Mercia Garden Products 06LOG127SG-V1, 06LOG127DG-V1 Instruction manual

General Instructions

Please retain product label and instructions for future reference

06LOG127SG-V1 & 06LOG127DG-V1

06LOG127SG-V1 28mm 3x3m corner cabin with single (glass) glazing.

06LOG127DG-V1 28mm 3x3m corner cabin with double (glass) glazing.

BEFORE YOU START PLEASE READ INSTRUCTIONS CAREFULLY

- Check the pack and make sure you have all the parts listed.

- When you are ready to start, make sure you have the right tools at hand (not supplied)

including a Phillips screwdriver, Stanley knife, wood saw, step ladder and drill with 2mm

bit.

- Ensure there is plenty of space and a clean dry area for assembly.

TIMBER

As with all natural materials, timber can be aected during various weather conditions.

For the duration of heavy or extended periods of rain, swelling of the wood panels may

occur. Warping of the wood may also occur during excessive dry spells due to an interior

moisture loss. Unfortunately, these processes cannot be avoided but can be helped. It is

suggested that the outdoor building is sprayed with water during extended periods of

warm sunshine and sheltered as much as possible during rain or snow.

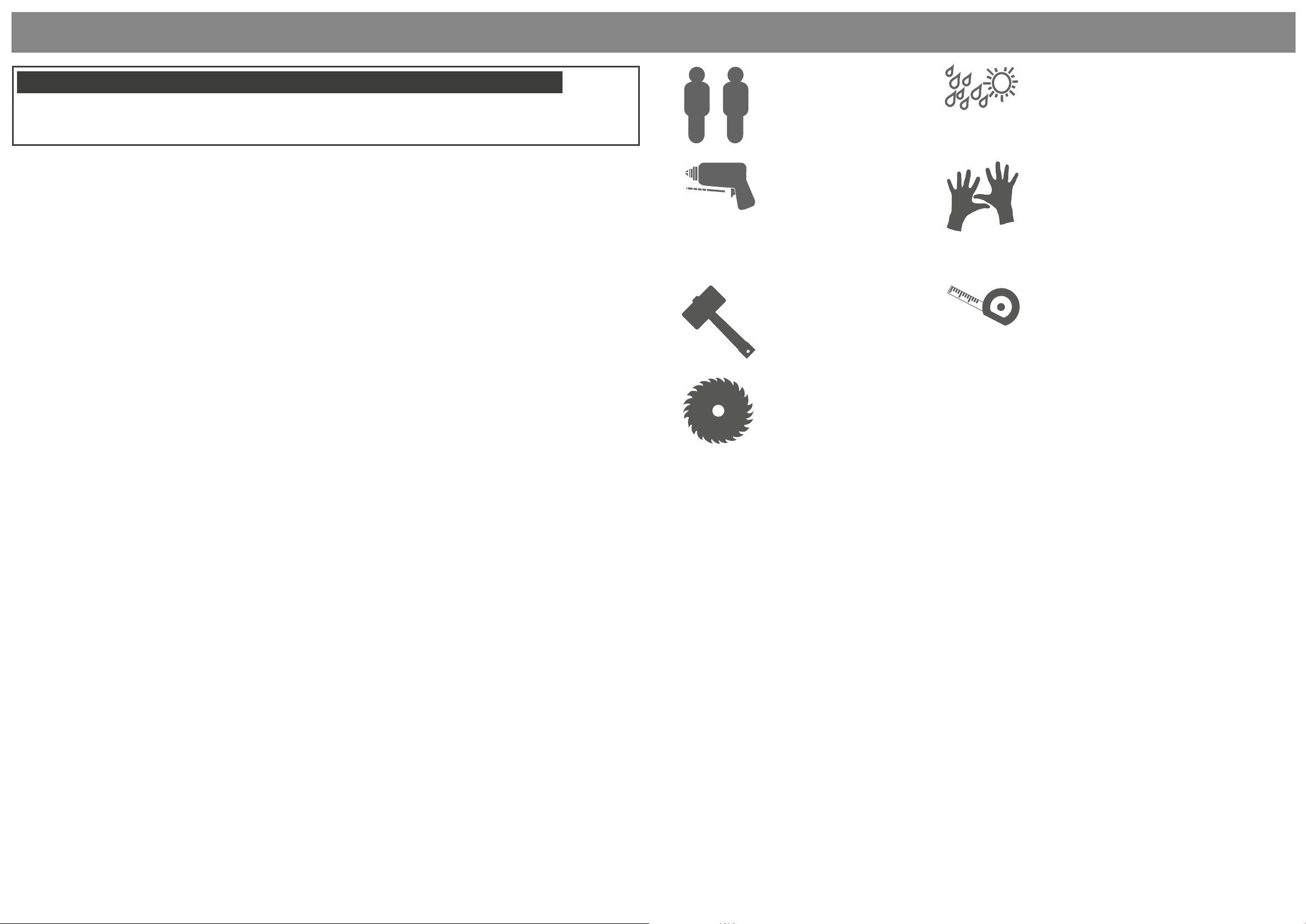

2mm Drill bit

All building’s should be

erected by two adults

For ease of assembly, you

MUST pilot drill all screw

holes and ensure all screw

heads are countersunk.

For ease of assembly use a

rubber mallet to t the log

boards. Do NOT use a heavy

hammer.

It is advisable to use a

circular saw when cutting

roof and oor boards.

Winter = High Moisture = Expansion

Summer = Low Moisture = Contraction

