Page 1

Fault Code Manual

for

Mercedes-Benz

Analog Systems 1988-1997

Digital Systems 1993-2000

©Baum Tools Unlimited Inc. February 1, 2001

Page 2

Table of Contents

The Diagnostic Process

Information Gathering .................................................................... 4

Diagnostic Codes & Adaptation

Diagnostic Code Readout ................................................................. 6

About Stored, Registered and Current Faults ................................................... 6

Fault Code Types ....................................................................... 7

Check Engine Light (MIL) Diagnosis ......................................................... 7

Mixture Adaptation ....................................................................... 8

Resetting and Reactivating BOSCH Engine Control Module Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using the Data Stream.................................................................... 9

Equipment Connections

Connection Table....................................................................... 10

Connector Layout of Vehicle Diagnostic Connector ............................................. 11

8-pole Diagnostic Connector ......................................................... 11

16-pole Diagnostic Connector......................................................... 11

38-pin Diagnostic Connector ......................................................... 12

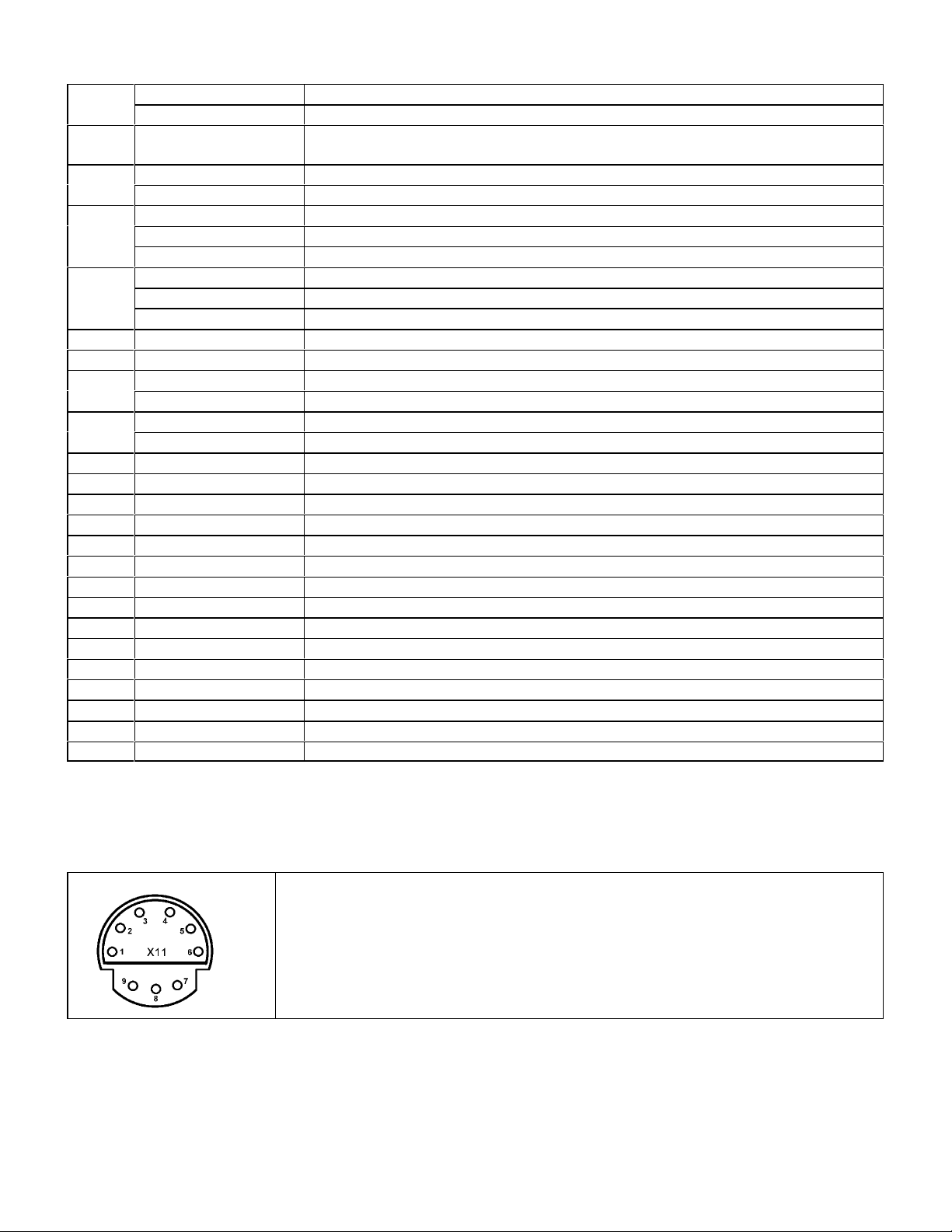

9-pole Diagnostic Connector (1980-94) ................................................. 13

Mercedes Model Identifier ............................................................... 100

Fault Codes

Engine Control

Electronic Diesel Idle Speed Control (ELR) .................................................... 14

Electronic Diesel System (EDS) ............................................................. 14

Continuous Fuel Injection System (CFI) ....................................................... 15

Continuous Fuel Injection System (MAS Controller) .............................................. 16

LH Sequential Multiport Fuel Injection System - Analog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LH Sequential Multiport Fuel Injection System - Digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

HFM Sequential Multiport Fuel Injection System - Analog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

HFM Sequential Multiport Fuel Injection System - Digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PMS (PEC) Fuel Injection System .......................................................... 25

ME Sequential Multiport Fuel Injection System ................................................. 26

Diagnostic Module (DM) - Analog ........................................................... 41

Diagnostic Module (DM) - Digital LH (104, 119, 120) ............................................. 43

Diagnostic Module (DM) - Digital HFM (104, 111) ............................................... 45

Base Module (BM) - LH-SFI ............................................................... 47

Distributor Ignition (DI) - LH-SFI ............................................................ 48

Cruise Control/idle Speed Control (CC/ISC) w/o ASR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Electronic Accelerator / Cruise Control / Idle Speed Control (EA/CC/ISC) w/ASR . . . . . . . . . . . . . . . . . . . . . . . 50

Chassis Control

Electronic Automatic Transmission Control (ETC) CFI (722.5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Electronic Automatic Transmission Control (ETC) 1990-95 (722.5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Automatic-engaged Four-wheel Drive (4MATIC) ................................................ 52

Electronic Automatic Transmission Control (ETC) 1996-2000 (722.6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Adaptive Damping System (ADS) ........................................................... 54

Automatic Locking Differential (ASD) ......................................................... 55

Anti-lock Brake System (ABS) .............................................................. 55

Anti-lock Brake system (ABS w/ASR) ........................................................ 56

Electronic Traction Systems (ASR, ETS) ...................................................... 57

Speed Sensitive Power Steering (SPS) ....................................................... 58

2

Page 3

Electronic Traction Systems (ABS, ASR, ETS, SPS) Digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Body Control

Cabriolet Soft Top (CST) ................................................................. 61

Roll Bar (RB) for CST .................................................................... 61

Roadster Soft Top (RST) ................................................................62, 63

Roll Bar (RB) for RST .................................................................... 63

Infrared Remote Control For Central Locking (IRCL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64, 65

Pneumatic Systems Equipment (PSE) ........................................................ 65

Anti-theft Alarm System( ATA) .............................................................. 66

Cellular Telephone (CT)................................................................... 66

Convenience Features (CF)................................................................ 67

Supplemental Restraint System (SRS) ....................................................... 68

Supplemental Restraint System (SRS) BAE, ZAE System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Supplemental Restraint System (SRS) with Side Airbags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Body Control Systems (SRS, IRCL, PSE, ATA. RST, MSC, CF) Digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Climate Control

Tempmatic A/C ......................................................................... 73

Automatic A/C .......................................................................... 74

A/C SELF DIAGNOSTIC SYSTEMS

TAU 2.1........................................................................... 75

129 Chassis 1990-95................................................................. 77

129 Chassis 1996-99................................................................. 79

140 Chassis 1992-95................................................................. 81

140 Chassis 1996-99................................................................. 86

202 Chassis 1995 ................................................................... 89

202 Chassis 1996-99................................................................. 93

210 Chassis 1996-99................................................................. 94

Mercedes Technical Acronyms ........................................................... 97

Mercedes Model Identifier ............................................................... 100

Mercedes Diagnostic Manuals .......................................................... 106

Technical Support Contact Information ................................................. 107

DISCLAIMER: All information contained in this document is correct to the best of our knowledge. Errors may occur

therefore Baum Tools Unlimited Inc. makes no warrantee, guarantee or assurance that damage may not occur from the

use of this information. The user takes all responsibility for its use.

Mercedes Benz is a registered trademark of Daimler Chrysler AG.

All rights reserved. Any reproduction in whole or in part without perm ission is strictly prohibited.

Copyright © 1998-2001 BAUM TOOLS UNLIMITED INC.

3

Page 4

This book is designed to help you in the basic diagnostic procedures for Mercedes Benz.

It is intended to be a starting point in the diagnostic process and is not intended to be a complete

resource.

THE DIAGNOSTIC PROCESS

The diagnostic process divides itself into several levels; Information Gathering, Analysis of Codes, Testing and then

Repair. We will cover Information Gathering and Analysis of codes in this book.

For those experienced in diagnostics jump to page

INFORMATION GATHERING

The information gathering stage always starts with the Customer.

Step 1

The Customer Interview

This is truly an art.

It consists of getting the Customer to tell you what the complaint is and under what conditions it occurs.

The customer of course is, as always, the “MOST HELPFUL” source of information. Their concise insight into the

problem is a valuable step in getting the problem solved and the car back on the road. Also it’s the most fun part of

the diagnostic process. Watching the customer use body gestures, make funny faces and funny sounds in an attempt

to imitate vehicle noises can really brighten your day.

Actually the process of getting the information out of the customer can be relatively painless if you ask the correct

questions.

Here are some suggestions:

1) What is the problem/symptom(s)?

2) When did it start?

3) Under what conditions did the problem/symptom occur (if intermittent)? Wet, dry, hot, cold or changing weather,

rough road,...etc.

4) Has there been any work done on the car recently? New radio, shocks, tires...etc?

5) Any jump starts or hard starts with long crank times.

6) Did you run out of gas recently?

7) Are you sure this hasn’t happened before, even for a short time?

Next the exact nature of the complaint must be addressed.

Step 2

The Test Drive

Go on a test drive with the Customer so you can/cannot experience the problem/symptom. This ensures that the

malfunction you try to diagnose and fix is the one with that the customer is concerned about and that it is a real

malfunction and not just a lack of understanding of normal vehicle operation.

Few things are more frustrating for you and the customer than repairing a suspension noise in the front of the car

(even if it did need new shocks, thrust bushings, brakes and a set of tires) when it was an engine noise that the

customer wanted fixed.

It is also a good idea to let the customer drive on the outbound leg so you can watch the customers driving technique.

The customer is more likely to be able to make the car “do it” then you will.

Sometimes a customer can mistake normal vehicle operation for a problem. An example of this is a customer whose

vehicle has an Anti-Lock Brake System (ABS), and is concerned because of a pulsating brake pedal when braking

hard. Since many people are unaware of this characteristic of normal ABS operation, they mistake this for a

malfunction.

Also if you start diagnosing a vehicle for a problem when the vehicle is operating normally, you can be in for a long

frustrating day.

4

Page 5

Step 3

Visually Inspect the Vehicle

Don’t leave out this step. You can save lots of time with this.

Engine - Look under the hood. Check for missing covers, oil and water splash, burn marks, nesting

materials, mis-routed wiring and anything else that looks out of place.

ABS/ASC/DSC/ASR - Lift hood and inspect the fluid level. Raise the car and inspect the brakes/wheels for

excess dust and corrosion. Check that all static charge grounding straps are in place.

