Page 1

SERVICE

MANUAL

MODELS

225 • 225 EFI • 250 EFI • 3.0 Litre

Marathon • 3.0 Litre SeaPro

With Serial Numbers

United States 0D280813 and Above. . .

1997, Mercury Marine

90-822900R3 DECEMBER 1997Printed in U.S.A.

Page 2

Notice

Throughout this publication, “Dangers”, “Warnings”

and “Cautions” (accompanied by the International

HAZARD Symbol

to special instructions concerning a particular service

or operation that may be hazardous if performed incorrectly or carelessly.

FULLY!

These “Safety Alerts” alone cannot eliminate the hazards that they signal. Strict compliance to these special instructions when performing the service, plus

“Common Sense” operation, are major accident prevention measures.

DANGER - Immediate hazards which WILL result

in severe personal injury or death.

) are used to alert the mechanic

OBSERVE THEM CARE-

DANGER

who uses a service procedure and/or tool, which is

not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the

products safety will be endangered by the service

procedure selected.

All information, illustrations and specifications contained in this manual are based on the latest product

information available at the time of publication. As required, revisions to this manual will be sent to all dealers contracted by us to sell and/or service these products.

It should be kept in mind, while working on the product, that the electrical system and ignition system are

capable of violent and damaging short circuits or severe electrical shocks. When performing any work

where electrical terminals could possibly be

grounded or touched by the mechanic, the battery

cables should be disconnected at the battery.

WARNING

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result

in minor personal injury or product or property

damage.

Notice to Users of This

Manual

This service manual has been written and published

by the Service Department of Mercury Marine to aid

our dealers’ mechanics and company service personnel when servicing the products described herein.

It is assumed that these personnel are familiar with

the servicing procedures of these products, or like or

similar products manufactured and marketed by

Mercury Marine, that they have been trained in the

recommended servicing procedures of these products which includes the use of mechanics’ common

hand tools and the special Mercury Marine or recommended tools from other suppliers.

Any time the intake or exhaust openings are exposed

during service they should be covered to protect

against accidental entrance of foreign material which

could enter the cylinders and cause extensive internal damage when the engine is started.

It is important to note, during any maintenance procedure replacement fasteners must have the same

measurements and strength as those removed.

Numbers on the heads of the metric bolts and on the

surfaces of metric nuts indicate their strength. American bolts use radial lines for this purpose, while most

American nuts do not have strength markings. Mismatched or incorrect fasteners can result in damage

or malfunction, or possibly personal injury. Therefore, fasteners removed should be saved for reuse in

the same locations whenever possible. Where the

fasteners are not satisfactory for re-use, care should

be taken to select a replacement that matches the

original.

We could not possibly know of and advise the service

trade of all conceivable procedures by which a service might be performed and of the possible hazards

and/or results of each method. We have not undertaken any such wide evaluation. Therefore, anyone

i90-822900R3 DECEMBER 1997

Page 3

Cleanliness and Care of

Outboard Motor

A marine power product is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten thousands of

an inch./mm. When any product component is serviced, care and cleanliness are important. Throughout

this manual, it should be understood that proper

cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is

considered standard shop practice even if not specifically stated.

Whenever components are removed for service,

they should be retained in order. At the time of installation, they should be installed in the same locations

and with the same mating surfaces as when removed.

