Page 1

30 - 60 HP Outboard

Installation Manual

NOTICE to INSTALLER

After completing assembly, these

instructions should be placed with the

product for the owner’s future use.

IMPORTANT: If the boat is to be water tested, the

operator should be familiar with the operation

procedures in the Operation and Maintenance

Manual.

Table of Contents

Boat Horsepower Capacity

U.S. COAST GUARD CAPACITY

MAXIMUM HORSEPOWER XXX

MAXIMUM PERSON

CAPACITY (POUNDS) XXX

MAXIMUM WEIGHT

CAPACITY XXX

Do not overpower or overload the boat. Most boats

will carry a required capacity plate indicating the maximum acceptable power and load as determined by

the manufacturer following certain federal guidelines.

If in doubt, contact your dealer or the boat manufacturer.

Electric Fuel Pump 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Boat Horsepower Capacity 1. . . . . . . . . . . . . . . . . . .

Outboard Remote Control 1. . . . . . . . . . . . . . . . . . . .

Selecting Accessories For The Outboard 1. . . . . . .

Installation Specifications 2. . . . . . . . . . . . . . . . . . . . .

Lifting Outboard 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Cable 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Cable Seal 3. . . . . . . . . . . . . . . . . . . . . . . . .

Steering Link Rod 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Outboard Non Thumb Screw Models 4. .

Installing Outboard Thumb Screws Models 5. . . . .

Wiring Harness 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Cable Connections 7. . . . . . . . . . . . . . . . . . .

Shift and Throttle Cable 30-40 Hp (2-Cyl.) 8. . . . . .

Shift and Throttle Cable 40-50 Hp (3-Cyl.) 10. . . . .

Shift and Throttle Cable 60 Hp 12. . . . . . . . . . . . . . .

Oil Injection Set Up 14. . . . . . . . . . . . . . . . . . . . . . . . .

Installing Remote Oil Tank (If Equipped) 14. . . . . . .

WARNING

Using an outboard that exceeds the maximum

horsepower limit of a boat can: 1. cause loss of

boat control 2. place too much weight at the transom altering the designed flotation characteristics of the boat or 3. cause the boat to break apart,

particularly around the transom area. Overpowering a boat can result in serious injury , death, or

boat damage.

Start in Gear Protection

The remote control connected to the outboard must

be equipped with a start-in-gear protection device.

This prevents the engine from starting in gear.

WARNING

Avoid serious injury or death from a sudden unexpected acceleration when starting your engine.

The design of this outboard requires that the remote control used with it must have a built in

start-in-gear protection device.

Propeller Installation 15. . . . . . . . . . . . . . . . . . . . . . . .

Trim-In Stop Adjustment – Power Trim Models 16.

Trim Tab Adjustment 16. . . . . . . . . . . . . . . . . . . . . . . .

Electric Fuel Pump

If an electric fuel pump is used, the fuel pressure must

not exceed 4 psig at the engine. If necessary, install

a pressure regulator to regulate the pressure.

Selecting Accessories For

The Outboard

Genuine Quicksilver Parts and Accessories have

been specifically designed and tested for this outboard.

Some accessories not manufactured or sold by

Quicksilver are not designed to be safely used with

this outboard or outboard operating system. Acquire

and read the installation, operation, and maintenance

manuals for all selected accessories.

90-10175010 100- 1 -Printed in U.S.A.

