Mercedes-Benz Unimog 435, Unimog 435.111, Unimog 435.110, Unimog 435.117, Unimog 435.160 Service Manual

...

Mercedes-

Benz

Unimog

Workshop Manual

Unimog

435

Volume 1

Service

© Buch&Bild, Helma Wessel

Buch&Bild hat 1994 vom Produktbereich Unimog der damaligen Daimler-Benz

AG

das Exklusivrecht

fUr

den Nachdruck der technischen Unimog- und MBtrac-Oldtimer-Literatur erhalten.

Silmtliche

Rechte der Verbreitung - in jeglicher Form und Technik

einschlieBlich der Einspeicherung

in

elektronische Medien - sind vorbehalten.

Technical details of the vehicle

in

relation to data and illustrations contained

in

this manual

are subject

to

change.

All

rights, including reprint, reproduction

or translation

(also of extracts), reserved.

Nachdruck

2008

Printed

in

Germany

Buch&Bild

Helma Wessel

Finkenweg 13

D 76571 Gaggenau

TeL

+49

(0)

7225/4347

Fax

+49

(0)

7225/4779

wessel@buchundbild.de

www.buchundbild.de

Stand 5.1989

UKD 30 402

21

42

03

The

present

Workshop

Manual

contains

the

descrip-

tions

of

all

important

assembly,

adjusting, testing

and

repair

work.

The

entire contents of

the

Workshop

Manual

are

subdi-

vided

according

to

the

well-known

group

system.

The

group

index

serves

to

facilitate

finding

the

individual

groups,

the

list

of

contents of

each

group

serves

to

find

the

individual

jobs

to

be

carried

out.

The

relevant

data,

settings,

dimensions

and

toleran-

ces

as

well

as

the

special

tools

are

compiled

on

the

first

pages

of

the

respective

groups.

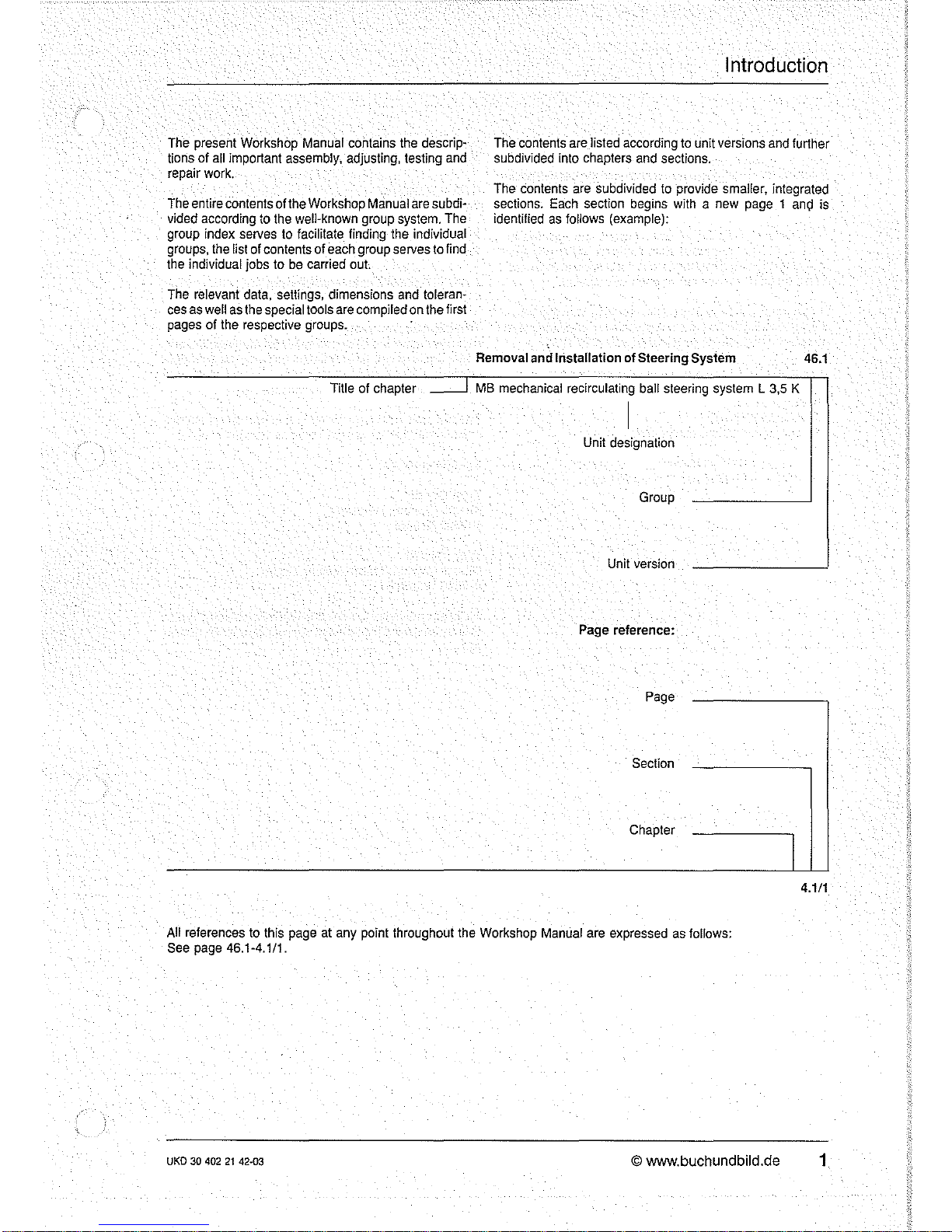

Introduction

The

contents

are

listed

according

to

unit

versions

and

further

subdivided

into

chapters

and

sections.

The

contents

are

subdivided

to

provide smaller, integrated

sections.

Each

section

begins

with a new

page

1

an~

is

identified

as

follows

(example):

Removat and Installation of Steering System

46.1

Title of chapter

~

MS

mechanical

recirculating

ball

steering

system L 3,5

K

I

Unit

designation

Group

Unit

version

Page

reference:

Page

Section

Chapter

I

4.1/1

All

references

to

this

page

at

any

point throughout

the

Workshop

Manual

are

expressed

as

follows:

See

page

46.1-4.1/1.

UKD

30

402

21

42·03

© www.buchundbild.de

1

Introduction

The

unit

versions

are consecutively numbered starting

with 1; i.e. each version has a special code number. In

addition, the unit designation

is

shown at the head of each

page.

A separating sheet and a detailed list of contents

head each unit.

The sections valid for

all unit versions are covered in

version

O.

The respective data (settings, tightening tor-

ques, machining dimensions etc.) and special

tools are

listed together

at

the start of each unit version.

The numerical values

in

SI

units resulting from the introduction of the international unit system are converted and

rounded-off values (in accordance with

DIN 1335).

The pressure values specified

in

bar are positive.

Pressure In

bar

Previous Unil kp/cm

2

(Kilo ponds per square centimeter)

1 bar = 1.019716 kp/cm

2

- 1.02 kp/cm

2

1 kp/cm

2

= 0.980665 bar - 0.981 bar

2

Power

in

kW (kilowatt)

Previous unit HP (horsepower)

1

kW=

1.360 HP

1 HP = 0.735 kW

Torque

in

Nm

(Newtonmeters)

Previous unit kpm (kilo pond meters)

1 Nm = 0.101972 kpm - 0.102 kpm

1 kpm = 9.80665 Nm -

9.81

Nm

The specified part numbers and the figure numbers in the

exploded views are designed

solely for identHication purposes and improve differentiation between the individual

versions. When ordering spare parts, always use the part

numbers

given

in

the

valid

microfiches.

The job descriptions provided

in

this Workshop Manual

make allowance for special versions (see

00 - 1.6/1).

Special vehicles:

Type

Condor

Messrs Thyssen Henschel

0-3500 Kassel

Type

TN 170

Messrs Thyssen Maschinenbau GmbH

0-5810

Wilten

6

We

shall endeavour to keep this Workshop Manual up-todate by supplying the relevant"Supplementswhen necessary.

Contents

Chapter

1 General

Installation

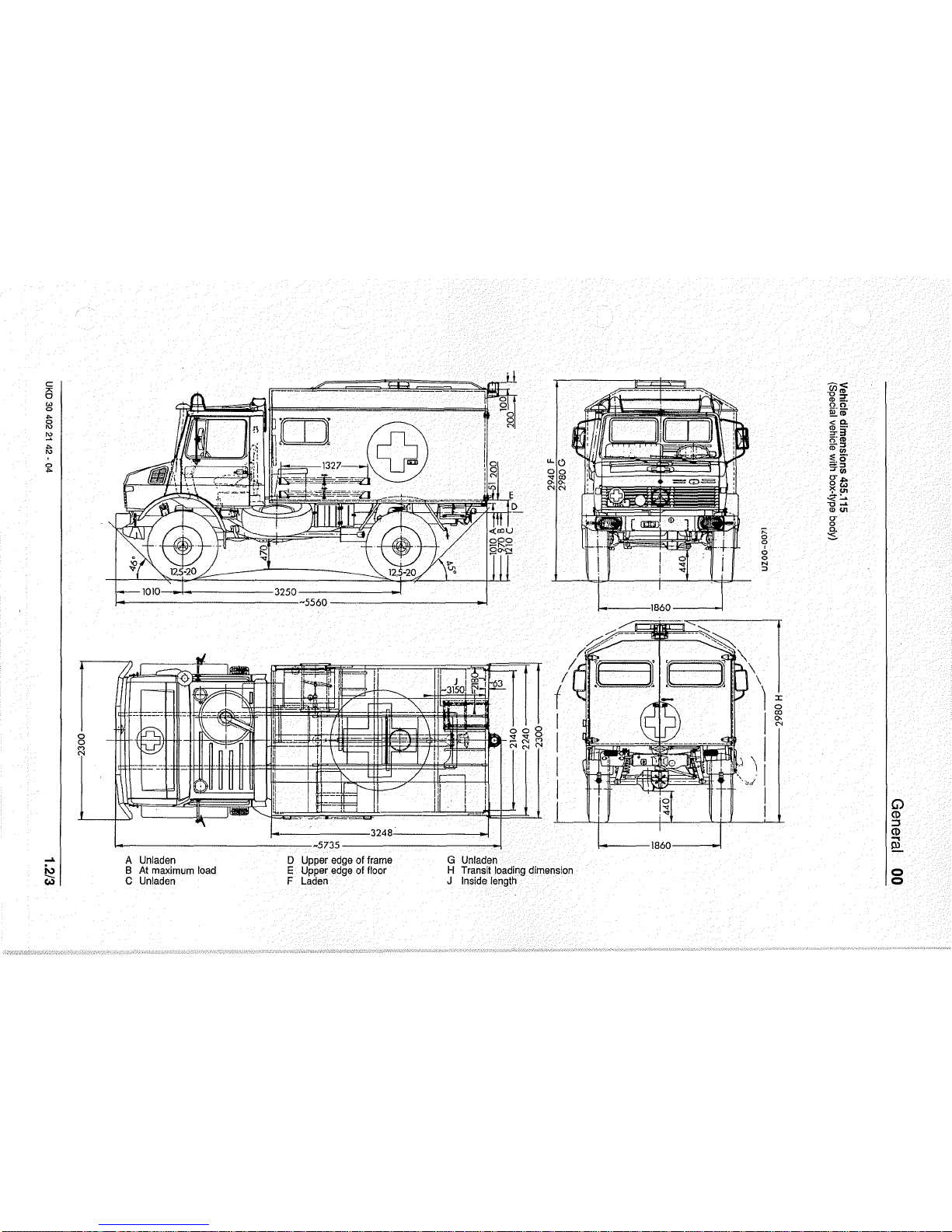

survey

General

view

Vehicle

dimensions

435.115

Vehicle

dimensions

435.111

Vehicle

dimensions

435.115

(special

vehicle

with

box-type

body)

