Page 1

Service Manual Outline

Section 1 - Important Information

A - Specifications

B - Maintenance

C - General Information

D - Outboard Installation

Section 2 - Electrical

A - Ignition

B - Charging & Starting System

C - Timing, Synchronizing & Adjusting

D - Wiring Diagrams

Section 3 - Fuel System

A - Carburetor/Fuel Pump

B - Emissions

Section 4 - Powerhead

Section 5 - Mid-Section

Section 6 - Lower Unit

A - Gear Housing

B - Jet Drive

Section 7 - Attachments/Control Linkage

A - Throttle/Shift Linkage

B - Tiller Handle

C - Side Shift

Section 8 - Manual Starter

Important Information

1

Electrical

2

Fuel System

3

Powerhead

4

Mid-Section

5

Lower Unit

6

Attachment/Control Linkage

7

Manual Starter

8

9

90-826883R2 JUNE 1998 Page iii

Page 2

Notice

Throughout this publication, “Dangers”, “Warnings” and “Cautions” (accompanied by the International HAZARD Symbol

cerning a particular service or operation that may be hazardous if performed incorrectly or

carelessly . OBSERVE THEM CAREFULLY!

These “Safety Alerts” alone cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus “Common Sense” operation,

are major accident prevention measures.

) are used to alert the mechanic to special instructions con-

DANGER

DANGER - Immediate hazards which WILL result in severe personal injury or death.

W ARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

Notice to Users of This Manual

This service manual has been written and published by the Service Department of Mercury

Marine to aid our dealers’ mechanics and company service personnel when servicing the

products described herein.

It is assumed that these personnel are familiar with the servicing procedures of these products, or like or similar products manufactured and marketed by Mercury Marine, that they

have been trained in the recommended servicing procedures of these products which includes the use of mechanics’ common hand tools and the special Mercury Marine or recommended tools from other suppliers.

We could not possibly know of and advise the service trade of all conceivable procedures

by which a service might be performed and of the possible hazards and/or results of each

method. We have not undertaken any such wide evaluation. Therefore, anyone who uses

a service procedure and/or tool, which is not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the products safety will be endangered by the

service procedure selected.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this

manual will be sent to all dealers contracted by us to sell and/or service these products.

It should be kept in mind, while working on the product, that the electrical system and ignition

system are capable of violent and damaging short circuits or severe electrical shocks. When

performing any work where electrical terminals could possibly be grounded or touched by

the mechanic, the battery cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed during service they should be covered

to protect against accidental entrance of foreign material which could enter the cylinders and

cause extensive internal damage when the engine is started.

90-826883R2 JUNE 1998 Page i

Page 3

It is important to note, during any maintenance procedure replacement fasteners must have

the same measurements and strength as those removed. Numbers on the heads of the metric bolts and on the surfaces of metric nuts indicate their strength. American bolts use radial

lines for this purpose, while most American nuts do not have strength markings. Mismatched or incorrect fasteners can result in damage or malfunction, or possibly personal

injury . Therefore, fasteners removed should be saved for reuse in the same locations whenever possible. Where the fasteners are not satisfactory for re-use, care should be taken to

select a replacement that matches the original.

Cleanliness and Care of Outboard Motor

A marine power product is a combination of many machined, honed, polished and lapped

surfaces with tolerances that are measured in the ten thousands of an inch/mm. When any

product component is serviced, care and cleanliness are important. Throughout this manual, it should be understood that proper cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is considered standard shop practice

even if not specifically stated.

Whenever components are removed for service, they should be retained in order. At the

time of installation, they should be installed in the same locations and with the same mating

surfaces as when removed.

Personnel should not work on or under an outboard which is suspended. Outboards should

be attached to work stands, or lowered to ground as soon as possible.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products de-

scribed in this manual.

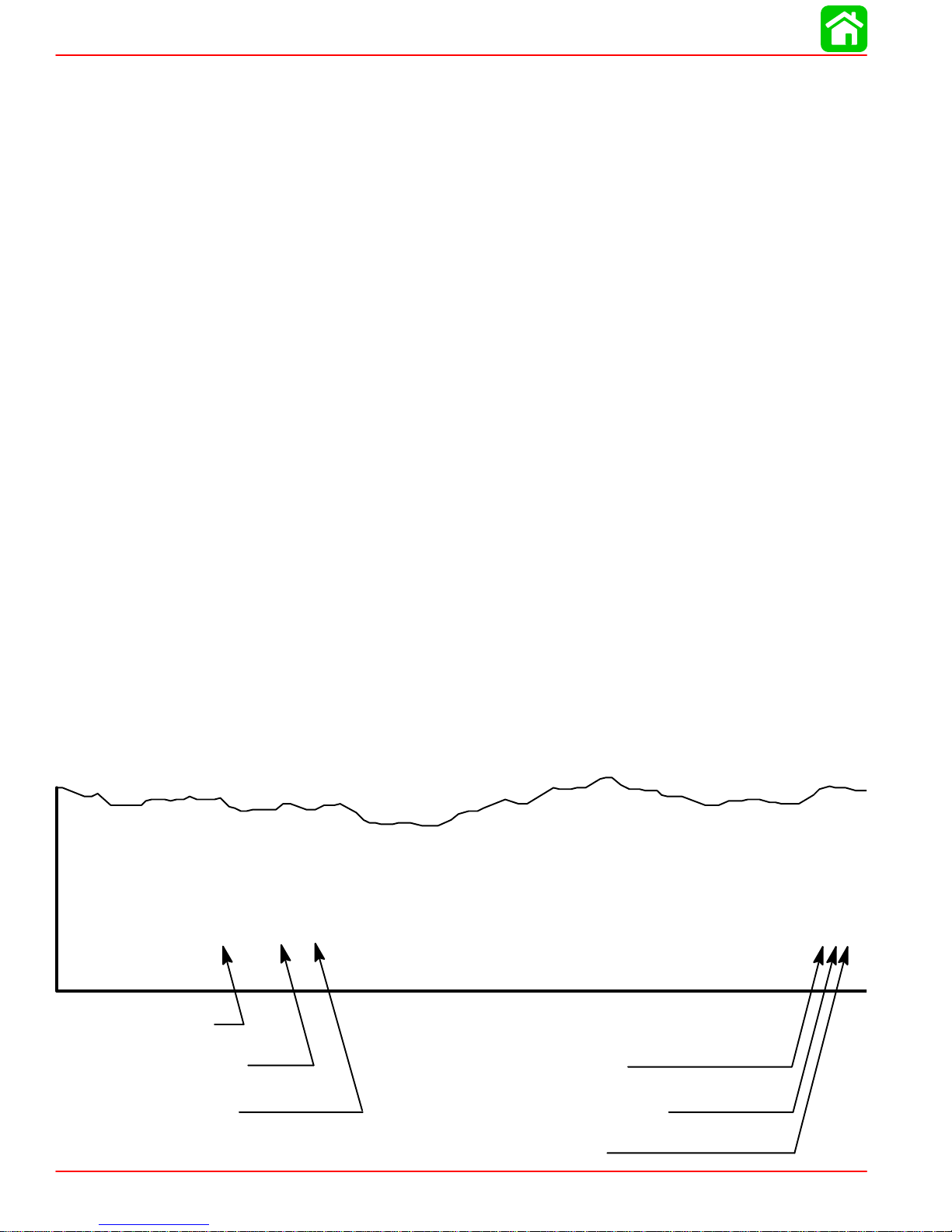

Page Numbering

Two number groups appear at the bottom of each page. The example below is self-explanatory .

90-826883 R2 JUNE 1998

EXAMPLE:

6A-7

Revision No. 2

Month of Printing

Year of Printing

Page ii 90-826883R2 JUNE 1998

Section Number

Part of Section Letter

Page Number

Page 4

SPECIFICATIONS

IMPORTANT INFORMATION

Section 1A - Specifications

Table of Contents

Master Specifications 1A-2. . . . . . . . . . . . . . . . . . . . . . . . .

1

A

90-826883R2 JUNE 1998 Page 1A-1

Page 5

SPECIFICATIONS

Master Specifications

Model 15XD/20 Jet /20/25

HORSEPOWER

(KW)

OUTBOARD

WEIGHT

CYLINDER

BLOCK

Model 20 Jet

Model 20

Model 25

15 in. (38 cm)

20 in. (51 cm)

20 Jet

Type

Displacement

20 (14.9)

20 (14.9

25 (18.7)

114 lbs - 52 kg

117 lbs - 53 kg

124 lbs - 56 kg

Two Cylinder - Two Cycle

24.4 cu. in. (400 cc)

STROKE Length 2.362 in. (60 mm)

CYLINDER

BORE

Diameter (Standard)

Taper/Out of Round Maximum*

2.562 in. (65.01 mm)

0.003 in. (0.08 mm)*

Bore Type:

S/N 0G202749 and Below

S/N 0G202750 and Above

CRANK SHAFT Top Main Bearing Journal

Center Main Bearing Journal

Bottom Main Bearing Journal

Connecting Rod Journal

End Play

CONNECTING

ROD

Piston Pin End (I.D.)

Crankpin End (I.D.)

1.251 in. (31.77 mm)

1.000 in. (25.40 mm)

1.125 in. (28.58 mm)

0.883 in. (22.43 mm)

0.004-0.019 (0.10-0.64 mm)

0.897 in. (22.78 mm)

1.196 in. (30.38 mm)

Chrome

Mercosil

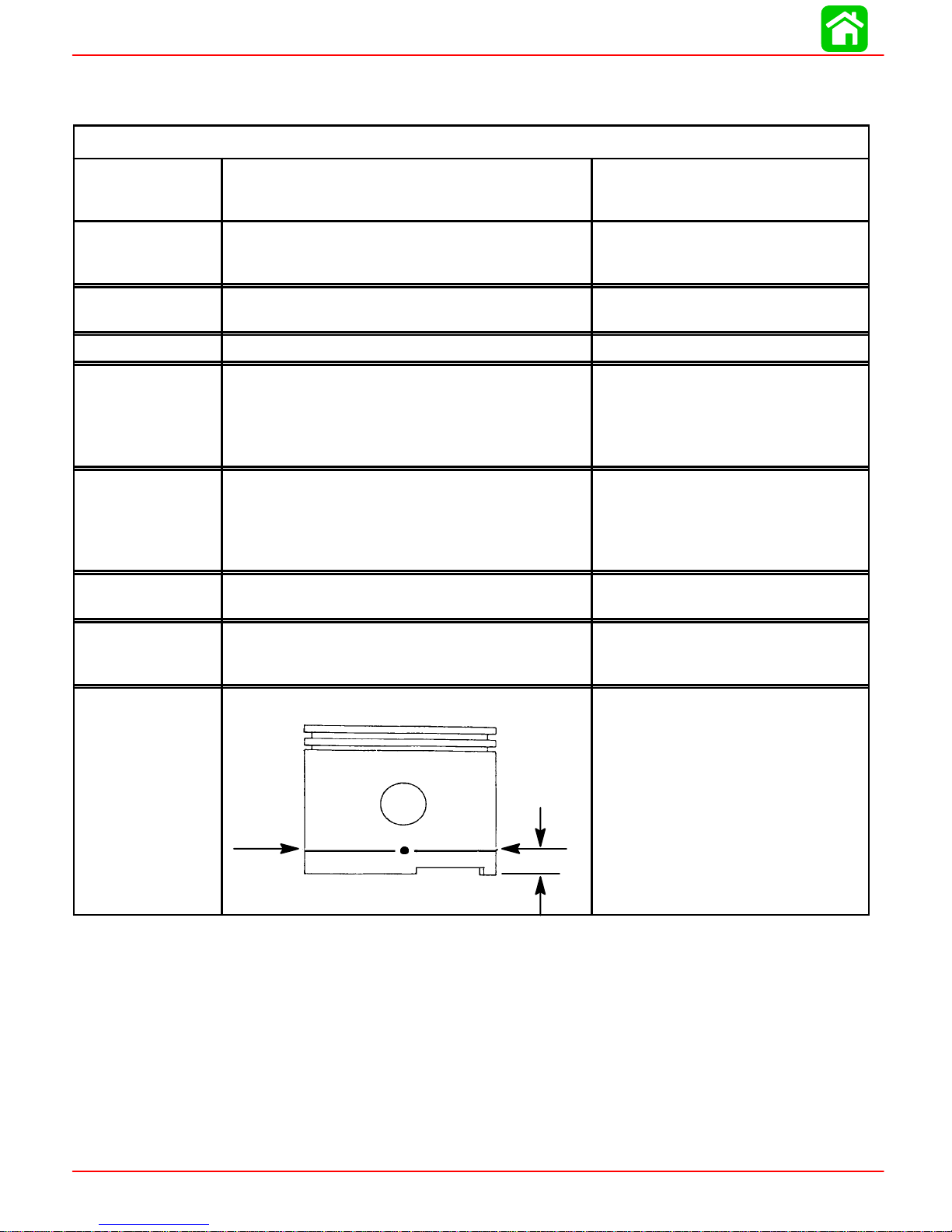

PISTON Piston Type

O.D. at Skirt (Standard)

Ring End Gap

PISTON DIA.

Dimension “A”

at Right Angle

°) to Pis-

(90

ton Pin

*Models S/N 0G202749 and Below:

NOTE: The cylinder bores are chrome and cannot be be rebored or efficiently honed.

Check each cylinder bore for an out-of-round “egg shaped” cylinder. A maximum of 0.003

in. (0076mm) is allowable.

*Models S/N 0G202750 and Above:

NOTE: The cylinder block is Mercosil and the cylinders can be rebored to 0.030 in. over-

sized. Check each cylinder bore for an out-of-round “egg shaped” cylinder. A maximum

of 0.003 in. (0.076mm) is allowed.

0.50 in.

(12.7 mm)

Aluminum

2.5583 - 2.5593 (64.98 - 65.00)

0.011-0.025 (.28 mm - .64 mm)

2.5583 in. ± .0005 in.

(64.98 mm ± .0127 mm)

micrometer , measure dimension

“A” at location shown. Dimension

“A” should be 2.5583 in. ± .0005 for

a STANDARD size piston (new) Dimension “A” will be 0.001 – 0.0015

less if coating is worn off piston

(used)

Using a

Page 1A-2 90-826883R2 JUNE 1998

Page 6

Master Specifications

SPECIFICATIONS

GEAR

HOUSING

Forward - Neutral - Reverse

Gear Ratio

Gearcase Capacity

Lubricant Type

Full Shift

2.25:1

8.8 fl.oz. (260 ml)

Quicksilver Gear Lube Premium

Blend

Forward Gear - No. of Teeth-Type

Pinion Gear - No. of Teeth-Type

Pinion

Foreword Gear Backlash

Reverse Gear Backlash

Water Pressure @ RPM

Water Pressure With 120° Thermostat

2-7 PSI @ 2000 RPM

27

12

Not Adjustable

Not Adjustable

Not Adjustable

0-6 PSI (SPORADIC) 2000 RPM

MID

SECTION

FUEL

SYSTEM

Transom Height - Short Shaft

- Long Shaft

Fuel Pump Type

Recommended Gasoline

15 in. (38 cm)

20 in. (51 cm)

Integral

Automotive Unleaded

with a Minimum Pump Posted

Octane Rating of 87

Fuel Tank Capacity

Operating Fuel/Oil Ratio

6.6 U.S. Gallons

50:1

OIL Recommended Oil (Pre-Mix @ 50:1) NMMA TC-W II or TC-W III

2-Cycle Outboard Oil

STARTING

SYSTEM

CHARGING

SYSTEM

Manual Start

Rope Length

Electric Start

Ampere Draw (cranking)

Alternator Output

BLACK Stator - 2 Magnet Flywheel

RED Stator - 4 Magnet Flywheel

(8 Pole)(4 Pulses)

(10 Pole)(5 Pulses)

Recoil

66 in. (1676 mm)

12 Volt

55 amperes

4 Amp. (48 Watt)

@ 6000 RPM

6 amp (72 Watt)

@ 6000 RPM

BATTERY Battery Rating 465 Marine Cranking Amps (MCA)

or 350 Cold Cranking Amps (CCA)

90-826883R2 JUNE 1998 Page 1A-3

Page 7

SPECIFICATIONS

IGNITION

SYSTEM

Readings taken @

68°F (20°C).

Type

Spark Plug Type (NGK)

Spark Plug Gap

Spark Plug Hex

Firing Order

20 Jet 1994

20/25 1994

1

/2 THRU 1998

1

/2 THRU 1996

Electronic Spark Advance

Idle @ 750 ± 50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Setup Timing

Stator High Speed Winding

Stator Low Speed Winding

Diode Test

Ignition Coil Resistance:

Primary

Secondary (w/o Boots)

20 Jet 1999 and Newer

20/25 1997/98 Models

Mechanical Spark Advance

Idle @ 750 ± 50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Stator High Speed Winding

Stator Low Speed Winding

Diode Test

Ignition Coil Resistance:

Primary

Secondary (w/o Boots)

Trigger

Capacitor Discharge Ignition

NGK BP8H-N-10

0.040 in. (1.0 mm)

18 mm

1-2

4°±2° B.T.D.C (Not Adjustable)

1400 RPM ± 250 RPM

25°±1 @5500 RPM

28° B.T.D.C. @ 3000 ± 200 R.P.M.

(Set-up timing of 28° B.T.D.C. will

be retarded to 25° B.T.D.C. @

5500 R.P.M.)

100 – 180 Ω (RED – BLK)

2900 – 3500 Ω (BLUE – BLACK)

2800 – 3400 Ω (RED – BLUE)

0 Ω

850 – 1200 Ω

6°±1° B.T.D.C

1500 RPM ± 200 RPM

25°±1 @5500 RPM

120 - 180 Ω (BLK/WHT - GRD)

3200 - 3800 Ω (BLK/YEL - GRD)

3100 – 3700 Ω (BLK/YEL - BLK/

WHT)

0.02 - 0.04 Ω

8000 - 11000 Ω

6500 - 8500 Ω

JET DRIVE Impeller Liner Clearance 0.030 in. (0.8 mm)

* Use NGK BPZ8H-N-10 Where Radio Frequency Interference (RFI) Suppression is

Required.

Page 1A-4 90-826883R2 JUNE 1998

Page 8

Master Specifications

SPECIFICATIONS

CARBURETOR

SPECIFI-

CATIONS

TIMING

SPECIFI-

CATIONS

Idle RPM (In Forward Gear)

Wide Open Throttle (WOT) RPM

20

25

Idle Mixture Screw

Adjustment (Preset-Turns Out)

20

20 Jet

25/25 Seapro/25 Marathon

Float Level

Main Jet Size

1

1994

/2 thru 1996

-20 (WMC-44)

-25/20 Jet (WMC-45)

-25 Seapro/Marathon (WMC-46)

-25 Seapro/Marathon (WMC-46A)

1997 and Newer

-20 Jet (WMC-45)

-20 (WMC-52)

-25 (WMC-53)

-25 Seapro/Marathon (WMC-54)

20 Jet 19941/2 THRU 1998

1

20/25 1994

/2 THRU 1996

Electronic Spark Advance

Idle @ 750 ± 50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Setup Timing

20/25 1997 AND NEWER

20 Jet 1999 AND NEWER

Mechanical Spark Advance

Idle @ 750 ± 50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

750 ± 50

4500 - 5500

5000 - 6000

1 ± 1/4 Turn

1-1/2 ± 1/2 Turn

1-1/4 ± 1/4 Turn

1.0 in. (25.4 mm)

0.044 in. (1.12 mm)

0.076 in. (1.93 mm)

0.076 in. (1.93 mm)

0.080 in. (2.03 mm)

0.076 in. (1.93 mm)

0.044 in. (1.12 mm)

0.076 in. (1.93 mm)

0.080 in. (2.03 mm)

4°±2° B.T.D.C (Not Adjustable)

1400 RPM ± 250 RPM

25°±1 @5500 RPM

28° B.T.D.C. @ 3000 ± 200 R.P.M.

(Set-up timing of 28° B.T.D.C. will

be retarded to 25° B.T.D.C. @

5500 R.P.M.)

6°±1° B.T.D.C

1500 RPM ± 200 RPM

25°±1 @5500 RPM

90-826883R2 JUNE 1998 Page 1A-5

Page 9

MAINTENANCE

IMPORTANT INFORMATION

Section 1B - Maintenance

Table of Contents

Table of Contents 1B-1. .. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubricant Capacity 1B-1. . . . . . . . . . . . . .

Special Tools 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quicksilver Lubricant/Sealant 1B-2. . . . . . . . . . . . . . .

Inspection and Maintenance Schedule 1B-3. . . . . . . . . .

Before Each Use 1B-3. . . . . . . . . . . . . . . . . . . . . . . . .

After Each Use 1B-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Every 100 Hours of Use or O nce Yearly,

Whichever Occurs First 1B-3. . . . . . . . . . . . . . . . . . . .

Every 300 Hours of Use or T hree Years 1B-3. . . . . .

Flushing The Cooling System 1B-4. . . . . . . . . . . . . . . . .

Fuel System 1B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Line Inspection 1B-5. . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel Filter 1B-5. . . . . . . . . . . . . . . . . . . . . . . . .

Corrosion Control Anode 1B-6. . . . . . . . . . . . . . . . . . . . .

Spark Plug Inspection 1B-7. . . . . . . . . . . . . . . . . . . . . . . .

1

B

Battery Inspection 1B-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse Replacement -- Electric Start Remote

Control Models 1B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication Points 1B-8.. .. .. .. .. .. .. .. .. .. .. .. .. .

Gear Case Lubrication 1B-10. . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubricant Capacity 1B-10. . . . . . . . . . . . .

Draining Gear Case 1B-10. . . . . . . . . . . . . . . . . . . . . .

Draining Gear Case 1B-1 1.. . . . . . . . . . . . . . . . . . . . .

Checking Lubricant Level and Refilling

Gear Case 1B-11. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

Storage Preparations 1B-12. . . . . . . . . . . . . . . . . . . . . . .

Fuel System 1B-12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protecting External Engine Components 1B-12. . . .

Protecting Internal Engine Components 1B-12. . . . .

Gear Case 1B-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Outboard for Storage 1B-13. . . . . . . . . .

Battery Storage 1B-13. . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Gear Case Lubricant Capacity

Gear Case Ratio Capacity

2.25:1 8.8 fl. oz. (260.0ml)

Special Tools

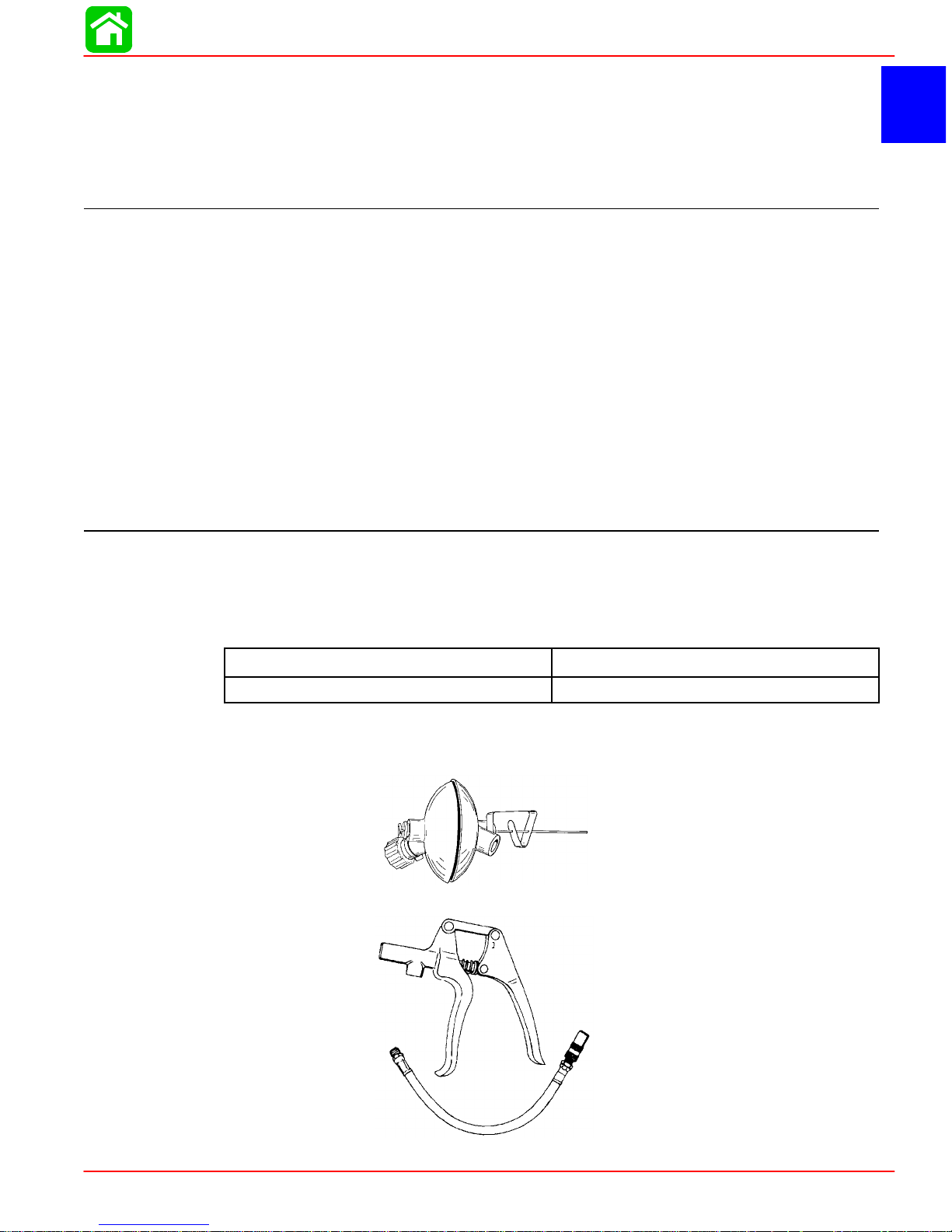

1. Flushing Attachment 44357A2

2. Grease Gun 91-37299A1

90-826883R2 JUNE 1998 Page 1B-1

Page 10

MAINTENANCE

Quicksilver Lubricant/Sealant

1. Quicksilver Anti-Corrosion Grease P/N 92-78376A6

2. 2-4-C Marine Lubricant with Teflon P/N 92-825407A12

3. SAE 30W Motor Oil P/N 92-97959

4. Quicksilver Gear Lubricant P/N 92-19007A24

Page 1B-2 90-826883R2 JUNE 1998

Page 11

Inspection and Maintenance Schedule

Before Each Use

1. Check that lanyard stop switch stops the engine.

2. Visually inspect the fuel system for deterioration or leaks.

3. Check outboard for tightness on transom.

4. Check steering system for binding or loose components.

5. Visually check steering link rod fasteners for proper tightness.

6. Check propeller blades for damage.

After Each Use

1. Flush out the outboard cooling system if operating in salt or polluted water.

2. Wash off all salt deposits and flush out the exhaust outlet of the propeller and gear

case with fresh water if operating in salt water.

