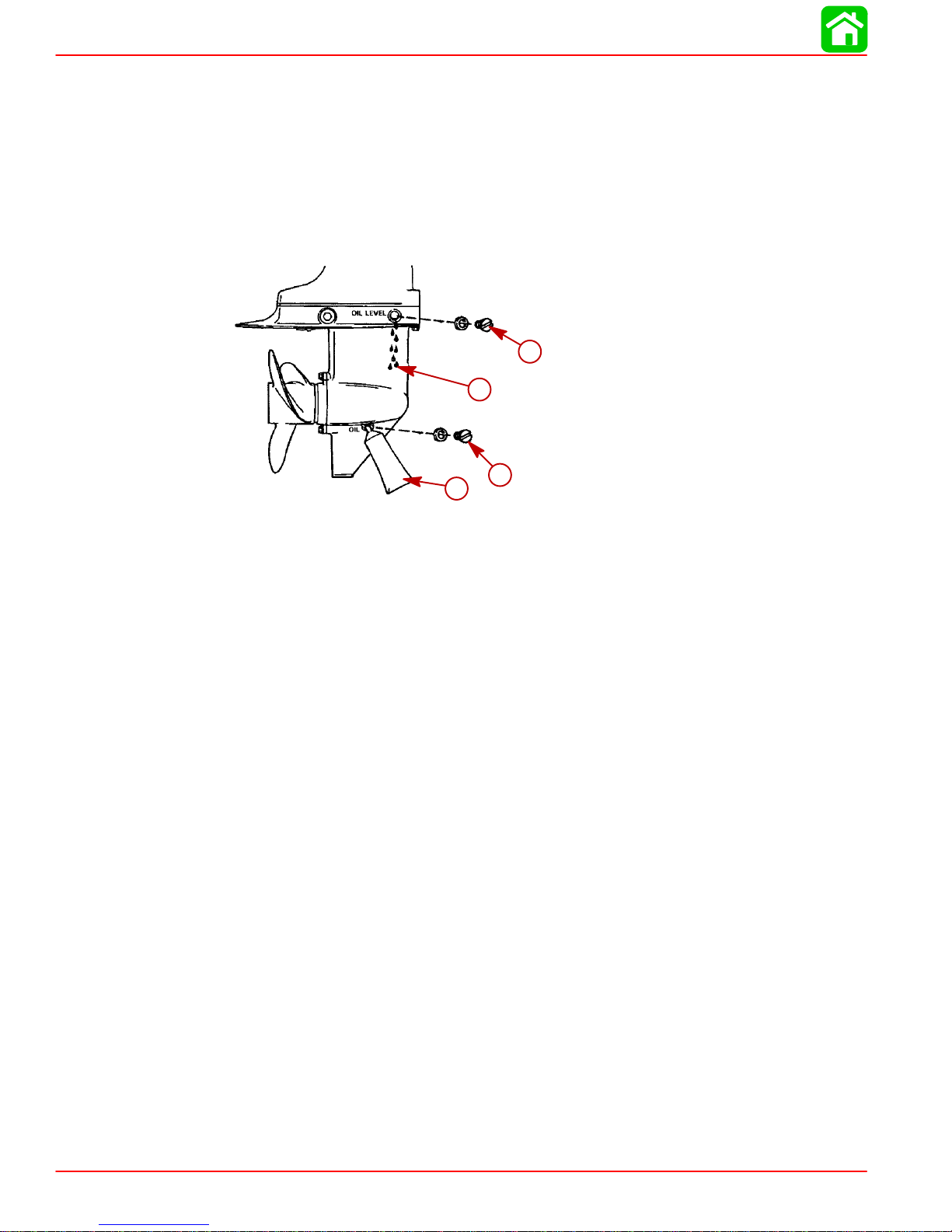

Checking Lubricant Level and Refilling Gear case

1. Place outboard in a vertical operating position.

2. Remove vent plug.

3. Place lubricant tube into the fill hole and add lubricant until it appears at the vent hole.

4. Stop adding lubricant. Install the vent plug and sealing washer before removing the lubricant tube.

5. Remove lubricant tube and reinstall cleaned fill/drain plug and sealing washer.

a

c

d

b

a- Vent Plug/Sealing Washer

b- Lubricant Tube

c- Vent Hole

d- Fill/Drain Plug and Sealing Washer

Storage Preparations

Fuel System

IMPORTANT: Gasoline containing alcohol (ethanol or methanol) can cause a formation of acid during storage and can damage the fuel system. If the gasoline being

used contains alcohol, it is advisable to drain as much of the remaining gasoline as

possible from the fuel tank, remote fuel line, and engine fuel system.

