Installation and Operation Manual

Heated Merchandising Cabinets

HMC Series

I&W #07.05.239.00

Do not operate this equipment unless you have

read and understood the contents of this manual!

Failure to follow the instructions contained in this

manual may result in serious injury or death. This

manual contains important safety information

concerning the maintenance, use, and operation

of this product. If you’re unable to understand the

contents of this manual, please bring it to the

attention of your supervisor. Keep this manual in

a safe location for future reference.

No opere este equipo al menos que haya leído y

comprendido el contenido de este manual!

Cualquier falla en el seguimiento de las

instrucciones contenidas en este manual puede

resultar en un serio lesión o muerte. Este manual

contiene importante información sobre seguridad

concerniente al mantenimiento, uso y operación

de este producto. Si usted no puede entender el

contenido de este manual por favor pregunte a su

supervisor. Almacenar este manual en una

localización segura para la referencia futura.

© 2010 Merco, LLC

CONTENTS

NOTICE

CAUTION

WARNING

Important Owner Information ...............................................i

Introduction............................................................................i

Important Safety Information...............................................1

Model Description.................................................................2

Model Designation ................................................................2

Specifications........................................................................3

Plug Configurations .........................................................3

Electrical Rating Chart .....................................................3

Dimensions......................................................................4

Installation.............................................................................5

General............................................................................5

Reversing the Access Door .............................................6

Relocating the Proximity Switch ......................................7

Operation...............................................................................8

General............................................................................8

Setting the Air Temperature.............................................8

Setting the Humidity Level ...............................................9

Food Holding Guide.........................................................9

IMPORTANT OWNER INFORMATION

Record the model number, serial number (specification label

located on the ceiling sheet inside the unit), voltage, and

purchase date of the unit in the spaces below. Please have this

information available when calling Merco for service assistance.

Model No. ____________________________________

Serial No. ____________________________________

Voltage ______________________________________

Date of Purchase ______________________________

Maintenance ........................................................................10

General..........................................................................10

Cleaning ........................................................................10

Removing the Glass Panels ..........................................10

Removing the Rotating Rack .........................................10

Draining the Water Reservoir.........................................11

Removing Lime and Mineral Deposits ...........................11

Replacing a Display Light ..............................................11

Troubleshooting Guide ......................................................12

Options and Accessories ...................................................13

Merco Limited Warranty .....................................Back Cover

Business 8:00

Hours: Central Standard Time (C.S.T.)

Telephone: 800.506.9565 (Technical Support)

Additional information can be found by visiting our web site at

www.mercoproducts.com.

AM to 5:00 PM

888.417.5462 (Customer Service)

Merco, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

INTRODUCTION

Merco Heated Merchandising Cabinets are designed to hold

prepared foods for prolonged periods of time while maintaining

that “just-made” quality. Heated Merchandising Cabinets

provide the best environment for food products by regulating

the air temperature while at the same time balancing the

humidity level. The use of controlled, moisturized heat

maintains serving temperature and food texture longer than

conventional dry holding equipment.

The Heated Merchandising Cabinet’s air flow pattern is

designed to maintain consistent cabinet temperature without

drying out foods. The precise combination of heat and humidity

creates a “blanket” effect around the food. The air flow rate

enables the cabinet to recover temperature rapidly after

opening and closing the door.

Merco Heated Merchandising Cabinets are products of

extensive research and field testing. The materials used were

selected for maximum durability, attractive appearance and

optimum performance. Every unit is inspected and tested

thoroughly prior to shipment.

This manual provides installation, safety, and operating

instructions for Heated Merchandising Cabinets. Merco

recommends all installation, operating, and safety instructions

appearing in this manual be read prior to installation or

operation of the unit.

Safety information that appears in this manual is identifie

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal

injury.

d by

i

Form No. HMCM-0210

IMPORTANT SAFETY INFORMATION

WARNING

NOTICE

CAUTION

WARNING

Read the following important safety information before using this equipment to avoid serious injury or death

and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install the proper voltage

and size electrical receptacle.

• Turn power switch OFF, unplug power cord, and allow

unit to cool before performing any maintenance or

cleaning.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• Do not steam clean or use excessive water on unit.

• Do not overfill water reservoir. Overfilling can cause

electrical shock. Water reservoir is full when “LO H2O”

stops flashing on CABINET TEMPERATURE display.

Stop filling when “LO H2O” stops flashing on display.

• Turn power switch OFF and allow unit to cool before

draining water reservoir.

• Do not pull unit by power cord.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power

cord. The cord must be replaced by Merco, a Factory

Authorized Service Agent, or a person with similar

qualifications.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Original Equipment Manufacturer (OEM)

Replacement Parts when service is required. Failure to

use OEM Replacement Parts will void all warranties and

may subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

OEM Replacement Parts are specified to operate safely

in the environments in which they are used. Some

aftermarket or generic replacement parts do not have

the characteristics that will allow them to operate safely

in Merco equipment.

FIRE HAZARD: Locate unit a minimum of 1″ (25 mm) from

combustible walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

The fluorescent light fixtures in this unit have plastic safety

shields covering the fluorescent tubes to meet National

Sanitation Foundation (NSF) standards. To avoid personal

injury and/or food contamination, always operate the unit

with the plastic safety shields properly installed.

This unit is not intended for use by children or persons

with reduced physical, sensory, or mental capabilities.

Ensure proper supervision of children and keep them away

from the unit.

Make sure all operators have been instructed on the safe

and proper use of the unit.

Make sure food product has been heated to the proper

food-safe temperature before placing in unit. Failure to heat

food product properly may result in serious health risks.

This unit is for holding pre-heated food product only.

Merco is not responsible for the actual food product

serving temperature. It is the responsibility of the user to

ensure that the food product is held and served at a safe

temperature.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact a Factory Authorized Service

Agent or contact the Merco Service Department at

800-506-9565.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

Locate unit at the proper counter height in an area that is

convenient for use. The location should be level to prevent

the unit or its contents from falling accidentally and strong

enough to support the weight of the unit and contents.

The National Sanitation Foundation (NSF) requires that

units over 36″ (914 mm) in width or weighing more than 80

lbs. (36 kg) either be sealed to or raised above the

installation surface. If unit cannot be sealed at the point of

use, 4″ (102 mm) legs are included to allow for proper

cleaning access below unit.

Transport unit in upright position only. Before moving or

tipping unit, secure all glass surfaces with tape and drain

water from water reservoir. Failure to do so may result in

damage to unit or personal injury.

