Extreme off-road Unimog BlueTec 6

Technical Manual

August 2014 issue

Technical Manual

Technical Manual for extreme off-road Unimog BlueTec 6

The present Technical Manual serves Unimog Sales as an advisory

document. In addition to the basic vehicle version, special equipment is

also covered. Regarding the availability of standard and special equipment,

please refer to the applicable price lists. Subject to technical modifications

without notice. All rights reserved. Reprinting or reproduction in electronic

form, including excerpts, is prohibited and requires the approval of

Mercedes-Benz Special Trucks.

The latest changes and additions are available through our updates on

the Extranet at:

www.specialtrucks-extranet.com

Daimler AG

Mercedes-Benz Special Trucks

Sales & Marketing

August 2014 issue

Part A

Concept and sales reasoning

Part B

Technical data

Mercedes-Benz Special Trucks

1

Contents

Contents – Part A

Technical Manual

Overview of models and components ................................ 6

Product concept ................................................................... 7

Unimog model series in comparison .................................. 7

Extreme off-road capability ................................................ 8

The Unimog concept for extreme torsional flexibility ......... 9

Angle of approach / departure and ramp breakover angle 10

Fording capability ............................................................. 11

Optional equipment – fording capability .......................... 12

Frame ...................................................................................13

Frame concept ................................................................. 13

Optional equipment – frame ............................................ 15

Engine .................................................................................. 17

Engine concept ................................................................ 17

Drive clutch ...................................................................... 19

High-performance engine brake ....................................... 20

Engine control .................................................................. 20

Exhaust gas aftertreatment – BlueTec 6 .......................... 21

Exhaust emissions – limiting values ................................. 23

Regeneration .................................................................... 24

Radiator system .............................................................. 25

Optional equipment – engine ........................................... 26

Transmission .......................................................................27

Main transmission ............................................................ 27

Overview .......................................................................... 28

Engine management ........................................................ 29

Electronic Quick Reverse (EQR) ....................................... 30

Optional equipment – transmission ................................. 31

Axles ....................................................................................33

Portal axles ...................................................................... 33

Axle suspension ............................................................... 35

Torque tube technology .................................................... 36

Drive system .................................................................... 37

Single tyres ...................................................................... 38

Optional equipment – axles.............................................. 39

Brakes ..................................................................................43

Dual-circuit braking system .............................................. 43

4-channel ABS .................................................................. 44

Optional equipment – brakes ........................................... 45

Steering ...............................................................................46

Power steering ................................................................. 46

Optional equipment – steering ......................................... 47

2

Mercedes-Benz Special Trucks

Technical Manual

Contents

Cab exterior .........................................................................48

Cab concept ..................................................................... 48

Doors ............................................................................... 49

Safety ............................................................................... 50

Optional equipment – cab exterior ................................... 51

Cab interior .........................................................................54

Spaciousness ................................................................... 54

Controls ........................................................................... 55

Steering and gear-changing ............................................. 56

Instrumentation ............................................................... 57

Standard controls ............................................................ 58

Air conditioning, heating and ventilation system .............. 59

Optional equipment – cab interior .................................... 60

Auxiliary drives ...................................................................64

Location ........................................................................... 64

Optional equipment – power take-offs ............................. 65

Hydraulics ...........................................................................68

Overview of hydraulic system........................................... 68

Optional equipment – hydraulic system ........................... 69

Electrical system ................................................................71

Electronic networking ...................................................... 71

Optional equipment – electrical system ........................... 72

Attachment and mounting areas ......................................77

Locations of attachment and mounting areas .................. 77

Mounting areas ................................................................ 78

Optional equipment – mounting areas ............................. 79

Mercedes-Benz Special Trucks

3

Contents

Contents – Part B

Technical Manual

Engine .................................................................................. 86

Engine data – OM934 ..................................................... 86

Engine diagram – OM934 ................................................ 87

Filling capacities .............................................................. 88

Engine brake .................................................................... 88

Compressed air generation .............................................. 89

Transmission .......................................................................90

Main transmission ............................................................ 90

Clutch .............................................................................. 90

Vehicle speeds – U 4023 / U 5023 ................................. 91

Vehicle speed conversion factor ......................................92

Axles ....................................................................................93

Suspension ...................................................................... 93

Technical data on axles .................................................... 93

Technical data on U 4023 rims ........................................94

Technical data on U 5023 rims ........................................95

Brakes ..................................................................................96

Braking system ................................................................ 96

Cab exterior .........................................................................97

Exterior ............................................................................ 97

Cab interior .........................................................................98

Interior ............................................................................. 98

Auxiliary drives ...................................................................99

[N05] Engine PTO to rear, with flange .............................. 99

[N13]/[N16]/[N19] Transmission PTO ........................... 100

Hydraulics .........................................................................101

Technical data on single hydraulic system ..................... 101

Electrical system ..............................................................102

On-board electrical system ............................................ 102

Lights ............................................................................. 102

4

Mercedes-Benz Special Trucks

Technical Manual

Contents

Weights ..............................................................................103

Permissible load values .................................................. 103

Trailer operation ...............................................................104

Pin-type trailer hitch ....................................................... 104

Hook-type trailer hitch (not for civilian use) ...................104

Towing capacities – U 4023, model designation

437.427, 170 kW ........................................................... 105

Towing capacity U 5023, model designation

437.437, 170kW ........................................................... 106

Wheels/tyres ....................................................................107

Tyre availability ...............................................................107

Tyres (technical data) .....................................................108

Tyre load capacity ..........................................................109

Speed allocations ........................................................... 110

MPT (multi-purpose tyres) .............................................. 112

AS tyres ......................................................................... 114

Dimensions .......................................................................115

Technical drawing for U 4023 BlueTec 6,

model designation 437.427 ........................................... 115

Technical drawing for U 5023 BlueTec 6,

model designation 437.437 ........................................... 116

General information .........................................................117

Vehicle climbing resistance ............................................ 117

Trailer climbing resistance .............................................117

Tractive force diagram – U 4023 (8.8 t) .........................118

Tractive force diagram – U 4023 (10.3 t) ....................... 118

Tractive force diagram – U 5023 (14.1 t) ....................... 119

Tractive force diagram – U 5023 (14.5 t) ....................... 119

Mercedes-Benz Special Trucks

5

Overview of models and components Technical Manual

Overview of models and components

Model name Model designation Wheelbase

(mm)

U 4023 437.427 3850 OM934 170/231 4 7.5 / 8.0 / 8.8 / 9.8 / 10.3

U 5023 437.437 3850 OM934 170/231 4 12.5 / 12.7 / 13.0 / 14.1 / 14.5

Engine Output

(kW/hp)

No. of

cylinders

Permissible gross vehicle

weight: Variants (t)

6

Mercedes-Benz Special Trucks

Technical Manual

Product concept

Unimog model series in comparison

Product concept

Unimog Implement Carrier BlueTec 6

• Compact all-terrain Unimog implement carrier

• Vehicle type: tractor unit/truck

• Vehicle width: from 2.15 m

• Wheelbases: 2800 mm – 3900 mm

• Straight, dimensionally stable and weight-optimised

ladder-type frame

• Panoramic cab with large windscreen and

low instrument support

• 4+3 implement mounting areas

• Extensive hydraulics package

• Mechanical engine and transmission PTOs

• Permanent all-wheel drive, differential locks engageable

Extreme off-road Unimog BlueTec 6

• Extreme off-road Unimog chassis

• Vehicle type: truck chassis

• Vehicle width: from 2.3 m

• Wheelbase: 3850 mm

• Dropped, flexible and torsionally flexible frame

• Cab-behind-engine truck with raised windscreen

• Long body length for greater load volume

• Integrated hydraulics system available

• Mechanical engine and transmission PTOs

• Rear axle drive, all-wheel drive and differential locks engageable

Unimog Implement Carrier BlueTec 6 Extreme off-road Unimog BlueTec 6

Mercedes-Benz Special Trucks

7

Product concept Technical Manual

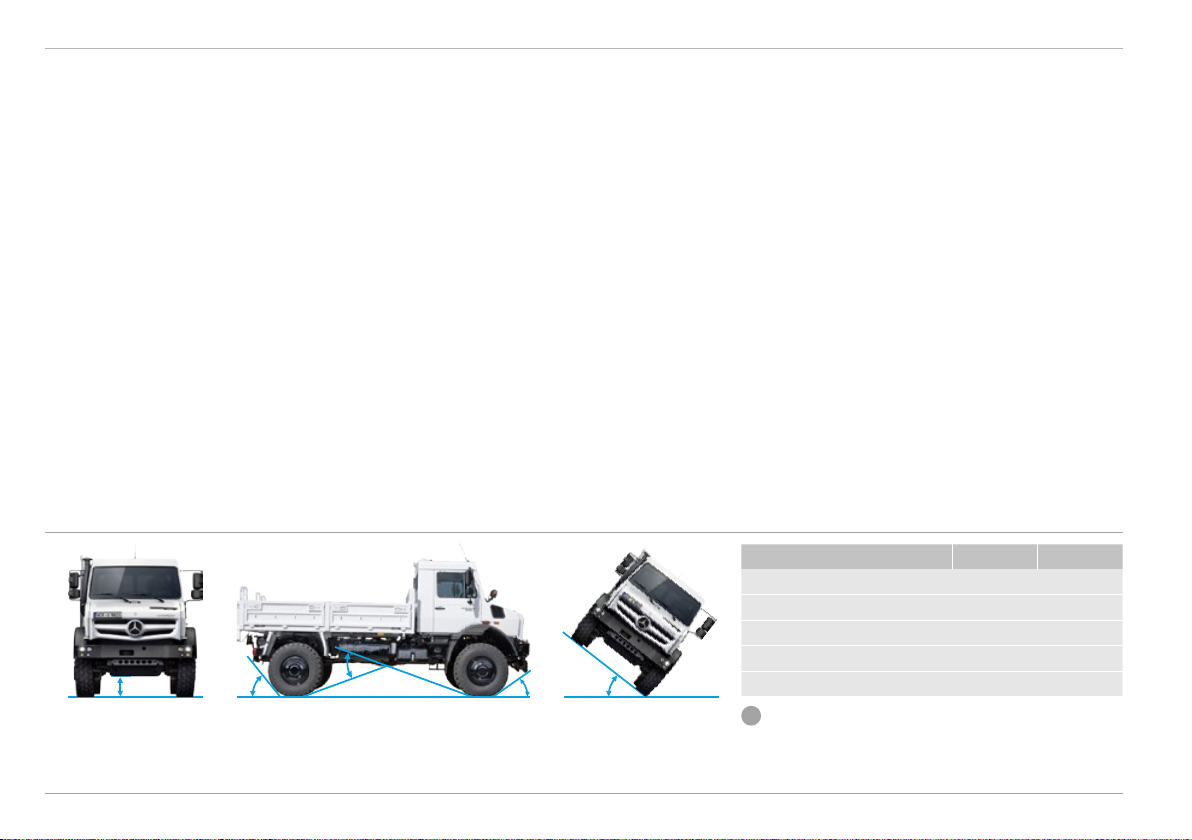

Extreme off-road capability

Feature

• Heavy-duty, torsionally flexible frame

• Portal axle with asymmetric differential arrangement

• Axle location via torque tube technology, coil springs and

transverse control arms

• Fording capability

• Atmospheric pressure equalisation of components

• Short frame overhangs at front and rear

• Low vehicle centre of gravity

• All-wheel drive and differential locks engageable and disengageable

via dog clutch while on the move

a

c

b

Advantage

• Good flexibility off-road on steep inclines and rough surfaces

• Large ground clearance when driving over obstacles

• Extreme diagonal torsional flexibility

• Central load application and bracing on gearbox

• Protection for drive shafts

• Enables fording of water to a depth of 80 cm (standard) /

120 cm [Z16]