Fill the fuel system (tank, hoses, fuel pumps, and fuel injection systems) with treated (stabilized) fuel to help prevent formation of varnish and gum. Proceed with following instructions.

1. Portable Fuel Tank – Pour the required amount of Quicksilver Gasoline Stabilizer (follow

instructions on container) into fuel tank. T ip fuel tank back and forth to mix stabilizer with

the fuel.

2. Permanently Installed Fuel Tank – Pour the required amount of Quicksilver Gasoline

Stabilizer (follow instructions on container) into a separate container and mix with approximately one quart (one liter) of gasoline. Pour this mixture into fuel tank.

3. Place the outboard in water or connect flushing attachment for circulating cooling water .

Run the engine for ten minutes to allow treated fuel to fill the fuel system.

Protecting External Engine Components

1. Lubricate all outboard components listed in the Inspection and Maintenance Schedule.

2. Touch up any paint nicks.

3. Spray Quicksilver Corrosion Guard on external metal surfaces (except corrosion control

anodes).

Page 1B-10 90-857138R1 MAY 2000

Protecting Internal Engine Components

NOTE: Before performing Steps 1 and 2, make sure the fuel system has been prepared for

storage.

1. Change the engine oil.

2. Place the outboard in water or connect flushing attachment for circulating cooling water .

Start the engine and let it run in neutral to warm up.

3. With engine running at fast idle, stop the fuel flow by disconnecting the remote fuel line.

When engine begins to stall, quickly spray Quicksilver Storage Seal into carburetor until

engine stops from lack of fuel.

4. Remove the spark plugs and inject a five second spray of Quicksilver Storage Seal

around the inside of each cylinder.

5. Rotate the flywheel manually several times to distribute the storage seal in the cylinders.

Reinstall spark plugs.

Gear Case

Drain and refill the gear case lubricant (refer to maintenance procedure).

