Page 1

9.9 and 15 HP (4-Stroke)

Outboard Installation Manual

NOTICE To INSTALLER

After completing assembly, these

instructions should be placed with the

product for the owner’s future use.

IMPORT ANT: If the boat is to be water tested, the

operator should be familiar with the operation

procedures in the Operation and Maintenance

Manual.

Table of Contents

Boat Horsepower Capacity

U.S. COAST GUARD CAPACITY

MAXIMUM HORSEPOWER XXX

MAXIMUM PERSON

CAPACITY (POUNDS) XXX

MAXIMUM WEIGHT

CAPACITY XXX

Do not overpower or overload the boat. Most boats

will carry a required capacity plate indicating the maximum acceptable power and load as determined by

the manufacturer following certain federal guidelines.

If in doubt, contact your dealer or the boat manufacturer.

Installing Outboard 2. . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Cable 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Cable Seal 2. . . . . . . . . . . . . . . . . . . . . . . . .

Steering Link Rod 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Harness 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Cable Connections 4. . . . . . . . . . . . . . . . . . .

Shift and Throttle Cable 4. . . . . . . . . . . . . . . . . . . . . .

Propeller Installation 6. . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

Using an outboard that exceeds the maximum

horsepower limit of a boat can: 1. cause loss of

boat control 2. place too much weight at the transom, altering the designed flotation characteristics of the boat or 3. cause the boat to break apart,

particularly around the transom area. Overpowering a boat can result in serious injury , death, or

boat damage.

Start in Gear Protection

The remote control connected to the outboard must

be equipped with a start-in-gear protection device.

This prevents the engine from starting in gear.

WARNING

Avoid serious injury or death from a sudden unexpected acceleration when starting your engine.

The design of this outboard requires that the remote control used with it must have a built in

start-in-gear protection device.

Selecting Accessories For

The Outboard

Genuine Quicksilver Parts and Accessories have

been specifically designed and tested for this outboard.

Some accessories not manufactured or sold by

Quicksilver are not designed to be safely used with

this outboard or outboard operating system. Acquire

and read the Installation, Operation, and Maintenance manuals for all selected accessories.

90-10203990 398- 1 -Printed in U.S.A.