• No excess pressure in components

• Large angle of approach/departure and ramp breakover angle

• High climbing and tipping angle

• High tractive power available at all times

• 100 % locking effect

• No interruption in tractive power, no stopping

U 4023 U 5023

a) Ground clearance (mm) 410 460

b) Angle of approach (°) 42 46

c) Ramp breakover angle (°) 32 36

d) Angle of departure (°) 46 50

ed

e) Tipping angle (°) 38 38

i

Angle not dependent on load condition or tyres.

8 Mercedes-Benz Special Trucks

Technical Manual

Product concept

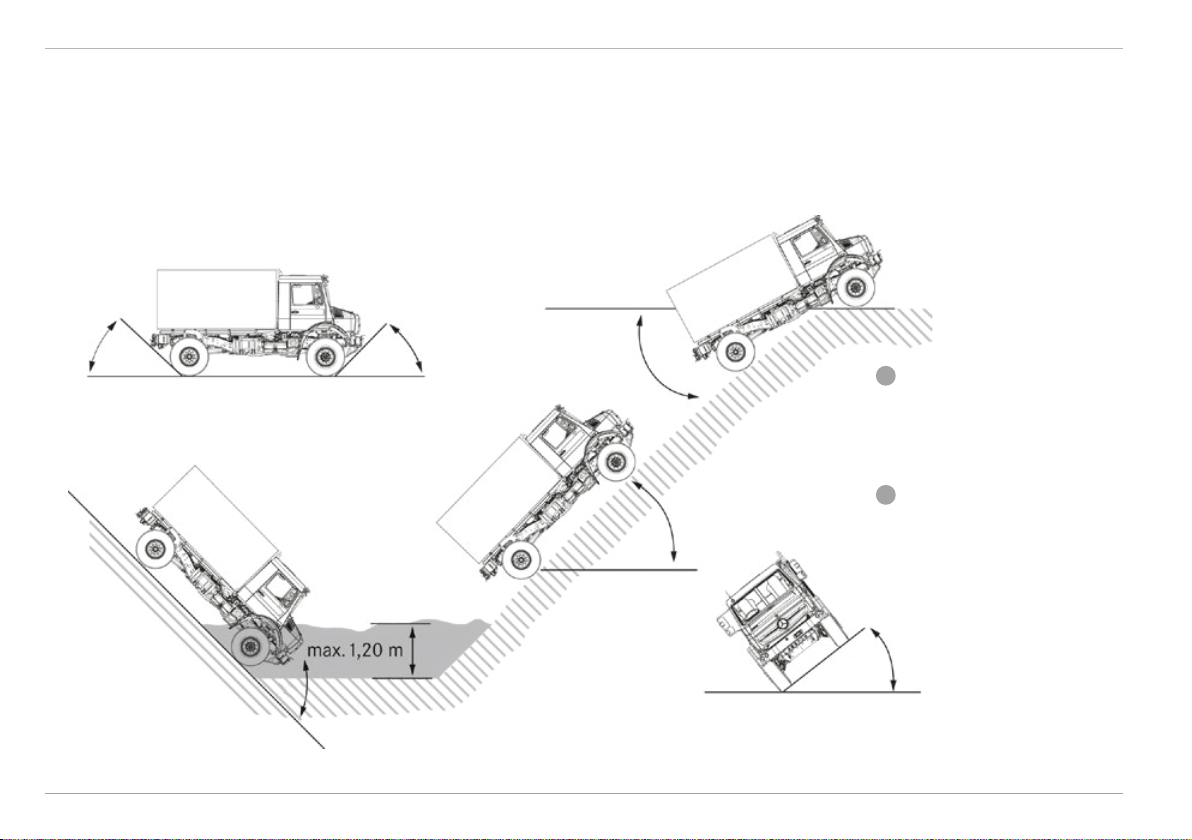

The Unimog concept for extreme torsional flexibility

30°30°

Driving over obstacles optimised by asymmetric arrangement of the axle differentials Major axle articulation made possible by torque tube concept and coil springs

Driving over sharp crests possible thanks to large ramp breakover angle and

angle of approach/departure

Mercedes-Benz Special Trucks

3-point mounting of engine, gearbox and cab. Double 3-point body mounting

9

Product concept Technical Manual

Angle of approach / departure and ramp breakover angle

Figures shown are static values for the chassis of a U5023.

Ramp breakover angle

50° 46°

Angle of approach and departure

Approach

10

46°

Fording capability, approach angle

36°

45°

Slope angle

i

For the angles of the individual

vehicle models, please refer to the

dimensioned drawings in Section B.

Illustrations show 365/85 R20 tyres.

i

The permissible roll angle is 38 degrees

in static state (vehicle functional);

the dynamic limit is 16.5 degrees

(corresponding to 30 %).

