Extreme off-road Unimog BlueTec 6

Technical Manual

August 2014 issue

Technical Manual

Technical Manual for extreme off-road Unimog BlueTec 6

The present Technical Manual serves Unimog Sales as an advisory

document. In addition to the basic vehicle version, special equipment is

also covered. Regarding the availability of standard and special equipment,

please refer to the applicable price lists. Subject to technical modifications

without notice. All rights reserved. Reprinting or reproduction in electronic

form, including excerpts, is prohibited and requires the approval of

Mercedes-Benz Special Trucks.

The latest changes and additions are available through our updates on

the Extranet at:

www.specialtrucks-extranet.com

Daimler AG

Mercedes-Benz Special Trucks

Sales & Marketing

August 2014 issue

Part A

Concept and sales reasoning

Part B

Technical data

Mercedes-Benz Special Trucks

1

Contents

Contents – Part A

Technical Manual

Overview of models and components ................................ 6

Product concept ................................................................... 7

Unimog model series in comparison .................................. 7

Extreme off-road capability ................................................ 8

The Unimog concept for extreme torsional flexibility ......... 9

Angle of approach / departure and ramp breakover angle 10

Fording capability ............................................................. 11

Optional equipment – fording capability .......................... 12

Frame ...................................................................................13

Frame concept ................................................................. 13

Optional equipment – frame ............................................ 15

Engine .................................................................................. 17

Engine concept ................................................................ 17

Drive clutch ...................................................................... 19

High-performance engine brake ....................................... 20

Engine control .................................................................. 20

Exhaust gas aftertreatment – BlueTec 6 .......................... 21

Exhaust emissions – limiting values ................................. 23

Regeneration .................................................................... 24

Radiator system .............................................................. 25

Optional equipment – engine ........................................... 26

Transmission .......................................................................27

Main transmission ............................................................ 27

Overview .......................................................................... 28

Engine management ........................................................ 29

Electronic Quick Reverse (EQR) ....................................... 30

Optional equipment – transmission ................................. 31

Axles ....................................................................................33

Portal axles ...................................................................... 33

Axle suspension ............................................................... 35

Torque tube technology .................................................... 36

Drive system .................................................................... 37

Single tyres ...................................................................... 38

Optional equipment – axles.............................................. 39

Brakes ..................................................................................43

Dual-circuit braking system .............................................. 43

4-channel ABS .................................................................. 44

Optional equipment – brakes ........................................... 45

Steering ...............................................................................46

Power steering ................................................................. 46

Optional equipment – steering ......................................... 47

2

Mercedes-Benz Special Trucks

Technical Manual

Contents

Cab exterior .........................................................................48

Cab concept ..................................................................... 48

Doors ............................................................................... 49

Safety ............................................................................... 50

Optional equipment – cab exterior ................................... 51

Cab interior .........................................................................54

Spaciousness ................................................................... 54

Controls ........................................................................... 55

Steering and gear-changing ............................................. 56

Instrumentation ............................................................... 57

Standard controls ............................................................ 58

Air conditioning, heating and ventilation system .............. 59

Optional equipment – cab interior .................................... 60

Auxiliary drives ...................................................................64

Location ........................................................................... 64

Optional equipment – power take-offs ............................. 65

Hydraulics ...........................................................................68

Overview of hydraulic system........................................... 68

Optional equipment – hydraulic system ........................... 69

Electrical system ................................................................71

Electronic networking ...................................................... 71

Optional equipment – electrical system ........................... 72

Attachment and mounting areas ......................................77

Locations of attachment and mounting areas .................. 77

Mounting areas ................................................................ 78

Optional equipment – mounting areas ............................. 79

Mercedes-Benz Special Trucks

3

Contents

Contents – Part B

Technical Manual

Engine .................................................................................. 86

Engine data – OM934 ..................................................... 86

Engine diagram – OM934 ................................................ 87

Filling capacities .............................................................. 88

Engine brake .................................................................... 88

Compressed air generation .............................................. 89

Transmission .......................................................................90

Main transmission ............................................................ 90

Clutch .............................................................................. 90

Vehicle speeds – U 4023 / U 5023 ................................. 91

Vehicle speed conversion factor ......................................92

Axles ....................................................................................93

Suspension ...................................................................... 93

Technical data on axles .................................................... 93

Technical data on U 4023 rims ........................................94

Technical data on U 5023 rims ........................................95

Brakes ..................................................................................96

Braking system ................................................................ 96

Cab exterior .........................................................................97

Exterior ............................................................................ 97

Cab interior .........................................................................98

Interior ............................................................................. 98

Auxiliary drives ...................................................................99

[N05] Engine PTO to rear, with flange .............................. 99

[N13]/[N16]/[N19] Transmission PTO ........................... 100

Hydraulics .........................................................................101

Technical data on single hydraulic system ..................... 101

Electrical system ..............................................................102

On-board electrical system ............................................ 102

Lights ............................................................................. 102

4

Mercedes-Benz Special Trucks

Technical Manual

Contents

Weights ..............................................................................103

Permissible load values .................................................. 103

Trailer operation ...............................................................104

Pin-type trailer hitch ....................................................... 104

Hook-type trailer hitch (not for civilian use) ...................104

Towing capacities – U 4023, model designation

437.427, 170 kW ........................................................... 105

Towing capacity U 5023, model designation

437.437, 170kW ........................................................... 106

Wheels/tyres ....................................................................107

Tyre availability ...............................................................107

Tyres (technical data) .....................................................108

Tyre load capacity ..........................................................109

Speed allocations ........................................................... 110

MPT (multi-purpose tyres) .............................................. 112

AS tyres ......................................................................... 114

Dimensions .......................................................................115

Technical drawing for U 4023 BlueTec 6,

model designation 437.427 ........................................... 115

Technical drawing for U 5023 BlueTec 6,

model designation 437.437 ........................................... 116

General information .........................................................117

Vehicle climbing resistance ............................................ 117

Trailer climbing resistance .............................................117

Tractive force diagram – U 4023 (8.8 t) .........................118

Tractive force diagram – U 4023 (10.3 t) ....................... 118

Tractive force diagram – U 5023 (14.1 t) ....................... 119

Tractive force diagram – U 5023 (14.5 t) ....................... 119

Mercedes-Benz Special Trucks

5

Overview of models and components Technical Manual

Overview of models and components

Model name Model designation Wheelbase

(mm)

U 4023 437.427 3850 OM934 170/231 4 7.5 / 8.0 / 8.8 / 9.8 / 10.3

U 5023 437.437 3850 OM934 170/231 4 12.5 / 12.7 / 13.0 / 14.1 / 14.5

Engine Output

(kW/hp)

No. of

cylinders

Permissible gross vehicle

weight: Variants (t)

6

Mercedes-Benz Special Trucks

Technical Manual

Product concept

Unimog model series in comparison

Product concept

Unimog Implement Carrier BlueTec 6

• Compact all-terrain Unimog implement carrier

• Vehicle type: tractor unit/truck

• Vehicle width: from 2.15 m

• Wheelbases: 2800 mm – 3900 mm

• Straight, dimensionally stable and weight-optimised

ladder-type frame

• Panoramic cab with large windscreen and

low instrument support

• 4+3 implement mounting areas

• Extensive hydraulics package

• Mechanical engine and transmission PTOs

• Permanent all-wheel drive, differential locks engageable

Extreme off-road Unimog BlueTec 6

• Extreme off-road Unimog chassis

• Vehicle type: truck chassis

• Vehicle width: from 2.3 m

• Wheelbase: 3850 mm

• Dropped, flexible and torsionally flexible frame

• Cab-behind-engine truck with raised windscreen

• Long body length for greater load volume

• Integrated hydraulics system available

• Mechanical engine and transmission PTOs

• Rear axle drive, all-wheel drive and differential locks engageable

Unimog Implement Carrier BlueTec 6 Extreme off-road Unimog BlueTec 6

Mercedes-Benz Special Trucks

7

Product concept Technical Manual

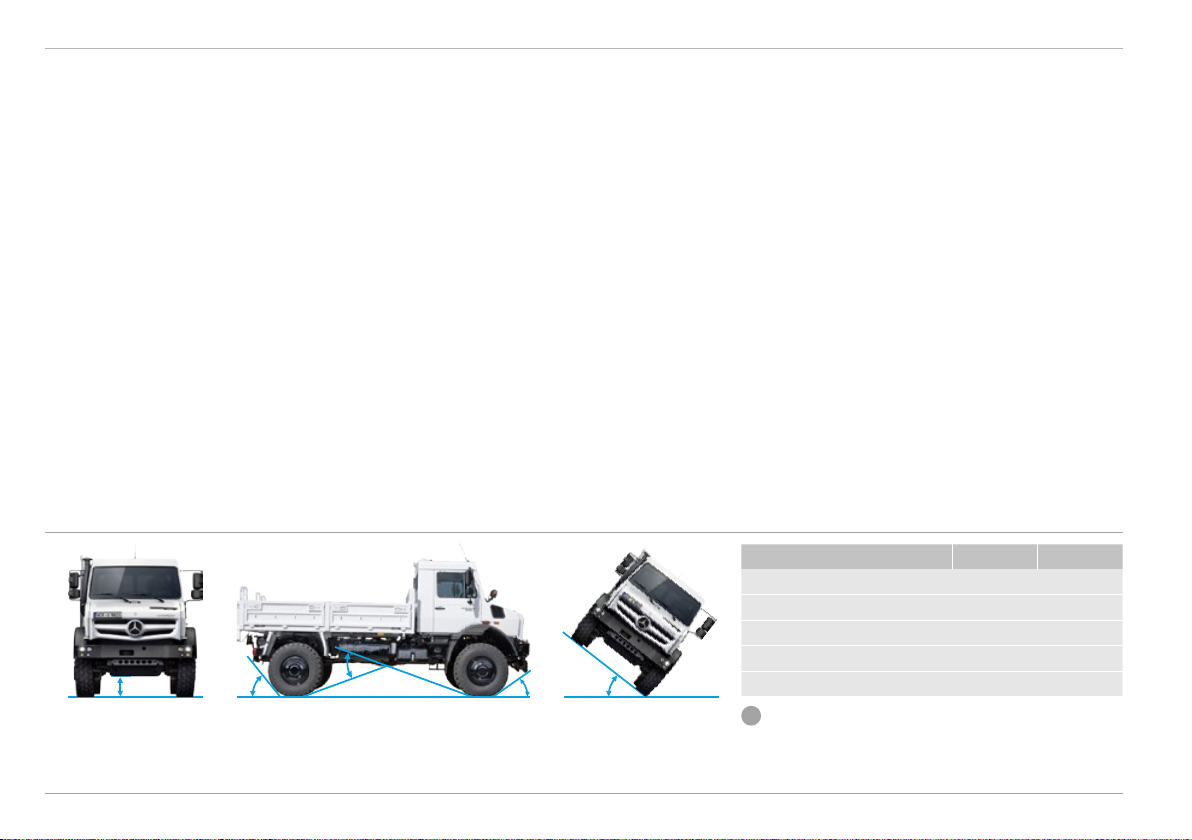

Extreme off-road capability

Feature

• Heavy-duty, torsionally flexible frame

• Portal axle with asymmetric differential arrangement

• Axle location via torque tube technology, coil springs and

transverse control arms

• Fording capability

• Atmospheric pressure equalisation of components

• Short frame overhangs at front and rear

• Low vehicle centre of gravity

• All-wheel drive and differential locks engageable and disengageable

via dog clutch while on the move

a

c

b

Advantage

• Good flexibility off-road on steep inclines and rough surfaces

• Large ground clearance when driving over obstacles

• Extreme diagonal torsional flexibility

• Central load application and bracing on gearbox

• Protection for drive shafts

• Enables fording of water to a depth of 80 cm (standard) /

120 cm [Z16]

• No excess pressure in components

• Large angle of approach/departure and ramp breakover angle

• High climbing and tipping angle

• High tractive power available at all times

• 100 % locking effect

• No interruption in tractive power, no stopping

U 4023 U 5023

a) Ground clearance (mm) 410 460

b) Angle of approach (°) 42 46

c) Ramp breakover angle (°) 32 36

d) Angle of departure (°) 46 50

ed

e) Tipping angle (°) 38 38

i

Angle not dependent on load condition or tyres.

8 Mercedes-Benz Special Trucks

Technical Manual

Product concept

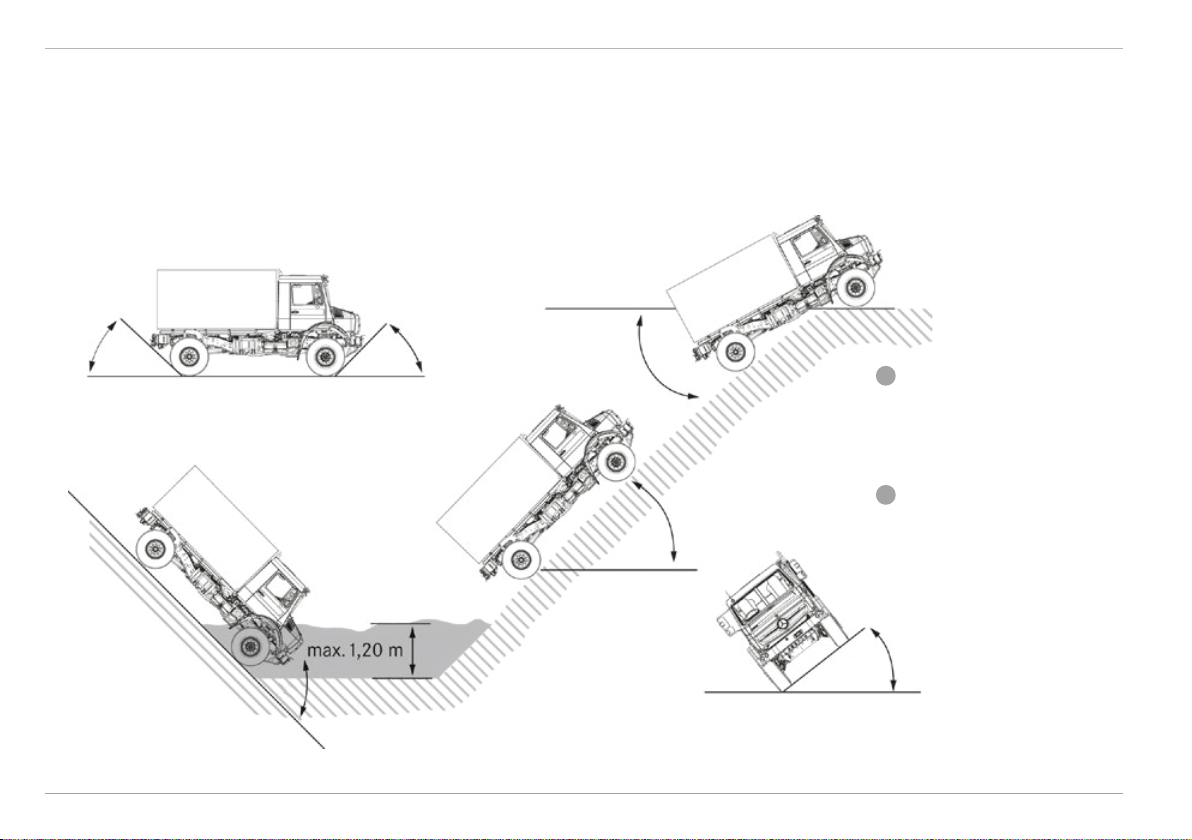

The Unimog concept for extreme torsional flexibility

30°30°

Driving over obstacles optimised by asymmetric arrangement of the axle differentials Major axle articulation made possible by torque tube concept and coil springs

Driving over sharp crests possible thanks to large ramp breakover angle and

angle of approach/departure

Mercedes-Benz Special Trucks

3-point mounting of engine, gearbox and cab. Double 3-point body mounting

9

Product concept Technical Manual

Angle of approach / departure and ramp breakover angle

Figures shown are static values for the chassis of a U5023.