Use of distilled water in the water reservoir of humidified

units is recommended to preserve the life of electrical and

mechanical components. If non-distilled water is used, the

reservoir will require periodic cleaning and deliming (refer

to the MAINTENANCE section for cleaning procedure). Unit

failure due to lime or mineral deposits is not covered under

warranty.

Do not use deionized water. Deionized water will shorten

the life of the water pan and heating element.

Use non-abrasive cleaners only. Abrasive cleaners could

scratch the finish of the unit, marring its appearance and

making it susceptible to soil accumulation.

Clean unit daily to avoid malfunctions and maintain

sanitary operation.

Form No. HMCM-0210

1

MODEL DESCRIPTION

H M C - 1 X

Heated Merchandising Cabinet

1 = One Door

2 = Two Doors

No Motorized

Rack Rotation

All Models

All Heated Merchandising Cabinets have an air heating system,

humidity system with low water control protection, fluorescent

lamps, tempered glass sides, and a door. The standard access

door can be hinged left or right. The pretzel tree display rack is

stainless steel and the other display racks are nickel-plated. All

units are available in several Designer colors.

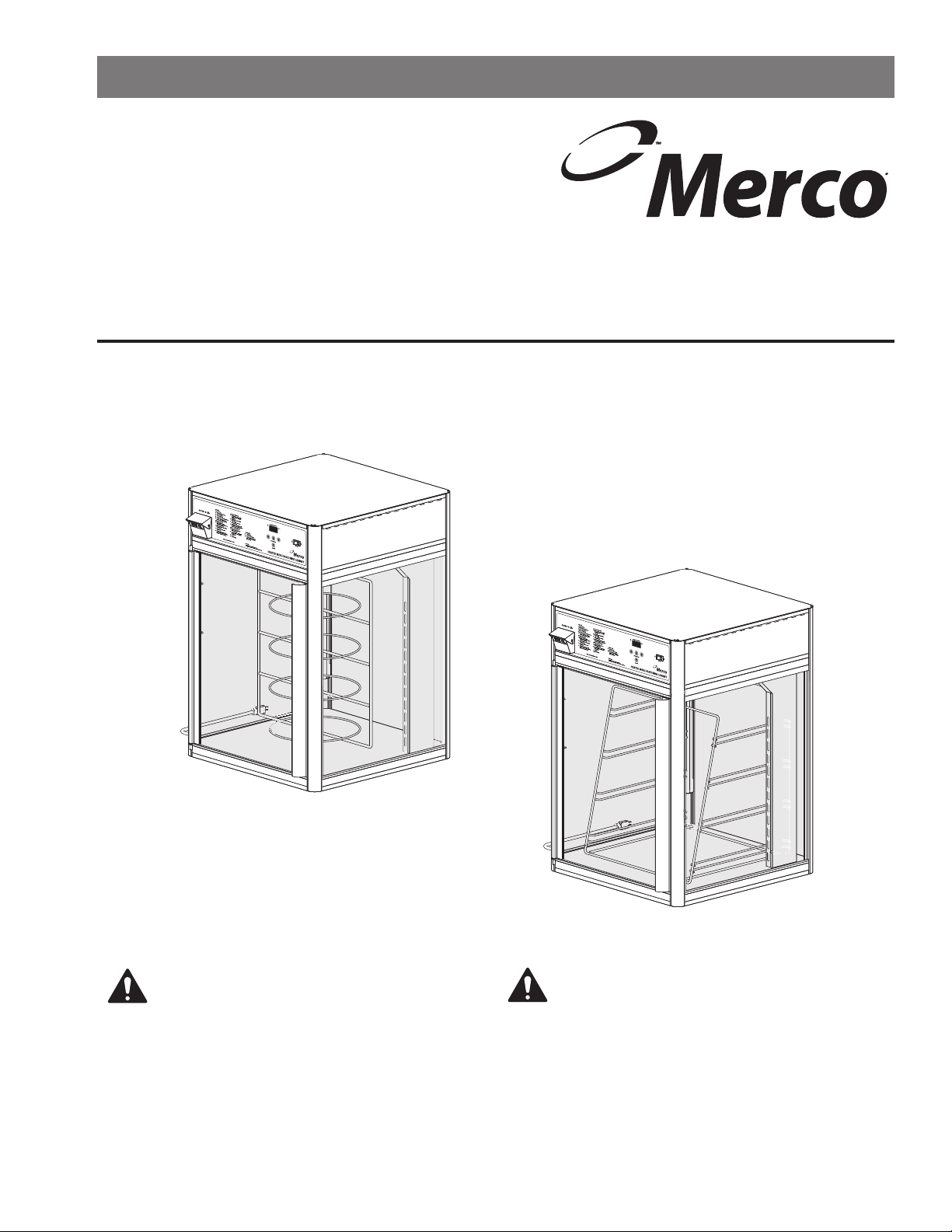

Model HMC-1

Model HMC-1 is a single door model with a motorized rotating

display. It comes standard with a pizza rack that holds up to

four (4) round pizza pans with a maximum diameter of 15″ (381

mm). The rotating rack stops automatically when the door is

opened. Additional rack options are available. Refer to the

OPTIONS AND ACCESSORIES section for details.

Model HMC-1X

The HMC-1X is similar to the HMC-1, but features a stationary

4-slot pan rack instead of the rotating display. The rack can hold

pans with a maximum width of 13″ (330 mm) and a depth of 18″

(457 mm). Additional rack options are available. Refer to the

OPTIONS AND ACCESSORIES section for details.