Transmission - Look for beverage spillage on the center console area. Look for problems in the operation of

the instrument cluster and on-board computer. These systems share data with the engine, transmission and

traction systems. Inspect the transmission housing and connection cables.

SRS/Airbag - Has the car been in a collision, jumped a curb, been to the body shop (welded) or jump started.

Any or all of these can be signs of something amiss.

Remember you’re gathering information at this point so don;’t ignore anything at this step.

Step 4

Check the Battery

Visually inspect the battery for corroded cables and terminals. Also old batteries are pure trouble in a late model car.

If you see any problem clean it up and grab your DMM (Fluke 88, Vantage, or whatever volt meter you use) and ...

Check voltage Key Off Engine Off, KOEO and KOER.

Key Off Engine Off >11.4Volts

KOEO >11.4Volts

KOER >13.2 but not higher than 14.2volts

Step 5

Recall Fault Codes

Even without a “Check this or that Light” illuminated, pull the codes from all systems, not just the suspect system.

Late model cars have highly integrated controls and faults can cascade from one system to another. Simple things like

and wrong size tire can turn on the Transmission Failure message, yet not turn on the ABS or ASR light. Both

systems, though, may register codes.

Record and then Clear the codes.

Write them down. Write them down. W rite them down.

There is nothing more fun then the call to tech support that starts.

Technician: “I got this code. Something about the O2 sensor. I replaced it but the code came back the next day.

Why?”

Tech Support: “What is the type and year of the car and what was the fault code number?”

Technician: “It was a ‘94 C220, but I don’t remember the code number. It came in last week.”

Tech Support: (Knocking back another bottle of Mallox) “Could it have been a Lambda Control code?”

Technician: “Ya! I think that was it. Why’d the new plugs make it go away and not the new O2 sensor?”

Test drive the car then pull the codes again. For some codes you will need to perform 2 test drives to get a code.

5

Page 6

Diagnostic Codes & Adaptation

Diagnostic Trouble Code (DTC) Readout:

The engine control module (N3/4) for the LH-SFI, HFM-SFI and ME-S FI sys tems are equipped with diagnostic trouble

code (DTC) memory. Malfunctions are recognized and stored as trouble codes and are distinguished as follows:

u Malfunctions which are constantly present,

u Malfunctions which occur longer than a pre determined number of seconds,

u Intermittent contact malfunctions which have occurred 5x during a trip.

The DTC memory remains active even if the vehicle's battery is disconnected.

Malfunctions which are no longer present, are automatically erased again after a maximum of 19 trips.

Under HFM-SFI a TRIP has occurred if:

u Engine running more than 5 minutes

u Vehicle speed >4 km/h (2.5 mph),

u Engine speed >700 rpm,

u Engine shut off for 30 seconds.

Under ME-SFI a TRIP is

u Engine running for more than 20 minutes,

u Engine temperature is greater than -7 degrees C,

u Engine speed is greater than 500 RPM,

The stored diagnostic trouble codes (DTCs) can be read at the 16 (124 E-class) or 38 pin data link connector (X11/4) with

the ignition switched "ON" or with the "engine running".

Diagnosis via an on-off ratio readout has been eliminated in all models.

About Stored, Registered and Current Faults

Stored or Permanent Faults - These faults generally turn on the MIL (malfunction indicator lamp previously known as

the Check Engine Light) and are recorded in the permanent memory of the cars system controller. Clearing these codes

most often will extinguish the MIL. (See Registered Faults below.)

Registered or Pending Faults - These faults can keep the MIL on. These faults are recorded in the temporary memory

of the of the cars system controller. This temporary memory records the number of times a component fails. When a

certain number of failures has occurred the fault is moved to permanent storage and the Check Engine Light (MIL) will

be illuminated. On cars equipped with Fault Registers the Check Engine Light may stay on after the Stored or Permanent

Fault has been erased if another occurrence of the fault has happened since the original Permanent Fault was stored.

To ensure the MIL is extinguished, erase the Stored and Registered faults.

Current or Actual Faults - These faults are detected while the car is running at idle or speed. They represent components

currently failing or, in the case of HFM and LH systems, components not present. These codes cannot be erased, and

are only meaningful with the ignition on and the engine running. Codes found in this system with the KOEO have no

meaning. Components not present on the vehicle may be flagged as failing by the cars internal diagnostics due to the

generic nature of the cars software. This is particularly true in C-Class (202) cars.

6

Page 7

Fault Code Types

There are basically 2 code types. Component failure codes and System Malfunction or Logic codes.

Component Failure Codes are just that. The ECU specifically targets a “component” as failing. These codes make it easy

to spot the problem.

Some of these components are:

Oxygen Sensor

MAP

MAF

TPS

Vehicle Speed Sensor

Coolant Temperature Sensor

Intake Air Temperature Sensor

Camshaft Position Sensor

Crankshaft Position Sensor

Exhaust Temperature Sensor

Injectors

Ignition (coils)

Idle Air Valve

Pressure Regulator (optional)

EGR Valve

EVAP Purge Valve

Secondary Air Valve

Secondary Air Pump...etc.

System Failure or Logic Codes indicate that, when the “system” operated it did not produce the desire result.

Examples of these codes are;

Fuel Trim, O2 Control at Limit (Lambda control)

Possible cause: Fuel tank ran empty, Incorrect Fuel Pressure, Injector valve defective or coked, Engine

Temperature Sensor defective, EGR valve leak, Secondary air leak, EVAP control system defective, Air Mass

Meter defective, O2 sensor aging (slow response) or inactive, Combustion disturbed by mechanical failure

(Spark plugs, compression, intake/exhaust valves, ...etc.)

Ignition Feedback Fault

Possible cause: Coils, Sparkplug Wires, Sparkplugs, ECU, Low or high battery voltage.

ASR CAN Signal to Another Controller Lost.

Possible cause: ABS/ASR Control Unit Fault, ABS/ASR Component Fault, CAN Bus Communications Fault,

Faulty Electronic Accelerator (EA) controller, Faulty EA Actuator, Low or high battery voltage.

Electronic Accelerator Fuel Cutoff Signal to Engine Control

Possible cause: Faulty EA Actuator System, Faulty EA Actuator, Low or high battery voltage

ECU Faults

Internal Control M odule, internal communication fault

Internal Control Module, Keep Alive Memory (CMOS)

Internal Control Module, Memory check sum (ROM/RAM)

Internal Control Module, RAM

Internal Control Module, EEPROM.

Load Calculation Cross Check, Range/Perf....etc.

These types of codes are more difficult to diagnose, but generally there will be other conditions that can give you a clue.

Other fault codes will be present, physical engine condition (wear and tear), nature of the complaint itself, and information

from the datastream can help refine your analysis.

7

Page 8

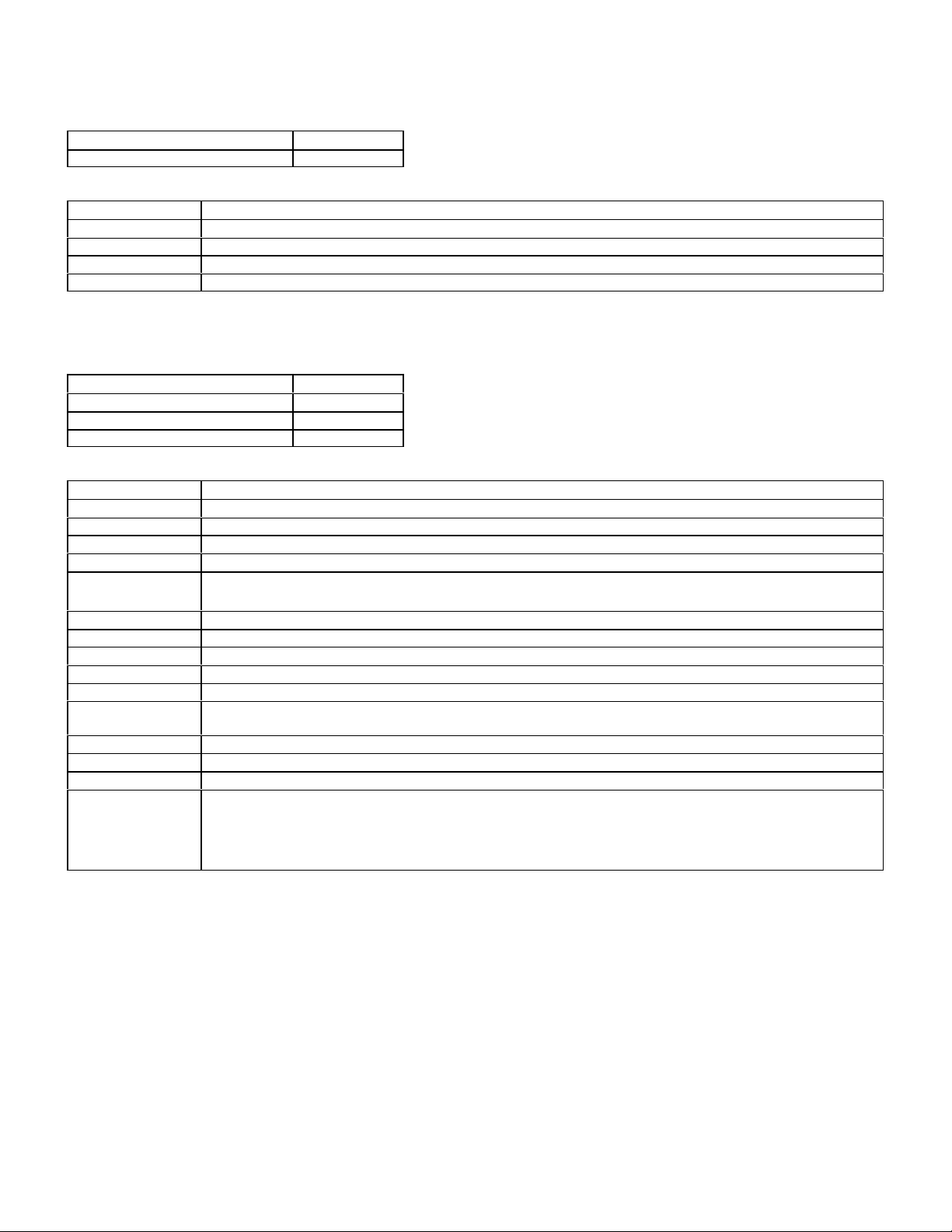

Check Engine Light (MIL) Diagnosis

Mercedes S(140), SL(129), E(124, 210) and C(202) class have multiple systems which can turn on an Check Engine Light.

All related systems must be tested for codes and repaired before the light will extinguish.