38°

Tipping angle

Mercedes-Benz Special Trucks

Technical Manual

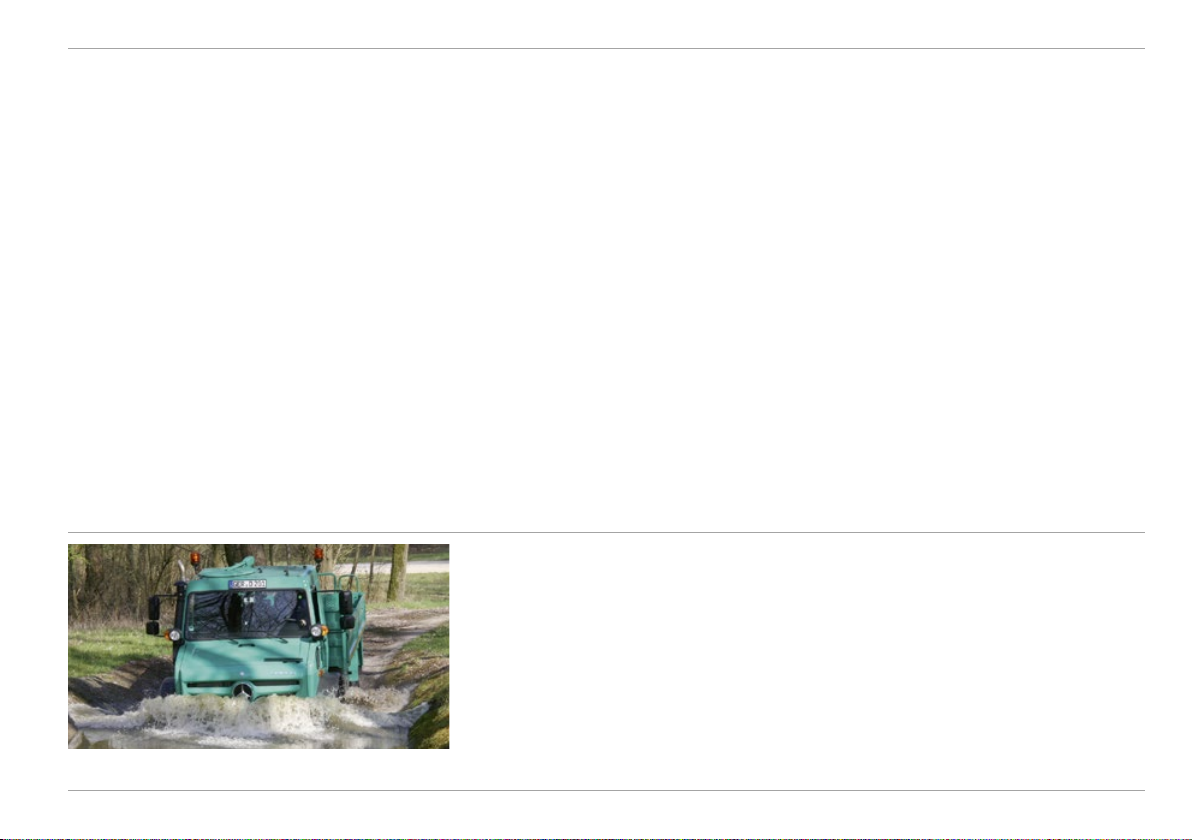

Fording capability

Product concept

Feature

• Torque tube technology

• Air intake pipe at level of cab roof

• Large ground clearance

• Fan with electronic viscous clutch, mechanically driven via

propeller shaft, raised

• Key components and electrical devices protected against

splashing water

Advantage

• Enables standard fording capability to 80 cm

• No permanent drive, fan remains operational

• No damage resulting from exposure to water

• No sagging of a V-belt

Standard fording capability to 80 cm

Mercedes-Benz Special Trucks

11

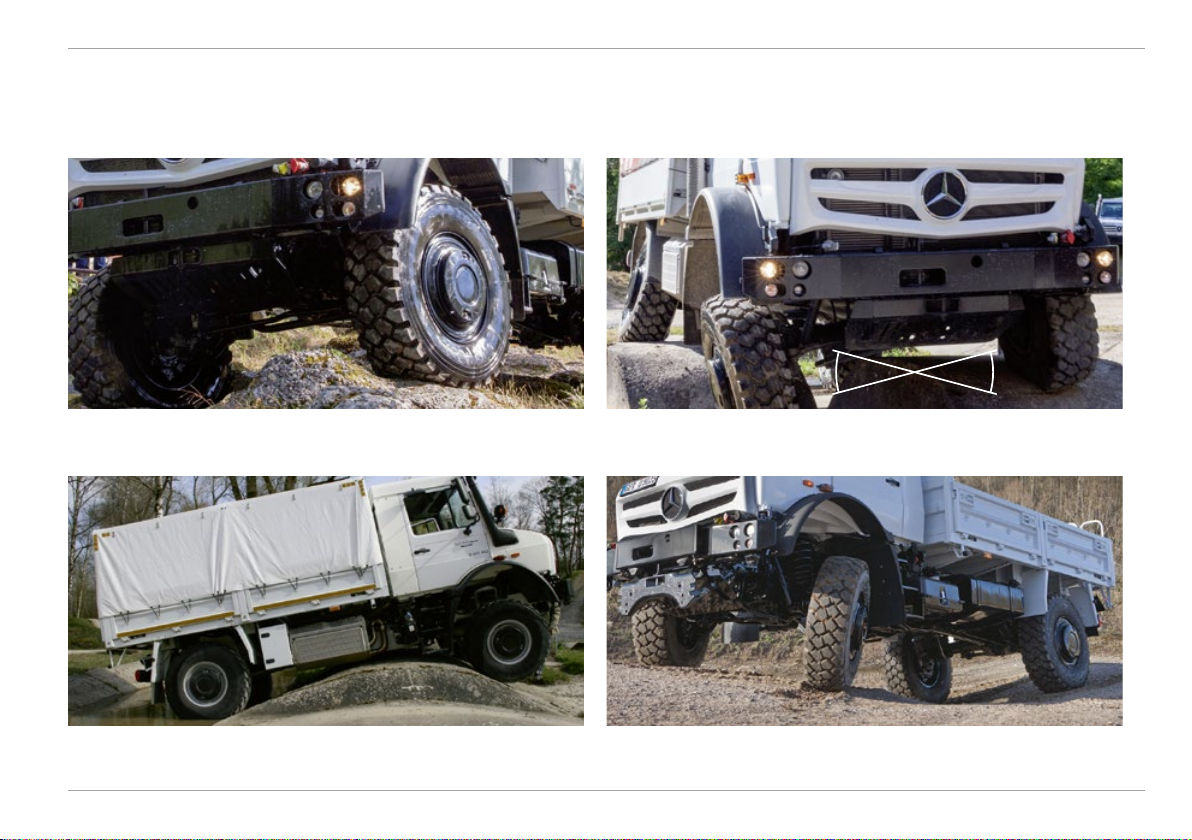

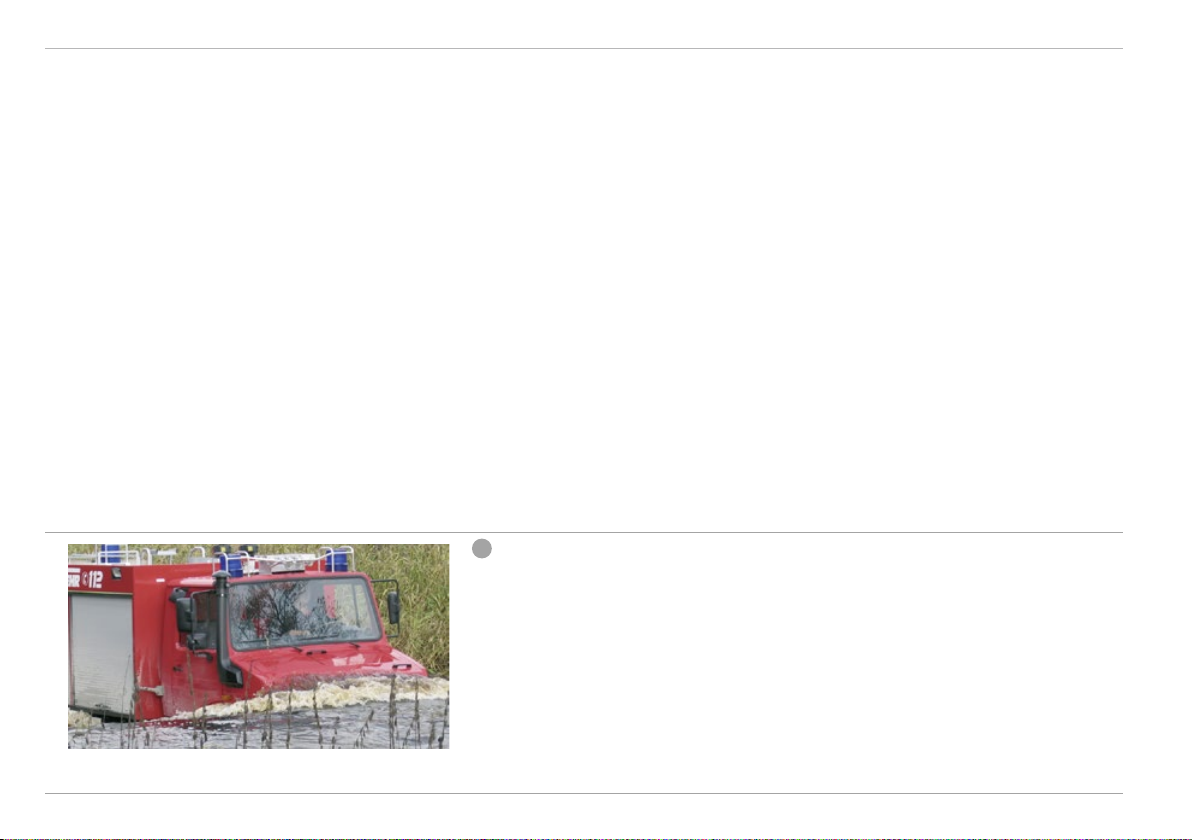

Product concept Technical Manual

Optional equipment – fording capability

Feature

[Z16] Special parts, fording capability

• Raised pressure compensating lines for axles, gearbox,

working gear range, torque tube, fuel tank, air drier,

solenoid valves, brake system, etc.

• Waterproof main headlights with central, raised ventilation

• New position for auxiliary heater [D6N]

Advantage

• Enable fording capability to 120 cm

• Atmospheric pressure compensation with vent lines from the

components prevents entry of water and fine sand

• No reduction in fording capability with optional auxiliary heater

i

Recommended special equipment:

• Double sealing of wheel hubs, for

operations in muddy conditions

[A27]

Special equipment, special parts for fording capability to

120cm [Z16]

12 Mercedes-Benz Special Trucks

Technical Manual

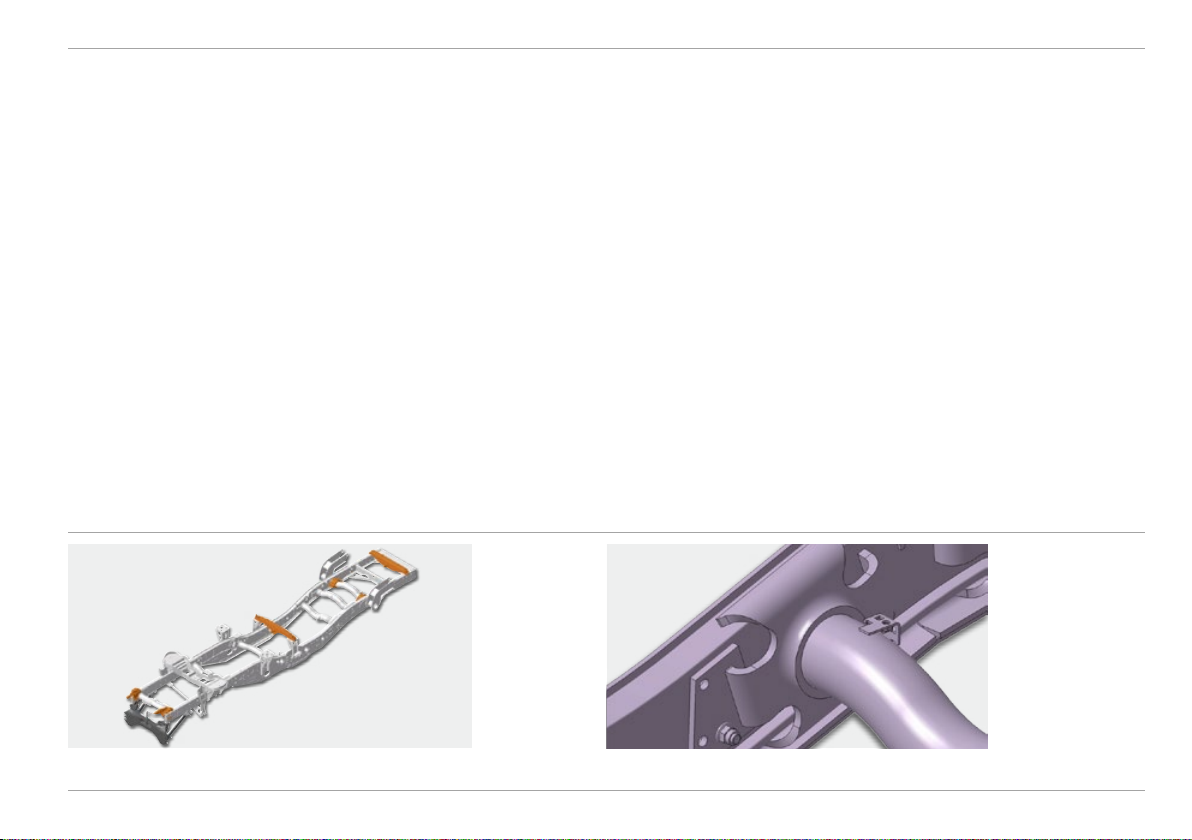

Frame

Frame concept

Frame

Feature

• 2 U-section longitudinal frame members with welded tubular

cross-members and reinforcements in the frame profile

• Offset design, no components protruding downwards

• Robust steel bumper

• Special torsionally flexible connection flange

Advantage

• Heavy-duty, flexible and torsionally flexible frame offering

high elasticity

• No permanent deformation even after extreme diagonal torsion

• Enables all four wheels to remain permanently in contact with the

ground in all driving situations

• Safe and controlled off-road driving

• Installation of drive units at lowest possible point:

low centre of gravity, high ground clearance

• Protection of components in off-road terrain

• Robust protection from mechanical influences in collisions

• Transmission of high torsional forces between longitudinal and

transverse members

Frame with attachment fixtures for non-MB bodies [CD5], front mounting

brackets [CA2], front mounting plate [CP3], cable winch brackets (CH5)