Every 100 Hours of Use or Once Yearly, Whichever Occurs First

1. Lubricate all lubrication points. Lubricate more frequently when used in salt water.

MAINTENANCE

2. Inspect and clean spark plugs.

3. Check fuel line filter for contaminants.

4. Check carburetor adjustments, if required.

5. Check corrosion control anodes. Check more frequently when used in salt water.

6. Drain and replace gear case lubricant.

7. Lubricate splines on the drive shaft.*

8. Electric start models -- Inspect battery.

9. Remote control models -- Check control cable adjustments. *

10. Remove engine deposits with Quicksilver Power Tune Engine Cleaner.

11. Check tightness of bolts, nuts, and other fasteners.

12. Clean fuel tank pick up filter.

Every 300 Hours of Use or Three Years

1. Replace water pump impeller (more often if overheating occurs or reduced water

pressure is noted).*

*These items should be serviced by an authorized dealer.

90-826883R2 JUNE 1998 Page 1B-3

Page 12

MAINTENANCE

Flushing The Cooling System

Flush theinternal waterpassages of theoutboard with freshwater after eachuse in salt,

polluted, or muddy water. This will help prevent a buildup of deposits from clogging the

internal water passages.

Use a Quicksilver accessory (or equivalent) flushing attachment.

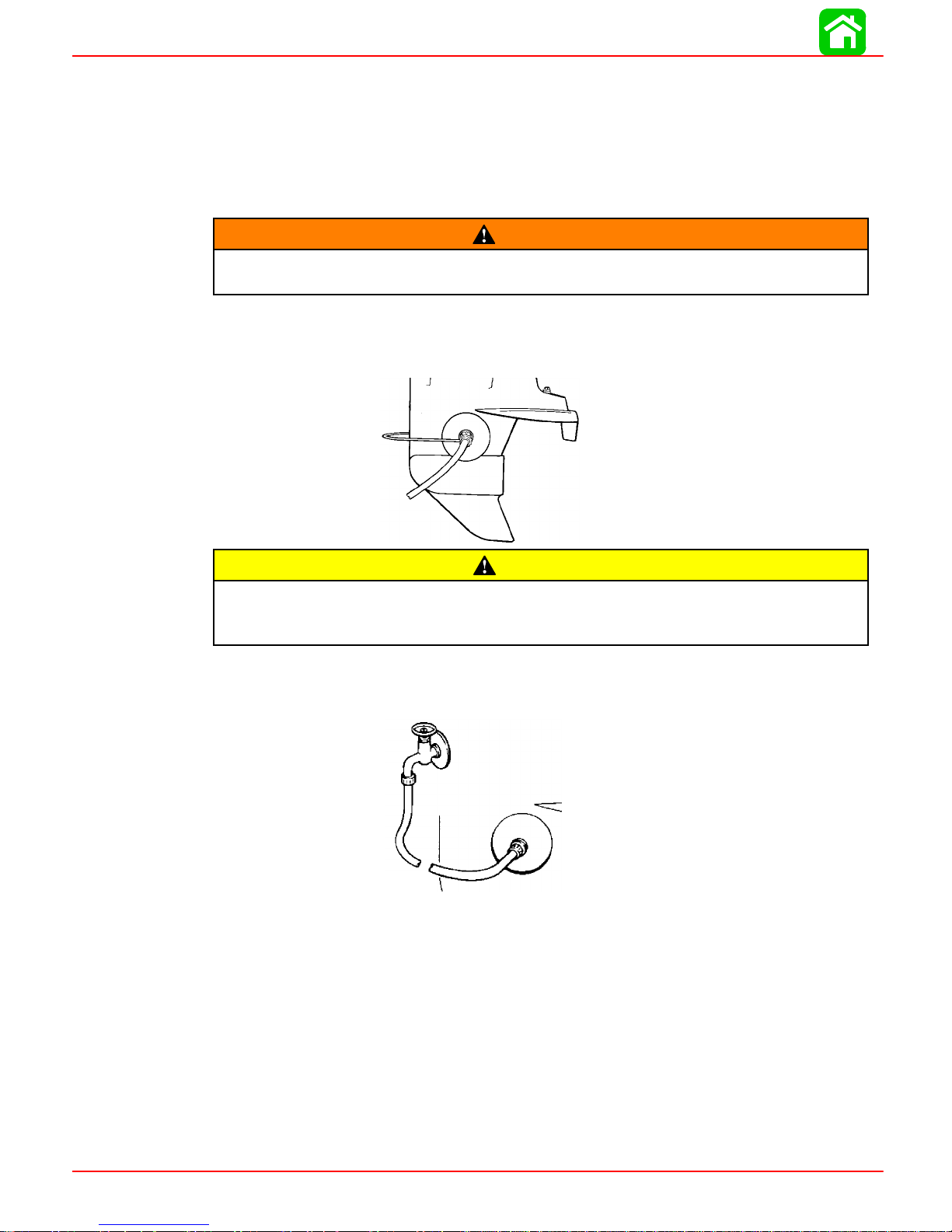

To avoid possible injury when flushing, remove the propeller.Refer to Propeller

Replacement.

1. Removepropeller(referto PropellerReplacement).Installtheflushing attachmentso

the rubber cups fit tightly over the cooling water intake holes.

WARNING

CAUTION

Never start or run your outboard (even momentarily) without water circulating

through the cooling water intake inthe gearcase toprevent damage to the water

pump (running dry) or overheating of the engine.

2. Attacha waterhose to theflushing attachment.Turnon the waterand adjustthe flow

sowaterisleaking aroundtherubbercupstoensurethe enginereceivesanadequate

supply of cooling water.

3. Start the engine and run it at idle speed in neutral shift position.

Page 1B-4 90-826883R2 JUNE 1998

Page 13

4. Adjust water flow (if necessary) so excess water continues leaking out from around

5. Checkfor asteady stream ofwater flowingoutof thewater pumpindicatorhole. Con-

6. Stopthe engine,turn offthe water, andremove theflushing attachment.Reinstall the

Fuel System

MAINTENANCE

therubbercupstoensuretheengine isreceivinganadequatesupplyofcoolingwater.

tinue flushingthe outboard for 3 to 5 minutes,carefully monitoring watersupply at all

times.

propeller.

WARNING

Avoidserious injury or death fromgasoline fire or explosion. Carefullyfollow all

fuel system service instructions. Always stop the engine and DO NOT smoke or

allow open flames or sparks in the area while servicing any part of the fuel system.

Beforeservicinganypartofthefuelsystem,stop engine anddisconnectthebattery.Drain

the fuelsystem completely. Use an approved containerto collect andstore fuel.Wipe up

any spillageimmediately.Material usedto containspillage must bedisposed of inan approved receptacle. Anyfuel system service must be performed in a well ventilated area.

Inspect any completed service work for sign of fuel leakage.

Fuel Line Inspection

Visuallyinspectthe fuellineandprimer bulbforcracks, swelling,leaks,hardness orother

signsof deterioration ordamage.If anyoftheseconditions isfound,the fuellineorprimer

bulb must be replaced.

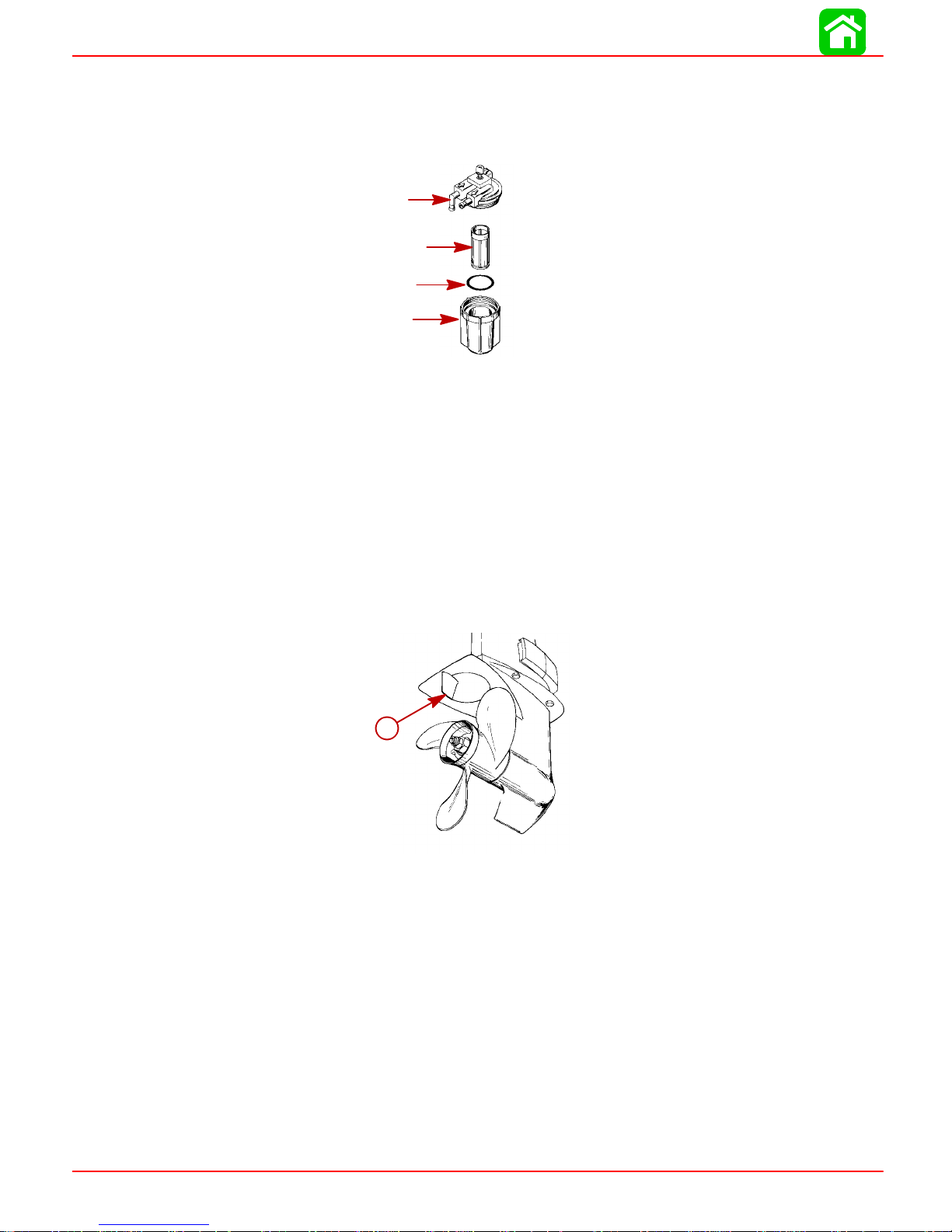

Engine Fuel Filter

Inspectthe sightbowl forwater accumulationand inspectthe filter elementfor sediment.

Clean filter as follows.

REMOVAL

1. Hold onto the cover to prevent it from turning.

2. Turn off the sight bowl.

3. Pull out the filter element and wash it with cleaning solvent.

90-826883R2 JUNE 1998 Page 1B-5

Page 14

MAINTENANCE

INSTALLATION

1. Push the filter element (with open end toward cover) into cover.

2. Place the O-ring seal into the sight bowl and screw the sight bowl hand tight intothe

cover.

1

3/4

3. Visually inspect for fuel leakage around the sight bowl by squeezing the primer bulb

until firm, forcing fuel into the sight bowl.

Corrosion Control Anode

Your outboard has a corrosion control anode installed to the gear case. An anode helps

protecttheoutboardagainstgalvaniccorrosionbysacrificingitsmetaltobeslowlyeroded

instead of the outboard metals.

5

2

The anode requires periodic inspection especially in salt water which will accelerate the

erosion.Tomaintainthis corrosionprotection, alwaysreplace theanode beforeit iscompletely eroded.Never paint or apply a protective coatingon the anode as this will reduce

effectiveness of the anode.

a

a - Anode

Page 1B-6 90-826883R2 JUNE 1998

Page 15

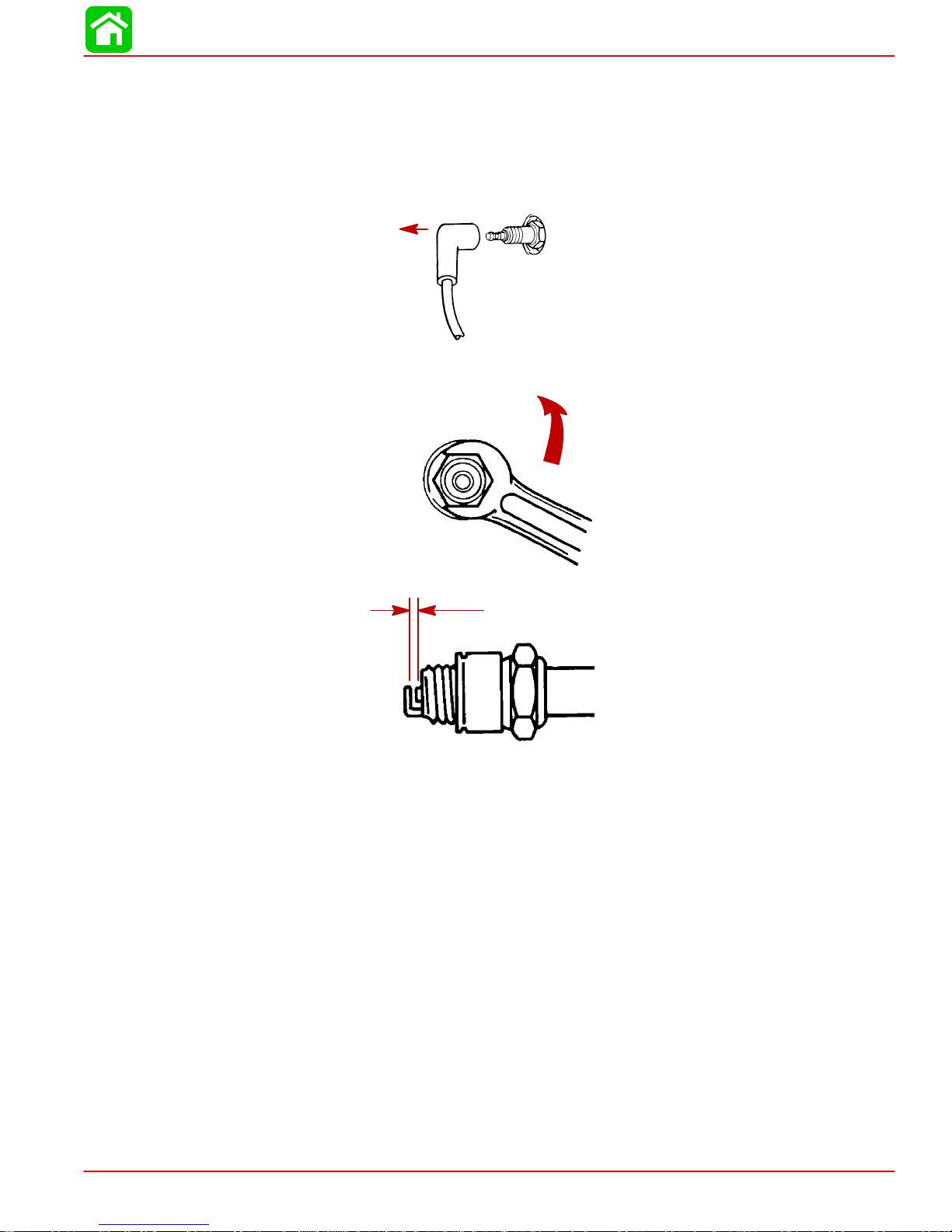

Spark Plug Inspection

Inspect spark plugs at the recommended intervals.

1. Remove the spark plug leads by twisting the rubber boots slightly and pull off.

2. Removethe sparkplugs to inspectand clean.Replace sparkplug ifelectrode isworn

or the insulator is rough, cracked, broken, blistered or fouled.

MAINTENANCE

3. Set the spark plug gap. See Specification Chart in General Information Section.

4. Before reinstalling sparkplugs, clean away dirt on the spark plug seats. Install plugs

finger tight, and tighten 1/4 turn or torque to 20 lb. ft. (27.1 N·m).

Battery Inspection

Thebattery shouldbe inspected atperiodic intervalstoensure properengine startingcapability.

IMPORTANT: Read the safety and maintenance instructions which accompany

your battery.

1. Turn off the engine before servicing the battery.

2. Add water as necessary to keep the battery full.

3. Make sure the battery is secure against movement.

4. Batterycable terminals shouldbeclean,tight, andcorrectlyinstalled.Positive topositive and negative to negative.

5. Make sure thebattery is equipped with anonconductive shield to prevent accidental

shorting of battery terminals.

90-826883R2 JUNE 1998 Page 1B-7

Page 16

MAINTENANCE

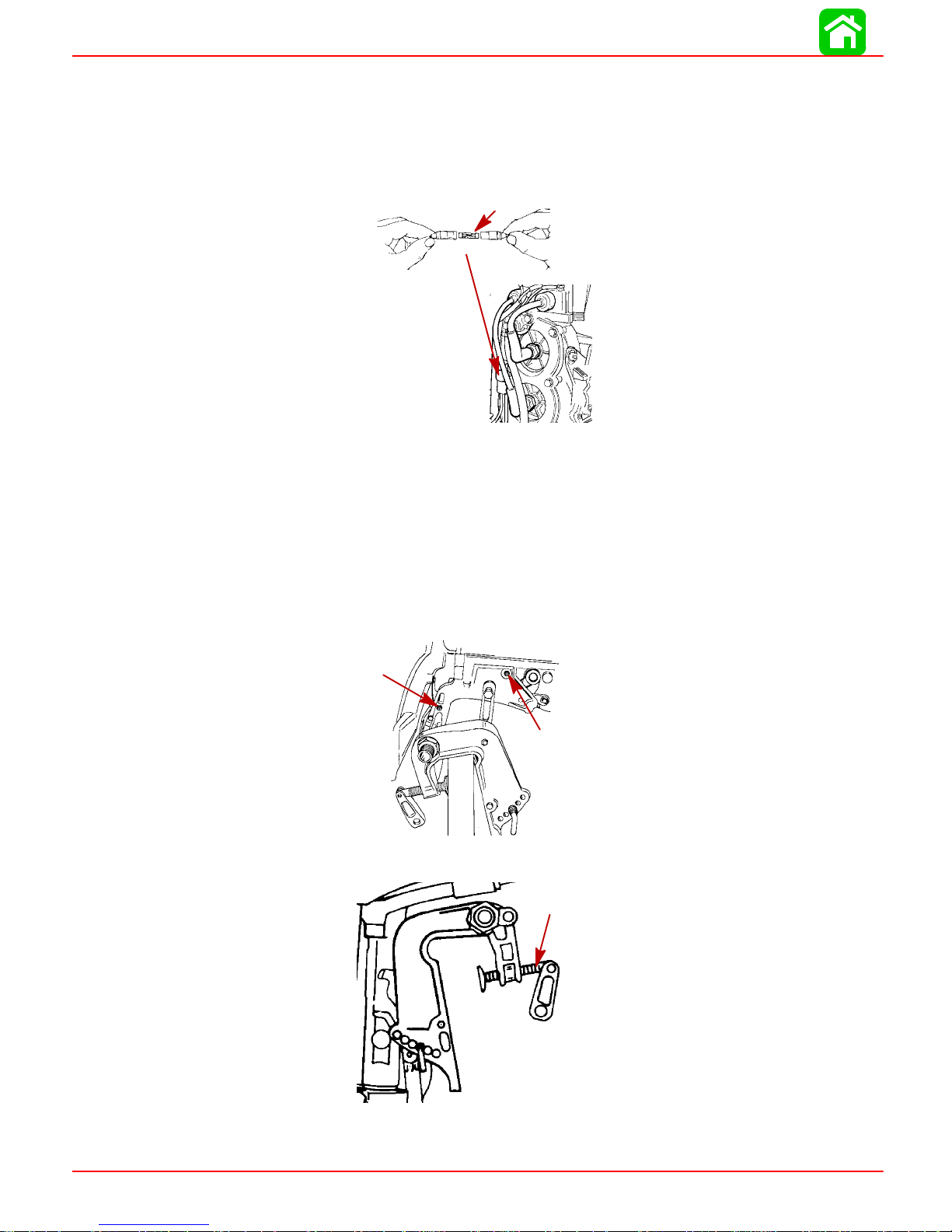

Fuse Replacement -- Electric Start Remote Control Models

The electric startingcircuit is protected from overload by a SFE 20 AMP fuse.If the fuse

is blown,the electric starter motor will not operate.Try to locate and correctthe cause of

the overload. If the cause is not found, the fuse may blow again. Replace the fuse with

a fuse of the same rating.

Replace with a new SFE 20 AMP fuse.

Lubrication Points

Lubricate Points 1 thru 6 with Quicksilver 2-4-C Marine Lubricant with Teflon or

Special Lubricant 101.