CAUTION

Every eort has been made during the

manufacturing process to eliminate the

prospect of splinters on rough surfaces of the

timber. You are strongly advised to wear gloves

when working with or handling rough sawn

timber.

Ensure to measure and check before cutting

boards.

Our buildings are pre treated with a water based treatment**; this only helps to protect

the product during transit and for upto 3 months against mould. To validate your

guarantee and ensure longevity of the product, it is ESSENTIAL the building is treated

with a wood preserver within the rst three months of assembly and thereafter in

accordance with the manufactures recommendations. Care must be taken to ensure

the product is placed on a suitable base.

BUILDING A BASE

When thinking about where the building and base is going to be constructed:

Ensure that there will be access to all sides for maintenance work and annual

treatment.

Ensure the base is level and is built on rm ground, to prevent distortion. Refer to

diagrams for the base dimensions, The base should be slightly smaller than the external

measurement of the building, i.e. The cladding should overlap the base, creating a run

o for water. It is also recommended that the oor be at least 25mm above the

surrounding ground level to avoid ooding.

TYPES OF BASE

- Concrete 75mm laid on top of 75mm hard-core.

- Slabs laid on 50mm of sharp sand.

Whilst all products manufactured are made to the highest standards of Safety and in

the case of childrens products independently tested to EN71 level, we cannot accept

responsibility for your safety whilst erecting or using this product.