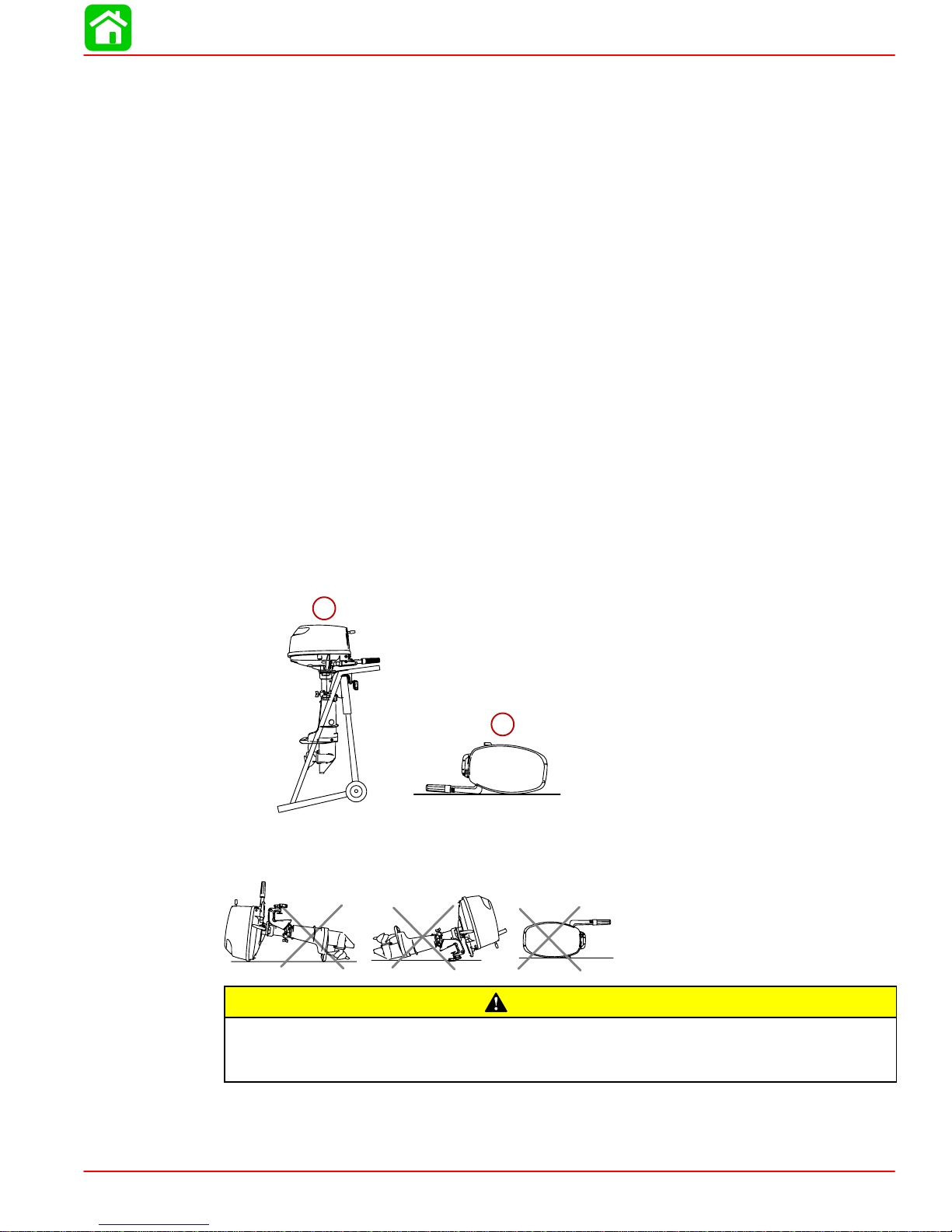

Positioning Outboard for Storage

1. Carry, transport or store the outboard only in these two positions. These positions will

prevent oil from draining out of the crankcase.

MAINTENANCE

a. Upright

b. Tiller Side Down

a

b

2. Never carry, store or transport the outboard in these positions. Engine damage could

result from oil draining out of the crankcase.

If outboard is on a boat and is stored tilted up in freezing temperature, trapped cooling water or rain water that may have entered the propeller exhaust outlet in the gear

case could freeze and cause damage to the outboard.

90-857138R1 MAY 2000 Page 1B-11

CAUTION

GENERAL INFORMATION

IMPORTANT INFORMATION

Section 1C - GENERAL INFORMATION

Table of Contents

Serial Number Location 1C-2. . . . . . . . . . . . . . . . . . . . . . . .

Conditions Affecting Performance 1C-2. . . . . . . . . . . . . . .

Weather 1C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boat 1C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 1C-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Following Complete Submersion 1C-6. . . . . . . . . . . . . . . .

Submerged While Running 1C-6. . . . . . . . . . . . . . . . . .

Salt Water Submersion 1C-6. . . . . . . . . . . . . . . . . . . . . .

Fresh Water Submersion 1C-6. . . . . . . . . . . . . . . . . . . .

1

C

Propeller Selection 1C-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Removal/Installation 1C-8. . . . . . . . . . . . . . . . . .

Compression Check 1C-10. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Leakage Testing 1C-11. . . . . . . . . . . . . . . . . . . . . .

Analysis 1C-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Painting Procedures 1C-12. . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning & Painting Aluminum Propellers &

Gear Housings 1C-12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Application 1C-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Removal 1C-13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions for “Wet” Application 1C-13. . . . . . . . . . . .