Mercedes-Benz Special Trucks

Special torsionally flexible connection flange

13

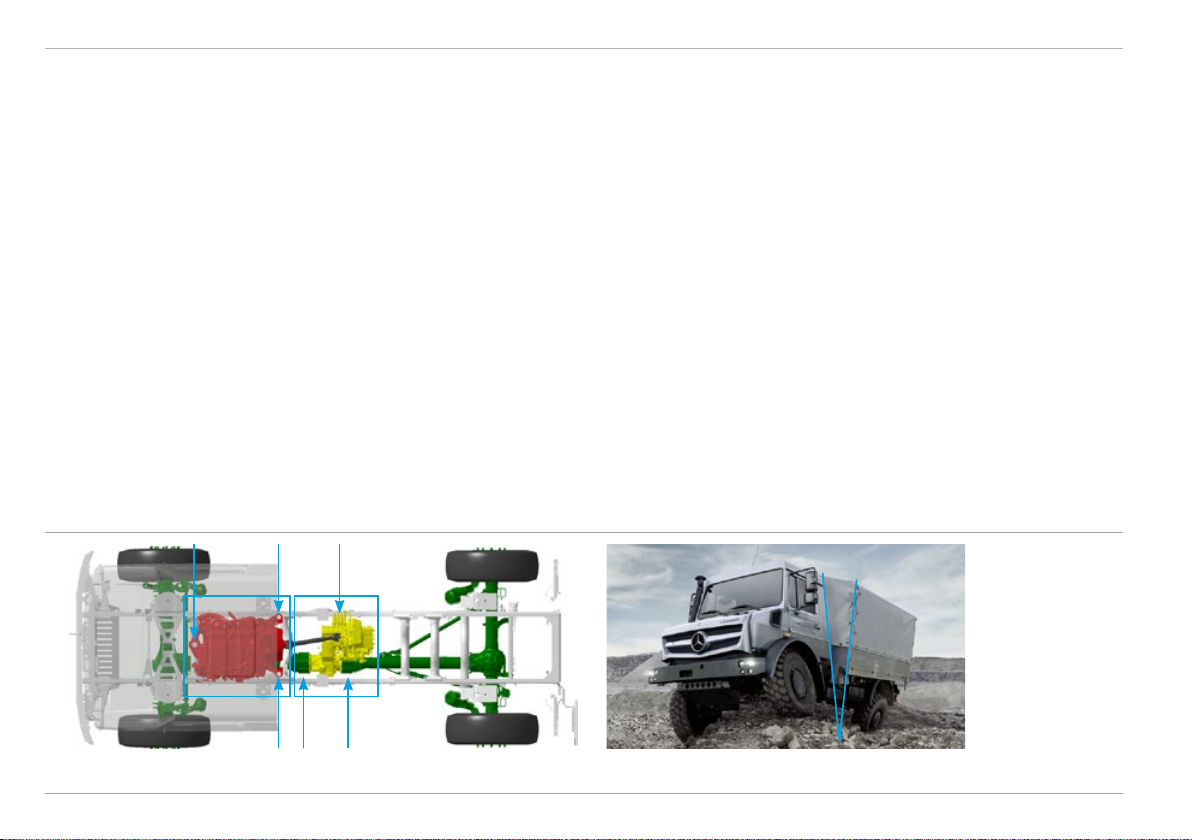

Frame Technical Manual

Feature

• Integrated attachment points

• 3-point mounting of cab, engine and gearbox

• Double 3-point mounting for bodies and attached equipment

Advantage

• Suitable for attaching heavy front- and rear-mounted implements

with defined transmission of forces

• Torsion and stress-free mounting of components and bodies

• No restriction of off-road capabilities

• Equipment, attachments and bodies can be mounted in the ideal

positions with regard to torsion and centre of gravity

• Transmission of trust, tensile and weight forces to the intended

points in the frame

• Safe, secure and simple attachment and mounting of equipment

Even with extreme

axle articulation (30°)

there is only a limited

amount of twist

between cab and

body (12°)

3-point mounting of engine and gearbox

14 Mercedes-Benz Special Trucks

Technical Manual

Optional equipment – frame

Frame

Feature

[Q32] End cross-member, for increased towing capacity

• Reinforced end cross-member

[Q35] Additional towing jaw at front, lowered

• Additional trailer hitch at front

Advantage

• Enables use of draw-bar trailers

up to 15.4 t (U 4023) and 19.9t (U 5023)

• Enables use of rigid draw-bar trailers and centre-axle trailers up to

9 t (U 4023 / U 5023)

• Facilitates manoeuvring

• Towing possible, e.g. with towing bar

End cross-member, for increased towing capacity [Q32]

Mercedes-Benz Special Trucks

15

Frame Technical Manual

Feature

[Q06] Trailer coupling, larger jaw, annual spring, pin 38.5

• Jaw size 280 x 170 mm

• Make, type: Ringfeder 86 G 110

• Drawbar load: 500 kg

• Pin diam.: 38.5 mm

• Swivelling coupling pin

[Q86] Trailer hitch, small jaw, Rockinger, increased load

• Jaw size 200 x 100 mm

• Make, type: Rockinger 225 G 110

• Drawbar load: 700 kg / 1500kg*

• Pin diam.: 38.0 mm

[Q88] Trailer hitch, small jaw, Rockinger

• Jaw size 200 x 100 mm

• Make, type: Rockinger 227 G 110 J

• Drawbar load: 500 kg / 1250 kg*

• Pin diam.: 38.5 mm

[Q97] Trailer hitch, large jaw, Rockinger

• Jaw size 360 x 215 mm

• Make, type: Rockinger 4040 G 135, version A

• Drawbar load: 700 kg / 1000 kg*

• Bolt Ø: 38.5 mm for 40-mm eyelets

• Swivelling coupling pin

* Only in conjunction with [Q32].

Advantage

• For trailer operation with 40 mm towing lug

• For trailer operation with 40 mm towing lug

• High trailer loads possible

• For trailer operation with 40 mm towing lug

• Minimal installation space required

• For trailer operation with 40 mm towing lug

• One-hand operation optimised

• Optimisation of locking and bearing points on coupling body

• 30 – 40 % longer lifespan

16

Mercedes-Benz Special Trucks

Technical Manual

Engine

Engine concept

Engine

Feature

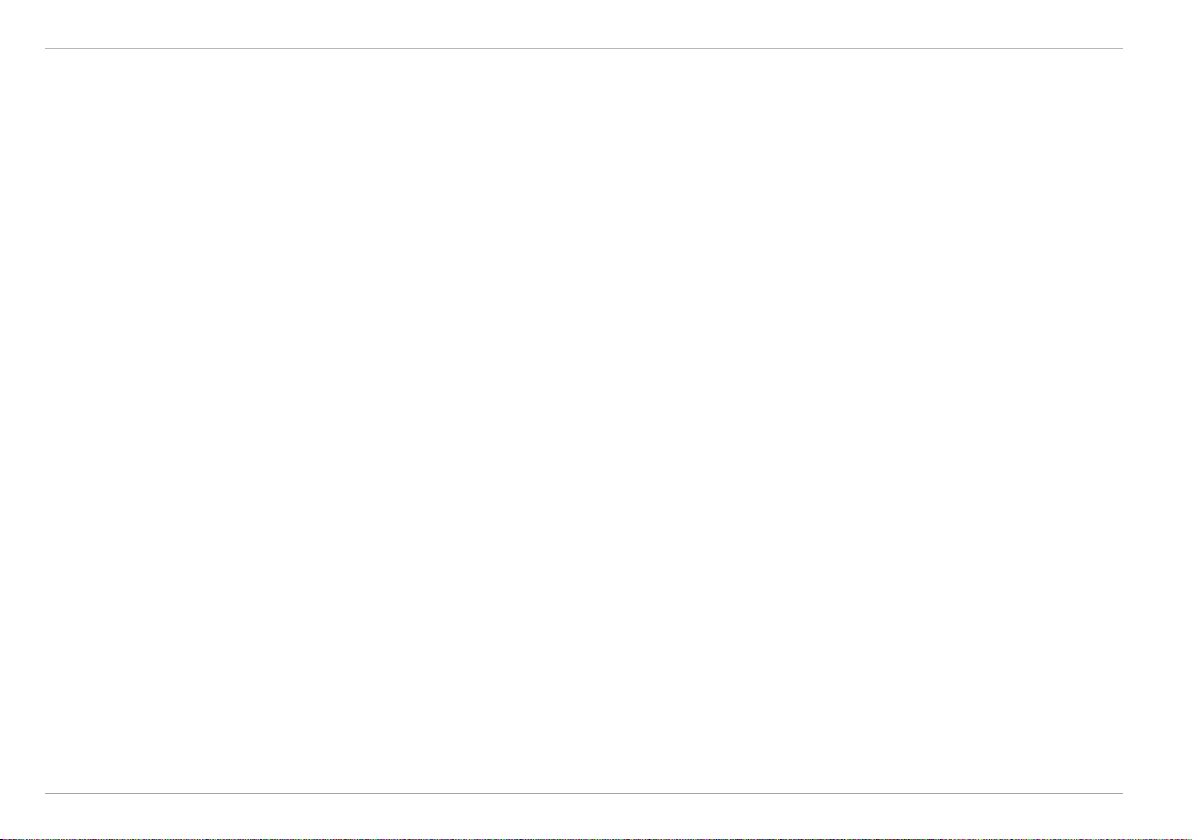

• Newly developed Mercedes-Benz 4-cylinder OM934 engine

rated at 170 kW/231hp and 5.1 l displacement

• Common rail direct injection with high injection pressures

(up to 2400 bar)

• Multistage injection

• Twin-stage turbocharger

• Mercedes-Benz BlueTec 6 technology, Euro VI compliant:

combined SCR technology with particulate filter and cooled exhaust

gas recirculation (EGR)