For assistance please contact customer care on: 01636 880514

Mercia Garden Products Limited,

Sutton On Trent,

Newark,

Nottinghamshire,

NG23 6QN

Refer to the instructions pages for you specic product code

www.merciagardenproducts.co.uk

P 1

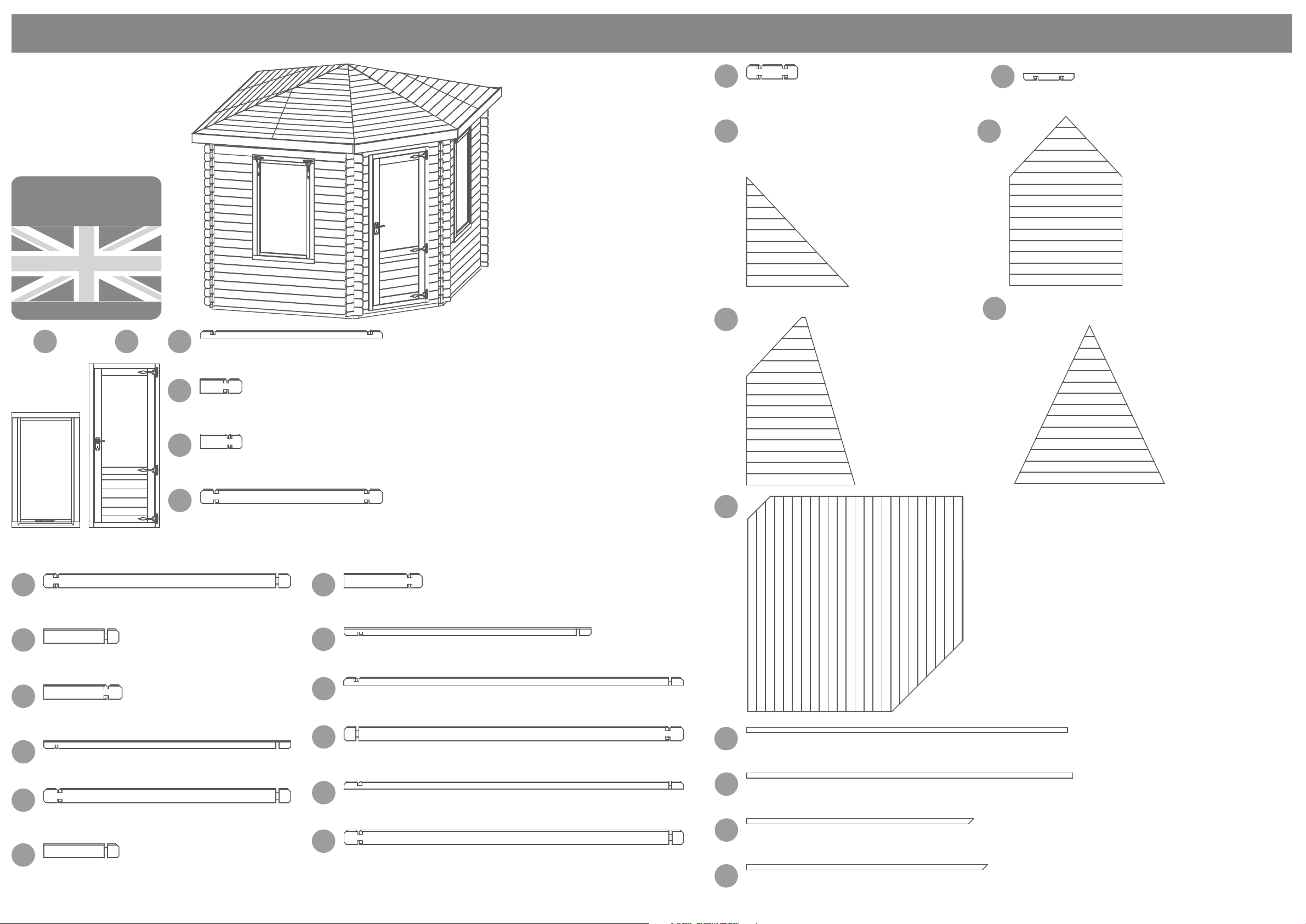

06LOG127SG-V1 & 06LOG127DG-V1

Please retain product label and instructions for future reference

Overall Dimensions:

Width = 4482mm

Depth = 3723mm

Height = 2923mm

Base Dimensions:

Width = 3255mm

Depth = 3899mm

Before assembly

please make sure you have a

suitable base ready to erect your

building

MADE IN GREAT BRITAIN

21

3

Starter Board (S1) - 28x66x1515mm

LB28RT66-1515mm

4

Log Board (B) - 28x120x347mm Left QTY 18

LB28-347mm (Left)

5

Log Board (B) - 28x120x347mm Right QTY 18

LB28-347mm (Right)