1. Steering Friction Adjustment Shaft (Tiller Handle Models) -- Lubricate fitting.

2. Swivel Bracket -- Lubricate fitting.

1

2

3. Transom Clamp Screws -- Lubricate threads.

Page 1B-8 90-826883R2 JUNE 1998

Page 17

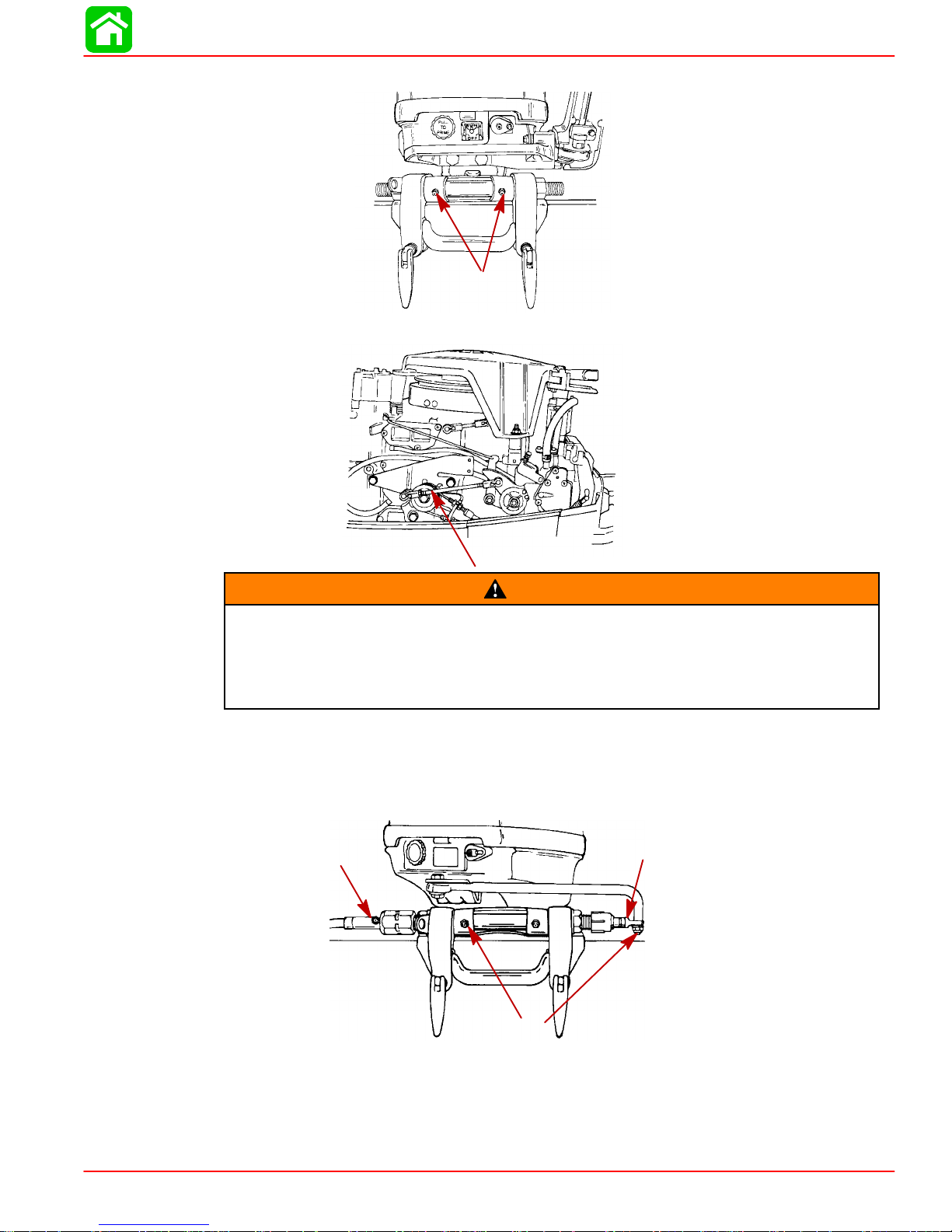

MAINTENANCE

4. Tilt Tube -- Lubricate fittings.

5. Lubricate the throttle and shaft cables, moving components and pivot locations.

WARNING

The end of the steering cable must be fully retracted into the outboard tilt tube

before adding lubricant. Adding lubricant to steering cable when fully extended

could cause steering cable to become hydraulically locked. An hydraulically

lockedsteering cable willcauseloss ofsteeringcontrol, possibly resultinginserious injury or death.

6. SteeringCableGreaseFitting (IfEquipped)--Rotatesteering wheeltofullyretractthe

steering cable end (a) into the outboard tilt tube. Lubricate through fitting (b).

Lubricate points 7 With Light Weight Oil

7. Steering Link Rod Pivot Points -- Lubricate points.

6-b

7

6-a

90-826883R2 JUNE 1998 Page 1B-9

Page 18

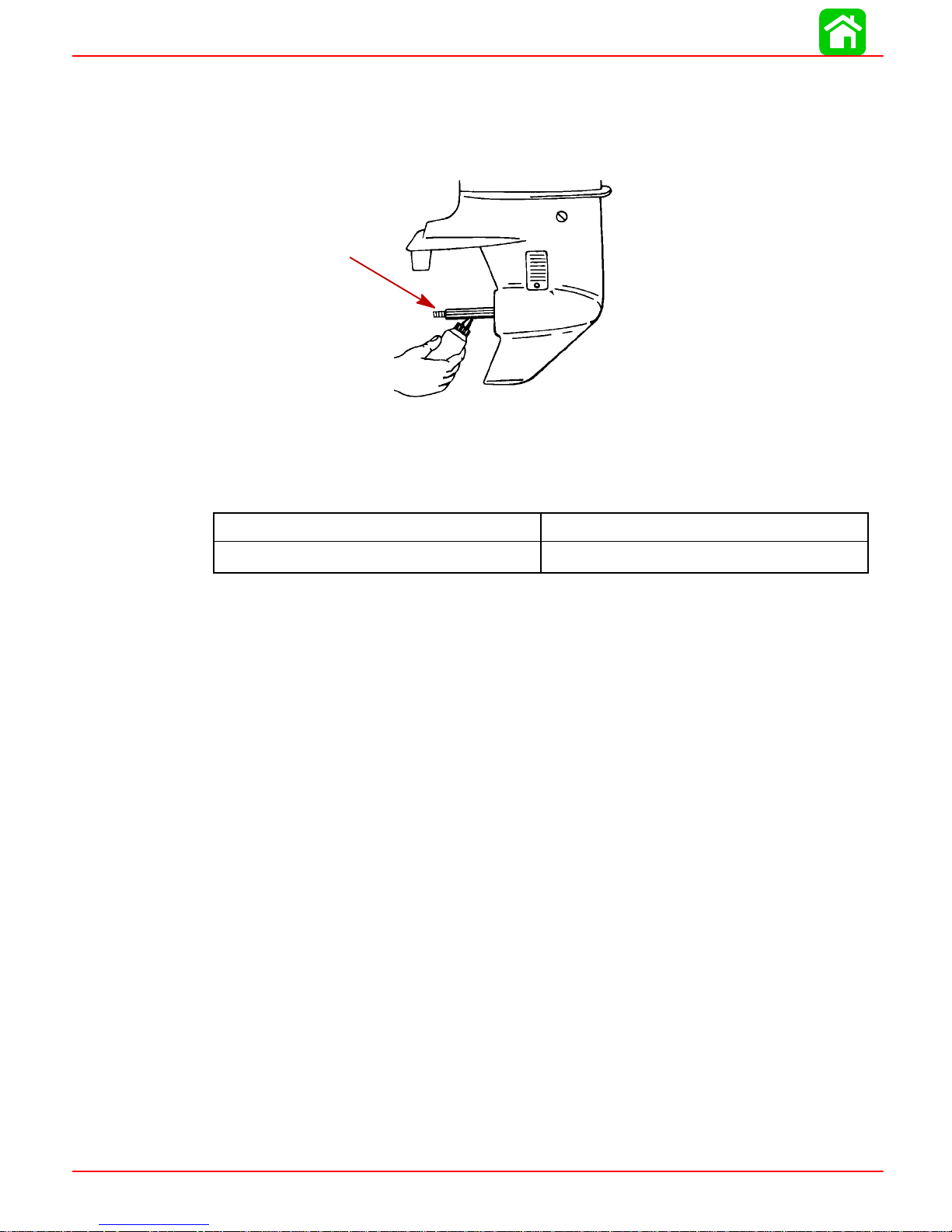

MAINTENANCE

Lubricate Point 8 with Quicksilver Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

8. Propeller Shaft -- Refer to Propeller Replacement for removal and installation of the

propeller. Coat the entire propeller shaft with lubricant to prevent the propeller hub

from corroding to the shaft.

8

Gear Case Lubrication

Gear Case Lubricant Capacity

Draining Gear Case

When adding or changing gear case lubricant, visually check for the presence of water

inthelubricant.If waterispresent,itmay have settledtothebottomand willdrainoutprior

tothelubricant,or itmaybemixed withthelubricant,givingit amilkycoloredappearance.

Ifwater isnoticed, have thegear casecheckedby yourdealer.Waterinthe lubricant may

resultinprematurebearingfailureor,in freezingtemperatures, will turn toice anddamage

the gear case.

Whenever you remove the fill/drain plug, examine the magnetic end for metal particles.

A smallamount of metalfilings or finemetal particles indicatesnormal gear wear. An excessive amount of metal filings or larger particles (chips) may indicate abnormal gear

wear and should be checked by an authorized dealer.

Gear Case Ratio Capacity

2.25:1 8.8 fl. oz. (260.0ml)

Page 1B-10 90-826883R2 JUNE 1998

Page 19

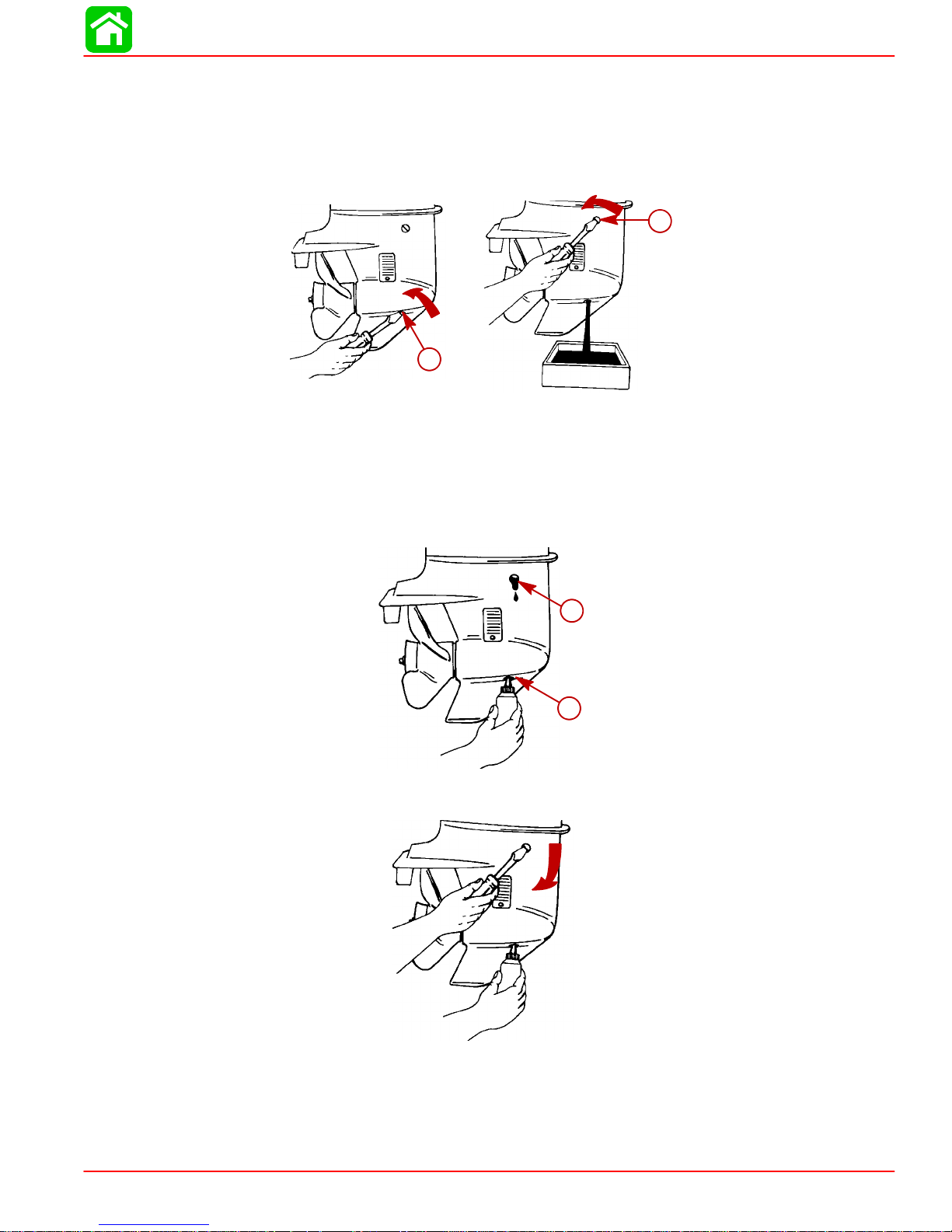

Draining Gear Case

1. Place outboard in a vertical operating position.

2. Place drain pan below outboard.

3. Remove fill/drain plug (a) and vent plug (b) and drain lubricant.

a

Checking Lubricant Level and Refilling Gear Case

1. Place outboard in a vertical operating position.

2. Remove vent plug from vent hole (a).

MAINTENANCE

b

3. Place lubricant tube into the fill hole (b) and add lubricant until it appears at the vent

hole (a).

a

b

4. Stop adding lubricant. Install the vent plug and sealing washer before removing the

lubricant tube.

90-826883R2 JUNE 1998 Page 1B-11

Page 20

MAINTENANCE

5. Remove lubricant tube and reinstall cleaned fill/drain plug and sealing washer.

Storage Preparations

Fuel System

IMPORTANT: Gasoline containing alcohol (ethanol or methanol) can cause a formation of acid during storage and can damage the fuel system. If the gasoline being used contains alcohol, It is advisable to drain as much of the remaining gasoline as possible from the fuel tank, remote fuel line, and engine fuel system.

Fillthe fuel system(tank,hoses, fuel pumps,andfuelinjection systems)withtreated(stabilized)fuel tohelp prevent formationof varnishand gum.Proceedwith followinginstructions.

1. PortableFuel Tank--Pourthe requiredamountof Quicksilver GasolineStabilizer(followinstructionsoncontainer) intofueltank.Tipfueltankback and forthtomixstabilizer with the fuel.

2. Permanently InstalledFuel Tank -- Pour the required amountof Quicksilver Gasoline

Stabilizer(follow instructionson container) intoa separatecontainerand mixwith approximately one quart (one liter) of gasoline. Pour this mixture into fuel tank.

3. Placethe outboard inwater orconnectflushing attachment forcirculating coolingwater. Run the engine for ten minutes to allow treated fuel to fill the fuel system.

Protecting External Engine Components

1. Lubricate all outboard componentslisted in the Inspection and Maintenance Schedule.

2. Touch up any paint nicks.

3. SprayQuicksilverCorrosionGuard on externalmetalsurfaces(exceptcorrosioncontrol anodes).

Protecting Internal Engine Components

NOTE: Before performingSteps 1 and 2, make surethe fuel system hasbeen prepared

for storage.

1. Placethe outboard inwater orconnectflushing attachment forcirculating coolingwater. Start the engine and let it run in neutral to warm up.

2. With engine running at fast idle, stop the fuel flow by disconnecting the remote fuel

line.Whenenginebegins tostall,quicklysprayQuicksilver Storage Sealintocarburetor until engine stops from lack of fuel.

3. Remove the spark plugs and inject a five second spray of Quicksilver Storage Seal

around the inside of each cylinder.

Page 1B-12 90-826883R2 JUNE 1998

Page 21

4. Rotate the flywheelmanually several times to distribute the storage seal inthe cylinders. Reinstall spark plugs.

Gear Case

Drain and refill the gear case lubricant (refer to maintenance procedure).

Positioning Outboard for Storage

Store outboard in an upright position to allow water to drain out of outboard.

If outboard is stored tilted up in freezing temperature, trapped cooling water or

rain water that may have entered the propeller exhaust outlet in the gear case

could freeze and cause damage to the outboard.

Battery Storage

1. Follow the battery manufacturers instructions for storage and recharging.

2. Remove the battery from the boat and check water level. Recharge if necessary.

3. Store the battery in a cool, dry place.

4. Periodically check the water level and recharge the battery during storage.

MAINTENANCE

CAUTION

90-826883R2 JUNE 1998 Page 1B-13

Page 22

GENERAL INFORMATION

IMPORTANT INFORMATION

Section 1C - General Information

Table of Contents

Table of Contents 1C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Location 1C-1. . . . . . . . . . . . . . . . . . . . . . .

Conditions Affecting Performance 1C-2. . . . . . . . . . . . . .

Weather 1C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boat 1C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 1C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Following Complete Submersion 1C-5. . . . . . . . . . . . . . .

Submerged While Running

(Special Instructions) 1C-5. . . . . . . . . . . . . . . . . . . . . .

Salt Water Submersion (Special Instructions) 1C-5.

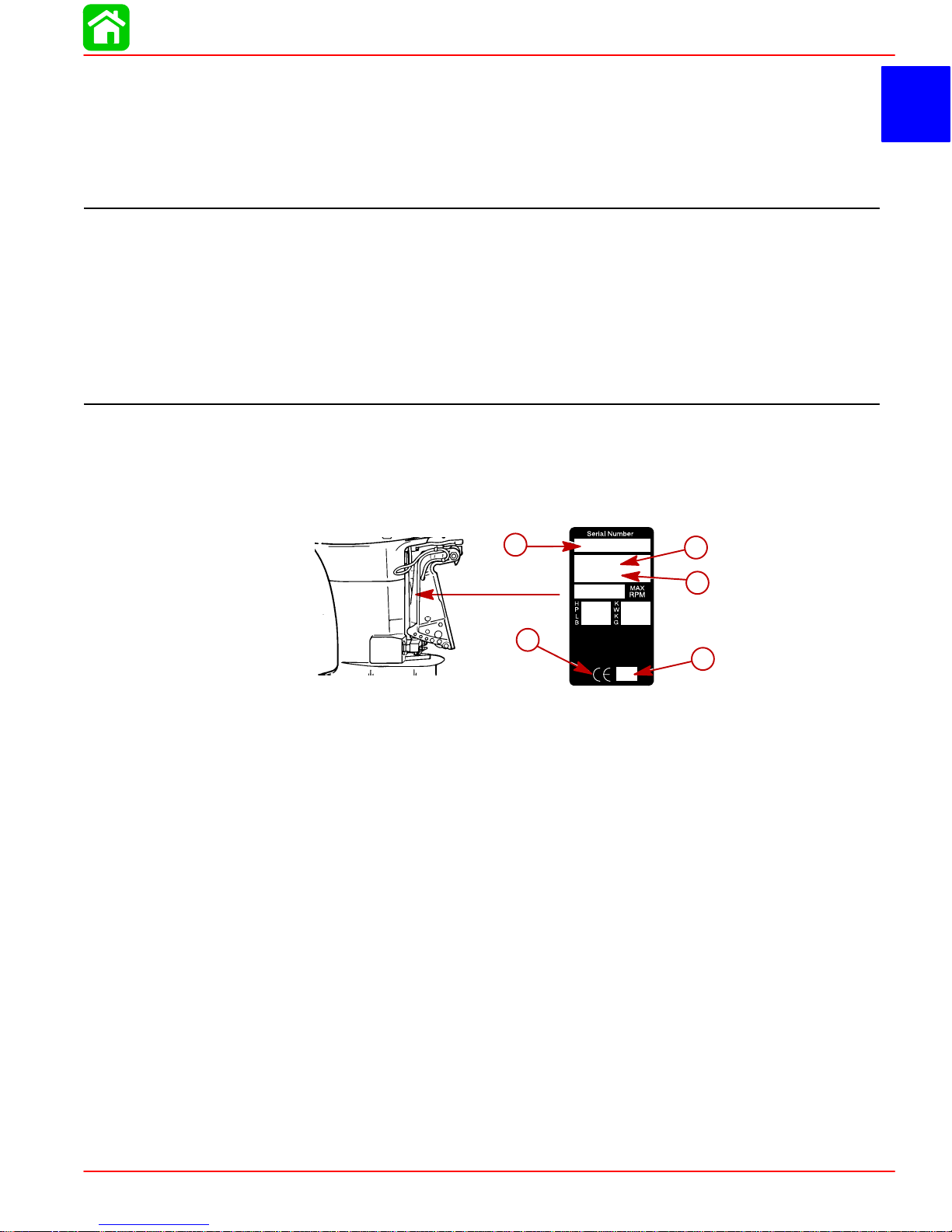

Serial Number Location

The Outboard serial number is located on the lower starboard side of the engine block.

A serial number is also located on the starboard side of the swivel bracket.

1

C

Fresh Water Submersion (Special Instructions) 1C-5

Propeller Selection 1C-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Removal/Installation 1C-7. . . . . . . . . . . . . . . . .

Compression Check 1C-9. . . . . . . . . . . . . . . . . . . . . . . . . .

Painting Procedures 1C-10. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning & Painting Aluminum Propellers

& Gear Housings 1C-10. . . . . . . . . . . . . . . . . . . . . . . .

Decal Application 1C-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Removal 1C-11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions for “Wet” Application 1C-11. . . . . . . . . . .

a - Serial Number

b - Model Year

c - Model Description

d - Year Manufactured

e - Certified Europe Insignia

a

OGXXXXXX

19XX

XXXX

b

c

e

d

XX

90-826883R2 JUNE 1998 Page 1C-1

Page 23

GENERAL INFORMATION

Conditions Affecting Performance

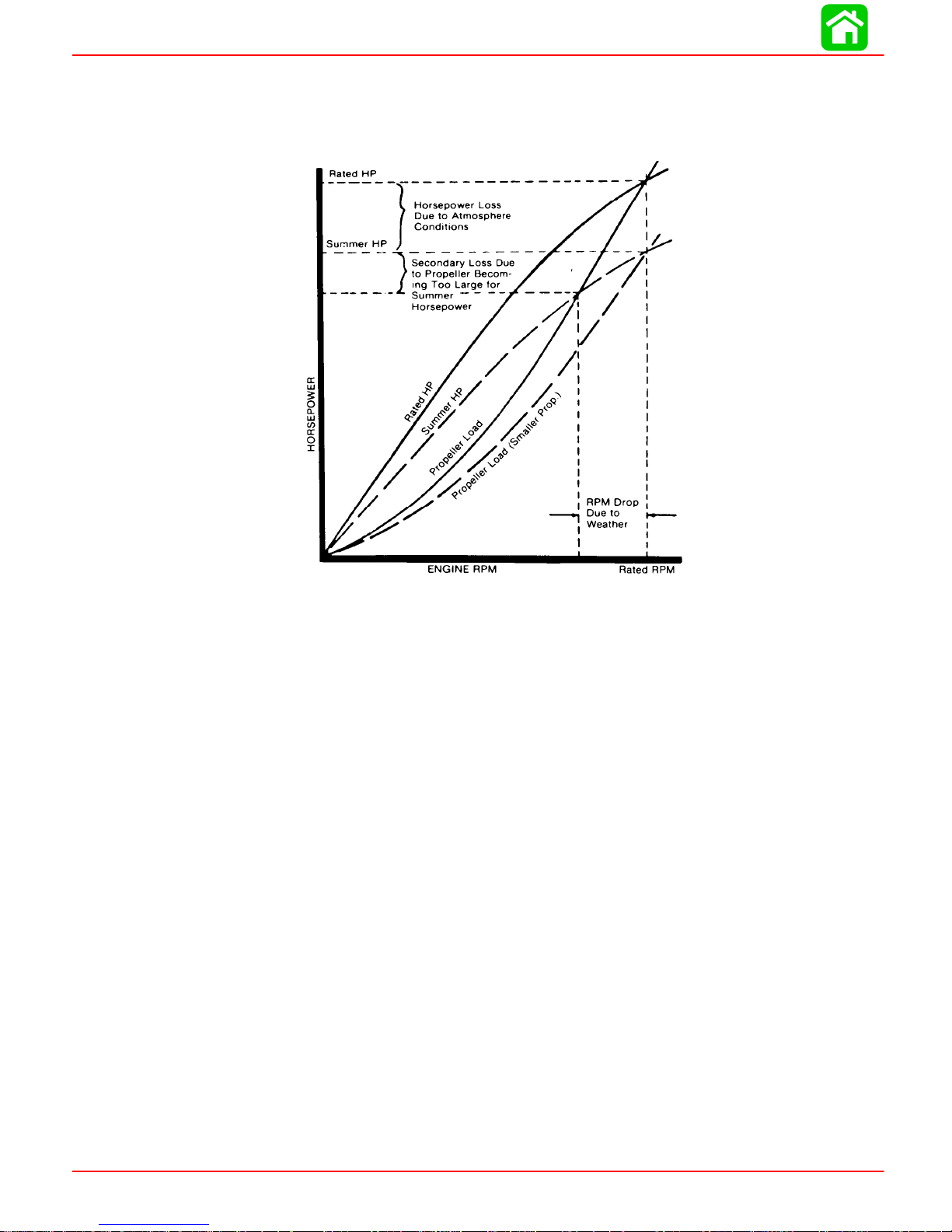

Weather

It is a known fact that weather conditions exert a profound effect on power output of internal combustion engines. Therefore, established horsepower ratings refer to the power

that the engine will produce at its rated RPM under a specific combination of weather conditions.

Corporations internationally have settled on adoption of I.S.O. (International Standards

Organization) engine test standards, as set forth in I.S.O. 3046 standardizing the computation of horsepower from data obtained on the dynamometer, correcting all values to the

power that the engine will produce at sea level, at 30% relative humidity at 77° F (25°C)

temperature and a barometric pressure of 29.61 inches of mercury.

Summer Conditions of high temperature, low barometric pressure and high humidity all

combine to reduce the engine power. This, in turn, is reflected in decreased boat speeds-as much as 2 or 3 miles-per-hour (3 or 5 Km per-hour) in some cases. (Refer to previous

chart.) Nothing will regain this speed for the boater, but the coming of cool, dry weather.