Page 2

Installation Specifications

a

a

b

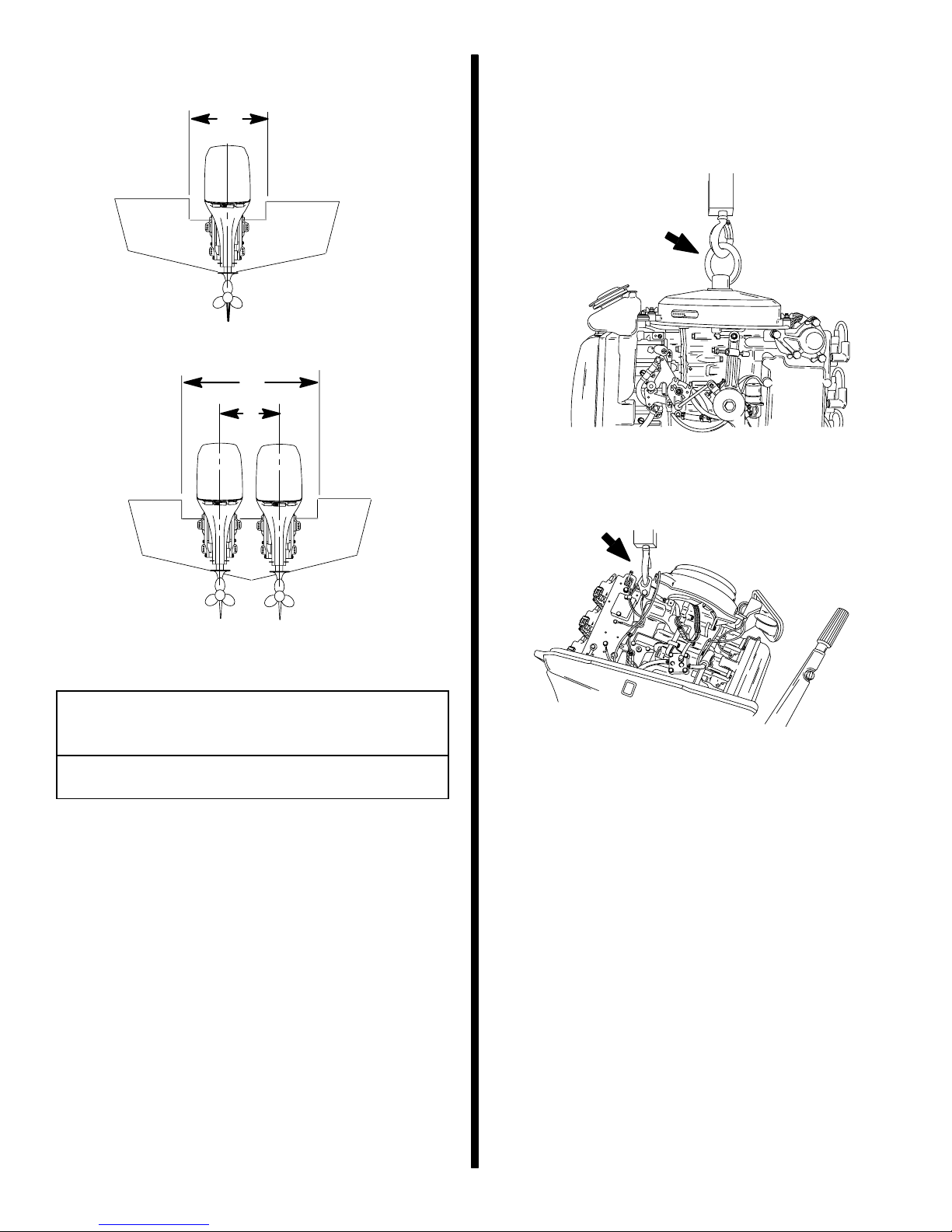

Lifting Outboard

Electric Start Models – Remove plastic cap from fly-

wheel hub. Thread lifting ring into flywheel a minimum

of 5 turns. Replace plastic cap after installation.

Manual Start Models – Use lifting eye.

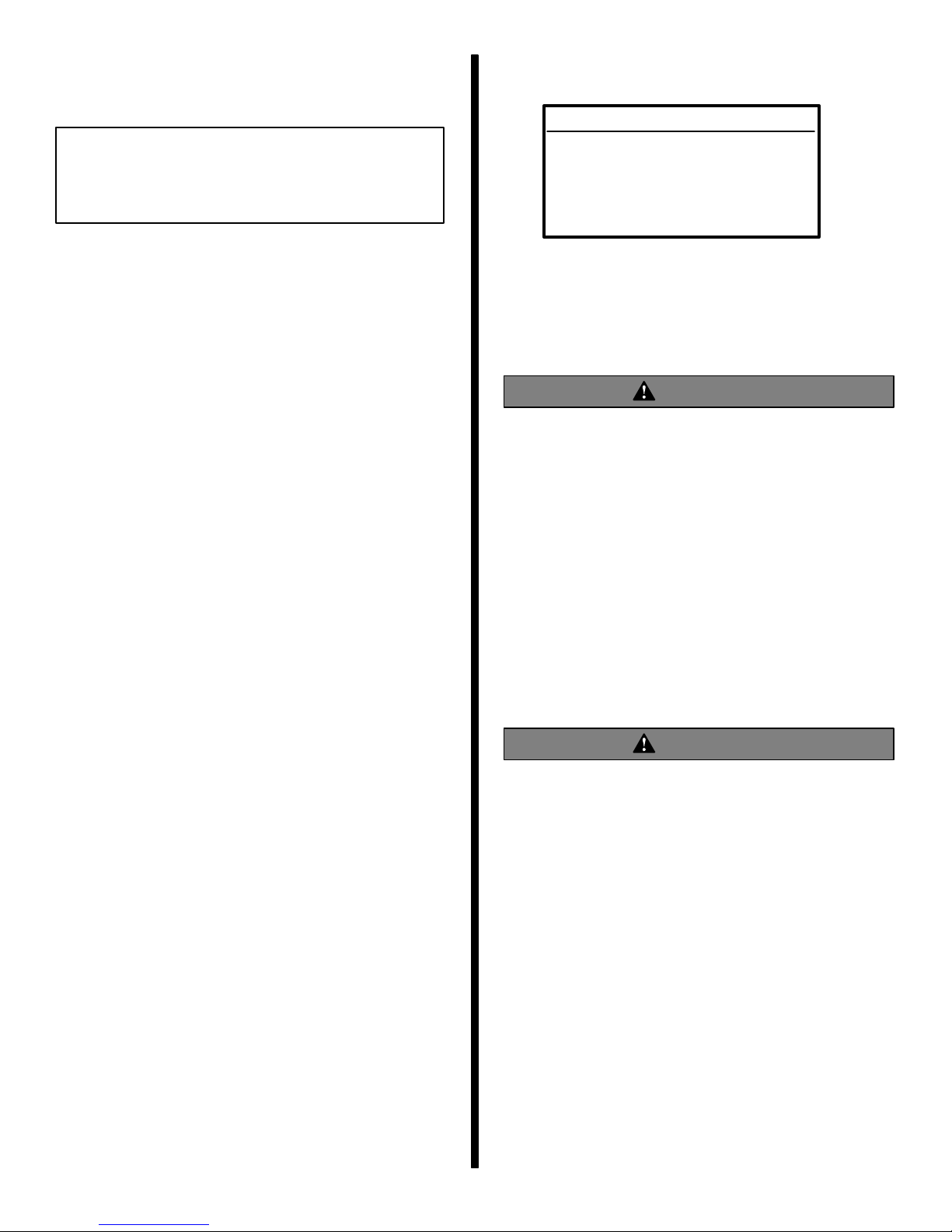

a – Transom Opening – Minimum

Single Engine – 19 in. (483 mm)