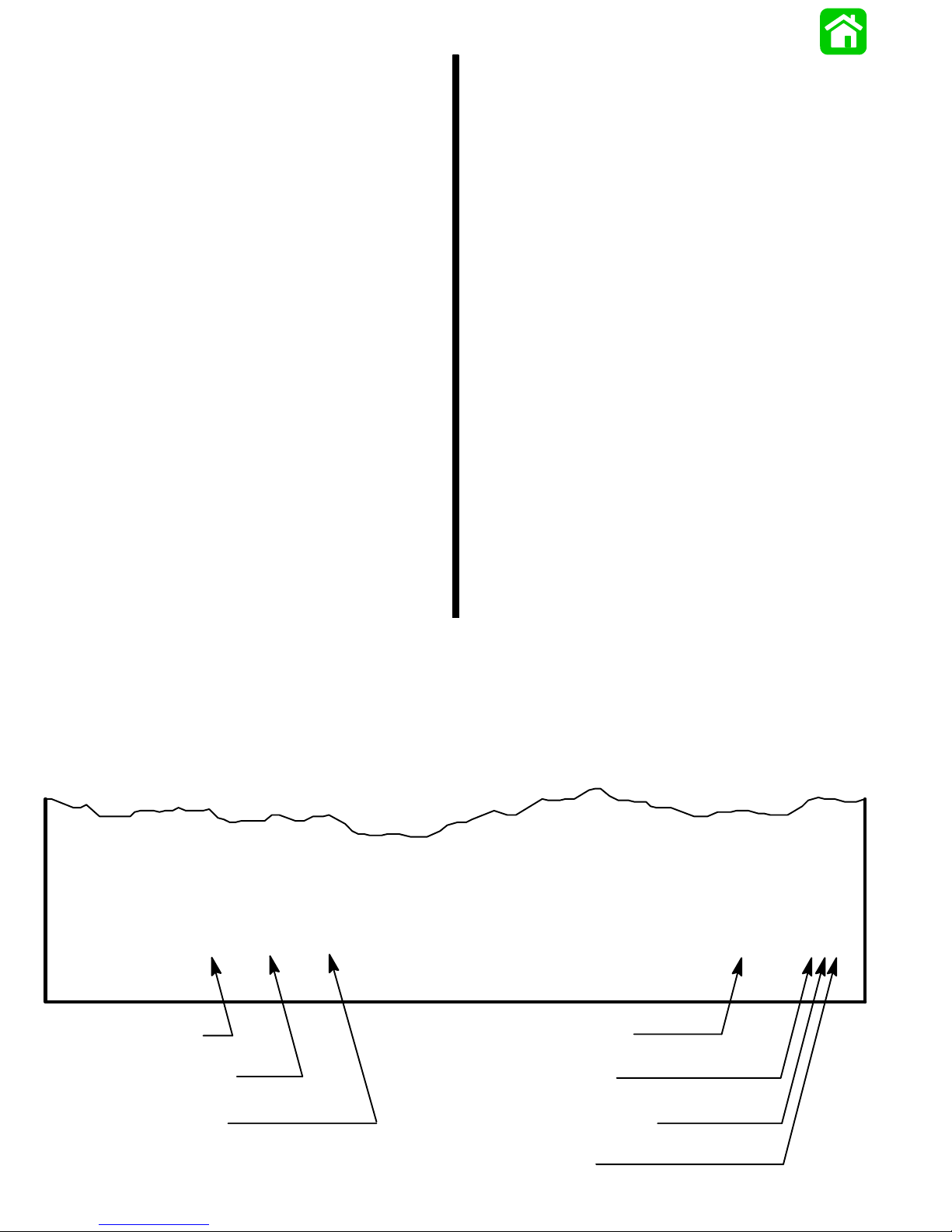

Before raising or removing and outboard engine from

a boat, the following precautions should be adhered

to:

1. Check that flywheel is secured to end of crankshaft with a locknut and lifting eye is threaded into

flywheel a minimum of 5 turns.

In addition, personnel should not work on or under an

outboard which is suspended. Outboards should be

attached to work stands, or lowered to ground as

soon as possible.

We reserve the right to make changes to this manual

without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products described in this

manual.