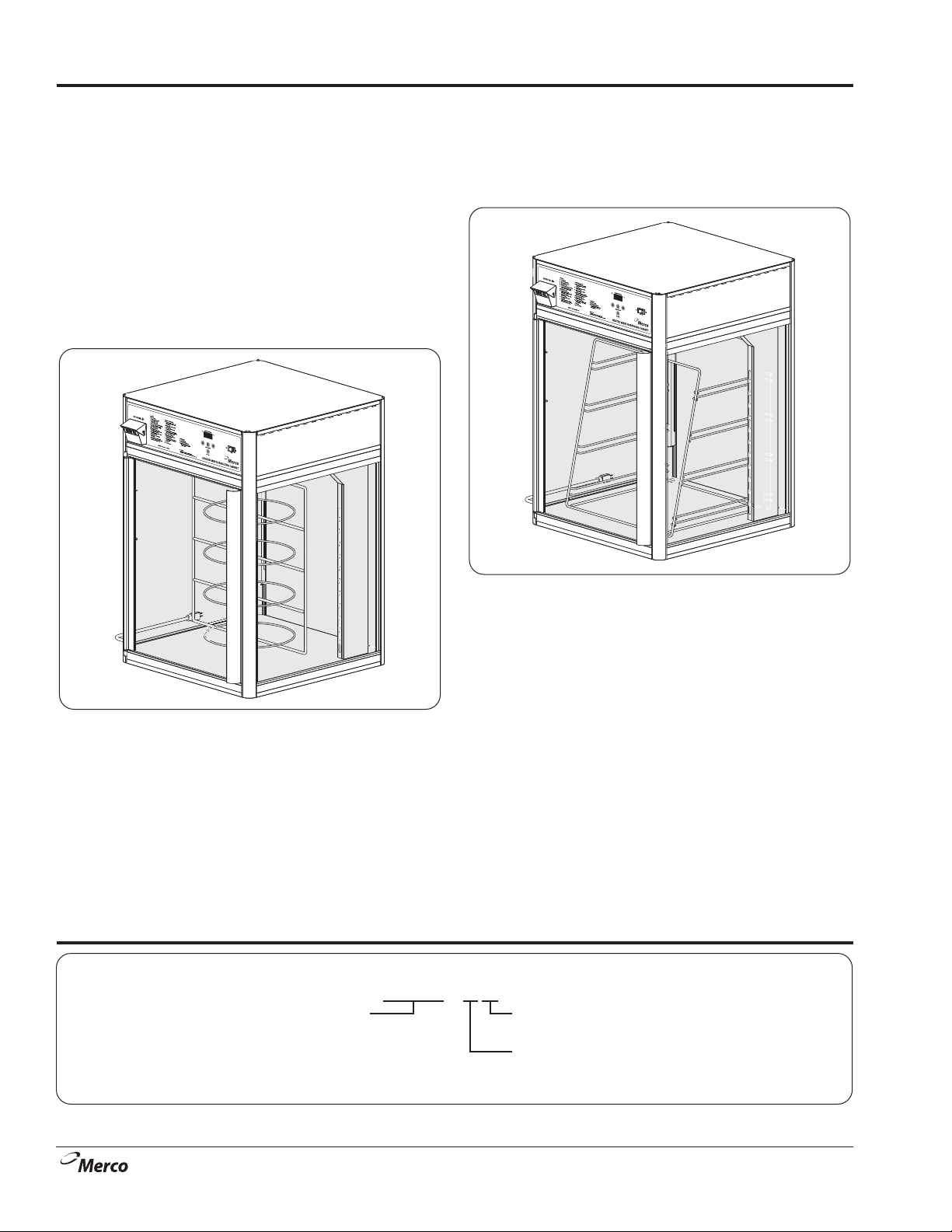

Figure 1. HMC-1

NOTE: Model HMC-1 cannot be converted to a model

HMC-2 or HMC-2X.

Model HMC-2

The HMC-2 is the same as model HMC-1, but has an additional

door on the opposite side of the controls for pass-through

convenience.

MODEL DESIGNATION

Figure 2. HMC-1X

NOTE: Model HMC-1X cannot be converted to a model HMC-

1, HMC-2, or HMC-2X.

Model HMC-2X

The HMC-2X is the same as model HMC-1X, but has an

additional door on the opposite side of the controls for passthrough convenience.

NOTE: Model HMC-2X cannot be converted to a model

HMC-2.