Maximum

speeds

435.115/117

Maximum

speeds

435.110/111

Weights

and

trailer

loads

Service

products,

capacities

Special

versions

considered U 1300

L

UKD

30

40021

42

- 04

General 00

Page

1.1/1

1.1/5

1.211

1.212

1.213

1.3/1

1.3/2

1.4/1

1.5/1

1.6/1

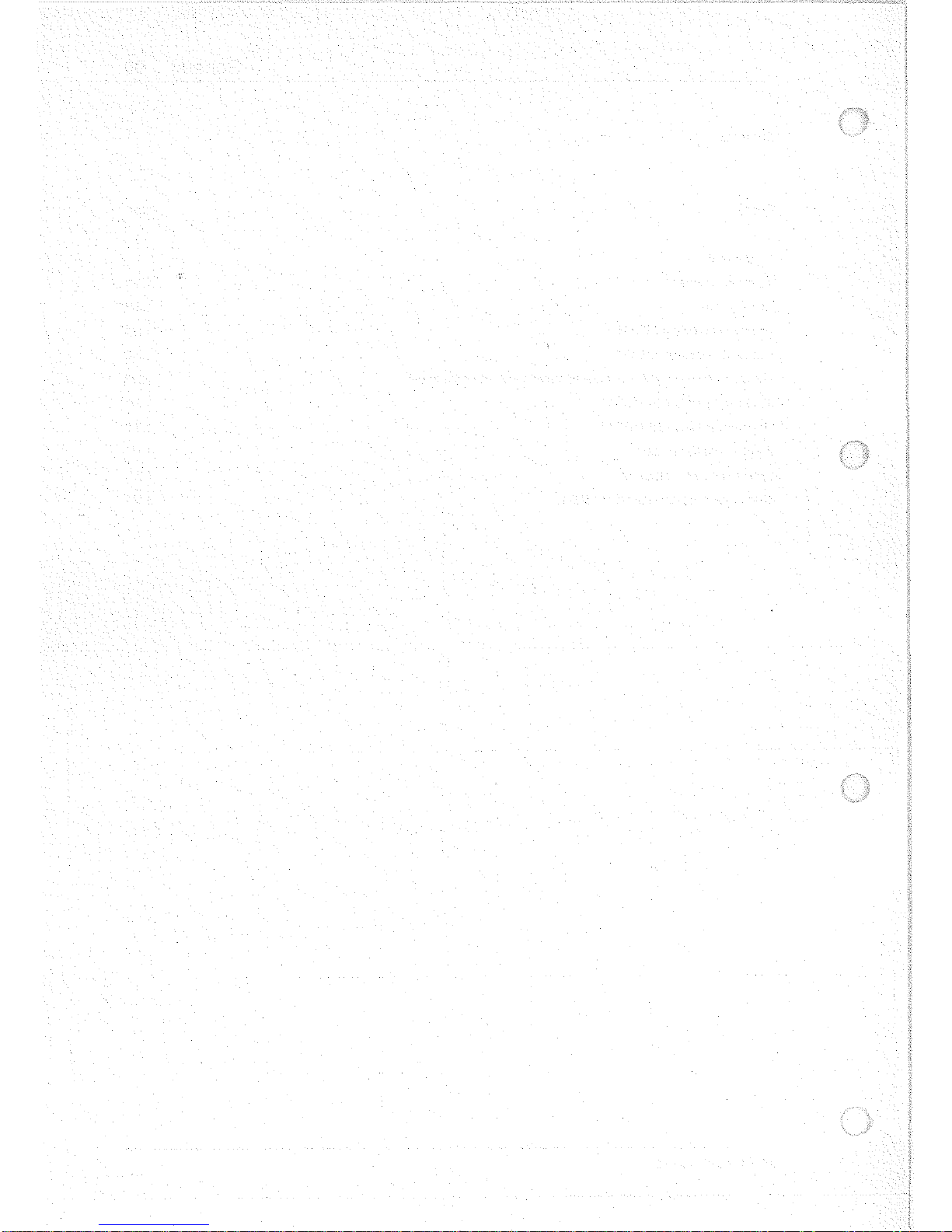

General 00

General

view

UROO~01:tR

435.113

435.113

UKD

30

402

21

42 • 04

1.1/7

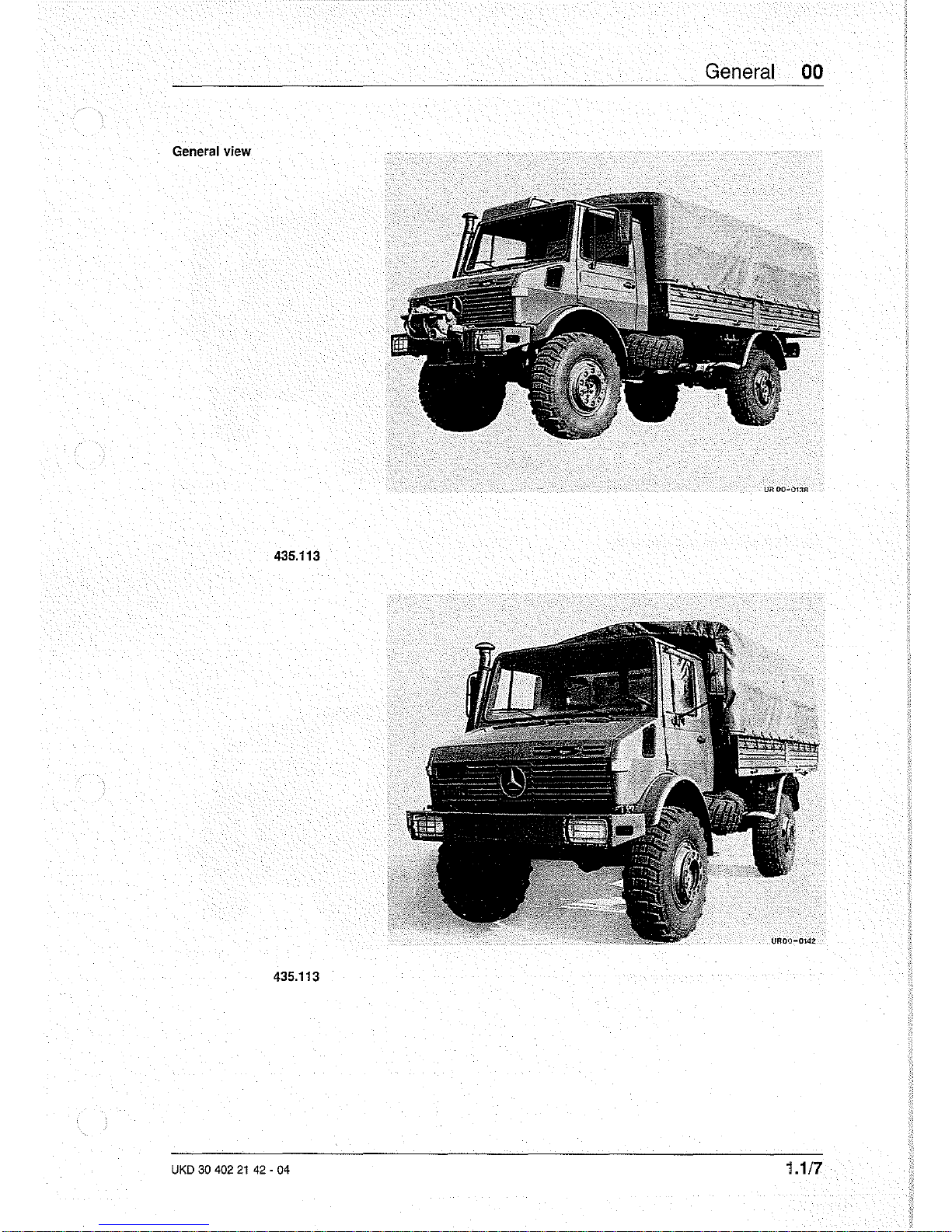

00 General

General view

435.115

Front-

with box-type body

435.115

Rear- with box-type body

1.1/8

General 00

Installation

Survey

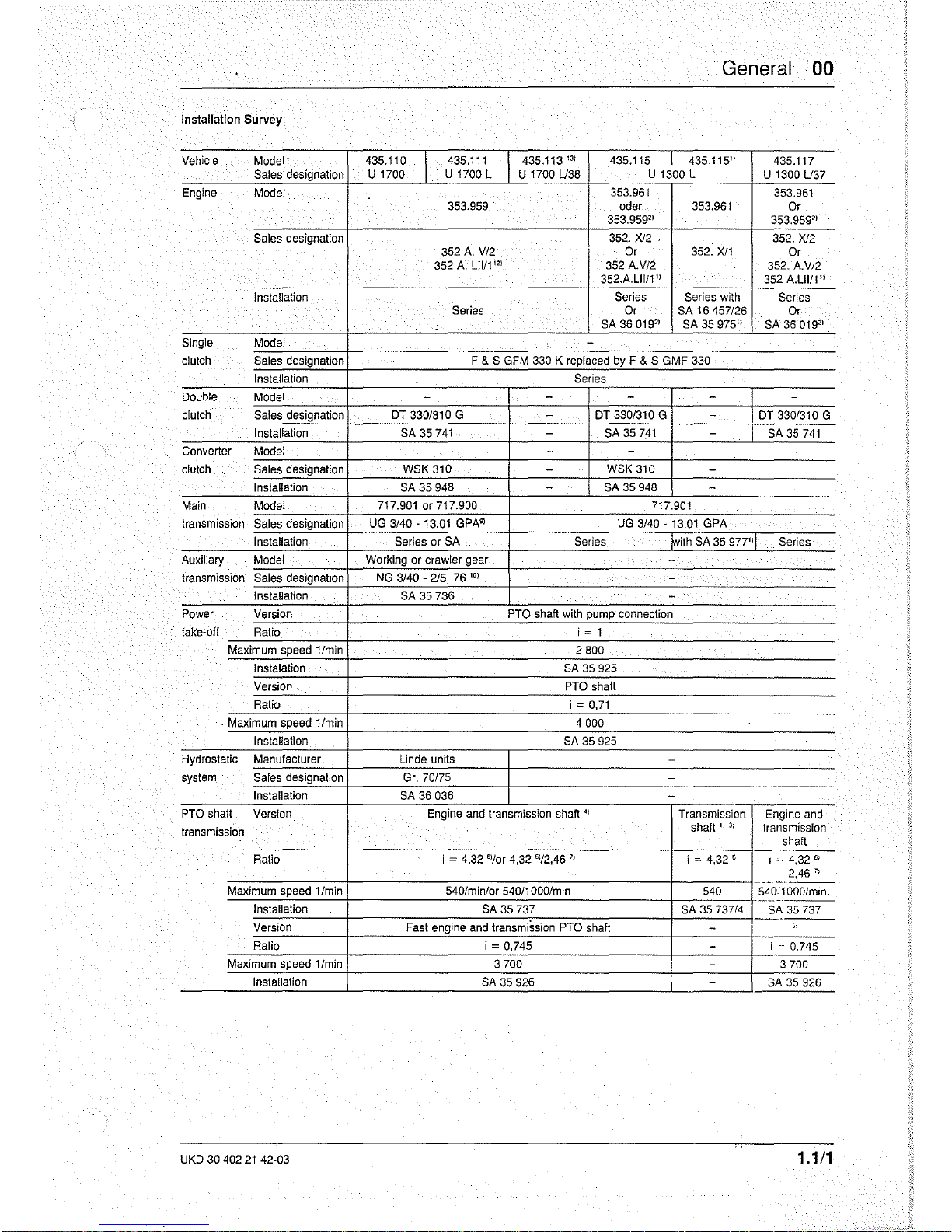

Vehicle Model 435.110

I

435.111

435.113

",

435.115 I 435.115"

435.117

Sales designation

U

1700 U 1700 L U 1700

U38

U 1300 L

U

1300

U37

Engine

Model

353.961

353.961

353.959 oder

353.961

Or

353.959"

353.959"

Sales

designation

352. Xl2 .

352. Xl2

352

A.

VI2

Or 352.

Xl1

Or

352

A.

L1111

'"

352

A.V12

352.

A.V12

352.A.L1li1 "

352

A.L1111"

Installation

Series

Series

with

Series

Series

Or SA 16457126 Or

SA

36019"

SA 35

975"

SA 36 019"

Single

Model

. -

clutch Sales designation F & S GFM 330 K replaced by F & S GMF 330

Installation

Series

Double Model

- - - -

-

clutch

Sales designation

DT 3301310 G

-

DT 3301310 G

-

DT 3301310 G

----

Installation SA 35

741

-

SA

35

7!11

-

SA

35

741

Converter Model

-

- - -

-

clutch Sales designation

WSK 310

-

WSK 310

-

Installation SA 35 948

-

SA

35 948

-

Main Model 717.901 or 717.900 7t7.901

transmission

Sales designation UG

3140

- 13,01

GPA"

UG

3140

- 13,01 GPA

Installation

Series or

SA

Series

ft,ith SA 35 977"1

Series

Auxiliary Model Working or crawler gear

-

transmission

Sales designation

NG

3140 -215,

76

'"

-

Installation

SA

35 736

-

Power

Version

PTO shaft with pump connection

iake'off Ratio i

= 1

Maximum speed

1/min

2800

'

..

Instalation SA 35 925

Version

PTO shaft

Ratio i

=

0,71

. Maximum speed 1/min

4000

Installation

SA

35 925

Hydrostatic Manufacturer

Unde units

-

system Sales designation

Gr.

70/75

-

.-----

Installation SA 36 036

-

PTO shaft

Version

Engine

and

transmission

shaft

4)

--,..----.

Transmission Engine

and

transmission

shaft

1]

31

transmission

shaft

..

_---

Ratio

i = 4,32

SI/or

4,32

6)/2,46

7)

i = 4,32 '

I·

4,32

61

2,46 "

---,-"

Maximum speed 1/min 540lmin/or 540/1000/min

540

540:1000Imin.

._-_.

Installation

SA

35 737

SA

35

73714

SA

35737

-

Version

Fast engine and transmission PTO shaft

-

'"

Ratio i = 0,745

-

i"

0,745

Maximum speed 1/min

3700

-

3700

Installation

SA

35 926

-

SA

35

926

UKD

30 402

21

42-03

1.1/1

00 General

Installation

Survey

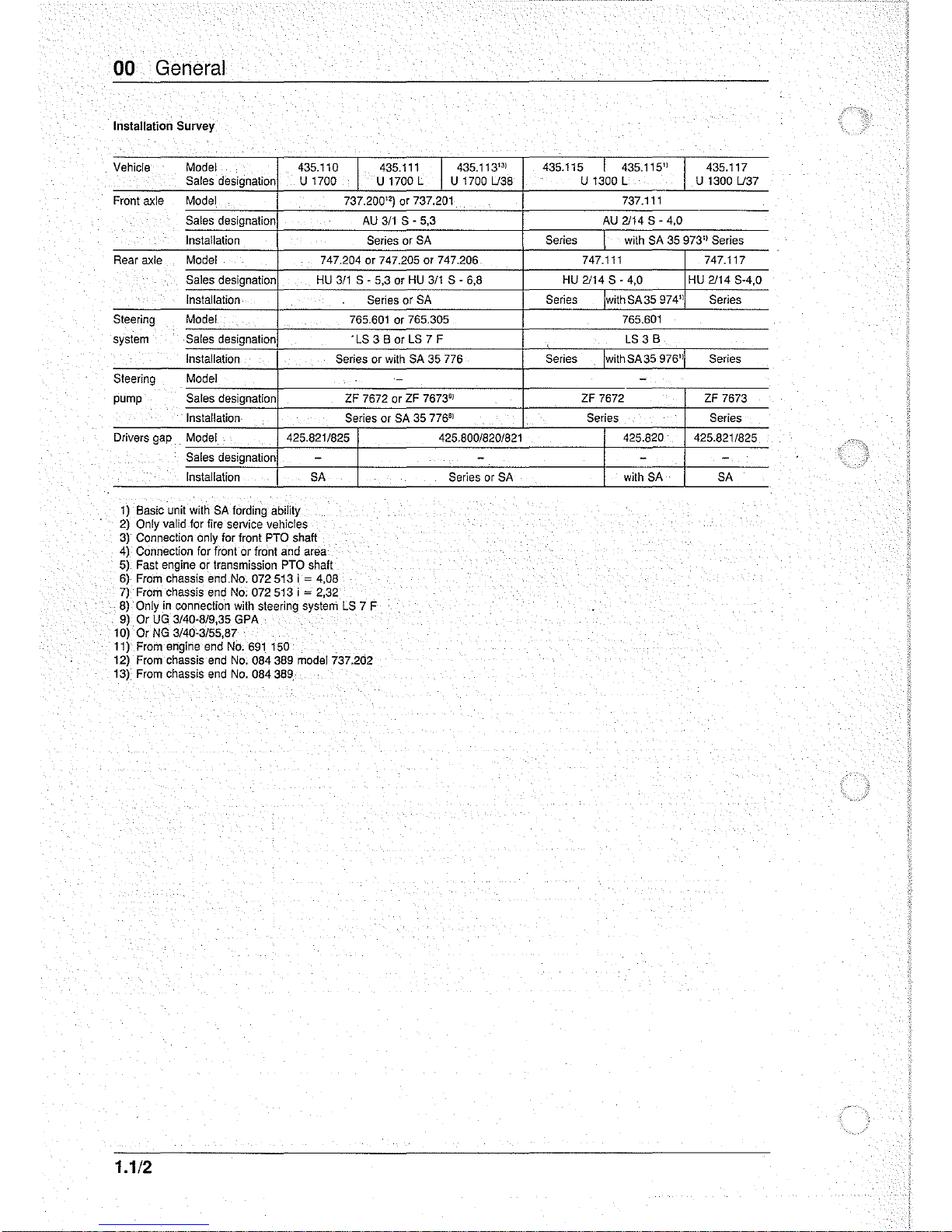

Vehicle Model 435.110 435.111

I 435.113'"

435.115

I 435.115" 435.117

Sales designation U 1700 U 1700 L U 1700 U38 U 1300 L U 1300 U37

Front axle

Model

737.200") or 737.201

737.111

Sales designation

AU

311

S - 5,3

AU

2114

S - 4,0

Installation Series or SA

Series

with SA 35 973" Series

Rear axle Model 747.204 or 747.205 or 747.206 747.111 747.117

Sales designation

HU

311

S - 5,3 or

HU

311

S - 6,8

HU

2114

S - 4,0

HU

2114

S-4,0

Installation Series

or SA

Series

withSA35974"

Series

Steering Model 765.601 or 765.305 765.601

system

Sales designation

-LS3BorLS7F

LS

3 B

Installation

Series or with SA 35 776

Series

withSA35976"

Series

Steering

Model

-

-

pump Sales designation

ZF 7672 or ZF 7673"

ZF 7672

ZF

7673

.

Installation

Series

or SA 35

776"

Series

Series

Drivers gap Model 425.8211825

425.80018201821

425.820 425.8211825

Sales designation

- - - -

Installation

SA

Series or SA

with SA

SA

1)

Basic unit with SA fording ability

2)

Only valid for fire service vehicles

3)

Connection only for front PTO shaft

4) Connection for front or front and area

5) Fast engine or transmission

PTO shaft

6)

From chassis end.No.

072513

i = 4,08

7)

From chassis end No. 072 513 i = 2,32

8)

Only

.in

connection with steering system

LS

7 F

9)

Or UG

3140-819,35

GPA

10) Or

NG

3140-3155,87

11) From engine end No.

691

150

12) From chassis end

No.

084389

model 737.202

13) From chassis end

No.

084389

1.1/2

General 00

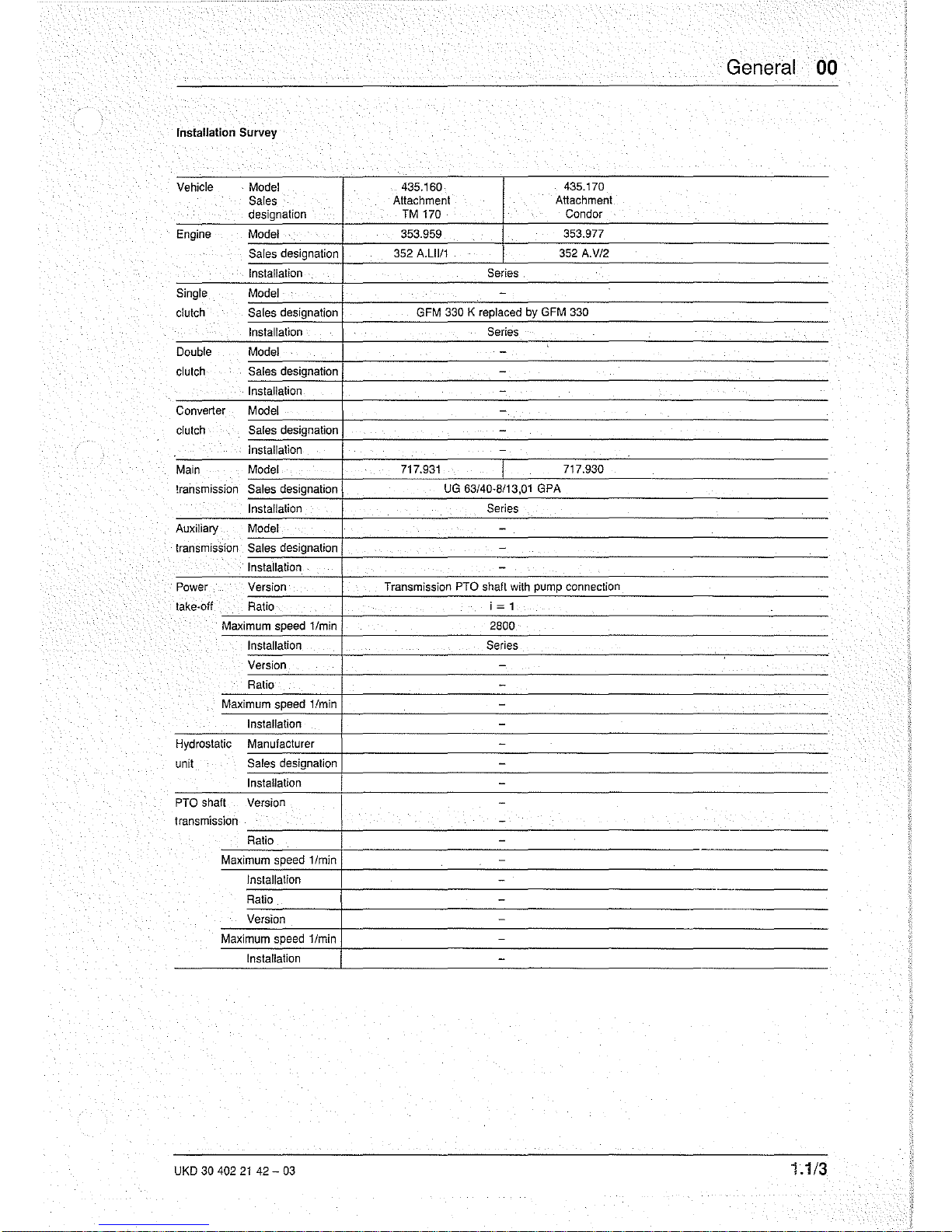

Installation

Survey

Vehicle

. Model

435.160

435.170

Sales

Attachment

Attachment

designation

TM

170 Condor

Engine Model

353.959 353.977

Sales designation 352 A.LIII1 352 A.V!2

Installation Series.

Single

Model -

clutch

Sales designation

GFM 330 K replaced by GFM 330

Installation

Series

.