Dual Engines – 40 in. (1016 mm)

b – Engine Center Line For Dual Engine

22-1/2 in. (572 mm) Minimum

- 2 -

Page 3

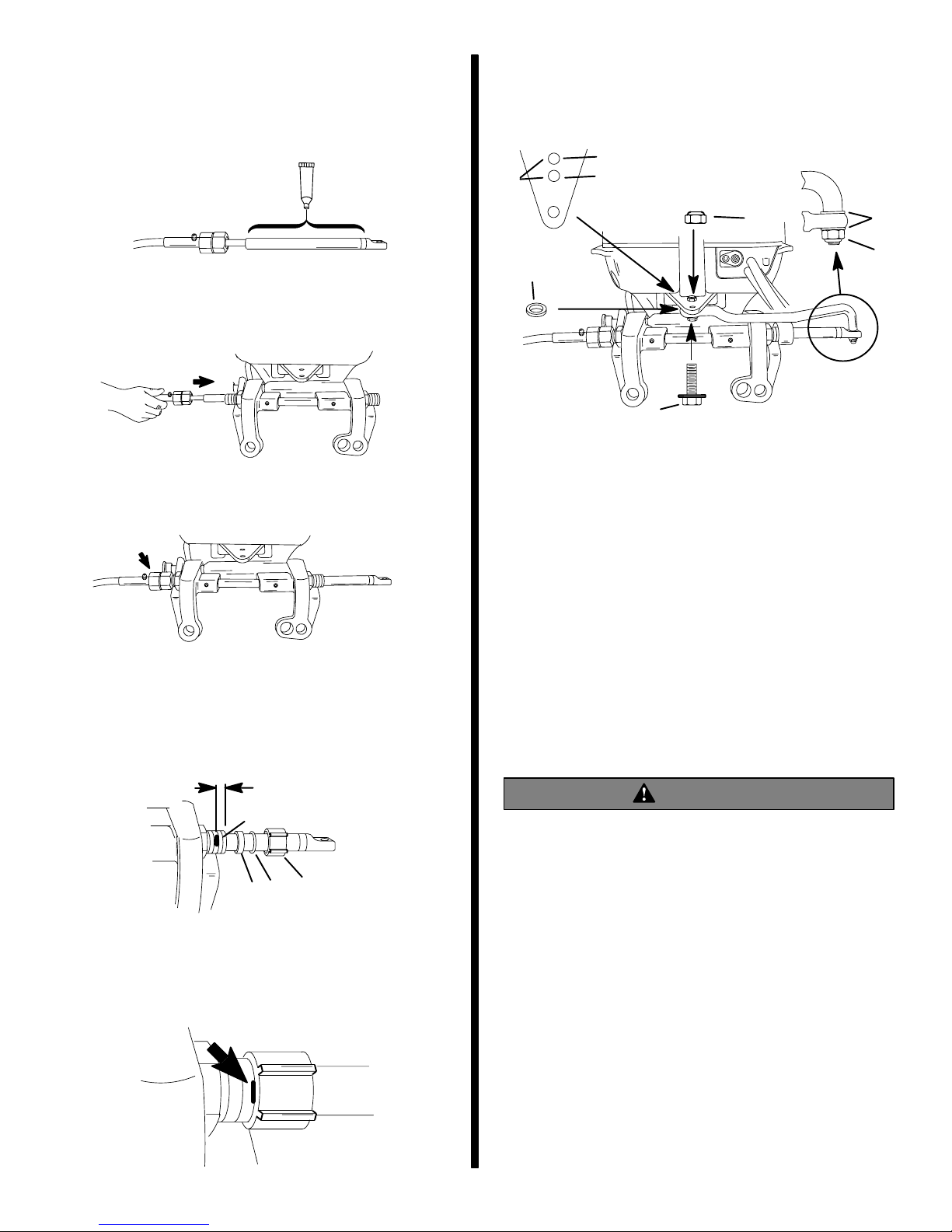

Steering Cable

Steering Link Rod

STARBOARD SIDE ROUTED CABLE

1. Lubricate the entire cable end.

a

a - Quicksilver 2-4-C Marine Lubricant with Teflon

2. Insert steering cable into tilt tube.

3. Torque nut to 35 lb. ft. (47.5 N·m).

1. Install steering link rod per illustration.

60 Hp

f

30-40-50 Hp

b

c

a

a - Special Bolt (10-90041) Torque to 20 lb. ft.(27.1 N·m)

b - Nylon Insert Locknut (11-34863) Torque to

20 lb. ft.(27.1 N·m)

c - Spacer (12-71970)

d - Flat Washer (2)

e - Nylon Insert Locknut (11-34863) Tighten Locknut Until it

Seats, Then Back Nut Off 1/4 Turn

f - Use Correct Hole

d

e

Steering Cable Seal

1. Mark tilt tube 1/4 in. (6.4 mm) from end. Install

seal components.