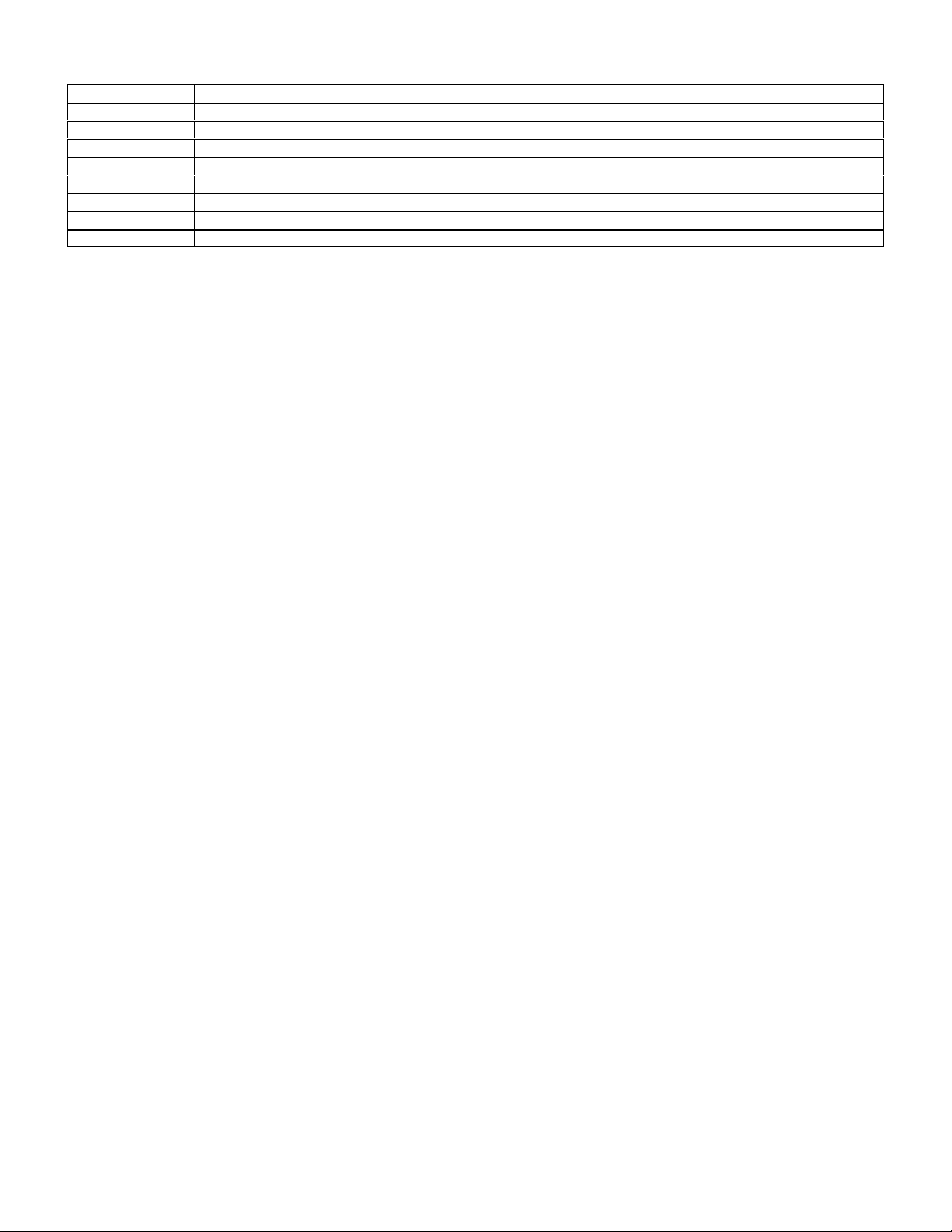

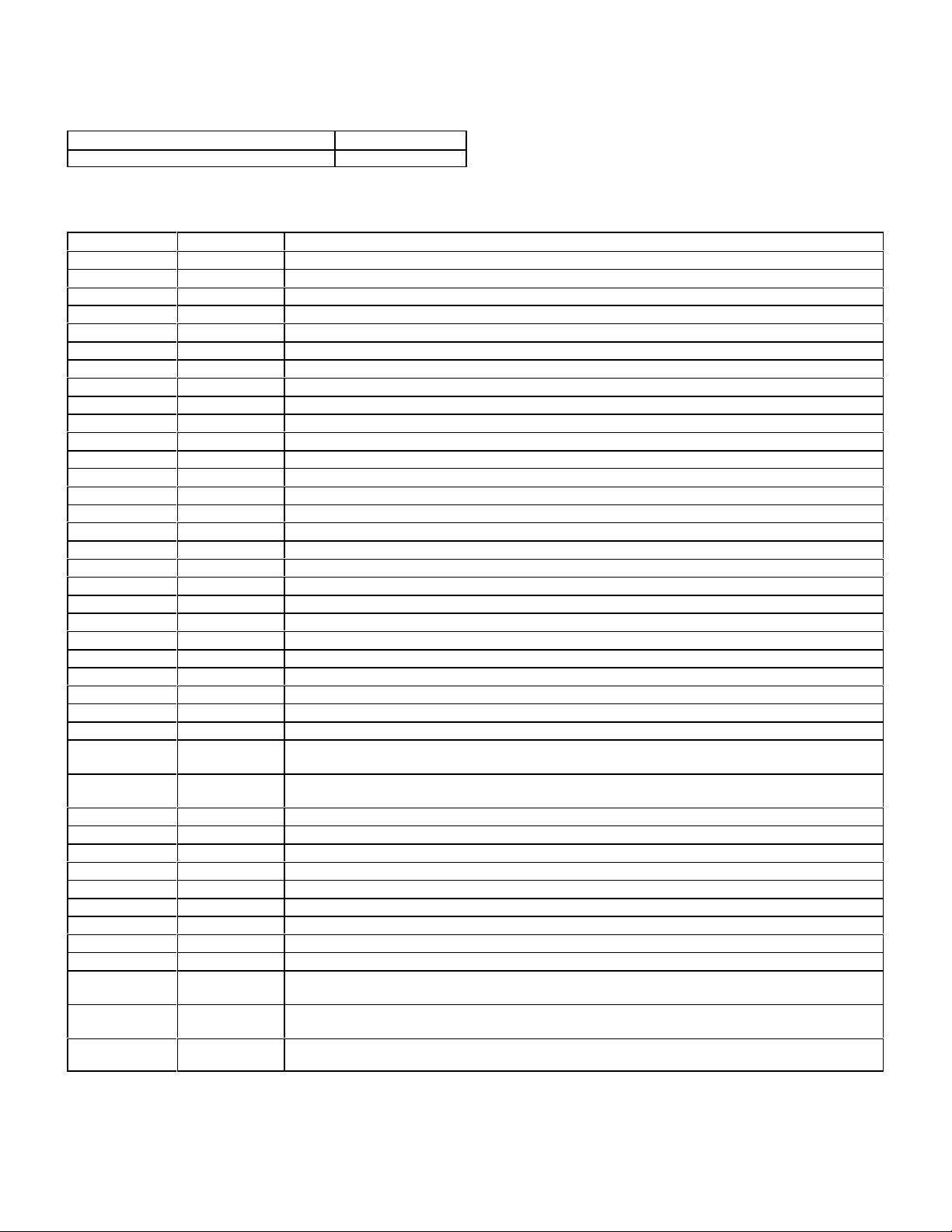

Injection System Diagnostic Socket Pin and CS1000 System to Use

129 LH

(1992-95)

140 LH

(1992-95)

124 HFM

(1993-95)

140 HFM

(1993-96)

202 HFM

(1995-96)

210 HFM

(1996-97)

LH (pin 4 & 5), EA/CC/ISC (pin 7), BM (pin 8), DI (pin 17 & 18) and DM (pin 19 check stored and

registered codes only)

LH (pin 4), EA/CC/ISC (pin 7), BM (pin 8), DI (pin 17) and DM (pin 19 check stored and

registered codes only)

HFM (pin 8), EA/CC/ISC (pin 14), and DM (pin 3 check stored and registered codes only)

HFM (pin 4), EA/CC/ISC (pin 7) and DM (pin 19 check stored and registered codes only)

HFM (pin 4), EA/CC/ISC (pin 7) (except C220) and DM (pin 19 check stored and registered

codes only)

HFM (pin 4), EA/CC/ISC (pin 7) and DM (pin 19 check stored and registered codes only)

Note: ME-SFI injected vehicles integrate Injection, Ignition, Electronic Accelerator,

Diagnostic Module and Base module into the ME controller module.

Mixture Adaptation:

The Lambda control system precisely determines fuel injection duration so that the fuel/air ratio is consistently kept at

Lambda equal 1 (Lambda=1 is 14.7 kg air per 1 kg fuel) under all operating conditions.

Should a malfunction occur in the form of:

u Intake air leaks

u Injector defects or carbon build-up,

u Air Flow Sensor defects

u Pressure regulator defects, such as a blown diaphragm.

u Fuel tank purge control valve defects or EVAP system leaks.]

u EGR defects

u Vacuum leaks of any kind.

u Mechanical engine wear, such as, chipped valves or leaking rings.

The engine control module automatically performs a mixture adjustment. The degree of correction is calculated constantly

and stored in KAM (Keep Alive Memory) RAM. The self-adaptation is performed at idle and under partial load. Maximum

correction towards rich or lean is 25%. After repair work is performed, the engine control module will automatically adapt

itself again after approx. 10 trips. After eliminating a malfunction or after trial installation of an engine control module from

another vehicle, the self-adaptation feature must be reset to its mean value.

8

Page 9

"Resetting and Reactivating for BOSCH Engine Control Module Memory"

For LH & HFM systems only.

To reset and reactivate the module :

1. Read and clear all fault codes

2. After display of 1 (No faults present) short the diagnostic plug (pin 8 for 16 pin diagnostic socket, pin

4 for 38 pin diagnostic socket) to ground for 6 to 8 seconds

3. Switch ignition off and wait at least 5 seconds

4. Turn ignition on, wait minimum of 10 seconds then restart engine.

Long Term Adaptation (Additive) - Engine at idle.

Short Term Adaptation (Multiplicative) - Engine at partial load

The correction towards rich or lean is + - 1.0 msec (Injection Duration) at idle and the factor of 0.68-1.32 at partial load.

After repair work is performed the engine control will automatically adapt itself again (ME injection) over the course of 10

TRIPS.

Codes Present in the Absent of Trouble Light

Not all control systems will trigger codes or turn on malfunction lights when codes are stored.

INJECTION/IGNITION system problems will trigger trouble codes, but may not turn on the MIL unless the fault results

in a change in the exhaust gases or can damage the engine in the short term. Also some mechanical problems in

earlier cars (pre 1988-96) can cause poor drivability without ever tripping a code or turning on the light. On later

models that is much less likely.

BRAKING/TRACTION systems will only turn on their check light when the system has become inactive. It does not

mean there isn’t a problem and codes haven’t been stored.

TRANSMISSION systems will turn on the “Check Engine” light if any shared system is detected as failing test.

AIRBAG and RESTRAINT SYSTEMS will turn on the light and record codes if incorrectly coded for the car. A good

example is the 1995 C280 and the 1995 S320. The same controller is used in both vehicles, however the S-class has

more features in the Airbag system such as side bags and baby seat detection. The coding of the controller for the

C280 masks the features not present so the controller doesn’t register a code. The controllers generally come off the

parts dept. shelf coded for maximum features.

In All Systems low or high battery voltages can trigger invalid or multiple codes without real failures of the indicated

components. Always check the battery condition before starting analysis.

Using the Data Stream to Diagnose/Confirm Faults

The Serial Data Information Stream of the ECU is a “window” into the operation of the system under test. By looking at

the values of the suspect components in operation and the computed values of the ECU, we can build a picture of the

operation of the system and what is causing the fault. The interpretation of the Data Stream is beyond the scope of

this book. Please refer to the Diagnostic Manuals from Mercedes Benz for complete discussion of the topic.

The nominal values for all Mercedes vehicles 1990-2000 can be found in the Mercedes Engine Diagnostic Manual

Volume 1 Section A.

A listing of these manuals can be found at the end of this document.

Multiple system and component faults can almost always be traced to faulty wiring

harnesses or water damage.