Double Model

-

clutch Sales designation

-

Installation -

Converter Model -

.

clutch Sales designation

-

Installation

-

Main Model 717.931

717.930

!ransmission

Sales designation

UG

63/40-8/13,01 GPA

Installation

Series

Auxiliary

Model

-

transmission

Sales designation

-

Installation

-

Power

Version

Transmission

PTO

shaft

with

pump

connection

take·off

Ratio i = 1

Maximum speed

1/min 2800

.

Installation

Series

Version

-

Ratio

-

Maximum speed

llmin

-

Installation

-

Hydrostatic

Manufacturer

-

unit

Sales designation

-

Installation

-

PTO shaft

Version

-

transmission

-

Ratio -

Maximum speed

llmin

-

Installation

-

..

Ratio

-

Version

-

Maximum speed

limin

-

Installation

-

UKD 30 402

21

42 -

03

1.1/3

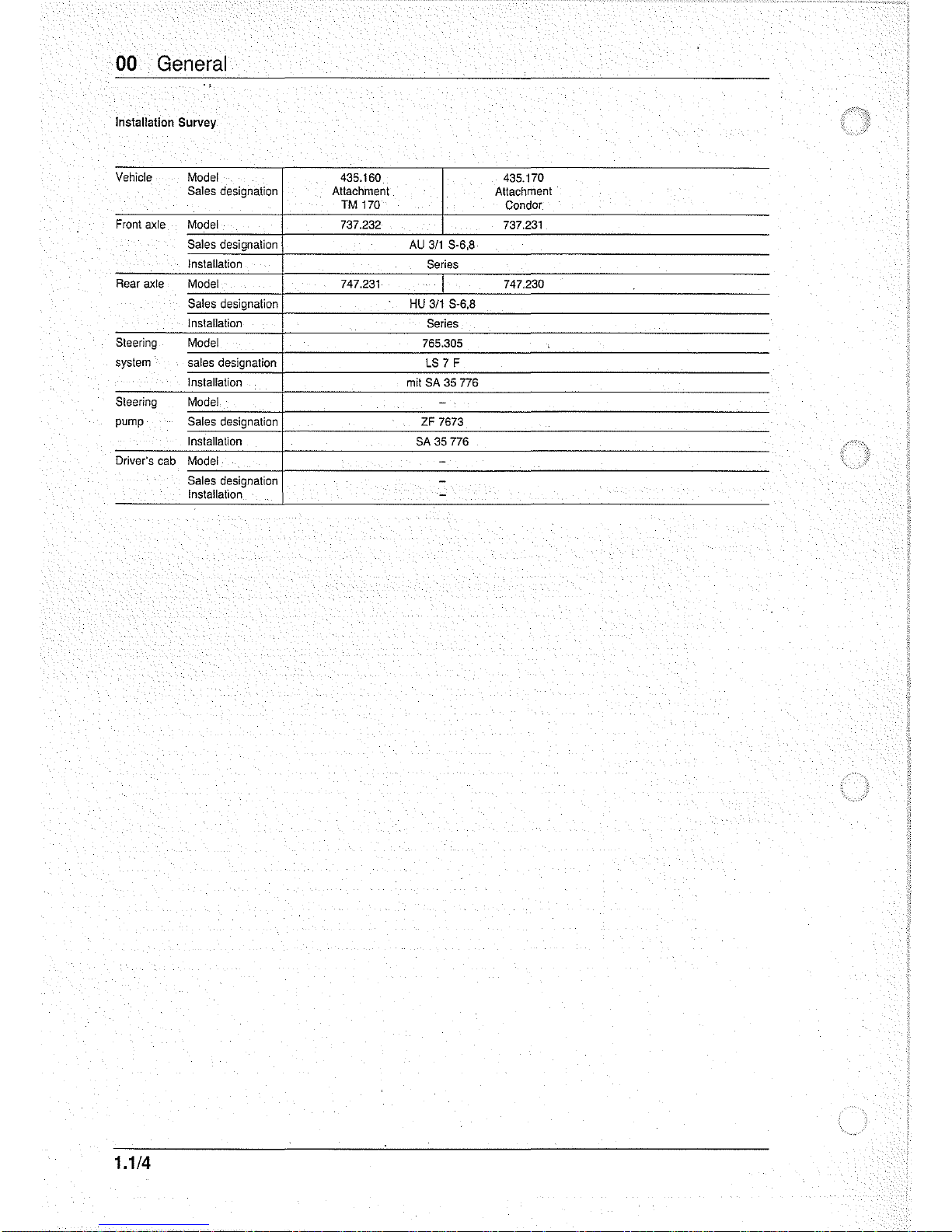

00 General

Installation

Survey

Vehicle Model 435.160

435.170

Sales designation Attachment Attachment

TM 170

Condor

Front

axle Model

737.232 737.231

Sales designalion

AU

3/1

S·6,8

Installation

Series

Rear axle

Model

747.231 747.230

Sales designation

HU

3/1

S-6,8

Inslallalion

Series

Sleering

Model

765.305

system

sales

designation

LS

7 F

Installation

mil

SA 35 776

Sleering Model

-

pump

Sales

designation

ZF 7673

Inslallalion

SA

35 776

Driver's

cab

Model

-

Sales designalion

-

Installation

-

1.1/4

General

00

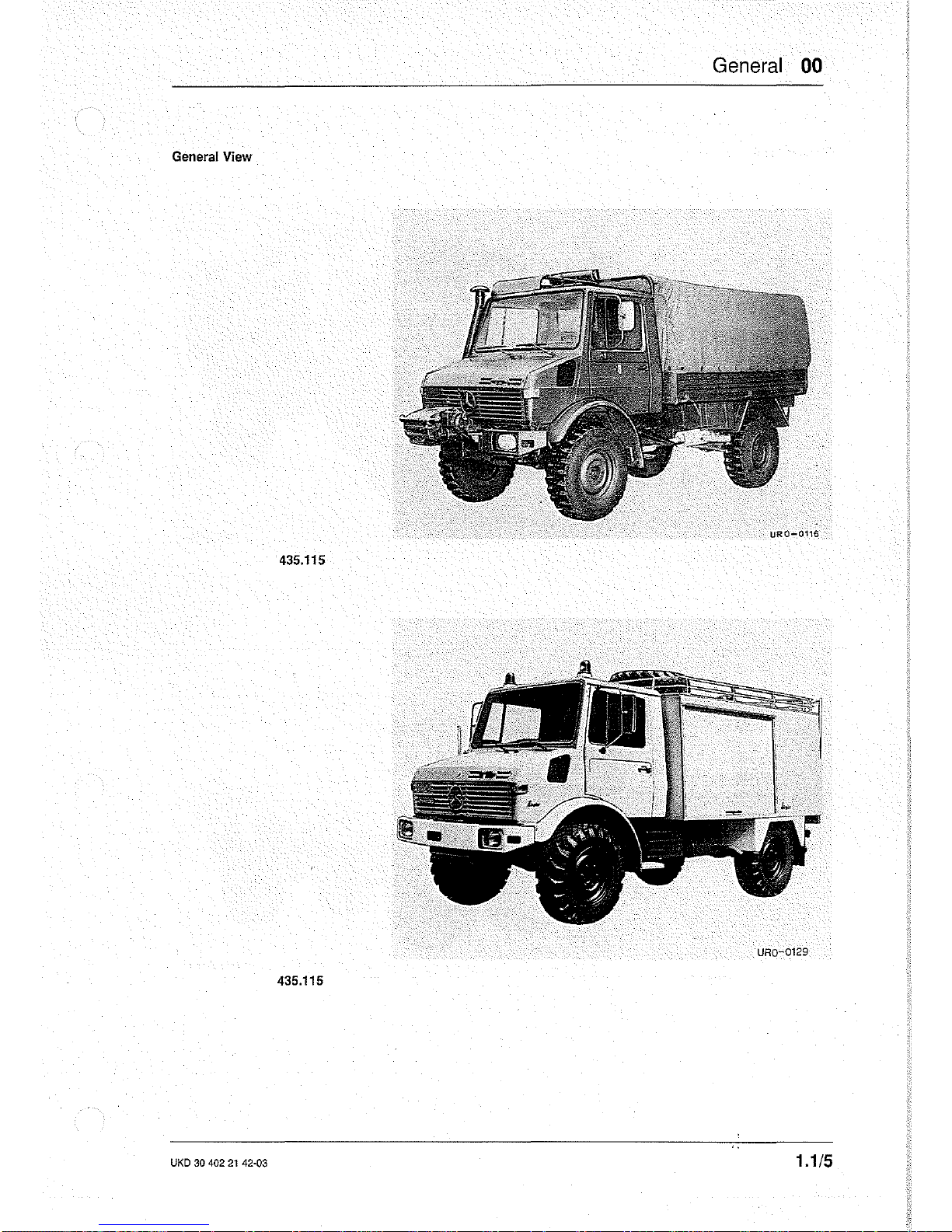

General

View

435.115

URO-0129

435.115

UKD

30 402

21

42'()3

1.1/5

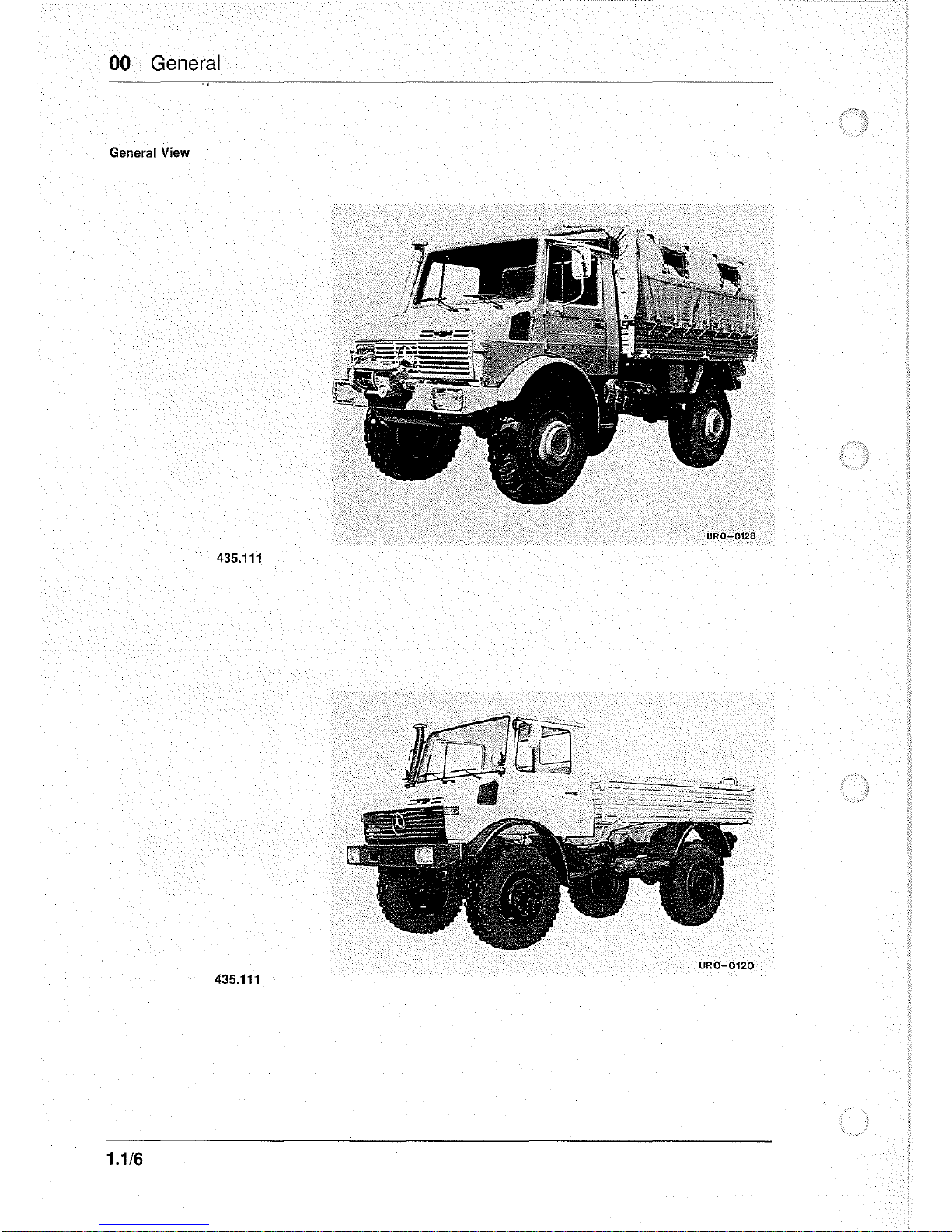

00 General

General View

URO-0128

435.111

URO-0120

435.111

1.1/6

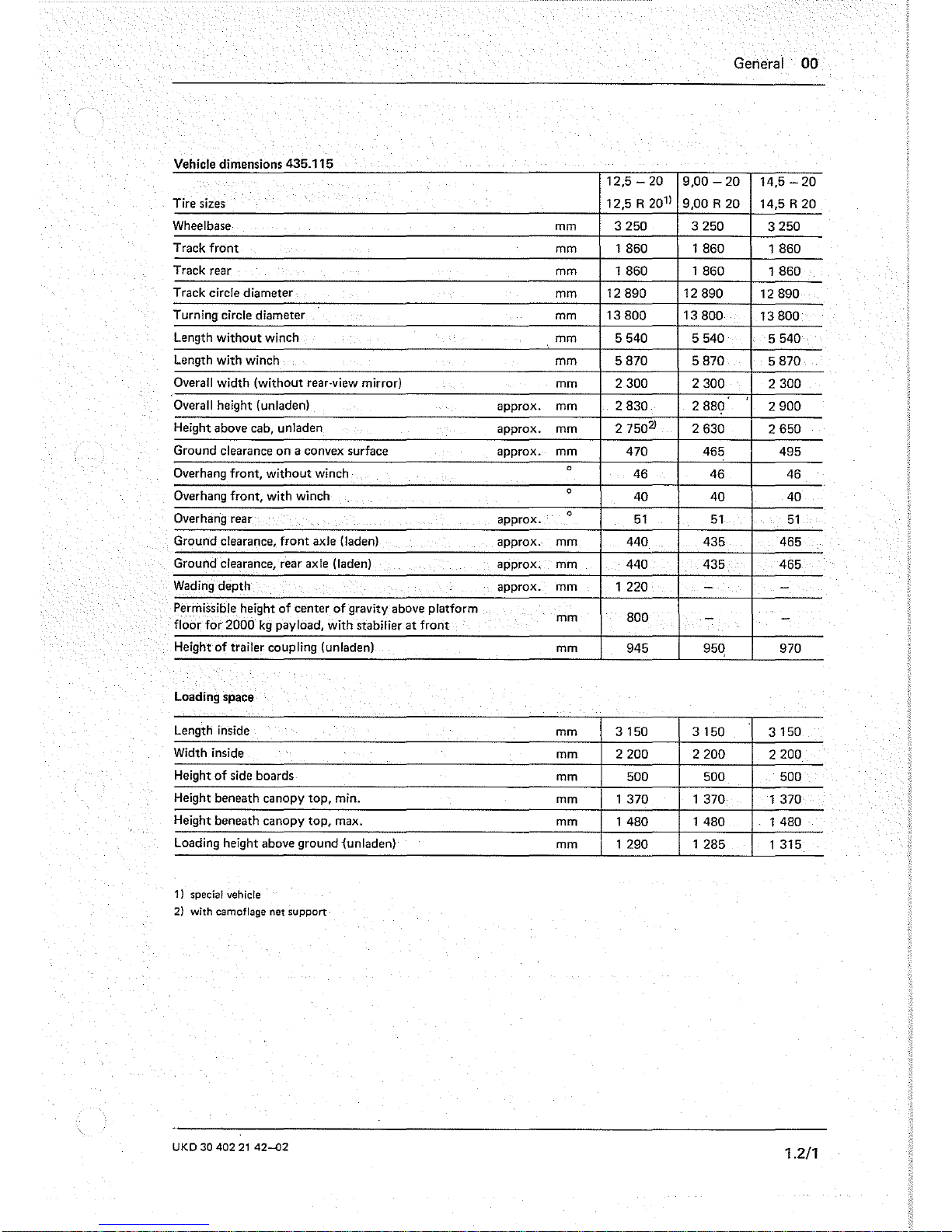

General

00

Vehicle dimensions

435115

12,5

-20

9,00 - 20

14,5 - 20

Tire

sizes 12,5 R 20

11

9,00 R 20

14,5 R 20

Wheelbase

mm

3250

3250

3250

Track

front

mm 1 860

1

860 1 860

Track rear

mm

1 860

1860

1860

Track circle diameter

mm

12890

12890

12890

Turning circle diameter

mm

13800 13800

13800

Length

without

winch

mm

5540

5540 5540

Length

with

winch

mm

5870 5870

5870

Overall

width

(without

rear·view mirror)

mm

2300

2300

2300

Overall height (unladen)

2830

2880

,

2900

approx. mm

Height above

cab,

unladen

approx. mm

27502)

2630

2650

Ground clearance on a convex surface

approx. mm

470 465 495

Overhang

front,

without

winch

0

46

46 46

Overhang

front,

with

winch

0

40

40

40

Overhang rear

0

51

51

51

approx.