Ramp breakover angle

50° 46°

Angle of approach and departure

Approach

10

46°

Fording capability, approach angle

36°

45°

Slope angle

i

For the angles of the individual

vehicle models, please refer to the

dimensioned drawings in Section B.

Illustrations show 365/85 R20 tyres.

i

The permissible roll angle is 38 degrees

in static state (vehicle functional);

the dynamic limit is 16.5 degrees

(corresponding to 30 %).

38°

Tipping angle

Mercedes-Benz Special Trucks

Technical Manual

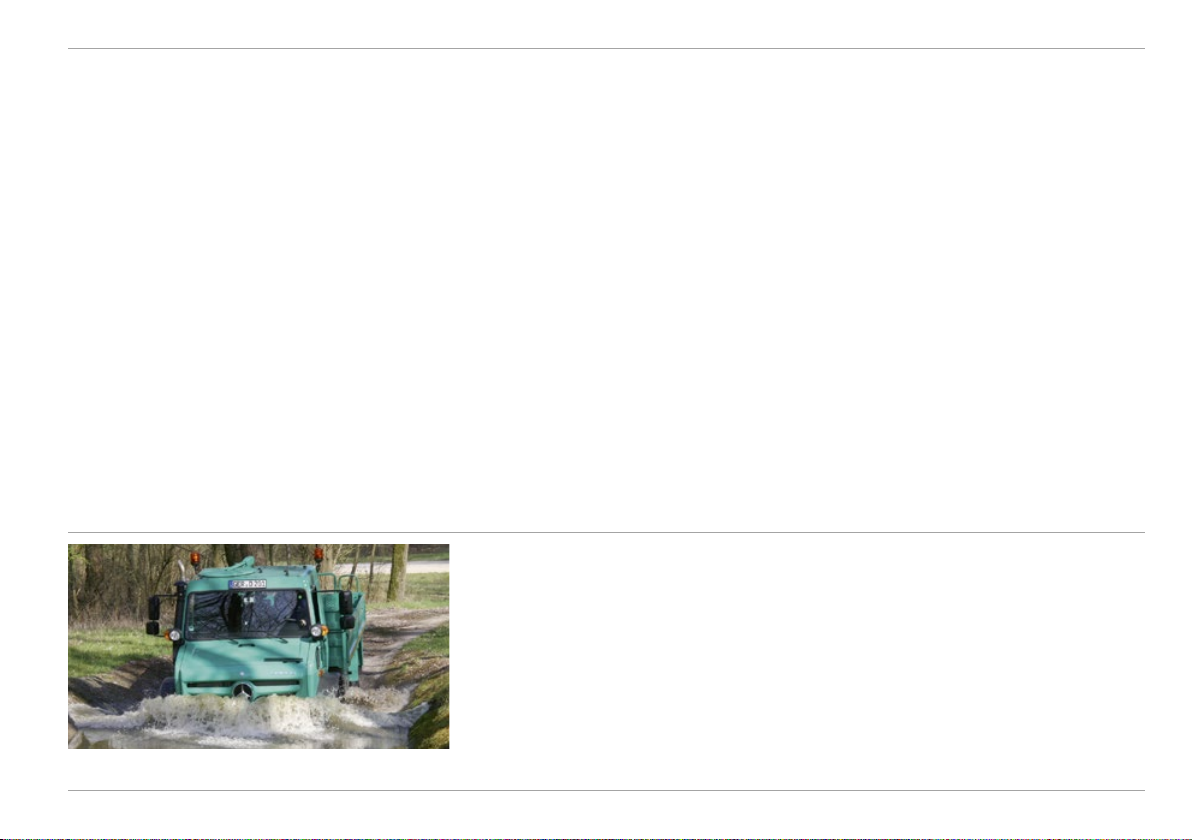

Fording capability

Product concept

Feature

• Torque tube technology

• Air intake pipe at level of cab roof

• Large ground clearance

• Fan with electronic viscous clutch, mechanically driven via

propeller shaft, raised

• Key components and electrical devices protected against

splashing water

Advantage

• Enables standard fording capability to 80 cm

• No permanent drive, fan remains operational

• No damage resulting from exposure to water

• No sagging of a V-belt

Standard fording capability to 80 cm

Mercedes-Benz Special Trucks

11

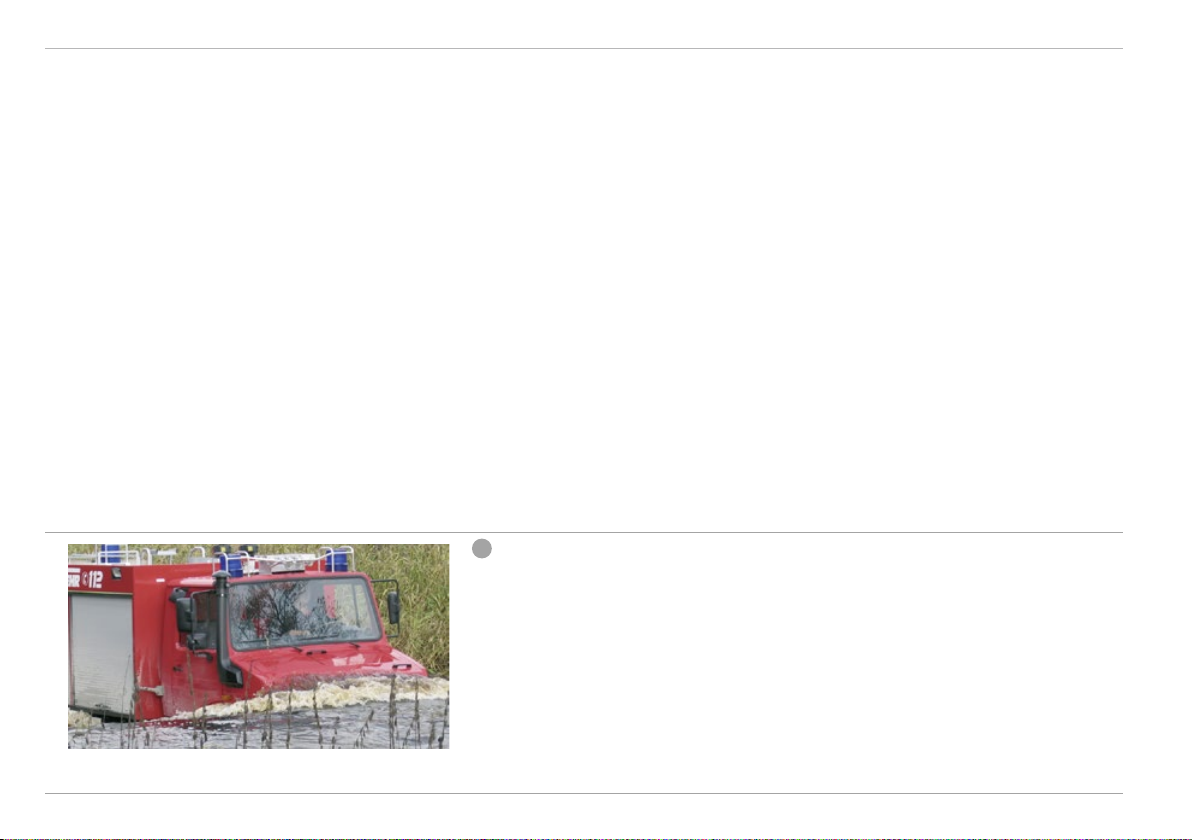

Product concept Technical Manual

Optional equipment – fording capability

Feature

[Z16] Special parts, fording capability

• Raised pressure compensating lines for axles, gearbox,

working gear range, torque tube, fuel tank, air drier,

solenoid valves, brake system, etc.

• Waterproof main headlights with central, raised ventilation

• New position for auxiliary heater [D6N]

Advantage

• Enable fording capability to 120 cm

• Atmospheric pressure compensation with vent lines from the

components prevents entry of water and fine sand

• No reduction in fording capability with optional auxiliary heater

i

Recommended special equipment:

• Double sealing of wheel hubs, for

operations in muddy conditions

[A27]

Special equipment, special parts for fording capability to

120cm [Z16]

12 Mercedes-Benz Special Trucks

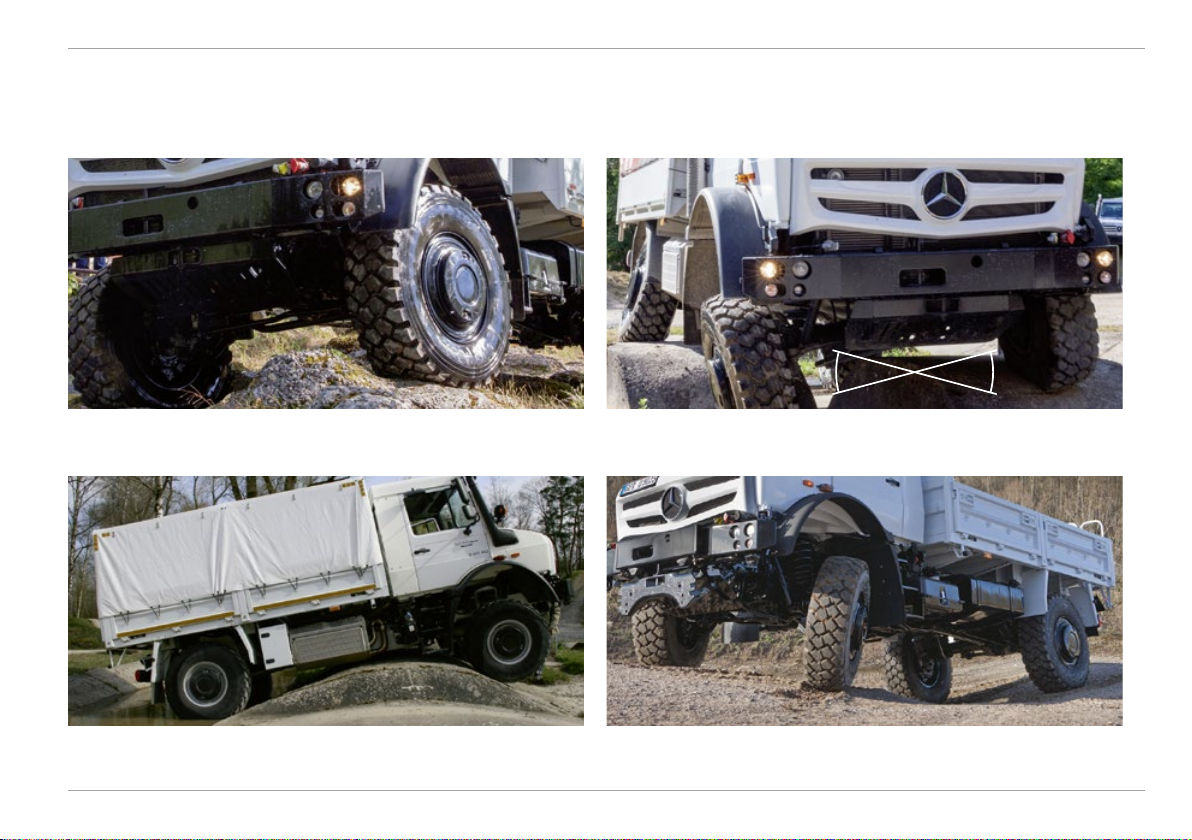

Technical Manual

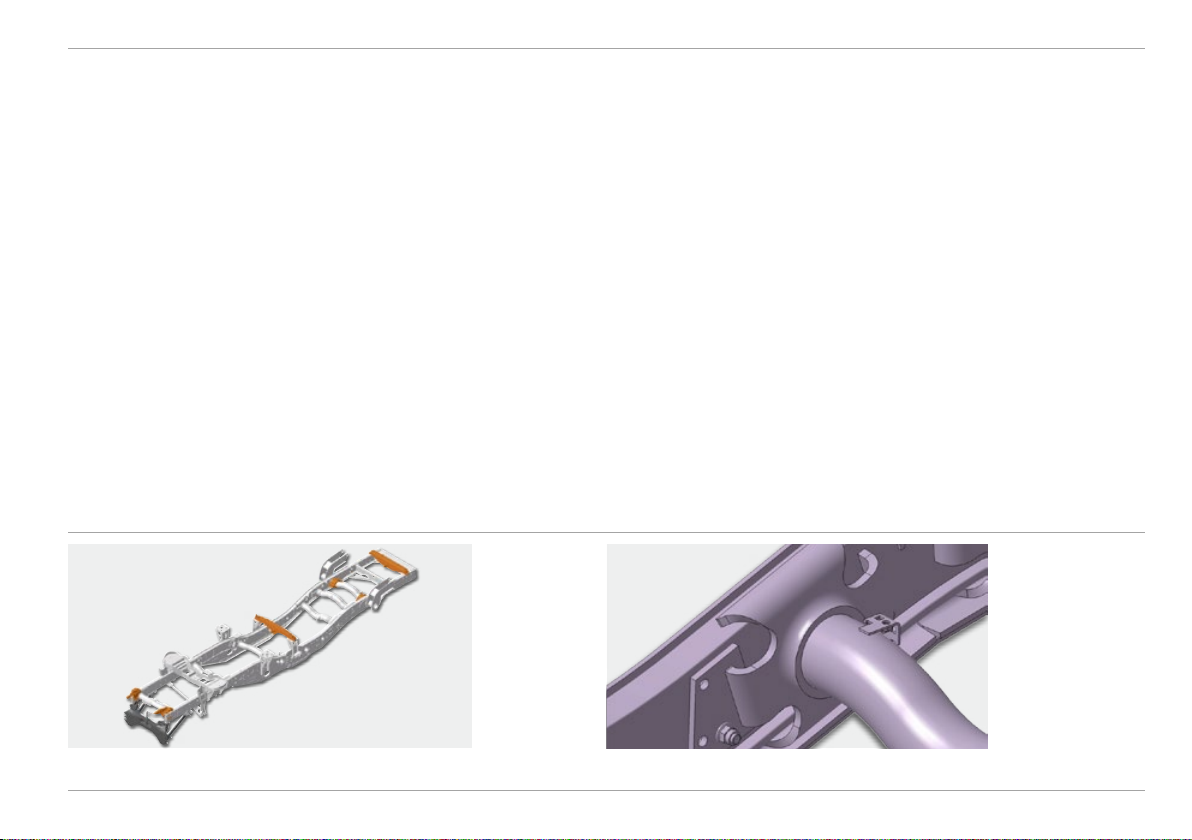

Frame

Frame concept

Frame

Feature

• 2 U-section longitudinal frame members with welded tubular

cross-members and reinforcements in the frame profile

• Offset design, no components protruding downwards

• Robust steel bumper

• Special torsionally flexible connection flange

Advantage

• Heavy-duty, flexible and torsionally flexible frame offering

high elasticity

• No permanent deformation even after extreme diagonal torsion

• Enables all four wheels to remain permanently in contact with the

ground in all driving situations

• Safe and controlled off-road driving

• Installation of drive units at lowest possible point:

low centre of gravity, high ground clearance

• Protection of components in off-road terrain

• Robust protection from mechanical influences in collisions

• Transmission of high torsional forces between longitudinal and

transverse members

Frame with attachment fixtures for non-MB bodies [CD5], front mounting

brackets [CA2], front mounting plate [CP3], cable winch brackets (CH5)