Advantage

• Proven engines of the Mercedes-Benz volume series

• High power reserves

• Efficient and clean combustion

• Optimised fuel consumption

• Smooth running

• High torque even at low engine speeds

• Reduced NO

emissions

x

• Reduced particulate emissions

OM934 4-cylinder engine

Mercedes-Benz Special Trucks

17

Engine Technical Manual

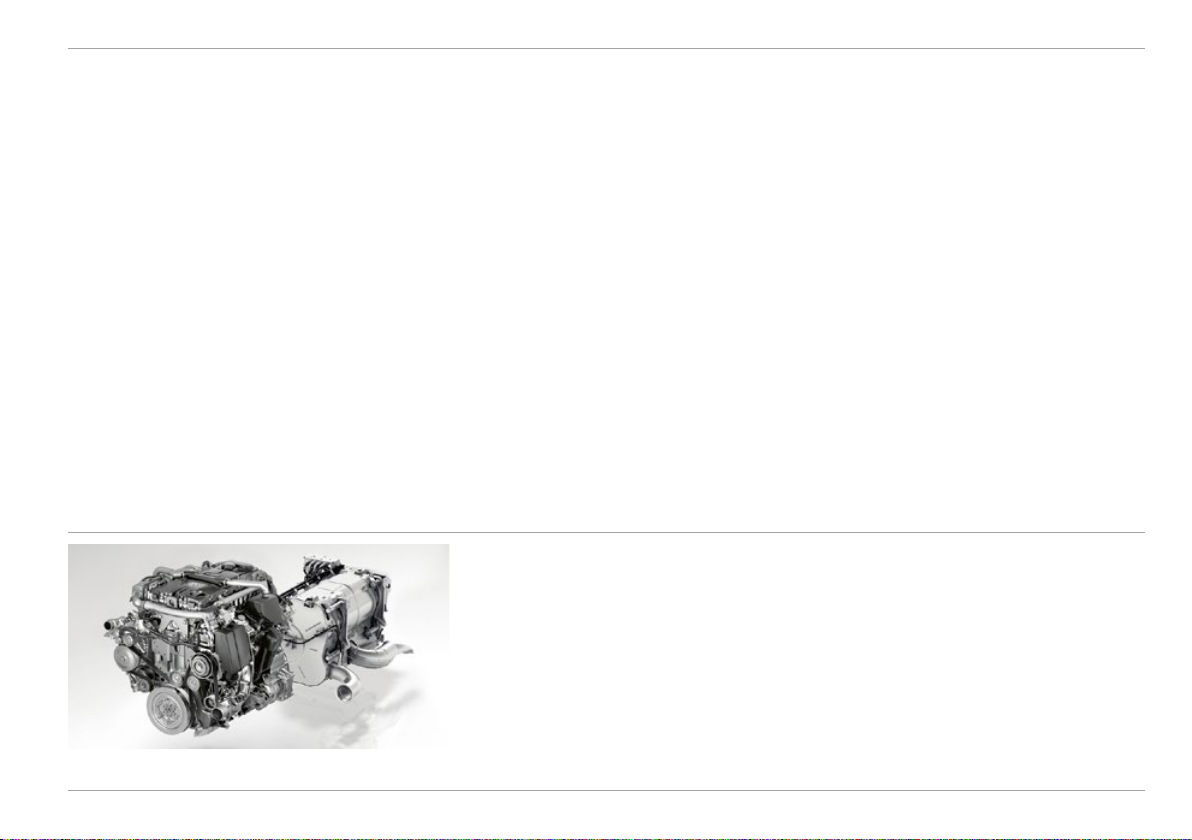

Feature

• Optimised choice of materials and manufacturing process

• Extended maintenance intervals – 1400 operating hours

• High torque, max. 900 Nm

• Optimised in-engine combustion

• Air intake on right of cab at roof level

1500 300

1000

500

170 kW900 Nm

200

100

Output and torque

diagram for

OM934, 170 kW,

900 Nm

Advantage

• Service life extended by 20 %

• Extended use period, low service requirements, reduced

operating costs

• High pulling power and holding ability of torque

• High adaptability on very rough off-road terrain with steep gradients

®

• Significantly reduced AdBlue

consumption

• Intake of combustion air from area with low dust content

• No entry of water into the intake during fording

• Reduced soiling and extended service life for the air filter

Torque [Nm]

200 0

600 1000 1400 1800 2200

Engine speed (rpm)

18 Mercedes-Benz Special Trucks

2600

Engine power [kW]

Technical Manual

Drive clutch

Engine

Feature

• 395mm single-plate dry clutch

• Hydraulic central clutch release bearing

• Pneumatic clutch pressure booster

• Position sensor

• Wear compensation

• Aluminium clutch housing

• Organic, asbestos-free clutch linings

Advantage

• Easy to regulate, long service life

• No lubrication of moving parts necessary

• Low pedal force (approx. 150 N)

• Wear detectable without disassembly

• Secure frictional connection

• Weight optimisation

• Environmentally compatible

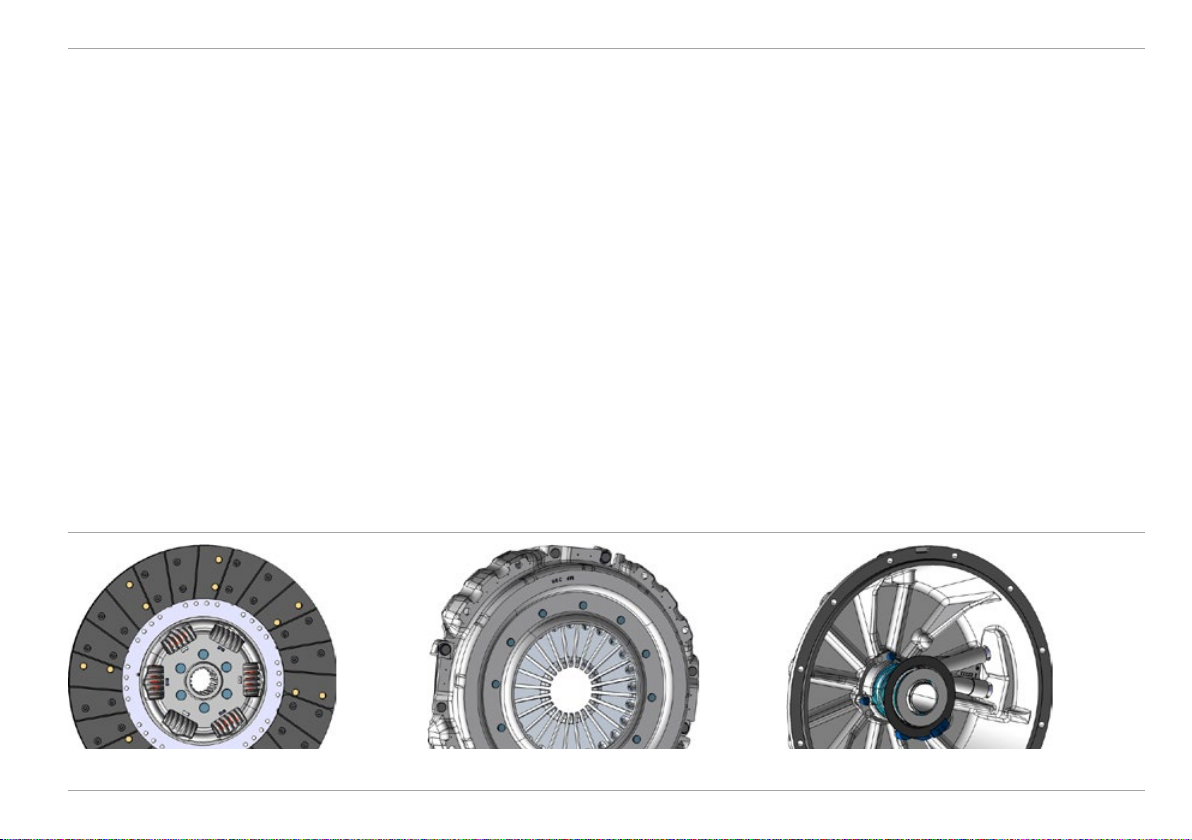

Clutch plate Clutch pressure plate Clutch housing

Mercedes-Benz Special Trucks

19

Engine Technical Manual

High-performance engine brake

Feature

• 2-stage decompression brake

• Control via exhaust camshaft

• Power output up to 178 kW

Engine control

Feature

• 2 selectable engine control characteristics

— Torque control (elastic rpm characteristics)

— Work speed control (rigid rpm characteristics)

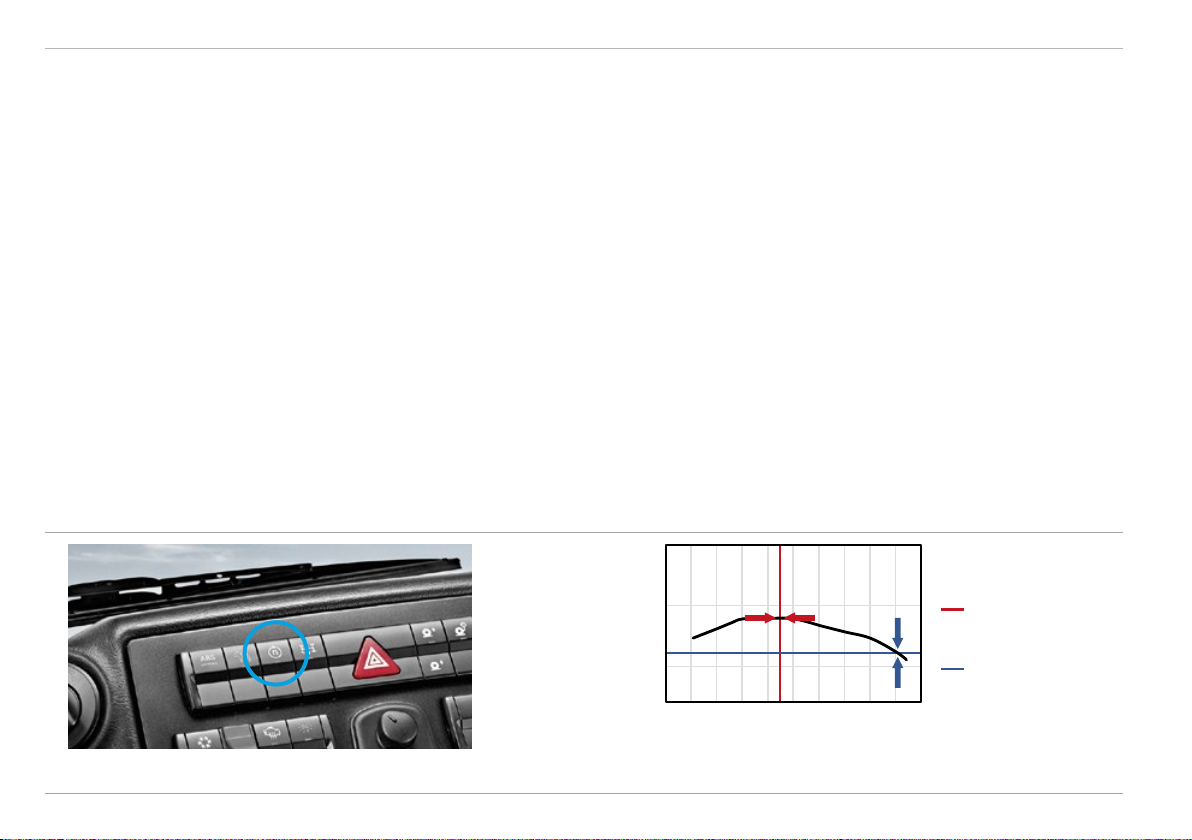

Switch to select engine control characteristic on dashboard (middle)

