Page 1

US/Canadian2007SprinterDieselV6DodgeServiceManualSwirlValveInfo

Actuator-Swirl Valve

DESCRIPTION

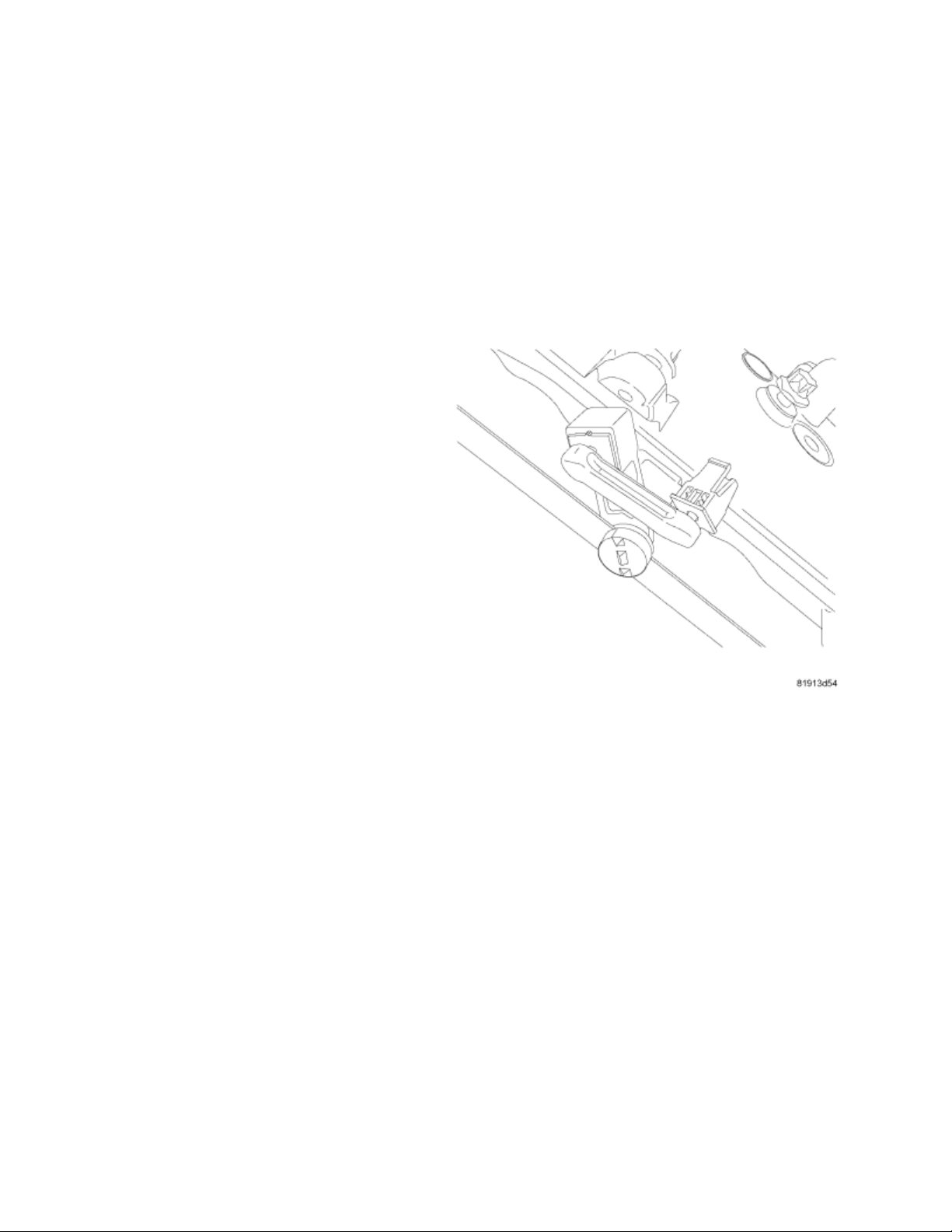

The swirl valve linkage links the swirl valves

in the intake manifold to the swirl valve

actuator.

The swirl valve linkage has two different

style clips. The square clip (1) is a two piece

design, and the round clip (2) is a one piece

design.