Ground

clearance,

front

axle (laden)

approx.

mm

440 435

465

Ground

clearance, rear axle (laden)

approx. mm

440

435

465

Wading depth

approx. mm

1 220

- -

Permissible height

of

center

of

gravity above

platform

mm

800

-

-

floor

for

2000

kg

payload,

with

stabilier at

front

Height

of

trailer coupling (unladen)

mm

945 950 970

loading

space

Length inside

mm

3150 3150 3150

Width inside

mm

2200

2200

2200

Height

of

side boards

mm

500 500 500

Height beneath canopy

top,

min.

mm 1

370 1 370

1370

Height beneath canopy top, max.

mm

1480

1 480

1480

Loading height above ground -(unladen)'

mm 1 290 1 285

1 315

1) special vehicle

2) with camoftage net support

UKO

30

402

21

42-02

1.2/1

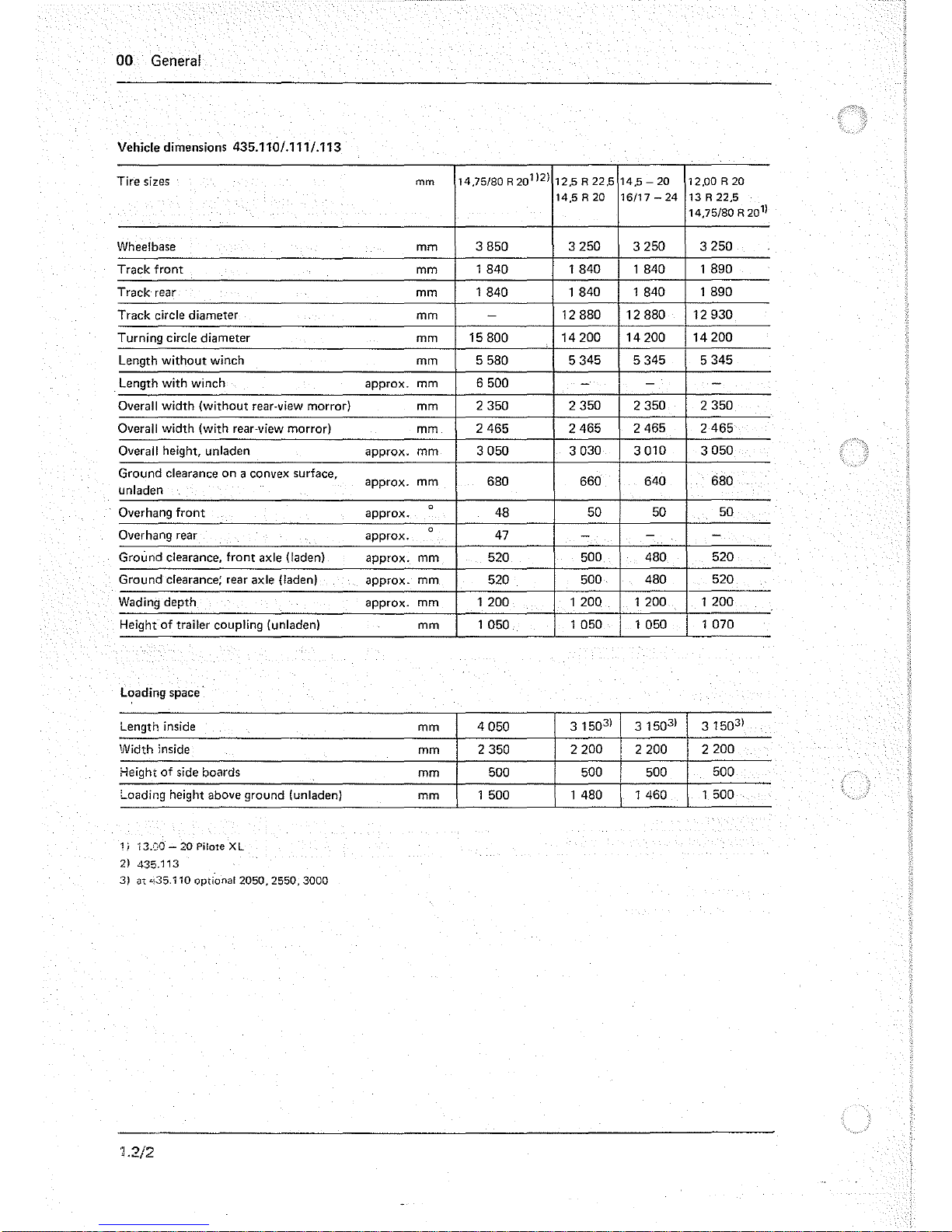

00

General

Vehicle dimensions 435.110/.111/.113

Tire sizes

mm

14}5/80

R

201)2)

12.5R22.5

14.5

- 20

12.00 R 20

14.5 R 20

16/17-24

13 R 22.5

14.75/80

R

20

1

)

Wheelbase mm

3850

3250

3250 3250

Track

front

mm

1840

1840

1 840 1 890

Track rear

mm

1840

1 840

1840

1 890

Track

circle diameter

mm

-

12880

12880

12930

Turning circle diameter mm

15800

14200

14200

14200

Length

without

winch

mm

5580

5345 5345 5345

Length

with

winch approx. mm

6500

-

-

-

Overall

width

(without

rear·view morror) mm

2350

2350 2350

2350

Overall

width

(with

rear·view morror)

mm

2465 2465

2465

2465

Overall height, unladen

approx. mm

3050

3030

3010

3050

Ground clearance on a convex surface,

unladen

approx. mm

680

660 640 680

Overhang

front

0

48 50

50

50

approx.

Overhang rear

0

47

approx.

-

-

-

Ground clearance,

front

axle (laden)

approx. mm

520

500

480

520

Ground clearance; rear axle (laden) approx. mm

520

500 480

520

Wading depth approx. mm 1 200 1 200

1200

1 200

Height

of

trailer coupling (unladen) mm

1050

1050

1050

1 070

Loading

space

Length inside

mm

4050

3 150

3

)

3 150

3

)

3150

3

)

Width inside

mm

2350

2200

2200

2200

Height

of

side

boards

mm

500

500 500 500

L.oading

height above ground (unladen)

mm 1

500 1 480

1460

1 500

1;

13.>:'0

- 20 Pilate

XL

2)

435.113

3)

at

L~35.110

opti'onal2050, 2550,

3000

'1.2/2

c

"

o

'"

o

"

:;l

'Y

I:>

~

......

~

------.-==--~~-~

0'

"-

....

JC[]

ffi\

• I • 3250 • I

I-

-5560 • I

A Unladen

B At maximum load

C Unladen

o Upper edge of frame

E Upper edge of floor

F Laden

iil

f

I

I

I

II

I I I I I

G Unladen

H Transit loading dimension

J Inside length

= , -

;;:

o

o

,

o

o

N

:::>

\

I ;

I~

, \ I

-<

(JJ

..

"O::r

<1>

_,

Q.2.

!!C

..

<e:

~3

_

...

!2"

<1>

en

:; 0'

;::;'::l

::Ten

0'

....

0""

Xu.

~~

"0

~

mu.

8:

:::.

G)

CD

::J

CD

@

o

o

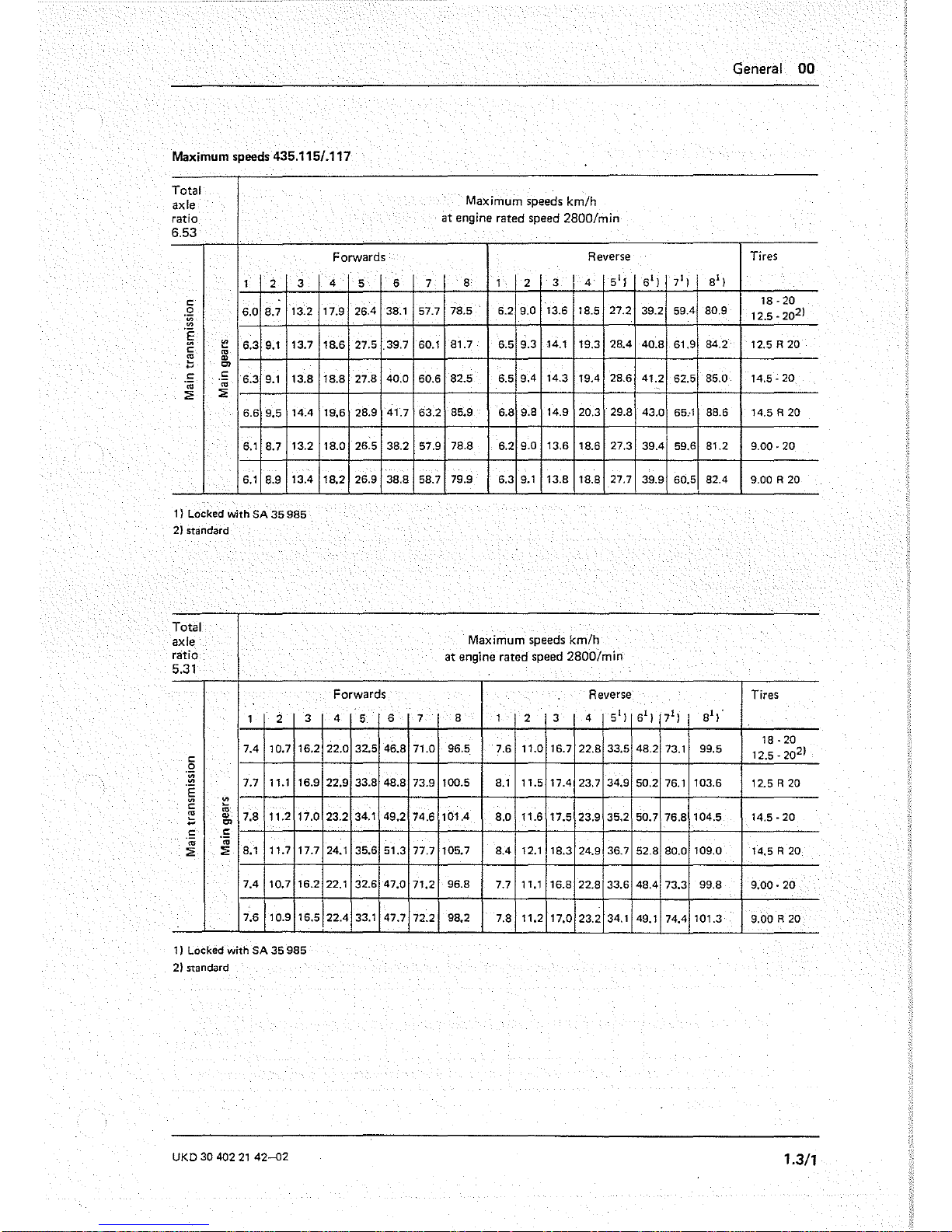

Maximum speeds 435.115/.117

Total

axle

ratio

6.53

1 2

3

c:

.~

6.0

8.7

13.2

~

.~

t::!

6.3

9.1

13.7

c:

'"

b

"

Cl

.S

c:

6.3

9.1

13.8

'"

.;;

:;;

:;;

6.6

9.5

14.4

6.1

8.7

13.2

6.1

8.9

13.4

1) Locked with

SA

35

985

2} standard

Total

axle

ratio

5.31

1 2

3

7.4

10.7

16.2

c:

.~

7.7

11.1 16.9

'E

c:

~

:;;

b

"

7.8

11.2

17.0

Cl

.S

.S

'"

'"

:;;

:;;

8.1 11.7

17.7

7.4

10.7

16.2

7.6

10.9 16.5

1)

Locked with

SA

35

985

2) standard

UKD

30

402

21

42--D2

Forwards

4

5

6

17.9 26.4 38.1

la6

27.5

.39.7

18.8

27.8

40.0

19.6

28.9

41.7

18.0

26.5

38.2

18.2

26.9

38.8

Forwards

4

5

6

22.0

32.5

46.8

22.9

33.8

48.8

23.2

34.1

49.2

24.1

35.6

51.3

22.1 32.6

47.0

22.4

33.1 47.7

7

57.7

60.1

60.6

63.2

57.9

58.7

7

71.0

73.9

74.6

77.7

71.2

72.2

General

00

Maximum speeds km/h

at

engine rated speed 2800/min

Reverse

Tires

8 1 2 3

4

51

f

61) 71 )

81)

18·20

78.5

6.2

9.0

13.6

18.5

27.2

39.2 59.4

80.9

12.5 -

20

2

)

81.7

6.5

9.3

14.1

19.3

28.4

40.8

61.9

84.2

12.5 R

20

82.5

6.5

9.4

14.3

19.4

28.6

41.2

62.5

85.0 14.5 -

20

85.9

6.8

9.8

14.9

20.3

29.8

43.0

65

..

1

88.6 14.5 R

20

78.8

6.2

9.0

13.6

18.6 27.3

39.4

59.6

81.2

9.00·20

79.9

6.3

9.1

13.8

18.8 27.7

39.9

60.5

82.4

9.00 R 20

Maximum speeds km/h

at engine rated speed

2800/min

Reverse

Tires

8 1

2 3

4

51

)

61 ) 71)

81,'

96.5. 7.6

11.0 16.7

22.8

33.5

48.2

73.1

99.5

18 -

20

12.5 - 20

21

100.5

8.1

11.5 17.4

23.7

34.9

50.2

76.1

103.6

12.5R20

101.4

8.0

11.6 17.5

23.9

35.2

50.7

76.8

104.5

14.5 -

20

105.7

8.4

12.1 18.3

24.9

36.7

52.8

80.0

109.0

14.5 R 20

96.8

7.7 11.1 16.8

22.8

33.6

48.4

73.3

99.8

9.00 -

20

98.2

7.8 11.2

17.0

23.2

34.1

49.1 74.4

101.3

9.00

R 20

1.3/1

00 General

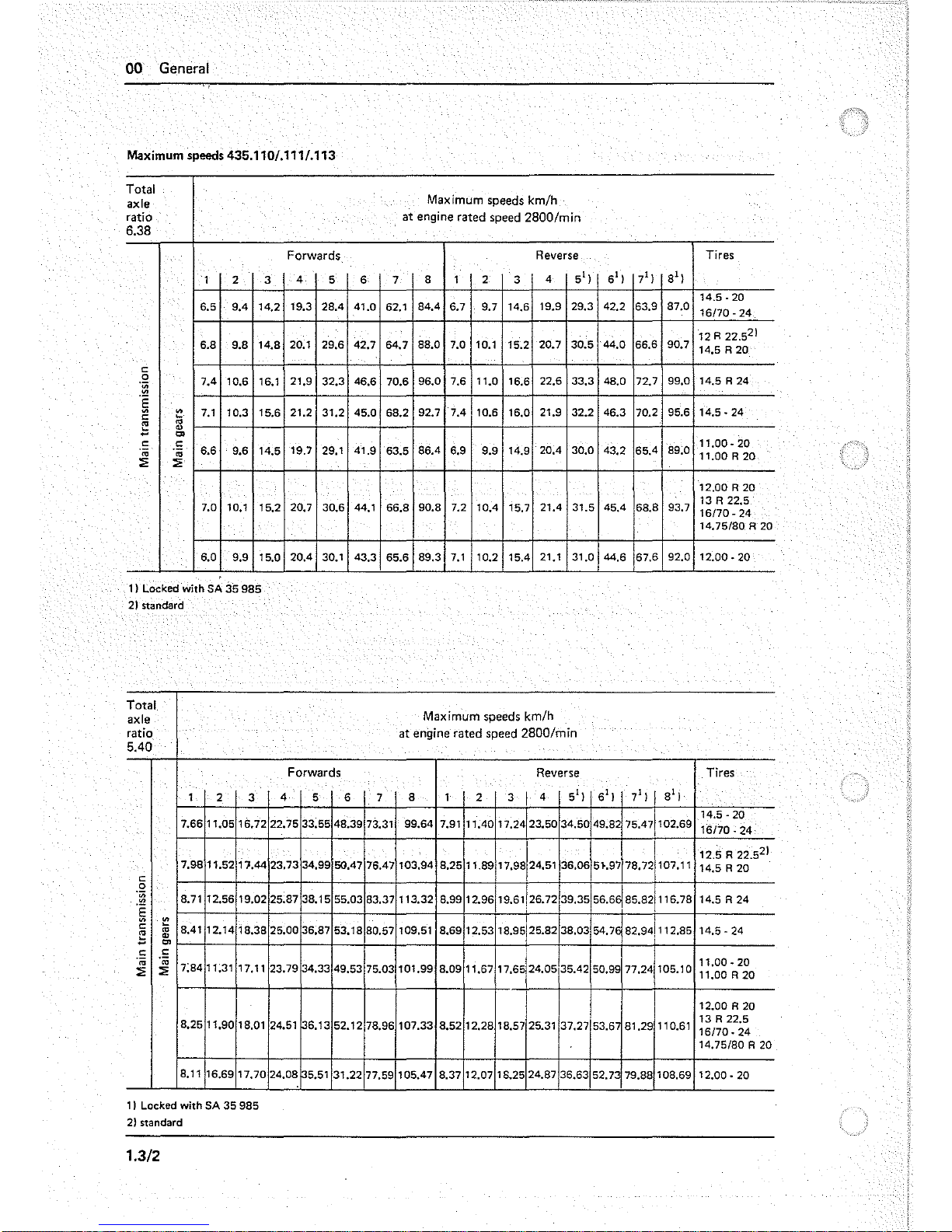

Maximum

speeds 435.110/.111/.113

Total

axle

Maximum speeds km/h

ratio at engine rated speed

2800/min

6.38

Forwards

Reverse

1 2 3

4

5 6 7

8 1 2

3

4

5'}

6'}

7'

}

8'}

6.5

904

14.2 19.3 2804

41.0

62.1

84.4

6.7 9.7 14.6

19.9 29.3

42.2

63.9

87.0

6.8

9.8

14.8

20..1

29.6

42.7

64.7

88.0

7.0

10..1

15.2 20.7 30..5 44.0.

66.6

90..7

c:

0

7.4

10..6 16.1

21.9

32.3

46.6

70..6

96.0.

7.6 11.0.

16.6

22.6

33.3

48.0 72.7

99.0

oB;

"§

~

7.1

10.3 15.6

21.2

31.2

45.0.

68.2

92.7

704

10..6

16.0

21.9 32.2

46.3

70..2 95.6

c:

~

..

"

'"

c:

c:

.n;

.n;

6.6

9.6

14.5

19.7

29.1

41.9

63.5

86.4

6.9

9.9

14.9

20.04

30.0

43.2

65.4

89.0

:2 :2

7.0

10..1

15.2

20..7

30..6

44.1

66.8

90..8 7.2

lOA

15.7

21.4

31.5

4504

68.8

93.7

6.0.