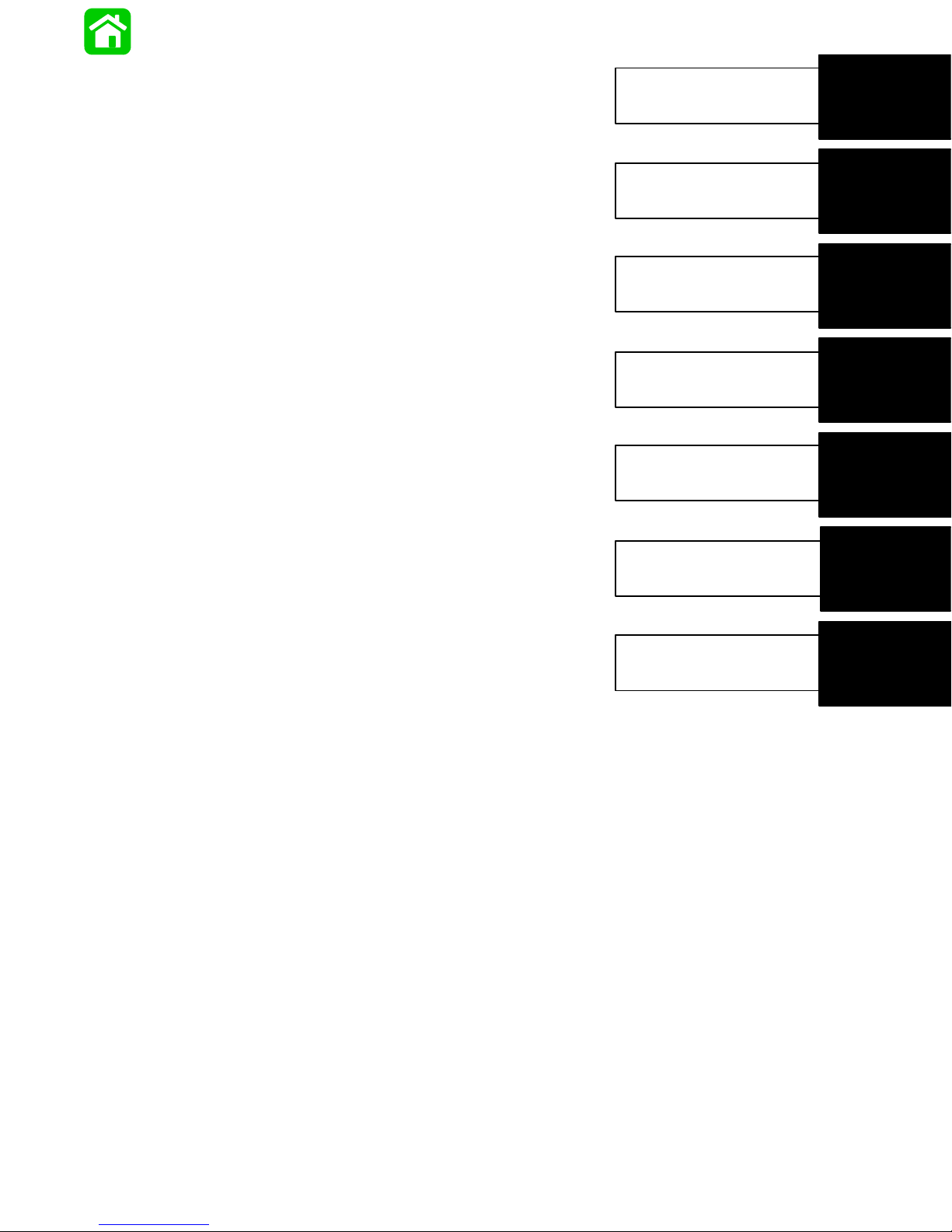

Page Numbering

Two number groups appear at the bottom of each

page. The example below is self-explanatory.

2. Connect a hoist of suitable strength to the lifting

eye.

EXAMPLE:

