Merco FW, LFW, NW, HWFW, HWLFW Installation & Operating Instructions Manual

...

INSTALLATION & OPERATING

INSTRUCTIONS

for

MERCO® OVERHEAD FOOD WARMERS

MODELS FW & NW SERIES

EZNW-36 shown

Upon receipt of this unit, immediately unpack and inspect for possible concealed shipping damage. If unit is found

to be damaged, save all packing materials and contact your delivery carrier within 5 days. Refer to “Shipping

Damage Instructions” enclosed for detailed instructions. Failure to follow these instructions will negate Merco

Savory’s or your ability to file claims and receive compensation for shipping damage.

TO BE SERVICED ONLY BY AUTHORIZED PERSONS

P/N: 001201 REV: 8/8/07

GENERAL INFORMATION

MODELS FW, LFW, NW, HWFW, HWLFW, FW-DUAL and LFW-DUAL series with or without prefix EZ

Merco Food Warmers are shipped completely assembled with wiring and ready for mounting. Use wire suitable

for 90°C (200°F).

Each unit is shipped with two hanger tags mounted on each end. These should be used for chain mounting. Use

#16 single-jack chain or equivalent. For undershelf or pass-through installation on 8” wide models, bend the

hanger tag 90°.

INSTALLATION

CAUTION – on FW, EZFW, LFW, EZLFW, FW-DUAL, EZFW-DUAL, LFW-DUAL & EZLFW-DUAL series units,

do not install closer than ¼ inch from the top of the unit, 1 inch at ends, and 3 inches at the sides. Do not install

over a combustible surface closer than 12 inches for UL models and 15 inches for CSA models. On NW and

EZNW series warmers, do not install closer than 2 ¼ inches from the top of the unit, 1 inch at the ends, and 3

inches at the sides. Do not install over a combustible surface closer than 18 inches. On HWQFW, HWEZFW,

HWLFW, and HWEZLFW series warmers, do not install closer than 1 ½ inches from the top of the unit, 1 inch at

end, and 3 inches at the sides. Do not install over a combustible surface closer than 20 inches.

** Do not make any additional holes in the outside shell for BX or conduit. **

CAUTION

Remove packing from around center and both ends of the heat tube when installing this unit.

Use porcelain wire connectors – DO NOT USE PLASTIC WIRE CONNECTORS.

Use high-temp glass cloth electrical tape when securing connectors. DO NOT USE PLASTIC ELECTRICAL

TAPE.

If your unit was supplied with appliance lamps, they are teflon coated. When replacing these bulbs they must be

replaced with similarly coated bulbs. This is mandatory to comply with NSF regulations. These bulbs may be

purchased from one of the Merco Savory authorized maintenance and repair centers.

TEMPERATURE ADJUSTMENT

Standard Merco Food Warmers

The standard unit comes only with an on/off toggle switch and does not have the capability of adjustable heat.

Units with optional Infinite Control

Due to the wide variation in applications, products and environments, the control dial(s) have setting numbers for

your convenience. For this reason you will need to experiment with the control dial(s) to determine which setting

maintains the best food qualities for your products. Due to a break-in period, the settings may need adjusting

during the first 30 days. To adjust the control dial(s), turn the dial(s) to setting #4 and monitor the temperature of

your product. If the product temperature is too low, adjust the dial(s) to a higher setting. If the temperature is too

high, adjust the dial(s) to a lower setting.

CLEANING

Turn unit off or disconnect the power supply and allow a few minutes for the unit to cool down before cleaning.

Your unit should be wiped down daily with a soft damp cloth and cleaned weekly with a scotch-brite pad. Avoid

excessive water or cleaning solution on the unit as it may allow the electrical connections to become corroded

and/or cause the unit to fail. Your unit may require more frequent cleaning depending on conditions in your

particular environment. The heat tube should be rotated one or two turns weekly to ensure a clean and proper

connection which will help lengthen the life of the heating element(s).