Mercedes-Benz Special Trucks

Special torsionally flexible connection flange

13

Frame Technical Manual

Feature

• Integrated attachment points

• 3-point mounting of cab, engine and gearbox

• Double 3-point mounting for bodies and attached equipment

Advantage

• Suitable for attaching heavy front- and rear-mounted implements

with defined transmission of forces

• Torsion and stress-free mounting of components and bodies

• No restriction of off-road capabilities

• Equipment, attachments and bodies can be mounted in the ideal

positions with regard to torsion and centre of gravity

• Transmission of trust, tensile and weight forces to the intended

points in the frame

• Safe, secure and simple attachment and mounting of equipment

Even with extreme

axle articulation (30°)

there is only a limited

amount of twist

between cab and

body (12°)

3-point mounting of engine and gearbox

14 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – frame

Frame

Feature

[Q32] End cross-member, for increased towing capacity

• Reinforced end cross-member

[Q35] Additional towing jaw at front, lowered

• Additional trailer hitch at front

Advantage

• Enables use of draw-bar trailers

up to 15.4 t (U 4023) and 19.9t (U 5023)

• Enables use of rigid draw-bar trailers and centre-axle trailers up to

9 t (U 4023 / U 5023)

• Facilitates manoeuvring

• Towing possible, e.g. with towing bar

End cross-member, for increased towing capacity [Q32]

Mercedes-Benz Special Trucks

15

Frame Technical Manual

Feature

[Q06] Trailer coupling, larger jaw, annual spring, pin 38.5

• Jaw size 280 x 170 mm

• Make, type: Ringfeder 86 G 110

• Drawbar load: 500 kg

• Pin diam.: 38.5 mm

• Swivelling coupling pin

[Q86] Trailer hitch, small jaw, Rockinger, increased load

• Jaw size 200 x 100 mm

• Make, type: Rockinger 225 G 110

• Drawbar load: 700 kg / 1500kg*

• Pin diam.: 38.0 mm

[Q88] Trailer hitch, small jaw, Rockinger

• Jaw size 200 x 100 mm

• Make, type: Rockinger 227 G 110 J

• Drawbar load: 500 kg / 1250 kg*

• Pin diam.: 38.5 mm

[Q97] Trailer hitch, large jaw, Rockinger

• Jaw size 360 x 215 mm

• Make, type: Rockinger 4040 G 135, version A

• Drawbar load: 700 kg / 1000 kg*

• Bolt Ø: 38.5 mm for 40-mm eyelets

• Swivelling coupling pin

* Only in conjunction with [Q32].

Advantage

• For trailer operation with 40 mm towing lug

• For trailer operation with 40 mm towing lug

• High trailer loads possible

• For trailer operation with 40 mm towing lug

• Minimal installation space required

• For trailer operation with 40 mm towing lug

• One-hand operation optimised

• Optimisation of locking and bearing points on coupling body

• 30 – 40 % longer lifespan

16

Mercedes-Benz Special Trucks

Technical Manual

Engine

Engine concept

Engine

Feature

• Newly developed Mercedes-Benz 4-cylinder OM934 engine

rated at 170 kW/231hp and 5.1 l displacement

• Common rail direct injection with high injection pressures

(up to 2400 bar)

• Multistage injection

• Twin-stage turbocharger

• Mercedes-Benz BlueTec 6 technology, Euro VI compliant:

combined SCR technology with particulate filter and cooled exhaust

gas recirculation (EGR)

Advantage

• Proven engines of the Mercedes-Benz volume series

• High power reserves

• Efficient and clean combustion

• Optimised fuel consumption

• Smooth running

• High torque even at low engine speeds

• Reduced NO

emissions

x

• Reduced particulate emissions

OM934 4-cylinder engine

Mercedes-Benz Special Trucks

17

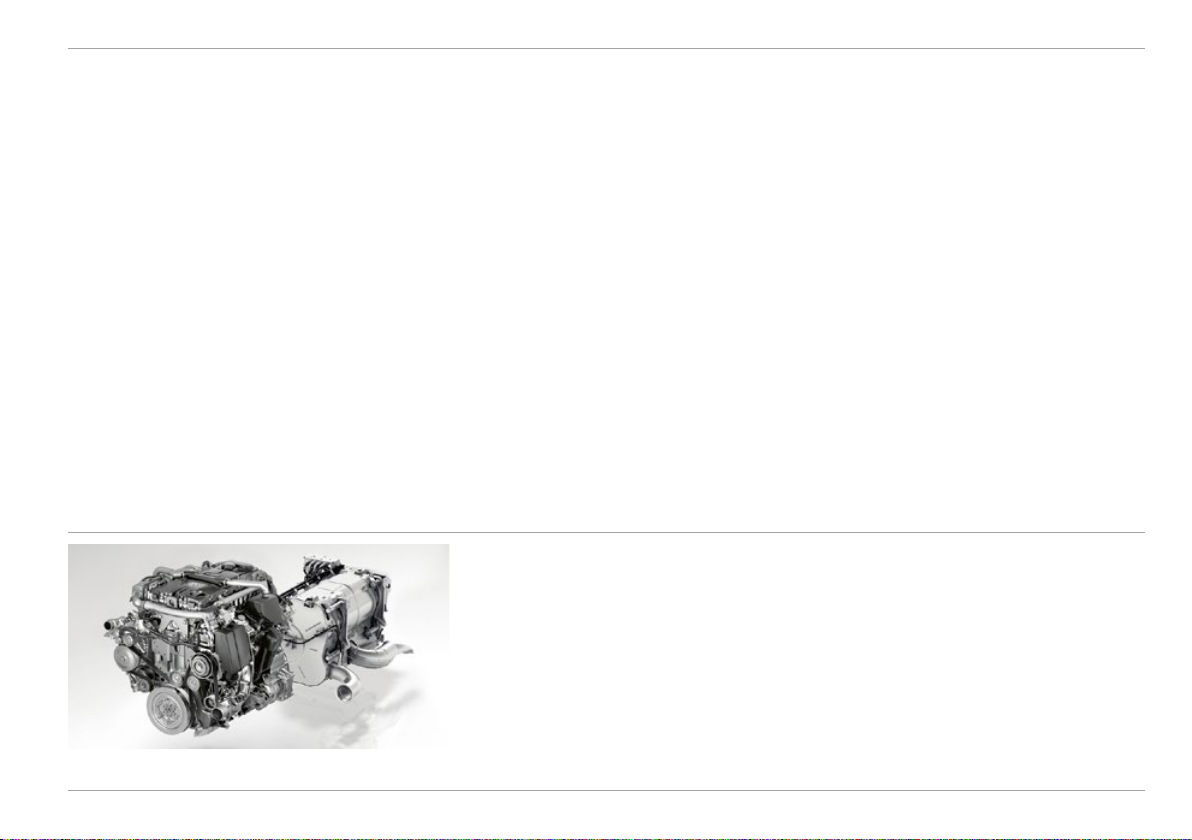

Engine Technical Manual

Feature

• Optimised choice of materials and manufacturing process

• Extended maintenance intervals – 1400 operating hours

• High torque, max. 900 Nm

• Optimised in-engine combustion

• Air intake on right of cab at roof level

1500 300

1000

500

170 kW900 Nm

200

100

Output and torque

diagram for

OM934, 170 kW,

900 Nm

Advantage

• Service life extended by 20 %

• Extended use period, low service requirements, reduced

operating costs

• High pulling power and holding ability of torque

• High adaptability on very rough off-road terrain with steep gradients

®

• Significantly reduced AdBlue

consumption

• Intake of combustion air from area with low dust content

• No entry of water into the intake during fording

• Reduced soiling and extended service life for the air filter

Torque [Nm]

200 0

600 1000 1400 1800 2200

Engine speed (rpm)

18 Mercedes-Benz Special Trucks

2600

Engine power [kW]

Technical Manual

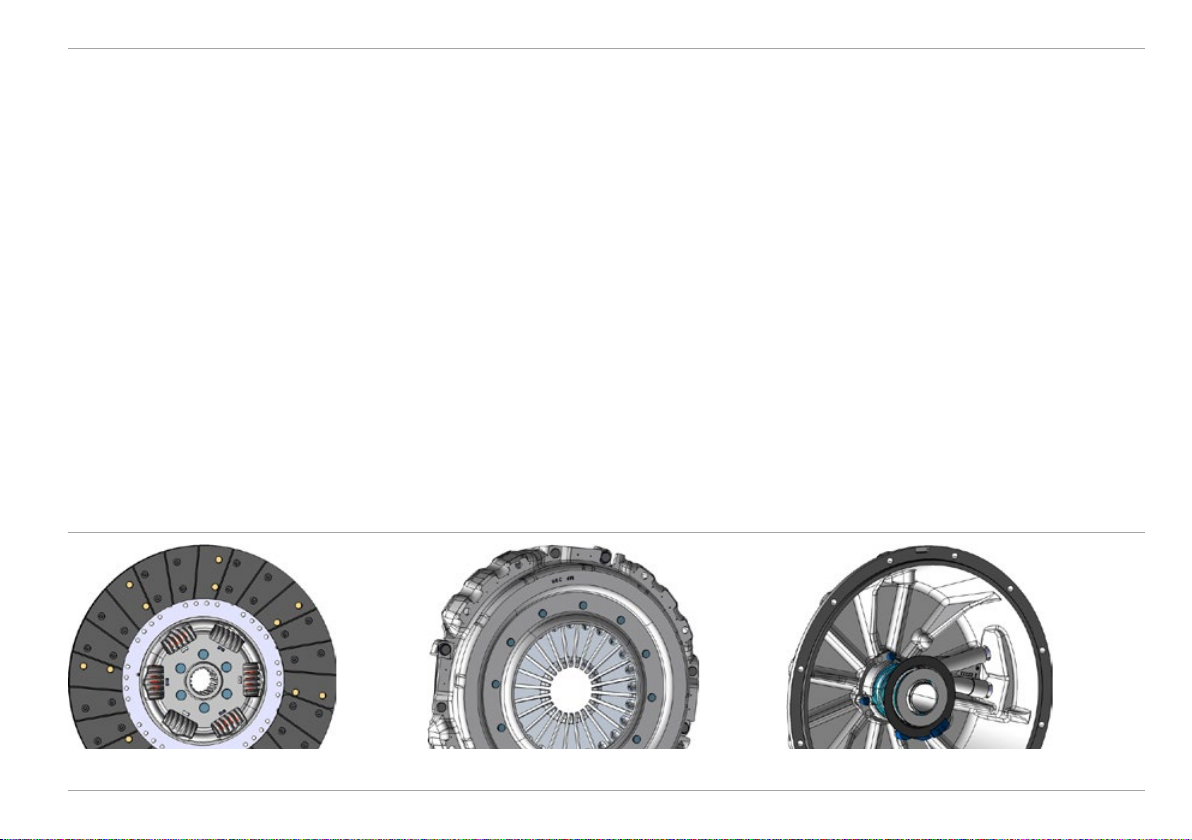

Drive clutch

Engine

Feature

• 395mm single-plate dry clutch

• Hydraulic central clutch release bearing

• Pneumatic clutch pressure booster

• Position sensor

• Wear compensation

• Aluminium clutch housing

• Organic, asbestos-free clutch linings

Advantage

• Easy to regulate, long service life

• No lubrication of moving parts necessary

• Low pedal force (approx. 150 N)

• Wear detectable without disassembly

• Secure frictional connection

• Weight optimisation

• Environmentally compatible

Clutch plate Clutch pressure plate Clutch housing

Mercedes-Benz Special Trucks

19

Engine Technical Manual

High-performance engine brake

Feature

• 2-stage decompression brake

• Control via exhaust camshaft

• Power output up to 178 kW

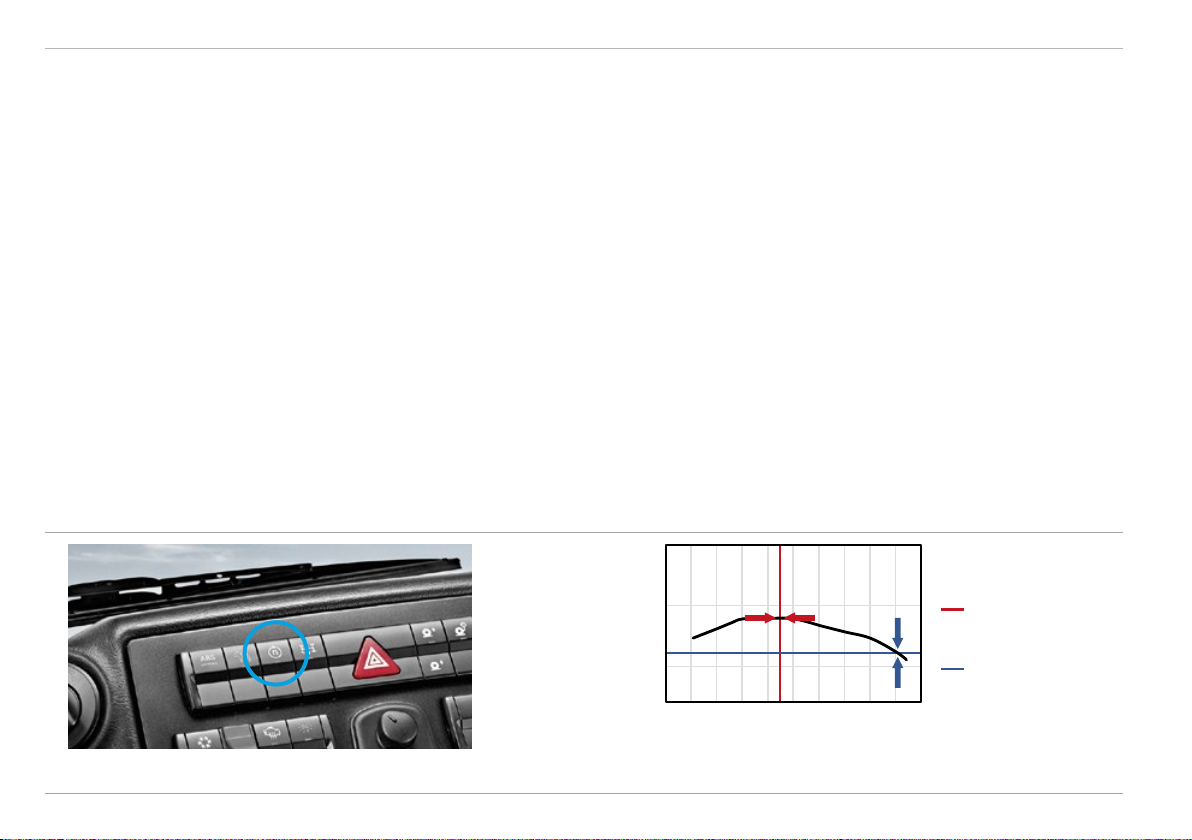

Engine control

Feature

• 2 selectable engine control characteristics

— Torque control (elastic rpm characteristics)