Advantage

• Wear-free auxiliary brake, reduces heating and wear of the

service brake

• High brake power, very good deceleration

Advantage

• Rpm characteristics optimally tailored to the operating mode

— Operation under normal conditions, road travel, transport

— Implement use at constant engine speed

— Operation on difficult terrain with speed setpoint, only minimum

engine speed deviation

1500

1000

Torque [Nm]

500

600 1200 1800 2600

Engine speed/torque control

Engine speed (rpm)

Torque and work speed

control:

Engine speed control

for implement operation

Torque control for

driving mode

20 Mercedes-Benz Special Trucks

Technical Manual

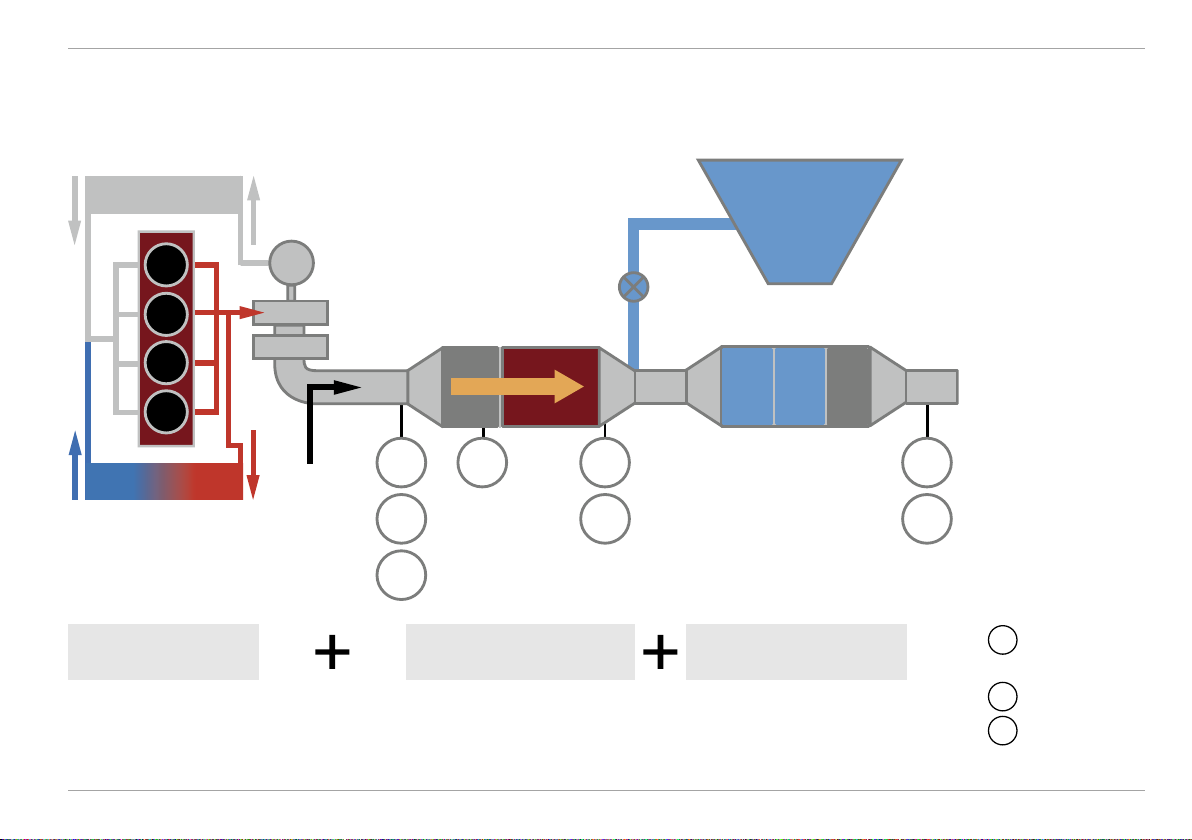

Exhaust gas aftertreatment – BlueTec 6

Intercooler

Engine

AdBlue® tank

EGR cooling

Exhaust gas

recirculation (EGR)

Mercedes-Benz Special Trucks

V

TT

Fuel injection

®

AdBlue

metering

Exhaust

P T T T

NO

X

P

P

Diesel particulate filter

(DPF)

Selective Catalytic

Reduction (SCR)

NO

X

P

Pressure

sensor

NO

NOX sensor

X

T

Temperature

sensor

21

Engine Technical Manual

Feature

• Newly developed Mercedes-Benz engines and exhaust box with

®

BlueTec

diesel technology

• Exhaust gas recirculation

• Diesel particulate filter

• SCR catalytic converter

®

• Optimised AdBlue

injection

• Regeneration of diesel particulate filter during operation

• Downward-facing tailpipe as standard, upward tailpipe available

as option [K7A]

1

SCR catalytic converter

2

AdBlue® tank

3

2

1

3

AdBlue® metering unit

Advantage

• Euro VI compliance

• Proven technology of the Mercedes-Benz volume series, optimised

design to minimise space requirements

• Low NO

emissions

x

• Particulate matter in exhaust flow reduced by 90 %

• Converts NO

conjunction with AdBlue

into harmless nitrogen and water vapour in

X

®

• Reduced AdBlue® consumption

• Longer filter replacement intervals and long filter service life

• Equipment customisable to intended application of vehicle

AdBlue® components

22 Mercedes-Benz Special Trucks

Reduced environmental impact with BlueTec 6, e.g. in

conservation areas

Technical Manual

Exhaust emissions – limiting values

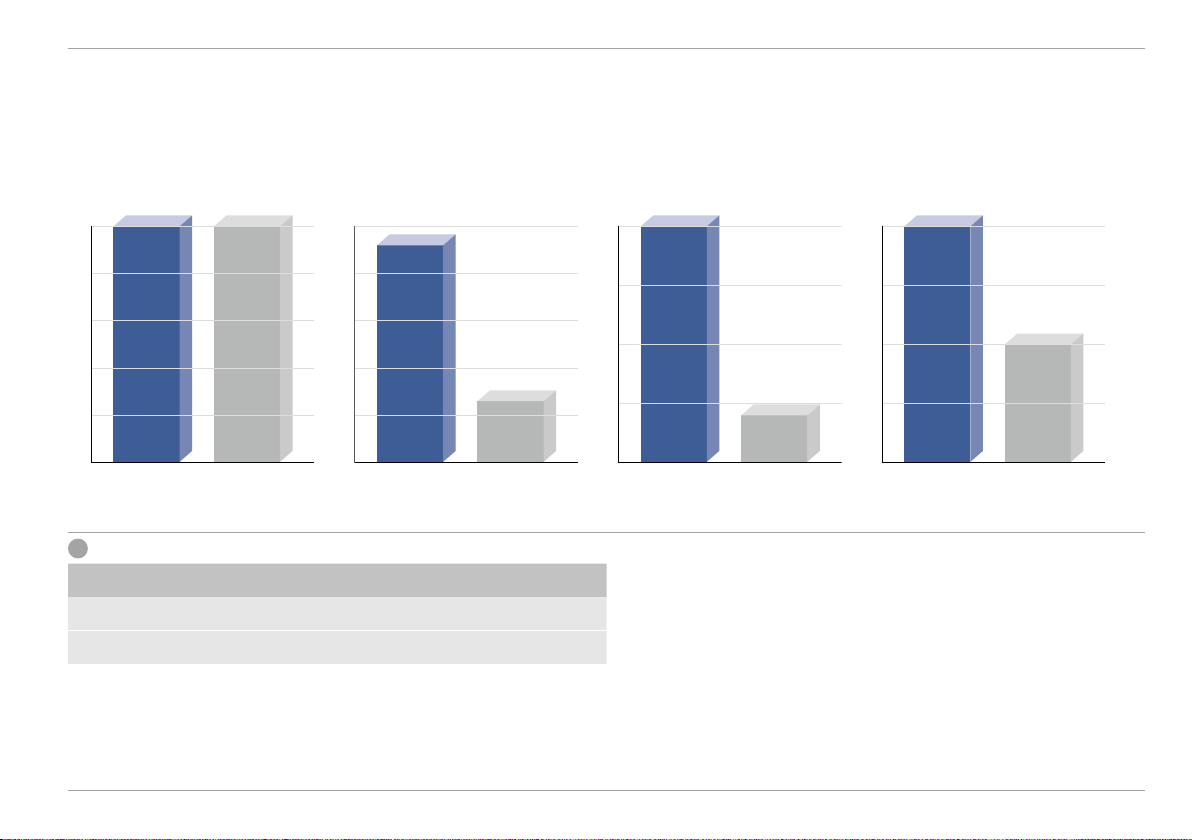

CO: HC: NOX: PM:

Engine

1.5

0.46

Emissions [g/kWh]

Emissions [g/kWh]

0.13

Euro V Euro VI

Euro V Euro VI Euro V Euro VI Euro V Euro VI

i

Standard Vehicle category Legal requirement since/from

Euro V Trucks > 3.5 t 01.10.2009

Euro VI Trucks > 3.5 t 01.01.2014

Mercedes-Benz Special Trucks

2.0 0.021.5

Emissions [g/kWh]

Emissions [g/kWh]

