Sensotronic Brake Control

(SBC)

327 HO 09 SBC (WJB) 03 -05-04

1

R230 and W211: Starting MY2003

Objectives

At the end of this presentation, you should be able to:

1. Explain the function of and purpose for SBC

2. Describe the customer interface with SBC

3. List the hydraulic and electronic components used for SBC

4. Describe how the “normal” feel of the brake pedal is maintained

5. Explain emergency operation of the SBC braking system

6. Describe “temperature compensation”

7. Explain “Deactivation” and describe when it is necessary to do it

8. “Activate” the SBC system

9. Locate tools and the proper procedure for bleeding brakes

These technical training materials are current as of the date noted on the materials, and may be revised or updated without notice. Always check for revised or updated information.

To help avoid personal injury to you or others, and to avoid dam age to the vehicle on which you are working, you must always refer to the latest Mercedes-Benz Technical Publication and follow all

pertinent instructions when testing, diagnosing or making repair.

Illustrations and descriptions in this training reference are based on preliminary information and may not correspond to the final US version vehicles. Refer to the official introduction manual and WIS

when available. Copyright Mercedes-Benz USA, LLC, 2004

WIS document numbers shown apply to WIS Version USA/CDN at date of writing.

Reproduction by any means or by any information storage and retr ieval system or translation in whole or part is not permitted without written authorization from Mercedes -Benz USA, LLC or it's

successors. Published by Mercedes-Benz USA, LLC Printed in U. S.A.

2

Contents

Advantages of SBC 5

Driving with SBC 8

SBC components 13

Brake operating unit (BOU) 17

Traction system hydraulic unit 27

Three pressure stages 32

Temperature Compensation 38

Deactivation 39

System activation 42

Bleeding the system 49

3

SBC Incorporates these Functions:

ABS (Anti lock Brakes 1984)

+ ASR (Automatic Slip Regulation 1991)

+ ETS (Electronic Traction System 1995)

+ ESP (Electronic Stability Program 1996)

+ BAS (Brake Assist System 1998)

4

Advantages of SBC

• Improves metering of required brake pressure

– each wheel can be precisely controlled

• Improved BAS function

– monitors release of accelerator pedal and application of

brake

– maximum pressure available immediately

– pre-filling of system (overcoming play)

– when the BAS function is anticipated, slight pressure is

applied

5

Advantages of SBC

• Electronic Brake Proportioning: EBP

– allows brake proportioning front to back and side to side

• No pedal vibration during ABS operation

– eliminates “distraction” to the driver during critical moments

– indicator light in instrument cluster signals traction loss

• Improved driving dynamics: ABS, ASR, and ESP

– faster response to brake request inputs

6

Advantages of SBC

• Pressure reduction at standstill

– reduces stress on components

• Dry braking function

– wiper input via CAN

– ~every 7 to 14 minutes

– brake actuation changes

time interval

7

Driving with SBC - Wake -Up

SBC is functional as soon as it is “wakened” by:

• opening a door (via CAN)

• operating the central locking system (via CAN)

• depressing the brake pedal

• turning key to position 1

• operating parking brake

•The Wake-Up may be followed by a Pre-Drive self

Check performed by SBC

8

Driving with SBC – Pre-Drive Check (PDC)

When SBC performs a PDC after a "wake-up", the following are

checked:

Warning! Pressure is applied to brake calipers (~60 bar)

• reservoir pressure (if low, it will be corrected by running the

high pressure charge pump in the hydraulic unit)

• pressure sensors

• control valves

• leak tests

• operational checks

Note: self-tests are constantly conducted during driving (~ once every 16

brake applications)

9

Driving with SBC – Delayed Off Function

Time that SBC remains operational after use:

• with vehicle stationary and was locked = 20 seconds

• with vehicle stationary and ignition in “0”,

brake pedal not operated = 2 minutes

• with vehicle stationary, ignition in “0”,

brake pedal operated in delayed off phase and

released again = 4 minutes

10

Warning Display

Complete ESP control module failure -

Instrument cluster will scroll through failure displays

11

Warning Display

SBC control module failure

Certain faults will trigger audible signal

12

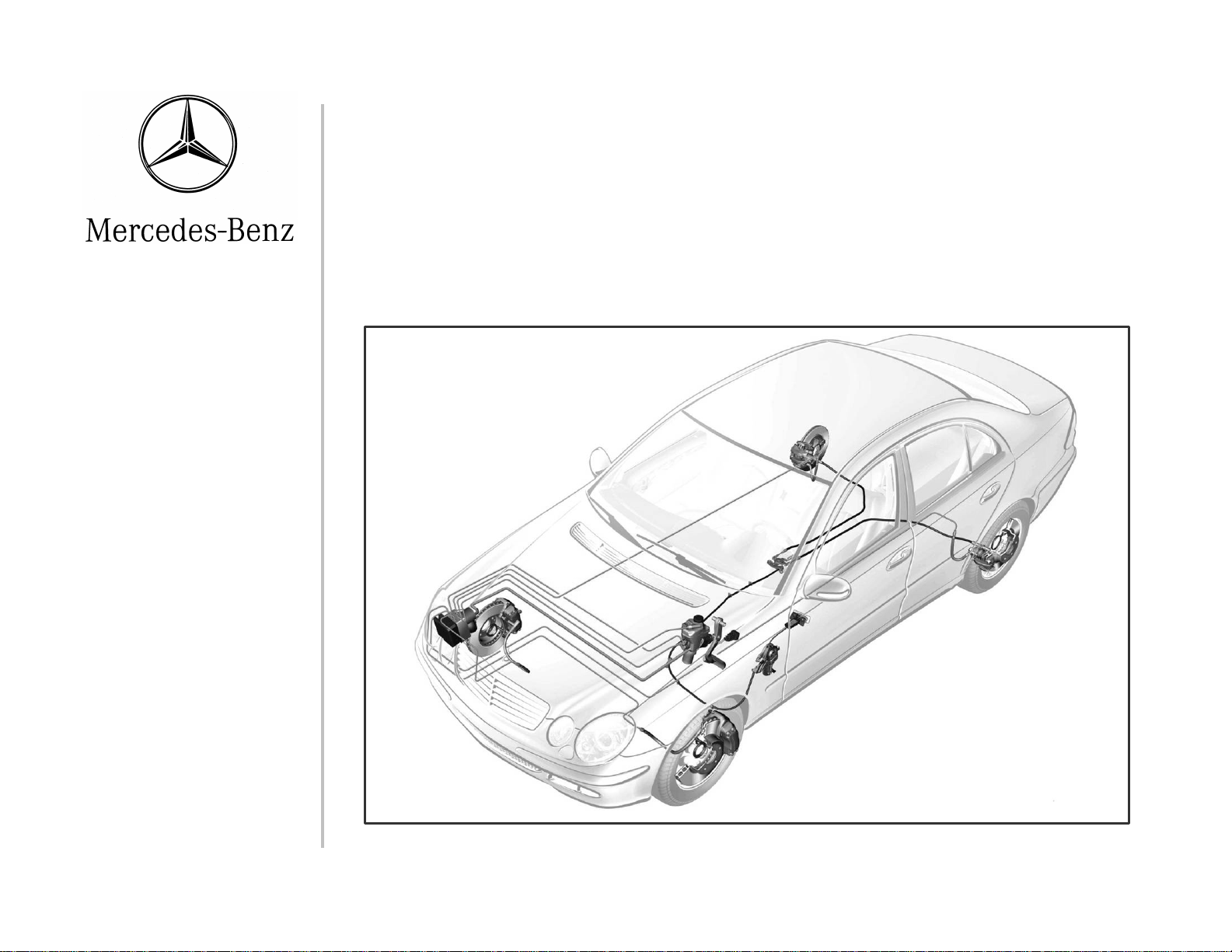

SBC Components

• Brake Operating Unit (BOU)

• Wheel speed sensors

• Traction System Hydraulic

Unit (A7/3)