Page 2

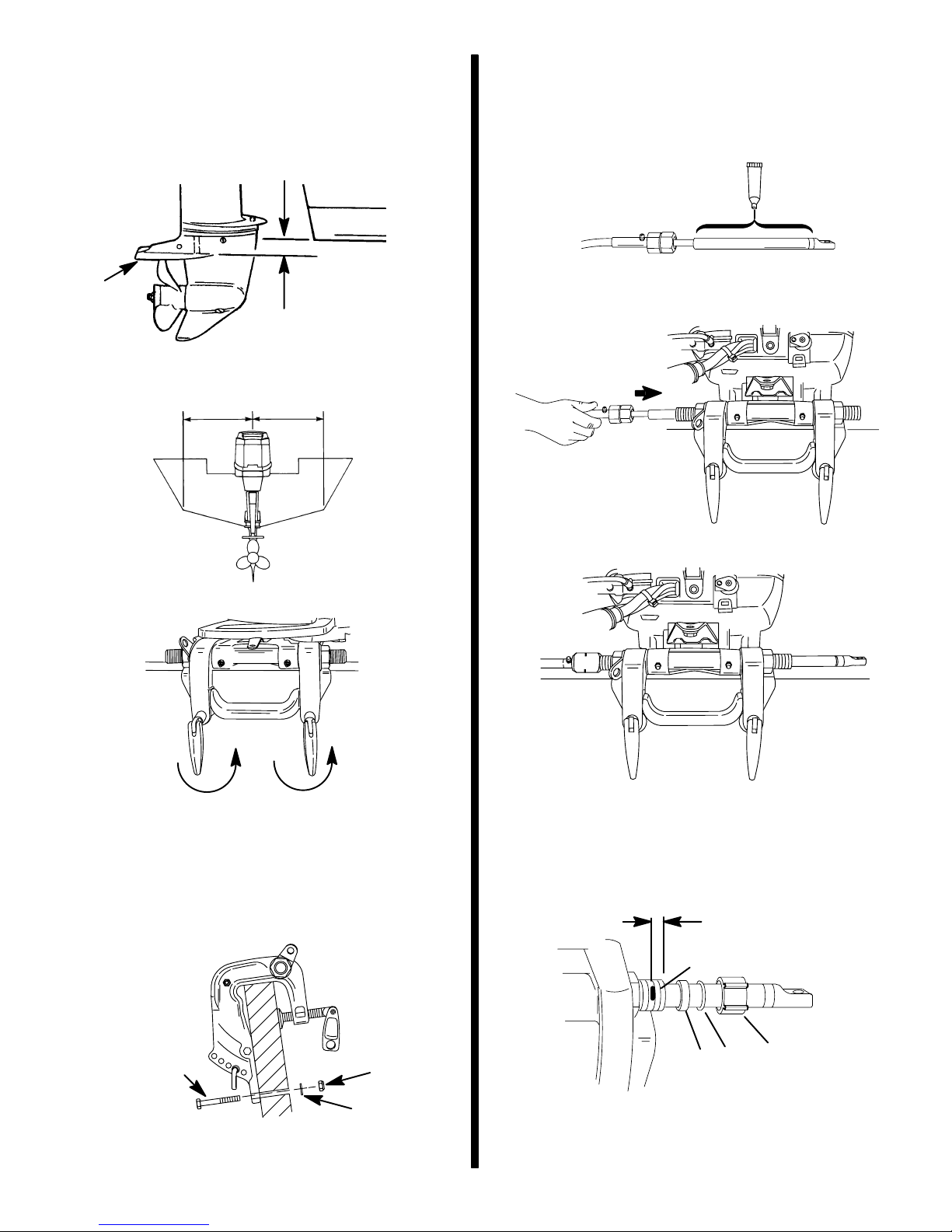

Installing Outboard

Steering Cable

1. Measure the transom height of your boat. The

boat bottom should be aligned or be within 1 in.

(25mm) above the anti-ventilation plate (a) of the

outboard.

a

0-1in.

(0-25mm)

a - Anti-Ventilation Plate

2. Place outboard on center line of transom.

STARBOARD SIDE ROUTED CABLE

1. Lubricate the entire cable end.

a

a - Quicksilver 2-4-C Marine Lubricant with Teflon

2. Insert steering cable into tilt tube.

3. Torque nut to 35 lb. ft. (47.5 N·m).

3. Tighten transom clamp handles.

4. To prevent loss of outboard overboard, fasten

outboard by drilling two 5/16 in. (7.9 mm) holes

through the transom using transom clamp holes

as a template. Fasten with two bolts, flat washers

and locknuts. Use a marine waterproofing sealer

in holes and around bolts to make the installation

water tight.

Steering Cable Seal

1. Mark tilt tube 1/4 in. (6.4 mm) from end. Install

seal components.

1/4 in. (6.4mm)

a

a

a - Bolts (2)

b - Flat Washers (2)

c - Locknuts (2)

c

b

a - 1/4 in. (6.4 mm) Mark

b - Plastic Spacer

c - O-Ring Seal

d - Cap

- 2 -

b

d

c

Page 3

2. Thread cap to the mark.

Wiring Harness

Remote Wiring Harness Connection

to Engine

1. Apply Quicksilver Dielectric Grease inside the

connection.

2. Plug the remote wiring connector into the outboard wiring harness connector.

Steering Link Rod

1. Install steering link rod per illustration.

c

d

b

a

a - Special Bolt (10-90041) Torque to 20 lb. ft.(27.1 N·m)

b - Nylon Insert Locknut (11-34863) Torque to

20 lb. ft.(27.1 N·m)

c - Spacer (12-71970)

d - Flat Washer (2)

e - Nylon Insert Locknut (11-34863) Tighten Locknut Until it

Seats, Then Back Nut Off 1/4 Turn

f - Use Middle Hole

IMPORT ANT: The steering link rod that connects

the steering cable to the engine must be fastened

using special bolt (“a” - Part Number 10-90041)

and self locking nuts (“b”& “c”- Part Number

11-34863). These locknuts must never be replaced with common nuts (non locking) as they

will work loose and vibrate off, freeing the link rod

to disengage.