— Work speed control (rigid rpm characteristics)

Switch to select engine control characteristic on dashboard (middle)

Advantage

• Wear-free auxiliary brake, reduces heating and wear of the

service brake

• High brake power, very good deceleration

Advantage

• Rpm characteristics optimally tailored to the operating mode

— Operation under normal conditions, road travel, transport

— Implement use at constant engine speed

— Operation on difficult terrain with speed setpoint, only minimum

engine speed deviation

1500

1000

Torque [Nm]

500

600 1200 1800 2600

Engine speed/torque control

Engine speed (rpm)

Torque and work speed

control:

Engine speed control

for implement operation

Torque control for

driving mode

20 Mercedes-Benz Special Trucks

Technical Manual

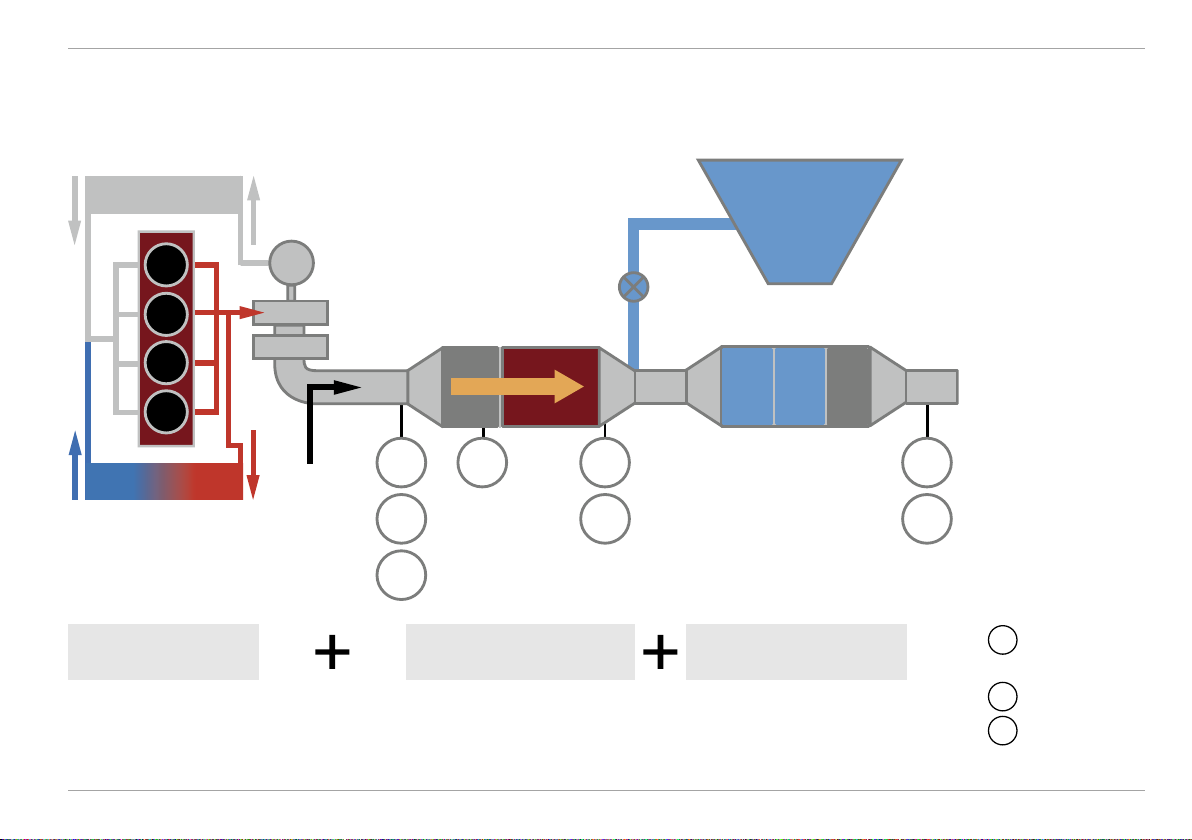

Exhaust gas aftertreatment – BlueTec 6

Intercooler

Engine

AdBlue® tank

EGR cooling

Exhaust gas

recirculation (EGR)

Mercedes-Benz Special Trucks

V

TT

Fuel injection

®

AdBlue

metering

Exhaust

P T T T

NO

X

P

P

Diesel particulate filter

(DPF)

Selective Catalytic

Reduction (SCR)

NO

X

P

Pressure

sensor

NO

NOX sensor

X

T

Temperature

sensor

21

Engine Technical Manual

Feature

• Newly developed Mercedes-Benz engines and exhaust box with

®

BlueTec

diesel technology

• Exhaust gas recirculation

• Diesel particulate filter

• SCR catalytic converter

®

• Optimised AdBlue

injection

• Regeneration of diesel particulate filter during operation

• Downward-facing tailpipe as standard, upward tailpipe available

as option [K7A]

1

SCR catalytic converter

2

AdBlue® tank

3

2

1

3

AdBlue® metering unit

Advantage

• Euro VI compliance

• Proven technology of the Mercedes-Benz volume series, optimised

design to minimise space requirements

• Low NO

emissions

x

• Particulate matter in exhaust flow reduced by 90 %

• Converts NO

conjunction with AdBlue

into harmless nitrogen and water vapour in

X

®

• Reduced AdBlue® consumption

• Longer filter replacement intervals and long filter service life

• Equipment customisable to intended application of vehicle

AdBlue® components

22 Mercedes-Benz Special Trucks

Reduced environmental impact with BlueTec 6, e.g. in

conservation areas

Technical Manual

Exhaust emissions – limiting values

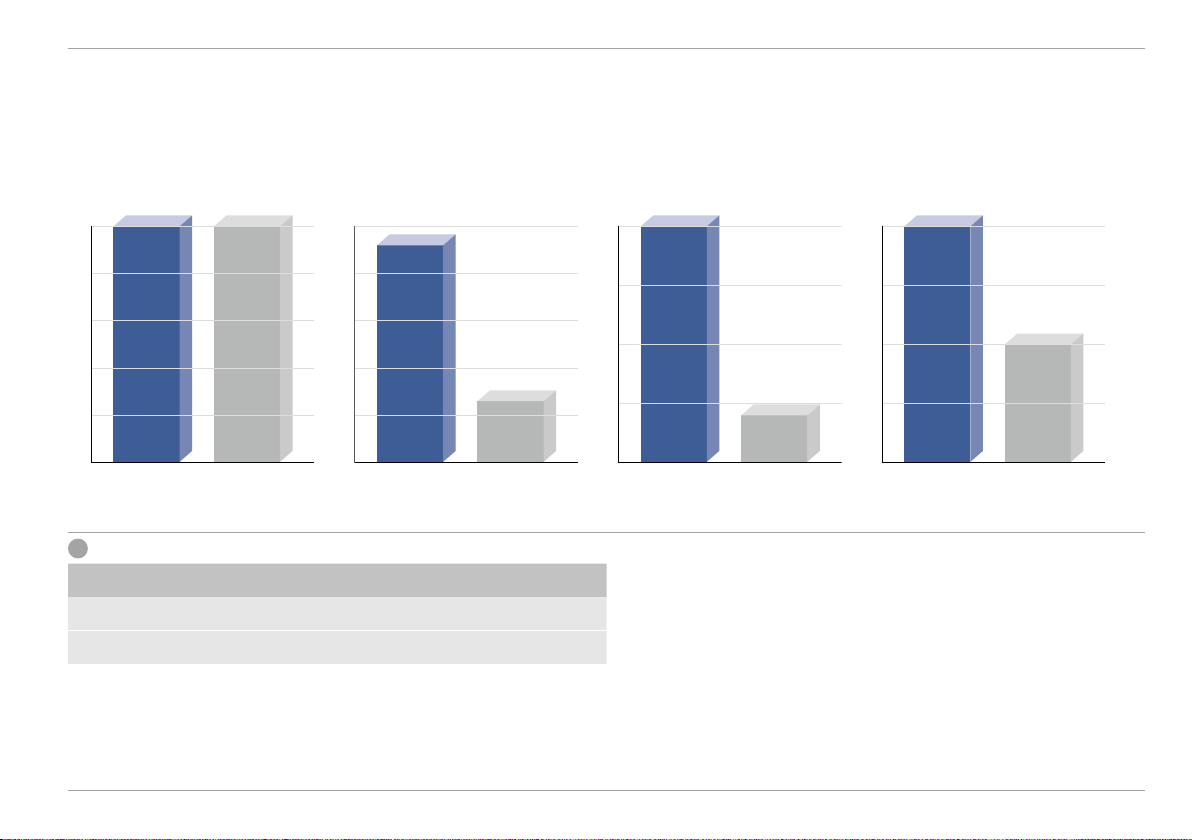

CO: HC: NOX: PM:

Engine

1.5

0.46

Emissions [g/kWh]

Emissions [g/kWh]

0.13

Euro V Euro VI

Euro V Euro VI Euro V Euro VI Euro V Euro VI

i

Standard Vehicle category Legal requirement since/from

Euro V Trucks > 3.5 t 01.10.2009

Euro VI Trucks > 3.5 t 01.01.2014

Mercedes-Benz Special Trucks

2.0 0.021.5

Emissions [g/kWh]

Emissions [g/kWh]

0.01

0.4

23

Engine Technical Manual

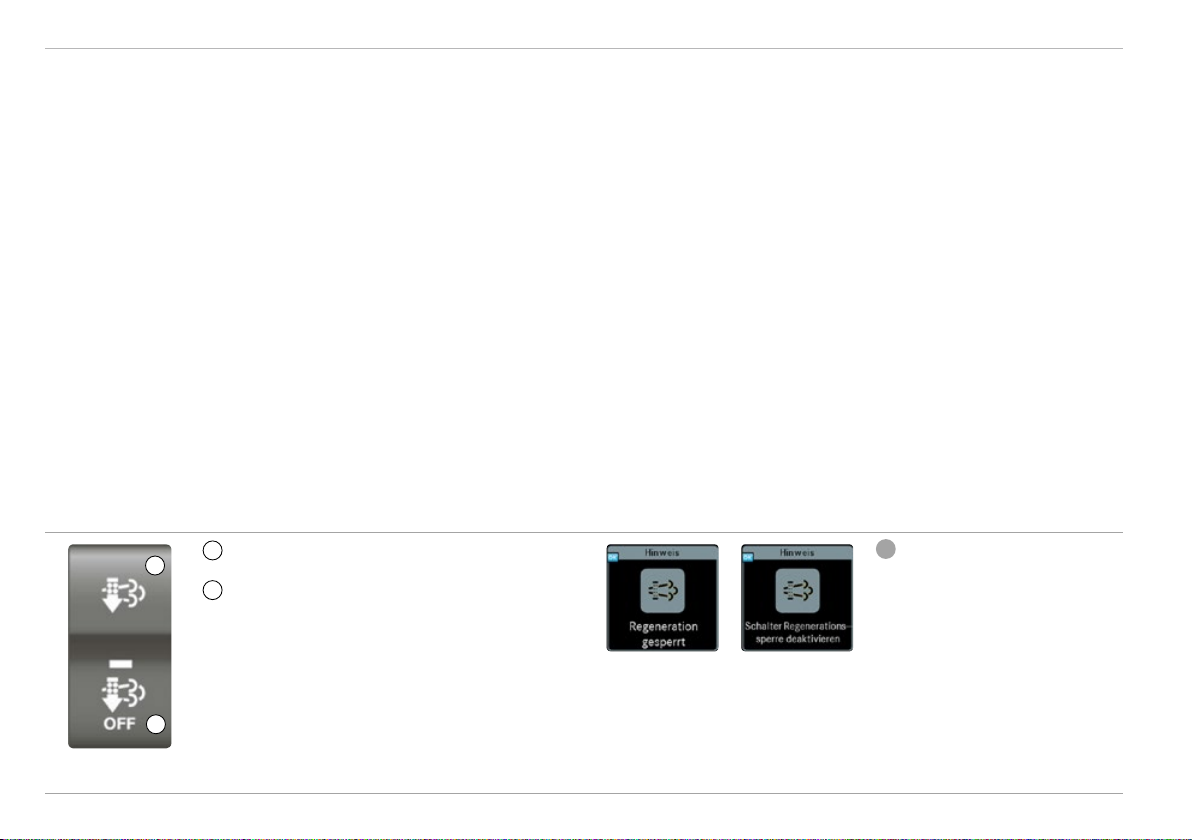

Regeneration

Soot from diesel combustion continuously accumulates in the closed

diesel particulate filter. To guarantee longer filter change intervals and

a long filter service life, regular regeneration of the diesel particulate

filter is necessary.

High exhaust temperatures effectively reduce the soot. As the exhaust

gas temperatures are not always sufficient to produce continual soot

reduction (passive regeneration), there is an automatic triggering of

active regeneration, which is dependent on the operational profile

of the vehicle. If necessary, the driver will be requested to initiate the

regeneration manually when the vehicle is stationary. To do this the

idling speed is increased to approx. 1400 rpm in order to achieve

the optimum exhaust gas temperature.

Passive regeneration

• Continuous, at exhaust gas temperatures > 250°C

• No additional diesel injection into exhaust flow

• Takes place during driving without the driver noticing

Active regeneration

• Takes place subject to conditions of vehicle operation

• Triggered automatically with notification in instrument cluster,

no action required from driver

• Additional diesel injection to increase the exhaust temperature

• Can be suppressed by means of theInhibit switch in dangerous

situations or special operations

• Regeneration can be effected manually with vehicle at a standstill

when notification appears in instrument cluster

The percentage of passive or active regeneration is dependent on the

engine load and the vehicle’s usage profile.

1

2

1

DPF regeneration

switch

24 Mercedes-Benz Special Trucks

Inhibit function (block/allow regeneration)

2

Initiate regeneration manually

Special operations/emergencies

The Inhibit function serves solely to suppress the regeneration process briefly in exceptional situations and must

be reset manually after use. Permanent use of the Inhibit

function will lead to premature filter loading which cannot

be reduced. Unscheduled replacement of the filter will

then be necessary.