In pointing out the practical consequences of weather effects, an engine--running on a

hot, humid summer day--may encounter a loss of as much as 14% of the horsepower it

would produce on a dry , brisk spring or fall day. The horsepower , that any internal combustion engine produces, depends upon the density of the air that it consumes and, in turn,

this density is dependent upon the temperature of the air, its barometric pressure and water vapor (or humidity) content.

Accompanying this weather-inspired loss of power is a second but more subtle loss. At

rigging time in early spring, the engine was equipped with a propeller that allowed the engine to turn within its recommended RPM range at full throttle. With the coming of the summer weather and the consequent drop in available horsepower, this propeller will, in effect, become too large. Consequently , the engine operates at less than its recommended

RPM.

Page 1C-2 90-826883R2 JUNE 1998

Page 24

Due to the horsepower/RPM characteristics of an engine, this will result in further loss of

horsepower at the propeller with another decrease in boat speed. This secondary loss,

however, can be regained by switching to a smaller pitch propeller that allows the engine

to again run at recommended RPM.

For boaters to realize optimum engine performance under changing weather conditions,

it is essential that the engine have the proper propeller to allow it to operate at or near the

top end of the recommended maximum RPM range at wide-open-throttle with a normal

boat load.

Not only does this allow the engine to develop full power, but equally important is the fact

that the engine also will be operating in an RPM range that discourages damaging detonation. This, of course, enhances overall reliability and durability of the engine.

Boat

WEIGHT DISTRIBUTION

1. Proper positioning of the weight inside the boat (persons and gear) has a significant

effect on the boat’s performance, for example:

a. Shifting weight to the rear (stern)

GENERAL INFORMATION

(1.)Generally increases top speed.

(2.)If in excess, can cause the boat to porpoise.

BOTTOM

For maximum speed, a boat bottom should be nearly a flat plane where it contacts the

water and particularly straight and smooth in fore-and-aft direction.

1. Hook: Exists when bottom is concave in fore-and-aft direction when viewed from the

2. Rocker: The reverse of hook and much less common. “Rocker” exists if bottom is con-

3. Surface Roughness: Moss, barnacles, etc., on boat or corrosion of outboard’s gear

WATER ABSORPTION

It is imperative that all through hull fasteners be coated with a quality marine sealer at time

of installation. Water intrusion into the transom core and/or inner hull will result in additional boat weight (reduced boat performance), hull decay and eventual structural failure.

(3.)Can make the bow bounce excessively in choppy water.

(4.)Will increase the danger of the following - wave splashing into the boat when

coming off plane.

b. Shifting weight to the front (bow)

(1.)Improves ease of planing off.

(2.)Generally improves rough water ride.

(3.)If excessive, can make the boat veer left and right (bow steer).

side. When boat is planing, “hook” causes more lift on bottom near transom and allows

bow to drop, thus greatly increasing wetted surface and reducing boat speed. “Hook”

frequently is caused by supporting boat too far ahead of transom while hauling on a

trailer or during storage.

vex in fore-and-aft direction when viewed from the side, and boat has strong tendency

to porpoise.

housing increase skin friction and cause speed loss. Clean surfaces when necessary .

90-826883R2 JUNE 1998 Page 1C-3

Page 25

GENERAL INFORMATION

CAVITATION

Engine

DETONATION

Cavitation is caused by water vapor bubbles forming either from a sharp edge or angle

on the gear case or from an irregularity in the propeller blade itself. These vapor bubbles

flow back and collapse when striking the surface of the propeller blade resulting in the erosion of the propeller blade surface. If allowed to continue, eventual blade failure (breakage) will occur.

Detonation in a 2-cycle engine resembles the “pinging” heard in an automobile engine.

It can be otherwise described as a tin-like “rattling” or “plinking” sound.

Detonation is an explosion of an unburned portion of the fuel/air charge after the spark

plug has fired. Detonation creates severe shock waves in the engine, and these shock

waves often find or create a weakness: The dome of a piston, cylinder head/gasket, piston

rings or piston ring lands, piston pin and roller bearings.

A few of the most common causes of detonation in a marine 2-cycle application are as

follows:

• Over-advanced ignition timing.

• Use of low octane gasoline.

• Propeller pitch too high (engine RPM below recommended maximum range).

• Lean fuel mixture at or near wide-open-throttle.

• Spark plugs (heat range too hot - incorrect reach - cross-firing).

• Inadequate engine cooling (deteriorated cooling system).

• Combustion chamber/piston deposits (result in higher compression ratio).

Detonation usually can be prevented if:

1. The engine is correctly set up.

2. Diligent maintenance is applied to combat the detonation causes.

Damaged Piston Resulting from Detonation

Page 1C-4 90-826883R2 JUNE 1998

51115

Page 26

Following Complete Submersion

Submerged While Running (Special Instructions)

When an engine is submerged while running, the possibility of internal engine damage

is greatly increased. If, after engine is recovered and with spark plugs removed, engine

fails to turn over freely when turning flywheel, the possibility of internal damage (bent connecting rod and/or bent crankshaft) exists. If this is the case, the powerhead must be disassembled.

Salt Water Submersion (Special Instructions)

Due to the corrosive effect of salt water on internal engine components, complete disassembly is necessary before any attempt is made to start the engine.

Fresh Water Submersion (Special Instructions)

1. Recover engine as quickly as possible.

2. Remove cowling.

3. Flush exterior of outboard with fresh water to remove mud, weeds, etc. DO NOT attempt to start engine if sand has entered powerhead, as powerhead will be severely

damaged. Disassemble powerhead if necessary to clean components.

GENERAL INFORMATION

4. Remove spark plugs and get as much water as possible out of powerhead. Most water

can be eliminated by placing engine in a horizontal position (with spark plug holes

down) and rotating flywheel.

5. Pour alcohol into carburetor throats (alcohol will absorbed water). Again rotate flywheel.

6. Turn engine over and pour alcohol into spark plug openings and rotate flywheel.

7. Turn engine over (place spark plug openings down) and pour engine oil into throat of

carburetors while rotating flywheel to distribute oil throughout crankcase.

8. Again turn engine over and pour approximately one teaspoon of engine oil into each

spark plug opening. Again rotate flywheel to distribute oil in cylinders.

9. Remove and clean carburetors and fuel pump assembly.

10. Dry all wiring and electrical components using compressed air.

1 1. Disassemble the engine starter motor and dry the brush contacts, armature and other

corrodible parts.

12. Reinstall spark plugs, carburetors and fuel pump.

13. Attempt to start engine, using a fresh fuel source. If engine starts, it should be run for

at least one hour to eliminate any water in engine.

14. If engine fails to start, determine cause (fuel, electrical or mechanical). Engine should

be run within 2 hours after recovery of outboard from water, or serious internal damage may occur. If unable to start engine in this period, disassemble engine and clean

all parts. Apply oil as soon as possible.

Propeller Selection

For in-depth information on marine propellers and boat performance - written by marine

engineers - see your Authorized Dealer for the illustrated “What You Should Know

About Quicksilver Propellers... and Boat Performance Information” (Part No.

90-86144).

90-826883R2 JUNE 1998 Page 1C-5

Page 27

GENERAL INFORMATION

For best all around performance from your outboard/boat combination, select a propeller

that allows the engine to operate in the upper half of the recommended full throttle RPM

range with the boat normally loaded (refer to Specifications). This RPM range allows for

better acceleration while maintaining maximum boat speed.

If changing conditions cause the RPM to drop below the recommended range (such as

warmer, more humid weather, operation at higher elevations, increased boat load or a

dirty boat bottom/gear case) a propeller change or cleaning may be required to maintain

performance and ensure the outboard’s durability.

Check full-throttle RPM using an accurate tachometer with the engine trimmed out to a

balanced-steering condition (steering effort equal in both directions) without causing the

propeller to “break loose”.

Refer to “Quicksilver Accessory Guide” for a complete list of available propellers.

1. Select a propeller that will allow the engine to operate at or near the top of the recommended full throttle RPM range (listed in “Specifications,” preceding) with a normal

load. Maximum engine speed (RPM) for propeller selection exists when boat speed

is maximum and trim is minimum for that speed. (High RPM, caused by an excessive

trim angle, should not be used in determining correct propeller.) Normally, there is a

150-350 RPM change between propeller pitches.

2. If full throttle operation is below the recommended range, the propeller MUST BE

changed to one with a lower pitch to prevent loss of performance and possible engine

damage.

3. After initial propeller installation, the following common conditions may require that

the propeller be changed to a lower pitch:

a. Warmer weather and great humidity will cause an RPM loss.

b. Operating in a higher elevation causes an RPM loss.

c. Operating with a damaged propeller or a dirty boat bottom or gear housing will

cause an RPM loss.

d. Operation with an increased load (additional passengers, equipment, pulling ski-

ers, etc.).

Page 1C-6 90-826883R2 JUNE 1998

Page 28

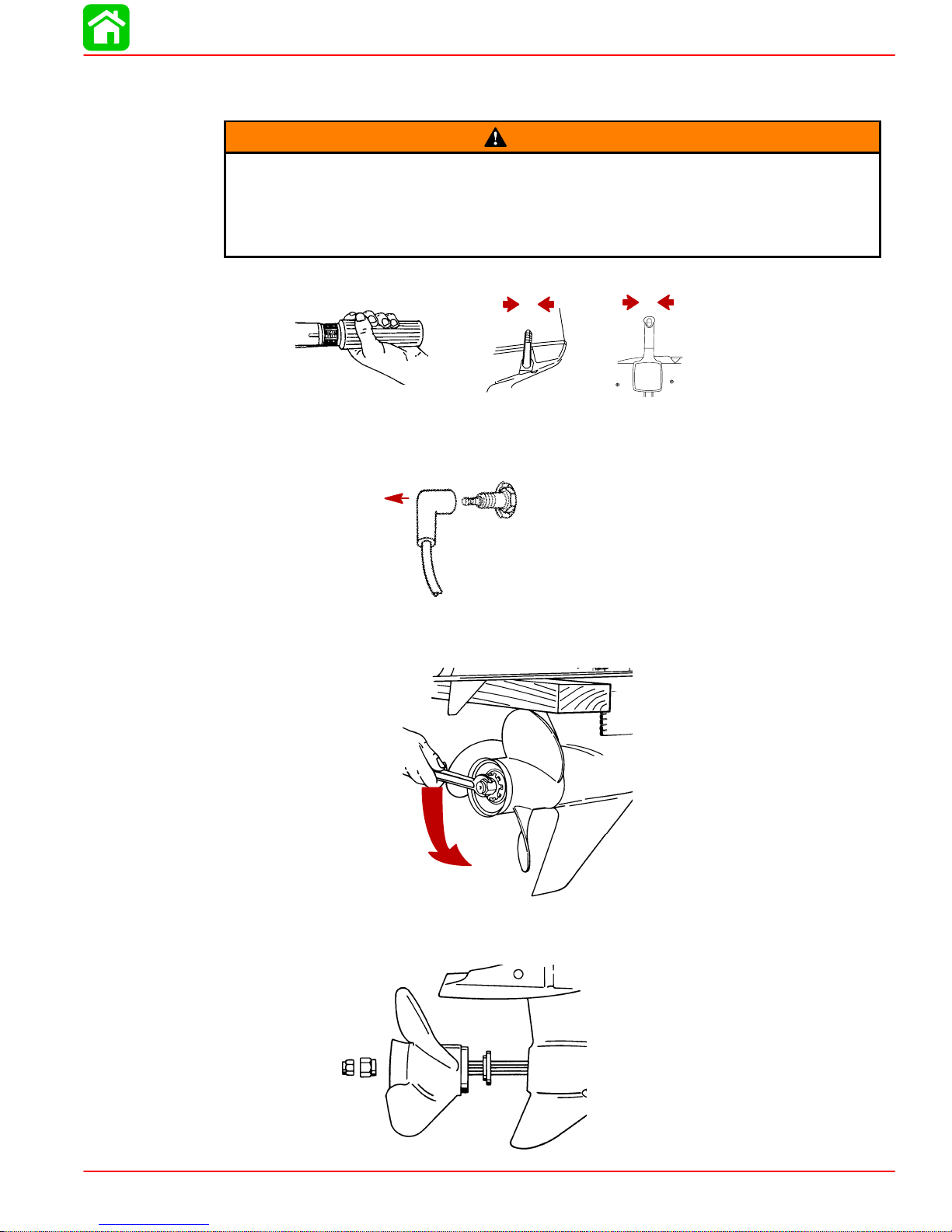

Propeller Removal/Installation

If the propeller shaft is rotated while the engine is in gear, there is the possibility

that the engine will crank over and start. T o prevent this type of accidental engine

starting and possible serious injury caused from being struck by a rotating propeller, always shift outboard to neutral position and remove spark plug leads

when you are servicing the propeller

1. Shift outboard to neutral position.

GENERAL INFORMATION

WARNING

N

2. Remove the spark plug leads to prevent engine from starting.

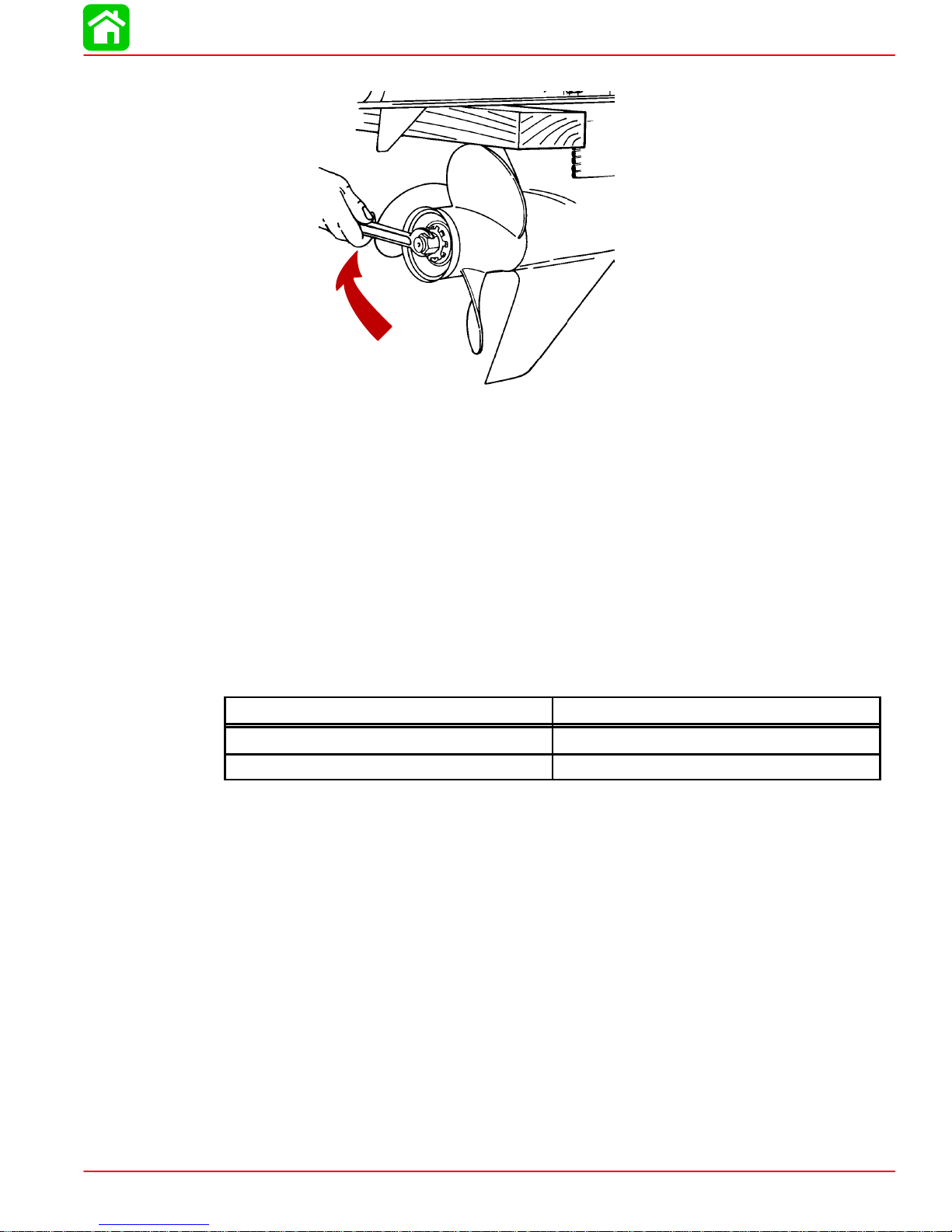

3. Place a block of wood between gear case and propeller to hold propeller and remove

propeller nut.

N

4. Pull propeller straight off shaft. If propeller is seized to the shaft and cannot be removed, have the propeller removed by an authorized dealer.

90-826883R2 JUNE 1998 Page 1C-7

Page 29

GENERAL INFORMATION

5. Coat the propeller shaft with Quicksilver Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

IMPORTANT: To prevent the propeller hub from corroding and seizing to the propeller shaft, especially in salt water, always apply a coat of the recommended lubricant to the entire propeller shaft at the recommended maintenance intervals and

also each time the propeller is removed.

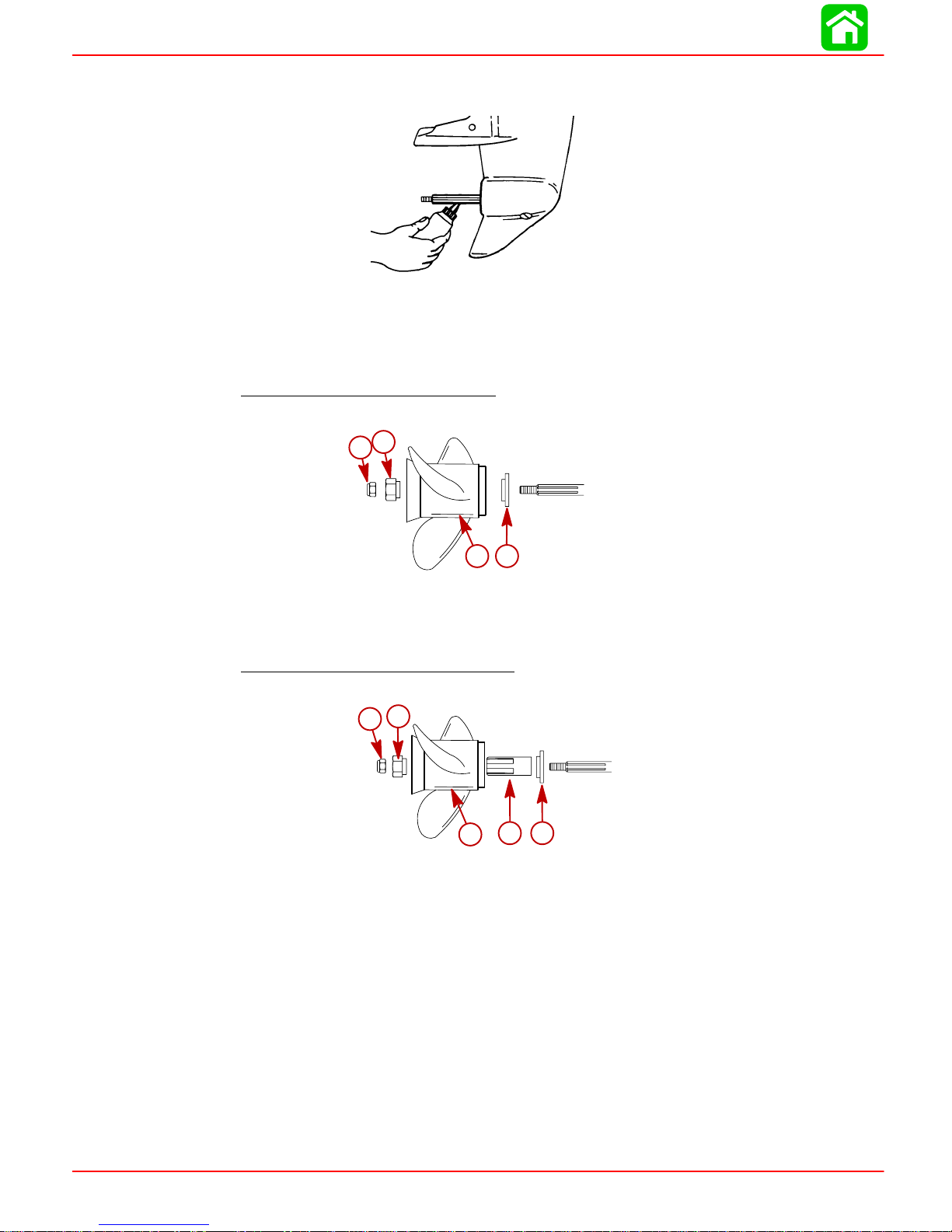

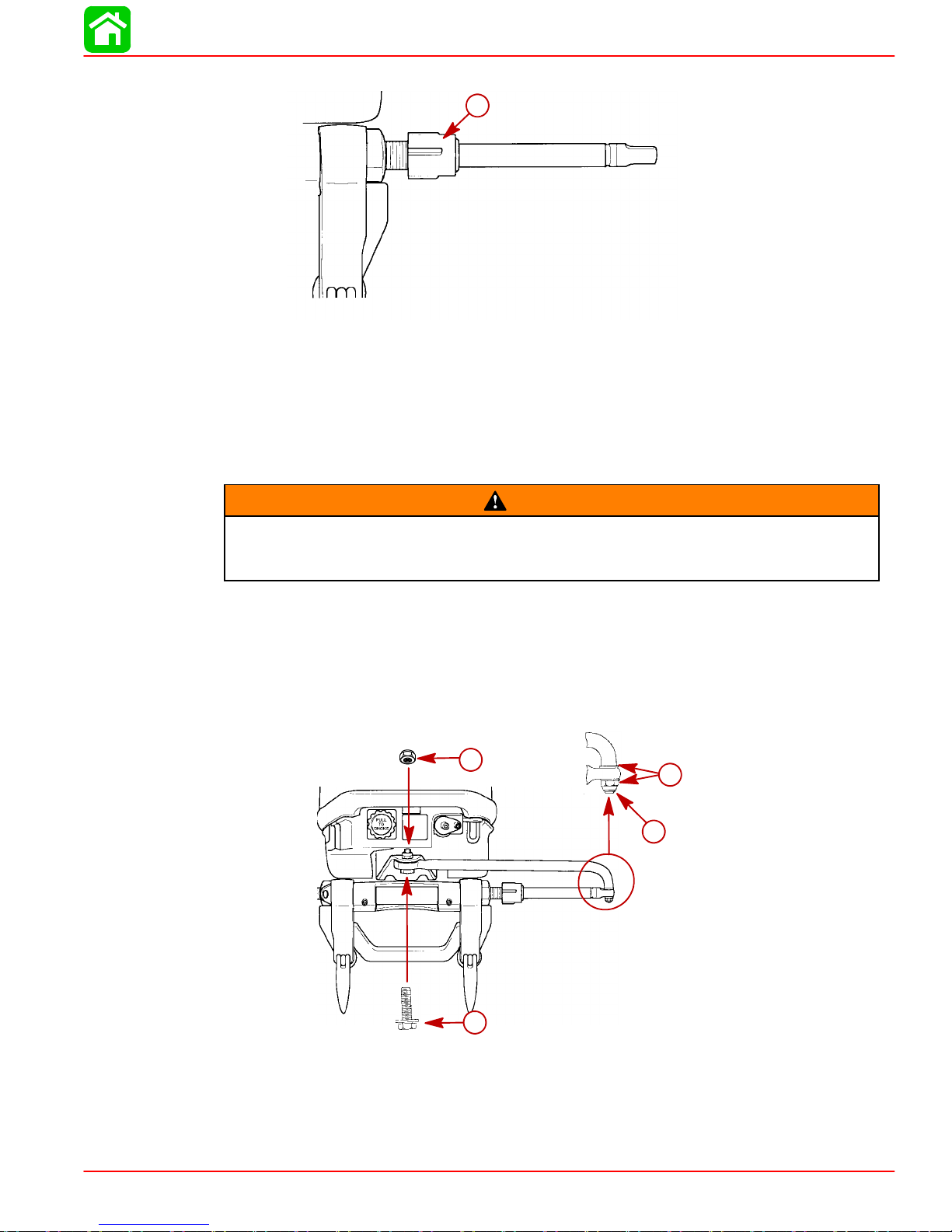

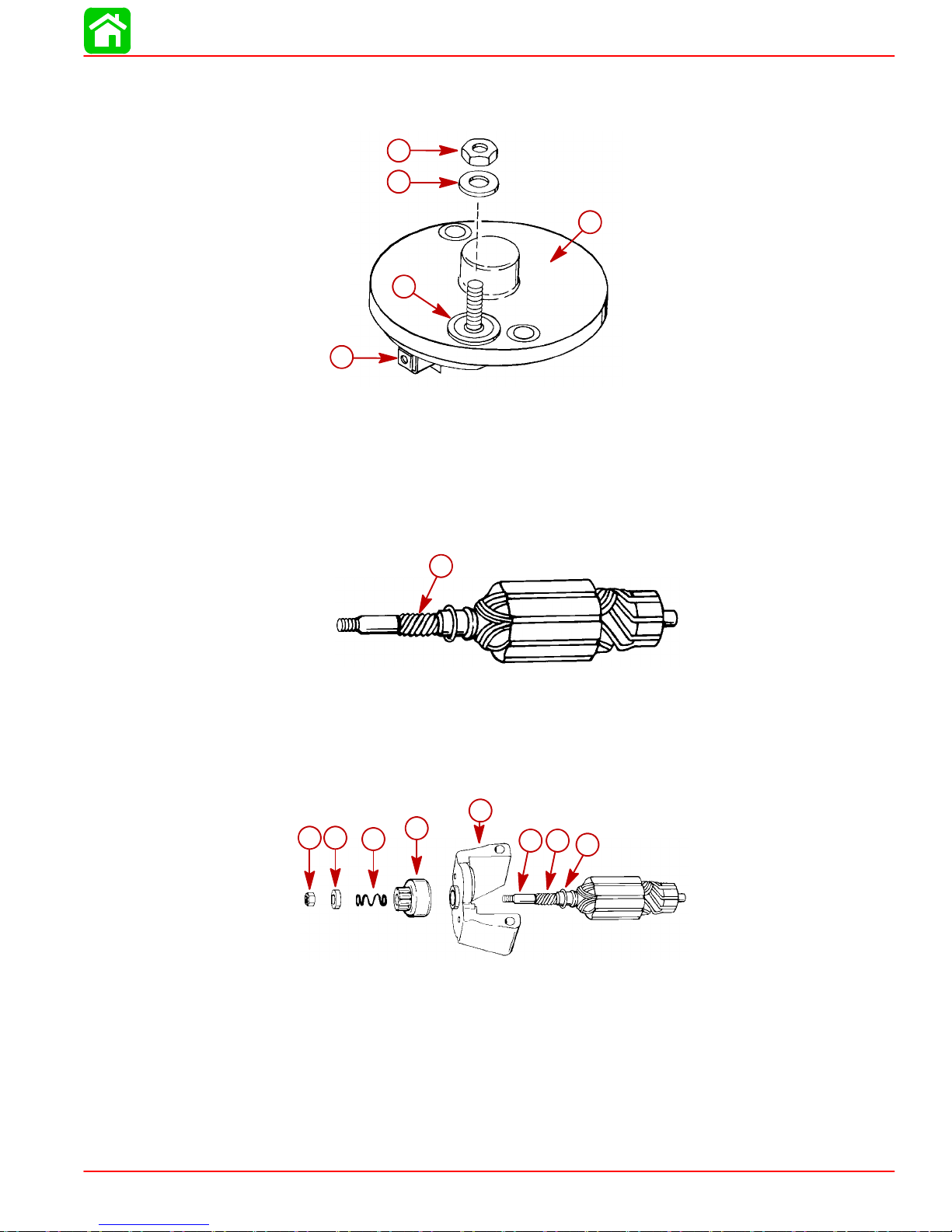

6. Flo-Torque I Drive Hub Propellers

– Install forward thrust hub, propeller, rear thrust

hub and propeller nut onto the shaft.