90-857138R1 MAY 2000 Page 1C-1

GENERAL INFORMATION

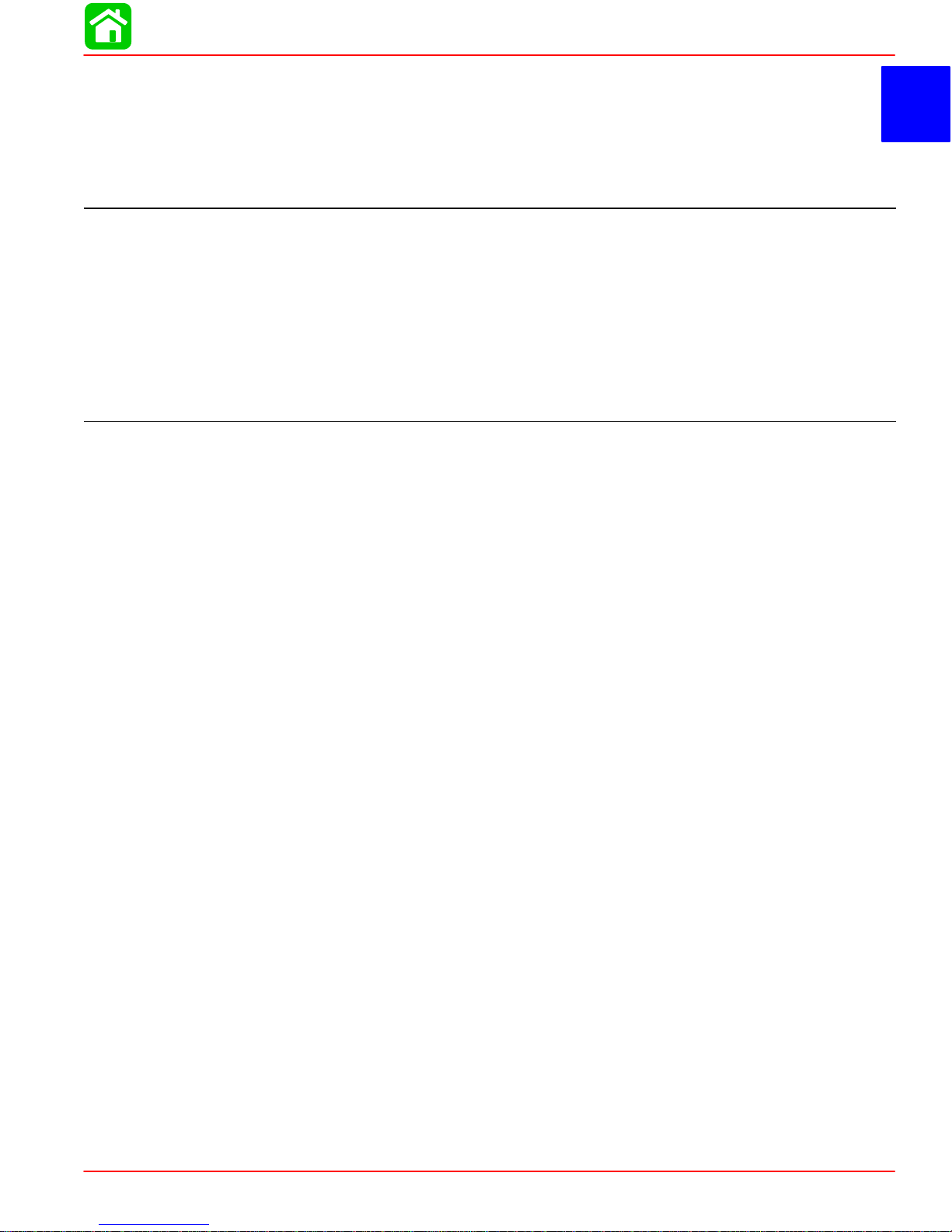

Serial Number Location

The Outboard serial number is located on the lower starboard side of the engine block. A

serial number is also located on the top side of the swivel bracket.