90-826148 R1 JANUARY 1993

LOWER UNIT - 6A-7

Revision No. 1

Month of Printing

Year of Printing

Section Description

Section Number

Part of Section Letter

Page Number

ii 90-822900R3 DECEMBER 1997

Page 4

Service Manual Outline

Section 1 - Important Information

A - Specifications

B - Maintenance

C - General Information

D - Outboard Installation

Section 2 - Electrical

A - Ignition

B - Charging & Starting System

C - Timing, Synchronizing & Adjusting

D - Wiring Diagrams

Section 3 - Fuel System

A - Fuel Pump

B - Carburetor

C - Fuel Injection

D - Oil Injection

E - Emissions

Section 4 - Powerhead

Section 5 - Mid-Section

A - Clamp/Swivel Brackets & Drive Shaft Housing

B - Power Trim

Section 6 - Lower Unit

A - Right Hand Rotation

B - Left Hand Rotation

Section 7 - Attachments/Control Linkage

Important

Information

1

Electrical

2

Fuel System

3

Powerhead

4

Mid-Section

5

Lower Unit

6

Attachments/

Control Linkage

7

90-822900R3 DECEMBER 1997

iii

Page 5

IMPORTANT

INFORMATION

1

A

SPECIFICATIONS

Page 6

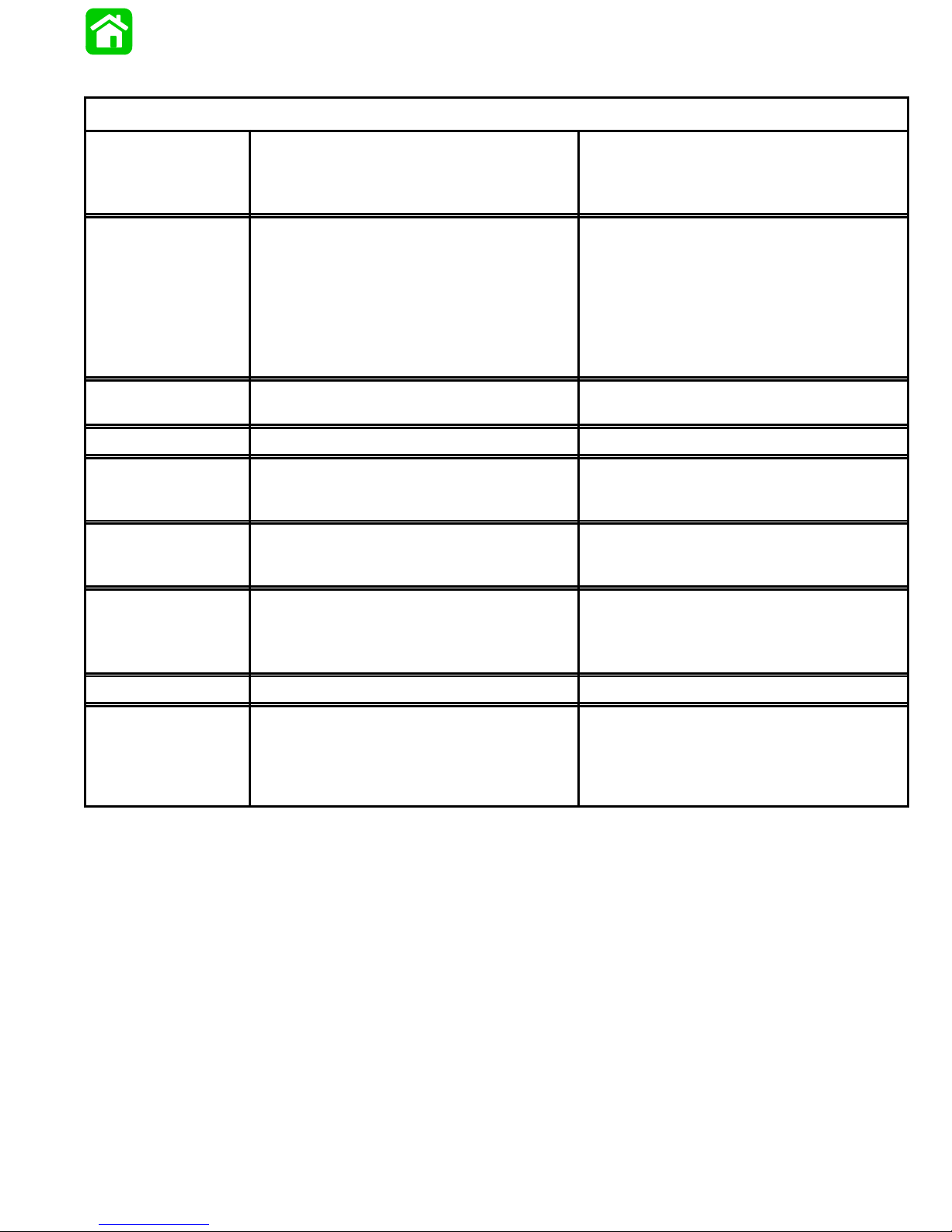

Table of Contents

Master Specifications 1A-1. . . . . . . . . . . . . . . . . . . . . . . .

Page

90-822900R3 DECEMBER 19971A-0 - IMPORTANT INFORMATION

Page 7

Master Specifications

Model 3 Litre Work/225 Carb/225 EFI/250EFI

HORSEPOWER

(KW)

OUTBOARD

WEIGHT

CYLINDER

BLOCK

STROKE Length (All Models) 3.00 in. (76.2mm)

CYLINDER

BORE

PISTON Piston Type

Model 3 Litre

Model 225 Carb

Model 225 EFI

Model 250 EFI

3 Litre/225 Carb

– 20 in. (50.8cm) Shaft

– 25 in. (63.5cm) Shaft

– 30 in. (76.2cm) Shaft

225 EFI/250 EFI

– 20 in. (50.8cm) Shaft

– 25 in. (63.5cm) Shaft

– 30 in. (76.2cm) Shaft

Type

Displacement

Diameter (Std)

Taper/Out of Round/Wear Maximum

Bore Type

Standard

225 (167.8)

225 (167.8)

225 (167.8)

250 (186.5)

440.0 lbs. (199.8kg)

445.0 lbs. (202.0kg)

461.0 lbs. (209.3kg)

450.0 lbs. (204.1kg)

455.0 lbs. (206.4kg)

471.0 lbs. (213.6kg)

V–6 Cylinder, Two Cycle, Loop Charged

185.9 cu. in. (3047cc)

3.6265 in. (92.1131mm)

0.003 in. (0.076mm)

Cast Iron

Aluminum

3.621 in. ± .0005 in. (91.973mm ±

0.0127mm)

COMPRESSION All Models – Using a fully charged

battery, throttle shutters wide open

and cylinder block warm

REEDS Reed Stand 0pen (Max.) 0.020 in. (0.50mm)

MID

SECTION

Power Trim (Total Tilt Range)

Power Trim (Tilt Range)

Steering Pivot Range

Tilt Pin Adjustment Positions

Allowable Transom Thickness

Variance between cylinders should not

exceed 15 psi (102.7 kPa)

2-3/8 in. (6.03cm) Maximum

90 – 110 psi

(616.3 – 753.5 kPa)