9

Page 10

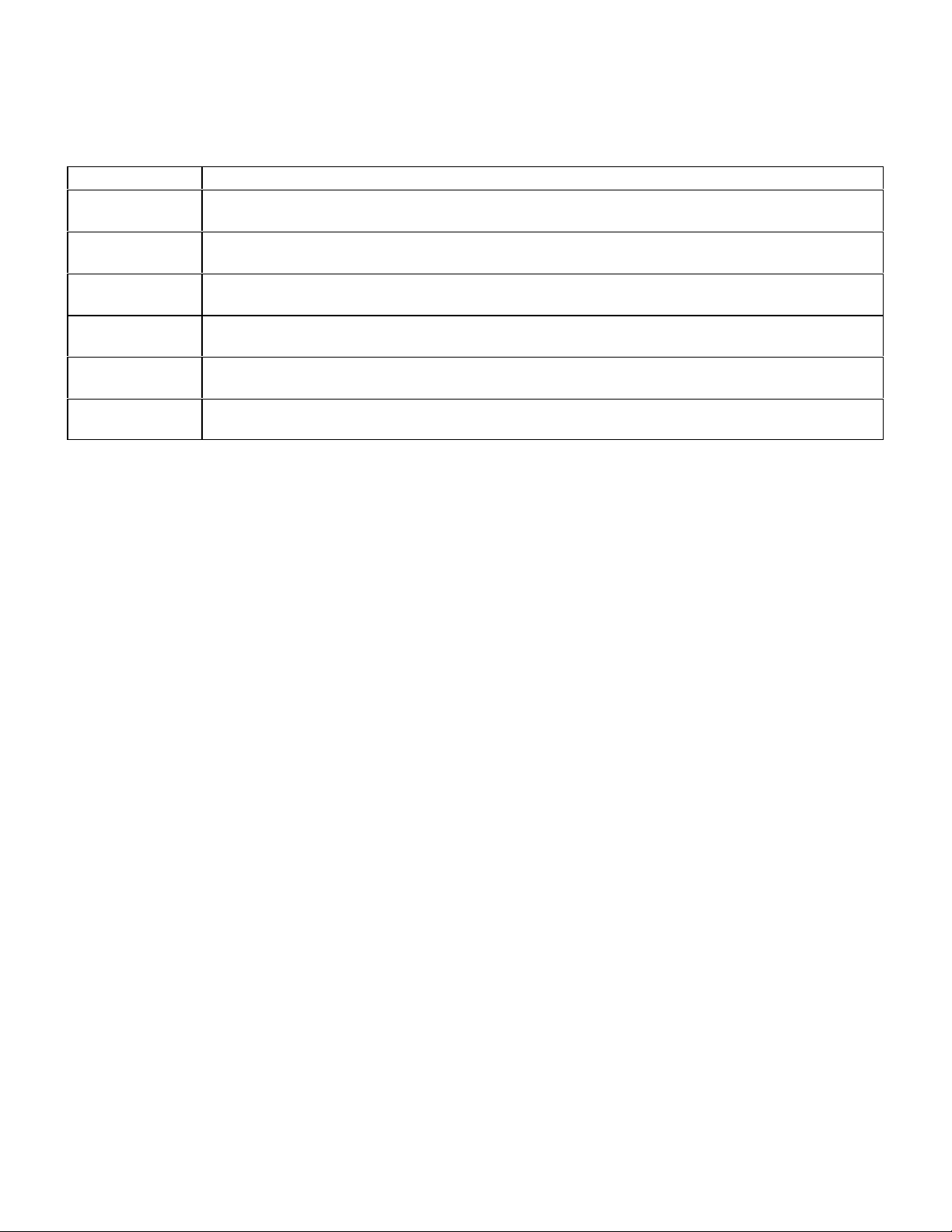

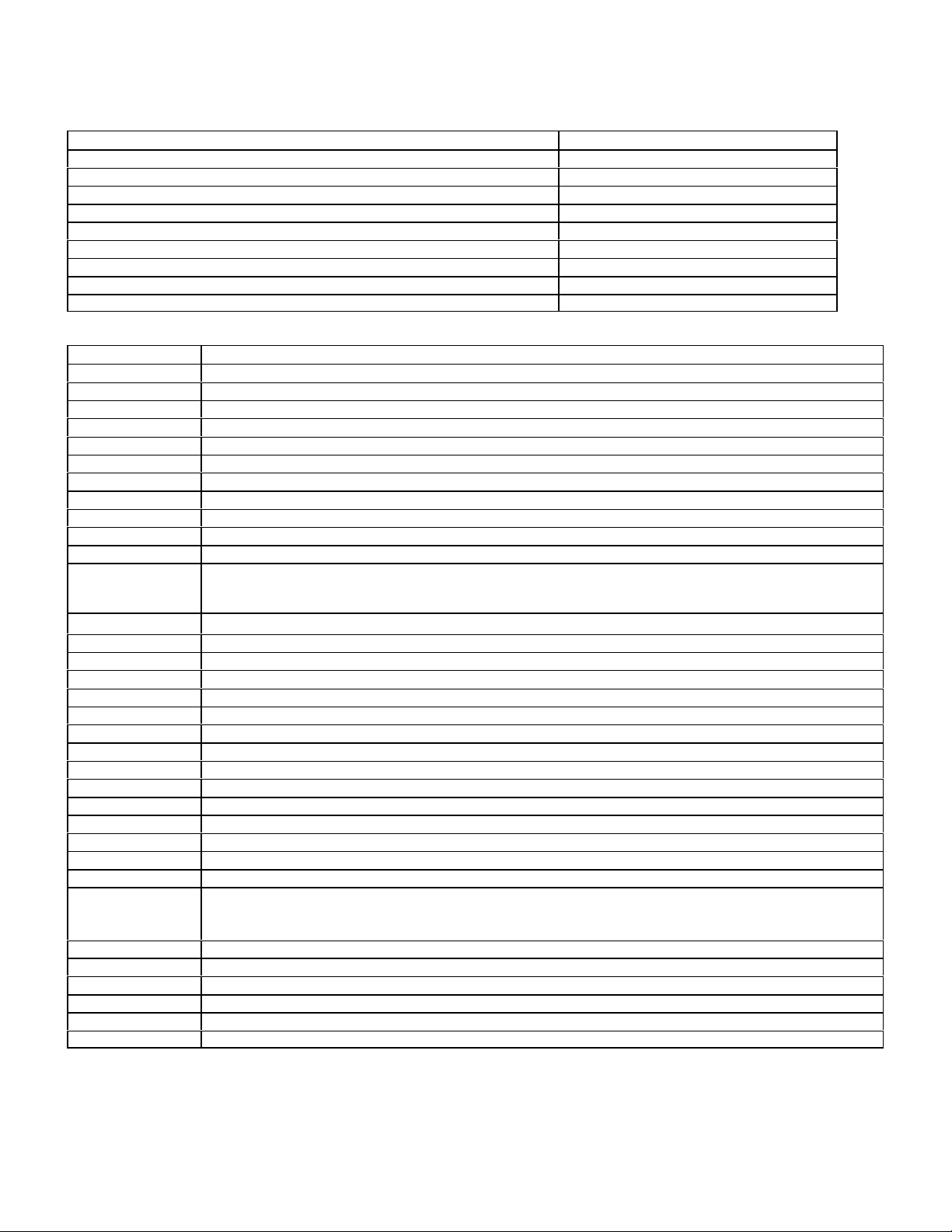

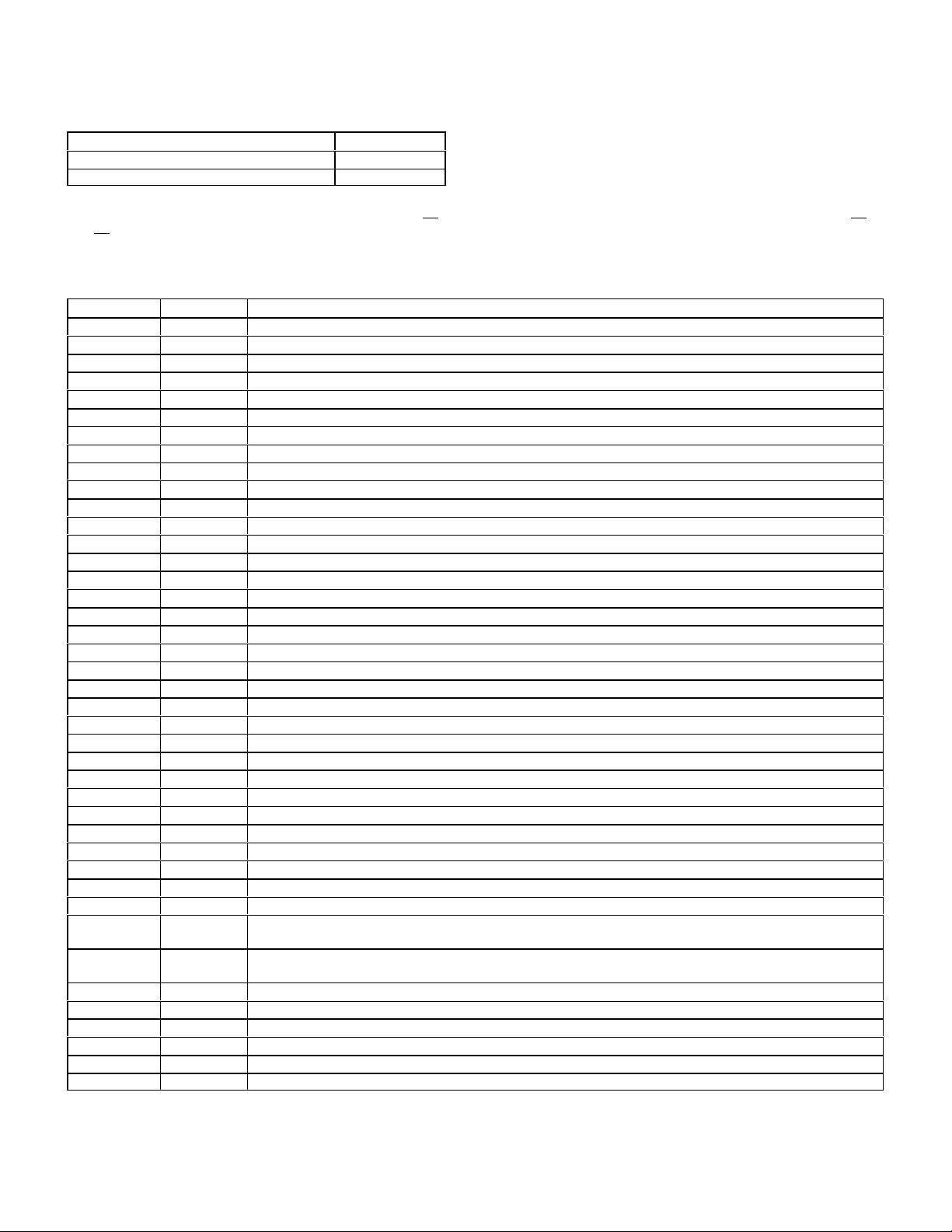

Connection Table

Test Lead of Cable Connection source

Red Power -To power supply socket or vehicle battery

Black Ground - To socket 1

Yellow To diagnostic test socket

Power supply (B+) socket on the vehicle Diagnostic Connectors

8-pole connector Use with the battery extension cable to the vehicle battery

16-pole connector Socket 16 (circuit 15 - ignition ON)*

Not present in some models. Use battery +.