9.9

15.0.

20.04

30..1

43.3

65.6

89.3

7.1

10.2

1504

21.1

31.0

44.6

67.6

92.0

I} Locked with SA

:is

985

2)

standard

Total

axle

ratio

5.40

1

2

3

7.66

11.0.5

16.72

7.98

11.52

17.44

c:

0

.~

8.71 12.56

19.0.2

.~

~

c:

:;;

8041

12.14

18.38

~

"

~

Cl

.!:

c:

'"

.n;

7;84 11;31

17.11

:2

:2

8.25

11.90.

18.0.1

8.11

16.69

17.70.

1}

Locked with SA

35

985

2} standard

1.3/2

Forwards

4

5 6 7

22.75

33.55

48.39 73.31

23.73

34.99

50047

76.47

25.87

38.15

55.0.3

83.37

25.00

36.87

53.18

80.57

23.79

34.33

49.53 75.0.3

24.51

36.13

52.12

78.96

24.08

5.51

31.22

77.59

Maximum speeds km/h

at

engine rated speed 2800/m

in

Reverse

8 1

2 3

I

4

5'

}

6'}

7'}

I

8'}

99.64

7.91

11040.

17.24

23.50

34.50. 49.82

75047

102.69

17.98/24.51

I

10.3.94

8.25

11.89

36.06

5}.97

78.721107.11

113.32

8.99

12.96

19.61 26.72

39.35

56.6~

85.821,,6.78

I

f

109.51

8.69

12.53

18.95125.82

38.0.3 54.76

82.941112.85

10.1.99 8.0.9

11.67

17.65124.05

35042

50.99

77.24

105.10

107.33

8.52

12.28

18.57

25.31

37.27153.6

81.29

110.61

105.47

8.37 12.07 18.25

24.87

36.63

52.73 79.88 108.69

Tires

14.5·20

16170.·24

12 R 22.5

2

}

14.5

R2o.

14.5

R 24

14.5·24

11.0.0.·20.

11.DDR2D

12.00R2D

13R22.5

16170.·24

14.75/80 R 20

12.00.·20.

Tires

14.5·20

16/70.·24

12.5

R 22.52}

14.5 R 20

14.5 R 24

14.5·24

11.00·20

11.0.0. R 20

12.00R20

13 R 22.5

16170.·

24

14.75/80 R 20

12.00.·20.

General 00

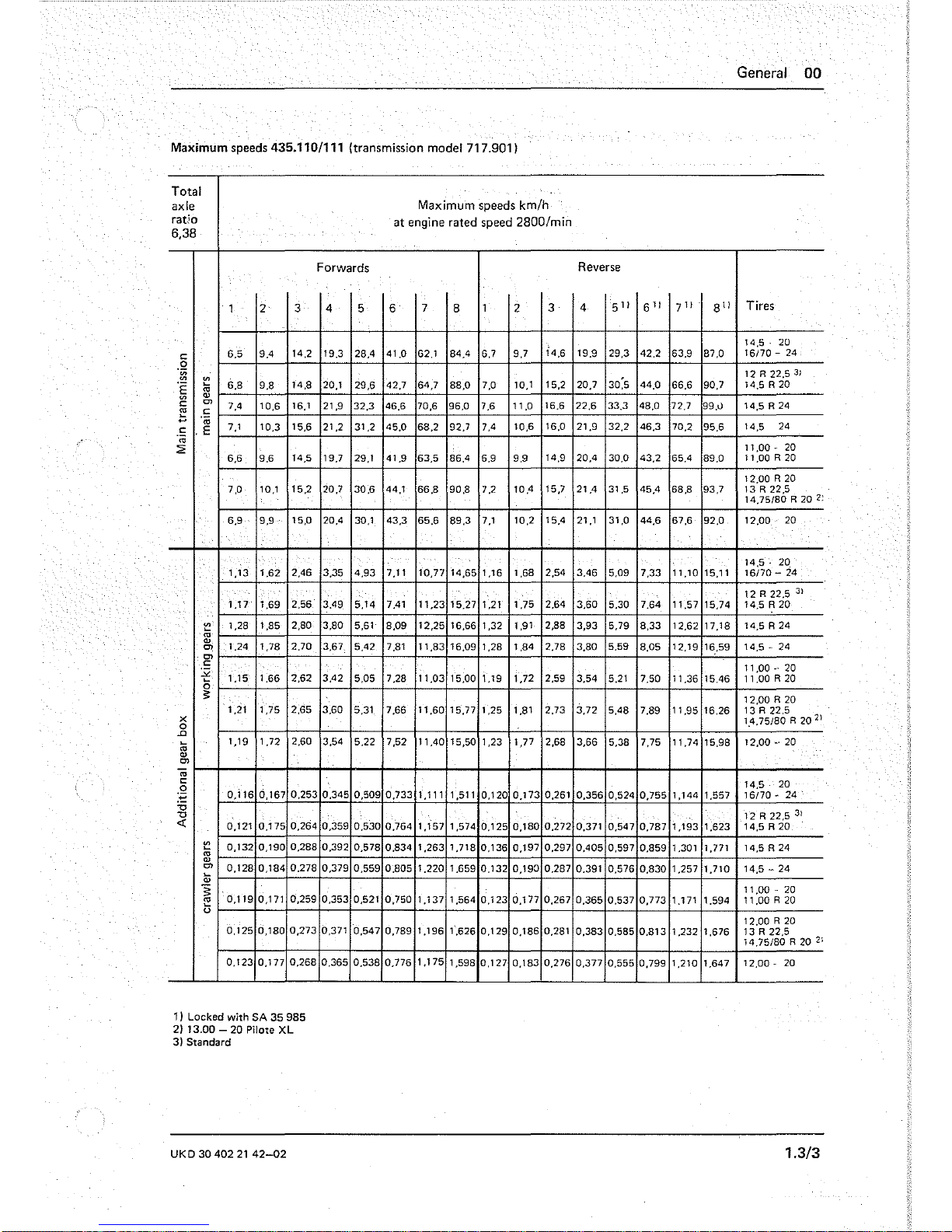

Maximum speeds 435.110/111 (transmission model 717.901)

Total

axle

Maximum speeds km/h

ratio

at

engine rated speed 2800/min

6,38

Forwards

Reverse

1 2 3 4 5 6

7

8

1

2

3 4

5"

6"

7"·

8

'1

Tires

14.6

14,5 ' 20

c:

6.5

9.4

14.2

19.3

28.4

41.0

62.1 84.4

6.7

9.7

19.9

29.3

42.2

63.9 87.0

16170 - 24

.~

12

R 22.5

3)

~

~

30;5

.~

'"

6.B

9.8

14,8

20.1

29.6

42,7

64,7

88.0 7.0 10.1

15.2

20,7

44.0

66.6

90.7

14.SR20

<1>

c:

'"

7.4

10.6

16,1

21,9

32,3

46,6

70,6

96,0

7.6

11,0

16,6

22.6

33,3

48,0

72.7

99.0

14.SR24

t:

c:

'm

c:

.E

7.1

10.3 15.6 21.2

31,2

45,0

68.2

92,7

7.4

10.6

16,0

21.9

32.2

46.3

70,2

95.6

14,5

24

'm

:2

11,00

¥ 20

6.6

9.6

14,5

19,7

29,1

41,9

63,5

86,4

6.9 9.9

14,9

20,4

30.0

43,2

65,4

89.0

11,OOR20

12.00A20

7.0

10.1 15.2 20.7

30.6

44,1

66.8

90.8 7.2

10,4

15.7

21.4

31,5

45,4

68.8

93,7

13 R 22,5

14.75/80 R 20

2;

6.9 9.9

15,0

20,4

30,1

43,3

65.6

89.3

7.1

10,2

15,4

21,1

31.0

44,6

67,6

92.0

12,00

20

14.5·

20

1,13

1.62

2,46

3.35

4,93

7,11

10,77

14,65

1,16

1,68

2,54

3.46

5.09

7,33

11,10

15,11

16170 - 24

12R22.5

3

}

1.17

1.69

2.56

3.49

5.14

7.41

11.23

15.27 1.21

1.75

2.64

3.60

5.30

7,64

11.57 15.74 14.5

A20

~

1,28

1,85

2.80

3.80

5.61 8.09

12.25

16,66

1.32 1,91 2.88

3,93

5.79

8.33

12.62

17,18

14,5 A 24

'"

<1>

'"

1

,24

1

,78

2.70

3.67

5.42

7,81

11.83

16,09

1,28

1,84

2.78

3.80

5.59

8.05

12,19

16.59

14.5 -24

'"

c:

11.00 .. 20

:;;

0

1.15 1.66 2.62

3.42

5.05 7.28

11.03

15.00

1,19

1.72

2.59

3.54

5.21

7.50 11.36 15.46

11.00 A 20

;:

12.00A20

1,21

1.75

2.65

3.60

5.31 7.66

11.60

15.77

1.25

1.81 2.73

3.72

5.48 7.89

11.95

16.26

13A22.5

x

1,4.75/80 R

20

2

)

0

.c

~

1,19

'"

1.72

2.60

3.54

5.22 7.52

11.40

15,50

1.23

1.7

7

2.68

3.66

5.38

7.75

11.74

15.98

12.00

-'

20

<1>

'"

m

c:

14,5

20

:~

0.116

0.167 0.253 0.345 0.509

0.733

1,11 1 1,511

0.120

0,173

0.261

0.356

0,524

0.755

1,144

1.557

16170-

24

'0

12R22,5

31

'0

<>:

0.121

0,175

0.264

0.359

0.530 0.764

1.157 1.574

0.125 0.180

0.272

0.371

0.547 0.787

1.193

1.623

14,5 A 20

~

0,132

0,190

0,288

0.392

0.578 0.834

1,263

1,718

0,136

0,197

0.297

0.405

0.597 0.859

1,301

1,771

14,5 R 24

~

'"

<1>

'"

0.128

0,184

0.278

0,379

0.559 0.805

1.220

1.659

0,132

0,190

0.287

0.391

0.576 0.830

1,257 1,710

14,5 -24

~

<1>

~

11,00 -20

'"

0,119

0.171 0.259

0.353

0.521

0.750

1,137

1.564

0,123

0.177 0.267

0.365

0,537

0,773

1 ,171

1.594 11.00 A 20

t;

12,OOR20

0.125

0,180

0,273

0,371

0.547 0.789

1,196

1,626

0,129

0.186

0.281

0.383

0.585

0.813

1,232

1,676

13 R 22,5

14.15/80

A 20 "

0.123

0,177

0.268 0.365

0.538

0.776

1.175

1,598

0,127 0,183

0.276

0,377

0.555 0.799

1,210 1,647

12,00

- 20

1) Locked

with

SA

35

985

2)

13.00 -20

Pilote

XL

3) Standard

UKD

30

402

21

42-02

1.3/3

00

General

Maximum speeds 435.110/.111 (transmission model 717.900)

Total

axle

Maximum speeds

km/h

ratio

at engine rated speed

2800/min

6,38

Forwards

Reverse

1 2 3

4

5

6

7 8

1 2 3

4

51:

6"

7"

8"

Tires

14,5 -

20

c

9.0

12.5 17.1

0

23.3

32.7

45.4

62.1

84,4

9,3

13,0

17,7

24,1

33,8

46,9

64,0

87,0

16170

74

.~

12 A 22,5

31

.~

~

9,4

13.1

17,9

24.3

34.1

47,3

64.7

88.0

9.7

13,5

18,4

25.1

35,2

48,9

66.7

90.7

14,5 R

20

~

'"

c

"

10,3

14.3

19.5

26,5 37,2

51,6

70,6

96.0

10,6

14.7

20.1

27,4

38.4

53,4

72,8

99.0

14,5 R

24

E

on

~

C

,S

'0;

9.9

13,8

18,8

25.6

35.9

49.8

68.2

92,7

10,2 14.2

19,4

26.4

37.1

51.5

70.3

95.6

14,5

24

'"

E

:;:

11,00 -20

9,2

12.8

17,5

23,9

33.4

46.4

63,5

86.4

9.5

13.3

18,1

24,6

34.6

48,0

65,5

89.1

11,00 A 20

12.00

A 20

9,7

13.5

18,4

25,1

35,2

48.9

66,8

90.9

10,0

13,9

19.0 25,9

36,4

50.5

68.9

93,7

13 R 22.5

14,75/80

R 20

21

9.6

13,3 18,1

24,7

34,6 48,0

65.6

89,3

9,9

13,7

18.7

25,4

35,7

49,6

67,7

92,1

12,00 -20

14,5 - 20

1.57

2,18

2,97

4,05

5.68

7,88

10,78

14.66

1,62 2,25

3.07

4,18

5,86

8,14 11,11 15,11 16170 24

12R22.5

3l

1.63

2;27

3,10

4,22

5,92

8,21

11,23

15.28

1.69

2,34

3,20

4.35

6.11

8.49

11,57

15.75

14,SR20

~

:;;

1,78

2,48

3.38

4.61 6,46

8.96

12,26

16,67

1,84

2,56

3A9

4,75

6,67

9,26

12.63

17,19

14,5 R 24

"

on

1,72

2.39

3.27

4.45

6,24

8.66

11,84 16,10

1,78

2,47

3,37

4,59

6,44

8,94

12,20 16,60

14,5 - 24

on

t:

""

11,00

20

"

1 ,60 2,23 3,04

4,14

5,81

8.07

11,03 15,00

1.66

2,30

3.14

4,27

6,00

8,33

11,37

15,47 11.00

R 20

;:

12,00 A

20

x

1,69 2,34

3.20

4,36

6.12

8.48

11,60

15,78

1.74

2.42

3,30

4,50

6,31

8,77

11,95 16,27

13 R 22,5

0

14,75/80 R 20

2J

.0

~

1.66

2.30

3.15

4,28

6,01

8,34

11,40

15,51

2,38

4,42

6,20

11.75 15.98

12,00 - 20

'"

1 ,71

3,24

8.61

"

on

-;;;

c

0

14,5·

20

.;:;

0,162

0.225

0.307

0,418

0,586

0,813

1,111 1,511

0.167

0,232

0,316

0,431

0,605

0,840

1,145

1,558

16/70 -24

'0

'0

«

12 R 22.5

3)

0,168

0,234

0,319

0,435

0,610

0.847

1,158

1.575

0.174 0,242

0,330

0.449

0,630

0.875

1.193

1,624 14.5 A

20

~

0.184

0,255

0,349

~

0,475

0,666

0.924

1.264 1,719

0,190

0,264

0,360

0,490

0,688 0,955

1,302

1.772

14,5 R 24

'"

"

0.178

0,247

0,337

0,459 0,643

0,892

1,221

1,660

0.183

0,255

0,347

0,473

0664

0,922

1,258 1,711 14,5 -

24

C>

~

"

11,00-

20'

~

0,165

0.230

0.314 0,427

0,600

0,832

1.137 1,547 0,171

0,237

0.324

0,441 0,619

0.859

1,172

1.595

11.00 R 20

E

u

12.00 R 20

0,174

0.242

0,330

0.449

0.631

0,875

1,196

1.627

0,180

0,250

0,340

0.463

0,651

0,904

1.232

1,677

13 R 22.5

14,75/80 R 20

2)

0,171

0,238

0.324

0,442

0,620

0,860

1.175

1,600

0,176

0.245

0,334

0,455

0,693

0,888

1211

1,648

12,00

- 20

1) Locked with SA

35985

2) 13.00 -

20

Pilot.