75°

20°

60°

5

90-822900R3 DECEMBER 1997 IMPORTANT INFORMATION - 1A-1

Page 8

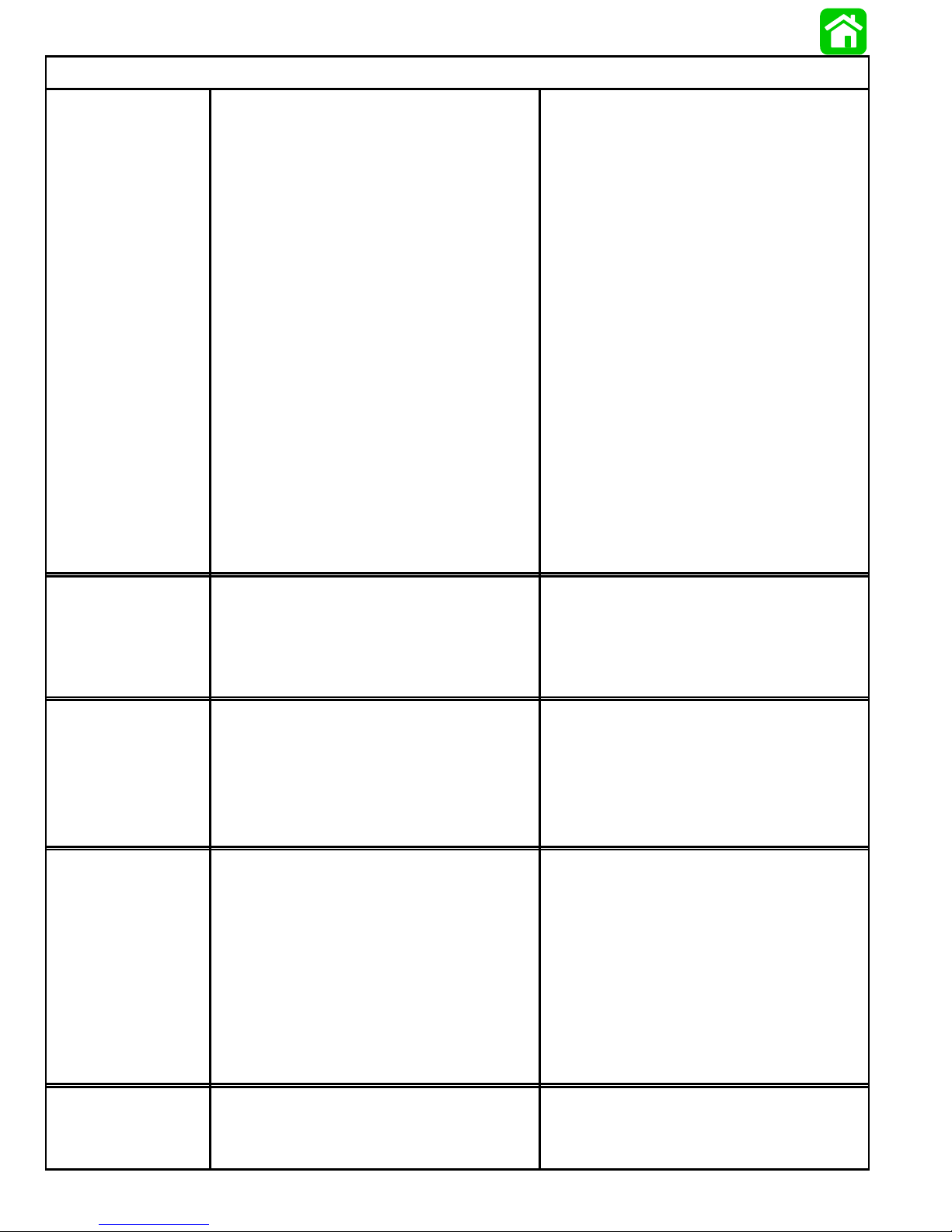

Model 3 Litre Work/225 Carb/225 EFI/250EFI

GEAR

HOUSING

Gear Ratio

1994 Standard Ratio All Models

1995/1996 Gear Ratios All Models

Optional High Altitude Ratio

(Right Hand Rotation)

3 Litre Work (All Shaft Lengths)

225 Carb (20 in. Shaft Length)

225 Carb (25 in./30 in. Length)

225 EFI (All Shaft Lengths)

250 EFI (All Shaft Lengths)

Gearcase Capacity

Pinion Height

Forward Gear Backlash

– 1.75:1/1.87:1

Reverse Gear Backlash

– Standard Rotation

– Counter Rotation

Water Pressure @ RPM

– @ Idle

– @ 5000 RPM

1.64:1 17/28 Teeth

Service Replacement Ratio for 1.64:1 is

1.62:1 13/21 Teeth

1.87:1 15/28 Teeth

1.75:1 12/21 Teeth

1.75:1

1.75:1

1.75:1

1.75:1

28.0 fl. oz. (828.0ml)

0.025 in. (0.64mm)

.

0.017 in. – 0.028 in. (0.43mm – 0.71mm)

0.028 in. to 0.052 in. (0.71mm to

1.32mm)

0.040 in. – 0.060 in. (1.0mm – 1.52mm)

1-1/2 – 4-1/2 psi (10.3 – 30.8kPa)

8 – 10 psi (54.8 – 68.5kPa) Minimum

FUEL

SYSTEM

STARTING

SYSTEM

IGNITION

SYSTEM

Fuel

Recommended Gasoline

Recommended Oil

Gasoline/Oil Ratio

Fuel Pressure – @ Idle

– @ WOT

Manual Start – All Models

Electric Start – All Models

Starter Draw (Under Load)

Starter Load (No Load)

Minimum Brush Length

Battery Rating

Type

Spark Plug Type

1994 – 1996 S/N 0D280813 0G437999 3 Litre Work/225 Carb

1997 S/N 0G438000 and UP

3 Litre Work/225 Carb

1994/95/96/97 225 EFI/250EFI

Spark Plug Gap

NGK BPZ8H-N-10

Champion QL77CC

Gasoline w/Oil Injection

Unleaded 87 Octane Minimum

Quicksilver TC-W3 2 Cycle Outboard Oil

50:1

2 psi (13.7kPa)