Figure 3. Model Designation

2

Form No. HMCM-0210

SPECIFICATIONS

WARNING

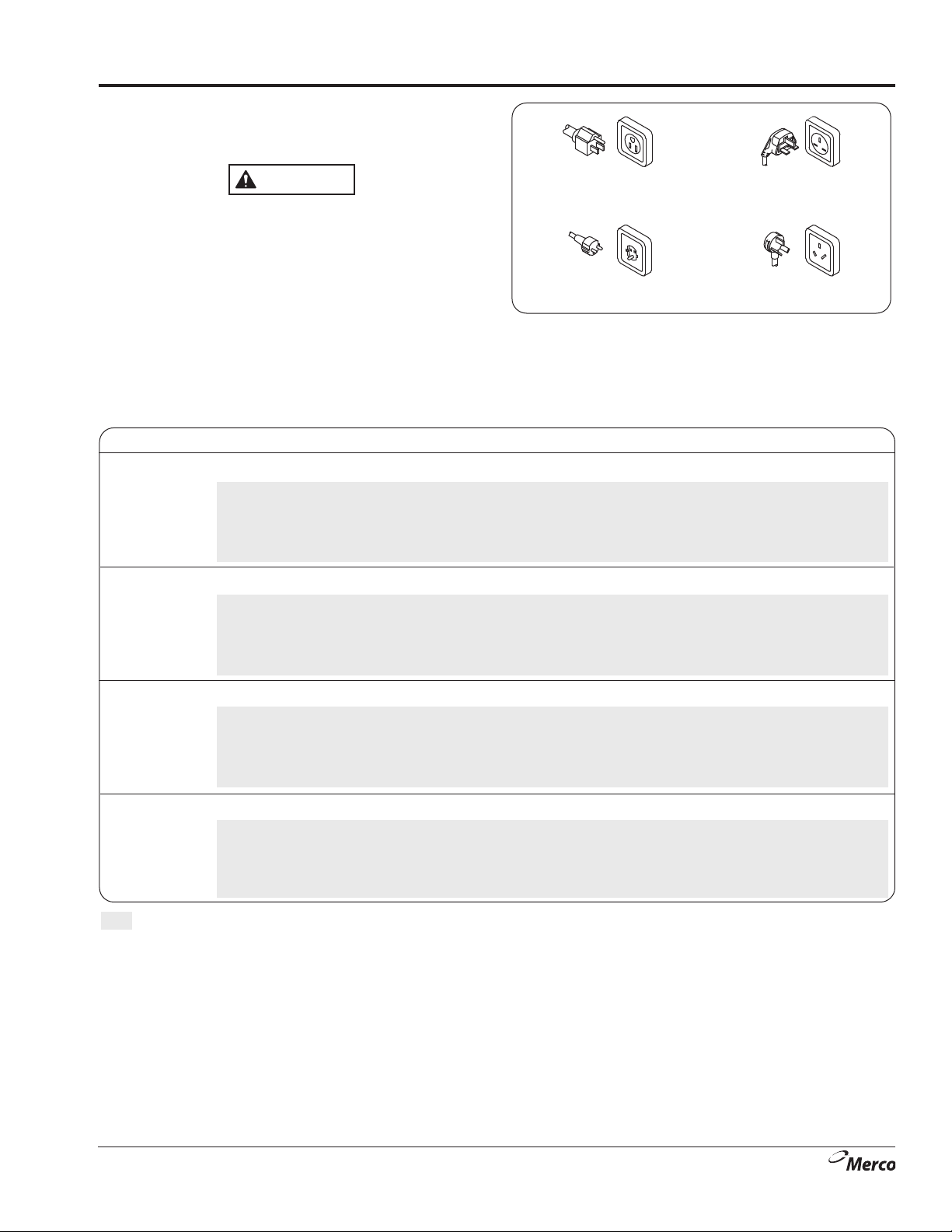

NEMA 5-15P

CEE 7/7 Schuko AS-3112

BS-1363

Plug Configurations

Units are supplied from the factory with an electrical cord and

plug installed. Plugs are supplied according to the applications.

ELECTRIC SHOCK HAZARD: Plug unit into a properly

grounded electrical receptacle of the correct voltage, size,

and plug configuration. If plug and receptacle do not

match, contact a qualified electrician to determine and

install the proper voltage and size electrical receptacle.

NOTE: The specification label is located on the ceiling sheet

Electrical Rating Chart

inside the unit. See label for serial number and

verification of unit electrical information.

NOTE: Receptacle not supplied by Merco.

Model Voltage Hertz Watts Amps Plug Configurations Shipping Weight

HMC-1, -1X 120 60 1440 12.0 NEMA 5-15P 120 lbs. (54 kg)

(with humidity) 220 50/60 1440 6.5 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

240 50/60 1440 6.0 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

220–230 (CE) 50/60 1440–1574 6.5–6.8 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

230–240 (CE) 50/60 1323–1440 5.8–6.0 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

Figure 4. Plug Configurations

HMC-1, -1X 120 60 1115 9.3 NEMA 5-15P 120 lbs. (54 kg)

(no humidity) 220 50/60 1115 5.1 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

240 50/60 1115 4.6 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

220–230 (CE) 50/60 1115–1219 5.1–5.3 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

230–240 (CE) 50/60 1025–1115 4.5–4.6 CEE 7/7 Schuko, BS-1363, AS 3112 120 lbs. (54 kg)

HMC-2, -2X 120 60 1440 12.0 NEMA 5-15P 122 lbs. (55 kg)

(with humidity) 220 50/60 1440 6.5 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

240 50/60 1440 6.0 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

220–230 (CE) 50/60 1440–1574 6.5–6.8 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

230–240 (CE) 50/60 1323–1440 5.8–6.0 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

HMC-2, -2X 120 60 1115 9.3 NEMA 5-15P 122 lbs. (55 kg)

(no humidity) 220 50/60 1115 5.1 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

240 50/60 1115 4.6 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

220–230 (CE) 50/60 1115–1219 5.1–5.3 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

230–240 (CE) 50/60 1025–1115 4.5–4.6 CEE 7/7 Schuko, BS-1363, AS 3112 122 lbs. (55 kg)

The shaded areas contain electrical information for International models only.

Form No. HMCM-0210

3

SPECIFICATIONS

A B

C

Front View SideView

Dimensions

Width Depth Height*

Model (A) (B) (C)

HMC-1 22-1/2″ 24″ 32-9/16″

(572 mm) (610 mm) (827 mm)

HMC-1X 22-1/2″ 24″ 32-9/16″

(572 mm) (610 mm) (827 mm)

HMC-2 22-1/2″ 25-3/8″ 32-9/16″

(572 mm) (645 mm) (827 mm)

HMC-2X 22-1/2″ 25-3/8″ 32-9/16″

(572 mm) (645 mm) (827 mm)

Cabinet Opening (all models):

19″W x 23-3/4″H (483 x 603 mm)

* Add 4″ (102 mm) to the height of the unit if the 4″ leg option

is installed.

Figure 5. Dimensions

4

Form No. HMCM-0210

INSTALLATION

CAUTION

WARNING

General

Heated Merchandising Cabinets are shipped with most

components installed and ready for operation. The following

installation instructions must be performed before plugging in

and operating the cabinet.

ELECTRIC SHOCK HAZARD: Unit is not weatherproof.

Locate unit indoors where the ambient air temperature is a

minimum of 70°F (21°C).

FIRE HAZARD: Locate unit a minimum of 2″ (51 mm) from

combustible walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

Locate unit at the proper counter height in an area that is

convenient for use. The location should be level to prevent

the unit or its contents from falling accidentally and strong

enough to support the weight of the unit and contents.

The National Sanitation Foundation (NSF) requires that

units over 36″ (914 mm) in width or weighing more than 80

lbs. (36 kg) either be sealed to or raised above the

installation surface. If unit cannot be sealed at the point of

use, 4″ (102 mm) legs are included to allow for proper

cleaning access below unit.

Transport unit in upright position only. Before moving or

tipping unit, secure all glass surfaces with tape and drain

water from water reservoir. Failure to do so may result in

damage to unit or personal injury.

1. Remove the unit from the carton. Two people are required

for this step.

2. Remove the information packet.

NOTE: To prevent delay in obtaining warranty coverage, fill out

and mail in the warranty card to Merco.

3. Remove tape and protective packaging from all surfaces of

the unit, shelves, and any accessories.

• Floor Sheet — The stainless steel floor in all cabinets is

protected during shipping with a sheet of corrugated

cardboard. This protection must be removed prior to

cabinet operation.

• Display Rack — The display rack has packing material

and cardboard attached for protection during shipping.

This protection must be removed prior to cabinet

operation.

• Legs — The cabinets are shipped with four rubber feet

attached to the bottom of the unit. For cabinets with the

optional 4″ (102 mm) adjustable legs, see the Options

and ACCESSORIES section for installation instructions.

NOTE: If installing 4″ (102 mm) legs, do not remove glass

protection until leg installation is complete. See the

OPTIONS AND ACCESSORIES section for installation

instructions.

• Glass Panels — The cabinets have tempered glass

panels that are protected during shipping using foam

sheets along the glass edges and tape to hold the panels

securely. The sheets and tape must be removed prior to

cabinet operation.