Page 2

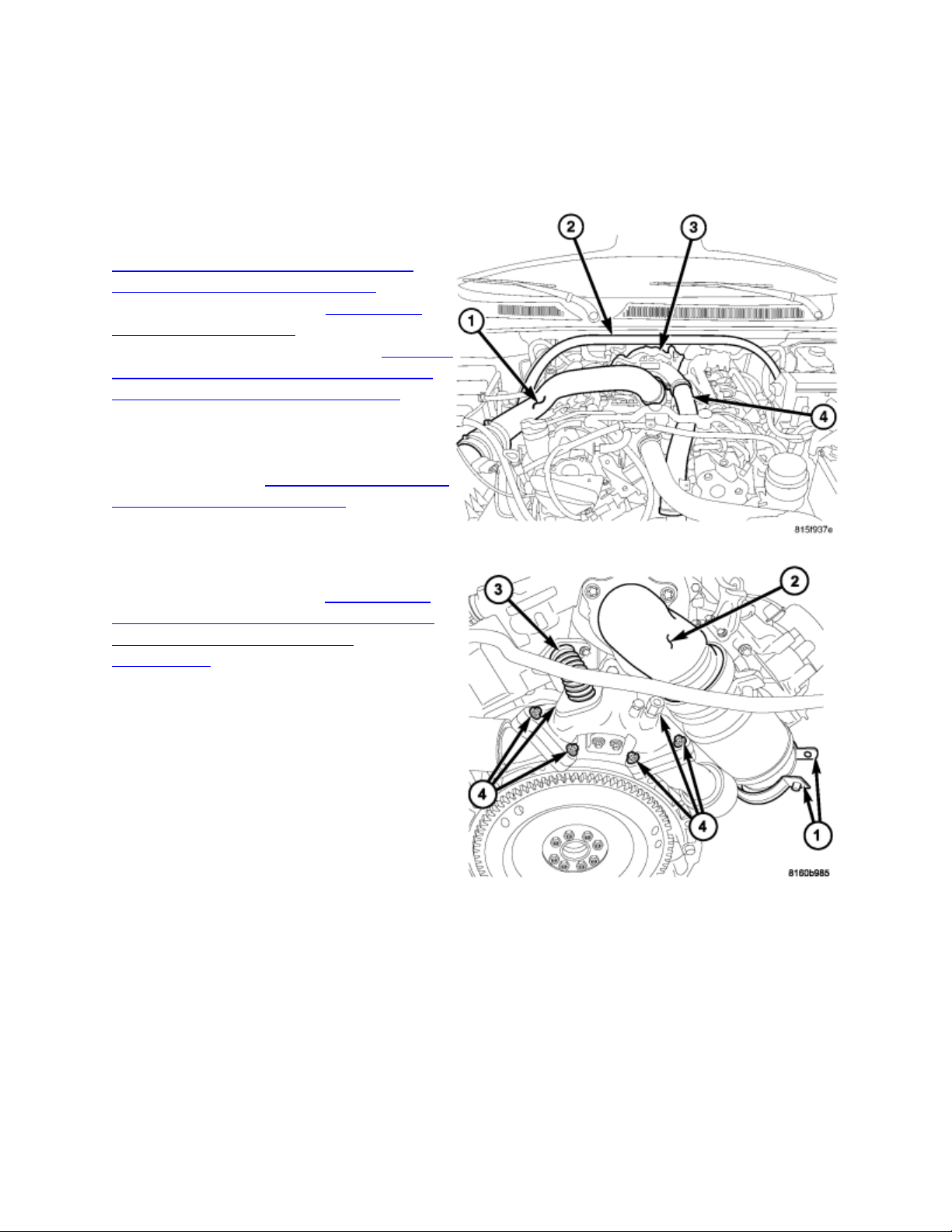

REMOVAL

1. Disconnect the negative battery cable.

(Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/CABLES - REMOVAL)

2. Remove the engine cover. (Refer to 9 -

ENGINE - REMOVAL)

3. Remove the air cleaner assembly. (Refer to

9 - ENGINE/AIR INTAKE SYSTEM/AIR

CLEANER HOUSING - REMOVAL)

4. Remove the air charge resonator.

5. Remove the air charge outlet tube (4).

6. Remove the vapor control valve.

7. Drain the coolant. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

8. Remove the belly pan.

9. Remove the turbocharger. (Refer to 11 -

EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER REMOVAL)

10. Remove the EGR tube (3).

Page 3

11. Remove the oil housing adapter (1).

12. Remove the rear engine lift bracket at the

intake manifold.

13. Remove the front engine lift bracket at

the cylinder heads.

14. Remove the left fuel rail and lines. (Refer

to 14 - FUEL SYSTEM/FUEL

INJECTION/FUEL INJECTOR REMOVAL)

15. Remove the right fuel rail and lines.

(Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/FUEL INJECTOR REMOVAL)

16. Disconnect the engine harness (2) and

position aside.