19

Log Board (A) - 28x120x652mm QTY 20

LB28-652mm

21

Roof Board Pack 1

AI-01LOG127SG/DG-V1RBP1

MB16P-1010mm (Angled) QTY 6

MB16P-906mm (Angled) QTY 6

MB16P-801mm (Angled) QTY 6

MB16P-697mm (Angled) QTY 6

MB16P-592mm (Angled) QTY 6

MB16P-488mm (Angled) QTY 6

MB16P-383mm (Angled) QTY 6

MB16P-279mm (Angled) QTY 6

MB16P-174mm (Angled) QTY 6

MB16P-70mm (Angled) QTY 6

Roof Board Pack 3

AI-01LOG127SG/DG-V1RBP3

23

MB16P-1077mm (Angled) QTY 2

MB16P-1044mm (Angled) QTY 2

MB16P-1011mm (Angled) QTY 2

MB16P-978mm (Angled) QTY 2

MB16P-945mm (Angled) QTY 2

MB16P-912mm (Angled) QTY 2

MB16P-878mm (Angled) QTY 2

MB16P-845mm (Angled) QTY 2

MB16P-812mm (Angled) QTY 2

MB16P-779mm (Angled) QTY 2

MB16P-704mm (Angled) QTY 2

MB16P-566mm (Angled) QTY 2

MB16P-428mm (Angled) QTY 2

MB16P-291mm (Angled) QTY 2

MB16RG92P-153mm (Angled) QTY 2

22

24

20

Log Board (AR) - 28x54x652mm

LB28RG54-652mm

Roof Board Pack 2

AI-01LOG127SG/DG-V1RBP2

MB16-1114mm QTY 18

MB16P-1114mm (Angled) QTY 2

MB16P-1040mm (Angled) QTY 2

MB16P-831mm (Angled) QTY 2

MB16P-623mm (Angled) QTY 2

MB16P-414mm (Angled) QTY 2

MB16P-206mm (Angled) QTY 2

Roof Board Pack 4

AI-01LOG127SG/DG-V1RBP4

MB16P-1407mm (Angled) QTY 1

MB16P-1381mm (Angled) QTY 1

MB16P-1274mm (Angled) QTY 1

MB16P-1168mm (Angled) QTY 1

MB16P-1062mm (Angled) QTY 1

MB16P-955mm (Angled) QTY 1

MB16P-849mm (Angled) QTY 1

MB16P-742mm (Angled) QTY 1

MB16P-636mm (Angled) QTY 1

MB16P-530mm (Angled) QTY 1

MB16P-423mm (Angled) QTY 1

MB16P-317mm (Angled) QTY 1

MB16P-211mm (Angled) QTY 1

MB16P-104mm (Angled) QTY 1

6

Log Board (A) - 28x120x1515mm QTY 2

Window

Door

LB28-1515mm

QTY 2

7

Log Board (A) - 28x120x2054mm Left QTY 8

LB28-2054mm

8

Log Board (B) - 28x120x652mm QTY 12

LB28-652mm

9

Log Board (B) - 28x120x652mm Left QTY 12

LB28-652mm Left

10

Log Board (AR) - 28x66x2054mm Left

LB28RT66-2054mm Left

11

Log Board (A) - 28x120x2054mm Right QTY 8

LB28-2054mm Right

12

Log Board (B) - 28x120x652mm QTY 12

LB28-652mm

13

Log Board (B) - 28x120x652mm Right QTY 12

LB28-652mm Right

14

Log Board (AR) - 28x66x2054mm Right

LB28RT66-2054mm Right

15

Log Board (S1) - 28x66x2662mm Left

LB28RT66-2662mm Left

16

Log Board (A) - 28x120x2662mm Left QTY 20

LB28-2662mm Left

17

Log Board (S1) - 28x66x2662mm Right

LB28RT66-2662mm Right

18

Log Board (A) - 28x120x2662mm Right QTY 20

LB28-2662mm Right

25

26

Bearer - 44x44x2669mm QTY 9

F4444-2669mm

27

Bearer - 44x44x2713mm

F4444-2713mm

28

Bearer - 44x44x1890mm QTY 2

F4444-1910mm (Angled)

29

Bearer - 44x44x2005mm

F4444-2025mm (Angled)

Floor Board Pack

AI-01LOG127SG/DG-V1FBP

MB16P-2531mm (Angled tongue side) QTY 1

MB16P-2643mm (Angled tongue side) QTY 1

MB16P-2696mm (Angled tongue side) QTY 1

MB16-2696mm QTY 13

MB16P-2696mm (Angled groove side) QTY 1

MB16P-2597mm (Angled groove side) QTY 1

MB16P-2485mm (Angled groove side) QTY 1

MB16P-2373mm (Angled groove side) QTY 1

MB16P-2261mm (Angled groove side) QTY 1

MB16P-2149mm (Angled groove side) QTY 1

MB16P-2037mm (Angled groove side) QTY 1

MB16P-1925mm (Angled groove side) QTY 1

P 2

Please retain product label and instructions for future reference

30

Bearer - 44x44x2248mm

F4444-2268mm (Angled)