Information field

“Regeneration

deactivated”

Information field

“Regeneration

overdue”

i

Information fields on the display show

when the Inhibit switch is active and

indicate when regeneration is overdue.

Technical Manual

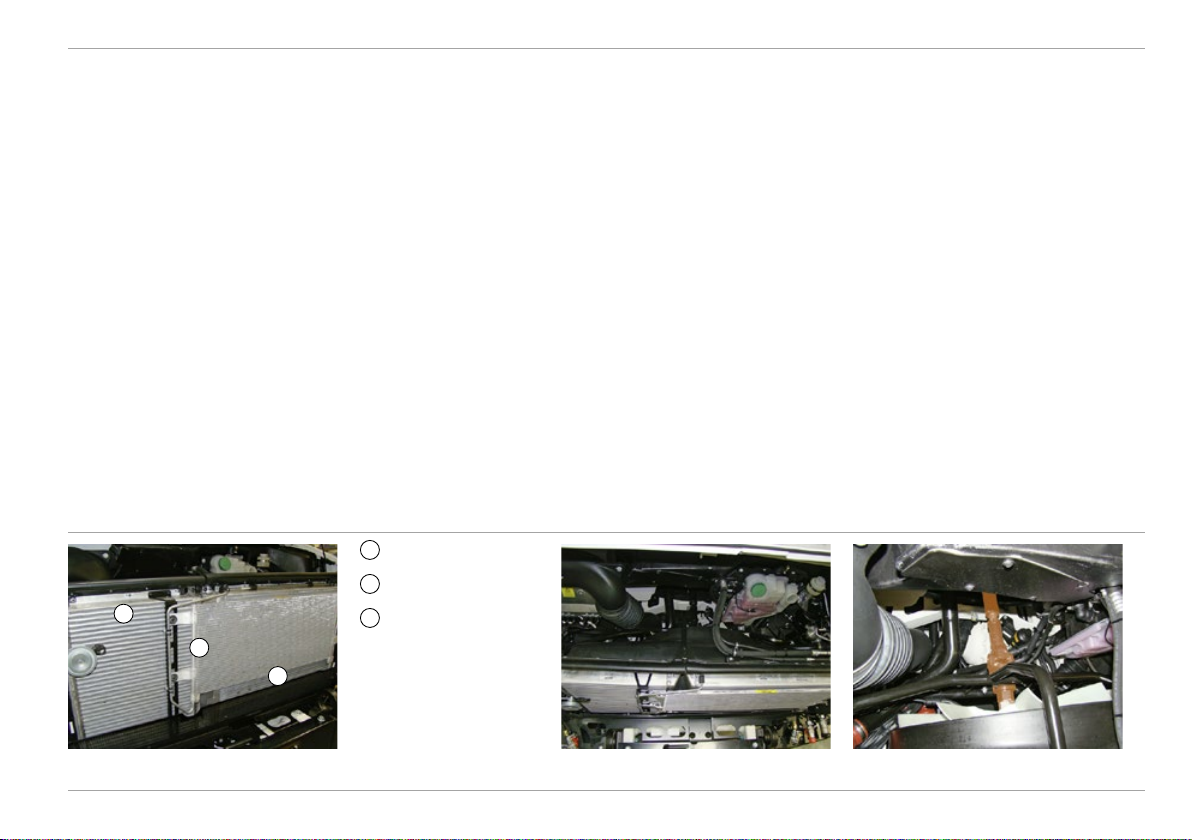

Radiator system

Engine

Feature

• Separate charge air and water cooler (arranged next to one another)

• One fan for both coolers with electronic viscous coupling, mechanically driven via propeller shaft

• High ground clearance of approx. 1100 mm with 365/85 R20 tyres

• Installation location above frame protected by solid underride guard

• All radiators designed for dirt-intensive applications

• Easily removable cover on front of vehicle

1

Charge air cooler

2

Radiator

1

3

2

3

Air conditioning

condenser

Advantage

• Improved cooling capacity

• Reduced risk of soiling

• Easier cleaning

• Safety during fording

• Enhanced cooler efficiency ► fuel savings

• Protection from external factors (stones, branches, mud, etc.)

• Maximum functional reliability maintained even when driving

through water

• Protection from mechanical influences

• Long cleaning intervals

• Excellent accessibility for cleaning

Separate cooler assemblies Coolers for charge air and engine cooling

water arranged next to one another

Mercedes-Benz Special Trucks

Fan with electronic viscous clutch,

mechanically driven via propeller shaft

25

Engine Technical Manual

Optional equipment – engine

Feature

[M55] Fuel preheating, with water separator

• The container consists of a prefilter with heated water

separator. It removes coarse impurities and water fractions

from the fuel upstream of the standard filter.

• Auxiliary heating system to preheat the fuel

• Water storage tank (0.5 l)

[Z0A] Cold climate package

[K7A] Exhaust system, tailpipe vertical

• Exhaust pipe extending up to cab roof on right-hand side of

vehicle

• Stainless steel heat guard

Advantage

• Even low-grade fuel is supplied to the engine free of particulate

matter and water. Avoidance of damage to the injection pumps as a

result of increased water content and dirt

• High operational reliability despite poor fuel quality, unscheduled

maintenance and service costs are avoided

• Enhanced operational reliability at low temperatures, as the

risk of gelling as a result of paraffin separation is reduced

• Problem-free engine start at extremely low outside temperatures

down as low as -26 °C

• Exhaust gases are discharged upwards:

— advantageous during stationary operations (e.g. crane operation)

— no hot exhaust gases close to the ground

• Also prevents corrosion, resulting in longer value retention

26

Mercedes-Benz Special Trucks

Technical Manual

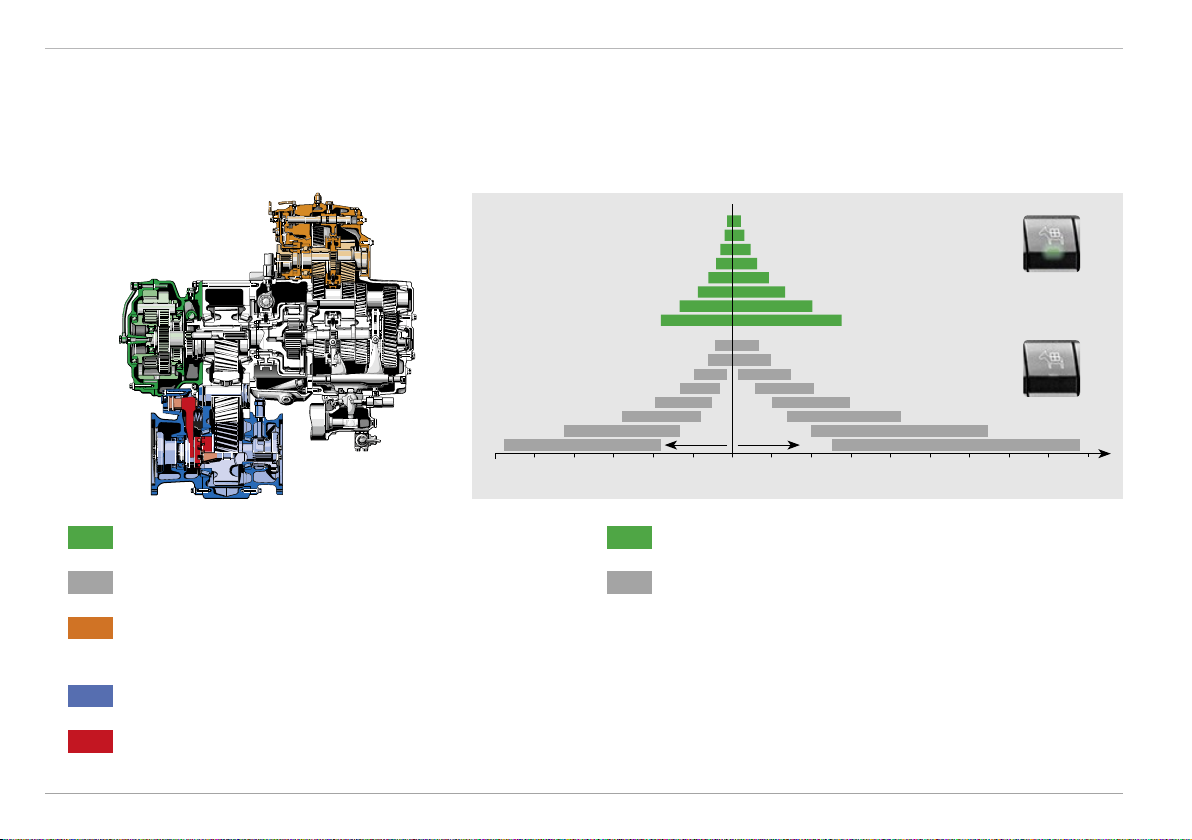

Transmission

Main transmission

Transmission

Feature

• Fully synchronised manual gearbox with eight forward and

six reverse gears

• Helically geared

• Integrated transfer case with torque ball connection

• Reverse gears are ⅓ slower than forward gears

• Synchronised reversing group (EQR) for direct changeover

between forward and reverse gears

• Discrete design

• Low mounting

• Double cone synchronisation

• Optionally extendable by eight off-road gears [G22]

Advantage

• Appropriate forward and reverse speeds for on- and off-road use,

simple and swift gear-changing

• Very smooth running, long service life, high efficiency

• Enables extreme axle articulation

• More effective gear spacing for manoeuvring

• Fast turning, rocking free

• Minimal transmission of engine vibrations

• Torsional flexibility

• Low vehicle centre of gravity

• Long service life

• Short shift times

• Ideal gear-step ratio for any application profile

Modular design of engine and gearbox (side view) Modular design of engine and gearbox (from above)

Mercedes-Benz Special Trucks

27

Transmission Technical Manual

Overview

Fully synchronised Daimler 8-speed EPS manual transmission

Reverse Forward

60 50 40 30 20 10 0 10 20 30 40 50 60 70 80 90

V [km/h]

Range group with off-road range [G22]

Main gearbox

Off-road gears [G22]: approx. 2.1 km/h – 27.1 km/h

Basic gears: approx. 6.6 km/h – 90 km/h

Synchronised Electronic Quick Reverse gearshift

(EQR gearshift)

Transfer case

Engagement of front-axle drive via dog clutch

28

Mercedes-Benz Special Trucks

Technical Manual

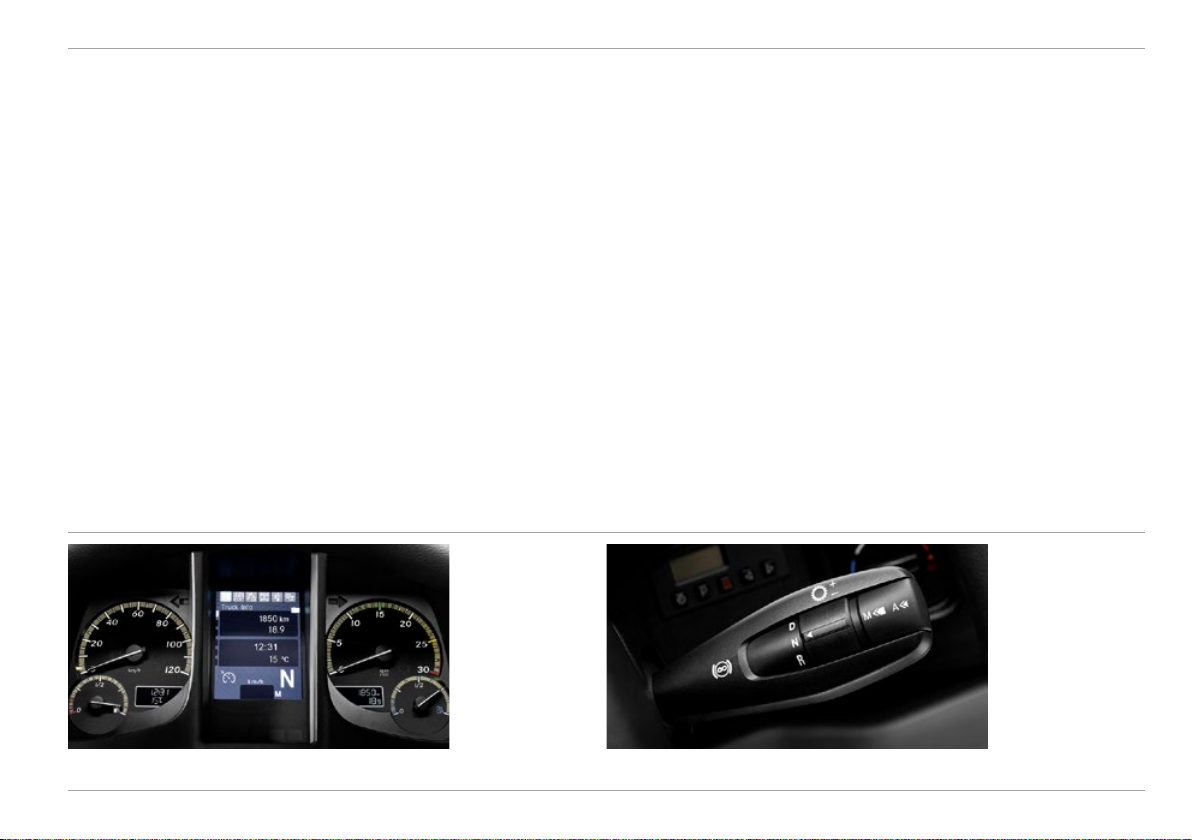

Engine management

Transmission

Feature

• Operation via multifunction lever

• Automatic determination of the correct subsequent gear, indication

on display

• Depress clutch for gear change, changeover occurs automatically

• No mechanical/hydraulic connection between selector lever and

gearbox

• Minimal physical effort required of driver, shifting work performed

by pneumatic cylinder

• Neutral switch with detent position in multifunction lever

Advantage

• Convenient arrangement of shift elements and controls

• Optimal gear pre-selection

• Protection of engine, clutch and transmission

• During gear changes the right hand is free (e.g. for operating

implements)

• No transmission of vibrations to cab

• Allows drivers to relax and concentrate on driving

• Direct shifting to neutral from any gear

• Automatic gear selection from neutral, at any speed

Gear selection indicator in instrument cluster Multifunction lever

Mercedes-Benz Special Trucks

29

Transmission Technical Manual

Electronic Quick Reverse (EQR)

Feature

• Direct changeover between the forward and reverse gears in all

working gears and up to 3rd gear of the road range

• Pre-selection of forward/reverse gears on multifunction lever,

confirmation via clutch

Advantage

• Reliable and fast changeover, high adaptability through rapid

changes between gears

• Changeover to reverse gears possible from all forward gears

• Highly reliable shifting

• Reduced driver workload, better handling, better response during

turning, e.g. when rocking free in off-road terrain

EQR gearshift on multifunction lever EQR gearshift enables rocking free on off-road terrain

30 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – transmission

Transmission

Feature

[G48] Automatic Shift (EAS*)

• Automatic gearshifts

• Automatic clutch operation

• Automatic torque control during clutching

• Manual gear-change selectable

• Manual clutch operation with clutch pedal folded out

• Remote clutch control integrated [G5F]

* EAS: Electronic Automated Gearshift

i

A = Automatic gear change

Automatic shifting according to load condition, accelerator

pedal position, engine mode, uphill/downhill gradient and

engine brake.