3. Secure the connection together with retainer, as

shown.

a - Remote Wiring Connector

b - Outboard Wiring Harness Connector

c - Retainer

WARNING

Disengagement of a steering link rod can result in

the boat taking a full, sudden, sharp turn. This potentially violent action can cause occupants to be

thrown overboard exposing them to serious injury or death.

- 3 -

Page 4

Battery Cable Connections

Shift and Throttle Cable

SINGLE OUTBOARD

a

(+)

b

(–)

a - Red Sleeve (Positive)

b - Black Sleeve (Negative)

c - Starting Battery

DUAL OUTBOARD

1. Connect a common ground cable (wire size same

as engine battery cables) between negative (–)

terminals on starting batteries.

c

Install cables into the remote control following the

instructions provided with the remote control.

NOTE: Install the shift cable to the engine first. The

shift cable is the first cable to move when the remote

control handle is moved out of neutral.

Shift Cable Installation

1. Position remote control into Forward gear.

F

2. Remove Cover.

(–)

d

(–)

d - Ground Cable (Same Wire Size As Engine Battery Cable –

Connect Between Negative (–) Terminals

a

a - Cover

3. Shift outboard into forward gear.

a

a - Rotate Shift Arm Forward

- 4 -

Page 5

4. Install cable to the shift lever. Secure with cable

latch.

5. Adjust the cable barrel so that it fits into the anchor

pocket.

b

Throttle Cable Installation

1. Position remote control into neutral.

N

2. Install throttle cable on pin. Lock in place with

cable latch.

3. Adjust cable barrel until the link rod is centered in

slot.

a

a - Cable Latch

b - Cable Barrel

6. Check shift cable adjustment as follows:

a. Shift remote control into forward. The propel-

ler shaft should be locked in gear. If not, adjust

the barrel closer to the cable end.

b. Shift remote control into neutral. The propel-

ler shaft should turn freely without drag. If not,

adjust the barrel away from the cable end. Repeat steps a and b.

c. Shift remote control into reverse while turning

propeller. The propeller shaft should be

locked in gear. If not, adjust the barrel away

from the cable end . Repeat steps a thru c.

d. Shift remote control back to neutral. The pro-

peller shaft should turn freely without drag. If

not, adjust the barrel closer to the cable end.

Repeat steps a thru d.

c

a

a - Shift Cable

b - Cable Barrel

c - Link Rod – Adjust Barrel so Link Rod is Centered in Slot

IMPORTANT: After installation, move the remote

control handle a few times from the neutral position to the wide-open-throttle position in forward

gear. Move handle back to neutral and visually

Check that the link rod is still centered. If necessary, readjust the barrel.

4. Reinstall Cover.

b

a

a - Cover

- 5 -

Page 6

Propeller Installation

Big Foot Gear Case

Standard Gear Case

WARNING

If the propeller shaft is rotated while the engine is

in gear, there is the possibility that the engine will

crank over and start. T o prevent this type of accidental engine starting and possible serious injury caused from being struck by a rotating propeller, always shift outboard to neutral position and

remove spark plug leads when you are servicing

the propeller.

Flo-Torq I Drive Hub Propellers

c

d

a - Forward Thrust Hub

b - Propeller

c - Rear Thrust Hub

d - Propeller Nut – Tighten

a

b

WARNING

If the propeller shaft is rotated while the engine is

in gear, there is the possibility that the engine will

crank over and start. T o prevent this type of accidental engine starting and possible serious injury caused from being struck by a rotating propeller, always shift outboard to neutral position and

remove spark plug leads when you are servicing

the propeller.

Flo-Torq I Drive Hub Propellers

c

a - Forward Thrust Hub

b - Propeller

c - Propeller Nut – Tighten

Flo-Torq II Drive Hub Propellers

e

d

a

b

Flo-Torq II Drive Hub Propellers

d

e

c

a - Forward Thrust Hub

b - Replaceable Drive Sleeve

c - Propeller

d - Rear Thrust Hub

e - Propeller Nut – Tighten

c

a - Forward Thrust Hub

b - Propeller

c - Replaceable Drive Sleeve

d - Rear Thrust Hub

e - Propeller Nut

a

b

a

b

- 6 -

Loading...

Loading...