38-pole connector Socket 3 (circuit 30 - Battery+)

*Must be performed with the ignition ON to power up the scanner

Ground (-) socket on the vehicle Diagnostic Connectors

8-pole connector socket 1

16-pole connector socket 1

38-pole connector socket 1

10

Page 11

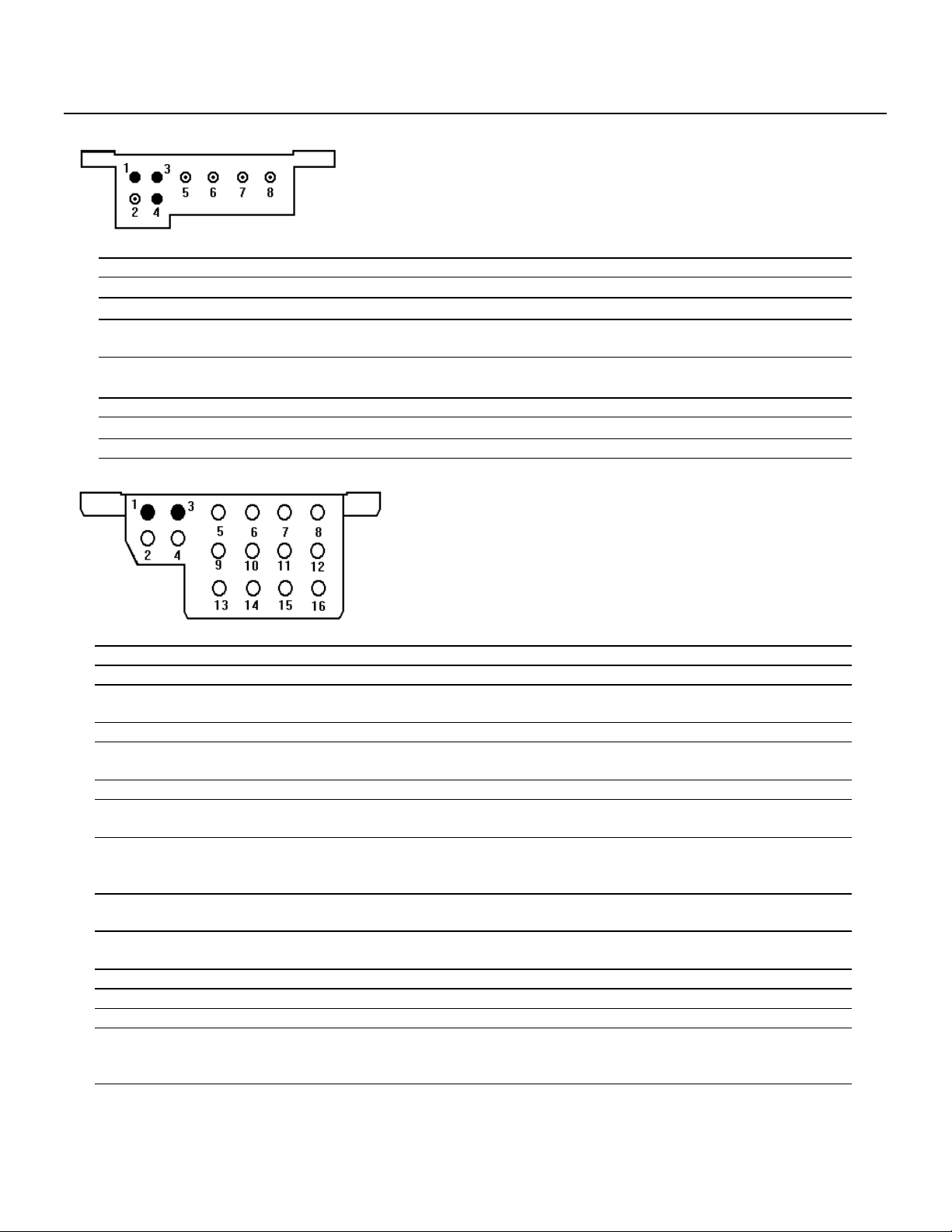

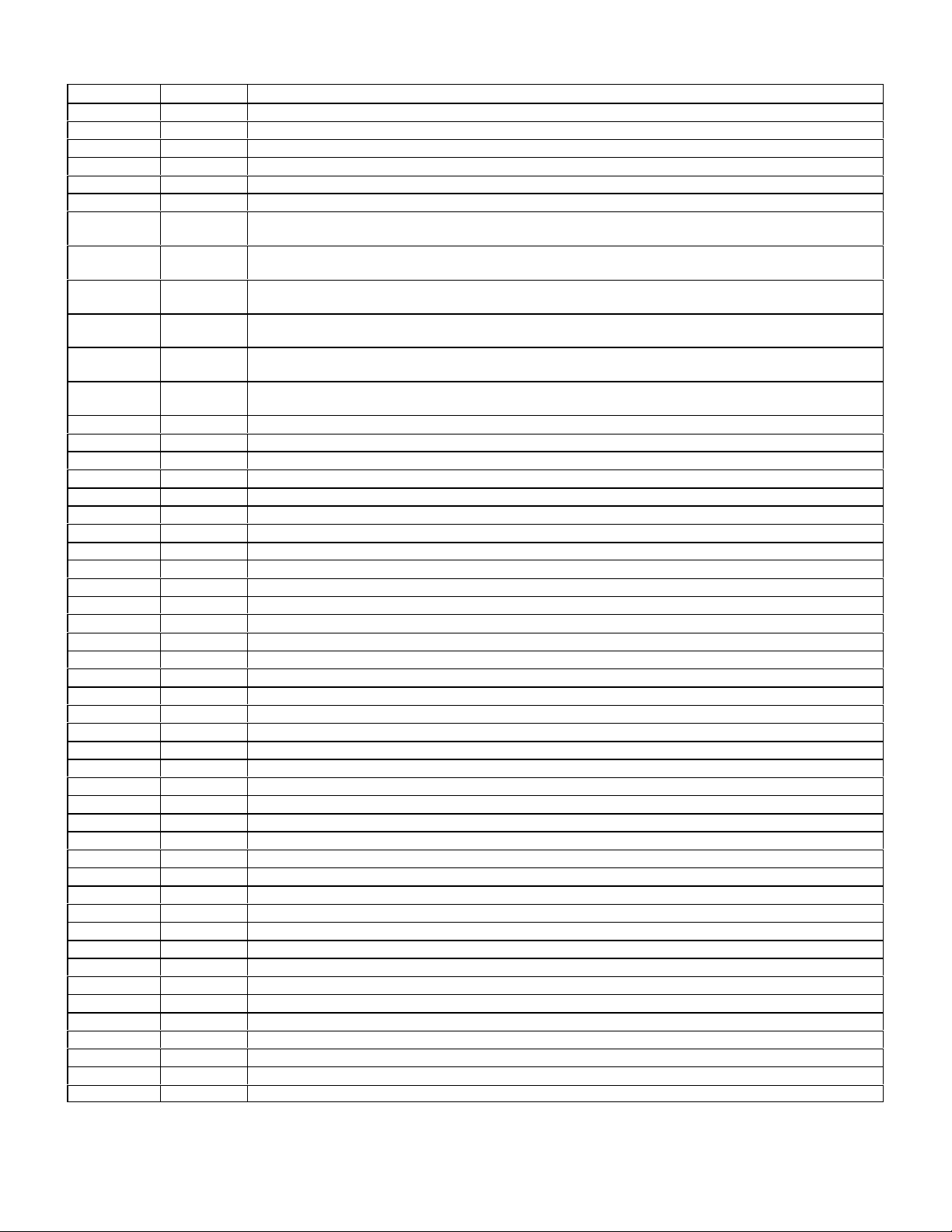

Connector Layout of Vehicle Diagnostic Connector

8-pole Diagnostic Connector

Models 201, 124, 126

1 Ground

2 Not used

3 CIS-E Continuous fuel injection system (CFI)

4 ELR

EDS

5 ASD

4MATIC

6 SRS Supplemental Restraint System

7 A/C Air Conditioning

8 Not used

Diesel injection system - Electronic idle speed control system

Electronic diesel system

Automatic locking differential

Automatic-engaged four wheel drive (124 only)

16-pole Diagnostic Connector

Models 124, 129

1 Ground

2 OBD Push-button for On Board Diagnostic (California only)

3 CIS-E

DM

4 EDS Electronic diesel system

5 ASD

4MATIC

6 SRS / AB Supplemental Restraint System / Air Bag

7 A/C

RB

8DI

HFM-SFI

PEC

9 ADS

RB

10 RST Roadster Soft Top (Model 129)

11 ATA Anti Theft Alarm system

12 IRCL Infrared Remote Central Locking

13 ETC Electronic automatic Transmission Control

14 EA

CC / ISC

ESCM

Continuous Fuel injection system (CFI)

Diagnostic Module - LED (California only)

Automatic locking differential

Automatic-engaged four wheel drive

Air Conditioning (Model 124)

Roll Bar (Model 129)

Distributor ignition

HFM Sequential multi-port Fuel Injection/Ignition system

Pressurized engine control

Adaptive Damping System

Roll Bar (Model 124)

TN-signal (Gasoline)

Electronic Accelerator (Model 124)

Cruise Control / Idle Speed Control (Model 124)

Engine System Control Module (MAS), (Model 129)