M = Manual gear change

Manual gear selection on the multifunction lever. The driver

determines the gear, clutch operation occurs automatically.

Selected gear is maintained when driving uphill or downhill.

Advantage

• Relieves driver workload in all shift-intensive applications

• Full concentration on traffic

• 2-pedal system

• Reduced clutch wear

• Driver selects optimal gear in implement operation or off-road

• Sensitive control in difficult driving situations

• Drivetrain remains closed in extreme situations, even at idling

speed

• External control of the clutch possible, e.g. for switching in power

take-off

i

In difficult driving situations, such

as are encountered in extreme

off-road use and work operations,

the clutch pedal can be folded out

to enable sensitive control. When

folded in, driving with automatic

Folding clutch pedal

clutch operation considerably

facilitates work.

Mercedes-Benz Special Trucks

31

Transmission Technical Manual

Feature

[G22] Range group with off-road range

• Additional range with eight forward and reverse gears

downline of the main gearbox

• Reduced gear-ratio step, approx. 2.2 to 27 km/h

• Step-down ratio relative to road range i = 3.19

[G28] Preparation for working / off-road gear range

• Technical modifications to the main gearbox to prepare for

retrofitting of the off-road gear range [G22]

[G50] Gearbox oil cooler

• Mandatory:

— operation in hot countries

— use of mineral oils

— for non-civilian use

— in case of continuous power take-off > 50 kW

[G5F] Clutch, remote-controlled

• Clutch remote control for power take-off in conjunction

with [E87]

Advantage

• For low operating speed

• For increased tractive power with narrowly defined speed steps

• Improved manoeuvrability in extreme off-road terrain

• Allows cost-effective retrofitting at a qualified workshop

• Delivers the necessary cooling capacity even in extreme conditions

• Controlling and switching the power take-off on and off are also

possible from outside the cab, e.g. for operating the pump on fire

engines

32

Mercedes-Benz Special Trucks

Technical Manual

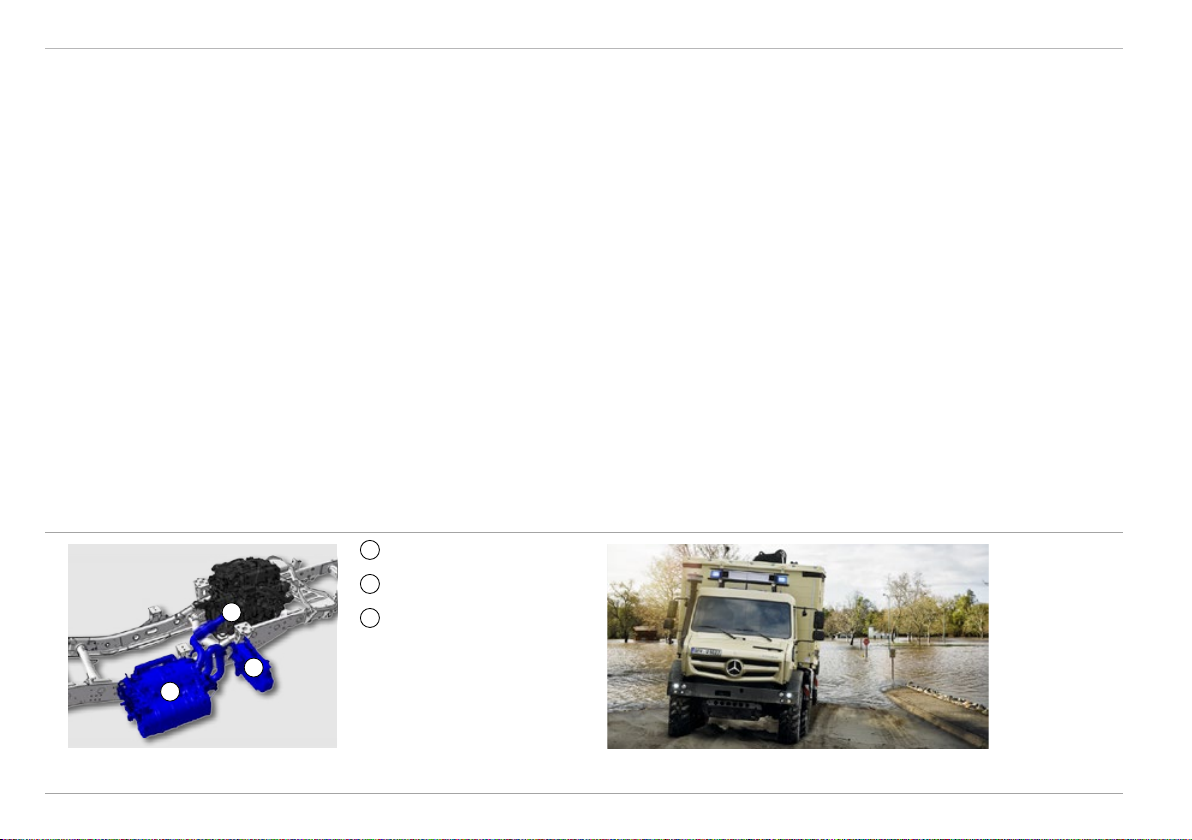

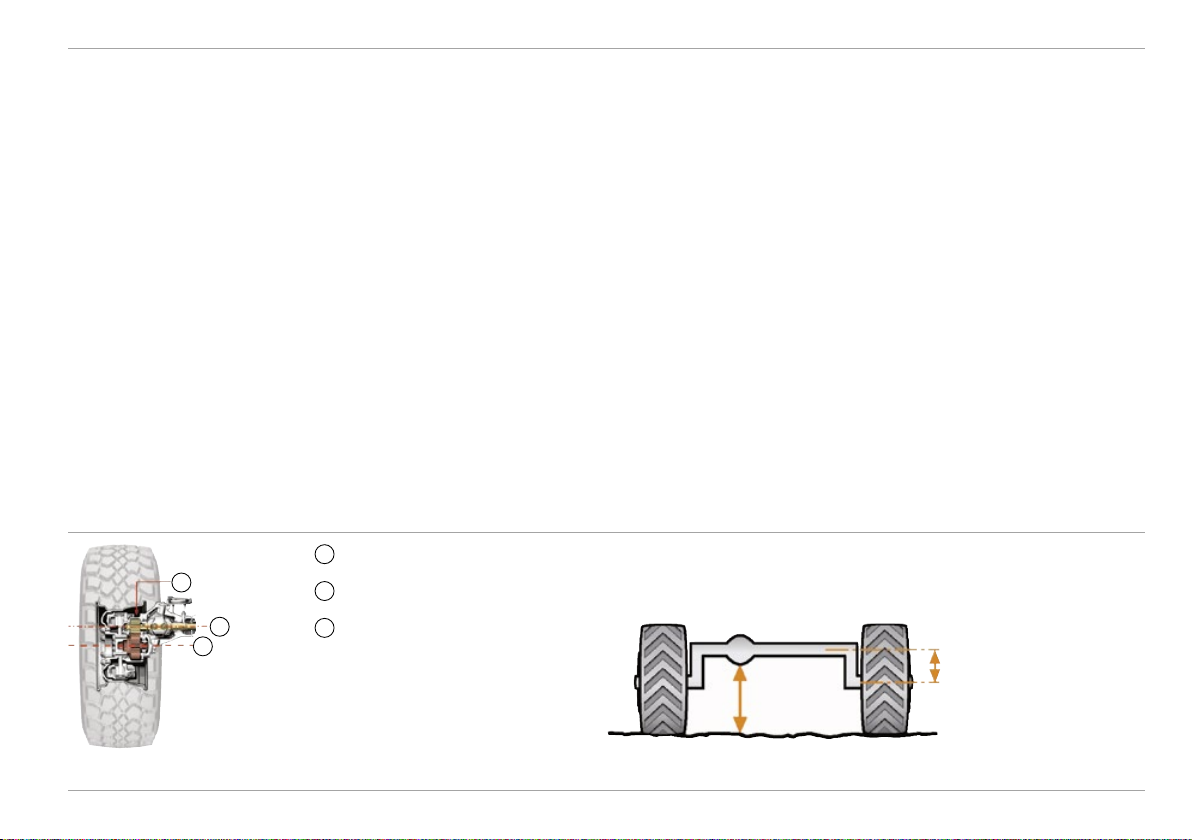

Axles

Portal axles

Axles

Feature

• Axles in portal configuration, connected via torque tubes to the

gearbox, eccentric differential

• Axle tube and differential lie above the wheel centre

• Gear ratio step in hub reduction gear

• Uniform speed of front and rear axle in all-wheel-drive mode

• High front axle load in relation to gross weight

• Reinforced axles

1

Hub reduction gear

1

3

2

2

Wheel centre

3

Axle centre

Advantage

• Extreme ground clearance in conjunction with a low centre of gravity

• Enables safe driving over obstacles

• Vehicle can be driven through deep wheel tracks without

becoming stuck

• Sleek drivetrain, smaller axle housing

• Increased traction in off-road terrain

• High payload, attachment of heavy front-mounted implements

• Maximum utilisation of the vehicle by means of duly configured

implement combinations

• Higher axle loads

Portal axle with hub reduction gear

Mercedes-Benz Special Trucks

33

Axles Technical Manual

1

Cross strut

2

Stabiliser

3

Torque tube

4

Spring-loaded

5

parking brake

5

Axle strut

3

4

3

1

2

Front and rear axle U 5023 in portal configuration with cross strut and stabilisers

34

Mercedes-Benz Special Trucks

Technical Manual

Axle suspension

Feature

• Torque tube with cross strut

• Coil springs with progressive compliance characteristic and wide

distance between spring centres

• Shock absorbers on all four wheels

• Stabilisers at front and rear

• New stabiliser mounting as molecular bearing

Axles

Advantage

• Axle location in transverse and longitudinal direction

• Offers high degrees of freedom

• Long spring travel and extensive axle articulation

• Enable shorter frame overhangs (at front and rear) in comparison to

leaf springs

• Higher angle of approach/departure and short front end

• Permanent ground contact possible for all four wheels, even on

extremely uneven surfaces

• High driving stability and ideal suspension set-up for every load condition

• High driving stability, reduced roll tendency

• Firm grip for all wheels in all speed ranges

• No restriction of ground clearance

• Improved cornering stability, reduced roll tendency

• Improved driving safety with attachments which have a high centre

of gravity

• Durable and robust

1

Cross strut

2

Stabiliser

Coil springs with telescopic shock absorbers Rear view

Mercedes-Benz Special Trucks

1

2

35

Axles Technical Manual

Torque tube technology

Feature

• Torsionally flexible fixing/mounting of axles via torque balls on

gear housing

• Propeller shaft is located in the torque tube

• The spring system does not affect propulsion in any way

• No trailing arm required

Advantage

• Enables very long spring travel

• Maximum possible diagonal torsional flexibility for the axles

• Protects the propeller shaft from soiling and damage

• No risk of entanglement from plants

• Improved traction in comparison to leaf springs, no S-shape

deformation

• Tractive power boosted by weight transmission

• Wear- and maintenance-free axle suspension

• Lower kerb weight

Extreme spring travel and extensive axle articulation (up to

30°) as a result of torque tube technology and coil springs

36 Mercedes-Benz Special Trucks

Torque tube protects propeller shaft from soiling

and damage, even in extreme terrain

Diagonal torsional flexibility with torque tube

t echnology

Technical Manual

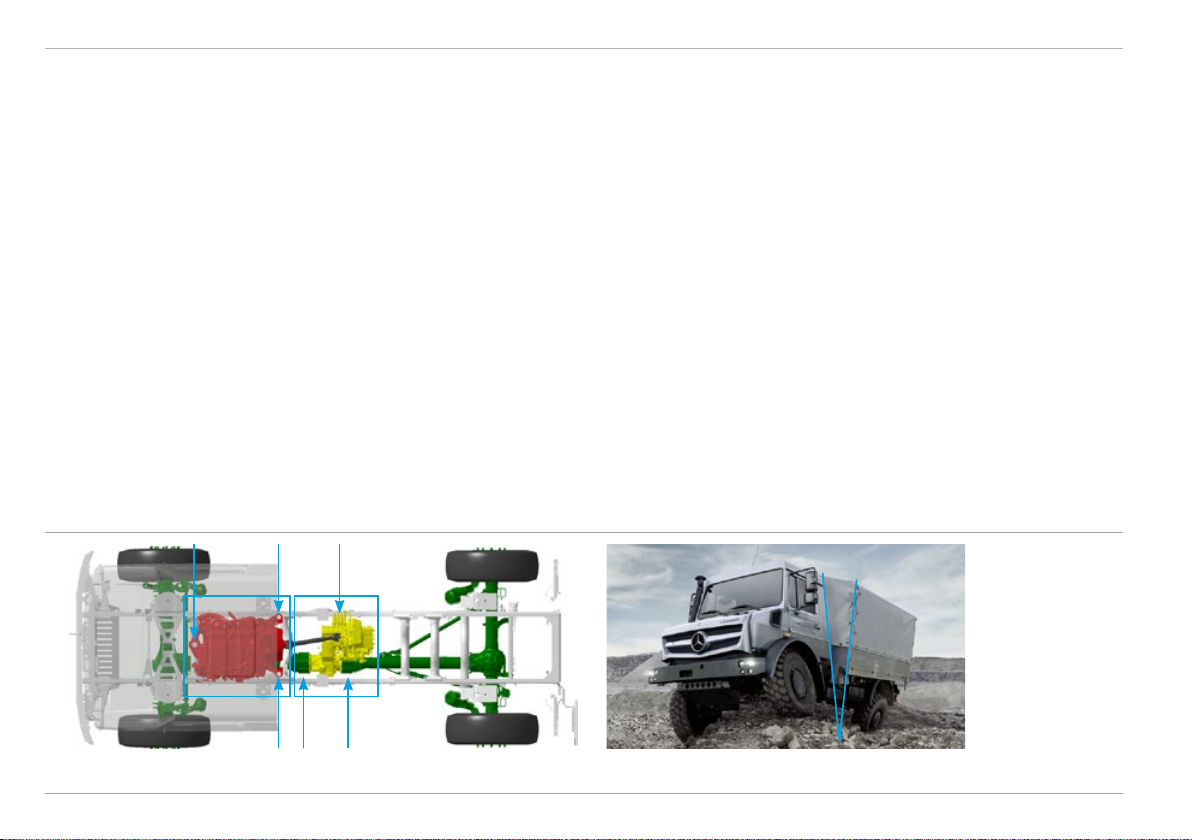

Drive system

Axles

Feature

• Rear-axle drive

• All-wheel drive engageable while on the move via dog clutch

• Differential locks in both axles with 100 % locking effect via positive

connection (dog clutch units)

• Differential locks engageable and disengageable while on the move

• Operated by rotary switch on the dashboard

1

2

Advantage

• For road use: agile, economical, reduced tyre wear, straightforward

handling

• For off-road use: wear-free as a result of positive connection and

slip-free transmission to front axle

• For extreme terrain: slip-free power transmission to all four wheels,

synchronisation of the four wheels, full power transmission (also

possible via one wheel in extreme cases)

• No interruption of pulling power during shifting

• No need to stop the vehicle

• Convenient engagement

3

4

2

1

3

4

Optimum power transmission to the axles on

varying surfaces

Mercedes-Benz Special Trucks

Drive variants and differential locks: (1) rear-wheel drive; (2) all-wheel drive; (3) all-wheel drive, rear-axle differential

locked; (4) all-wheel drive, front- and rear-axle differential locked

37

Axles Technical Manual

Single tyres

Feature

• Broad spectrum of tyre types, such as MPT and traction tyres with

high-cleat tread

• Large-volume MPT low-pressure tyres (broad tyre pressure range

from 1 to 6 bar)

• Four tyres of identical size and width

• Same track width front and rear

Advantage

• Specific equipment for different operating conditions:

on- and off-road, soft ground, desert, etc.