8 psi (54.8kPa)

Emergency Start Rope

165 Amperes

25 Amperes

0.25 in. (65.4mm)

630 Marine Cranking Amps (MCA)

or 490 Cold Cranking Amps (CCA)

Capacitor Discharge

NGK BPZ8H-N-10

Champion QL77CC

Champion QL77CC

0.040 in. (1.0mm)

0.035 in. (0.89mm)

CHARGING

Alternator Output (Regulated)

SYSTEM

Brush Length

30 Amperes @ 750 RPM

60 Amperes @ 2000 RPM

Std. Exposed Length: 0.413 in. (10.5mm)

Min. Exposed Length: 0.059 in. (1.5mm)

90-822900R3 DECEMBER 19971A-2 - IMPORTANT INFORMATION

Page 9

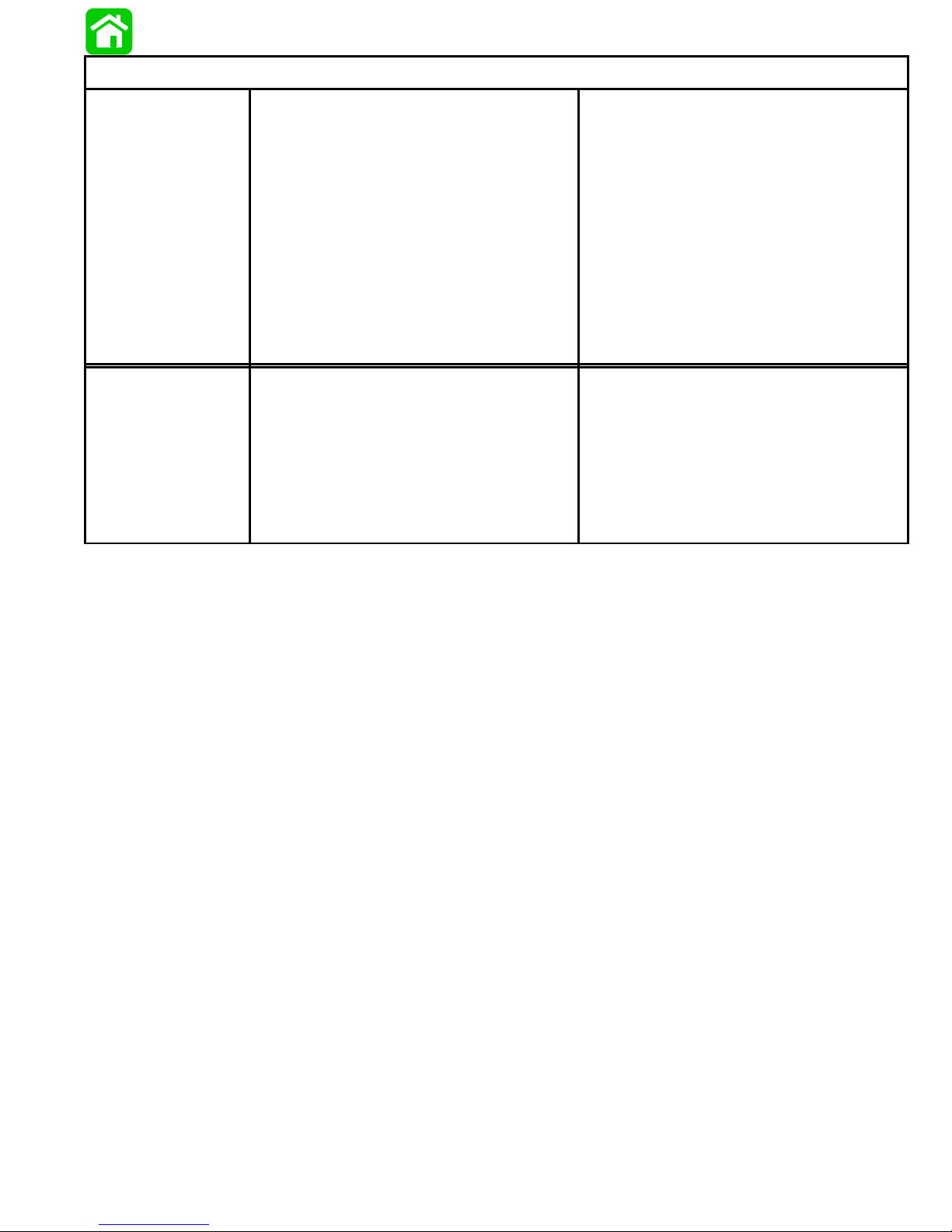

Model 3 Litre Work/225 Carb/225 EFI/250EFI

F

U

E

L

I

N

J

E

C

T

I

O

N

OIL

INJECTION

Idle RPM

– Model 225 EFI/250 EFI

Wide Open Throttle (WOT) RPM

– Model 225 EFI

– Model 250 EFI

Float Adjustment (Vapor Separator)