1/4 in. (6.4mm)

a

d

c

b

a - 1/4 In. (6.4 mm) Mark

b - Plastic Spacer

c - O-Ring Seal

d - Cap

2. Thread cap to the mark.

IMPORTANT: The steering link rod that connects

the steering cable to the engine must be fastened

using special bolt (“a” - Part Number 10-90041)

and self locking nuts (“b” & “c” - Part Number

11-34863). These locknuts must never be replaced with common nuts (non locking) as they

will work loose and vibrate off, freeing the link rod

to disengage.

WARNING

Disengagement of a steering link rod can result in

the boat taking a full, sudden, sharp turn. This potentially violent action can cause occupants to be

thrown overboard exposing them to serious injury or death.

- 3 -

Page 4

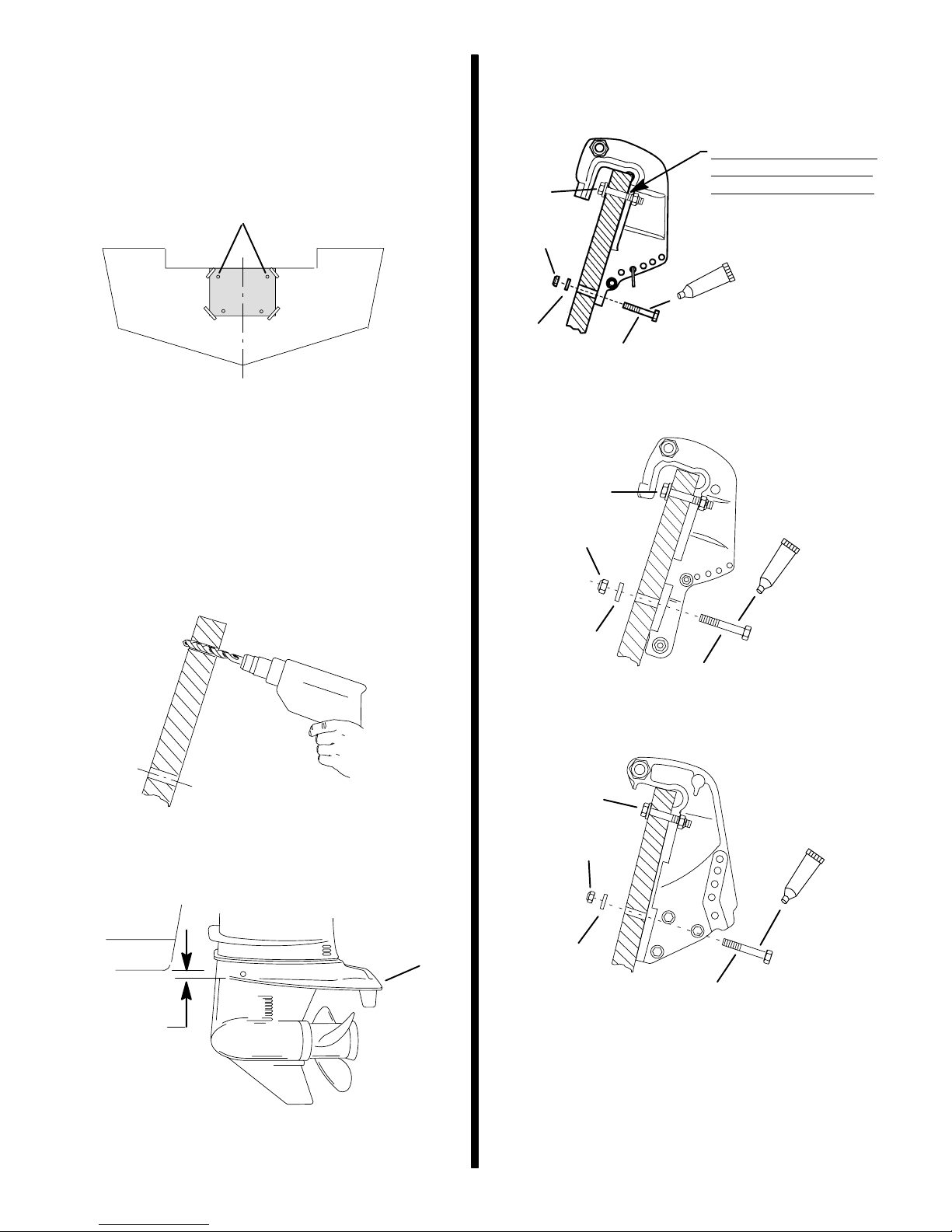

Installing Outboard – Non

Thumb Screw Models

1. Attach (tape) engine mounting template (located

in center on this manual) to boat transom.

NOTE: Drill only the top holes for Type 1

Brackets

6. Fasten outboard with provided mounting hardware shown.

Type 1 Bracket

DRILL Only the Upper

Holes Using Template

a

d

On This Type Bracket.

Mark and drill lower holes

after outboard height is

set.

e

c

b

2. T ype 1 Bracket – 30-40 Hp (2 Cyl.) Short Shaft

Versions – Mark the two upper holes and drill

17/32 in. (13.5mm) holes. Set Outboard height

(Step 5) and Drill two 3/8 in. (9.5mm) lower

mounting holes

3. Type 2 Bracket – 30-40-50 Hp – Mark and drill

four 17/32 in. (13.5mm) mounting holes.

4. Type 3 Bracket – 60 Hp – Mark and drill four

17/32 in. (13.5mm) mounting holes.