2

FW & NW Series Ops Manual

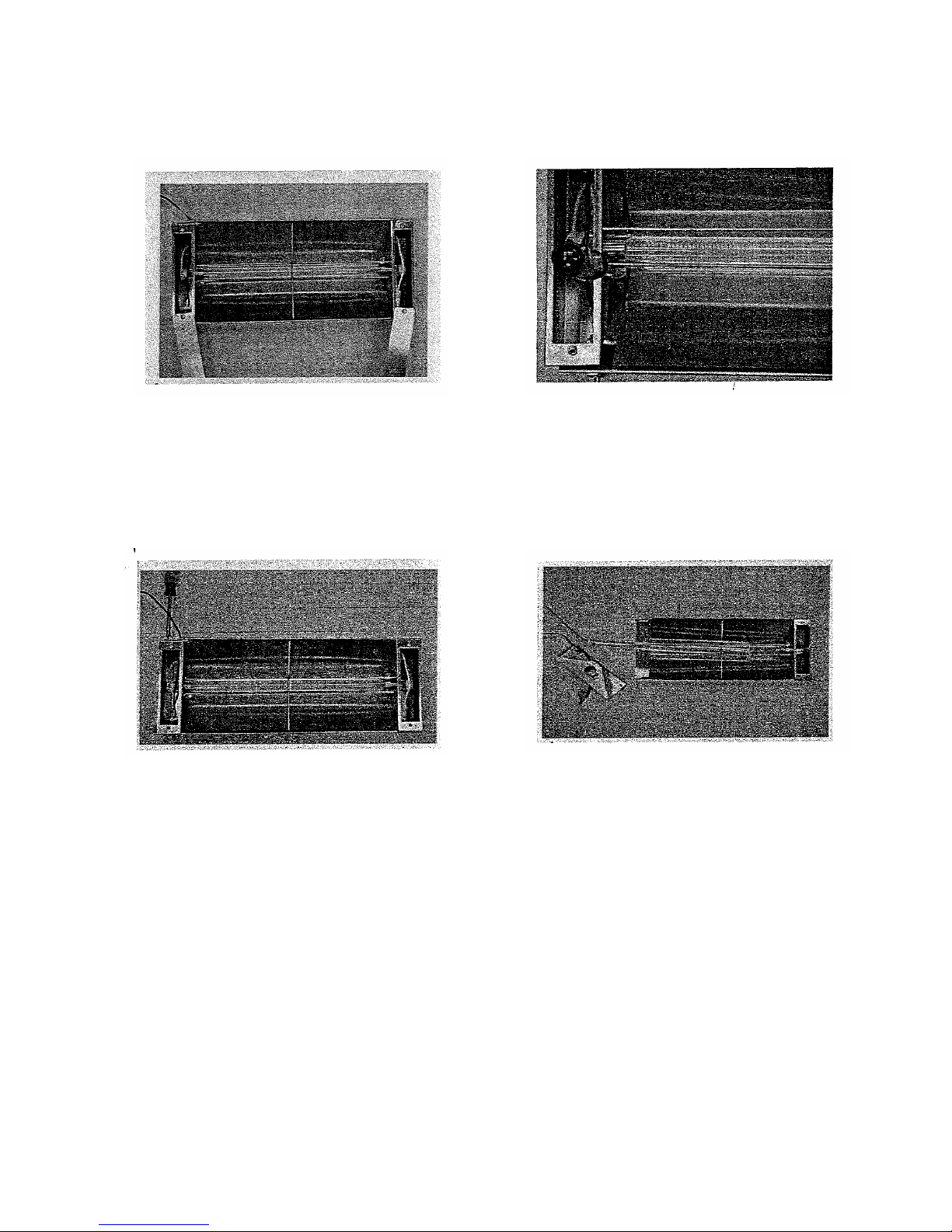

1. Remove the 4 screws holding

the access panels onto the unit

(2 per panel).

3. Remove the hex headretaining nut from the on/off

switch. Remove the 3 screws

holding the end panel onto the

unit (switch end).

2. Loosen the screws on the

heat tube collars (one on each

end of the tube).

4. Carefully remove the end

panel, remove the on/off switch

and disconnect the white wire.*

Remove the wire nut from the

opposite end of the heat tube.

The tube is now ready to be

taken out of the unit.

5. Reassemble in reverse order.

* For units with an infinite control, both ends of the heat tube will have wire nuts.

FW & NW Series Ops Manual

3

Loading...

Loading...