XL

3) Standard

1.3/4

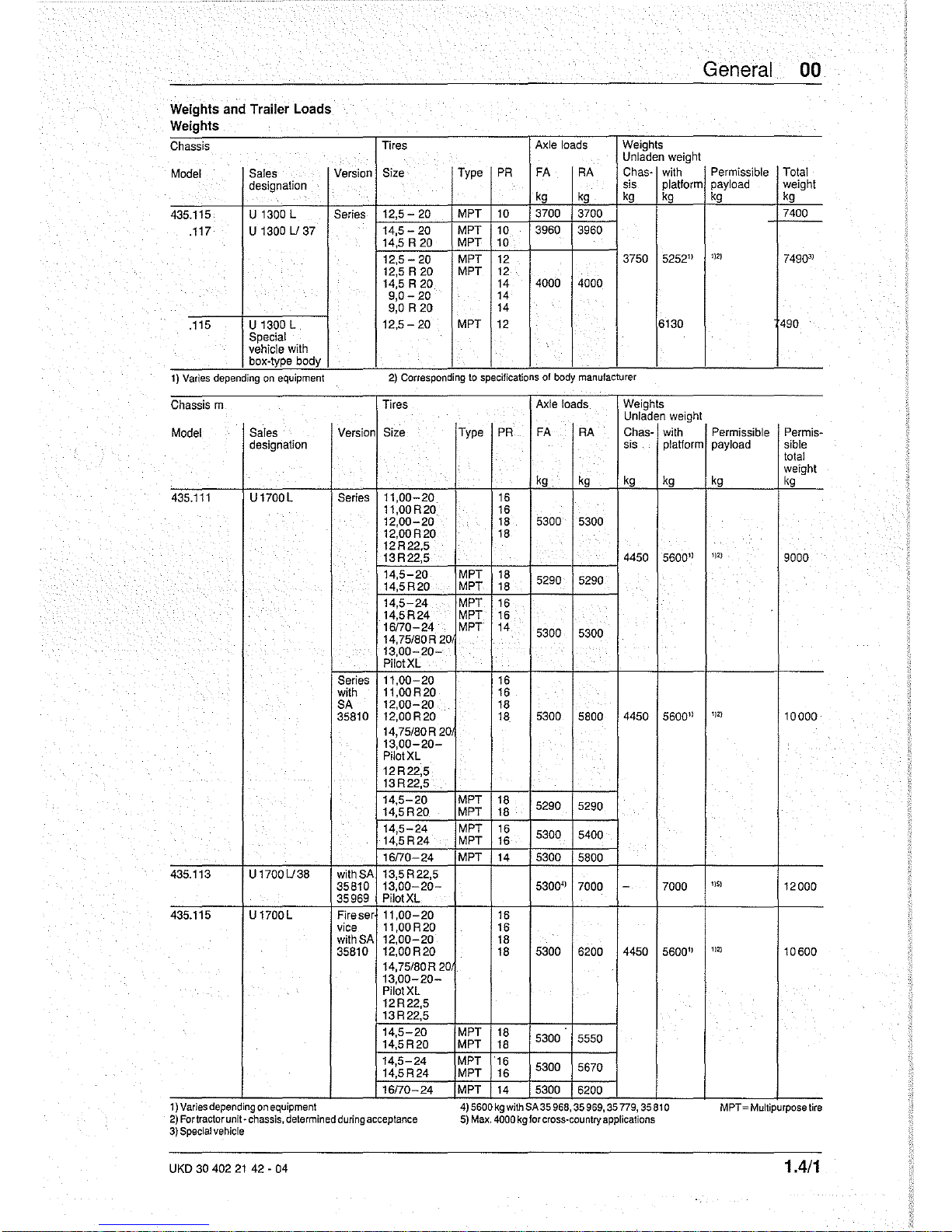

Weights

and

Trailer

Loads

Weights

Chassis

Model

Sales

designation

435.115 U

1300 L

.117

U1300U37

.115 U 1300 L

Special

vehicle with

box-type body

Tires

Version

Size Type

Series

12,5 - 20

MPT

14,5 -

20

MPT

14,5 R

20

MPT

12,5-20

MPT

12,5 R

20

MPT

14,5 R

20

9,0-

20

9,0

R 20

12,5 - 20 MPT

Axle loads

Weights

Unladen weight

PR

FA

RA

Chas-

with

sis

plaHorm

kg kg

kg

kg

10

3700 3700

10

3960 3960

10

12

3750

5252"

12

14

4000 4000

14

14

12

6130

>

1)

Varies

depending

on

equipment

2)

Corresponding

to

specificatIOns

of

body

manufacturer

Chassis m

Tires

Axle loads

Weights

Unladen weight

Model

Sales

Version

Size Type

PR

FA

RA

Chas-

with

designation

sis

platform

kg

kg

kg

kg

435.111

U1700L

Series

11,00-20

16

11,00

R20

16

12,00-20

18

5300

5300

12,00R20

18

12R22,5

13R22,5

4450

5600"

14,5-20

MPT

18

5290 5290

14,5R20

MPT

18

14,5-24

MPT 16

14,5R24

MPT

16

16170-24 MPT 14

5300

5300

14,75/80R 20

13,00-20Pilot XL

Series

11,00-20

16

with

11,00R20 16

SA

12,00-20

18

35810 12,00R20

18.

5300

5800

4450

5600"

14,75/80R 20

13,00-20Pilot XL

12R22,5

13R22,5

14,5-20

MPT

18

5290 5290

14,5R20

MPT

18

14,5-24

MPT

16

5300 5400

14,5R24

MPT

16

16170-24 MPT

14

5300

5800

435.113

U1700U38

with SA 13,5R22,5

35810

13,00-20-

5300" 7000

-

7000

35969 Pilot XL

435.115

U1700L

Fireser

11,00-20

16

vice

11,00R20 16

with

SA

12,00-20

18

35810

12,00R20

18

5300

6200

4450

5600"

14,75/80R

20

13,00-20-

Pilot XL

12R22,5

13R22,5

14,5-20

MPT

18

5300

5550

14,5R20

MPT

18

14,5-24

MPT

·16

5300

5670

14,5R24

MPT 16

16170-24 MPT

14

5300

6200

1)

Vanes

depending

on

equipment

4)

5600

kg

with

SA35

968,

35

969,

35

n9,

35810

2)

Fortractor

unit·

chassis,

determined

during

acceptance

5)

Max.

4000

kg

for

cross-country

applications

3)

Special

vehicle

UKD 30 402

21

42 - 04

General 00

Permissible

Total

payload weight

kg kg

7400

1)2)

7490"

490

Permissible

Permis-

payload sible

total

weight

kg

kg

1)2)

9000

I

1)2)

10000

I)S)

12000

1)2)

10600

MPT

=Multlpurpose

tlr8

1.4/1

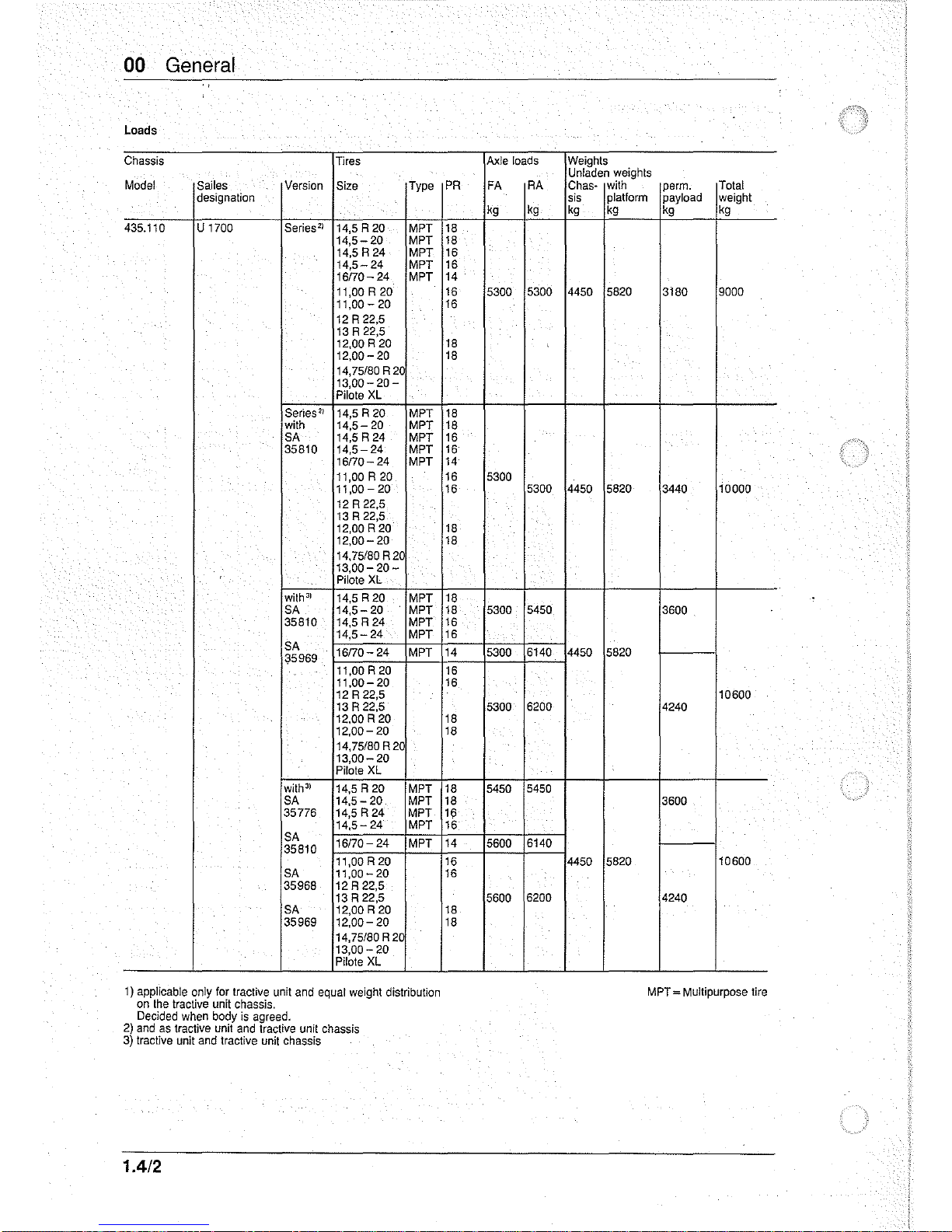

00 General

Loads

Chassis

Tires

Model Sailes

Version

Size Type

designation

435.110 U

1700

Series

Z

)

14,5 R 20 MPT

14,5-20

MPT

14,5 R 24

MPT

14,5-24

MPT

16170-24

MPT

11,00 R 20

11,00-

20

12 R 22,5

13 R 22,5

12,00 R

20

12,00-20

14,75/80 R

20

13,00-

20-

Pilots

XL

Series

Z

)

14,5 R 20 MPT

with

14,5-20

MPT

SA 14,5 R 24

MPT

35810

14,5-24

MPT

16170-24

MPT

11,00 R 20

11,00-20

12 R 22,5

13 R 22,5

12,00 R

20

12,00-20

14,75/80R20

13,00-

20-

Pi

late

XL

with

J

)

14,5 R 20

MPT

SA

14,5-

20 MPT

35810 14,5 R 24 MPT

14,5-24

MPT

SA

16170- 24

MPT

35969

11,00 R

20

11,00-20

12 R 22,5

13 R 22,5

12,00 R

20

12,00-20

14,75/80 R 20

13,00-20

Pilote

XL

with

3

)

14,5 R 20

MPT

SA 14,5 - 20 MPT

35776 14,5 R 24 MPT

14,5-24

MPT

SA

16170- 24

MPT

35810

11,00R20

SA

11,00 -

20

35968

12R22,5

13

R 22,5

SA 12,00 R

20

35969

12,00-

20

14,75/80 R

2C

13,00-

20

Pilote

XL

1)

applicable only for tractive unit and equal weight distribution

on

the

tractive

unit

chassis.

Decided when body

is

agreed.

2)

and

as

tractive unit

and

tractive unit chassis

3)

tractive unit and tractive unit chassis

1.4/2

Axle loads Weights

Unladen weights

PR

FA

RA

Chas- with

perm.

Total

sis

platform

payload weight

kg

kg kg kg kg kg

18

18

16

16

14

16

5300

5300

4450 5820 3180 9000

16

18

18

18

18

16

16

14

16

5300

16

5300 4450 5820

3440

10000

18

18

18

18

5300

5450

3600

16

16

14

5300 6140 4450 5820

16

16

10600

5300

6200 4240

18

18

18

5450

5450

18

3600

16

16

14

5600

6140

16

4450 5820

10600

16

5600

6200

4240

18

18

MPT = Multipurpose tire

General 00

Authorized towed weights

Trailers with brakes

Chassis

Trailer, gross weight

Model

Sales

Gross weight of

with

non-continuous with continuous brake

. designation

towing vehicle brake (over-run brake)

kg

kg

kg

435.115 U 1300 L

.

7490

7020

to

7500

10480

435.111 U 1700 L

9000

12600

10 000

8000

14000

10600

14840

Trailers without brakes

Chassis

Trailer

Model

Sales

Gross weight of towing Gross weight

designation vehicle

kg kg

435.115

U 1300 L

7490

2300

435.111

U 1700 L

9000

10000

2000

10600

Trailers with brakes

Chassis

41

Trailer, gross weight Trailer

Model

Sales

Gross weight

of

with non-continuous

with coninuous

coupling

11

designation

towing vehicle

brake (over-run brake)

brake

.

kg kg kg

9000

29000

all

10000

3

)

8000

28000

435.110 U 1700

10600

1131

25600

64G

1350r

605

10600

2131

27400

225G

110

.113

U 1700 L/38

12000

-

12000

64 G 135

1)

see

technical data

31.3

-1.1/1

Trailers without brakes

Chassis

41

Trailer

Model

Sales

Gross weight of towing

Gross weight

designation

vehicle

kg

kg

9000

10 000

31

2000

435.110 U 1700

106001)31

10600

2131

435.113

U 1700 L/38

12000

2500

1) with reinforced rear axle

2) with reinforced

rear-

and

front axle

and

steering

LS

7 F.

SA

35968.

SA

35969,

SA

35

776

31

exhaust

brake

SA

35

810

4)

tractor and chassis tractor

UKD

30

402

21

42-02

1.4/3

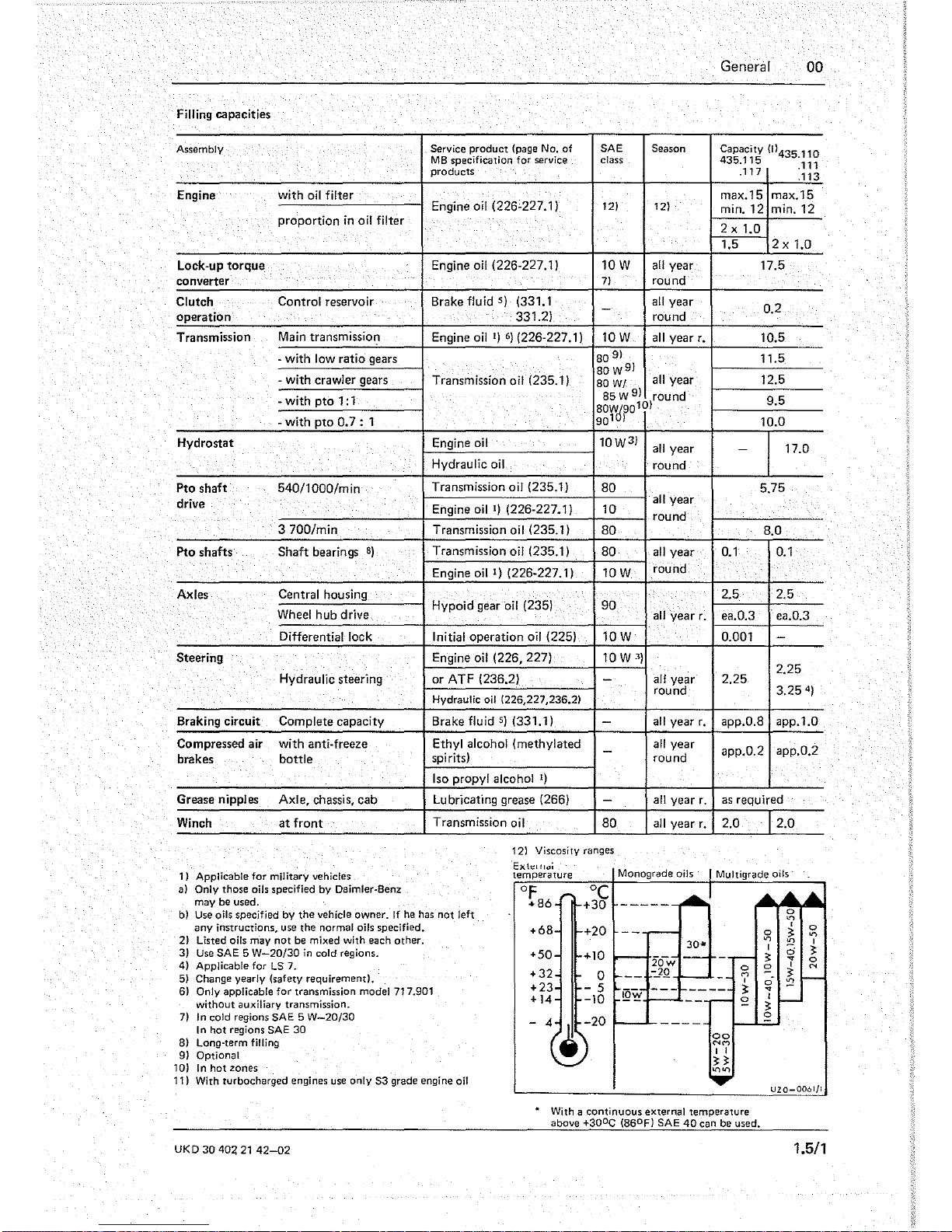

Filling capacities

Assembly Service product (page No.

of

SAE

Season

MS specification for service class

products

Engine with

oil

filter

Engine oil (226·227.1)

121

121

proportion

in

oil filter

Lock·up

torque

Engine oil (226·227.1)

lOW

all

year

converter

71

round

Clutch Control reservoir

Brake fluid

S)

(331.1

all

year

-

operation

331.2)

round

Transmission

Main

transmission

Engine

oil

1)

6)

(226·227.1)

lOW

all

year

r.

· with low ratio gears

80

91

- with

crawler

gears

Transmission oil (235.1)

80w

91

all

year

80

W/

· with

pto

1:1

85 W

91

round

80Wd90101

· with

pto

0.7

: 1

901 I

Hydrostat Engine oil

lOW3)

all

year

.

Hydraulic oil

round

Pto shaft

540/1000/min

Transmission oil (235.1)

SO

drive

Engine

oil

1)

(226·227.1)

10

all

year

round

3700/min

Transmission oil (235.1)

SO

Pto shafts

Shaft bearings

8)

Transmission oil (235.1)

SO

all

year

.

Engine oil

1)

(226-227.1)

lOW

round

Axles

Central housing

Wheel hub drive

Hypoid gear

oil

(235)

90

all

year

r.

Differential lock

Initial operation oil (225)

lOW

Steering Engine oil

(226.227)

10 W

3)

Hydraulic steering

or

ATF (236.2)

Hydraulic

oil

1226,227,236.21

-

all

year

round

Braking circuit Complete capacity

Brake fluid

5)

(331.1)

-

all

year

r.

Compressed air

with

anti· freeze

Ethyl alcohol (methylated

all

year

brakes bottle

spirits)

-

round

Iso

propyl alcohol

1)

Grease nipples

Axle, chassis, cab

Lubricating grease (266)

-

all

year r.

Winch

at

front

Transmission

oil

SO

all

year

r.

121

Viscosity

ranges

1) Applicable

for

military

vehicles

a)

Only those oils specified by Daimler·Benz

may be used,

b)

Use oils specified

by

the vehicle owner.