0.01

0.4

23

Engine Technical Manual

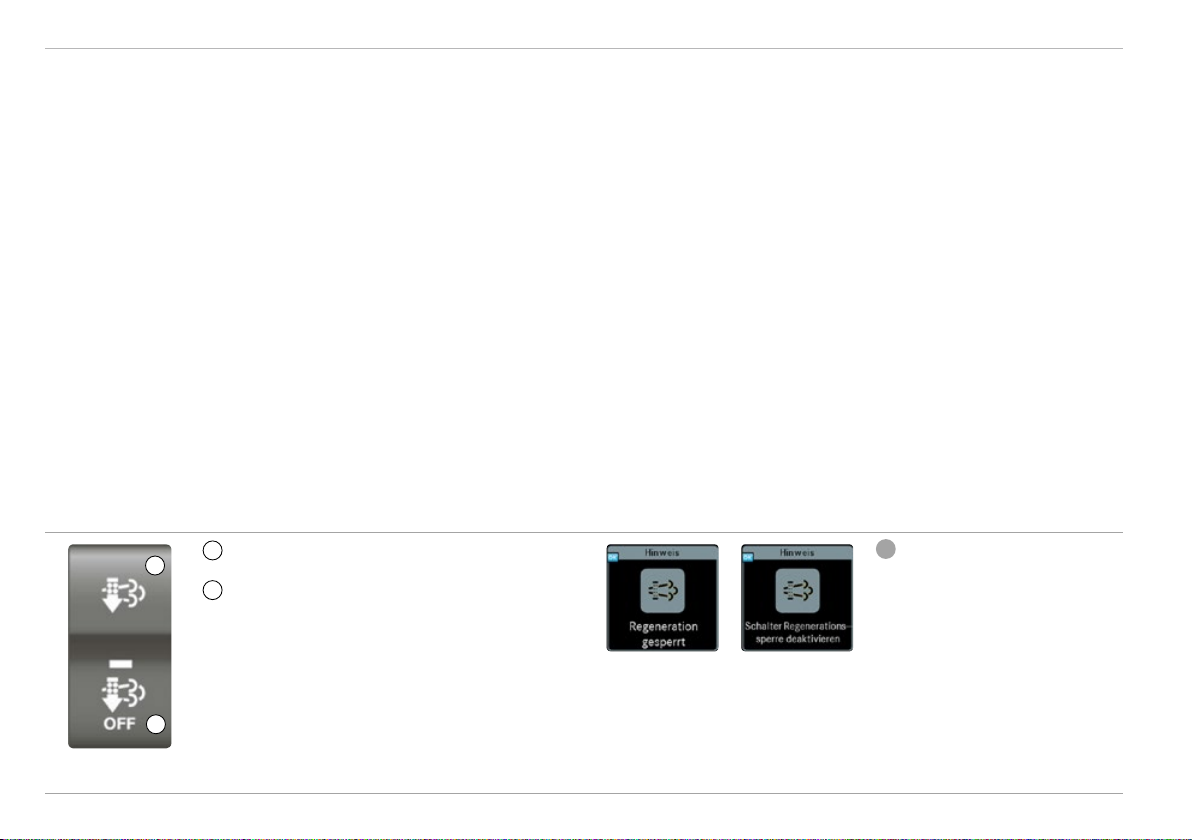

Regeneration

Soot from diesel combustion continuously accumulates in the closed

diesel particulate filter. To guarantee longer filter change intervals and

a long filter service life, regular regeneration of the diesel particulate

filter is necessary.

High exhaust temperatures effectively reduce the soot. As the exhaust

gas temperatures are not always sufficient to produce continual soot

reduction (passive regeneration), there is an automatic triggering of

active regeneration, which is dependent on the operational profile

of the vehicle. If necessary, the driver will be requested to initiate the

regeneration manually when the vehicle is stationary. To do this the

idling speed is increased to approx. 1400 rpm in order to achieve

the optimum exhaust gas temperature.

Passive regeneration

• Continuous, at exhaust gas temperatures > 250°C

• No additional diesel injection into exhaust flow

• Takes place during driving without the driver noticing

Active regeneration

• Takes place subject to conditions of vehicle operation

• Triggered automatically with notification in instrument cluster,

no action required from driver

• Additional diesel injection to increase the exhaust temperature

• Can be suppressed by means of theInhibit switch in dangerous

situations or special operations

• Regeneration can be effected manually with vehicle at a standstill

when notification appears in instrument cluster

The percentage of passive or active regeneration is dependent on the

engine load and the vehicle’s usage profile.

1

2

1

DPF regeneration

switch

24 Mercedes-Benz Special Trucks

Inhibit function (block/allow regeneration)

2

Initiate regeneration manually

Special operations/emergencies

The Inhibit function serves solely to suppress the regeneration process briefly in exceptional situations and must

be reset manually after use. Permanent use of the Inhibit

function will lead to premature filter loading which cannot

be reduced. Unscheduled replacement of the filter will

then be necessary.

Information field

“Regeneration

deactivated”

Information field

“Regeneration

overdue”

i

Information fields on the display show

when the Inhibit switch is active and

indicate when regeneration is overdue.

Technical Manual

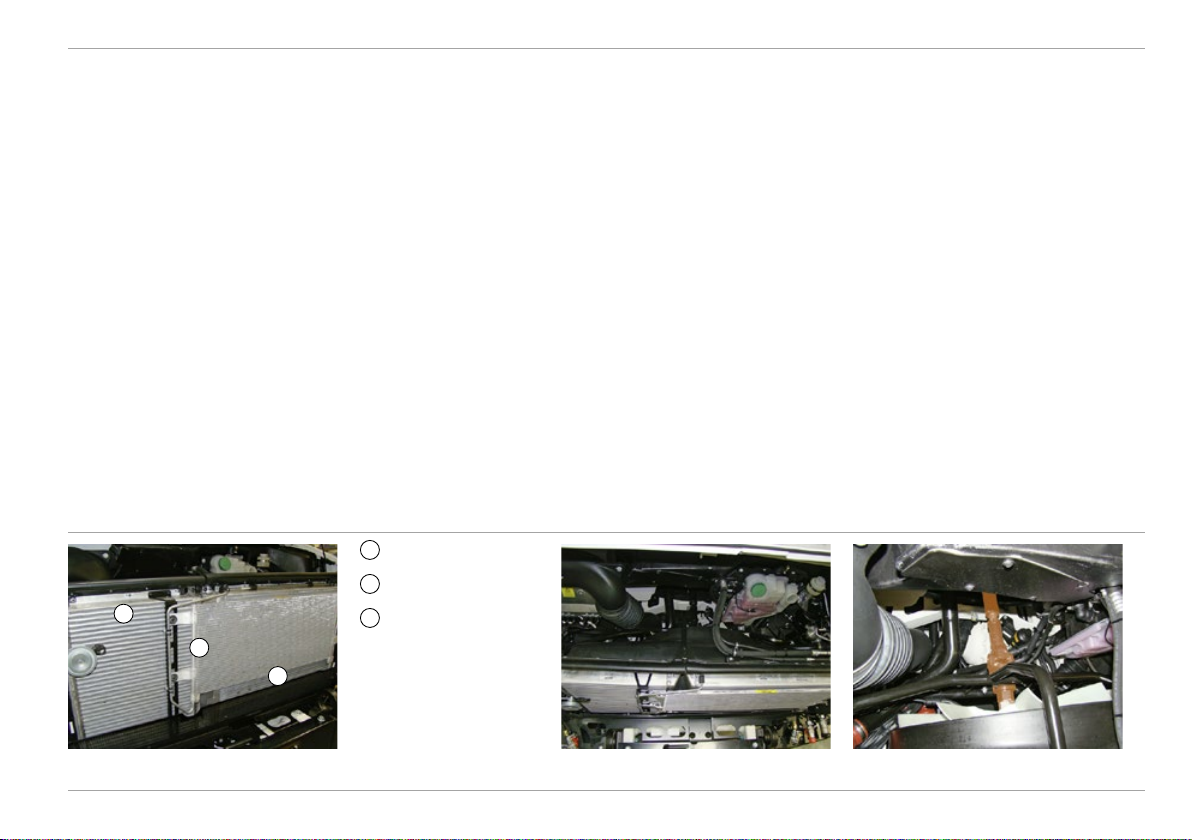

Radiator system

Engine

Feature

• Separate charge air and water cooler (arranged next to one another)

• One fan for both coolers with electronic viscous coupling, mechanically driven via propeller shaft

• High ground clearance of approx. 1100 mm with 365/85 R20 tyres

• Installation location above frame protected by solid underride guard

• All radiators designed for dirt-intensive applications

• Easily removable cover on front of vehicle

1

Charge air cooler

2

Radiator

1

3

2

3

Air conditioning

condenser

Advantage

• Improved cooling capacity

• Reduced risk of soiling

• Easier cleaning

• Safety during fording

• Enhanced cooler efficiency ► fuel savings

• Protection from external factors (stones, branches, mud, etc.)

• Maximum functional reliability maintained even when driving

through water

• Protection from mechanical influences

• Long cleaning intervals

• Excellent accessibility for cleaning

Separate cooler assemblies Coolers for charge air and engine cooling

water arranged next to one another

Mercedes-Benz Special Trucks

Fan with electronic viscous clutch,

mechanically driven via propeller shaft

25

Engine Technical Manual

Optional equipment – engine

Feature

[M55] Fuel preheating, with water separator

• The container consists of a prefilter with heated water

separator. It removes coarse impurities and water fractions

from the fuel upstream of the standard filter.

• Auxiliary heating system to preheat the fuel

• Water storage tank (0.5 l)

[Z0A] Cold climate package

[K7A] Exhaust system, tailpipe vertical

• Exhaust pipe extending up to cab roof on right-hand side of

vehicle

• Stainless steel heat guard

Advantage

• Even low-grade fuel is supplied to the engine free of particulate

matter and water. Avoidance of damage to the injection pumps as a

result of increased water content and dirt

• High operational reliability despite poor fuel quality, unscheduled

maintenance and service costs are avoided

• Enhanced operational reliability at low temperatures, as the

risk of gelling as a result of paraffin separation is reduced

• Problem-free engine start at extremely low outside temperatures

down as low as -26 °C

• Exhaust gases are discharged upwards:

— advantageous during stationary operations (e.g. crane operation)