a-Serial Number

b-Model Year

c-Model Description

d-Year Manufactured

e-Certified Europe Insignia

Conditions Affecting Performance

Weather

a

a

e

e

OGXXXXXX

19XX

XXXX

XX

b

b

c

c

d

d

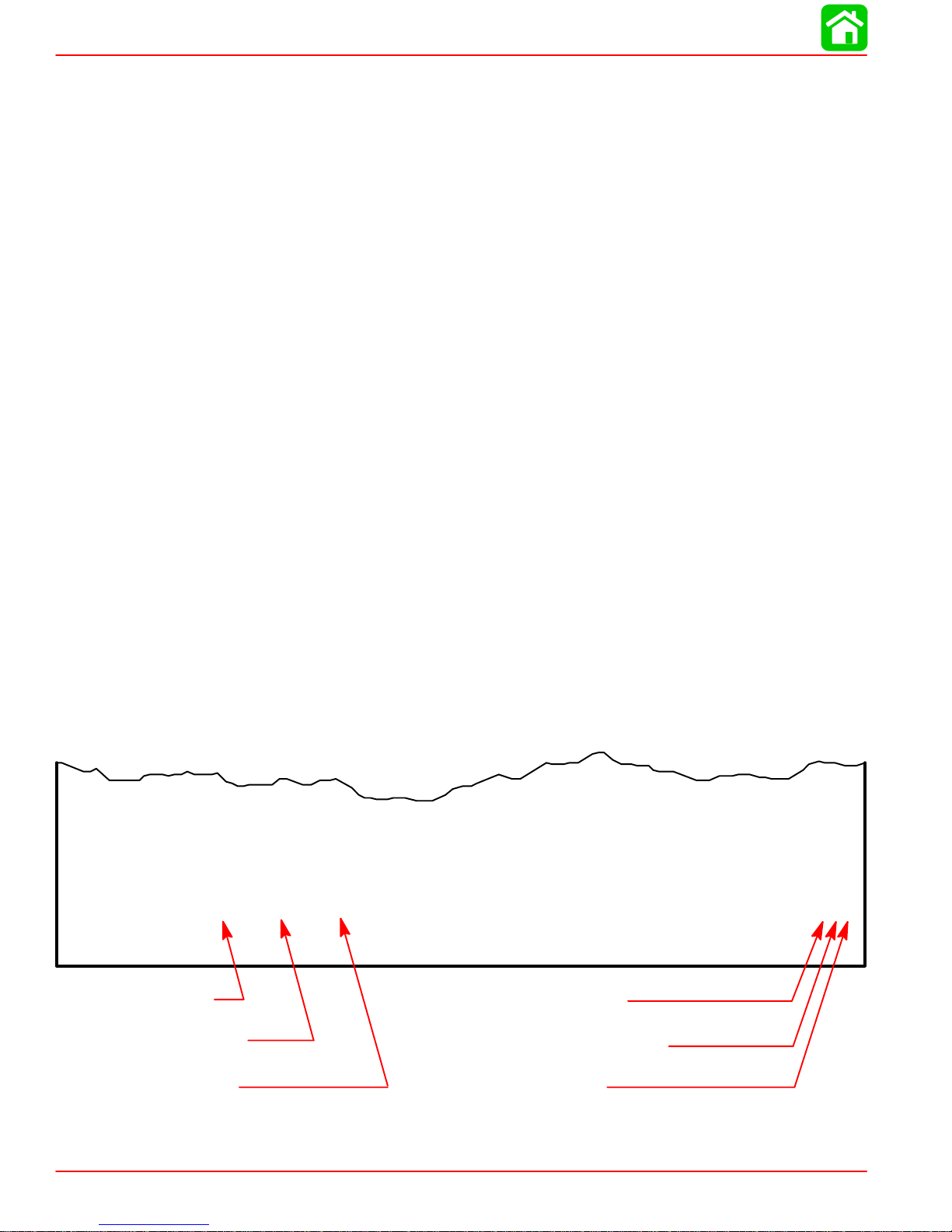

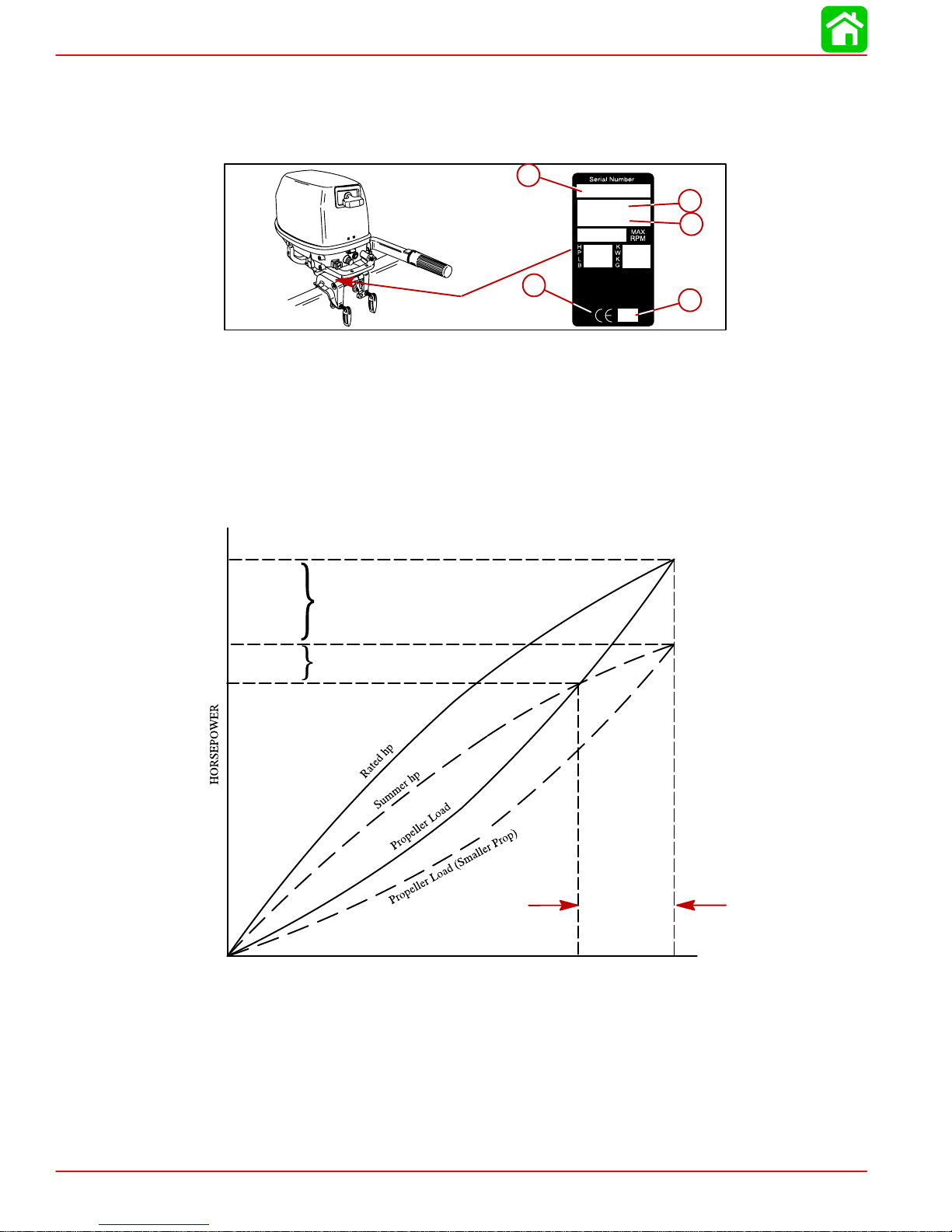

Rated hp

Horsepower Loss

Due to Atmosphere

Summer hp

Conditions

Secondary Loss Due to

Propeller Becoming To

Large for Summer

Horsepower

ENGINE RPM

RPM Drop Due

to Weather

Rated RPM

It is a known fact that weather conditions exert a profound effect on power output of internal

combustion engines. Therefore, established horsepower ratings refer to the power that the

engine will produce at its rated rpm under a specific combination of weather conditions.

Corporations internationally have settled on adoption of I.S.O. (International Standards Organization) engine test standards, as set forth in I.S.O. 3046 standardizing the computation

of horsepower from data obtained on the dynamometer, correcting all values to the power

that the engine will produce at sea level, at 30% relative humidity at 77° F (25°C) temperature and a barometric pressure of 29.61 inches of mercury.

Page 1C-2 90-857138R1 MAY 2000

GENERAL INFORMATION

Summer Conditions of high temperature, low barometric pressure and high humidity all

combine to reduce the engine power. This, in turn, is reflected in decreased boat speeds--as

much as 2 or 3 miles-per-hour (3 or 5 Km per-hour) in some cases. (Refer to previous chart.)

Nothing will regain this speed for the boater, but the coming of cool, dry weather.

In pointing out the practical consequences of weather effects, an engine--running on a hot,

humid summer day--may encounter a loss of as much as 14% of the horsepower it would

produce on a d r y, bris k spring or fall day. The horsepower, that any internal combustion engine produces, depends upon the density of the air that it consumes and, in turn, this density

is dependent upon the temperature of the air, its barometric pressure and water vapor (or

humidity) content.