To remove a glass panel, grasp the panel firmly from

inside and outside of the cabinet. Lift up and out of the

bottom channel, then carefully lower the glass panel until

it clears the upper channel.

To reinstall, position the glass panel top edge under the

cabinet lip. Raise the panel until it clears the bottom

channel, then carefully lower the panel until it rests in the

bottom channel.

4. Place the unit in the desired location. Two people are

required for this step.

• Locate the unit in an area where the ambient air

temperature is constant and a minimum of 70° F (21° C).

Avoid areas that may be subject to active air movements

or currents (i.e., near exhaust fans/hoods and air

conditioning ducts).

• Make sure the unit is at the proper counter height in an

area convenient for use.

• Make sure the countertop is level and strong enough to

support the weight of the unit and food product.

Form No. HMCM-0210

5

INSTALLATION

Hinge Assembly

Bottom Hinge Pin Screw and

Nylon Washer(s)

Door Rotated 180°

Top Hinge

Pin Screw

Striker Plate and

Hardware

Reversing the Access Door

The Heated Merchandising Cabinet access door(s) may be

hinged on either the left or right side for convenience. Use the

following procedure to reverse the access door.

NOTE: For models equipped with a motorized rotating rack

(HMC-1 and HMC-2), the “Relocating the Proximity

Switch” procedure in this section must be performed

after reversing the access door(s).

1. Remove the top hinge pin screw holding the door to the

hinge.

2. Tip the door assembly forward (away from cabinet) and lift

gently to clear the bottom hinge assembly. Remove the

nylon washer(s).

3. Reinstall the top hinge pin screw that was removed in Step 1.

4. Remove the screws holding the hinges to the cabinet.

5. Remove the screws from the striker plates on the non-hinge

side of the cabinet.

6. Install the striker plates on the opposite side of the cabinet

where the hinges were previously mounted.

7. Install the hinges on the opposite side of the cabinet where

the striker plates were previously mounted using the original

hinge mounting screws.

8. Carefully rotate the door 180°.

9. Remove the hinge pin screw from the end that is now the

top.

10. Carefully place the door assembly with the nylon washer(s)

into the bottom hinge.

11. Tip/tilt the door assembly towards the cabinet and align the

door top with the hinge. Reinstall the top door hinge pin

screw through the hinged and into the door top.

Figure 6. Reversing the Access Door

6

Form No. HMCM-0210

INSTALLATION

Proximity Switch

Orientation with Door

Opening from Left

(Hinged Right)

Proximity Switch

Orientation with Door

Opening from Right

(Hinged Left)

Screw

Relocating the Proximity Switch

(Rotating Rack Models Only)

Units equipped with a rotating rack will require relocating the

proximity switch(es) after reversing the door(s).

The proximity switch signals the rack motor to stop when a door

is opened and to start when the door is closed. Follow the steps

listed below to move the proximity switch(es) to the proper

position after reversing the door(s). Unit requires one switch per

door.

1. Turn off the unit. Unplug the unit from the power source.

2. Remove the four screws and top cover.

3. Remove the screw and nut securing the proximity switch to

the cabinet ceiling sheet. The screw is accessed from inside

the cabinet. Reinstall screw and nut into hole after removing

switch.

4. Cut the cable tie securing the proximity switch wires to the

wiring harness. Mark the two wires for reassembly and

unplug the wires from the proximity switch wire leads. Route

the wires to the opposite corner and reattach the wires to

the switch wire leads.

NOTE: Make sure to install the proximity switch in the

orientation shown below for the specific installation

location. Incorrect orientation will result in malfunction of

the proximity switch.

5. Remove the screw and nut from the new mounting hole.

Secure the proximity switch to the mounting hole with the

screw and nut. Make sure to maintain proper switch

orientation when tightening the hardware.

6. Make sure wires do not interfere with the other components

inside the cabinet, then secure switch wires to wiring

harness with a cable tie (not supplied).

NOTE: On models equipped with two doors, it may be

necessary to move the air chamber to access the

proximity switch on the customer-side door. Drain all

water from the unit, remove the drain plug from inside

the cabinet, and remove the four screws securing the air

chamber assembly to the cabinet. Carefully move the

air chamber out of the way to access the proximity

switch. Reassemble after relocating switch.

7. Install the top cover and four screws.

8. Plug the unit into the proper power source.

9. Turn on the unit and test the operation of the proximity

switch(es) by making sure the rack rotates when the doors

are closed and stops rotating when a door is opened.

Form No. HMCM-0210

Figure 7. Relocating the Proximity Switch

7

OPERATION

Fill Cup

NOTICE

WARNING

WARNING

WARNING

General

Use the following procedures to operate the Heated

Merchandising Cabinet.

Read all safety messages in the IMPORTANT SAFETY

INFORMATION section before operating this equipment.

Startup

1. Plug unit into a properly grounded electrical receptacle of

the correct voltage, size and plug configuration. See the

SPECIFICATIONS section for details.

2. Move the Power ON/OFF switch to the ON position.

• The display lights will turn on and the heating system will

start up.

• The cabinet temperature display will flash “LO H2O” four

times and then flash the cabinet temperature. It will

continue to alternate this way until the water reservoir is

filled. Once the reservoir is full, “LO H2O” will stop flashing

and the display will show the cabinet temperature.

Use of distilled water in the water reservoir of humidified

units is recommended to preserve the life of electrical and

mechanical components. If non-distilled water is used, the

reservoir will require periodic cleaning and deliming (refer

to the MAINTENANCE section for cleaning procedure). Unit

failure due to lime or mineral deposits is not covered under

warranty.

Do not use deionized water. Deionized water will shorten

the life of the water pan and heating element.

NOTE: Unit failure caused by deionized water is not covered by

warranty.

3. Fill the water reservoir with clean

water. To fill the reservoir:

a. Lift up the fill cup cover and pull

forward.

b. Slowly pour the water into the cup

until “LO H2O” stops flashing on

the cabinet temperature display.

*IMPORTANT NOTE*

When using distilled water, add one teaspoon of salt to the

water reservoir during the initial water fill only. This will ensure

proper operation of the water level sensors.

ELECTRIC SHOCK HAZARD: Do not overfill water reservoir.

Overfilling can cause electrical shock. Water reservoir is full

when “LO H2O” stops flashing on CABINET TEMPERATURE

display. Stop filling when “LO H2O” stops flashing on display.