Float Level

Injectors

– All Models (Quantity)

– Fuel ECU Receives Signal from:

– #2 Primary Ignition Circuit

– #4 Primary Ignition Circuit

– #6 Primary Ignition Circuit

Line Pressure @ Injectors

Recommended Oil

Oil Tank Capacity (in boat)

Approx. Time

– Model 225/250

Reserve Capacity/Approx. Time

Output @ 1500 RPM for 3 Minutes

with Pump @ Full Open

650 ± 50

5000 – 5800

5000 – 5800

Preset @ Factory

6

#1 and #2 Injectors (WHITE Lead)

#3 and #4 Injectors (DARK BLUE Lead)

#5 and #6 Injectors (YELLOW Lead)

34 psi – 36 psi (234kPa – 248kPa)

Quicksilver TC-W3

3 gal. (11.4Liter)

6.0 hrs. Approx.

1.5 qt. (1.45 Liter) 30 – 35 min.

31.5cc @ 1500 RPM

90-822900R3 DECEMBER 1997 IMPORTANT INFORMATION - 1A-3

Page 10

Model 3 Litre Work/225 Carb/225 EFI/250EFI

C

A

R

B

U

R

E

T

O

R

Model 3 Litre Work

Idle RPM

Wide Open Throttle (WOT) RPM

Idle Mixture Screw Adjustment

Float Adjustment

WMV 6

– Cylinder #1

– Main Jet

– Idle Jet

– Vent Jet

650 ± 50

5000 – 5500

1-1/2±1/4

Float is Level with top of Bowl w/Bowl In-

verted

.078

.042

.080

– Cylinder #2

– Main Jet

– Idle Jet

– Vent Jet

.078

.042

.080

– Cylinder #3

– Main Jet

– Idle Jet

– Vent Jet

.080

.056

.080

– Cylinder #4

– Main Jet

– Idle Jet

– Vent Jet

.078

.018

.080

– Cylinder #5

– Main Jet

– Idle Jet

– Vent Jet

– Cylinder #6

– Main Jet

– Idle Jet

– Vent Jet

.088

.056

.080

.078

.018

.080

90-822900R3 DECEMBER 19971A-4 - IMPORTANT INFORMATION

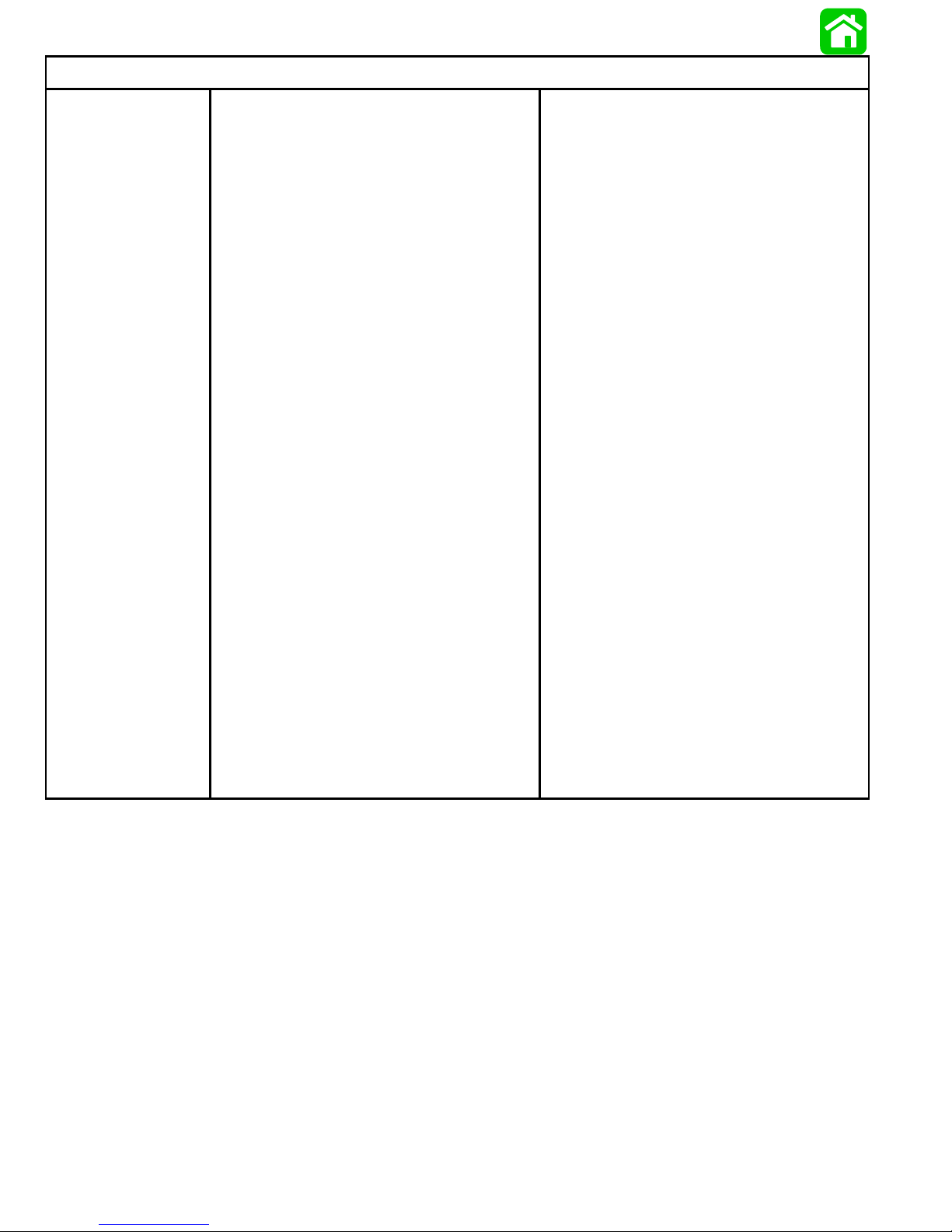

Page 11

Model 3 Litre Work/225 Carb/225 EFI/250EFI

C

A

R

B

U

R

E

T

O

R

Model 3 Litre Work

Idle RPM

Wide Open Throttle (WOT) RPM

Idle Mixture Screw Adjustment

Float Adjustment

WMV 11

– Cylinder #1

– Main Jet

– Idle Jet

– Vent Jet

650 ± 50

5000 – 5500

1-1/2±1/4

Float is Level with top of Bowl w/Bowl In-

verted

.082

.040

.080

– Cylinder #2

– Main Jet

– Idle Jet

– Vent Jet

.082

.046

.080

– Cylinder #3

– Main Jet

– Idle Jet

– Vent Jet

.082

.058

.080

– Cylinder #4

– Main Jet

– Idle Jet

– Vent Jet

.086

.048

.080

– Cylinder #5