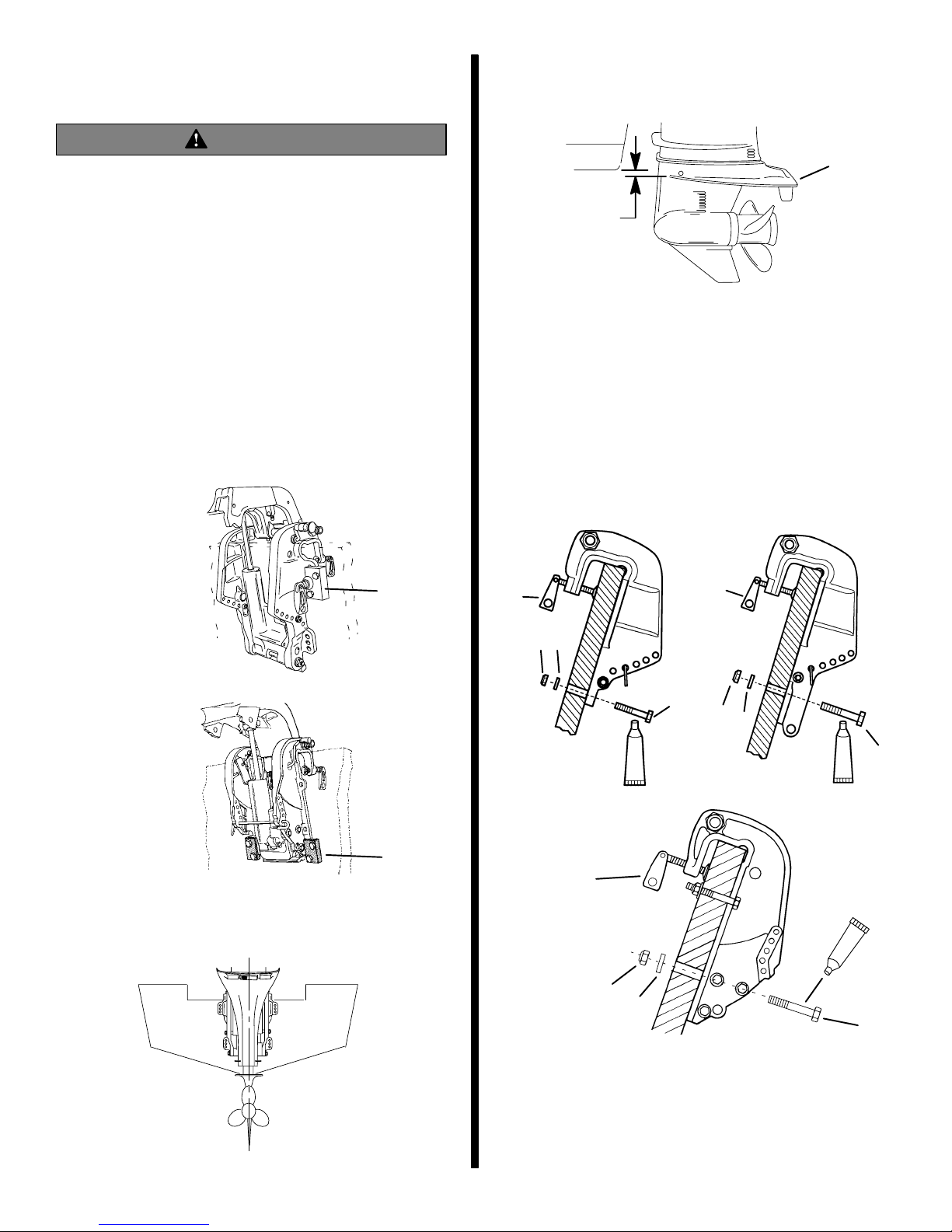

5. Install the outboard so that the anti-ventilation

plate is in-line or within 1 in. (25 mm) below the

bottom of the boat.

Type 2 Bracket

a

d

e

c

a

Type 3 Bracket

a

d

e

0 - 1 in.

(0 - 25mm)

a - Anti Ventilation Plate

a

c

a

a - 1/2 In. Diameter Bolts (2)

b - 3/8 In. Diameter Bolts (2)

c - Flat Washers (4)

d - Locknuts (4)

e - Marine Sealer - Apply to Shanks of Bolts, Not Threads

- 4 -

Page 5

Installing Outboard – Thumb

Screw Models

WARNING

Outboard must be fastened to boat transom one

of two ways: 1. permanently fastened to transom

with thumb screws, and mounting bolts (provided), or 2. secured to the transom using the optional outboard mounting kit (shown below).

Should the outboard strike an underwater object

or be steered into a sharp turn, failure to fasten

outboard correctly to the boat transom with

mounting bolts or optional mounting kit could result in outboard ejecting suddenly off boat transom causing serious injury, death, boat damage,

or loss of outboard.

1. Optional Outboard Mounting kits shown, must be

used if outboard will not be permanently fastened

to the transom with mounting bolts.

30-40-50 Hp

3. Install the outboard so that the anti-ventilation

plate is in-line or within 1 in. (25 mm) below the

bottom of the boat.

a

0 - 1 in

(0 - 25mm)

a - Anti Ventilation Plate

4. Type 1 Bracket – 30-40 Hp – Mark and drill two

3/8 in. (9.5mm) lower mounting holes.

5. Type 2 Bracket – 30-50 Hp – Mark and drill two

17/32 in. (13.5mm) lower mounting holes.

6. Type 3 Bracket – 55-60 Hp – Mark and drill four

17/32 in. (13.5mm) mounting holes.