c

d

a

b

a - Forward Thrust Hub

b - Propeller

c - Rear Thrust Hub

d - Propeller Nut

7. Flo-Torque II Drive Hub Propellers – Install forward thrust hub, replaceable drive

sleeve propeller, rear thrust hub and propeller nut onto the shaft.

d

e

a

b

c

a - Forward Thrust Hub

b - Replaceable Drive Sleeve

c - Propeller

d - Rear Thrust Hub

e - Propeller Nut

Page 1C-8 90-826883R2 JUNE 1998

Page 30

8. Place a block of wood between gear case and propeller and tighten propeller nut.

Compression Check

1. Remove spark plugs.

2. Install compression gauge in spark plug hole.

GENERAL INFORMATION

3. Hold throttle plate at W.O.T.

4. Crank the engine over until the compression reading peaks on the gauge. Record the

reading.

5. Check and record compression of each cylinder. The highest and lowest reading

recorded should not differ by more than 15% (see example chart below). A reading

below 120 psi might indicate a total engine wear problem.

Example of compression test differences

Maximum (psi)

Minimum (psi)

180 162

150 127.5

6. Compression check is important because an engine with low or uneven compression

cannot be tuned successfully to give peak performance. It is essential, therefore, that

improper compression be corrected before proceeding with an engine tuneup.

7. Cylinder scoring: If powerhead shows any indication of overheating, such as discolored or scorched paint, visually inspect cylinders for scoring or other damage as outlined in Section 4 “Powerhead.”

90-826883R2 JUNE 1998 Page 1C-9

Page 31

GENERAL INFORMATION

Painting Procedures

Cleaning & Painting Aluminum Propellers & Gear Housings

WARNING

Avoid serious injury from flying debris. A void serious injury from airborne particles. Use eye and breathing protection with proper ventilation.

PROPELLERS

1. Sand the entire area to be painted with 3M 120 Regalite Polycut or coarse ScotchBrite, disc or belts.

2. Feather edges of all broken paint edges. Try not to sand through the primer.

3. Clean the surface to be painted using PPG Industries DX330 Wax and Grease Remover or equivalent (Xylene or M.E.K.).

4. If bare metal has been exposed, use Quicksilver’s Light Gray Primer.

5. Allow a minimum of 1 hour dry time and no more than 1 week before applying the finish

coat.

6. Apply the finish coat using Quicksilver’s EDP Propeller Black.

GEAR HOUSINGS

The following procedures should be used in refinishing gear housings. This procedure will

provide the most durable paint system available in the field. The materials recommended

are of high quality and approximate marine requirements. The following procedure will

provide a repaint job that compares with a properly applied factory paint finish. It is recommended that the listed materials be purchased from a local Ditzler Automotive Finish Supply Outlet. The minimum package quantity of each material shown following is sufficient

to refinish several gear housings.

Procedure:

1. Wash gear housing with a muriatic acid base cleaner to remove any type of marine

growth, and rinse with water, if necessary.

2. Wash gear housing with soap and water, then rinse.

3. Sand blistered area with 3M 180 grit sandpaper or P180 Gold Film Disc to remove

paint blisters only. Feather edge all broken paint edges.

4. Clean gear housing thoroughly with (DX-330) wax and grease remover.

5. Spot repair surfaces where bare metal is exposed with (DX-503) alodine treatment.

IMPORT ANT : Do not use any type of aerosol spray paints as the paint will not properly adhere to the surface nor will the coating be sufficiently thick to resist future

paint blistering.

6. Mix epoxy chromate primer (DP-40) with equal part catalyst (DP-401) per manufacturers instructions, allowing proper induction period for permeation of the epoxy primer and catalyst.

7. Allow a minimum of one hour drying time and no more than one week before top coating assemblies.

8. Use Ditzler Urethane DU9000 for Mercury Black, DU34334 for Mariner Grey, and

DU35466 for Force Charcoal, and DU33414M for Sea Ray White. Catalyze all three

colors with Ditzler DU5 catalyst mixed 1:1 ratio. Reduce with solvents per Ditzler label.

Page 1C-10 90-826883R2 JUNE 1998

Page 32

Be sure to comply with instructions on the label for ventilation and respirators.

Using a spray gun, apply one half to one mil even film thickness. Let dry , flash off

for five minutes and apply another even coat of one half to one mil film thickness.

This urethane paint will dry to the touch in a matter of hours, but will remain sensitive to scratches and abrasions for a few days.

9. The type of spray gun used will determine the proper reduction ratio of the paint.

IMPORTANT: Do not paint sacrificial zinc trim tab or zinc anode.

10. Cut out a cardboard “plug” for trim tab pocket to keep paint off of mating surface to

maintain good continuity circuitry between trim tab and gear housing.

Decal Application

Decal Removal

1. Mark decal location before removal to assure proper alignment of new decal.

2. Carefully soften decal and decal adhesive with a heat gun or heat blower while removing old decal.

GENERAL INFORMATION

CAUTION

3. Clean decal contact area with a 1:1 mixture of isopropyl alcohol and water.

4. Thoroughly dry decal contact area and check for a completely cleaned surface.

Instructions for “Wet” Application

NOTE: The following decal installation instructions are provided for a “Wet” installation.

All decals should be applied wet.

TOOLS REQUIRED

1. Plastic Squeegee*

2. Stick Pin

3. Dish Washing Liquid/Detergent without ammonia** “Joy” and “Drift” are known to

be compatible for this process.

** Automotive Body Filler Squeegee

** Do not use a soap that contains petroleum based

solvents.

SERVICE TIP: Placement of decals using the “Wet” application will allow time to

position decal. Read entire installation instructions on this technique before proceeding.

TEMPERATURE

IMPORTANT: Installation of vinyl decals should not be attempted while in direct

sunlight. Air and surface temperature should be between 60°F (15°C) and 100°F

(38°C) for best application.

SURFACE PREPARATION

IMPORT ANT: Do not use a soap or any petroleum based solvents to clean application surface.

Clean entire application surface with mild dish washing liquid and water. Rinse surface

thoroughly with clean water.

90-826883R2 JUNE 1998 Page 1C-1 1

Page 33

GENERAL INFORMATION

DECAL APPLICATION

1. Mix

NOTE: Leave protective masking, if present, on the face of decal until final steps of decal

installation. This will ensure that the vinyl decal keeps it’s shape during installation.

2. Place the decal face down on a clean work surface and remove the paper backing

3. Using a spray bottle, flood the entire “adhesive side” of the decal with the pre-mixed

4. Flood area where the decal will be positioned with wetting solution.

5. Position pre-wetted decal on wetted surface and slide into position.

6. Starting at the center of the decal, “lightly” squeegee out the air bubbles and wetting

7. Wipe decal surface with soft paper towel or cloth.

8. Wait 10 - 15 minutes.

9. Starting at one corner, “carefully and slowly” pull the masking of f the decal surface at

1

/2 ounce (16 ml) of dish washing liquid in one gallon (4 l) of cool water to use as

wetting solution.

from “adhesive side” of decal.

wetting solution.

solution with overlapping strokes to the outer edge of the decal. Continue going over

the decal surface until all wrinkles are gone and adhesive bonds to the cowl surface.

a 180° angle.

NOTE: T o remove any remaining bubbles, pierce the decal at one end of the bubble with

stick pin and press out the entrapped air or wetting solution with your thumb (moving toward the puncture).

Page 1C-12 90-826883R2 JUNE 1998

Page 34

OUTBOARD MOTOR INSTALLATION

IMPORTANT INFORMATION

Section 1D - Outboard Motor Installation

Table of Contents

Table of Contents 1D-1. .. .. .. .. .. .. .. .. .. .. .. .. .. .

Notice to Installer and Owner 1D-1. . . . . . . . . . . . . . . . . .

Boat Horsepower Capacity 1D-1.. .. .. .. .. .. .. .. .

Outboard Remote Control 1D-1. .. .. .. .. .. .. .. .. .

Selecting Accessories For The Outboard 1D-2. . . . .

Selecting Steering Cables and Remote Control

Cables 1D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Outboard 1D-3. .. .. .. .. .. .. .. .. .. .. .. .. .

Steering Cable and Steering Link Rod Installation 1D-4

Installing Ride Guide Steering Cable to

the Outboard 1D-4.. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Cable Seal 1D-4. .. .. .. .. .. .. .. .. .. .. ..

Steering Link Rod Installation 1D-5. . . . . . . . . . . . . . .

Notice to Installer and Owner

1

D

Remote Control Installation 1D-6. . . . . . . . . . . . . . . . . . .

Shift and Throttle Cable Installation to

the Outboard 1D-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Installation 1D-6. . . . . . . . . . . . . . . . . . . . .

Throttle Cable Installation 1D-7. . . . . . . . . . . . . . . . . .

Remote Wiring Harness Connection to Engine 1D-8. . .

Battery Cable Connections 1D-10. . . . . . . . . . . . . . . . . . .

Propeller Installation 1D-11. .. .. .. .. .. .. .. .. .. .. .. .

Tilt Pin Adjustment 1D-11. .. .. .. .. .. .. .. .. .. .. .. .. .

Placing Tilt Pin in Lower Holes 1D-11.. .. .. .. .. .. .

Placing Tilt Pin in Upper Holes 1D-12.. .. .. .. .. .. .

Trim Tab Adjustment 1D-12.. .. .. .. .. .. .. .. .. .. .. ..

Thismanualaswellassafetylabelspostedon the outboardusethefollowingsafetyalerts

to draw your attention to special safety instructions that should be followed.

DANGER -- Immediate hazards which WILL result in severe personal injury or death.

WARNING-- HazardsorunsafepracticeswhichCOULDresultinseverepersonalinjury

or death.

CAUTION -- Hazards or unsafe practices which could result in minor injury or product

or property damage.

Boat Horsepower Capacity

U.S. COAST GUARD CAPACITY

MAXIMUM HORSEPOWER XXX

MAXIMUM PERSON

CAPACITY (POUNDS) XXX

MAXIMUM WEIGHT

CAPACITY XXX

DANGER

WARNING

CAUTION

Do not overpower or overload your boat. Most boats will carry a required capacity plate

indicating the maximum acceptable power and load as determined by the manufacturer

following certainfederal guidelines. If in doubt, contact your dealer or the boat manufacturer.

90-826883R2 JUNE 1998 Page 1D-1

Page 35

OUTBOARD MOTOR INSTALLATION

WARNING

Using an outboard that exceeds the maximum horsepower limit of a boat can: 1.

cause loss of boat control 2. place too much weight at the transom altering the

designed flotation characteristics of the boat or 3. cause the boat to break apart

particularly around the transom area. Overpowering a boat can result in serious

injury, death, or boat damage.

Outboard Remote Control

Theremotecontrolconnectedtoyouroutboardmustbeequipped witha start-in-gearprotection device. This prevents the engine from starting when the outboard is in gear.

WARNING

Avoidseriousinjuryordeath from asuddenunexpectedacceleration whenstarting your engine. The design of this outboard requires that the remote control

used with it must have a built in start-in-gear protection device.

Selecting Accessories For The Outboard

Genuine Mercury Marine Quicksilver Accessories have been specifically designed and

tested for your outboard.

Mercury Marine Quicksilver accessories are available from Mercury Marine dealers.

Some accessories not manufactured or sold by Mercury Marine are not designed to be

safelyusedwithyouroutboardoroutboard operating system.Acquireandreadtheinstallation, operation, and maintenance manuals for all your selected accessories.

Selecting Steering Cables and Remote Control Cables

Installsteering mountand steeringwheel inaccordance withinstallation instructionsthat

accompany each.

IMPORTANT: Steering cable must be correct length. Sharp bends on too-short of

a cable result in “kinks;” too-long of a cable require unnecessary bends and/or

loops. Both conditions place extra stress on the cable.

Refer to “Quicksilver Accessories Guide” to determine correct length of steering cable.

Page 1D-2 90-826883R2 JUNE 1998

Page 36

Installing Outboard

1. Measure the transom height of your boat. The boat bottom should be aligned or be

within 1 in. (25mm) above the anti-ventilation plate (a) of the outboard.

a

a - Anti-Ventilation Plate

2. Place outboard on center line of transom.

OUTBOARD MOTOR INSTALLATION

0 -1in.

(0 - 25mm)

3. Tighten transom clamp handles.

4. To prevent loss of outboard overboard, fasten outboard by drilling two 5/16 in. (7.9

mm)holesthroughthetransomusingtransomclampholes as atemplate.Fastenwith

two bolts,flat washers and locknuts. Use a marinewaterproofing sealer inholes and

around bolts to make the installation water tight.

a

c

b

a - Bolts (2)

b - Flat Washers(2)

c - Locknuts (2)

90-826883R2 JUNE 1998 Page 1D-3

Page 37

OUTBOARD MOTOR INSTALLATION

Steering Cable and Steering Link Rod Installation

Installing Ride Guide Steering Cable to the Outboard

IMPORTANT: Before installing steering cable into tilt tube, lubricate entire cable

end with Quicksilver 2-4-C w/Teflon Marine Lubricant (92-825407A12).

1. Lubricate the entire cable end.

a

a - Quicksilver 2-4-C Marine Lubricant with Teflon

2. Insert steering cable end thru outboard tilt tube and secure steering cableto tilt tube

with steering cable attaching nut as shown. Torque nut to 35 lb. ft. (47.5 N·m).

Steering Cable Seal

3. Place amark on tilt tube5/8 in. (15.9mm) from port end of tube. Slideplastic spacer,

o-ring and cap over steering cable end, to tilt tube on engine.

b

a - Cable End

b - Attaching Nut [Torque to 35 lb. ft. (47.5 N·m)].

1/4 in.

(6.4mm

)

b

c

a

d

a - Mark

b - Spacer

c - O-ring

d - Cap

Page 1D-4 90-826883R2 JUNE 1998

a

Page 38

4. Thread cap up to the 1/4 in. (6.4mm) mark.

a - Cap

Steering Link Rod Installation

IMPORTANT: The steering link rod that connects the steering cable to the engine

mustbe fastened usingspecialwasher head bolt(“a” --PartNumber 10-14000)and

self locking nuts (“b” & “c” -- Part Number 11-34863). These locknuts must never

be replaced with common nuts (non locking) as they will work loose and vibrate

off freeing the link rod to disengage.

OUTBOARD MOTOR INSTALLATION

a

WARNING

Disengagement of a steering link rod can result in the boat takinga full, sudden,

sharp turn. This potentially violent action can cause occupants to be thrown

overboard exposing them to serious injury or death.

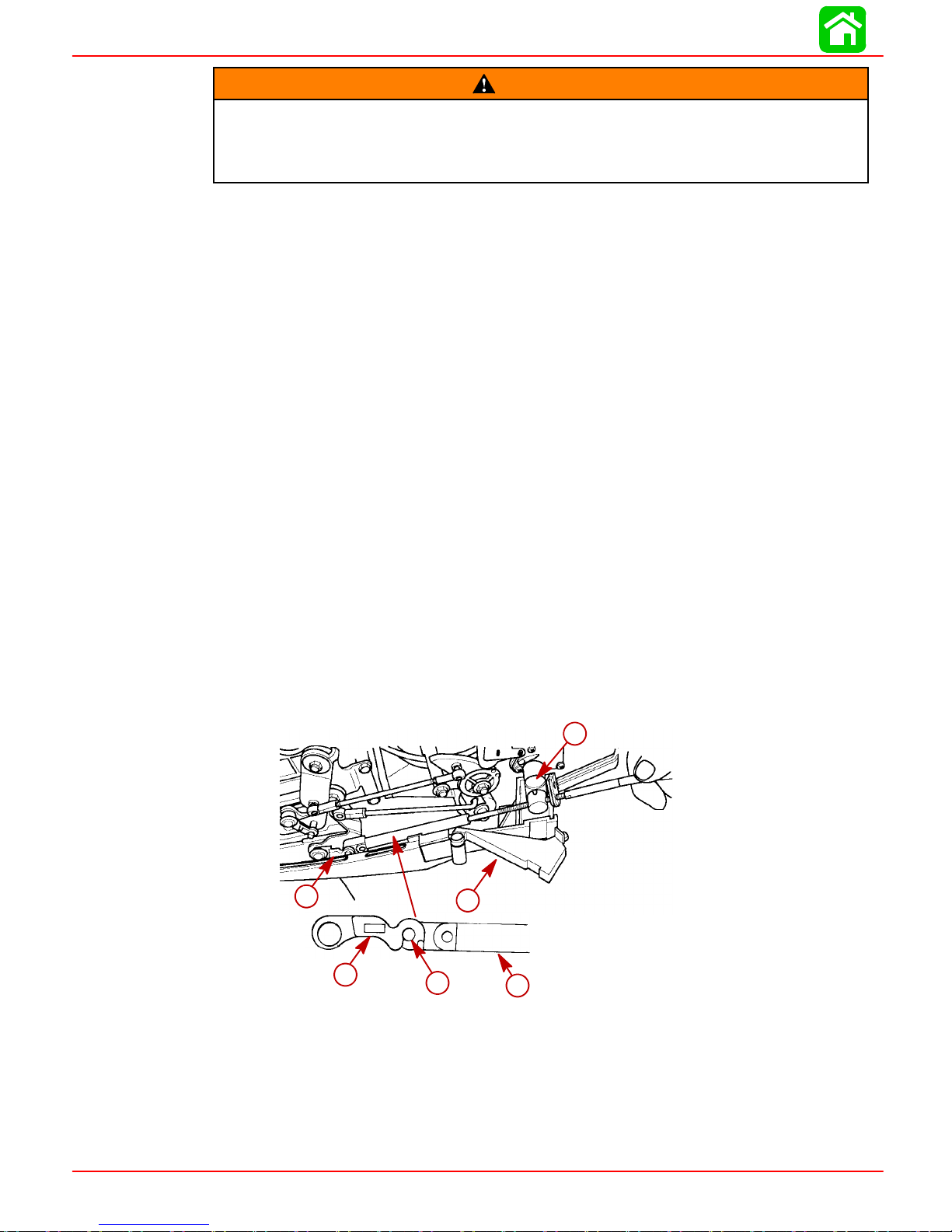

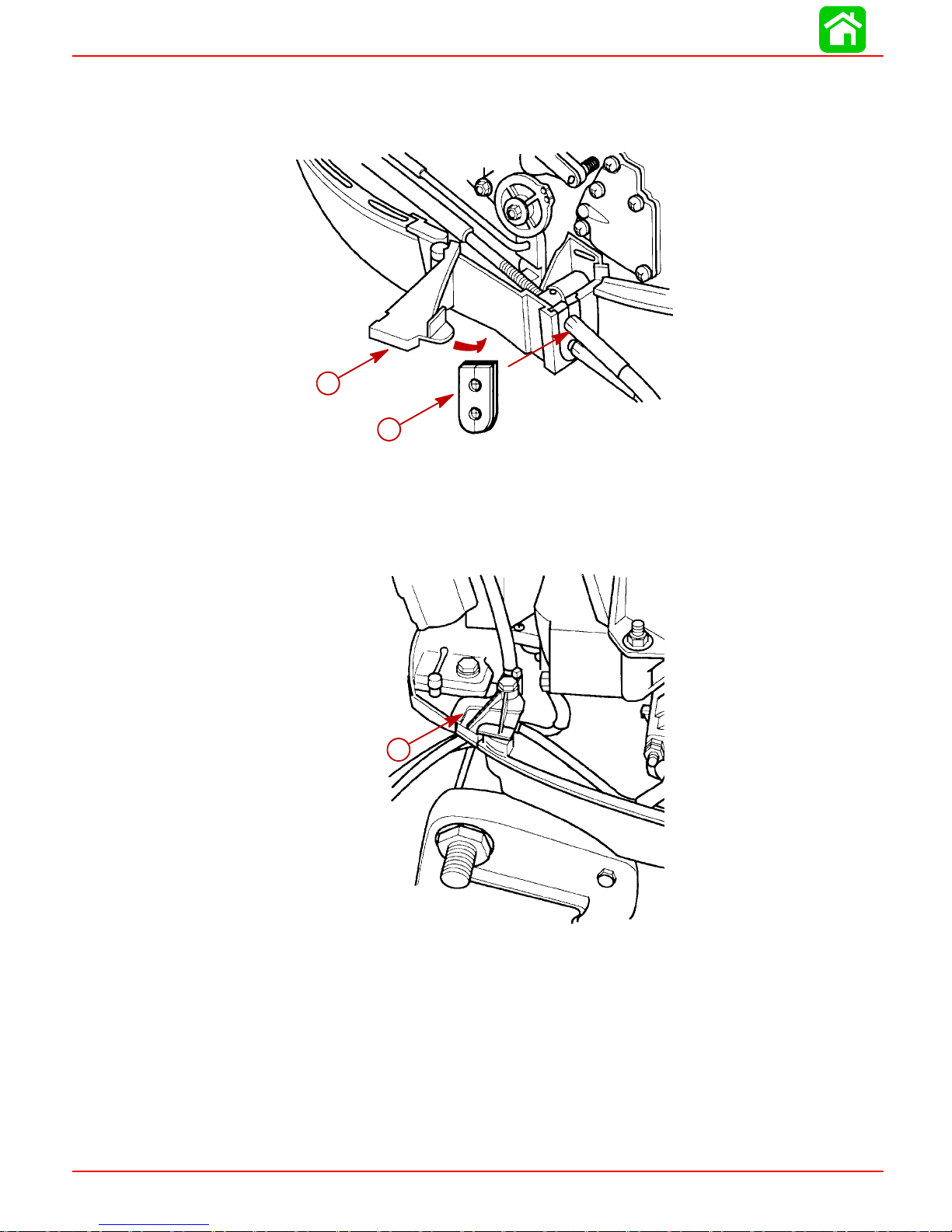

1. Assemblesteering linkrod to steeringcable withtwo flatwashers (d)andnylon insert

locknut(“b” -- Part Number 11-34863).Tighten locknut (b) untilit seats,then backnut

off 1/4 turn.