— no hot exhaust gases close to the ground

• Also prevents corrosion, resulting in longer value retention

26

Mercedes-Benz Special Trucks

Technical Manual

Transmission

Main transmission

Transmission

Feature

• Fully synchronised manual gearbox with eight forward and

six reverse gears

• Helically geared

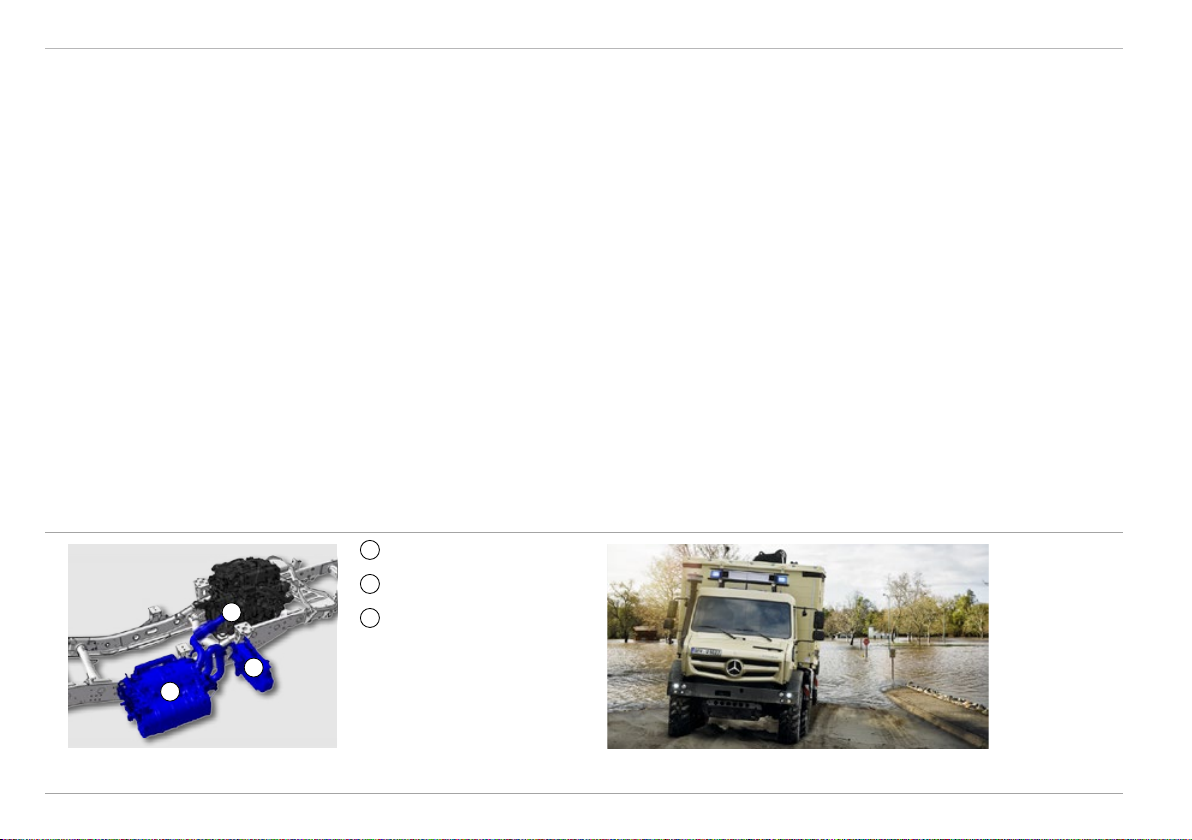

• Integrated transfer case with torque ball connection

• Reverse gears are ⅓ slower than forward gears

• Synchronised reversing group (EQR) for direct changeover

between forward and reverse gears

• Discrete design

• Low mounting

• Double cone synchronisation

• Optionally extendable by eight off-road gears [G22]

Advantage

• Appropriate forward and reverse speeds for on- and off-road use,

simple and swift gear-changing

• Very smooth running, long service life, high efficiency

• Enables extreme axle articulation

• More effective gear spacing for manoeuvring

• Fast turning, rocking free

• Minimal transmission of engine vibrations

• Torsional flexibility

• Low vehicle centre of gravity

• Long service life

• Short shift times

• Ideal gear-step ratio for any application profile

Modular design of engine and gearbox (side view) Modular design of engine and gearbox (from above)

Mercedes-Benz Special Trucks

27

Transmission Technical Manual

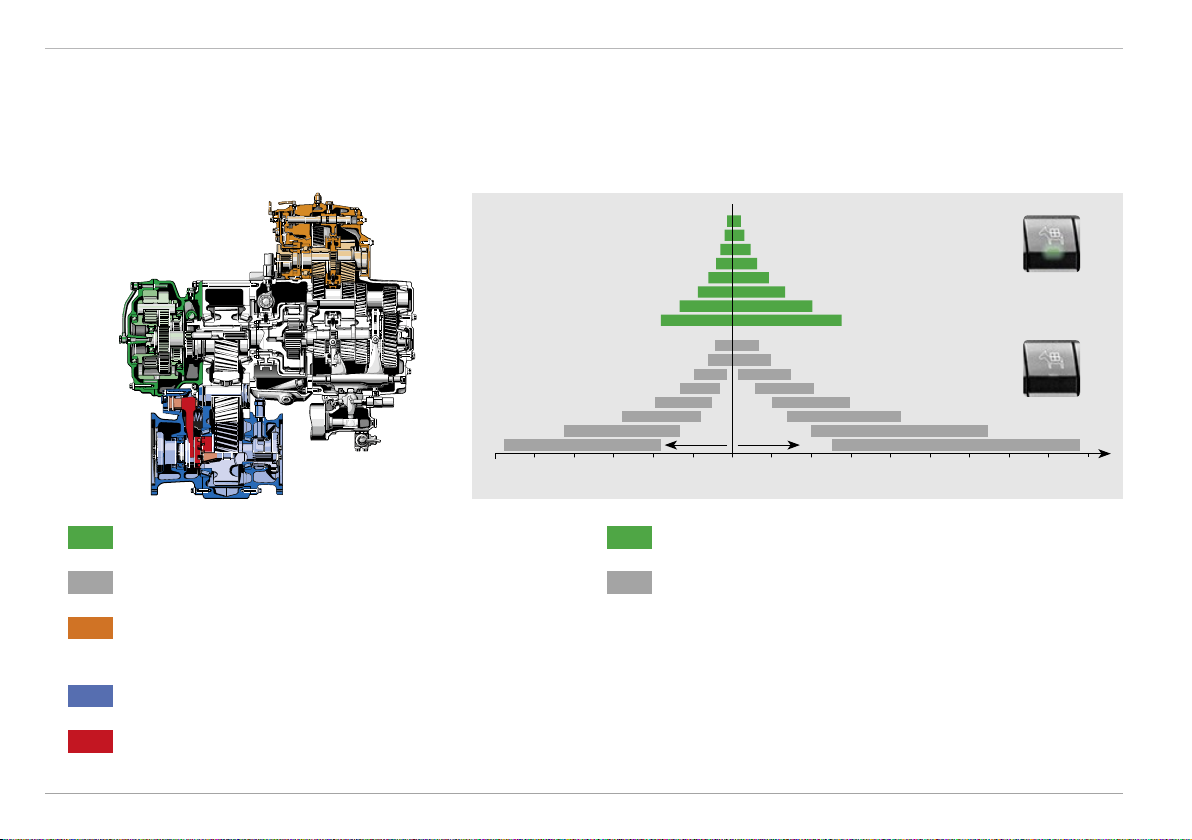

Overview

Fully synchronised Daimler 8-speed EPS manual transmission

Reverse Forward

60 50 40 30 20 10 0 10 20 30 40 50 60 70 80 90

V [km/h]

Range group with off-road range [G22]

Main gearbox

Off-road gears [G22]: approx. 2.1 km/h – 27.1 km/h

Basic gears: approx. 6.6 km/h – 90 km/h

Synchronised Electronic Quick Reverse gearshift

(EQR gearshift)

Transfer case

Engagement of front-axle drive via dog clutch

28

Mercedes-Benz Special Trucks

Technical Manual

Engine management

Transmission

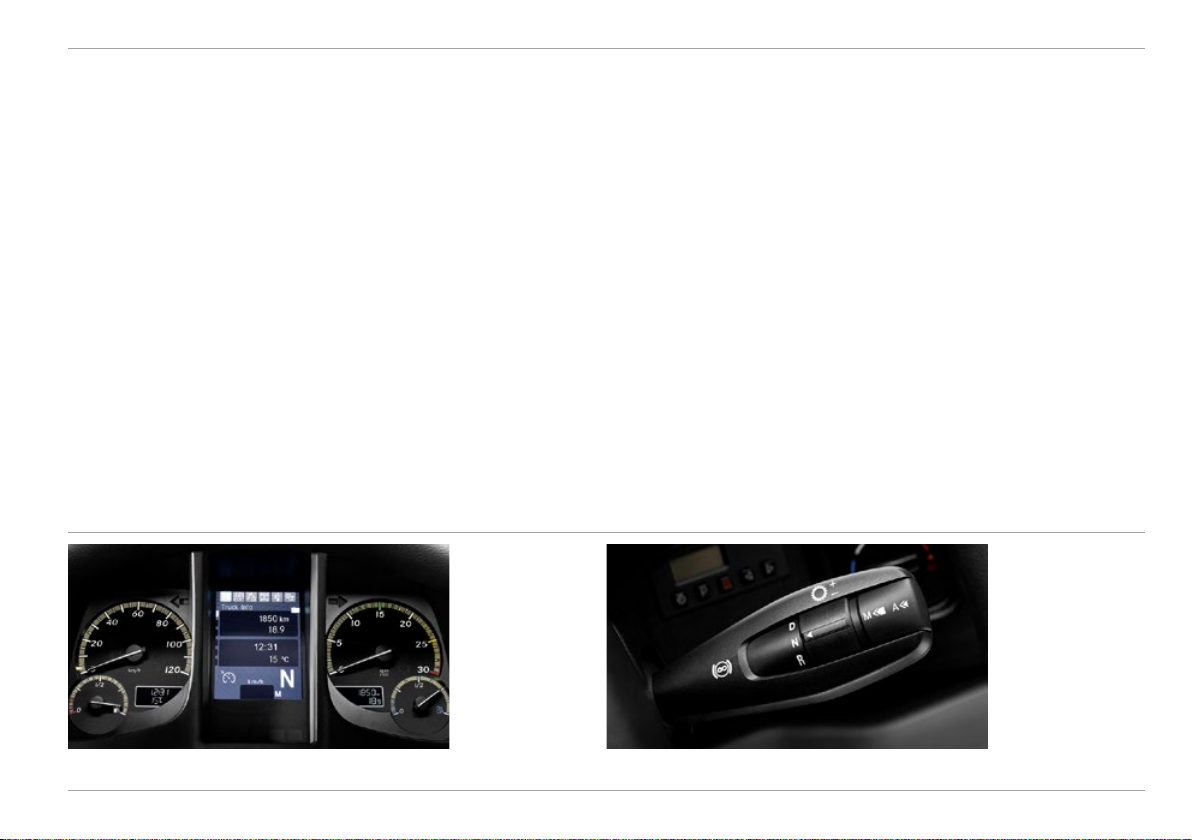

Feature

• Operation via multifunction lever

• Automatic determination of the correct subsequent gear, indication

on display

• Depress clutch for gear change, changeover occurs automatically

• No mechanical/hydraulic connection between selector lever and

gearbox

• Minimal physical effort required of driver, shifting work performed

by pneumatic cylinder

• Neutral switch with detent position in multifunction lever

Advantage

• Convenient arrangement of shift elements and controls

• Optimal gear pre-selection

• Protection of engine, clutch and transmission

• During gear changes the right hand is free (e.g. for operating

implements)

• No transmission of vibrations to cab

• Allows drivers to relax and concentrate on driving

• Direct shifting to neutral from any gear

• Automatic gear selection from neutral, at any speed

Gear selection indicator in instrument cluster Multifunction lever

Mercedes-Benz Special Trucks

29

Loading...

Loading...