NOTE: On the initial fill, the water reservoir capacity is one

gallon or 4 quarts (3.8 liters).

4. Set the humidity to the desired level (refer to the “Setting

the Humidity Level” procedure in this section). See the

“Food Holding Guide” for recommendations.

5. Set the air temperature to the desired temperature (refer to

the “Setting the Air Temperature” procedure in this section).

See the “Food Holding Guide” for recommendations.

6. Allow 30 minutes to heat the cabinet and a full reservoir of

water, and then load the cabinet with pre-heated food product.

Make sure food product has been heated to the proper

food-safe temperature before placing in unit. Failure to heat

food product properly may result in serious health risks.

This unit is for holding pre-heated food product only.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

Setting the Air Temperature

1. Press theAIRTEMPERATURE key to enter temperature mode

(“tSP” will appear on the CABINET TEMPERATURE display).

2. Press the AIR TEMPERATURE key again to show the

current temperature setting.

3. Press the Up Arrow key or Down Arrow key to reach the

desired temperature. The temperature range is 80°–195°F

(27°–91°C) in single degree increments. See the “Food

Holding Guide” in this section for recommendations.

4. After the desired temperature is set, wait 15 seconds without

pushing any keys for the cabinet temperature display to

return automatically to operational mode.

Figure 8. Heated Merchandising Cabinet Control Panel

8

Form No. HMCM-0210

OPERATION

Setting the Humidity Level

1. Press the HUMIDITY key to enter humidity mode (“hSP” will

appear on the CABINET TEMPERATURE display).

2. Press the HUMIDITY key again to show the current

humidity level.

3. Press the Up Arrow key or Down Arrow key to reach the

desired humidity level. Humidity range is 1 through 5 (1 is

the lowest amount of humidity and 5 is the highest). See

the “Food Holding Guide” in this section for

recommendations.

4. After the desired humidity level is set, wait 15 seconds

without pushing any keys for the CABINET TEMPERATURE

display to return automatically to operational mode.

NOTE: Temperature and humidity settings may vary depending

upon product make-up and consistency. The CABINET

TEMPERATURE display shows the lowest temperature

point inside the cabinet, not the product temperature.

The capacity of the water reservoir permits uninterrupted

operation for approximately 4–8 hours, depending on the

settings and how frequently the door is opened. When “LO

H2O” is flashing on the CABINET TEMPERATURE display, add

water to the reservoir. The water reservoir refill capacity is

approximately 96 ounces, or 3 quarts (2.8 liters). WARNING:

ELECTRIC SHOCK HAZARD — Do not overfill water

reservoir.

Figure 9. Setting the Humidity Level

Food Holding Guide

Maximum Humidity Temperature

Type of Food Holding Time Setting °F °C

Biscuits 4 Hours 4 130 55

Chicken Pieces (Fried) 4 Hours 5 175 80

Croissants 4 Hours 1 140 60

Fruit Pies 3-1/2 Hours 4 140 60

Onion Rings 1/2 to 1 Hour 1 175 80

Pizza — Thick Crust 1 Hour 4 185 85

Thin Crust 1 Hour 5 180 82

Pretzels 3 Hours 4 140 60

Wrapped Sandwiches 2 Hours 4 180 82

NOTE: All times and settings are recommendations only and may vary depending on product preparation, cooking time, and

internal food temperature.

Form No. HMCM-0210

9

MAINTENANCE

NOTICE

WARNING

Connecting

Pin

Bottom

Point

Connecting

Coupling

Rack

Shaft

General

Merco Heated Merchandising Cabinets are designed for

maximum durability and performance, with minimum

maintenance.

ELECTRIC SHOCK HAZARD:

• Turn the power switch OFF, unplug the power cord, and

allow the unit to cool before performing any

maintenance or cleaning.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Do not steam clean or use excessive water on unit.

• Use only OEM Replacement Parts when service is

required. Failure to use OEM Replacement Parts will

void all warranties and may subject operators of the

equipment to hazardous electrical voltage, resulting in

electrical shock or burn. OEM Replacement Parts are

specified to operate safely in the environments in which

they are used. Some aftermarket or generic

replacement parts do not have the characteristics that

will allow them to operate safely in Merco equipment.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact a Factory Authorized Service

Agent or contact the Merco Service Department at

800-506-9565.

Removing the Glass Panels

1. Lift the glass panel out of the bottom channel of the cabinet.

2. Pull the lower edge away from the cabinet.

3. Carefully lower the glass until the top clears the cabinet.

Replacing the Glass Panel

1. Position the glass panel with the top edge under the top

cabinet lip, and raise the glass until it clears the bottom

channel of the cabinet.

2. Move the bottom of the glass towards the cabinet until the

glass rests against the cabinet frame.

3. Carefully lower the glass until it rests in the bottom channel

of the cabinet.

Removing the Rotating Rack

(Models HMC-1 and HMC-2)

1. Open the front access door.

2. Remove the two (2) connecting pins from the connecting

coupling located at the top of the rack inside the cabinet.

3. Lower the connecting coupling until it is free of the motor

shaft and remove the rack from the cabinet.

Cleaning

To preserve the finish of the Heated Merchandising Cabinet,

perform the following cleaning procedure daily.

Use non-abrasive cleaners only. Abrasive cleaners could

scratch the finish of the unit, marring its appearance and

making it susceptible to soil accumulation.

NOTE: Both the rotating display rack and the stationary rack

1. Turn off the unit, unplug the power cord, and allow the unit

to cool.

2. Remove and wash all food pans.

3. Wipe down all interior and exterior metal surfaces with a

damp cloth. Stubborn stains may be removed with a good

non-abrasive cleaner. Clean hard to reach areas using a

small brush and mild soap.

are removable for cleaning, if necessary. Refer to the

“Removing the Rotating Rack” procedure in this section

for removal.

4. Clean the glass side panels and door panel(s) using

ordinary glass cleaner and a damp, soft cloth or paper

towel. The side panels are removable for detailed cleaning,

if necessary. Refer to the “Removing the Glass Panels”

procedure in this section for removal.

Figure 10. Removing Motorized Display Racks

Replacing the Rotating Rack

1. With the connecting coupling in position on the top rack

shaft, insert the rack into the cabinet through the access

door and place the rack bottom point in the dimple located

at the center of the cabinet floor.

2. Slide the connecting coupling up onto the motor shaft and

align the coupling holes.

3. Insert the two (2) connecting pins. The top connecting pin

goes through the connecting coupling and the motor shaft.