11

Page 12

15 Not used

16 Voltage, Ignition ON (Circuit 15) (Not equipped on all models.)

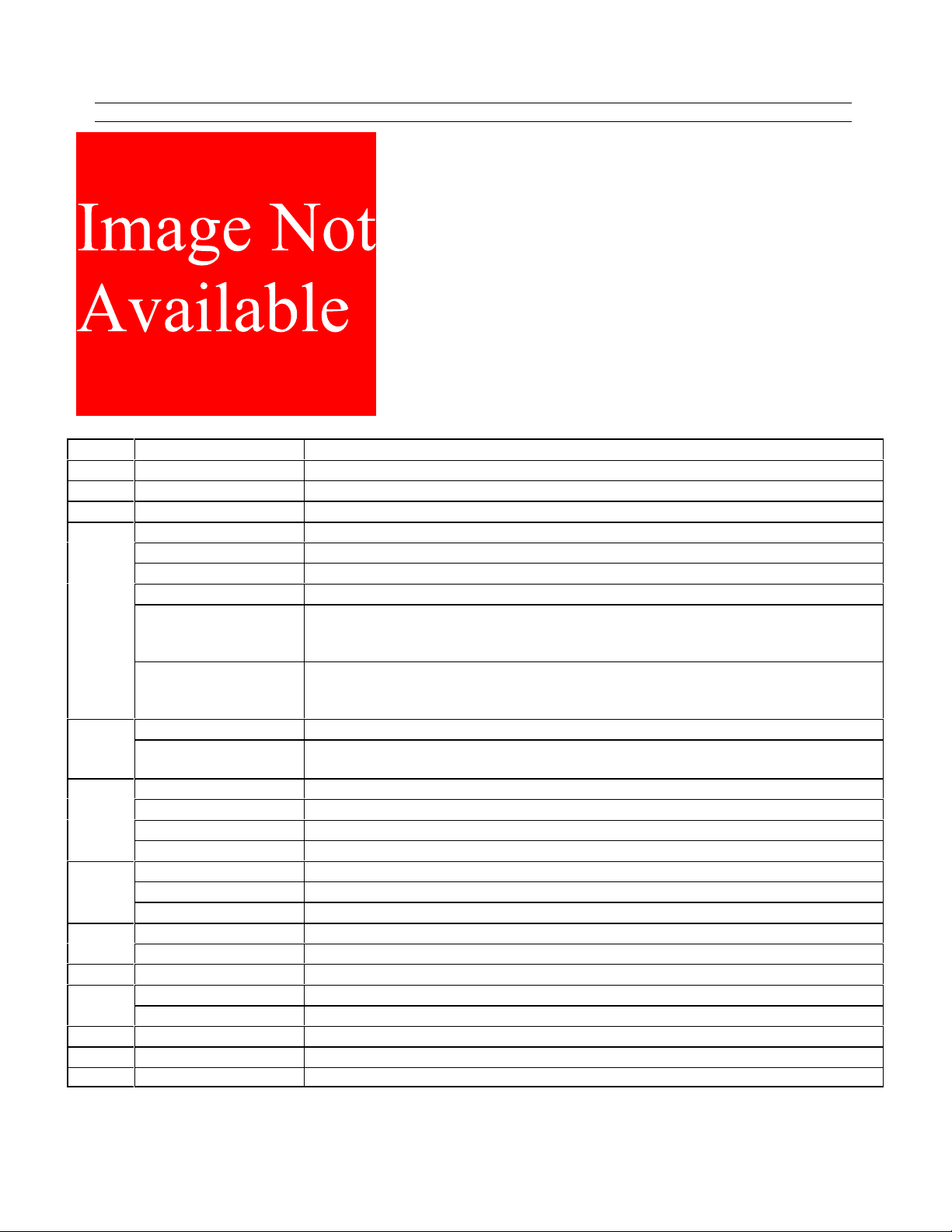

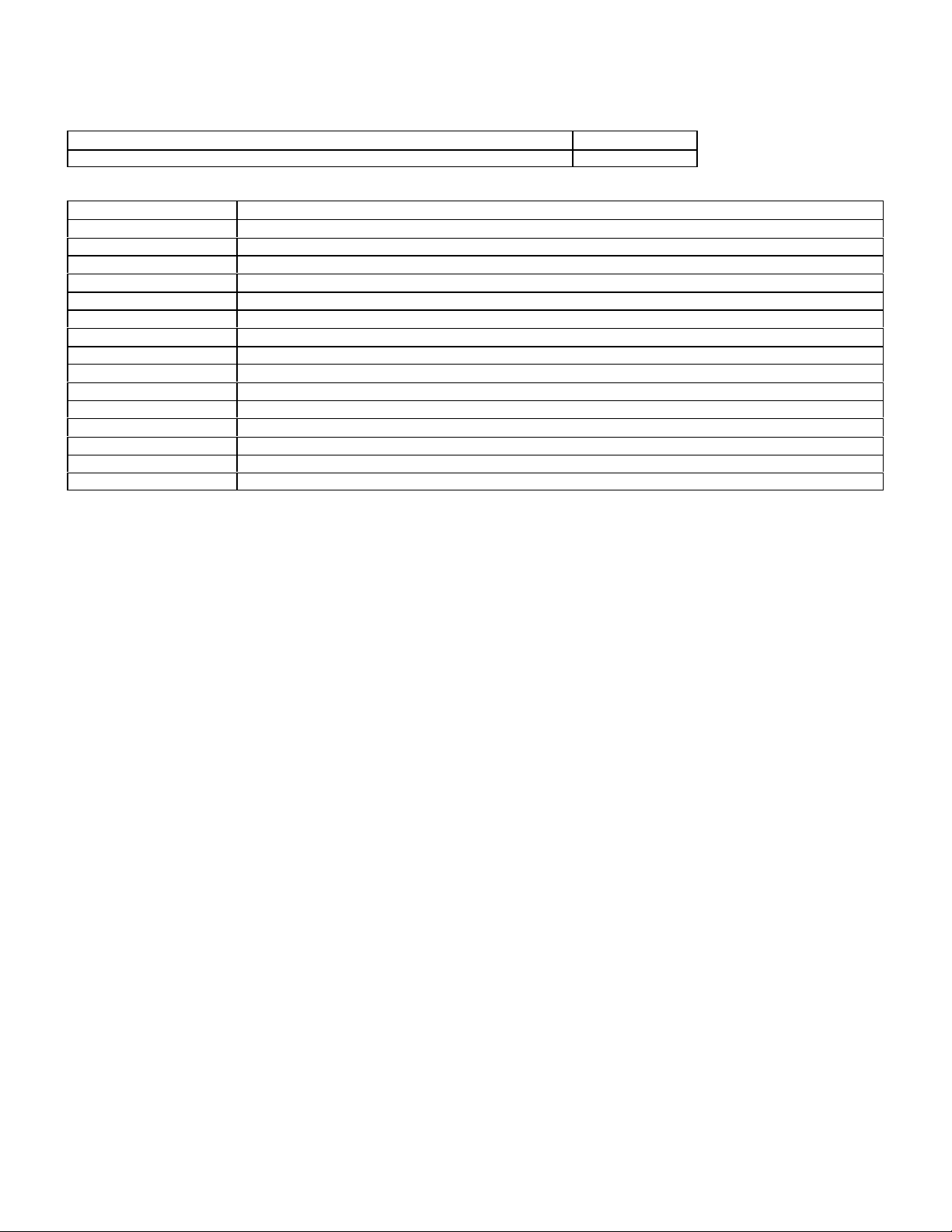

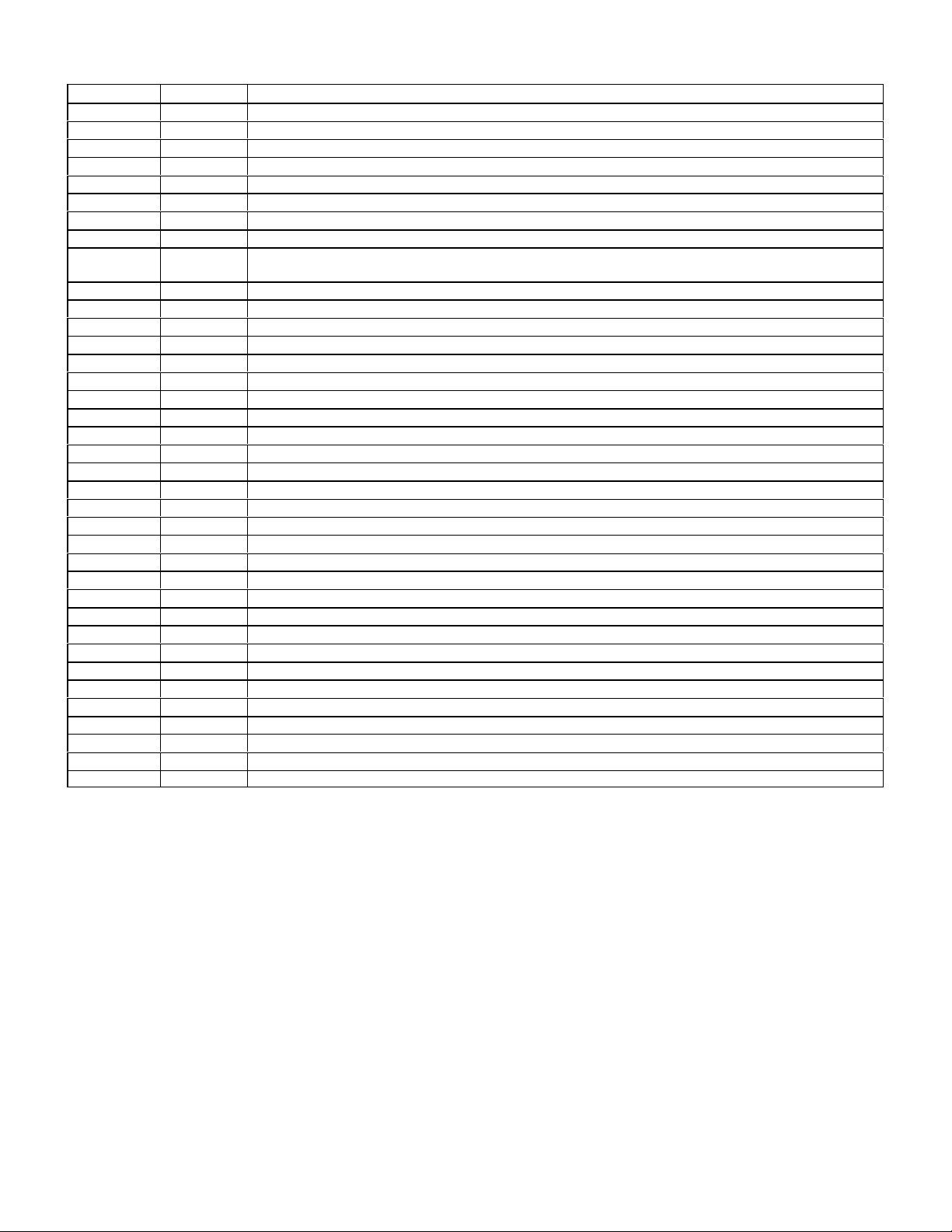

38-Pin Diagnostic Connector

Models 124.034/036, 129.058/063/067/076, 140, 170, 202, 208,

210, 215, 220

The Mercedes Diagnostic “Mushroom” #140-1463 available from

Baum Tools Unltd. is recommended to allow easy access to the

diagnostic connector. Call 800-848-6657 or 941-927-1414

for more information.

Pin System Description

1 Ground (Terminal 31) W12 (Chassis Ground), W15 (Electronics Ground)

2 Voltage, terminal 87 Ignition Switch 12volts +

3 Voltage, terminal 30 Battery 12volts +

4 EDS Electronic Diesel System

IFI In-line Fuel Injection

DFI Electronic Distributor-type Fuel Injection (Diesel)

HFM-SFI Hot-Film Engine Management Sequential Multiport Fuel Injection/ignition

LH-SFI LH Sequential Multiport Fuel Injection System

Engines 104, 119

Engine 120 Right Bank

ME-SFI Motor Electronics with Sequential Multiport Fuel Injection/ignition System

Engine 119

Engine 120, Right Bank

5 LH-SFI LH Sequential Multiport Fuel Injection, Engine 120 Left Bank

ME-SFI Motor Electronics with Sequential Multiport Fuel Injection/ignition System

Engine 120 Left Bank

6 ABS Anti-lock Brake System

ETS Electronic Traction System

ASR Acceleration Slip Regulation

ESP Electronic Stability Program

7 EA Electronic Accelerator+

ISC Idle Speed Control

CC Cruise Control/idle Speed Control

8 BM Base Module

BAS Brake Assist

9 ASD Automatic Locking Differential, Models 124, 129, 140

10 EATC Electronic Automatic Transmission Control (5-speed AT) (722.6)

ETC Electronic Transmission Control (722.6)

11 ADS Adaptive Damping System

12 SPS Speed-sensitive Power Steering

13 TD Speed Signal (Time Division) (Di) (Diesel) Models 202, 210

12

Page 13

TNA Signal (Gasoline) on LH-SFI

TN Speed Signal (DI/KSS) (Gasoline) on HFM-SFI, ME-SFI

14 Lambda on/off ratio LH-SFI Engine 119,

LH-SFI Engine 120 LH-SFI, Right Bank

15 Lambda on/off ratio LH-SFI Engine 120 Left Bank

IC Instrument Cluster

16 HEAT Automatic Heater

TA/C Air Conditioning (Tempmatic)

AA/C Air Conditioning (Automatic)

17 DI Distributor Ignition, Engines 104, 119, Engine 120, Right

TD Speed Signal (Time Division) (Di) (Diesel) Model 140

TN Speed Signal (DI/KSS) (Gasoline) on LH-SFI / model 202 HFM-SFI

18 DI Distributor Ignition, Engine 120, Left

19 DM Diagnostic Module

20 PSE Pneumatic System Equipment, Model 140

MFCM Multi-function Control Module, Model 210

21 CF Convenience Feature, Model 140

RST Roadster Soft Top, Model 129

22 RB Roll Bar, Model 129

23 ATA Anti-theft Alarm

24-25 -

26 ASD Automatic Locking Differential, Model 202

27 28 PTS Parktronic System, Model 140

29 30 AB Airbag/emergency Tensioning Retractor

31 RCL Remote Central Locking

32-33 -

34 CNS Communication and Navigation System

35 36 STH Stationary Heater

36 ZUH Heater Booster

37-38 -

The following connector is not for use with the CS1000 or CS2000 scanners

9-Pole Diagnostic Connector (1980-94)

The 9-pole Diagnostic Connector is used on earlier model vehicles. It can display on-off

ratio fault codes (1986-1992), RPM and Lambda sensor values. Various on-off ratio

Meters are available that provide access to this type of diagnostic connector. Call Baum

Tools at 800-848-6657 or 941-927-1414 for more information on these meters.