Accompanying this weather-inspired loss of power is a second but more subtle loss. At rigging time in early spring, the engine was equipped with a propeller that allowed the engine

to turn within its recommended rpm range at full throttle. With the coming of the summer

weather and the consequent drop in available horsepower, this propeller will, in ef fect, become too large. Consequently, the engine operates at less than its recommended rpm.

Due to the horsepower/rpm characteristics of an engine, this will result in further loss of

horsepower at the propeller with another decrease in boat speed. This secondary loss, however, can be regained by switching to a smaller pitch propeller that allows the engine to again

run at recommended rpm.

For boaters to realize optimum engine performance under changing weather conditions, it

is essential that the engine have the proper propeller to allow it to operate at or near the top

end of the recommended maximum rpm range at wide-open-throttle with a normal boat

load.

Not only does this allow the engine to develop full power, but equally important is the fact

that the engine also will be operating in an rpm range that discourages damaging detonation. This, of course, enhances overall reliability and durability of the engine.

Boat

WEIGHT DISTRIBUTION

1. Proper positioning of the weight inside the boat (persons and gear) has a significant ef-

fect on the boat’s performance, for example:

a. Shifting weight to the rear (stern).

b. Shifting weight to the front (bow).

c. Adjusting tilt pin to achieve best performance and handling.

BOTTOM

For maximum speed, a boat bottom should be nearly a flat plane where it contacts the water

and particularly straight and smooth in fore-and-aft direction.

(1.)Generally increases top speed.

(2.)If in excess, can cause the boat to porpoise.

(3.)Can make the bow bounce excessively in choppy water.

(4.)Will increase the danger of the following - wave splashing into the boat when

coming off plane.

(1.)Improves ease of planing off.

(2.)Generally improves rough water ride.

(3.)If excessive, can make the boat veer left and right (bow steer).

90-857138R1 MAY 2000 Page 1C-3

GENERAL INFORMATION

1. Hook: Exists when bottom is concave in fore-and-aft direction when viewed from the

2. Rocker: The reverse of hook and much less common. “Rocker” exists if bottom is con-

3. Surface Roughness: Moss, barnacles, etc., on boat or corrosion of outboard’s gear

WATER ABSORPTION

It is imperative that all through hull fasteners be coated with a quality marine sealer at time

of installation. Water intrusion into the transom core and/or inner hull will result in additional

boat weight (reduced boat performance), hull decay and eventual structural failure.

CAVITATION

Cavitation is caused by water vapor bubbles forming either from a sharp edge or angle on

the gear case, from an irregularity in the propeller blade itself or from improper engine installation (too high). These vapor bubbles flow back and collapse when striking the surface of

the propeller blade resulting in the erosion of the propeller blade surface. If allowed to continue, eventual blade failure (breakage) will occur.

side. When boat is planing, “hook” causes more lift on bottom near transom and allows

bow to drop, thus greatly increasing wetted surface and reducing boat speed. “Hook”

frequently is caused by supporting boat too far ahead of transom while hauling on a

trailer or during storage.

vex in fore-and-aft direction when viewed from the side, and boat has strong tendency

to porpoise.

housing increase skin friction and cause speed loss. Clean surfaces when necessary.

Page 1C-4 90-857138R1 MAY 2000

Engine

DETONATION

GENERAL INFORMATION

Detonation in a 4-cycle engine resembles the “pinging” heard in an automobile engine. It

can be otherwise described as a tin-like “rattling” or “plinking” sound.

Detonation is an explosion of an unburned portion of the fuel/air charge after the spark plug

has fired. Detonation creates severe shock waves in the engine, and these shock waves

often find or create a weakness: The dome of a piston, cylinder head/gasket, piston rings

or piston ring lands, piston pin and bearings.

A few of the most common causes of detonation in a marine 4-cycle application are as

follows:

• Over-advanced ignition timing.

• Use of low octane gasoline.

• Propeller pitch too high (engine rpm below recommended maximum range).

• Lean fuel mixture at or near wide-open-throttle.

• Spark plugs (heat range too hot - incorrect reach - cross-firing).

• Inadequate engine cooling (deteriorated cooling system).

• Combustion chamber/piston deposits (result in higher compression ratio).