2. Assemblesteeringlinkrod toenginewithspecialwasher head bolt(“a”-- PartNumber

10-14000)and nyloninsertlocknut (“c” --Part Number11-34863).Firsttorquebolt (a)

to 20 lb. ft. (27.1 N·m), then torque locknut (c) to 20 lb. ft. (27.1 N·m).

c

d

b

a - Bolt (10-14000)

b - Lock Nut (11-34863)

c - Lock Nut (11-34863)

d - Washers (2 each)

90-826883R2 JUNE 1998 Page 1D-5

a

Page 39

OUTBOARD MOTOR INSTALLATION

WARNING

After installation is complete (and before operating outboard), check that boat

willturn right whensteeringwheel isturned right andthat boat willturn left when

steering wheelis turned left. Check steeringthru full range (left and right) and at

all tilt angles to assure interference-free movement.

Remote Control Installation

Refer to Quicksilver Accessory Guide for appropriate electric or manual remote control.

Use instructions provided with control for proper installation.

Shift and Throttle Cable Installation to the Outboard

Installthe shift cableandthrottle cableintotheremote controland mounttheremote control following instructions which are provided with the remote control.

NOTE: Install the shift cable before thethrottle cable. The shift cable is the first cable to

move when the remote control handle is moved into gear.

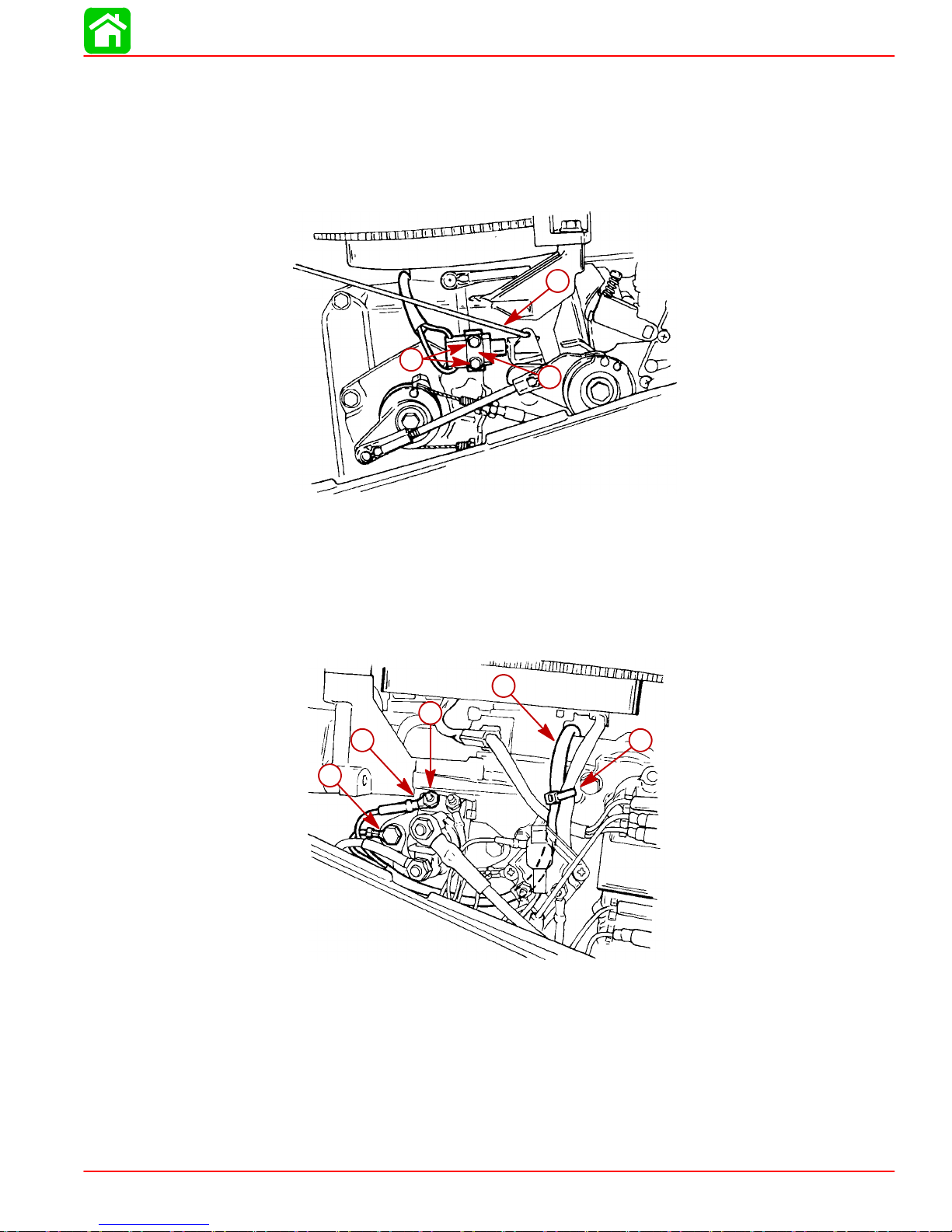

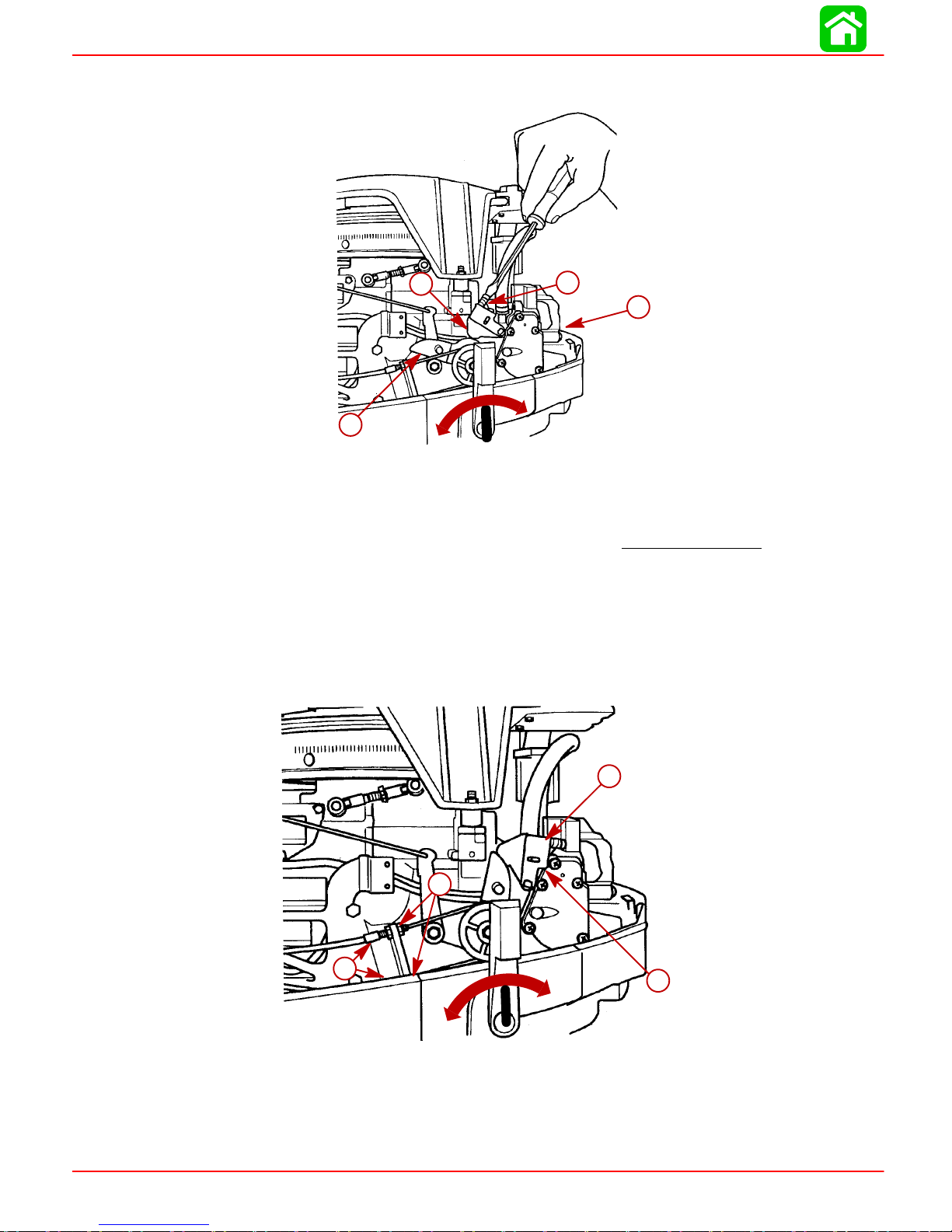

Shift Cable Installation

1. Move the remote control handle into full reverse position.

2. Place the engine shift lever (a) into reverse position (toward rear) while rotating propeller. The propeller shaft will not rotate in either direction when in reverse position.

3. Open up the cable retainer cover (b) and remove the barrel holder and front rubber

grommet.

4. Installthe shiftcable (c) ontotheshift leverpin (d). lockinplace withretainer latch(e).

5. Adjust theshift cablebarrel so itwill fit intothe bottom holeof the barrelholder (f)and

that thebarrel holder will slide freely into theretaining pocket without pre-loading the

shift cable.

f

a

b

a - Shift Lever

b - Cable Retainer Cover

c - Shift Cable

d - Shift Lever Pin

e - Retainer Latch

f - Barrel Holder

6. Check shift cable adjustments as follows:

Page 1D-6 90-826883R2 JUNE 1998

e

d

c

Page 40

a. With remote control shifted into forward the propeller shaft should lock solidly in

gear. If it does not, adjust the cable barrel closer to the engine shift lever.

b. Shift remote control into neutral. The propeller shaft should turn freely without

drag.If not,adjust the barrelaway fromthe engineshift lever. Repeatsteps aand

b.

c. Shift remote control into reverse while turning the propeller shaft. The propeller

shaftshould locksolidlyin gear. Ifnot,adjust thebarrelaway fromtheengine shift

lever. Repeat steps a thru c.

d. Return remote control handle to neutral. The propeller shaft should turn freely

withoutdrag. Ifnot, adjustthe barrelcloser tothe engineshift lever.Repeatsteps

a thru d.

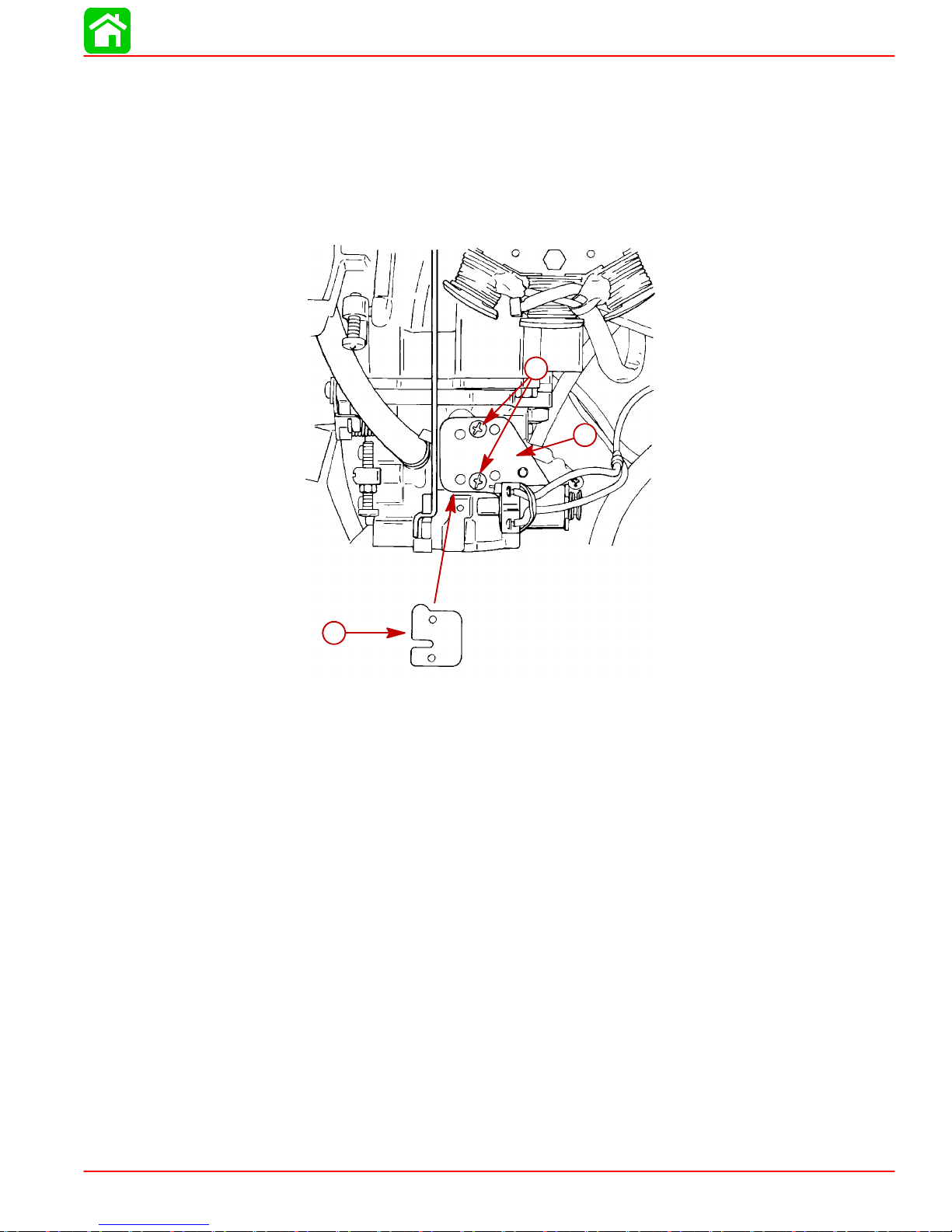

Throttle Cable Installation

NOTE: Attach Shift cable to engine prior to attaching throttle cable.

1. Position the remote control handle forward, to wide-open-throttle position.

2. Installthe throttle cable(a)onto thethrottlepin(b). lockinplace withretainerlatch(c).

3. Move throttle lever (g) until tab (e) contacts throttle stop (f). Adjust the barrel on the

throttle cable so that the barrel will fit into the barrel holder (d).

4. Slipthebarrelinto thebarrelholderandplacethe barrelholderintotheretainingpocket.

OUTBOARD MOTOR INSTALLATION

5. Check the throttle cable adjustment as follows.

a. Move the remote control handle back to neutral a few times and then return the

handle back to forward wide-open-position.

b. Recheck to make sure tab (e) is contacting throttle stop (f).

f

e

d

g

a - Throttle Cable

b - Throttle Pin

c - Retainer Latch

d - Barrel Holder

e - Tab

f - Throttle Stop

g - Throttle Lever

90-826883R2 JUNE 1998 Page 1D-7

c

b

a

Page 41

OUTBOARD MOTOR INSTALLATION

6. Place the rubber seal ( side with holes towards front)) onto the control cables and

install control cables, barrel holder and rubber seal into the cable holder as shown.

7. Lock the barrel holder in place with the cable retainer latch.

a - Rubber Seal

b - Cable Retainer Latch

b

a

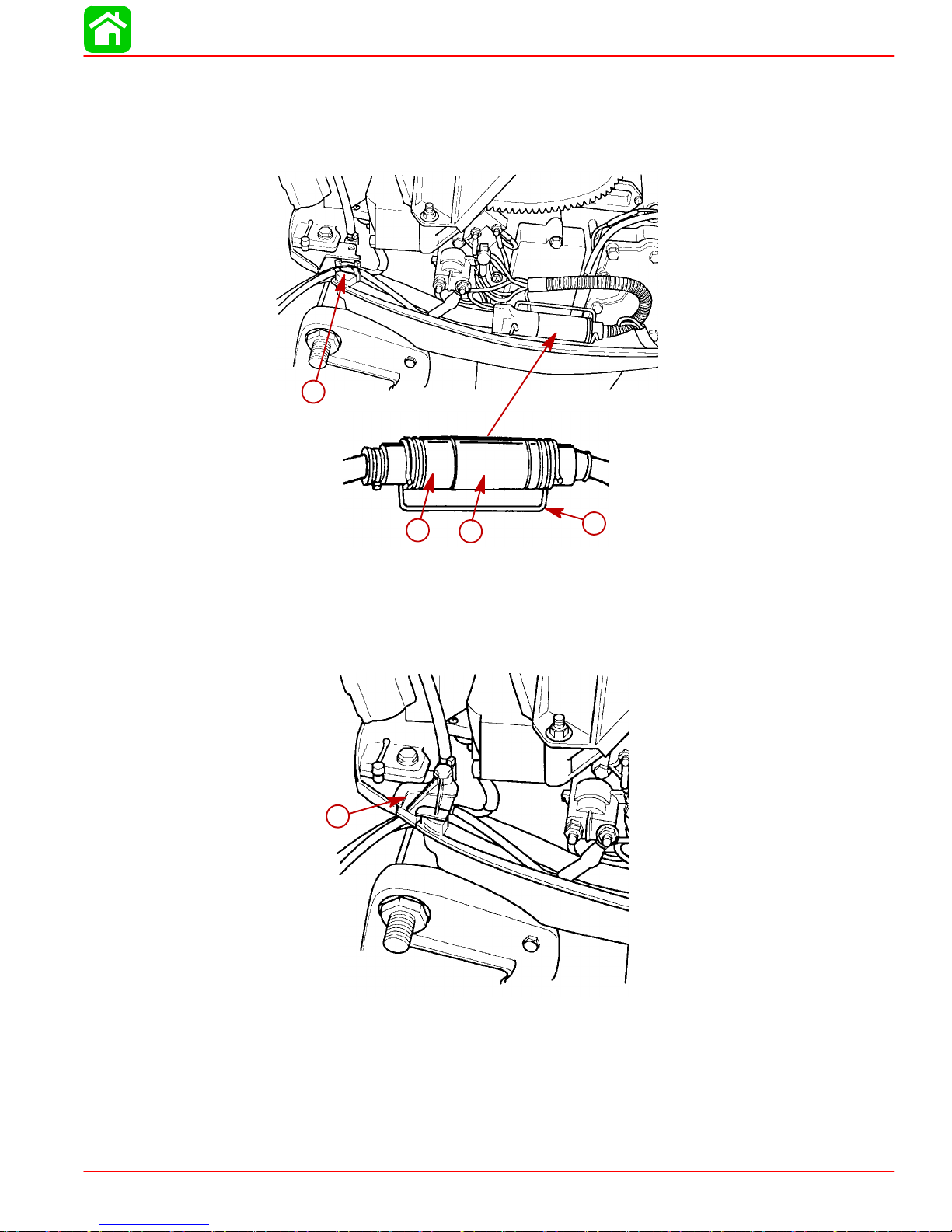

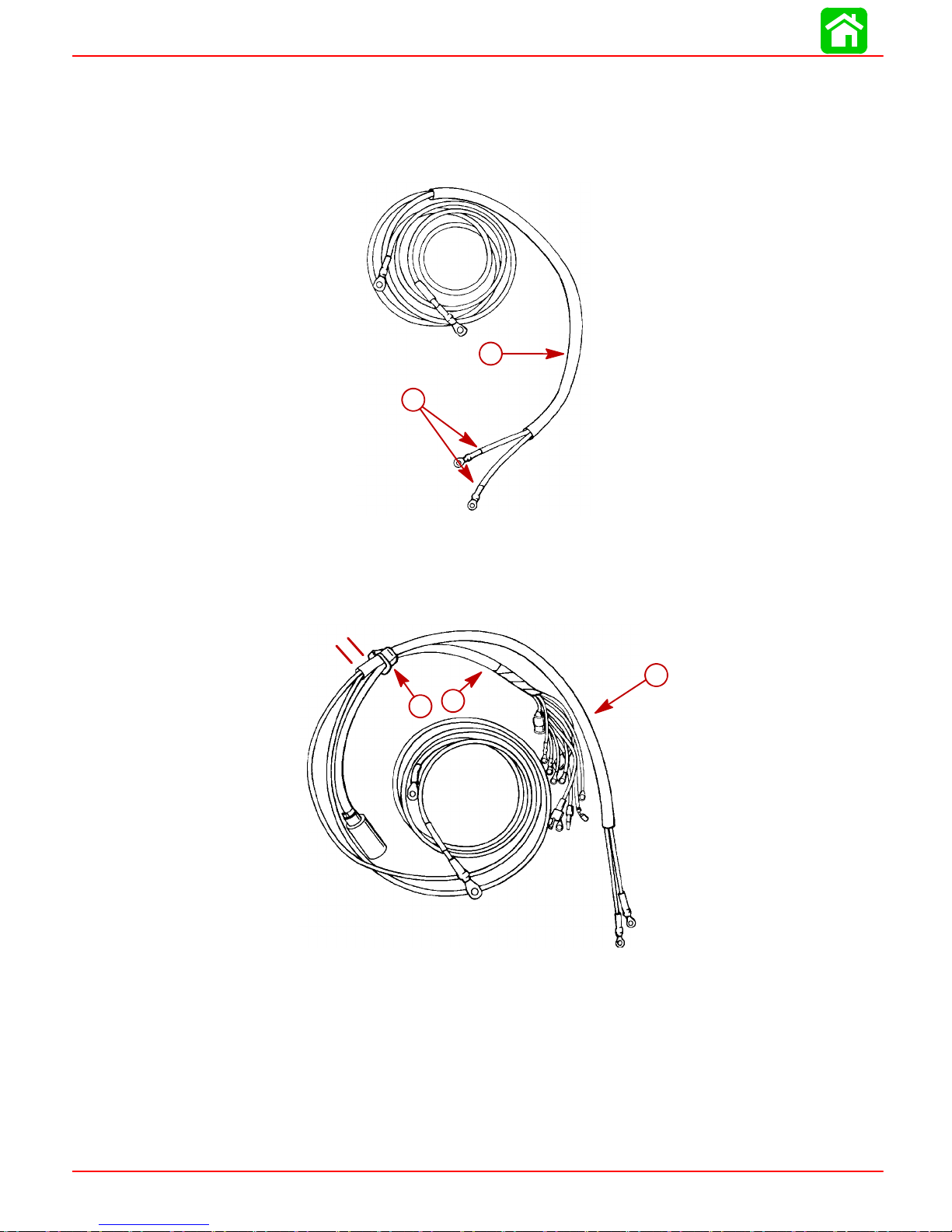

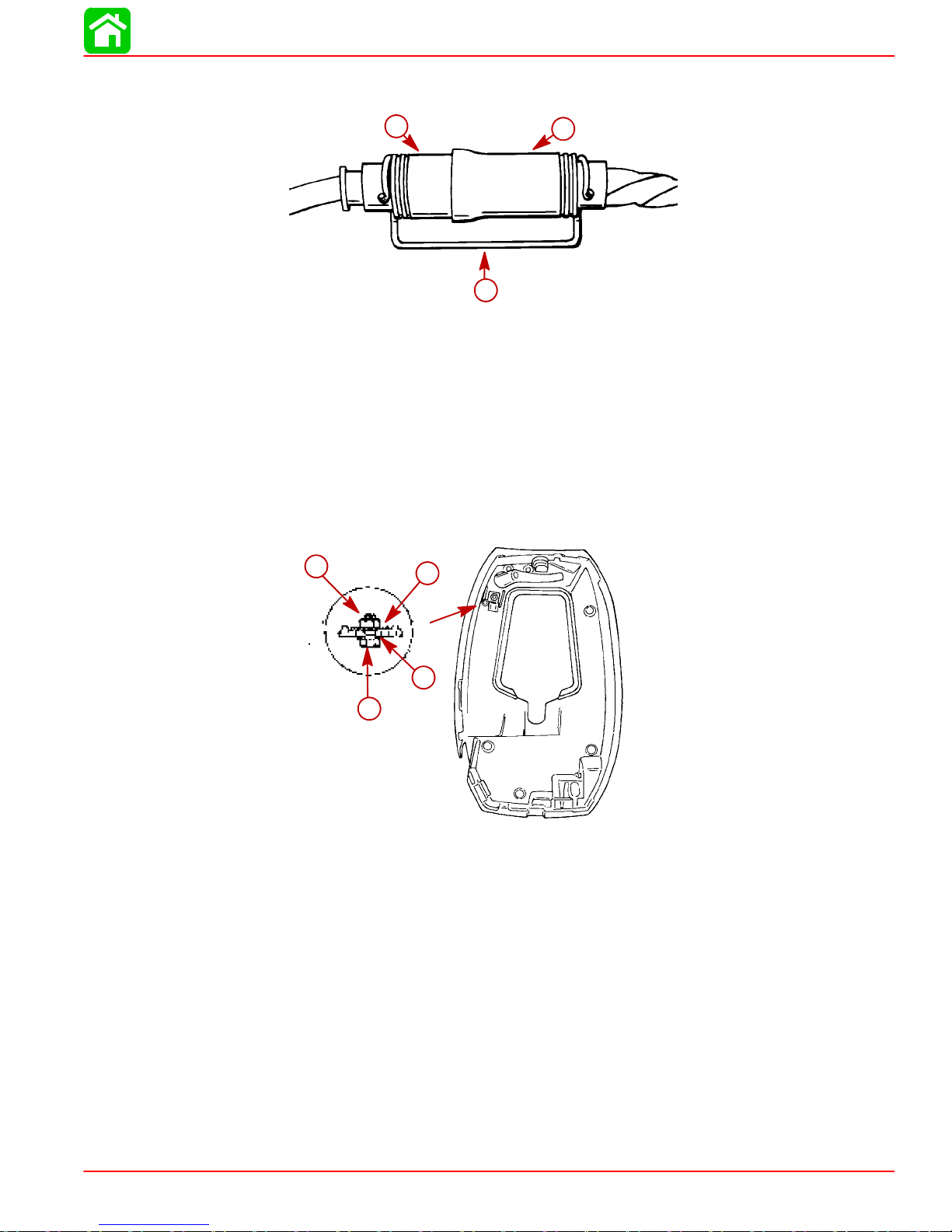

Remote Wiring Harness Connection to Engine

1. Remove wire retainer from the bottom cowl.

a

a - Wire Retainer

Page 1D-8 90-826883R2 JUNE 1998

Page 42

OUTBOARD MOTOR INSTALLATION

2. Position the remote wiring harness and battery cables thru the bottom cowl rubber

grommet as shown.