31

Bearer - 44x44x2481mm

F4444-2501mm (Angled)

32

Bearer - 44x44x1253mm

F4444-1293mm (Angled)

34

33

Bearer - 44x44x394mm

F4444-434mm (Angled)

35

Centre Purlin Right - 1095mm QTY 3

AI-06LOG127SG/DG-V1CPR

36

Front Purlin Left - 1746mm

AI-06LOG127SG/DG-V1FPL

37

Front Purlin Right - 1746mm

AI-06LOG127SG/DG-V1FPR

38 39

Long Purlin - 45x70x2273mm QTY 3

F4570-2313mm (Angled)

40 41

Spider Block - 45x120x143mm

F45120-163mm (Angled)

Top Block Door - 28x80x1254mm

LB28RG80-1254mm (Angled)

Centre Purlin Left - 1095mm QTY 3

AI-06LOG127SG/DG-V1CPL

Roof Block - 45x70x185mm QTY 3

F4570-205mm (Angled)

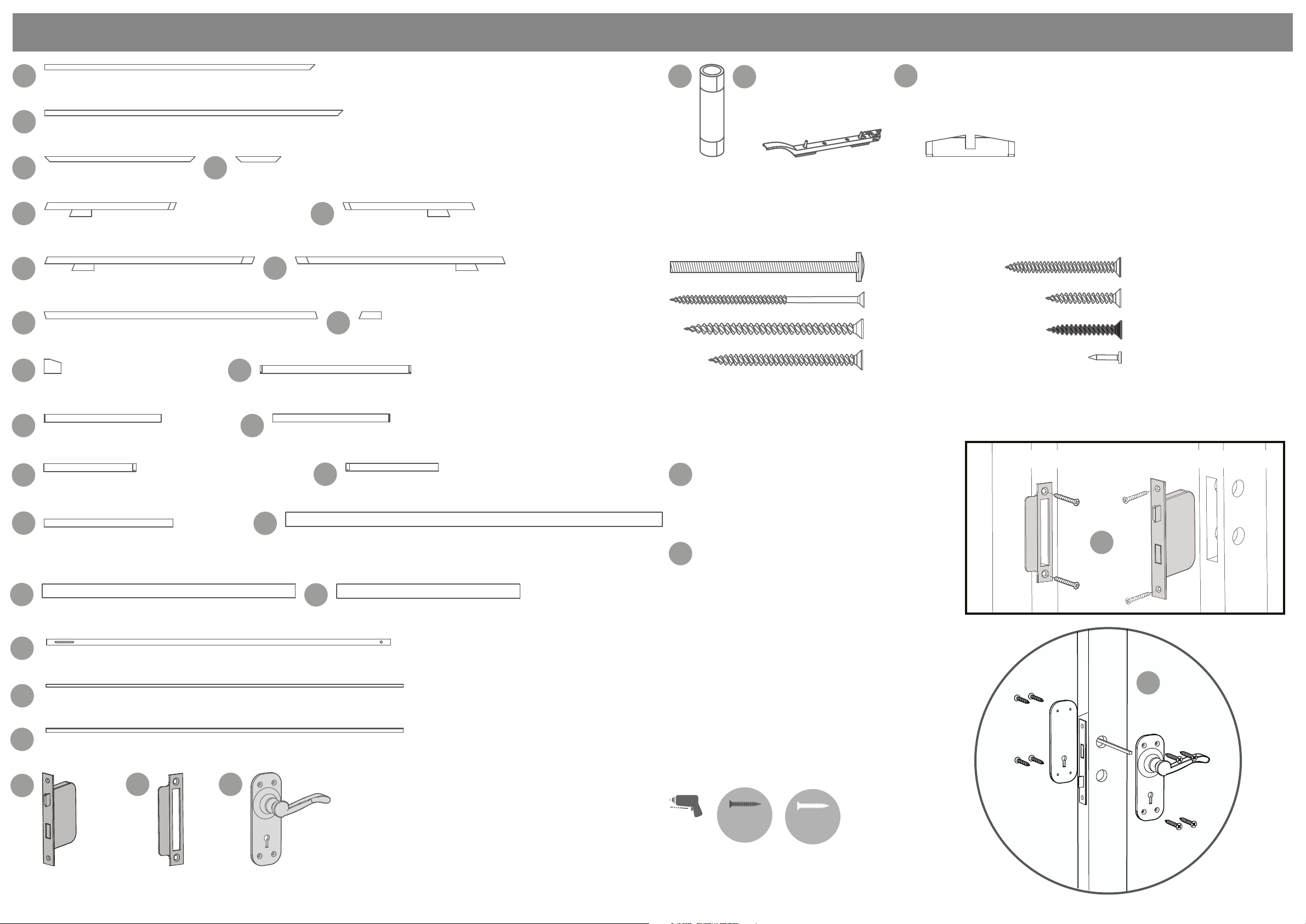

56

Felt

Nail Bag

57

Casement Stay QTY 2

58

Corner Top Block

AI-06LOG127-V1BACKB

80mm Bolt Set x17

120mm Screw x20

90mm Screw x100

70mm Screw x172

40mm Screw x353

30mm Screw x76

30mm Black Screw x21

Felt Tacks x867

42 43

Top Block Left - 28x80x974mm

LB28RG80-974mm (Angled)

44

Top Block Back Right - 28x80x768mm QTY 3

LB28RG80-768mm (Angled)

46

Top Block Centre 28x80x1071mm QTY 2

LB28RG80-1071mm

48

Window Fascia - 16x120x2160mm QTY 2