If

he

has

not left

any

instructions,

use

the normal oils specified.

2) Listed oils may

not

be mixed with each other.

3)

Use

SAE 5

W-20/30

in

cold regions.

4)

Applicable for LS 7.

5)

Change

yearly (safety requirement>.

6)

Only applicable for transmission model 717.901

without auxiliary transmission.

7)

In cold

regions

5AE 5 W-20/30

I n hot

regions

SAE

30

8) Long-term filling

9)

Optional

10)

In

hot

zones

"Exh:llldi

temperature

OF

+86

+6S

+50

+32

+23

+14

-

4

°C

+30

-----

+20

30-

+10

20-w

0

-']Q

- 5

@~

-10

General 00

Capacity (l)435 110

435.115

'111

.117

:113

max.15

max.15

min. 12 min. 12

2 x

1.0

1.5

2 x

1.0

17.5

0.2

10.5

11.5

12.5

9.5

10.0

-

17.0

5.75

S.O

0.1

0.1

2.5

2.5

ea.0.3 ea.0.3

0.001

-

2.25

2.25

3.25

4

)

app.O.S app.1.0

app.0.2 app.0.2

as

required

2,0

DD

NM

I I

n

...,...,

0

M

,

~

£

0

...,

I

~

£

ci

..,

I

~

0

2.0

0

'"

,

0

~

...,

...,

,

;;

~

..,

0

,

N

~

:2

11) With turbocharged

engines

use

only

53

grade

engine oil

~

_____

--'

__________

UZO-0061/1

UKD

30

404

21

42-02

With a continuous external temperature

above

+30

o

C (86

0

Fl SAE

40

can

be

used.

1.5/1

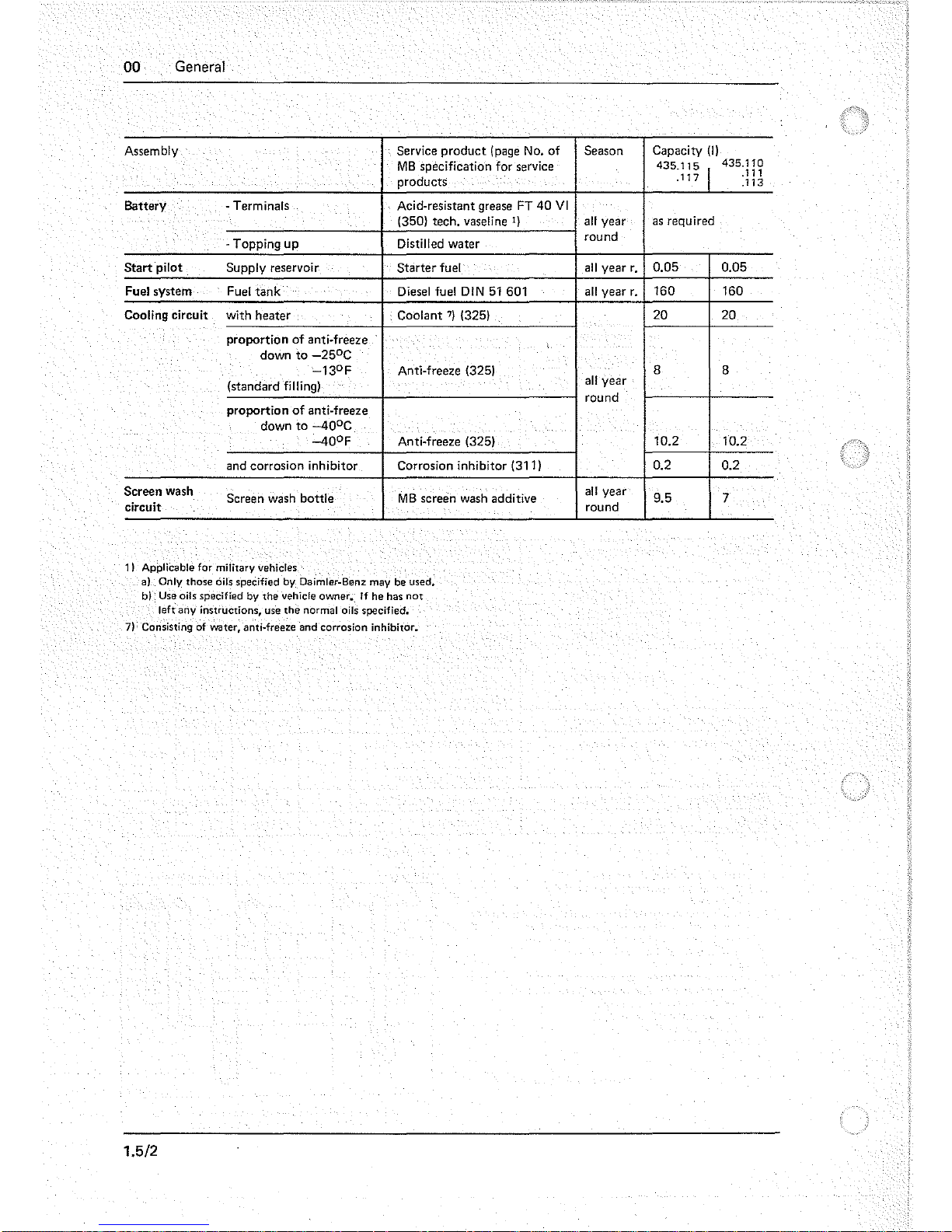

00

General

Assembly

Service

product

(page No.

of

MB

specification for service

products

Battery

- Terminals

Acid-resistant grease FT

40

VI

(350) tech. vaseline

1)

-Topping

up

Distilled water

Start

pilot Supply reservoir

Starter

fuel

Fuel system

Fuel

tank

Diesel fuel

DIN

51

601

Cooling circuit

with heater

Coolant

7)

(325)

proportion

of

anti-freeze

down

to

-25

0

C

-13

0

F Anti-freeze (325)

(standard filling)

proportion

of

anti-freeze

down

to

-40

0

C

-40

0

F

Anti-freeze (325)

and corrosion inhibitor

Corrosion inhibitor (311)

Screen wash

Screen wash bottle

MB

screen wash additive

circuit

11

Applicable for military vehicles

a)

Only those

oils

specified

by

Oaimler-Benz may

be

used.

b)

Use oils specified by the vehicle owner.

If

he has

not

left any instructions, use the normal oils specified.

7) Consisting of water, anti-freeze and'corrosion inhibitor.

1.5/2

Season

Capacity

(I)

435.115

I

435.110

.111

.117

.113

all

year

as

required

round

all

year

r.

0.05 0.05

all

year

r.

160 160

20 20

8

8

all

year

round

10.2 10.2

0.2 0.2

all

year

9.5 7

round

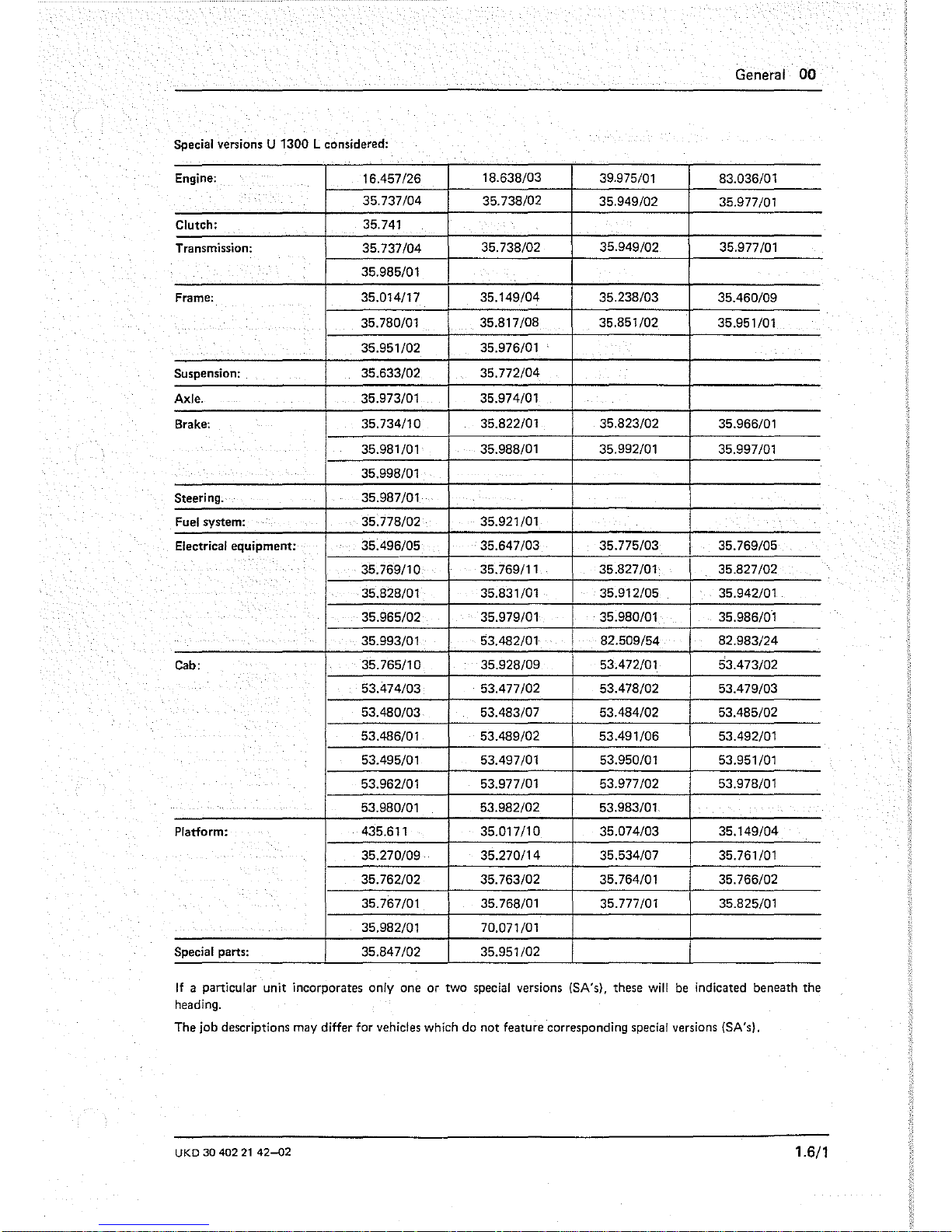

General

00

Special versions U 1300 L considered:

Engine:

16.457/26

18.638/03

39.975/01

83.036/01

35.737/04 35.738/02

35.949/02

35.977/01

Clutch: 35.741

Transmission:

35.737/04

35.738/02

35.949/02

35.977/01

35.985/01

Frame:

35.014117

35.149/04 35.238/03

35.460/09

35.780/01

35.817/08 35.851/02

35.951/01

35.951/02 35.976/01

'

Suspension: 35.633/02 35.772/04

Axle.

35.973/01

35.974/01

Brake: 35.734/10

35.822/01 35.823/02

35.966/01

35.981/01

35.988/01 35.992/01

35.997/01

35.998/01

Steering. 35.987/01

Fuel system: 35.778/02

35.921/01

Electrical equipment: 35.496/05

35.647/03 35.775/03

I

35.769/05

35.769/10

35.769/11 35.827/01 35.827/02

35.828/01

35.831/01 35.912/05 35.942/01

35.965/02

35.979/01

35.980/01

35.986/01

35.993/01 53.482/01

82.509/54 82.983/24

Cab:

35.765/10 35.928/09

53.472/01

53.473/02

53.474/03 53.477/02 53.478/02

53.479/03

53.480/03

53.483/07 53.484/02 53.485/02

53.486/01 53.489/02

53.491/06 53.492/01

53.495/01 53.497/01

53.950/01 53.951/01

53.962/01

53.977/01 53.977/02 53.978/01

53.980/01 53.982/02 53.983/01

Platform:

435.611

35.017/10

35.074/03

35.149/04

35.270/09 35.270/14 35.534/07

35.761/01

35.762/02 35.763/02

35.764/01

35.766/02

35.767/01 35.768/01 35.777/01 35.825/01

35.982/01

70.071/01

Special

parts:

35.847/02

I

35.951/02

If

a particular unit incorporates only one or two special versions (SA's), these

will

be

indicated beneath the

heading.

The job descriptions may differ for vehicles which do not feature corresponding special versions

(SA's),

UKD

30 402

21

42-02

1.6/1

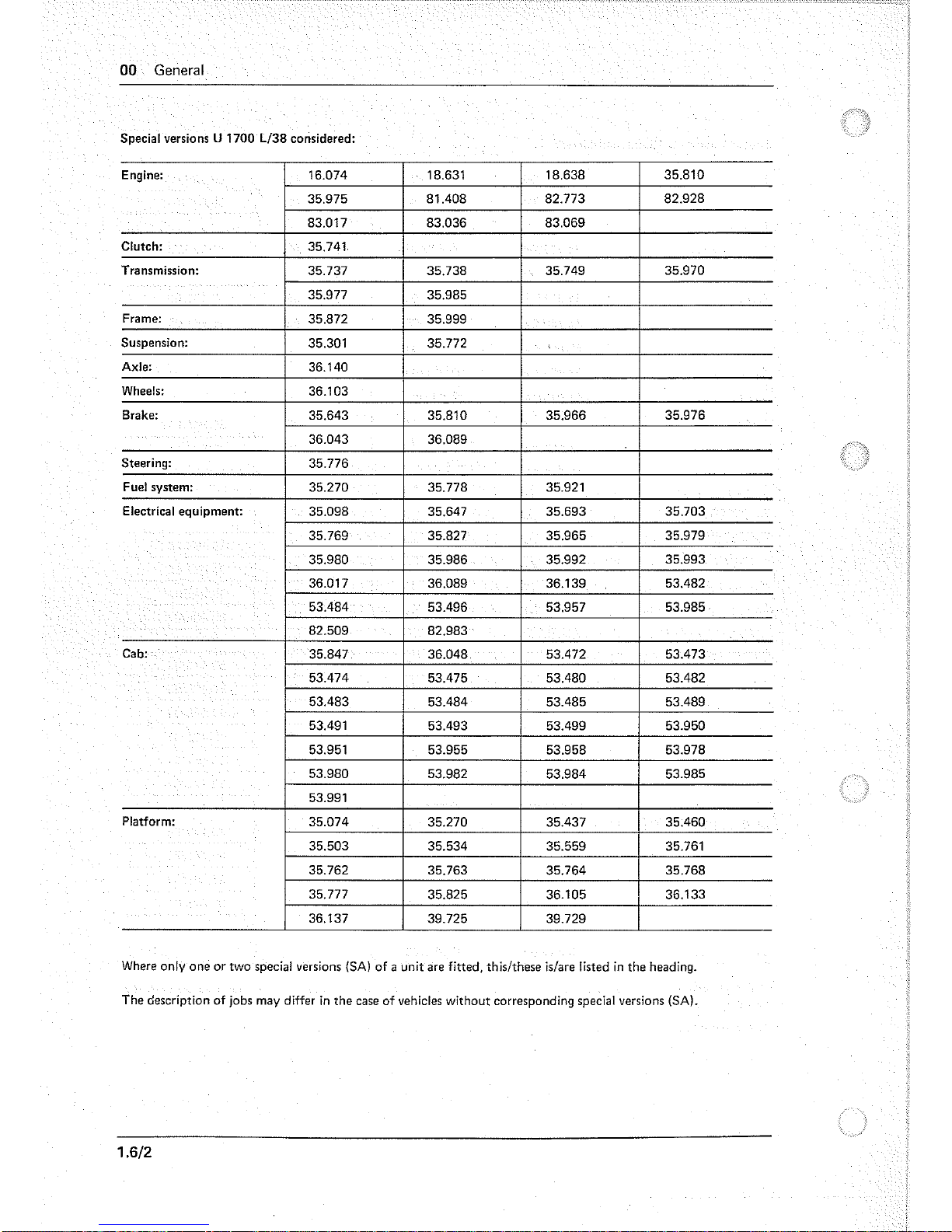

00 General

Special versions U 1700 L/38 considered:

Engine:

16.074 18.631

18.638 35.810

35.975 81.408 82.773

82.928

83.017 83.036 83.069

Clutch:

35.741

Transmission:

35.737 35.738

35.749 35.970

35.977

35.985

Frame:

35.872 35.999

Suspension:

35.301 35.772

,

Axle:

36.140

Wheels:

36.103

Brake:

35.643 35.810 35.966 35.976

36.043 36.089

Steering:

35.776

Fuel system:

35.270 35.778 35.921

Electrical equipment:

35.098 35.647 35.693 35.703

35.769 35.827 35.965

35.979

35.980 35.986 35.992

35.993

36.017 36.089 36.139 53.482

53.484

53.496 53.957 53.985

.

82.509 82.983

Cab:

35.847 36.048 53.472 53.473

53.474 53.475

53.480

53.482

53.483 53.484 53.485 53.489

53.491

53.493 53.499 53.950

53.951 53.955 53.958 53.978

53.980 53.982

53.984

53.985

53.991

Platform:

35.074

35.270 35.437 35.460

35.503

35.534 35.559 35.761

35.762 35.763 35.764 35.768

35.777 35.825 36.105 36.133

36.137

39.725 39.729

Where only one or two special versions

(SA)

of

a unit are fitted, thislthese is/are listed

in

the heading.

The description of jobs may differ

in

the case of vehicles without corresponding special versions (SA).