– Main Jet

– Idle Jet

– Vent Jet

– Cylinder #6

– Main Jet

– Idle Jet

– Vent Jet

.082

.054

.080

.082

.048

.080

90-822900R3 DECEMBER 1997 IMPORTANT INFORMATION - 1A-5

Page 12

Model 3 Litre Work/225 Carb/225 EFI/250EFI

C

A

R

B

U

R

E

T

O

R

Model 225

Idle RPM

Wide Open Throttle (WOT) RPM

Idle Mixture Screw Adjustment

Float Adjustment

WMV 7

– Cylinder #1

– Main Jet

– Idle Jet

– Vent Jet

650 ± 50

5000 – 5500

1-1/2±1/4

Float is Level with top of Bowl w/Bowl In-

verted

.086

.038

.080

– Cylinder #2

– Main Jet

– Idle Jet

– Vent Jet

.086

.038

.080

– Cylinder #3

– Main Jet

– Idle Jet

– Vent Jet

.088

.070

.080

– Cylinder #4

– Main Jet

– Idle Jet

– Vent Jet

.088

.020

.080

– Cylinder #5

– Main Jet

– Idle Jet

– Vent Jet

.088

.070

.080

– Cylinder #6

– Main Jet

– Idle Jet

– Vent Jet

.088

.032

.080

90-822900R3 DECEMBER 19971A-6 - IMPORTANT INFORMATION

Page 13

Model 3 Litre Work/225 Carb/225 EFI/250EFI

C

A

R

B

U

R

E

O

R

Model 225

Idle RPM

Wide Open Throttle (WOT) RPM

Idle Mixture Screw Adjustment

Float Adjustment

Float is Level with top of Bowl w/Bowl In-

650 ± 50

5000 – 5500

1-1/2±1/4

verted

WMV 13

T

– Cylinder #1

– Main Jet

– Idle Jet

– Vent Jet

.084

.046

.082

– Cylinder #2

– Main Jet

– Idle Jet

– Vent Jet

.082

.060

.082

– Cylinder #3

– Main Jet

– Idle Jet

– Vent Jet

.084

.054

.086

– Cylinder #4

– Main Jet

– Idle Jet

– Vent Jet

.086

.052

.086

– Cylinder #5

– Main Jet

– Idle Jet

– Vent Jet

.084

.058

.082

– Cylinder #6

T

M

– Main Jet

– Idle Jet

– Vent Jet

Idle Timing

I

Maximum BTDC

@ W.O.T (5000 RPM or Above)

.082

.052

.082

4° – 8° ATDC

I

N

G

MODEL 3 LITRE WORK/225 CARB

MODEL 225 EFI

MODEL 250 EFI

19° BTDC @ 5000 RPM

24° BTDC @ 5500 RPM

24° BTDC @ 5000 RPM

24° BTDC @ 5800 RPM

24° BTDC @ 5000 RPM

28° BTDC @ 5800 RPM

NOTE: Timing specifications listed are for 1998 model year engines. Refer to timing decal on engine for previous

model year timing specifications.

90-822900R3 DECEMBER 1997 IMPORTANT INFORMATION - 1A-7

Loading...

Loading...