13

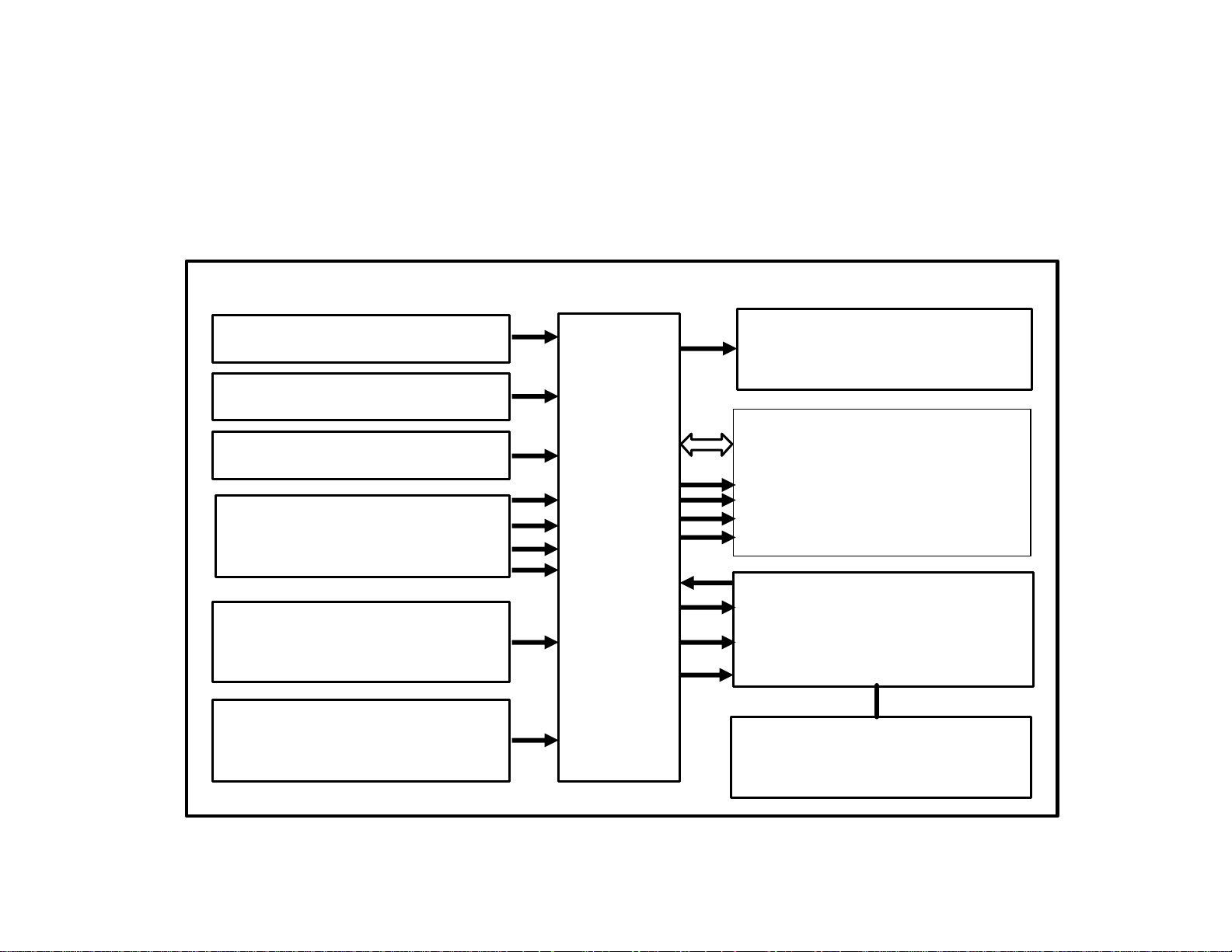

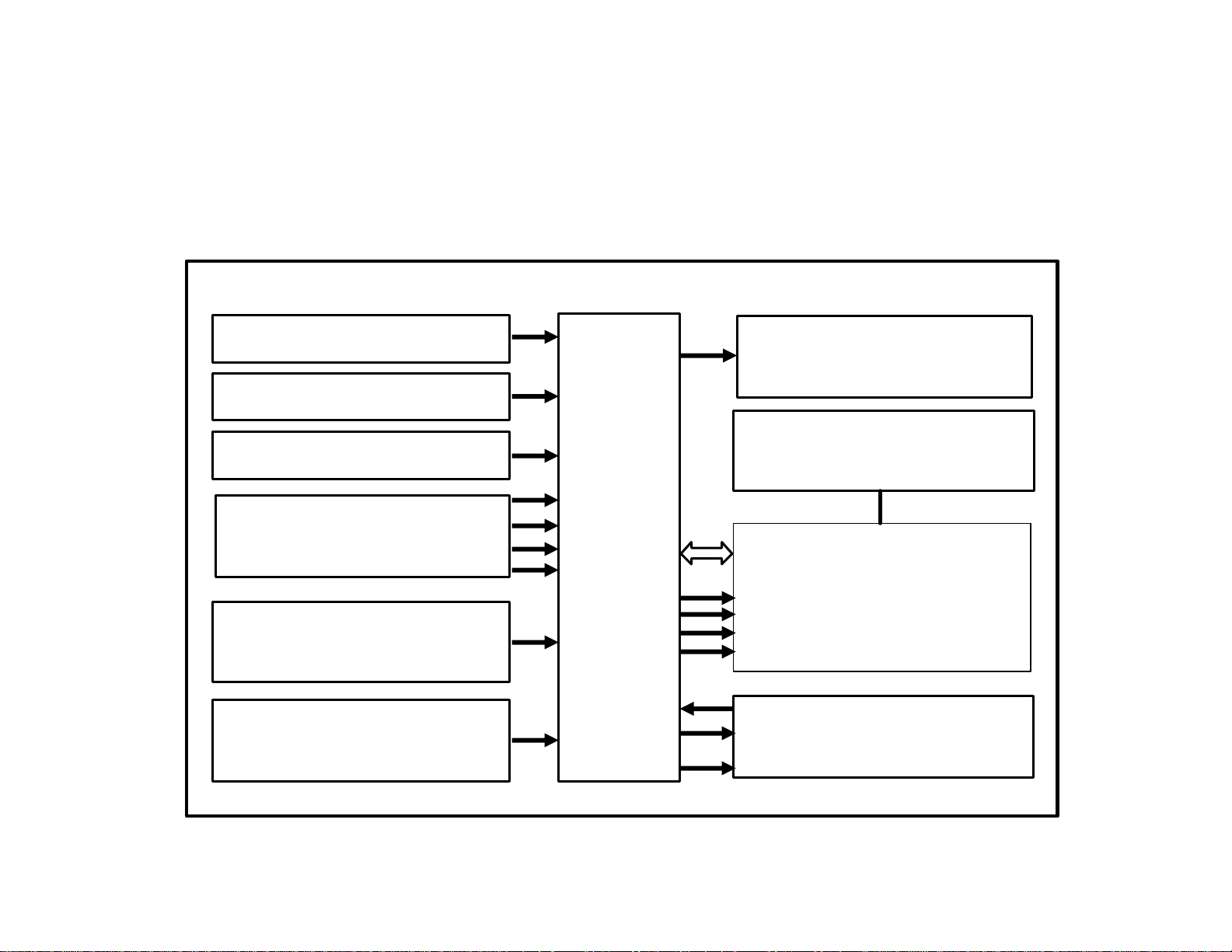

W211 System Overview

Circuit 30

Circuit 87

Circuit 31

Wheel speed sensors

L6/1, L6/2, L6/3, L6/4

Stop lamp switch

(S9/1)

SBC pedal travel

sensor (B37/1)

SBC

control

module

(A7/3n1)

SBC

CAN

Brake lights

Rear SAM

(N10/2)

ESP control

Wheel

speeds

Wake up

Brake lights

Speed status

Diagnostics

module (N47/5)

Front

SAM

(N10/1)

Diagnostic connector

(X11/4)

14

R230 System Overview

Circuit 30

Circuit 87

Circuit 31

Wheel speed sensors

L6/1, L6/2, L6/3, L6/4

Stop lamp switch

(S9/1)

SBC pedal travel

sensor (B37/1)

SBC

control

module

(A7/3n1)

SBC

CAN

Brake lights

Rear SAM

(N10/8)

Diagnostic connector

(X11/4)

ESP control

Wheel

speeds

Wake up

Brake lights

Speed status

module (N47/5)