17. Remove the swirl port actuator (3).

18. Remove the heater hose at the EGR

valve.

19. Remove the EGR control assembly.

Page 4

20. Remove the coolant hose at the

thermostat housing.

21. Remove the glow plug module.

22. Remove the throttle control assembly.

23. Remove the intake manifold.

24. Loosen the EGR cooler bolts to gain

access to the swirl valve linkage clips.

25. Remove the swirl valve linkage clips (2).

Page 5

INSTALLATION

1. Install the round clips (2) into the swirl

valve linkage.

2. Clean the intake manifold sealing surfaces.

3. Install new intake manifold gaskets.

12. Install the swirl valve actuator. (Refer to

9 - ENGINE/MANIFOLDS/ACTUATORSWIRL VALVE - INSTALLATION).

13. Install the fuel filter assembly (Refer to

14 - FUEL SYSTEM/FUEL

4. Install the EGR cooler.

5. Position the intake manifold and torque to 20.34

N.m (180 lbs. in.)

6. Install the throttle control assembly.

7. Instal the glow plug module.

8. Install the coolant hose at the thermostat

housing.

9. Install the EGR control assembly.

10. Install the EGR control assembly chamber

retaining bolts.

11. Install the EGR control assembly retaining

bracket.

Page 6

DELIVERY/FUEL FILTER - INSTALLATION).

14. Install the fuel lines. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES -

INSTALLATION)

15. Position and connect the engine harness.

16. Install the front lifting bracket.

17. Install rear lifting bracket.

18. Install the EGR tube.

19. Install the turbocharger. (Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - INSTALLATION)

20. Install the engine compartment lower silencer.

21. Fill the cooling system. (Refer to 7 - COOLING - STANDARD PROCEDURE)

22. Install the vapor control valve.

23. Instal the charge air outlet tube (4).

24. Install the charge air resonator.

25. Install the air cleaner assembly. (Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR

CLEANER HOUSING - INSTALLATION)

26. Install the engine cover. (Refer to 9 - ENGINE - INSTALLATION)

27. Connect the batteries. (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/CABLES -

INSTALLATION)

Page 7

Linkage-Swirl Valve

DESCRIPTION

The intake manifolds feature swirl intake

ports to reduce particulates at low engine

speeds. Each cylinder incorporates one swirl

port and one charge port. The swirl ports can

be closed by the swirl valves. The valves are

connected together via a linkage which is

operated by the swirl valve actuator.

The swirl valves are normally open by spring

tension. The spring is integral with the swirl

valve actuator. In the lower engine speed and

load range, the swirl valves are closed by the

swirl valve actuator. The entire air mass

flows through the charge ports only, which

results in greater swirling. The increased

swirling produces uniform combustion for better engine performance and reduction of

particulates. As rotational speed and load increases, the swirl valves open, so that optimal

swirling and the required air mass are provided for the current operating conditions.

The linkage between the swirl valve actuator

and the intake manifold has two different

style clips. The square clip (1) is a two piece

design, and the round clip (2) is a one piece

design.

Page 8

REMOVAL

1. Disconnect negative battery cable. (Refer

to 8 - ELECTRICAL/BATTERY

SYSTEM/CABLES - REMOVAL)

2. Remove the engine cover. (Refer to 9 -

ENGINE - REMOVAL)

3. Drain the coolant. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

4. Remove the strut tower support (2).

5. Remove the intake air housing and tube.

(Refer to 9 - ENGINE/AIR INTAKE

SYSTEM/AIR CLEANER HOUSING REMOVAL)

6. Remove the charge air cooler tube (4).

7. Remove the resonator.

8. Remove the EGR tube.

CAUTION: Observe the position of the

turbocharger oil passage housing and

gasket. Failure to properly position the gasket during assembly will result in immediate

turbocharger failure after assembly.

9. Remove the turbocharger (3). (Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - REMOVAL)

10. Disconnect the engine harness and

position aside.

11. Disconnect the swirl valve actuator

connector.