13

Page 14

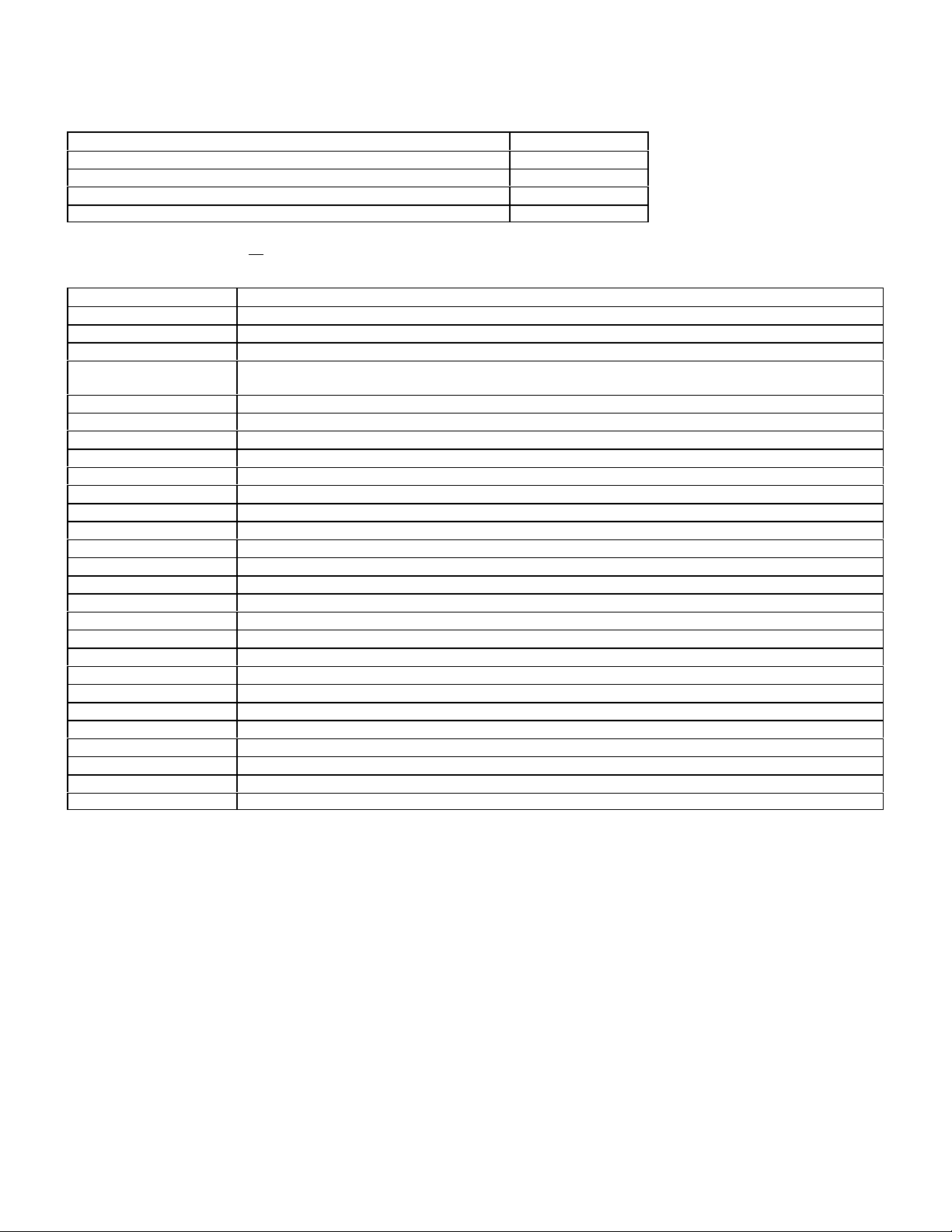

ELECTRONIC IDLE SPEED CONTROL (ELR)

Model Model Year

201.126 1989

FAULT CODE TABLE

DTC Readout Possible Cause of Failure

1 No fault found

2 Speed sensor signal

3 Coolant temperature sensor signal

4 ELR control unit or Idle speed control (ISC) system

ELECTRONIC DIESEL SYSTEM (EDS)

Model Model Year

124.128 1990-93

126.134 126.135 1990-91

140.134 1992-93

FAULT CODE TABLE

DTC Readout Possible Cause of Failure

1 No fault found

2 Fuel rack position sensor (L7)

3 Air flow sensor signal (B2/1)

4 Electronic diesel system (EDS) control unit (N39) or atmospheric pressure sensor

5 Exhaust gas recirculation (EGR) valve vacuum transducer (Y31/1) or fault in exhaust gas recirculation

(EGR) control circuit

6 Electronic diesel system (EDS) control unit (N39), internal voltage supply

7 Starter ring gear speed sensor (L3)

8 Engine coolant temperature sensor (B11/4)

9 Intake air temperature sensor (B2/1a)

10 Voltage supply insufficient

11 Electronic idle speed control actuator (Y22) or exhaust gas recirculation (EGR) valve vacuum transducer

(Y31/1) or Boost pressure cut-out switchover valve

12 Not used

13 Electronic diesel system control unit (N39), faulty (internal fault memory)

14 Electronic diesel system pressure sensor (B5/1), defective

15 Boost pressure control/ pressure control flap vacuum transducer (Y31/5) , or defect in Boost pressure

control circuit.

Or

Intake manifold air pressure control valve vacuum transducer (Y31/2), wastage vacuum transducer

(Y31/3), or malfunction Intake manifold air pressure circuit

14

Page 15

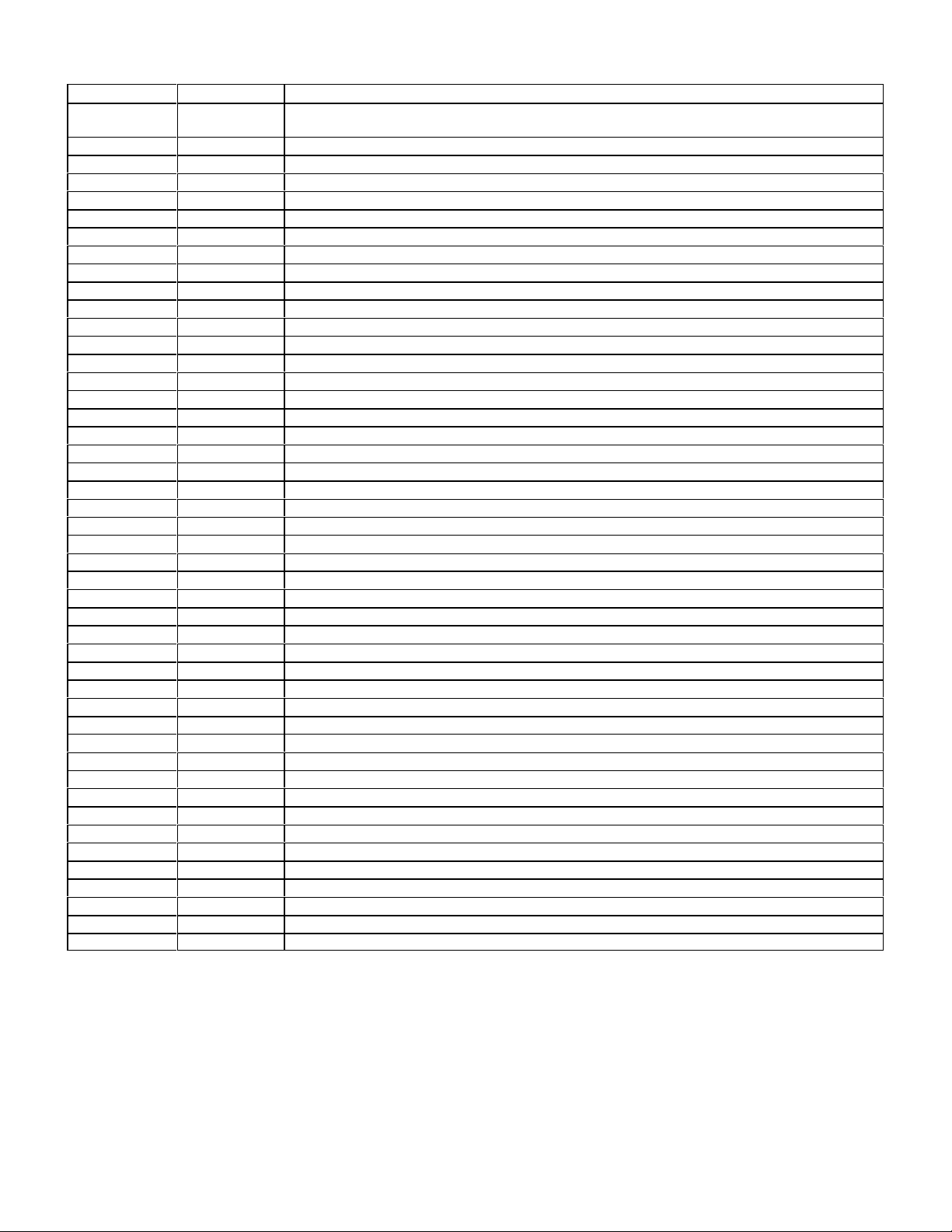

CONTINUOUS FUEL INJECTION SYSTEM (CFI)

Models Model Years

107.048 1988-91 (California version only)

124.026 124.030 124.050 124.090 1988-89 (California version only)

126.024 126.025 1988-89 (California version only)

126.035 126.039 126.045 1988-91 (California version only)

201.028 (1988-93) 201.029 1988-89 (California version only)

124.026 124.030 124.051 124.090 124.230 124.290 1990-93

126.024 126.025 1990-93

129.061 129.066 1990-92

201.029 1990-93

FAULT CODE TABLE

DTC Readout Possible Cause of Failure

1 No fault found

2 Throttle position switch - wide open throttle (WOT), signal faulty

3 Engine coolant temperature sensor faulty

4 Air flow sensor position potentiometer voltage illogical

5 Oxygen sensor signal illogical

6 Not used

7 TNA/TD signal (RPM) read by CFI control module

8 Altitude pressure signal from ignition control module illogical

9 Electronic hydraulic actuator (EHA) current faulty.

10 Throttle position switch - closed throttle position fault (idle)

11 Air injection system, open or short circuit

12 Absolute pressure values from EZL ignition control module are illogical

or

Exhaust gas recirculation temperature sensor

13 Intake air temperature reading is illogical

14 Vehicle speed signal read by CFI control module is illogical

15 Not used

16 Exhaust gas recirculation switchover valve, open or short circuit

17 Oxygen sensor is shorted to positive or ground

18 Current to idle control valve is illogical

19 Not used

20 Not used

21 Not used

22 Oxygen sensor heater voltage illogical

23 Short circuit to positive in purge switchover valve circuit

24 Not used

25 Short circuit to positive in start valve circuit

26 Short circuit to positive in upshift delay solenoid valve circuit

27 Data exchange between CFI control module and ignition control module interrupted

28 Intermittent contact in engine coolant temperature sensor circuit

29 CFI and ignition control module reading different engine coolant temperatures - Faulty sensor or wires

30 Not used

31 Intermittent contact in engine coolant temperature sensor circuit

32 Not used

33 Not used

34 Engine coolant temperature read from ignition control module illogical

15

Page 16

Continuous Fuel Injection System (MAS Controller)