Passenger side

SAM (N10/11)

15

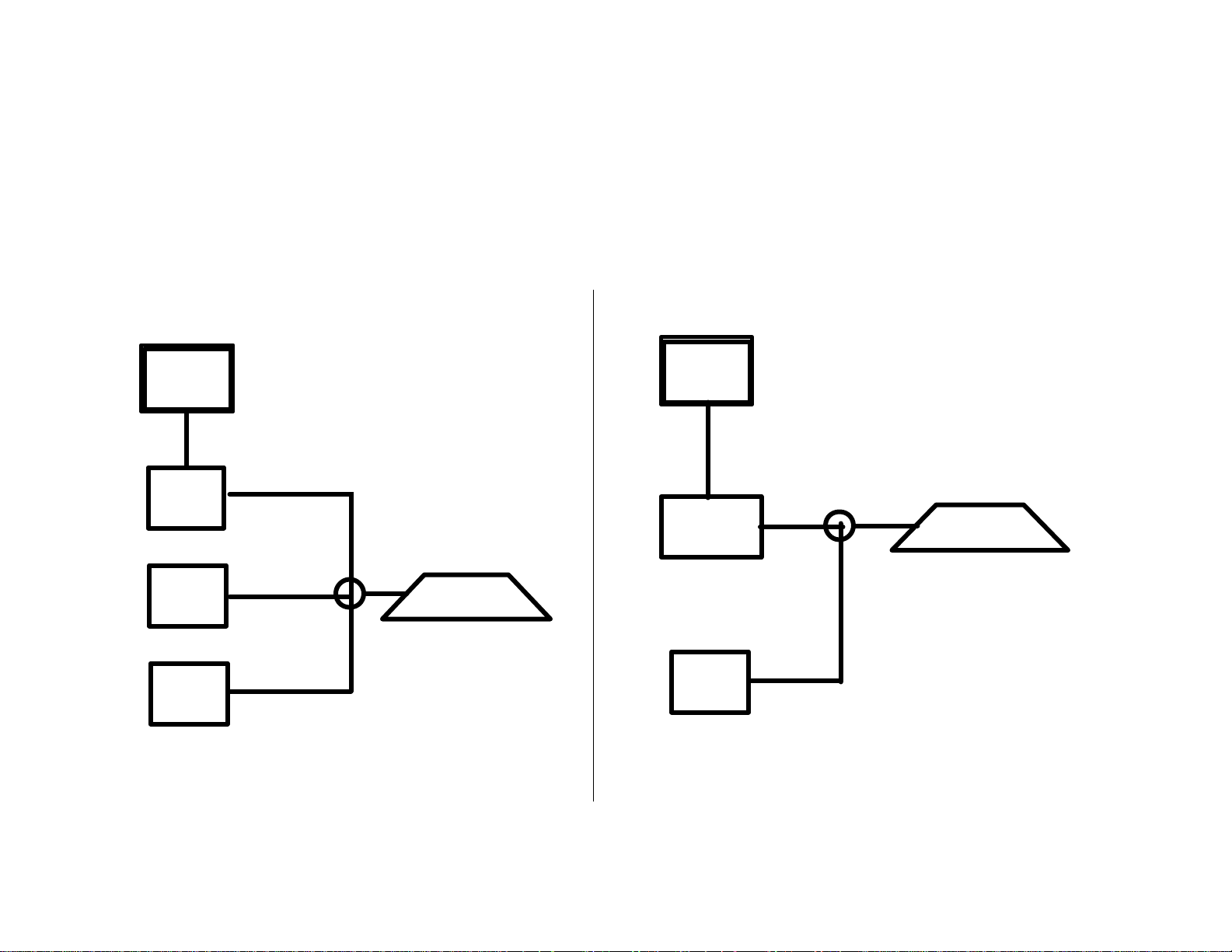

X11/4 Diagnosis Connection

A7/3n1

SBC

N47/5

ESP

N15/5

ESM

N51/2

ABC

Z6/33

R230

X11/4

Pin 9

W211

A7/3n1

SBC

X11/4

N10/1

L.F.SAM

Z70/4

Pin 9

N47/5

ESP

16

Loading...

Loading...