7. Fasten outboard with provided mounting hardware shown.

Type 1 Bracket

Type 2 Bracket

55-60 Hp

a - Outboard Mounting Kit Part No. 812432A4

b - Outboard Mounting Kit Part No. 812432A5

2. Center outboard on the transom.

a

g

e

d

g

b

e

d

a

f

Type 3 Bracket

f

b

g

f

e

d

c

a - 1/2 In. Diameter Bolts (2)

b - 3/8 In. Diameter Bolts (2)

c - 1/2 In. Diameter Bolts (4)

d - Flat Washers

e - Locknuts

f - Marine Sealer - Apply to Shanks of Bolts Not Threads

g - Thumb Screws - Tighten Securely

- 5 -

Page 6

Wiring Harness

IMPORTANT: Warning Horn Requirement – The

remote control or key switch assembly must be

wired with a warning horn. This warning horn is

used with the engine warning system.

1. Route wiring harness into bottom cowl.

30-40 Hp (2 Cyl.)

2. Connect wiring. Place harness into the holder.

30-40 Hp (2 Cyl.)

40-50 Hp (3 Cyl.)

60 Hp

BLU/WHT

GRN/WHT

TAN

BRN/WHT

40-50-60 Hp (3 Cyl.)

BLU/WHT

GRN/WHT

a

a - Power Trim Connections

- 6 -

BLU/WHT

GRN/WHT

TAN

BRN/WHT

BLU/WHT

GRN/WHT

a

Page 7

30-40 HP (2 CYL.) MANUAL START MODELS

USING QUICKSILVER 2000 SERIES SIDE

MOUNT REMOTE CONTROL

1. Route the remote control harness (a) around the

back of the engine block as shown. Position the

harness so that the harness will not interfere with

shift and throttle operation.

Battery Cable Connections

SINGLE OUTBOARD

a

(+)

b

a

2. Connect the black wire (a) to engine ground and

the black/yellow wire (b) to the black/yellow engine wire.

a

ENGINE GROUND

a

BLK/YEL

b

BLK/YEL

(–)

a - Red Sleeve (Positive)

b - Black Sleeve (Negative)

c - Starting Battery

c

DUAL OUTBOARD

1. Connect a common ground cable (wire size same

as engine battery cables) between negative (–)

terminals on starting batteries.

(–)

d

(–)

d - Ground Cable (Same Wire Size As Engine Battery Cable –

Connect Between Negative (–) Terminals

- 7 -

Page 8

Shift and Throttle Cable

30 and 40 Hp (2 Cyl.) Models

3. Push-in on the cable end until resistance is felt.

Adjust the cable ba r re l ( b) t o at t ai n t he measured

distance “a” taken in Step 2.

Install cables into the remote control following the

instructions provided with the remote control.

NOTE: Install the shift cable to the engine first. The

shift cable is the first cable to move when the remote

control handle is moved out of neutral.

30-40 Hp (2 Cyl.) – Shift Cable

Installation

1. Position remote control and outboard into neutral.

N

2. Measure distance “a” between mounting pin and

middle of the barrel holder.

4. Place cable barrel into the bottom hole in the barrel holder. Fasten cable to pin with retainer.

a

b

a

c

b

a - Distance Between Pin And Middle Of Barrel Holder

b - Mounting Pin

c - Barrel Holder

c

a - Move Cable Barrel To Attain The Measured Distance

Taken In Step 2

b - Cable Barrel

c - Barrel Holder – Place Barrel Into Bottom Hole

d - Retainer

5. Check shift cable adjustments as follows:

a. Shift remote control into forward. The propel-

ler shaft should be locked in gear. If not, adjust

the barrel closer to the cable end.

b. Shift remote control into neutral. The propel-

ler shaft should turn freely without drag. If not,

adjust the b arre l away from the cable end. Repeat steps a and b.

c. Shift remote control into reverse while turning

propeller. The propeller shaft should be

locked in gear. If not, adjust the barrel away

from the cable end. Repeat steps a thru c.

d. Shift remote control back to neutral. The pro-

peller shaft should turn freely without drag. If

not, adjust the barrel closer to the cable end.

Repeat steps a thru d.

d

- 8 -

Page 9

30-40 Hp (2 Cyl.) – Throttle Cable

Installation

1. Position remote control into neutral.

4. Check throttle cable adjustment as follows:

a. Shift outboard into gear a few times to activate

the throttle linkage. Make sure to rotate the

propeller shaft while shifting into reverse.

N

2. Install cable to the throttle lever. Secure with retainer.

b

a

a - Throttle Cable

b - Retainer

3. Adjust the cable barrel so that the installed throttle

cable will hold the throttle arm against the stop.

F

b. Return remote control to neutral. Place a thin

piece of paper between throttle arm and idle

stop. Adjustment is correct when the paper

can be removed without tearing, but has

some drag on it. Readjust cable barrel if necessary.

N

R

b

a

a

c

b

a - Cable Barrel – Adjust To Hold Throttle Arm Against Stop

b - Throttle Arm

c - Barrel Holder – Place barrel Into Top Hole

a - Throttle Arm

b - Idle Stop

5. Lock the barrel holder in place with the cable

latch.

- 9 -

Page 10

Shift and Throttle Cable

40 and 50 Hp (3 Cyl.) Models

3. Push-in on the cable end until resistance is felt.

Adjust the cable ba r re l ( b) t o at t ai n t he measured

distance “a” taken in Step 2.

Install cables into the remote control following the

instructions provided with the remote control.