1.6/2

(

Removal and installation

of

engine/engine housing 01.8

Contents

Chapter

1 General

Installation survey

Section drawing

Performance diagram

Technical data

Special tools

Filling capacities

Necessary materials

Tightening torques

Exploded view

Cylinder bores diagnosis

2 Reconditioning engine

Removal

and

installation

of

engine

Removal

and

installation

of

engine parts

3

Removal

and

installation

of

cylinder head cover

4

Removal

and

installation

of

cylinder head

5

Disassembly

and

assembly

of

cylinder head

6 Reconditioning

of

cylinder head

Checking. exchanging valve guides

Refacing valve seats with valve seat

cutter

Refacing valve seats with hand

cutter

Removal and installation

of

valve seat rings

Remachining basic bore

for

valve seat rings

7

Checking compression pressures

UKD

30

402

21

42-01

352/352

A

Page

1.1

/1

1.1/2

1.1/4

1.2/1

1.3/1

1.3/2

1.3/2

1.4/1

1.5/1

1.6/1

2.111

2.3/1

3.1/1

4.111

5.1/1

6.1/1

6.2/1

6.3/1

6.4/1

6.5/1

7.1/1

General

01.8

352/352 A

Installation

Survey

Chassis Engine

Model

Sales

Series

Model Sales Series/SA

designation

Chassis end No.

designation

Engine end No.

435.110 U 1700

Irom 002 230

Series from 577 967

.111

U 1700

L"

from

000 008

353.959 352 A V/2

Series from 413 968

.113

U 1700 U38 from 084 642 352

A.

LI1t1" Series from 693 577

.115

U 1300

L"

from 000 019

352.X/2

Series from 482 095

353.961

352J(fl"

SA

16 457/26"

SA 35

975"

from 000

061"

"

SA

83

036"

from 509 465

---

from

PS"

353.959 352 A V/2

SA

36

019"

,

352

ALll/l"

from

PBJ)

.117 U 1300 U37

from

PBJJ

353.961 352.Xl2

Series

from

PBJJ

from

071

796

353.959

352 A V/2

SA

36

019"

352 A

L11/1"

from

627 976

.160 Attachment TM 170 from

PS"

353.959 352

ALlltl

from

PBJ)

.170 Attachment Condor from

PS"

353.977 352

AV/2

Series from 575 178

'--

1) L = Truck

2)

Special vehicle SW

3)

PS

= Start of production

4)

Valid only for fire service vehicles

5)

From engine end No.

691

150

UKD

30 402

21

42·03

1.1/1

01.8 General

352/352 A

General View

Engine 353.961

Engine 353.959

1.1/2

General 01.8

352 A

General view

UROI-0191

Engine 353.977

UKD

30

402

21

42-02

1.1/3

01.8 General

352/352 A

Performance diagram

Engine 353.961

P

[KW]

140

-_.-

--l"··"·¥

_.-

.

1-

1

---[--

-I

--

1-1-

I

r-1--i-;

I i

r

-'--

I,

i

IT

.

I ,

i/

120

100

80

60

40

f-

V

,

20

1--

i

I

o

--

---

-

~-

1---

L_

I

--r--

I

I

1200

p

--

f-~

,

;

-

....

,

f

---

-

I

./

p

/

/

V

r--....

I

'm

-

---

2000

2800

9

6

kW

[DIN)

'-

l

I-

M

Nm]

500

460

420

380

340

300

~

>-

L

-

t

[KW]

r--,---,----r-----r--.,--,---,--,

1401--+-+--I--+---+_J-1--

r--

---1---

---

i--I---+-,,+p-l

~4

kW

[DIN]

120

~t

___

--~-~_

~:~

____

1_-/1-"

______

+

__

100

-I----J/~+--+___l

/---

--l---r

-lI'--t---+--l--j

80--'-7

----

f----

1

-t-1I

-~-+i--l

60

I M

!

I;

[Nm]

401--I---+-L-,--+--+--I-----i--

r500

i i

i--t---i--~ii,/

A~t-.Ji"-..c---f--

~460

20

~

420

I

/i

i M

I--+----f-L+_

380

I,

+'

I

o

f----r--+-+----'-:

--1---1

340

I--+----i---I---t--+--+

I L

300

I I i I

-+'-+--1

I 1 i i - i

.~

o

400

n[l/minJ

I g

1200

2000

2800

Engine 353.957

to

engine end No.

691

149

_977

1.1/4

Performance Diagram

P

[kW]

140

120

100

80

60

40

20

o

o

400

n~/min]

1

Engine 353.959

from

engine end No. 691 150

UKD

30

402

21

42-02

J

I

I

I

•

/

I

I

I

1200

-

P

/

,I

1/

~

.........

"

M

1

.

2000

2800

.

p

12

4kW(DIN)

Q

-

M

Nm]

580

-

-

-

-

-

-

-

-

-

540

500

460

420

380

340

300

General 01.8

352/352 A

1.1/5

General

01.8

3521352

A

Technical

Data

Mercedes

Benz

type

352 352 A

Model

353.961

353.959

I

353.977

Combustion

system

Four-stroke

diesel

with

direct

Four-stroke

diesel

with

direct

injection

injection

Number

of

cylinders Cylinder arrangement

6,

vertical

in-line

Bore

0

mm

97

Stroke

mm

128

Total

displacement

cm

3

5657

Compression

ratio

17

16

Compression

bar

22

up

to

24

min.

20

at

starting

speed

Continuous

output

kW

(HP)

96 (130) 124 (168)

at

nominal

speed

l/min

2800 2800

-

Maximum

torque

Nm

363

491

1

)

I

5302'1

I

491

at

speed

l/min 1700 1600 1600 1600

Idle

speed

l/min

700

Start

of

delivery

before

TDC

0

18

21

1

)

I

19

2

)

I

21

Injection

sequence

1-5-3-6-2-4

Valve

ciearance,

cold

Inlet

mm

0,20

I

0,25" I

0,20

Exhaust

mm

0,30

I

0,40" I

0,30

Opening

pressure

new

bar

200 + 10

of

injection nozzles

used

bar

min.

180

Operating

temperature

'C

95

Oil

pressure

normal

bar

2

to

5

at

idle

speed

bar

min.

0.6

Weight,

dry

kg

460

480

1)

To

end

engine

No.

691

149.

2)

From

end

engine

No.

691

150.

UKD

30

402

21

42 - 04

1.2/1

01.8 General

352/352 A

Crankcase

Engine Type 352

I 352 A

b

Overall height of crankcase

359,10

a

mm

(Production size)

.

359,00

Repair stage I "

mm

358,80

358,70

a

Repair stage

11

'I

mm

358,50

358,40

Repair stage

III

'I

mm

358,20

358,10

Permissible

Crosswise

b 0,017

mm

unevenness

UZOI

- 0021

of mating surface

Lengthwise

e mm 0,03

e

Peak-ta-valley height

mm

0,008

up

to

0,016

of upper mating surface

Permissible parallel misalignment

of upper

to

lower mating surface

d mm

0,1

in lengthwise direction

Pressure test

in

water

bar

2,5

Piston may recede

= -

mm 0,07

Piston

may project

=+

mm

0,30

1) If mating surface

is

remachined to next repair stage, pistons of reduced compression height must

be

installed.

Cylinder Bores

(e)

Normal

Normal

I Normal

11

Repair

Repair

Repair

stage

I

stage

11

stage

III

mm mm mm

mm

mm mm

97,010

97,085 97,135

97,510

" 98,010 "

98,510

'I

96,990 97,065

97,115

97,490 97,990 98,490

97,010

21

-

-

97,0102)

96,990 96,990

Permissible ovality

mm

0.01

Permissible conicity

mm

0,01

Permissible deviation of

c~linder

bores

perpendicular to cranksha t axis, relative to

200 mm length

mm

0,04

Peak-ta-valley

height of the cylinder bores

mm

0,003 up to 0,005

Waviness of cylinder bores

mm

max.

50% of peak-ta-valley height

at top reversal point

mm

max.0,12

Wear

in

liner

of 1 st piston ring

in centre of

liner

mm

max.0.05

Bore depth for machining to the repair stages

mm

min.

250

1) Not engine 353.9591 977.

2)

Possible repair- crankcase with dry cylinder liners may be installed. If necessary, the scope of work

can

be requested.

Camshaft

Bearings

Basic

bores

in

crankcase

1.2/2

60,030

60,000

General

01.8

352/352 A

Valve

tappet bores

Normal

Repair

stage

1

Repair

stage

11

Repair

stage

III

mm

mm

mm

mm

28,033 28,233 28,533

28,783

28,000 28,200 28,500

28,750

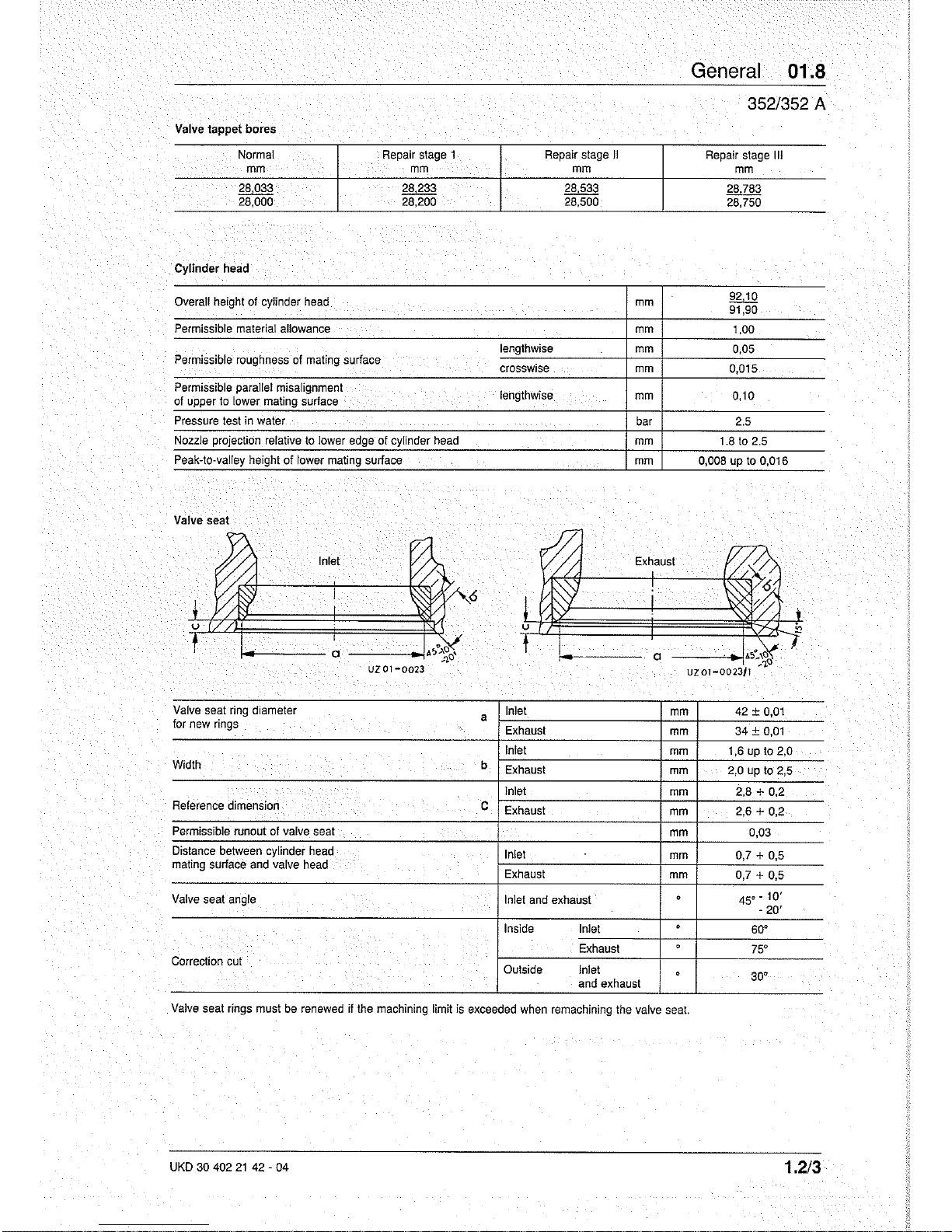

Cylinder

head

Overall

height

of

cylinder

head

mm

92,10

91,90

Permissible

material

allowance

mm

1,00

lengthwise

mm

0,05

Permissible

roughness

of

mating

surface

crosswise

mm

0,015

Permissible

parallel misalignment

lengthwise

mm

0,10

of

upper

to

lower

mating

surface

Pressure

test

in

water

bar

2.5

Nozzle

projection

relative

to

lower

edge

of cylinder

head

mm

1.8

to

2.5

Peak-to·

valley

height of

lower

mating

surface

mm

0,008

up

to

0,016

Valve sea!

Exhaust

~--------a ------~~

l---

a

Valve

seat

ring

diameter

a

Inlet

mm

42 ± 0,01

for

new

rings

Exhaust

mm

34+

0,01

Inlet

mm

1,6

up

to

2,0

Width

b

Exhaust

mm

2,0

up

to

2,5

Inlet

mm

2,8 + 0,2

Reference

dimension

C

Exhaust

mm

2,6 + 0,2

Permissible

runout

01

valve

seat

mm

0,03

Distance

between

cylinder

head

Inlet

mm

0,7 + 0,5

mating

surface

and

valve

head

Exhaust

0,7 + 0,5

mm

Valve

seat

angle

Inlet

and

exhaust

·

45.-

10

'

-

20'

Inside

Inlet

·

60·

Exhaus!

·

75·

Correction

cut

Outside

Inlet

·

30·

and

exhaust

Valve

seat

rings

must

be

renewed

il

the

machining

limit

is

exceeded

when

remachining

the

valve

seat.

UKD

30 402

21

42 - 04

1.2/3

01.8

General

352/352 A

Valve Seat

Rings

Cl

i=ffi

A

B

UZ01-0019

Exhaust A Inlet B

I 1)

1)

Outside diameter

Normal

mm

38,080 45,080 45,880

valve

seat ring c and d 38,070

45,070

45,870

Repair stage I mm

38,380

45,380

46,180

38,370

45,370

46,170

Repair stage

11

mm

38,580 I

-

45,580

-

38,570

45,570

Bore

diameter

Normal

mm

38,025 45,025 45,825

in

cylinder head c 1 38,000

45,000

45,800

and d 1

Repair stage

I

mm

38,325 45,325 46,125

38,300

45,300

46,100

Repair stage

11

mm

38.525 I

-

45,525

-

38,500 45,500

Installation

depth in cylinder head

e mm

11,20

11,10

Distance between cylinder head face and

b 1 mm

2,6 + 0,2 2,8 + 0,2

valve

seat ring

Basic bore in

cylinder head

mm

38,000 + 0,025 45,000 + 0,025

Height of valve seat rings

a mm 8,5 -

0,1

8,3 -

0,1

Valve seat ring overlap in cylinder head

mm 0,045

to

0,080

Valve

Guides

Dislance between

valve guide

Exhaust inlet

vaive spring seat

a mm

24 -

0,5

mm

10,022 9,022

10,000

9,000

,

Inside diameter

Length

mm 73

78

~

Normal Repair Repair Repair

stage

I stage

11

stage

III

mm mm mm mm

Outside diameter

15.046 15,146 15.246 15,546

15,028

15,128

15,228 15,528

Bore

in

cylinder head

15.018 15,118 15,218 15,518

15,000

15,100

15,200

15,500

Overlap

mm + 0,010

to

+ 0,046

1)

Engine model 353.959 from engine end No. 549 882.

1.2/4

General 01.8

352/352 A

Special

Tools

Cons.

Tool

Tool No.

Tool

Set

No.

1

Ring wrench for injeclion lines

000 589 07 03 00 A

2

Pliers for connecting nipple of rocker shafts

312589013700

A

3

Claw wrench for protective sleeve

in

cylinder head

346 589

00 07 00

B

4

30 mm socket for pressure screw

in

nozzle holder

000 589 75 09 00

B

5

Extractor for nozzle holder

352 589

00 33 00

B

.

6

Centering drift

425 589

00

61

00 B

7

Drift for removing inlet valve guide

110589021500

C

8

Drift for removing exhaust valve guide

615589011500

C

9

Fitting drift for valve seat rings

346589031500

C

10

Inslaller for valve guide 352 589 00 43 00 C

11

Reamer, 9 mm

diameter

for

inlet

valve

guide

000589105300

C

12 Reamer,

10 mm diameter for exhaust valve

gUide

000 589

11

53 00

C

13

Reamer for valve guide sleever bore in cylinder head

000589

185300

C

14 Hand cutter for valve seal rings

000589126600

C

15

Special wrench to retighlen injeclion lines 000 589 68 03

00

D

16 Limit plug gauge dia. 9 mm inlet valve guide

116589082100

D

17

Connection piece for compression test 352 589

00

21

00 D

18

Limit plug gauge,

10 mm dia. for exhaust valve guide

617589052300

D

19 Handle for cylinder head

(2

necessary)

31258901

31

00

D

20

Rud

special lifling chane 435 589 00 62 00 D

. -

UKD

30 402

21

42·03

1.3/1

01.8 General

352/352

A'

Capacities

Assembly

Engine

With

oil

filler

Proportion

in

oil filter

Cooling system With heater

Antifreeze proportion

(Standart

filling)

Antifreeze proportion

And

corrosion

protection

1)

Viscosity grades

Outdoor temperature

Single grade oil

°rS6

°C

+30

-----

+68

+20

+50

+10

+32

0

+23

- 5

+14

-10

00

NM

I I

33

"''''

max.

--:--

mm.

down to - 25°C

-13°F

down

to

-40°C

o

'"

I

3

o 0

M

, 0

3 ..

o I

3

o

-40°F

o

'"

I

3

o

N

UZD-D061!1

')

SAE 40 may be used if outdoor temperatures are permanently above

+ 30°C (86°C F).

21

To engine end No. 502 247

3 From engine end

No.

502 248

4

Consisting

of

water,

antifreeze

and

anticorrosion

oil

5 For supercharged engines, onty use engine oil of "S

3"

quality.

Necessary material

Cons.

Designation

No.

1 Loctite

Nr.

241

2 Loctite Nr. 573

3 Curil T