• Low standing pressure

• High traction

• Reduced track in off-road use

• Good self-cleaning

• Advantageous for all-road use

• Low rolling resistance off-road

• High driving stability

• High traction as a result of genuine four-wheel drive

• Simple fitting of snow chains

• Rear wheels run in the track of the front wheels, avoiding the

power-sapping need to form their own track (genuine four-wheel

drive effect)

• Good track overlap

• High driving stability

Single tyres MPT treads High-cleat tread

38 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – axles

[A30] Tyre pressure control system

Overview

The tyre pressure control system is an electro-pneumatic system

installed in the vehicle for automatic tyre inflation and deflation at

the front and rear axles while on the move.

1 2 3 4 5

13 12 11 10 9 8 7 6

1

Hose line to the wheel rim

2

Wheel rim:

3

Wheel hub

4

Drive gear

5

Axle tube

6

Compressed air line

7

Shaft seals

8

O-ring

9

Sleeve

10

Fitting

11

Quick-release coupling

12

Test and filling valve

13

Wheel nut cover

Axles

Mercedes-Benz Special Trucks

39

Axles Technical Manual

[A30] Tyre pressure control system

Feature

• Adaptation of the tyre pressure during driving

Advantage

• Adjustment of tyre pressure from the cab while on the move

• Fast and flexible adaptation to road and ground conditions

• Tyre pressure at front and rear axles individually adjustable on

basis of pre-programmed pressure levels

• Equalisation of pressure loss, in case of tyre damage vehicle can

be driven to the nearest workshop

• Adjustment of actual rolling circumferences of front and

rear wheels

• Consideration of different axle loads

• 4-channel system

• Operation via steering wheel buttons and intuitive menu navigation

• Indication of the tyre pressure on the display

Pre-selection of tyre pressure on display,

operation via steering wheel buttons

40 Mercedes-Benz Special Trucks

Push-button switch for tyre pressure

control system

• User-friendly, safe control via pre-programmed tyre pressure levels

• Monitoring of the settings and detection of pressure loss

• Prevention of tyre damage

Left: attachable hose line, test and filling valve for rim and tyre

Right: driving condition, valve and line protected under the wheel hub

Technical Manual

Axles

[A30] Tyre pressure control system

Halving the tyre pressure off-road means doubling the ground contact

area and the tractive force.

High tyre pressure on the road

• Small contact area

• Low tyre wear

• Low fuel consumption

• High load capacity at

high speed

• Good track-holding and

very stable steering

Tractive force [kN]

Traction conditions depending on the tyre pressure

50

40

30

20

10

1.5 2 2.5 3 3.5 4 4.5 5

Tyre pressure [bar]

Low tyre pressure off-road

• Large contact area

• Low ground pressure,

less field damage

• Less slip

• High traction

• Good self-cleaning (tread)

• Minimal ground compaction,

fewer ruts

• No getting stuck

Mercedes-Benz Special Trucks

41

Axles Technical Manual

Feature

[A23] Guard plate for callipers

• Guard plates on the callipers to repel stones, branches,

wires, etc.

[A26] Reinforced wheel stud covers

• Reinforced covers for the wheel studs (wheel hub cover)

[A27] Double sealing of wheel hubs, for operations in muddy

conditions

• Additional sealing rings

[A28] Encapsulation of hub reduction gear, for operations in

extremely muddy conditions

• Complete encapsulation with additional sealing rings

• Mechanical drainage valves in compressed air system

• Only available as standard for U 4023, feasible for U 5023

via CTT code [UA28]

Advantage

• Protect brake callipers from damage in off-road use

• Protection from damage in extreme off-road territory

• Prevents water and fine sand from entering into the hub

reduction gear

• Prevents water and fine sand from entering into the hub reduction

gear and the brakes

• Special protection for operations in extremely muddy and sandy

terrain (e.g. open-pit mining operations)

• Facilitates drainage of the compressed air system

42

Mercedes-Benz Special Trucks

Technical Manual

Brakes

Dual-circuit braking system

Brakes

Feature

• Pneumatic disc brakes at all wheels

Advantage

• Uniform braking effect

• No overheating even under continuous stress

• Maintenance- and repair-friendly

• Automatic load-dependent brake (ALB)

• Brake wear indicator

• High-pressure system (18 bar) via gear-driven heavy-duty

compressor

• Air dryer

• Brake power regulation depending on the load condition

• Timely indication when maintenance is due

• High brake-air pressure

• Less space required for air tank, more space available on the vehicle

• No corrosion

• No freezing of the lines

• Spring-loaded parking brake, acting on the rear wheels

1

3 4

1 2

Design of a sliding-calliper disc brake system Disc brakes on all four wheels offer safety in off-road terrain,

Mercedes-Benz Special Trucks

Diaphragm cylinder

2

Brake calliper

3

Brake carrier

4

Brake disc

• High braking force, minimal braking effort required of driver

even with heavy bodies

43

Brakes Technical Manual

4-channel ABS

Feature

• In case of a locking tendency, the pressure of the wheel cylinder is

corrected according to the road surface condition and load condition

• 4-channel ABS in all model designations

• ABS can be switched to off-road mode

i

Up to 15 km/h: locking

15 – 40 km/h: brief locking

Over 40 km/h: no locking

Advantage

• Safe handling characteristics during braking

• Driving stability and steerability are preserved

• Reduced risk of accidents

• High level of safety through separate actuation of each wheel at

the front and rear axles

• Volume production-tested

• Wheels can lock to a certain extent, in order to build up an

earth wedge

Switch to change ABS mode (off-road)

44 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – brakes

Brakes

Feature

[B2Z] Parking brake, also on front axle

• Service and parking brakes are electro-pneumatically

coupled as a securing brake.

• The parking brake acts on the rear wheel, in addition

the service brake acts with reduced pressure on the

front wheels

• Only when the engine is running

[B5B] Trailer brake, 2-line

• Pressurised fill line (red)

• Unpressurised brake line (yellow)

• Braking effect from air admission to the brake line

[B5N] Compressed air filling connection, front

• External filling of the compressed air system from an

outside source

• Coupling head (red) on the bumper

• Air supply for service brake, spring-loaded cylinder,

®

gearshift, AdBlue

injection, suspension seat, etc.

[B68] Brake connection, front left

• External operation of another vehicle’s service brake system

or control of the vehicle’s own brake system from another

vehicle

• Coupling head (yellow) on the bumper

Advantage

• High stability possible in cable winch operations without additional

aids such as slope supports

• The full weight pressure of the vehicle is available as a holding

force, with due regard to the given coefficient of adhesion

• EU safety standard

• Accommodation of fast-running trailers

• Allows the brakes and spring-loaded cylinder to be activated so

that one’s own vehicle can continue its journey

• For towing the vehicle in the event of engine failure

• Broken-down vehicles can be moved quickly

• Continuous supply of compressed air from external source (hose

connection), maintaining the vehicle on standby for immediate

deployment (e.g. for fire-fighting operations)

• For towing the vehicle in the event of engine failure

• Control of towed vehicle’s service brake system (actuation of brake

from towing vehicle)

Mercedes-Benz Special Trucks

45

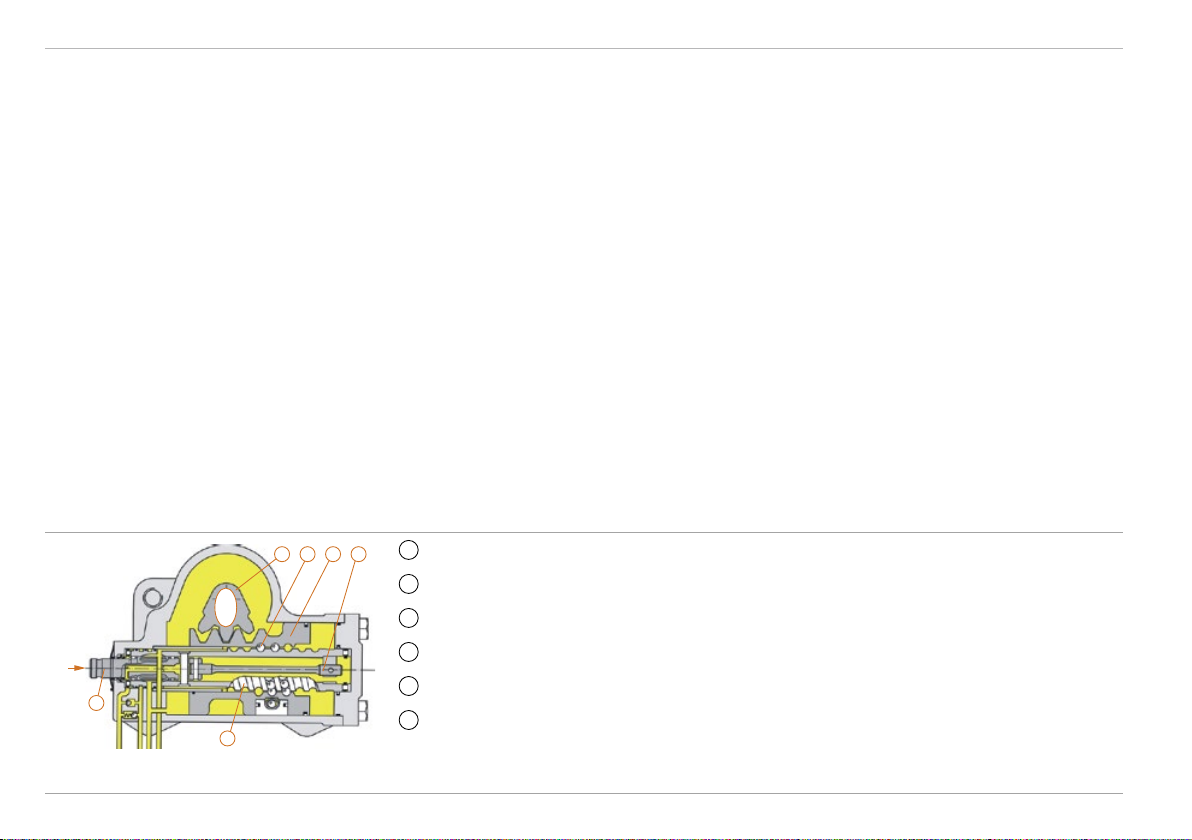

Steering Technical Manual

Steering

Power steering

Feature

• Hydraulically assisted recirculating-ball steering

• Own power steering fluid supply

• Safety steering wheel with angled steering column

• Steering gear on inside of frame, fluid tank above fording depth

1

3 4 56

to wheel

from steering wheel

1

2

Diagram of the ZF Servocom 8095 steering system

Primary shaft

2

Steering worm

3

Recirculating ball

4

Operating piston

5

Torsion bar

6

Steering shaft

Advantage

• Easy steering even with high front axle loads

• Mechanical part of the steering system remains functional, should

hydraulic power steering fail

• No mixing with hydraulic oil

— Prevents soiling of steering hydraulics

— Fully closed system

• Improved protection in case of collision or accident

• No restriction of approach angle

• Key components in protected area

46 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – steering

Steering

Feature

[Z01] Vehicle with left-hand drive

• Left-hand control arm

• Steering wheel adjustment

[Z03] Vehicle with right-hand drive

• Right-hand control arm

[Z5Y] Vehicle for right-hand traffic

• Headlamps for right-hand traffic

• Tail lights and rear fog lamps for right-hand traffic

• Mirror for right-hand traffic

[Z5Z] Vehicle for left-hand traffic

• Left-hand traffic headlamps with modified light pattern

• Tail lights with modified positions of the rear fog lamps

• Mirror holders for right and left side of vehicles as prerequisite for modified mirror position

Advantage

• Control of the vehicle on the left side

• Individual adaptation to the driver

• Steering of the vehicle on the right-hand side

• Deployment in countries with right-hand traffic, e.g. Germany

• Deployment in countries with left-hand traffic, e.g. Great Britain

Mercedes-Benz Special Trucks

47

Cab exterior Technical Manual

Cab exterior

Cab concept

Feature

• Engine is located under cab (mid-engine concept)

• Seating positioned behind the front axle

• Minimal frame overhang

• Cab-behind-engine design with short front end

• 3-point cab mounting with rubber elements and shock absorbers

• 120 mm higher and longer than Euro III and Euro V models

• Closed cab roof, optional roof hatch [F21]

+120 mm

+120 mm

Advantage

• Additional distribution of engine weight to rear axle

• Well-balanced vehicle in off-road terrain

• Optimum weight balance due to even loading of front and rear axle

• Seat position in low-vibration area reduces subjection to jolting in

off-road use

• Ergonomic entry

• Large approach and departure angles

• Good visibility to the front in off-road driving

• Reduced exposure to jolts from the road

• Compensation for torsional flexing of the vehicle

• Offers more stowage space behind driver’s and co-driver’s seats

• Great fore/aft seat adjustment range, improved legroom,

greater headroom

1

3

2

1

Front end dimension: 1050 mm

2

Distance steering wheel / front axle: 360 mm

(bottom steering wheel position, max. inclination

towards driver)

3

Position of driver’s seat

Proven cab-behind-engine with greater volume than the

predecessor model

48 Mercedes-Benz Special Trucks

Driver’s seat position behind the front axle, short front end

Technical Manual

Doors

Cab exterior

Feature

• Doors with large opening angle, entry behind front axle, steps and

grab rails

• Exterior mirrors heated and electrically adjustable on both sides

Advantage

• Safe, comfortable and ergonomic entry and exit

• Convenient and safe adjustment from the driver’s seat

Entrance, doors open to a wide angle

Mercedes-Benz Special Trucks

49

Cab exterior Technical Manual

Safety

Feature

• All cabs tested as per ECE-R-29/03 regulation on crash safety

ECE: Regulations of the United Nations Economic

Commission for Europe

ECE-R-29: Protection of cab occupants

Advantage

• High safety standard

• High chance of survival in accidents

i

ECE-R-29 is a voluntary, internationally recognised standard

which confirms the stability of the

survival space for all occupants in

the cabs of commercial vehicles.