Detonation usually can be prevented if:

1. The engine is correctly set up.

2. Diligent maintenance is applied to combat the detonation causes.

51115

Damaged Piston Resulting from Detonation

90-857138R1 MAY 2000 Page 1C-5

GENERAL INFORMATION

Following Complete Submersion

Submerged While Running (Special Instructions)

When an engine is submerged while running, the possibility of internal engine damage is

greatly increased. If, after engine is recovered and with spark plugs removed, engine fails

to turn over freely when turning flywheel, the possibility of internal damage (bent connecting

rod and/or bent crankshaft) exists. If this is the case, the powerhead must be disassembled.

Salt Water Submersion (Special Instructions)

Due to the corrosive effect of salt water on internal engine components, complete disassembly is necessary before any attempt is made to start the engine.

Fresh Water Submersion (Special Instructions)

1. Recover engine as quickly as possible.

2. Remove cowling.

3. Flush exterior of outboard with fresh water to remove mud, weeds, etc. DO NOT attempt

to start engine if sand has entered powerhead, as powerhead will be severely damaged.

Disassemble powerhead if necessary to clean components.

4. Drain engine oil. Do not refill engine oil at this time.

5. Drain carburetor and clean fuel pump assembly.

6. Remove spark plug and get as much water as possible out of powerhead. Most water

can be eliminated by placing engine in a horizontal position (with spark plug holes down)

and rotating flywheel.

7. Pour alcohol into carburetor throat (alcohol will absorbed water). Again rotate flywheel.

8. Turn engine over and pour alcohol into spark plug opening and rotate flywheel.

9. Turn engine over (place spark plug openings down) and pour engine oil into throat of

carburetor while rotating flywheel to distribute oil throughout crankcase.

10. Again turn engine over and pour approximately one teaspoon of engine oil into spark

plug opening. Again rotate flywheel to distribute oil in cylinder.

11. Dry all wiring and electrical components using compressed air.

12. Reinstall spark plug.

13. Refill engine crankcase with fresh oil.

14. Attempt to start engine, using a fresh fuel source. If engine starts, it should be run for

at least one hour to eliminate any water in engine.

15. If engine fails to start, determine cause (fuel, electrical or mechanical). Engine should

be run within 2 hours after recovery of outboard from water, or serious internal damage

may occur. If unable to start engine in this period, disassemble engine and clean all

parts. Apply oil as soon as possible.

Page 1C-6 90-857138R1 MAY 2000

Propeller Selection

For in-depth information on marine propellers and boat performance - written by marine engineers - see your Authorized Dealer for the illustrated “What You Should Know About

Quicksilver Propellers...and Boat Performance Information” (Part No. 90-86144).

For best all around performance from your outboard/boat combination, select a propeller

that all ows the engine to operate in the upper half of the recommended full throttle rpm range

with the boat normally loaded (refer to Specifications). This rpm range allows for better acceleration while maintaining maximum boat speed.

If changing conditions cause the rpm to drop below the recommended range (such as warmer, more humid weather, operation at higher elevations, increased boat load or a dirty boat

bottom/gear case) a propeller change or cleaning may be required to maintain performance

and ensure the outboard’s durability.

Check full-throttle rpm using an accurate tachometer with the engine trimmed out to a balanced-steering condition (steering effort equal in both directions) without causing the propeller to “break loose”.

Refer to “Quicksilver Accessory Guide” for a complete list of available propellers.

1. Select a propeller that will allow the engine to operate at or near the top of the recom-

mended full throttle rpm range (listed in “Specifications,” preceding) with a normal load.

Maximum engine speed (rpm) for propeller selection exists when boat speed is maximum and trim is minimum for that speed. (High rpm, caused by an excessive trim angle,

should not be used in determining correct propeller.) Normally, there is a 150-350 rpm

change between propeller pitches.

GENERAL INFORMATION

2. If full throttle operation is below the recommended range, the propeller MUST BE

changed to one with a lower pitch to prevent loss of performance and possible engine

damage.

3. After initial propeller installation, the following common conditions may require that the

propeller be changed to a lower pitch:

a. Warmer weather and great humidity will cause an rpm loss.

b. Operating in a higher elevation causes an rpm loss.

c. Operating with a damaged propeller or a dirty boat bottom or gear housing will cause

an rpm loss.

d. Operation with an increased load (additional passengers, equipment, pulling skiers,

etc.).

90-857138R1 MAY 2000 Page 1C-7

Loading...

Loading...