S16120-2160mm

50

Storm Brace - 27x44x2100mm QTY 8

F2744-2100mm

51

Skirting - 28x28x2400mm QTY 8

FS2828-2400mm

52

Interior Roof Trim - 27x44x2400mm QTY 8

F2744-2400mm

53

54

55

Top Block Right - 28x80x974mm

LB28RG80-974mm (Angled)

45

Top Block Back Left - 28x80x768mm QTY 3

LB28RG80-768mm (Angled)

47

Rear Fascia - 16x120x3145mm QTY 2

S16120-3145mm

49

Front Fascia - 16x120x1700mm

S16120-1700mm

Step 1

Fit the mortice lock (No. 53) into the recess

a

in the door (No. 2) and secure using the

screws provided. Attach the key plate

(No. 54) to the door framing with the

screws provided.

b

Fit the door handles (No.55) and connect

with the metalbar to the mortice lock

using 8x30mm screws. Ensure the lock

mechanism closes correctly. If not, remove

the lock and turn the catch around using

the small grub screw.

*Please note: This image is for illustrative purposes

and may dier from your choice in product

(regarding ironmongery). Nevertheless the process

of xing is the same.

8x30mm Black Screws

12x30mm Screws

The Mortice Lock is Reversible

a

b

Mortice Lock

Key Plate

Handles (Pair)