3. Plug the remote wiring harness into the engine wiring harness connector.

4. Secure the connection together using retainer.

a

b c

a - Rubber Grommet

b - Remote Wiring Harness

c - Engine Harness Connector

d - Retainer

d

5. Fasten the remote wiring harness and battery cables into the bottom cowl rubber

grommet with retainer.

a

a - Retainer

90-826883R2 JUNE 1998 Page 1D-9

Page 43

OUTBOARD MOTOR INSTALLATION

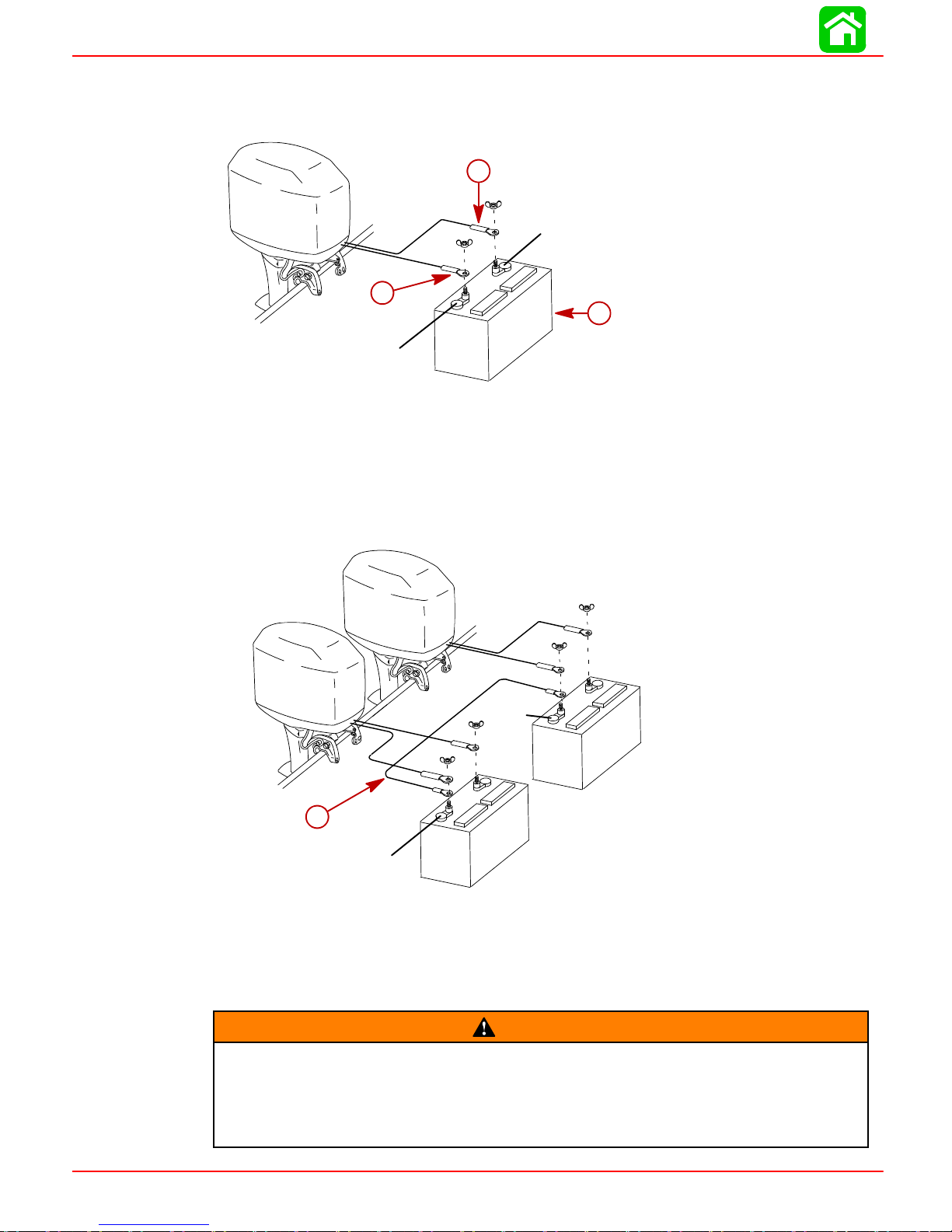

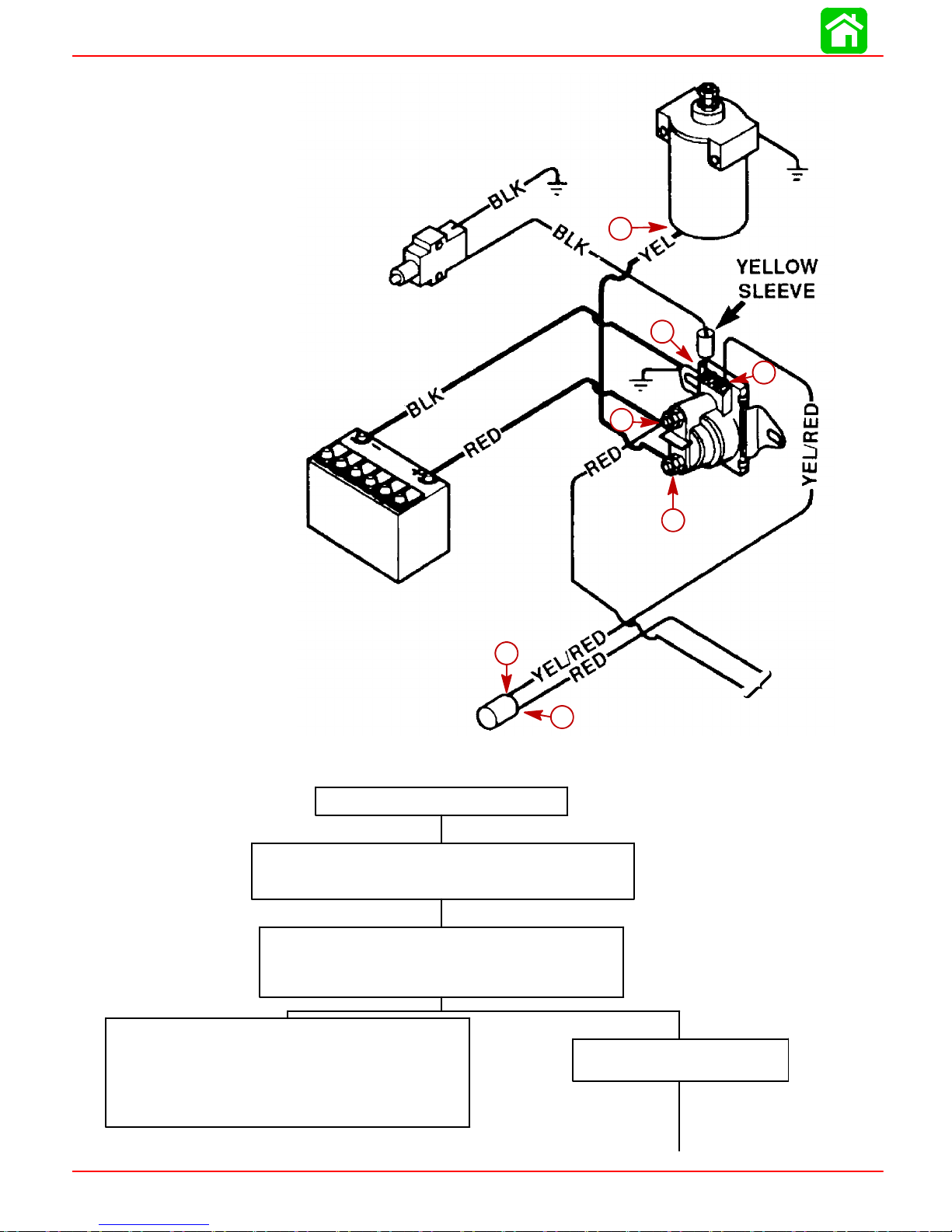

Battery Cable Connections

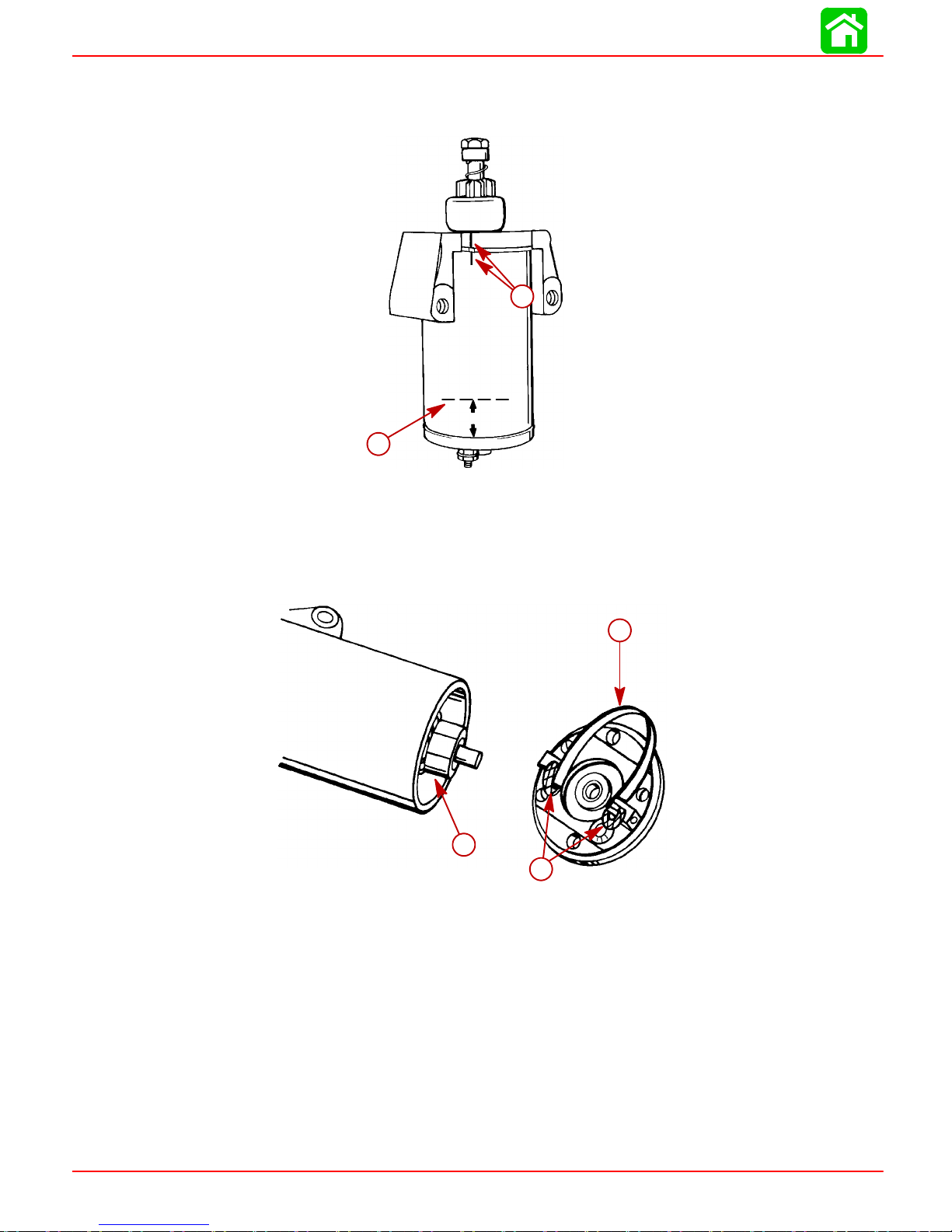

SINGLE OUTBOARD

b

(--)

a - RED Sleeve (POSITIVE)

b - BLACK Sleeve (NEGATIVE)

c - Starting Battery

DUAL OUTBOARD

1. Connecta commonground cable(wire sizesame asengine batterycables) between

negative (--) terminals on starting batteries.

a

(+)

c

a

a - Ground Cable (Same Wire Size As Engine Battery Cable -- Connect Between Negative (--)

Terminals

Propeller Installation

If thepropeller shaft isrotated while the engine is ingear,there is thepossibility

thatthe engine willcrankover andstart.Topreventthistype of accidentalengine

starting and possible serious injury caused from being struck by a rotating propeller, always shift outboard to neutral position and remove spark plug leads

when you are servicing the propeller.

(--)

(--)

WARNING

Page 1D-10 90-826883R2 JUNE 1998

Page 44

Flo-Torq I Drive Hub Propellers

c

d

a - Forward Thrust Hub

b - Propeller

c - Rear Thrust Hub

d - Propeller Nut -- Tighten

Flo-Torq II Drive Hub Propellers

d

e

OUTBOARD MOTOR INSTALLATION

a

b

a - Forward Thrust Hub

b - Replaceable Drive Sleeve

c - Propeller

d - Rear Thrust Hub

e - Propeller Nut -- Tighten

Tilt Pin Adjustment

Placing Tilt Pin in Lower Holes

1. Lower the bow.

2. Result in quicker planing off, especially with a heavy load or a stern heavy boat.

3. Generally improve the ride in choppy water.

b

c

a

4. Increasesteering torque orpulltothe right(withthenormal righthandrotationpropeller).

5. Inexcess,lowerthe bowofsomeboatsto a pointatwhichtheybegin toplowwiththeir

bow inthe waterwhile on plane.This can result in anunexpected turn in either direction called “bow steering” or “over-steering” if any turn is attempted or if a significant

wave is encountered.

90-826883R2 JUNE 1998 Page 1D-11

Page 45

OUTBOARD MOTOR INSTALLATION

Placing Tilt Pin in Upper Holes

1. Lift the bow out of the water.

2. Generally increase top speed.

3. Increase clearance over submerged objects or a shallow bottom.

4. Increasesteering torqueor pullto theleft at anormal installationheight (withthe normal right hand rotation propeller).

5. In excess, cause boat “porpoising” (bouncing) or propeller ventilation.

Trim Tab Adjustment

Propellersteering torquemay causeboat topull inone direction.This steering torqueresults from outboard not being adjusted so the propeller shaft is parallel to the water surface.Thetrimtabcanhelpcompensateforthis steering torqueandcanbeadjustedwithin

limits to reduce any unequal steering effort.

NOTE: Trim tab adjustmentwill have little effect reducingsteering torque if theoutboard

is installed with the anti-ventilation plate ap proximately 2 inches (50mm) or more above

the boat bottom.

Operateboatatnormalcruisingspeed,withtheoutboard set atthedesiredtransomangle

adjustment. Turn boat left and right and note the direction the boat turns more easily.

If adjustment isnecessary, loosentrim tab bolt and make small adjustments ata time. If

the boat turns more easily to the left, move the trailing edge of trim tab to the left. If the

boatturns moreeasily to theright movethetrailing edgeof trimtab tothe right. Retighten

bolt and retest.

Page 1D-12 90-826883R2 JUNE 1998

Page 46

Table of Contents

IGNITION

ELECTRICAL

Section 2A - Ignition

2

Specifications 2A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 2A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition/Electrical Components 2A-4. . . . . . . . . . . . . . . .

Ignition Description 2A-6.. .. .. .. .. .. .. .. .. .. .. .. ..

Electronic Spark Advance 2A-7. . . . . . . . . . . . . . . . . .

Mechanical Spark Advance 2A-7. . . . . . . . . . . . . . . .

15XD RPM Limiter 2A-7. .. .. .. .. .. .. .. .. .. .. .. .

Ignition Component Description 2A-7. . . . . . . . . . . . . . . .

Trigger Coil 2A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stator 2A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel 2A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Coil 2A-9.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Switch Box 2A-9. . . . . . . . . . . . . . . . . . . . . . . .

Electronic Spark Advance 2A-11. .. .. .. .. .. .. .. .. ..

Ignition Test Procedures 2A-12. . . . . . . . . . . . . . . . . . . . .

Direct V oltage Adapter (DVA) 2A-12. . . . . . . . . . . . . .

Ignition Troubleshooting 2A-13. . . . . . . . . . . . . . . . . . . . .

Ignition Diagnostic Procedures 2A-13. . . . . . . . . . . . . . .

Ignition Troubleshooting 2A-15. . . . . . . . . . . . . . . . . . . . .

Electronic Spark Advance 2A-15. .. .. .. .. .. .. .. ..

Tool: Multimeter/DVA Tester 91-99750A1 2A-15. .. .

Ignition Troubleshooting 2A-16. . . . . . . . . . . . . . . . . . . . .

Mechanical Spark Advance 2A-16. . . . . . . . . . . . . . .

Ignition Troubleshooting (RED Stator) 2A-17. . . . . . . . .

A

90-826883 R2 JUNE 1998 Page 2A-1

Page 47

IGNITION

Specifications

IGNITION

SYSTEM

Readings taken @

68°F (20°C).

Type

Spark Plug Type (NGK)

Spark Plug Gap

Spark Plug Hex

Firing Order

20 Jet 19941/2THRU 1998

20/25 19941/2THRU 1996

Electronic Spark Advance

Idle @ 750 ± 50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Setup Timing

Stator High Speed Winding

Stator Low Speed Winding

Diode Test

Ignition Coil Resistance:

Primary

Secondary (w/o Boots)

20 Jet 1999 and Newer

20/25 1997/98 Models

Mechanical Spark Advance

Idle @ 750 ± 50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Stator High Speed Winding

Stator Low Speed Winding

Diode Test

Ignition Coil Resistance:

Primary

Secondary (w/o Boots)

Trigger

Capacitor Discharge Ignition

NGK BP8H-N-10

0.040 in. (1.0 mm)

18 mm

1-2

4° ± 2° B.T.D.C (Not Adjustable)

1400 RPM ± 250 RPM

25° ± 1 @5500 RPM

28° B.T.D.C. @ 3000 ± 200 R.P.M.

(Set-up timing of 28° B.T.D.C. will be

retarded to 25° B.T.D.C. @ 5500 R.P.M.)

100 -- 180 W (RED -- BLK)

2900 -- 3500 W (BLUE -- BLACK)

2800 -- 3400 W (RED -- BLUE)

0 W

850 -- 1200 W

6° ± 1° B.T.D.C

1500 RPM ± 200 RPM

25° ± 1 @5500 RPM

120 - 180 W (BLK/WHT - GRD)

3200 - 3800 W (BLK/YEL - GRD)

3100 -- 3700 W (BLK/YEL - BLK/WHT)