12. Remove the swirl valve actuator (3) clips.

13. Remove the swirl valve actuator.

Page 9

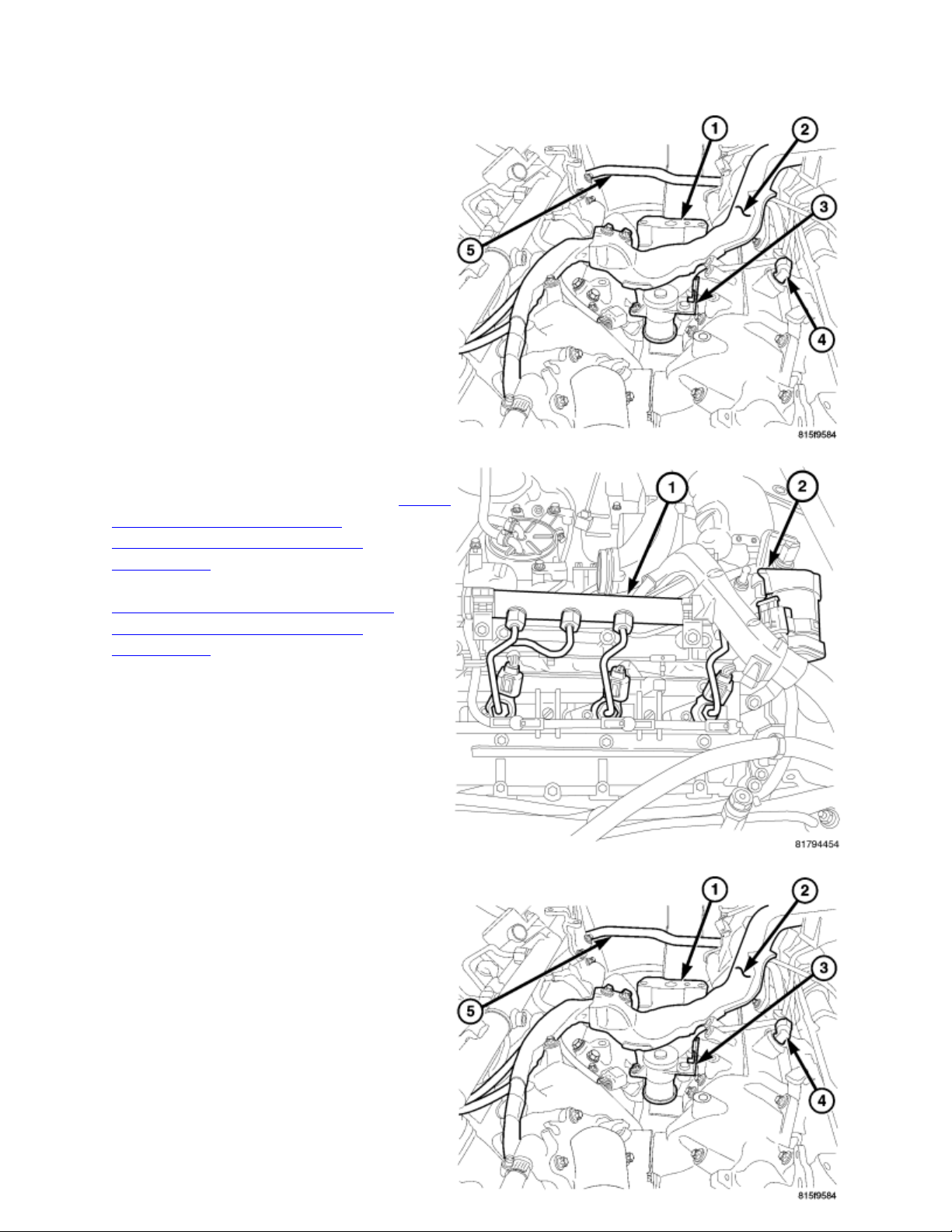

INSTALLATION

1. Assemble the two halves of the square clip

around the actuator arm, and place a 5/16” Oring (2) around the base of the clip (1) to hold

it together.

2. Position the clip into the actuator arm and push

the clip partially into the arm.

3. Cut the O-ring and press the clip the rest of the

way into the actuator arm. Make sure the clip

clicks into place.

Page 10

4. Install the swirl valve actuator. Tighten the bolts to 8 nm (44 lbs. in.).

5. Connect the swirl valve connector.

6. Position and connect the engine harness.

CAUTION: Observe the position of the turbocharger oil passage housing and gasket.

Failure to properly position the gasket during assembly will result in immediate

turbocharger failure after assembly.

7. Install the turbocharger. (Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - INSTALLATION)

8. Install the EGR tube.

9. Install the resonator.

10. Install the charge air cooler tube (4).

11. Install the air cleaner housing and air

tube. (Refer to 9 - ENGINE/AIR INTAKE

SYSTEM/AIR CLEANER HOUSING INSTALLATION)

12. Install the strut tower support (2).

13. Fill the cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE)

14. Install the engine cover. (Refer to 9 -

ENGINE - INSTALLATION)

15. Connect the battery. (Refer to 8 -

ELECTRICAL/BATTERY

SYSTEM/CABLES - INSTALLATION)

Loading...

Loading...