Pre drill

hole

30mm

screw

30mm

screw

P 3

Please retain product label and instructions for future reference

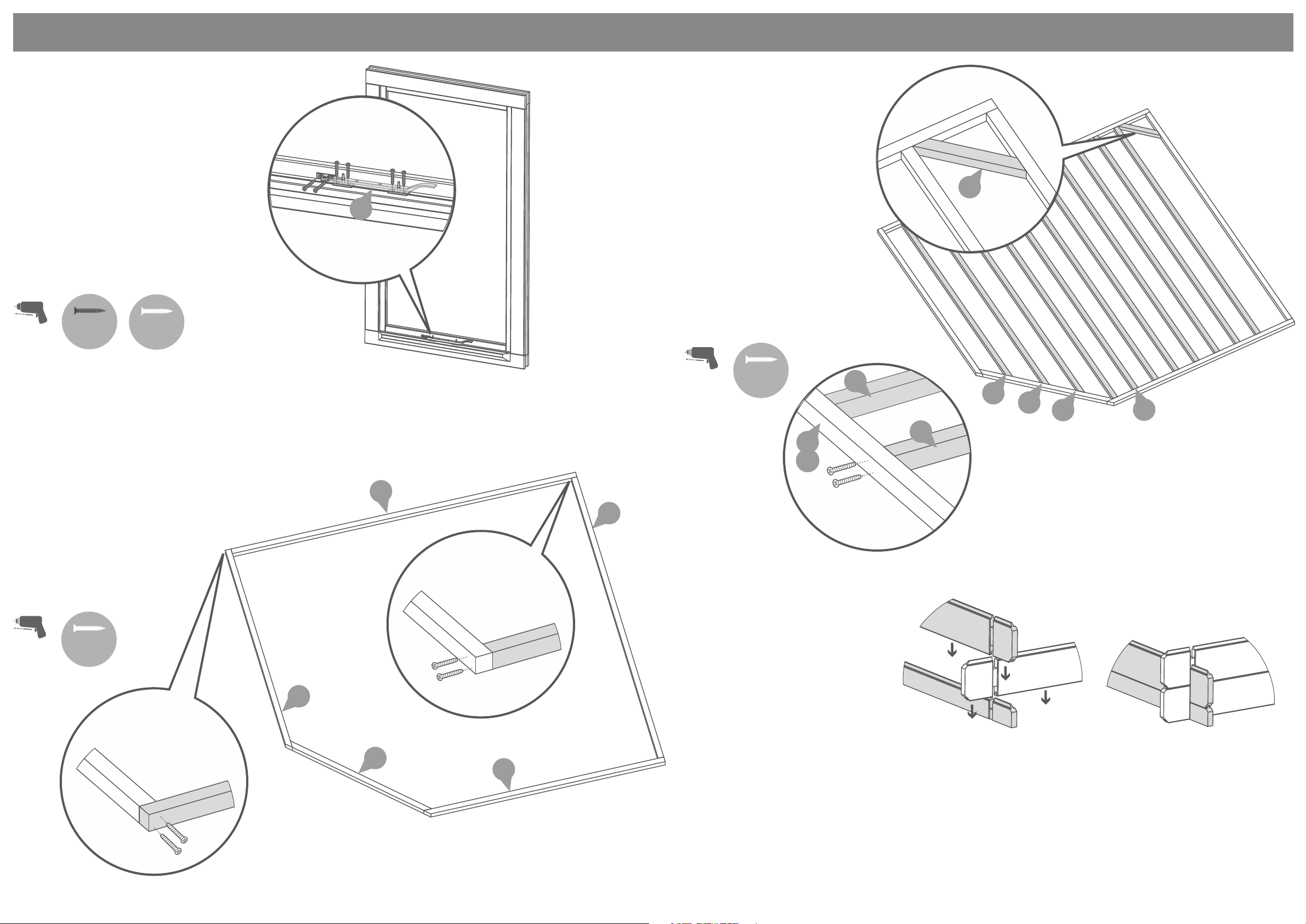

Step 2

Fix the casement stay (No. 57) onto

the window (No. 1) and the casement

stay pins to the window cill using

6x30mm (black) screws per casement

stay.

*Ensure the casement stay is centralised

on the window.

12x30mm Black Screws

12x30mm Screws

Depending on Ironmongery choices

Pre drill

hole

30mm

screw

30mm

screw

Step 3

57

Step 4

Following the same method

outlined in Step 3, arrange the

remaining framing (No’s. 26, 29

30, 31 & 33) as shown in the

illustration.

*Ensure there is an equal

amount of space between each

frame.

Secure each of the frames in place

using 4x70mm screws per frame,

ensuring the framing remains level.

44x70mm Screws

Pre drill

hole

70mm

screw

26

33

29

30

31

26

Lay the starters (No’s. 26, 27, 28

& 32) onto a rm and level surface

(free from areas where standing

water can collect) as shown in the

illustration.

Fix the framing together at each

corner using 10x70mm screws,

ensuring the frame is ush.

10x70mm Screws

Pre drill

hole

70mm

screw

27

26

28

27

26

Pre-assembly

*Please note:

Each board interlocks at

either end in a staggered pattern.

28

Before securing ensure that the boards

are tted properly in their respective

tongue’s and groove’s.

32

28

P 4

Loading...

Loading...