Survival spaces for occupants

50 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – cab exterior

Cab exterior

Feature

[CE3] 3-step entrance

• Full-size third step

• Elastomer mounting, manufactured to EN1846

fire brigade standard

[EM5] Monitor for camera system

• Monitor integrated in the roof lining

• Monitor with four inputs

[EF2] Front camera

• Mounted on front of vehicle, under bumper

[EF3] Rear-view camera

• Mounted on vehicle rear with the aid of a magnetic foot

Advantage

• Comfortable, ergonomic cab access

• Resilient during off-road driving, complies with

fire brigade standard

• In easy view

• Connecting several cameras possible (e.g. front and

reversing camera)

• Full view of the front area, enhanced safety

• Protected location, also for off-road driving

• Full view of the rear area, flexible use

Front camera under bumper Monitor for camera system

Mercedes-Benz Special Trucks

3-step entrance

51

Cab exterior Technical Manual

Feature

[F21] Roof hatch, round, swivelling

• Diameter 75 cm, set clockwise in direction of travel

[F3W] Cab tilting mechanism, mechanical / hydraulic

• Dual action hand pump with lift cylinder

• Automatic, hydraulic-mechanical lock

• Operated behind the front bumper lever on the right-hand

side, by means of lever and socket wrench

• Safety boom

• Only in combination with tilting brackets for cab [F64]

Advantage

• Access to roof attachments from inside the cab

• High flexibility for firefighting and defence operations,

e.g. firefighting from the cab (pump & roll)

• Driving with open roof hatch possible

• Facilitates access to engine compartment for repair operations also

outside workshops

• Safe tilting of the cab

i

Double cab

configurable via

CTT process –

available on

inquiry [UF07].

Cab tilting mechanism [F3W] on front right of vehicle Unimog in forest fire-fighting operation with cab roof hatch,

52 Mercedes-Benz Special Trucks

swivelling [F21]

Technical Manual

Cab exterior

Feature

[F6B] Windscreen, non-tinted, heated

• Heat-insulating windscreen with electric heating for

defrosting

• Operation with rocker switch

[L47] Additional headlamps for front attachments

• Repetition of the main headlights, higher position

[L50] Rotating beacon, yellow, left, with support

• Removable rotating beacon on support

• Support can be extended by approx. 40cm

[L51] Rotating beacons, yellow, left + right, with supports

• Removable rotating beacons on supports

• Supports can both be extended by approx. 40cm

Advantage

• Quick de-icing of the windscreen

• No icing-up of the windscreen while driving

• Windscreen is kept free of fogging

• Windscreen wiper does not ice up

• Compliance with legal provisions for front-mounted implements

• Full illumination, resulting in safer operation of front implements

• High level of passive safety through early identification of vehicle

• Good visibility even with high bodies

• High level of passive safety through early identification of vehicle

• Good visibility even with high bodies

Mercedes-Benz Special Trucks

53

Cab interior Technical Manual

Cab interior

Spaciousness

Feature

• Spacious interior, including stowage space and compartments and

bottle holders

• High cab roof

• Stowage tray, low, on engine tunnel, with cup holder

• 2-seat or 3-seat version available

Advantage

• Great freedom of movement

• Ample stowage space and compartments for personal items,

clothing and equipment

• Orderly and convenient stowage

• Large freedom of movement and headroom

• Frequently required items (shipping documents, mobile phone,

food, etc.) can be kept within the driver’s reach

• Variable seat arrangement, depending on type of application

Spacious interior Multifunction steering wheel

54 Mercedes-Benz Special Trucks

Technical Manual

Controls

Cab interior

Feature

• Control panel in dashboard (centre) with switches arranged

in blocks

• Back-lit controls with adjustable brightness

(when low beam is on)

• 24V power socket

Advantage

• Easy operation through logical switch arrangement

• Clear and ergonomic arrangement within the driver’s reach

• Clearly recognisable in the dark

• New position for parking brake

• High-quality look

• Safe and convenient operation in the dark

• Simple connection of various small appliances in the cab

Controls in the cockpit Inserts in cab roof

Mercedes-Benz Special Trucks

55

Cab interior Technical Manual

Steering and gear-changing

Feature

• Multifunction steering wheel, adjustable for height and tilt

• Multifunction lever

Advantage

• Many functions can be conveniently controlled on the

steering wheel

• Ergonomic seated position, non-tiring driving

• Individual adaptation of the workplace

• Integrated functions such as gearshift, premium engine brake,

Electronic Automatic Shift (EAS), quick reverse gearshift (EQR)

Multifunction lever and multifunction keys on the steering wheel

56 Mercedes-Benz Special Trucks

Adjustment range of the steering column

Technical Manual

Instrumentation

Cab interior

Feature

• Instrument cluster with graphics-capable 10.4 cm TFT display

• Ergonomic arrangement within the driver’s field of vision

• Bright, monochrome display for good, glare-free legibility

• Driver information system – call-up of relevant information such

as oil level, tyre pressure, coolant level, etc.

Advantage

• Swift, comprehensive information on the vehicle’s operating

conditions and status

• Clear, unambiguous presentation of important information

• Avoidance of misinterpretations

• Simplified departure check for the driver via standard start check

without visualisation

Instrument cluster

Mercedes-Benz Special Trucks

57

Cab interior Technical Manual

Standard controls

Instrument cluster

Displays information on:

• Overall vehicle

• Engine status

Multifunction steering wheel

Adjustable for height and tilt

Operation of:

• Radio

• Telephone

• Instrument cluster

• CRUISE CONTROL

• driver information system

• electronic manual throttle

Control panel in dashboard

Multifunction lever

Operation of:

• gear selection (forward/

reverse)

• Gear selection (up/down)

• mode selection (automatic /

manual)

• Engine brake

Operation of:

• all-wheel drive and differential locks

• heating and ventilation system

• Activation and deactivation of additional optional functions

(e.g. operation of tyre pressure control system)

58

Mercedes-Benz Special Trucks

Technical Manual

Air conditioning, heating and ventilation system

Cab interior

Feature

• Combined heating and ventilation system

• Four-speed blower

• Hot water heater with residual heat utilisation

• Pollen filter with coarse dirt grill

• Control unit on control panel (centre)

Advantage

• Individual control of the interior climate

• Fast de-icing of windows

• Fuel savings and environmental protection

• Suitable for dust- and dirt-intensive applications

• Clean and pure air in the passenger compartment, health protection

for driver and co-driver

• Readily accessible, simple cleaning

• Within driver’s reach

Control unit for air conditioning, heating and ventilation system Air flow directions (orange = air intake in recirculation mode)

Mercedes-Benz Special Trucks

59

Cab interior Technical Manual

Optional equipment – cab interior

Feature

[DF1] Suspension seat, air-sprung, driver

• Fitted backrest and integrated head restraint

• Integrated 3-point automatic seat belt

• Air-sprung suspension system, adjustable dampers

• Weight adjustment from 50 to 150 kg,

cycle stroke +/–40 mm, bellows

• 230 mm fore/aft adjustment, in increments of 10 mm

• 100 mm height adjustment, pneumatic assist

• Inclination adjustment 16°, (from –5° to +11°),

finely incremented

• Backrest adjustment in 2° steps (from –12° to +40°)

• Backrest folds down onto seat cushion

[DF3] Suspension seat, air sprung, with seat heating, driver,

corresponding to [DF1], plus:

• 24V seat heater

• 2-chamber lumbar support, armrest tilt-adjustable

[DB1] Suspension seat, air-sprung, co-driver

• Corresponding to [DF1]

[DB3] Suspension seat, air-sprung, with seat heating, co-driver

• Corresponding to [DF3]

[D3Z] Seat cover, imitation leather

• Highly durable, grime-resistant, washable imitation leather

• For driver’s and co-driver’s seat, not for middle seat [D17]

Advantage

• Good adaptation to the contour of the back

• Easily and quickly adjustable to individual heights and weights

• Good damping even on rough roads

• Improved seat climate resulting from fluted upholstery

• Fatigue-free driving

• Good access to stowage space

• Facilitates getting in and out

• Pleasant warmth in cold weather

• Preservation of healthy spinal column, back and kidney area

• Long-lasting quality and upmarket feel

• Easier to clean seats quickly, very good resilience to wear and

tear from getting in and out

60

Mercedes-Benz Special Trucks

Technical Manual

Cab interior

Feature

[D1Z] Centre seat, with seat belt

• Individual seat with head restraint and 3-point automatic

seat belt, in addition to co-driver’s seat

• Rigid seat without adjustment options for backrest and

seat cushion

[DV3] High stowage box with folding table

• Addition to the stowage facilities in the cab

[D6F] Air conditioning system

• Heating and ventilation system is complemented by

an effective integrated air conditioning system for the

single cab

• Air conditioning condenser (cooling output 4 kW) integrated

in engine compartment, bonnet with two air ducts on lefthand side

• Large air outlets on dashboard

• Temperature and blower adjustment in combination

with heating and ventilation system in the middle of the

dashboard

• 3-position rotary switch with pictogram

• Air distribution into the footwell and to the windscreen

• Swivelling nozzles

Advantage

• Comfortable sitting, even on longer journeys

• Space for two accompanying persons (e.g. for transport to and

from the place of work)

• High safety standard for both passengers

• Swift access to important and frequently required items (documents,

tools, mobile phone, food, etc.) within the driver’s reach

• Enhanced comfort and well-being thanks to reduced relative

humidity and pleasant temperature

• Driver fitness is maintained by reduction in the inside temperature

on hot days

• The air is dried during operation in heating mode and this prevents

the windows from misting up

Mercedes-Benz Special Trucks

61

Cab interior Technical Manual

Feature

[D6N] Auxiliary heater with engine preheating over diesel tank

• Auxiliary heater for heating the engine coolant and the cab,

from WEBASTO

• The time for starting heating can be pre-set at up to 7 days

• Three switch-on times can be programmed

• Pre-selection of the temperature

• Operating cycle 10 to 120 min

• Remaining time 1 to 120 min

• Can be switched on while driving

• The heat output is 1.8 to 7.6 kW

• Fuel consumption between 0.2 and 0.9 l/h

• Automatic altitude compensation

[DE4] Power windows, on both sides, with door trim

• Power windows on both doors

• Door trim

Advantage

• Preheated cab and clear view at departure

• Preheated engine, problem-free and gentle start-up of the engine,

even at extremely low outside temperatures

• Increased heat output in the cab

• Warm engine directly from engine start, fuel savings

• Easy engine start, reduced battery wear

• Convenient opening and closing of the windows on both sides

• Enhanced appearance and feeling of comfort

62

Mercedes-Benz Special Trucks

Technical Manual

Cab interior

Feature

[J2A] CD radio

• DIN installation

• CD drive (MP3)

• Mini-USB jack

• 2 x 20 W power output

• 6 station buttons

• 6 x 6 station presets

• AUX jack

• FM-RDS tuner (VHF), AM tuner (MW/LW/SW)

• RDS-EON

• External muting

• Diverse control options (e.g. multifunction steering wheel)

• Large, clearly defined buttons

• Factory installed

®

[J2B] CD radio with Bluetooth

®

• Bluetooth

hands-free unit

corresponding to [J2A], plus:

• Integrated microphone on the front (MIC)

[J1C] Instrument cluster 12.7 cm, with video function

• 12.7 centimetre colour display

• Video input

Advantage

• Highly user-friendly

• High functionality, reception and sound quality

• No malfunctions due to incorrect wiring

• Antenna and speakers included in the scope of delivery

• Fine finish, ergonomic and tailored to interior appointments

• Time-saving and cost-reducing installation at the factory

®

• Mobile phone can be used while on the move via Bluetooth

(recognised hands-free system)

• Radio loudspeakers ensure excellent intelligibility (volume control)

• Good, glare-free legibility with additional information avoids

misinterpretations

• An additional camera can be fitted for enhanced work safety and

optimised comfort

Mercedes-Benz Special Trucks

63

Auxiliary drives Technical Manual

Auxiliary drives

Location

1

2

1

[N05] Engine PTO to rear (with 6-hole flange)

2

[N13] Gearbox PTO, high-speed, with 6-hole flange

[N16] Gearbox PTO, high-speed, with 4-hole connection

[N19] Gearbox PTO, very high-speed, with 6-hole flange

64 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – power take-offs

Auxiliary drives

Feature

[N05 ] Engine PTO to rear, with 6-hole flange

• Alternative to direct drive of body assemblies with high

power requirement

• Gear ratio i = 0.933

• Independent of the manual transmission

• Electro-pneumatically actuated dog clutch unit

• Operation via push button in control panel in centre of

dashboard, with indicator lamp

• Activation when engine is off, deactivation possible at

any time

Advantage

• High output and torque, up to 600Nm

• No power interruption across the full speed range

• Convenient, defined switching on and off

• Can be used independently of the engaged gear or the drive clutch

i

The engine power take-off can be

switched on only with the engine OFF,

to prevent incorrect operation.

Engine PTO switch Engine PTO (highlighted in red)

Mercedes-Benz Special Trucks

65

Auxiliary drives Technical Manual

Feature

[N16] Gearbox PTO, high-speed, with 4-hole connection

• Standardised flange on manual gearbox (DIN 5480, 4-hole

flange, number of teeth: 14)

• Gear ratio i =1

• Rotational direction anticlockwise as seen in direction

of travel

• Electro-pneumatically actuated dog clutch unit

• Operation via push button in control panel in centre of

dashboard, with indicator lamp

• Only activated when drive clutch is operated and vehicle is

stationary

• Remote control of the clutch with Automatic Shift [G48],

signal picked up via implement socket [E87]

• Programming of the maximum rotational speed

[N13] Gearbox PTO, high-speed, with 6-hole flange

• Corresponding to [N16] with 6-hole flange

Advantage

• Use of commercially available hydraulic pumps

• Output speed and rotational direction identical to engine rpm

and rotational direction

• Convenient, defined switching on and off

• Protected against incorrect operation

• For implement operation from outside the vehicle

• No exceeding of the permissible maximum speed

[N16] Gearbox PTO, high-speed,

with 4-hole connection

66 Mercedes-Benz Special Trucks

[N13] Gearbox PTO, high-speed,

with 6-hole flange

Technical Manual

Auxiliary drives

Feature

[N19] Gearbox PTO, very high-speed, with flange

• Standardised flange at the manual transmission in

accordance with ISO 7646

• Gear ratio i =0.61

• Rotational direction clockwise in direction of travel

• Electro-pneumatically actuated dog clutch unit

• Operation via push button in control panel in centre of dashboard, with indicator lamp

• Only activated when drive clutch is operated and vehicle is

stationary

• Remote control of the clutch with Automatic Shift [G48],

signal picked up via implement socket [E87]

• Programming of the maximum rotational speed

[N18] Preparation for gearbox PTO

• Preparation for retrofitting of [N13]/[N16]/[N19]

Advantage

• Use of commercially available drive assemblies, e.g. fire

brigade pumps