NOTE: Install the shift cable to the engine first. The

shift cable is the first cable to move when the remote

control handle is moved out of neutral.

40-50 Hp (3 Cyl.) – Shift Cable

Installation

1. Position remote control and outboard into neutral.

N

2. Measure distance “a” between mounting pin and

middle of the barrel holder.

4. Place cable barrel into the bottom hole in the barrel holder. Fasten cable to pin with retainer.

a

b

a

c

b

a - Distance Between Pin And Middle Of Barrel Holder

b - Mounting Pin

c - Barrel Holder

c

a - Move Cable Barrel To Attain The Measured Distance

Taken In Step 2

b - Cable Barrel

c - Barrel Holder – Place Barrel Into Bottom Hole

d - Retainer

5. Check shift cable adjustments as follows:

a. Shift remote control into forward. The propel-

ler shaft should be locked in gear. If not, adjust

the barrel closer to the cable end.

b. Shift remote control into neutral. The propel-

ler shaft should turn freely without drag. If not,

adjust the b arre l away from the cable end. Repeat steps a and b.

c. Shift remote control into reverse while turning

propeller. The propeller shaft should be

locked in gear. If not, adjust the barrel away

from the cable end. Repeat steps a thru c.

d. Shift remote control back to neutral. The pro-

peller shaft should turn freely without drag. If

not, adjust the barrel closer to the cable end.

Repeat steps a thru d.

d

- 10 -

Page 11

40-50 Hp (3 Cyl.) – Throttle Cable

Installation

1. Position remote control into neutral.

4. Check throttle cable adjustment as follows:

a. Shift outboard into gear a few times to activate

the throttle linkage. Make sure to rotate the

propeller shaft while shifting into reverse.

N

2. Install cable to the throttle lever. Tighten locknut,

then back-off the locknut 1/4 turn.

a

b

c

a - Throttle Cable

b - Nylon Washer

c - Locknut – Tighten Locknut, Then Back-Off The Locknut 1/4

Turn

F

N

R

b. Return remote control to neutral. Place a thin

piece of paper between idle adjustment screw

and idle stop. Adjustment is correct when the

paper can be removed without tearing, but

has some drag on it. Readjust cable barrel if

necessary.

b

a

3. Adjust the cable barrel so that the installed throttle

cable will hold the idle adjustment screw against

the stop.

a

c

b

a - Idle Adjustment Screw

b - Idle Stop

5. Lock the barrel holder in place with the cable

latch.

a - Cable Barrel – Adjust To Hold Idle Adjustment Screw

Against Stop

b - Idle Adjustment Screw

c - Barrel Holder – Place barrel Into Top Hole

- 11 -

Page 12

Shift and Throttle Cable

60 Hp Models

3. Push-in on the cable end until resistance is felt.

Adjust the cable ba r re l ( b) t o at t ai n t he measured

distance “a” taken in Step 2.

Install cables into the remote control following the

instructions provided with the remote control.

NOTE: Install the shift cable to the engine first. The

shift cable is the first cable to move when the remote

control handle is moved out of neutral.

60 Hp – Shift Cable Installation

1. Position remote control and outboard into neutral.

N

2. Measure distance “a” between mounting pin and

middle of the barrel holder.

4. Place cable barrel into the bottom hole in the barrel holder. Fasten cable to pin with locknut.

a

b

d

a

c

a - Distance Between Pin And Middle Of Barrel Holder

b - Mounting Pin

c - Barrel Holder

e

c

a - Move Cable Barrel To Attain The Measured Distance

Taken In Step 2

b

b - Cable Barrel

c - Barrel Holder – Place Barrel Into Bottom Hole

d - Nylon Washer

e - Locknut – Tighten Locknut, Then Back-Off The Locknut 1/4

Turn

5. Check shift cable adjustments as follows:

a. Shift remote control into forward. The propel-

ler shaft should be locked in gear. If not, adjust

the barrel closer to the cable end.

b. Shift remote control into neutral. The propel-

ler shaft should turn freely without drag. If not,

adjust the b arre l away from the cable end. Repeat steps a and b.

c. Shift remote control into reverse while turning

propeller. The propeller shaft should be

locked in gear. If not, adjust the barrel away

from the cable end. Repeat steps a thru c.

d. Shift remote control back to neutral. The pro-

peller shaft should turn freely without drag. If

not, adjust the barrel closer to the cable end.

Repeat steps a thru d.

- 12 -

Page 13

60 Hp – Throttle Cable Installation

1. Position remote control into neutral.

N

4. Check throttle cable adjustment as follows:

a. Shift outboard into gear a few times to activate

the throttle linkage. Make sure to rotate the

propeller shaft while shifting into reverse.

2. Install cable to the throttle lever. Tighten locknut,

then back-off the locknut 1/4 turn.

a

b

c

a - Throttle Cable

b - Nylon Washer

c - Locknut – Tighten Locknut, Then Back-Off The Locknut 1/4

Turn

3. Adjust the cable barrel so that the installed throttle

cable will hold the idle adjustment screw against

the stop.

F

N

R

b. Return remote control to neutral. Place a thin

piece of paper between idle adjustment screw

and idle stop. Adjustment is correct when the

paper can be removed without tearing, but

has some drag on it. Readjust cable barrel if

necessary.

b

a

b

a

c

a - Cable Barrel – Adjust To Hold Idle Adjustment Screw

Against Stop

b - Idle Adjustment Screw

c - Barrel Holder – Place Barrel Into Top Hole

a - Idle Adjustment Screw

b - Idle Stop

5. Lock the barrel holder in place with the cable

latch.