The bottom connecting pin goes through the connecting

coupling and the rack shaft.

10

Form No. HMCM-0210

MAINTENANCE

Valve

Open

Valve

Closed

WARNING

WARNING

Draining the Water Reservoir

The water reservoir in humidified units must be drained prior to

moving the cabinet as well as during the “Removing Lime and

Mineral Deposits” procedure.

ELECTRIC SHOCK HAZARD: Turn the power switch OFF,

unplug the power cord, and allow the unit to cool before

performing any maintenance or cleaning.

1. Move the POWER ON/OFF switch to the OFF position and

unplug the power cord. Allow the unit to cool.

2. Locate the valve inside the cabinet on the underside of the

ceiling sheet. CAUTION: BURN HAZARD — Ceiling sheet

and water in reservoir are hot during operation. Allow to

cool before draining.

3. Position a one gallon (four liter) container under the valve.

4. Turn the valve handle from the horizontal position (closed)

to the vertical position (open) to drain the reservoir.

5. Once the reservoir is empty, return the valve handle to the

closed position.

Removing Lime and Mineral Deposits

Use the following procedure for periodic cleaning and de-liming

of the water reservoir in humidified units.

NOTE: The lime and mineral content of the water used for daily

operation will determine how often the deliming

procedure must be performed.

NOTE: Perform this procedure when the unit will not be used

for a period of time, such as the end of the day.

1. Move the POWER ON/OFF switch to the OFF position and

unplug the power cord. Allow the unit to cool.

2. After the unit has cooled down, perform the “Draining the

Water Reservoir” procedure in this section.

3. Fill the water reservoir with a mixture of 75% water and 25%

white vinegar. Do not use flavored vinegar.

4. Plug in and turn on the unit.

5. Set both the air temperature and humidity to their highest

settings and allow the unit to run for 30 minutes.

6. Move the POWER ON/OFF switch to the OFF position and

unplug the power cord. Allow the unit to cool.

7. Perform the “Draining the Water Reservoir” procedure to

empty the deliming solution from the water reservoir.

8. Continue to fill and drain the water reservoir with clean

water until the deliming solution is rinsed through and the

reservoir is clean.

9. Plug the unit into its power source and fill the reservoir as

usual for daily operation using the procedure in the

OPERATION section of this manual.

Figure 11. Draining Reservoir Valve

NOTE: If the water used has an excessive amount of lime or

mineral content, follow the REMOVING LIME AND

MINERAL DEPOSITS procedure for periodic cleaning

and deliming of the water reservoir.

NOTE: Unit failure caused by liming or sediment buildup is not

covered under warranty.

Replacing A Display Light

Make sure protective lamp cover(s) are installed in front of

fluorescent lamp(s). Breakage of fluorescent lamps not

properly protected could result in personal injury and/or

food contamination.

The unit is equipped with two fluorescent lamps that illuminate

the warming area. These lamps have a special lamp cover to

guard against injury and food contamination in the event of

breakage. When replacing a fluorescent lamp, use P/N

02.30.074.00. Use the following procedure to replace a

fluorescent lamp.

1. Turn off the unit, unplug the power cord, and allow the unit

to cool.

2. Remove the lamp cover from in front of the fluorescent

lamp.

3. Carefully twist the fluorescent lamp and pull out to remove

it from the sockets on each end.

4. Align the tabs on each end of the new fluorescent lamp

with the channels on each socket, and push the lamp into

the sockets.

5. Carefully twist the fluorescent lamp in the sockets until it

“snaps” into position.

6. Replace the lamp cover in front of the fluorescent lamp.

Form No. HMCM-0210

11

TROUBLESHOOTING GUIDE

WARNING

WARNING

This unit must be serviced by trained and qualified

personnel only. Service by unqualified personnel may lead

to electric shock or burn.

Symptom Probable Cause Corrective Action

Fluorescent lamp not working.

Unit operates, but is not

circulating air inside cabinet.

Unit is plugged in, but nothing

works.

Unit is operational, but rotating

rack (if equipped) does not turn.

Lamp loose or defective.

Blower motor is defective.

The correct voltage may not be

supplied to blower.

No power to unit.

Power cord connections are loose or

disconnected.

Power cord is damaged. Contact Factory Authorized Service Agent or

Defective ON/OFF switch.

Proximity switch was not relocated

after door reversal.

ELECTRIC SHOCK HAZARD: Turn the power switch OFF,

unplug the power cord, and allow the unit to cool before

performing any maintenance or cleaning.

Re-install or replace fluorescent lamp.

Contact Factory Authorized Service Agent or

Merco for assistance.

Contact Factory Authorized Service Agent or

Merco for assistance.

Check electrical receptacle and verify that power

supply matches specifications on unit. If receptacle

is not working, check circuit breaker and reset, or

plug unit into a different known working receptacle.

Contact Factory Authorized Service Agent or

Merco for assistance.

Merco for assistance.

Contact Factory Authorized Service Agent or

Merco for assistance.

See “Relocating the Proximity Switch” in the

INSTALLATION section of this manual.

Proximity magnet or proximity switch

not working properly.

Incorrect voltage is supplied to rack

motor.

Unit is not producing any “hot air”

inside cabinet.

Unit is heating, but is not

producing humidity inside

cabinet. Low water light is off,

and unit is full of water.

Unit is heating, but is not

producing humidity inside

cabinet. Low water light is on and

unit is full of water.

Safety high-limit is tripped or open. Contact Factory Authorized Service Agent or

Incorrect voltage supplied to heating

element.

Blower motor is not working.

Air heating element is defective. Contact Factory Authorized Service Agent or

Incorrect voltage supplied to water

heating element or heating element

is defective.

When using distilled water, no minerals

are being sensed by low water probe.

Low water protection system is

malfunctioning.

Error Codes

The following error codes may appear on the digital display to

indicate an error in the operating condition of the unit.

LO H20 = Low water probe does not detect water. Refill water

reservoir — refer to instructions in OPERATION

section of this manual.

Contact Factory Authorized Service Agent or

Merco for assistance.

Contact Factory Authorized Service Agent or

Merco for assistance.

Merco for assistance.

Contact Factory Authorized Service Agent or

Merco for assistance.

Check blower motor — refer to Symptom “Unit

operates, but is not circulating air inside cabinet.”

Merco for assistance.

Contact Factory Authorized Service Agent or

Merco for assistance.