0.02 - 0.04 W

8000 - 11000 W

6500 - 8500 W

Page 2A-2 90-826883R2 JUNE 1998

Page 48

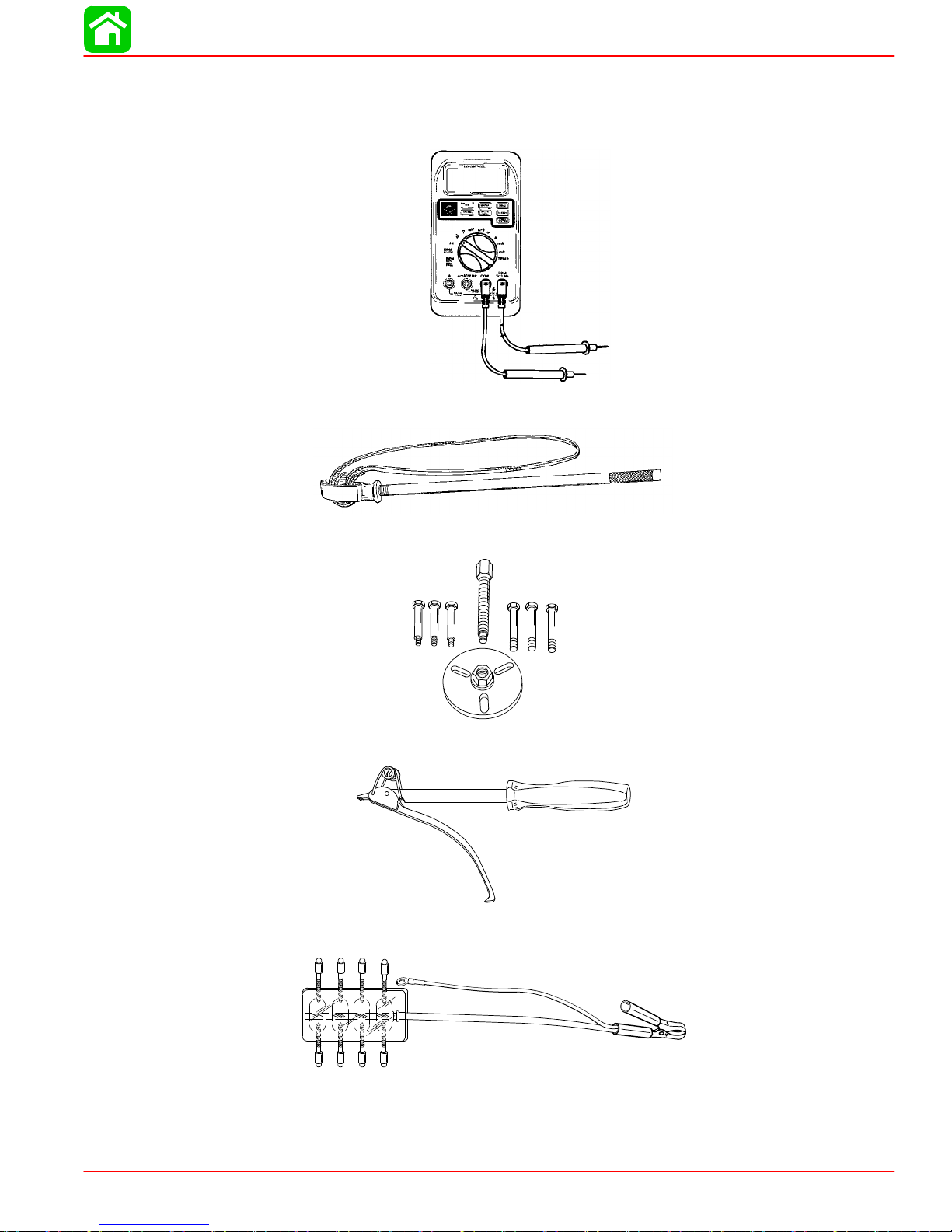

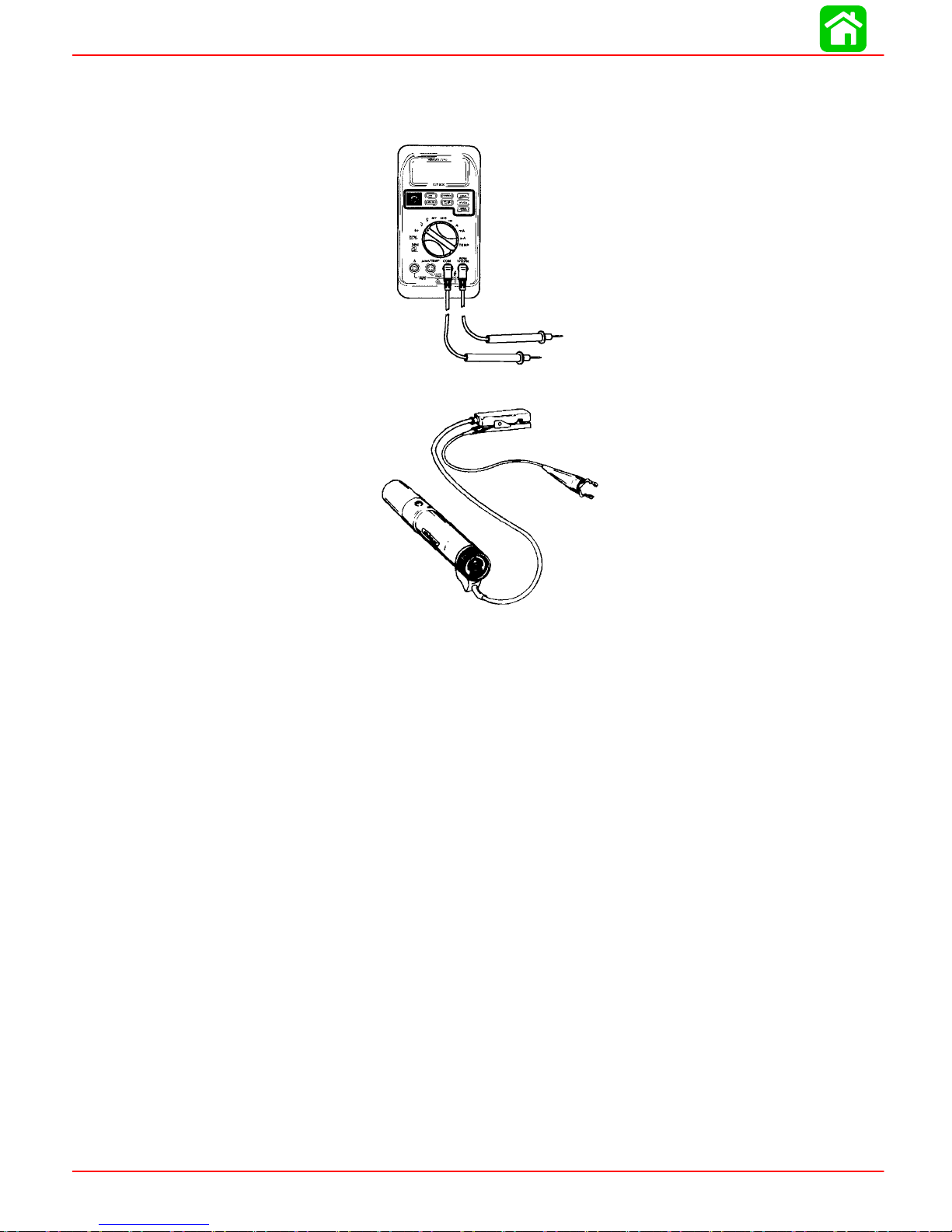

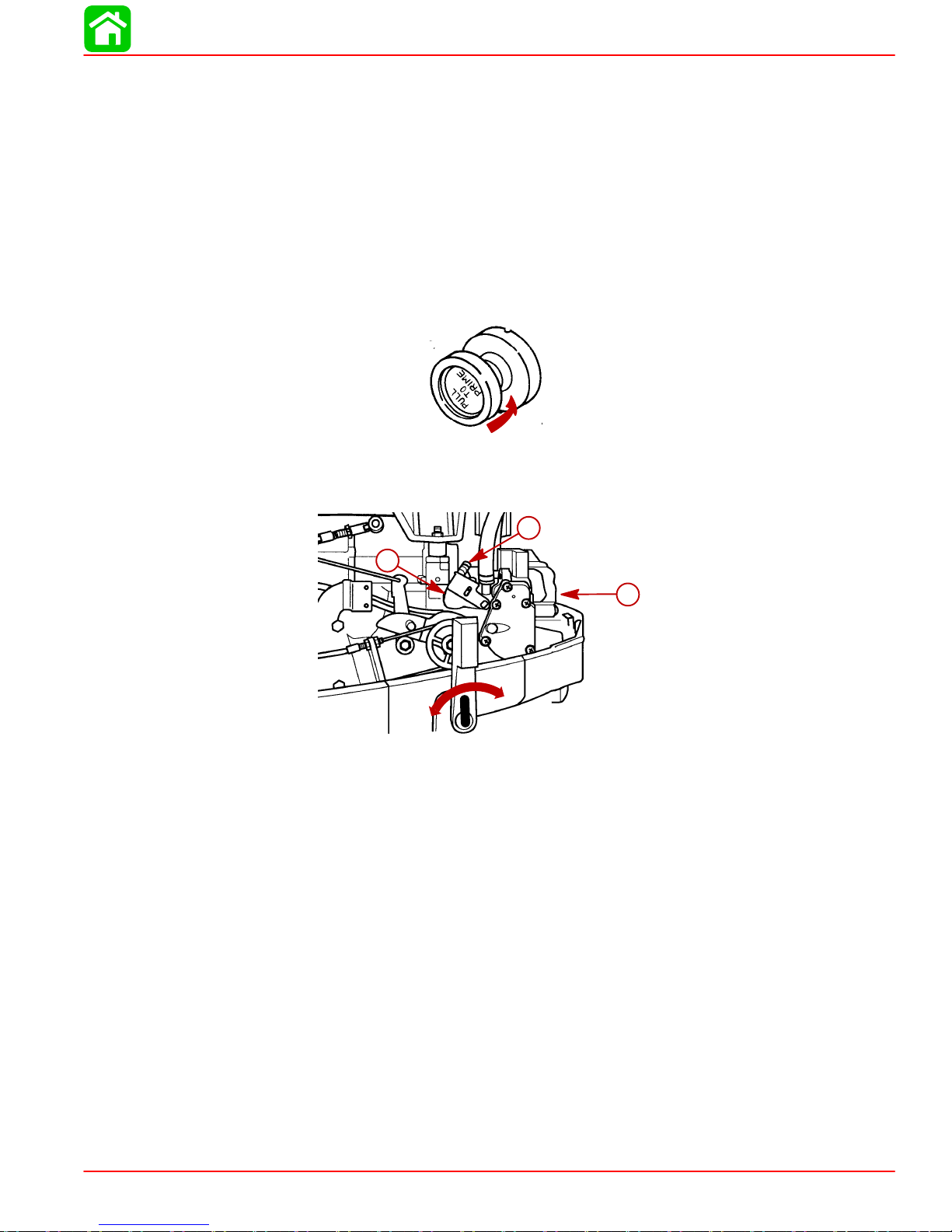

Special Tools

1. DMT 2000 Digital Tachometer Multi-meter P/N 91-854009A1

2. Flywheel Holder P/N 90-24937A1.

IGNITION

3. Flywheel Puller P/N 91-83164M.

4. Flywheel Holder 91-52344

5. Spark Gap Board 91-850439

54964

90-826883 R2 JUNE 1998 Page 2A-3

55117

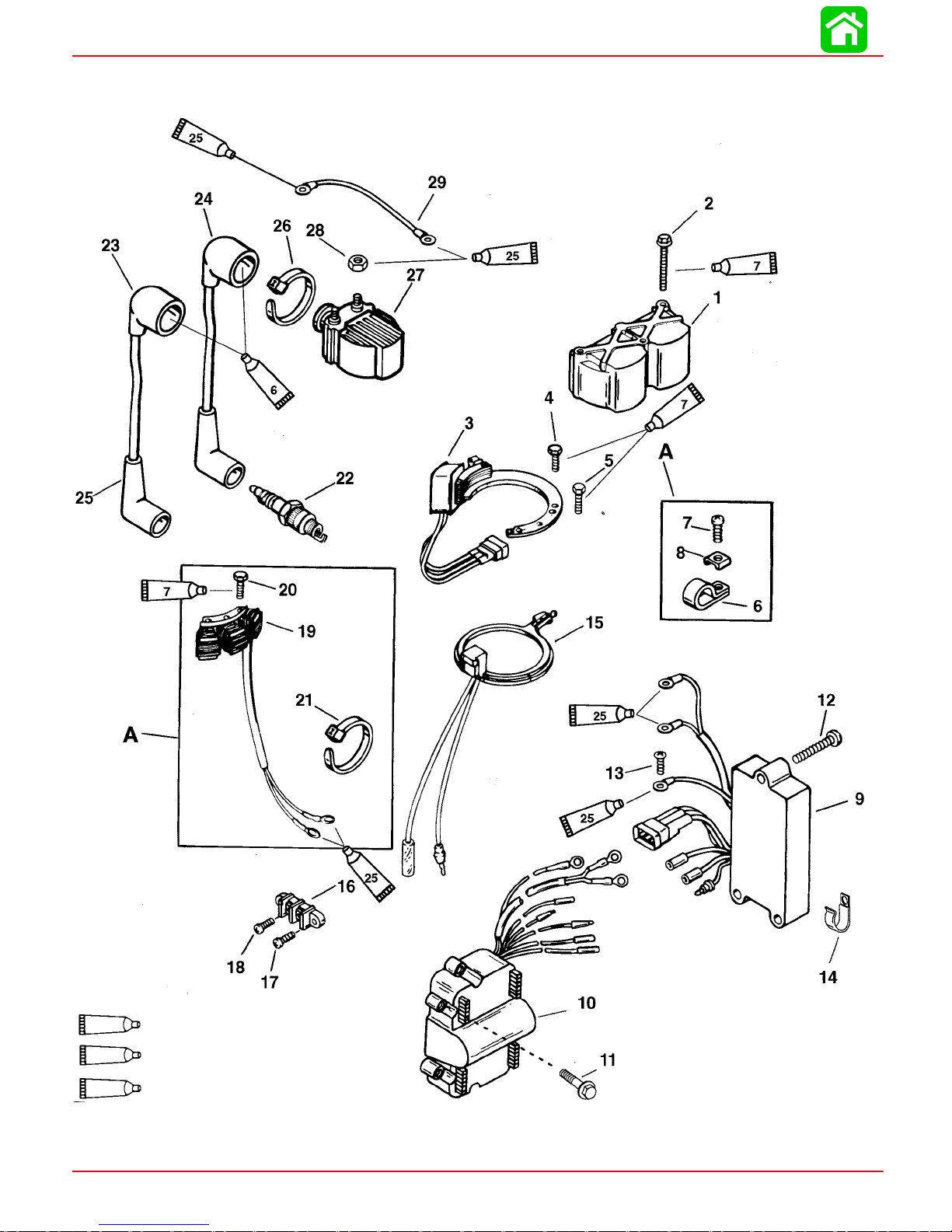

Page 49

IGNITION

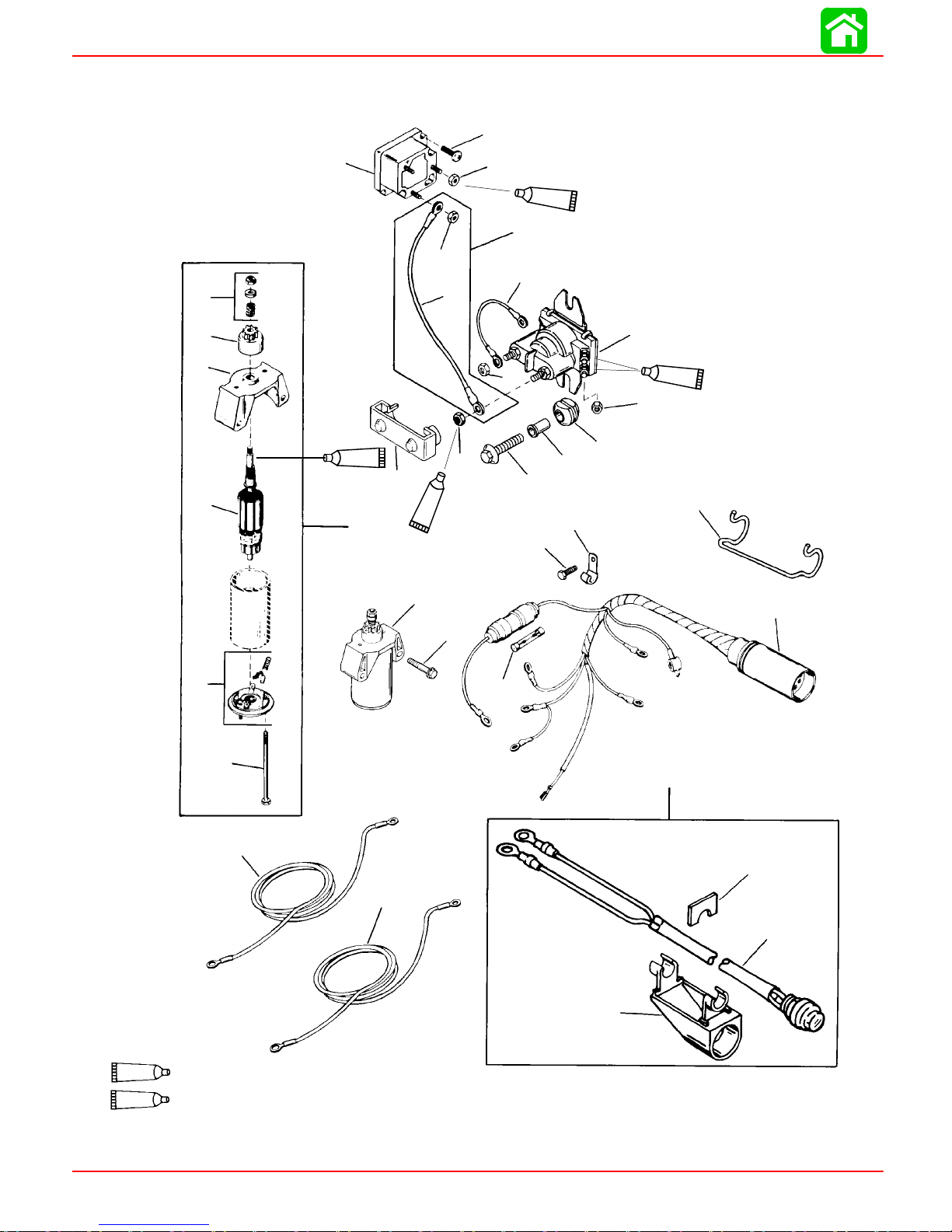

Ignition/Electrical Components

6

7

25

Dielectric Grease (92-823506--1)

Loctite 271 (92-809820)

Liquid Neoprene (92-25711--2)

A=ALTERNATOR VERSION ONLY

Page 2A-4 90-826883R2 JUNE 1998

Page 50

IGNITION

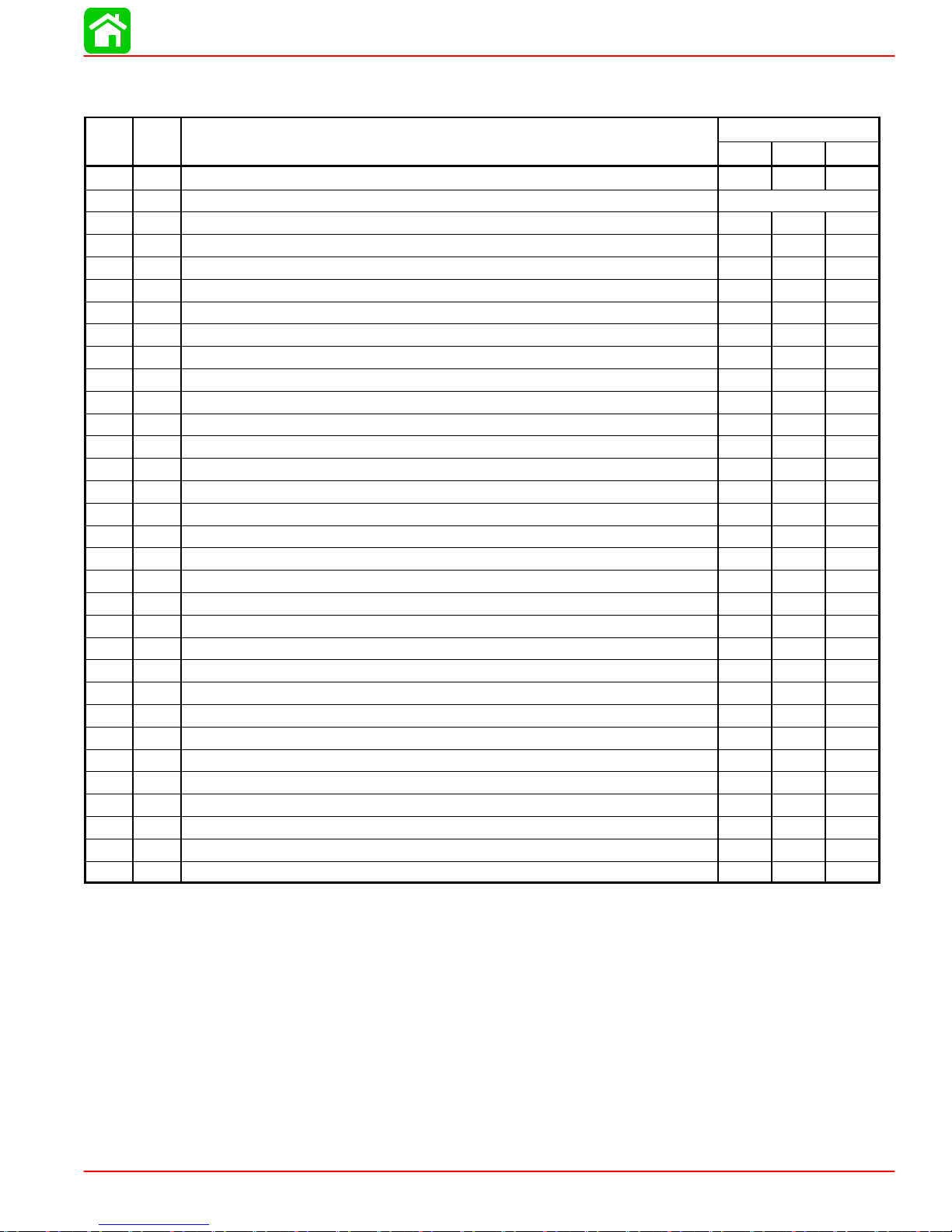

REF

.

9

1

0

2

2

Ignition/Electrical Components

TORQUE

QTY. DESCRIPTION lb. in. lb. ft. N·m

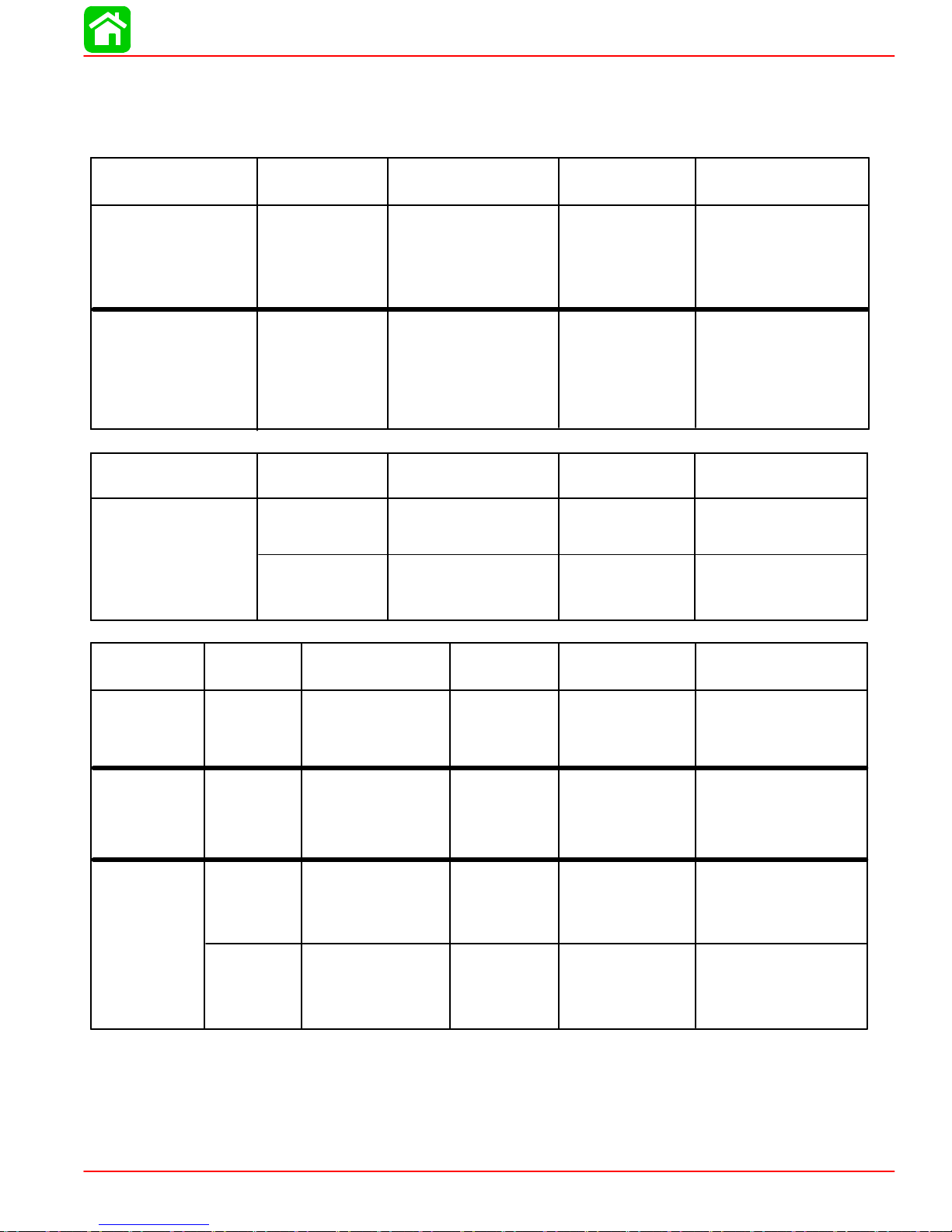

NO.

1 1 COVER--ignition coil

2 3 SCREW--ignition coil cover (M5x.8x55) 80 9.0

STATOR ASSEMBLY (20/25--USA-S/N-0G437999 & BELOW)

1

3

4 2 SCREW--stator attaching (M5x.8x25) 80 9.0

5 1 SCREW--stator attaching (M5x12) 80 9.0

6 1 CLIP

7 1 SCREW--clip to crankcase (#10-16x1/2 IN.) Drive Tight

8 1 C-WASHER-- clip screw

1 1 2 SCREW (M5 x 20)

12 3 SCREW (M5x.8x35 hex washer head) Drive Tight

13 1 SCREW--ground wire Drive Tight

14 1 CLIP

15 1 TRIGGER ASSEMBL Y

16 1 TERMINAL BLOCK

17 2

18 2 SCREW--terminal block (#10-16x3/8 IN.)

19 1 STATOR ASSEMBLY--auxiliary

20 3 SCREW (M5x.8x30 hex head) 80 9.0

21 AR STA-STRAP

23 1 HI-TENSION CABLE SET

24 1 HI-TENSION CABLE (Part of Ref. #22)

25 2 BOOT ASSEMBLY--spark plug

26 AR STA-STRAP

27 2 IGNITION COIL ASSEMBLY

28 4 NUT--coil terminal (1#10-32 Brass) 25 2.8

29 2 CABLE ASSEMBL Y (Black)

STATOR ASSEMBLY (20/25--USA-S/N-0G438000 & UP)

1

1 STATOR ASSEMBLY(JET 20)

1 SWITCH BOX (JET 20)(S# USA-0G590000 & UP)

1 SWITCH BOX (JET 20)(S#USA-0G589999 & BELOW)

SWITCH BOX (20/25--USA-S/N-0G437999 & BELOW)

1

SWITCH BOX (20/25--USA-S/N-0G438000 thru 0G589999)

1

SWITCH BOX (20/25--USA-S/N-0G590000 & UP)

1

SCREW--terminal block (#10-16x5/8 IN.) COMMERCIAL

2 SPARK PLUG (NGK #BP8H-N-10) 240 20 27.1

2 SPARK PLUG (NGK #BPZ8H-N-10) (CAN/BELG.) 20 27.1

BEL-S/N-9926999 & BELOW)

(BEL-S/N-9927000 thru 9973099)

(BEL-S/N-9973100 & UP)

(BEL-S/N-9926999 & BELOW)

(BEL-S/N-9927000 & UP)

90-826883 R2 JUNE 1998 Page 2A-5

Page 51

IGNITION

Ignition Description

The ignition system is an alternator driven capacitor discharge system. Major componentsof the ignitionsystemare theflywheel,stator,triggercoil,switch box,2ignitioncoils

and 2 spark plugs.

The flywheelhas permanent magnets mounted in both theouter rim andthe center hub.

TheBLACKstatorassembly ismountedbelowthe flywheelandhasalow speed(LS)and

ahigh speed(HS) capacitor chargingcoil. Lowspeedcoil providesprimaryvoltage tothe

switch box from idle to approximately 2500 RPM. The high speed coil provides primary

voltage from 2000 RPM to the maximum RPM the outboard is capable of achieving.

The RED stator assembly is mounted below the flywheel and has only one capacitor

charging coil.