- 13 -

Page 14

Oil Injection Set Up

Installing Remote Oil Tank

1.Fill engine oil tank with oil.

2.Inspect the oil pump inlet hose (a) for air bubbles.

If air exists, place a shop towel below the oil pump

and loosen bleed screw (c) four turns. Allow oil to

flow out of the bleed hole until air is removed from

the hose.

3.Inspect the oil pump outlet oil hose (b) for air

bubbles. If air exists, disconnect link rod from oil

pump. Start engine and run at 1000 to 1500 RPM.

Rotate (and hold) the pump arm full clockwise until the air is purged out of the hose.

b

a

(If Equipped)

MOUNTING OIL TANK

1.Mount the remote oil tank in the boat. The tank

should be restrained from moving. Use the oil

tank hold down kit provided.

2.Arrange the hoses so they will not get pinched,

kinked, or stretched during operation.

NOTE: A Quicksilver Accessory oil hose extension kit

(41729A3) is available.

c

e

a-Inlet Hose

b-Outlet Hose

c-Bleed Screw – Torque to 15 lb. in. (N·m

d-Link Rod

e-Pump Arm

4.Reconnect the link rod. Set carburetor linkage at

idle position. Alignment marks should line-up. If

necessary, adjust link rod.

)

d

CONNECTING REMOTE OIL TANK HOSES

3.Remove shipping caps from oil hose fittings and

connect hoses as shown. Fasten hose with stastrap.

Oil Hoses From Engine

Black

Black with

Blue Stripe

Black with

Blue Stripe

Oil Hoses From Remote Oil Tank

Black

a

a-Sta-Strap – Secure Hose Connections

4.Remove the filler cap and fill remote tank with oil. Oil

tank capacity is 3 gallons (11.5 liters). Reinstall filler

cap and tighten securely.

IMPORTANT: Always make sure the oil tank caps

are threaded on tight. An air leak will prevent oil

flow to the engine.

- 14 -

Page 15

Propeller Installation

Propeller Installation (Cont.)

3-1/4 in. (83mm) Diameter Gear Case

WARNING

If the propeller shaft is rotated while the engine is

in gear, there is the possibility that the engine will

crank over and start. To prevent this type of accidental engine starting and possible serious injury caused from being struck by a rotating propeller, always shift outboard to neutral position and

remove spark plug leads when you are servicing

the propeller.

Flo-Torq I Drive Hub Propellers

cb

a - Forward Thrust Hub

b - Propeller Nut Retainer

c - Propeller Nut

Flo-Torq II Drive Hub Propellers

c

d

e

a

4-1/4 in. (108 mm) Diameter Gear

Case

WARNING

If the propeller shaft is rotated while the engine is

in gear, there is the possibility that the engine will

crank over and start. To prevent this type of accidental engine starting and possible serious injury caused from being struck by a rotating propeller, always shift outboard to neutral position and

remove spark plug leads when you are servicing

the propeller.

Flo-Torq I Drive Hub Propellers

b

e

a - Forward Thrust Hub

b - Continuity Washer

c - Thrust Hub

d - Propeller Nut Retainer

e - Propeller Nut

Flo-Torq II Drive Hub Propellers

d

c

a

b

a - Forward Thrust Hub

b - Replaceable Drive Sleeve

c - Rear Thrust Hub

d - Propeller Nut Retainer

e - Propeller Nut

5. Tighten propeller nut to 55 lb.ft. (75 N·m). Bend

tabs against nut.

a

b

a - Propeller Nut - Torque To 55 lb. ft. (75 N·m)

b - Bend Tabs Against Nut

a

e

a - Forward Thrust Hub

b - Replaceable Drive Sleeve

c - Rear Thrust Hub

d - Propeller Nut Retainer

e - Propeller Nut

6. Tighten propeller nut to 55 lb.ft. (75 N·m). Bend

tabs into grooves.

c

d

b

a

a

b

b

a - Propeller Nut - Torque To 55 lb. ft. (75 N·m)

b - Bend Tabs Into Grooves

- 15 -

Page 16

Trim-In Stop Adjustment –

Trim Tab Adjustment

Power Trim Models

40-50 Hp

If an adjustment is required to the the trim-in stop, reposition the tilt stop pins as follows:

1. Lock the outboard in the full tilt position.

2. Remove bottom pivot pin.

3. Swing the power trim system outward to gain access to the tilt stop pins. Reposition the tilt stop

pins in the desired holes.

4. Reinstall the bottom pivot pin. Torque pivot pin

nuts to 18 lb. ft. (24.4 N·m).

a

a

The trim tab can be adjusted within limits to help to

compensate for steering torque.

Adjust trim tab as follows:

1. If boat tends to pull to the right, move the rear

edge of the trim tab to the right.

2. If boat tends to pull to the left, move the rear edge

of the trim tab to the left.

NOTE: Trim tab adjustment will have little effect reducing steering torque if the the anti-ventilation plate

is raised 2 inches (50mm) or more above the boat bottom.

b

28216

a Tilt Stop Pins

b - Bottom Pivot Pin

60 Hp

If an adjustment is required, purchase a stainless

steel tilt pin (P/N 17-49930A1) and insert it through

whatever pin hole is desired. The non-stainless steel

shipping bolt should not be used in this application

other than on a temporary basis.

a

a - Tilt Pin

28216

- 16 -

Loading...

Loading...