On initial fill, add one teaspoon of salt to the water

reservoir.

Contact Factory Authorized Service Agent or

Merco for assistance.

E1 = Air temperature sensor malfunctioning. Contact Factory

Authorized Service Agent or Merco for assistance.

E2 = Humidity temperature sensor malfunctioning. Contact

FactoryAuthorized Service Agent or Merco for assistance.

E4 = Water level probe(s) malfunctioning. Contact Factory

Authorized Service Agent or Merco for assistance.

12

Form No. HMCM-0210

OPTIONS AND ACCESSORIES

Decal

Lengthen

Shorten

Adjustable Tip

Corner Bracket

Rubber

Foot

4″ Leg

Motorless

Rack Coupling

4-Tier Circle Rack*

Top two tiers: 5”

(127 mm) on center.

Bottom two tiers: 5-1/4”

(133 mm) on center.

4-Tier Circle Rack*

Top two tiers: 5”

(127 mm) on center.

Bottom two tiers: 5-1/4”

(133 mm) on center.

7-Shelf

Multi-Purpose Rack

Shelves 1 & 5: 2-3/4” (70 mm) on center.

NOTE: Shelf 1 is the bottom shelf.

Shelves 2, 3 & 6: 3” (76 mm) on center.

Shelf 4: 3-1/4” (83 mm) on center.

Shelves 2, 3, 4, 6 & 7 are removable.

5-Shelf Angle Rack

All shelves 3-3/4”

(95 mm) on center.

All shelves are

removable.

4-Tier Pan Rack

Top tier: 4” (102 mm)

on center.

All others: 4-14”

(108 mm) on center.

3-Shelf Angle Rack

Top tier: 5” (127 mm)

on center.

All others: 5-1/4”

(133 mm) on center.

Middle shelf is removable.

Rack shelves slant

at 15° angle.

*Racks designed for use

with motorized display.

5-Tier Circle Rack*

All tiers: 4” (102 mm)

on center.

4″ (102 mm) Adjustable Legs

The 4″ (102 mm) adjustable legs are used to add additional

height to the unit.

1. Secure all glass sides and doors with tape. Lay the unit on

its side.

2. Remove the four screw-type rubber feet from the corner

brackets.

3. Screw the 4″ (102 mm) legs into

the holes in the middle of each

corner bracket. After all the legs

are tightened, return the unit to its

upright position. If the unit is not

level or rocks, turn the adjustable

tip of the appropriate leg to level

the unit.

Display Racks

Several styles of display racks are available to “customize”

Heated Merchandising Cabinets to each foodservice operation.

Figure 12. Installation of 4″ Legs

Merchandising Decal

Self-adhesive merchandising decals are available to promote

food products. The decals are designed to be installed on three

(3) sides of the cabinet above the glass panels.

Decal Installation

1. Before installing decals, clean the side panels with a nonoily cleaner, such as isopropyl alcohol (rubbing alcohol).

2. After the cleaned surfaces have dried, remove the

protective backing from the decal and apply to the panel.

3. Any air pockets or bubbles behind the sticker can be

removed by rubbing gently with a soft cloth from the center

towards the outer edges.

Form No. HMCM-0210

Figure 13. Decal Installation

Figure 14. Display Racks

Motorless Rack Coupling

The motorless rack coupling allows the

stationary installation of a 4-tier circle rack or

3-tier pretzel tree in cabinets that do not have

a rack motor (HMC-1X and HMC-2X).

13

MERCO LIMITED WARRANTY

1. PRODUCT WARRANTY

Merco LLC (“Merco”), warrants the products that it

manufactures (the “Products”) to be free from defects in

materials and workmanship, under normal use and service, for

a period of one (1) year from the date of purchase when

installed and maintained in accordance with Merco’s written

instructions or 18 months from the date of shipment from

Merco. Buyer must establish the Product’s purchase date by

returning Merco’s Warranty Registration Card or by other

means satisfactory to Merco in its sole discretion.

Merco warrants the following Product components to be free

from defects in materials and workmanship from the date of

purchase (subject to the foregoing conditions) for the period(s)

of time and on the conditions listed below:

a) One (1) Year Parts and Labor PLUS One

(1) Additional Year Parts-Only Warranty:

Heated Drawer Elements (metal sheathed)

Heated Drawer Rollers and Slides

Convenience Merchandiser Elements (metal sheathed)

Heated Merchandising Cabinet Elements

(metal sheathed air heating)

b) Ninety (90) Day Parts-Only Warranty:

Replacement Parts

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ANY OTHER WARRANTY, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OR PATENT OR OTHER

INTELLECTUAL PROPERTY RIGHT INFRINGEMENT.

Without limiting the generality of the foregoing, SUCH

WARRANTIES DO NOT COVER: Coated incandescent light

bulbs, fluorescent lights, decorative heat lamp bulbs, glass

components, and fuses; Product failure in water heating

equipment caused by liming, sediment buildup, chemical attack,

or freezing; or Product misuse, tampering or misapplication,

improper installation, or application of improper voltage.

2. LIMITATION OF REMEDIES AND DAMAGES

Merco’s liability and Buyer’s exclusive remedy hereunder will

be limited solely, at Merco’s option, to repair or replacement

using new or refurbished parts or Product by Merco or a factory

authorized service agency (other than where Buyer is located

outside of the United States, Canada, United Kingdom, or

Australia, in which case Merco’s liability and Buyer’s exclusive

remedy hereunder will be limited solely to replacement of part

under warranty) with respect to any claim made within the

applicable warranty period referred to above. Merco reserves

the right to accept or reject any such claim in whole or in part.

In the context of this Limited Warranty, “refurbished” means a

part or Product that has been returned to its original

specifications by Merco or a factory authorized service agency.

Merco will not accept the return of any Product without prior

written approval from Merco, and all such approved returns shall

be made at Buyer’s sole expense. MERCO WILL NOT BE

LIABLE, UNDER ANY CIRCUMSTANCES, FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING

BUT NOT LIMITED TO LABOR COSTS OR LOST PROFITS

RESULTING FROM THE USE OF OR INABILITY TO USE THE

PRODUCTS OR FROM THE PRODUCTS BEING

INCORPORATED IN OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT OR GOODS.

Merco, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804 USA

Technical Support: 800.506.9565

Customer Service: 888.417.5462

www.mercoproducts.com

Printed in U.S.A. February 2010 Part No. 07.04.499.00 Form No. HMCM-0210

Loading...

Loading...