Models Model Years

124.026 124.030 124.090 124.230 124.290 129.066 201.029 1990-92

FAULT CODE TABLE

DTC Readout Possible Cause of Failure

1 No fault found

2 Fuel pump relay (circuit 87) not functioning

3 TN/TD signal (RPM) interrupted

4 Output for oxygen sensor heater control defective

5 Output for air injection pump control defective

6 Output for kickdown switch control defective

7 Not used

8 Engine coolant temperature sensor signal out of range

9 Circuit 50 failure

10 Output failure of the start valve

11 A/C compressor engagement signal missing (87Z)

12 Output for A/C compressor control defective

13 Excessive A/C compressor clutch slippage

14 Vehicle speed signal illogical

15 Short circuit detected in fuel primp circuit

16

Page 17

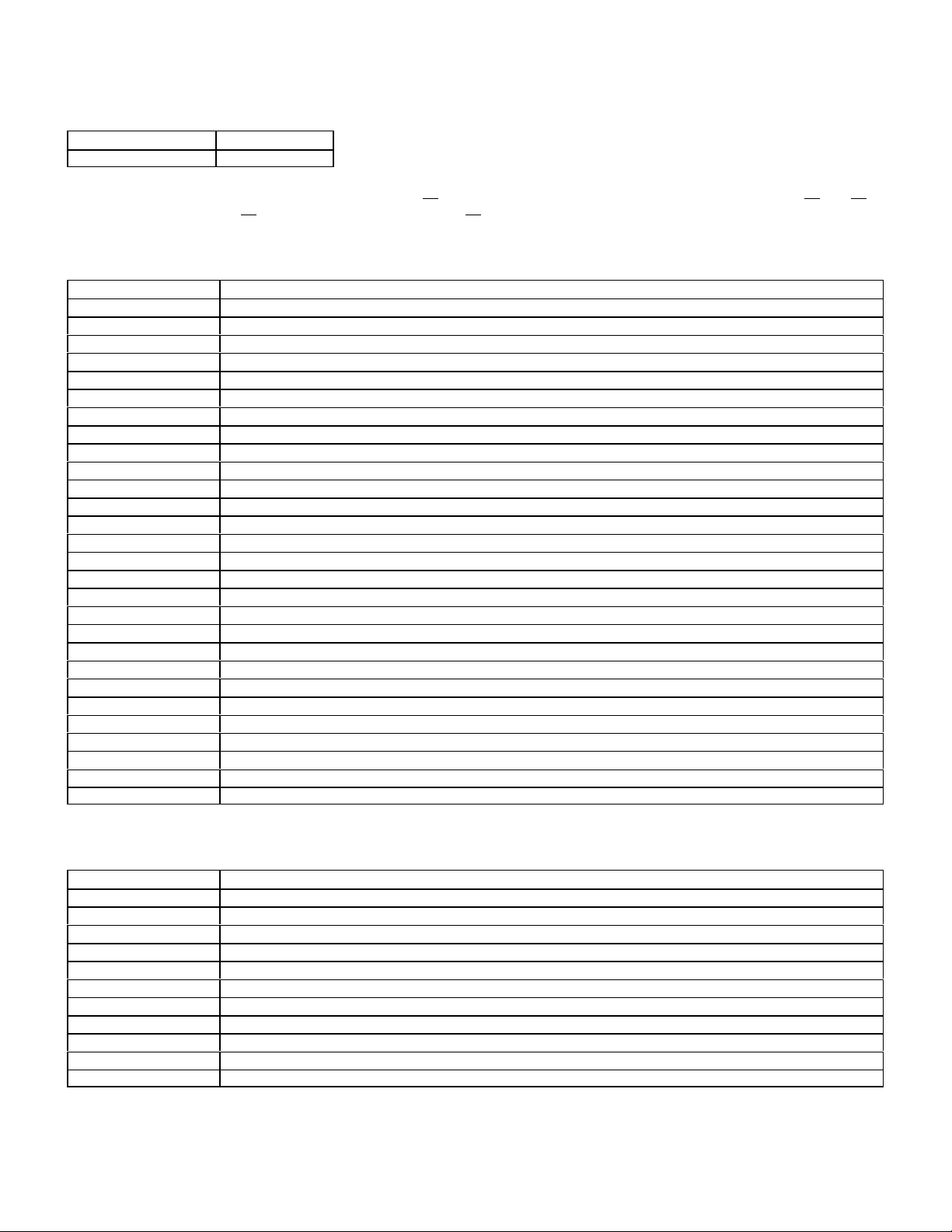

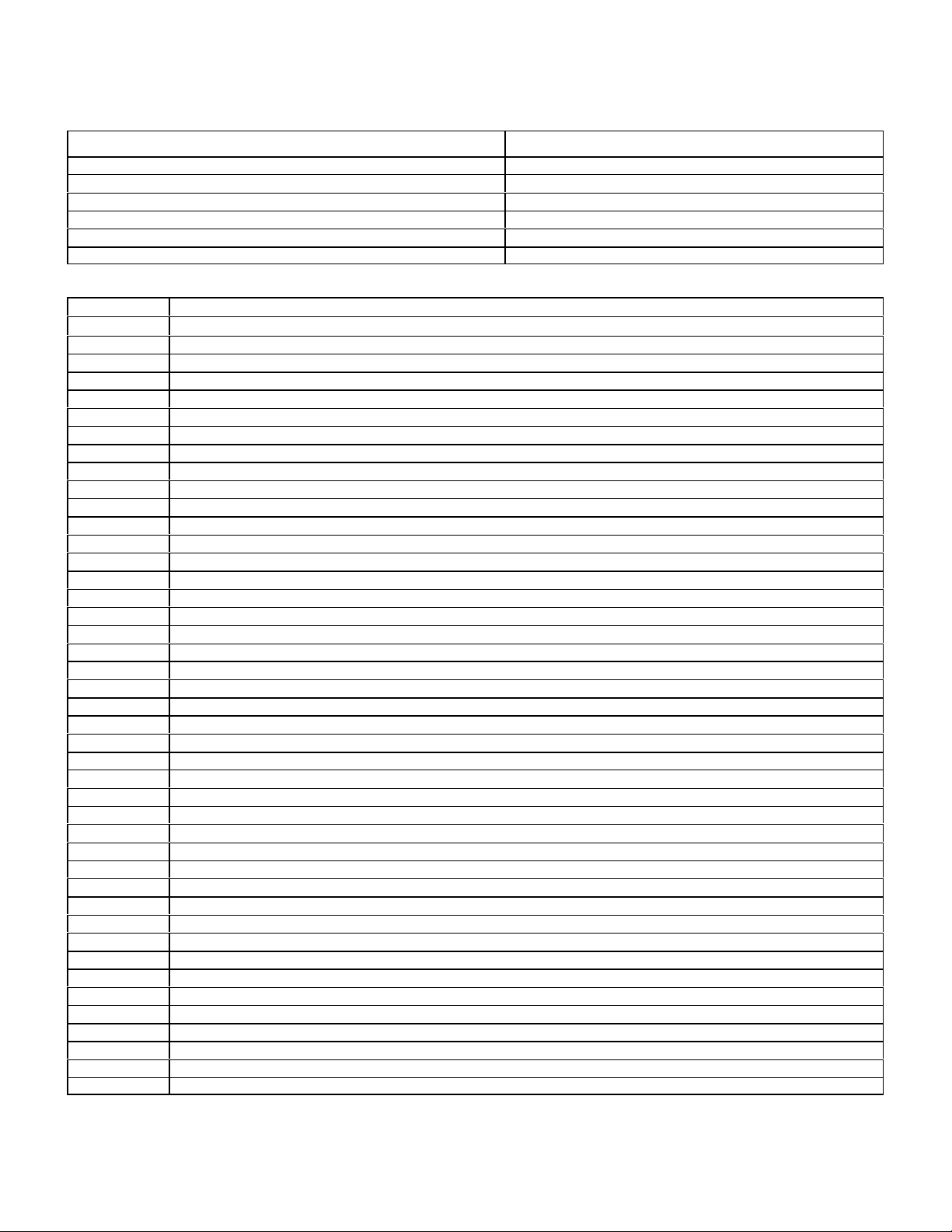

LH Sequential Multiport Fuel Injection - Analog

Models Model Years

140.032 140.057 140.076 1992-93

124.034 124.036 1992-93

129.067 1992-93

140.042 140.043 140.051 1992-93

See digital LH injection page 18 for models 3/93 and later.

FAULT CODE TABLE

DTC Readout Possible Cause of Failure

1 No fault found

2 Engine coolant temperature sensor circuit 1, open or short circuit.

3 Engine coolant temperature sensor circuit 2, open or short circuit.

4 Voltage at mass air sensor (MAF) with hot wire circuit insufficient or too high. Open or short circuit in

ground wire.

5 Not used

6 Not used

7 TNA-signal (rpm signal ) incorrect or open or short circuit.

8 Camshaft position sensor signal. Open or short circuit.

9 Starter signal (circuit 50) missing, open or short circuit.

10 Closed throttle position recognition from electronic accelerator control unit, short circuit.

11 Secondary air injection system, open or short circuit.

12 Burn-off control for mass air sensor with hot-wire, open or short circuit.

13 Intake air temperature sensor, open or short circuit.

14 Not used

15 Not used

16 Exhaust gas recirculation (EGR) switchover valve, open or short circuit.

17 CAN data: Electronic accelerator control module - no data transmission

18 CAN data: Ignition control module - no data transmission from DI module

19 Left LH-SFI control module no data transmission to right LH-SFI control module

20 LH-SFI control module - no data transmission

21 Oxygen sensor open circuit.

22 Oxygen sensor heater, open or short circuit.

23 Purge switchover valve, open or short circuit.

24 Left adjustable camshaft timing solenoid (Y49/1), open or short circuit

25 Adjustable camshaft timing solenoid, open or short circuit.

27 Injectors, open or short circuit.

29 I GR Start relay module (K29/1), open or short circuit

17

Page 18

LH Sequential Multiport Fuel Injection - Digital

Engines Model Years

104 119 120 1992-1995

Also check for codes in the Diagnostic Module (DM page 43), Electronic Accelerator/Cruise Control (EA/CC/ISC pages 50 and 49),

Distributor Ignition (DI page 48) and the Base Module (BM page 47).

(These fault codes numbers are only for the CS1000 Code Scanner. They are different from those found in the Mercedes Benz

original Diagnostic Manual fault code tables.)

LH-SFI “Stored” Fault Codes

DTC Readout Possible Cause of Failure

002 Engine coolant temperature sensor circuit 1, short or open circuit

003 Engine coolant temperature sensor circuit 2, short or open circuit

004 Voltage of Hot Wire MAF sensor too low or too high or ground wire has open circuit.

005 Not used.

006 Japan only Exhaust temperature sensor, circuit short or open

007 TNA-signal (rpm signal ) incorrect or open or short circuit.

008 Camshaft position sensor signal. Open or short circuit.

009 Starter signal (circuit 50) missing, open or short circuit.

010 Closed throttle position recognition from electronic accelerator control unit, short circuit.

011 Secondary air injection system, open or short circuit.

012 Burn-off control for mass air sensor with hot-wire, open or short circuit.

013 Intake air temperature sensor, open or short circuit.

014 Not used.

015 Not used.

016 EGR switchover valve, circuit open or short

017 CAN data: Electronic accelerator control module - no data transmission

018 CAN data: Ignition control module - no data transmission from DI module

019 Left LH-SFI control module no data transmission to right LH-SFI control module

020 LH-SFI control module - no data transmission (Left or Right)

021 Oxygen sensor open circuit.

022 Oxygen sensor heater, open or short circuit.

023 Purge switchover valve, open or short circuit.

024 Left adjustable camshaft timing solenoid (Y49/1), open or short circuit (119 only)

025 Adjustable camshaft timing solenoid, open or short circuit.

026 Upshift Delay Switchover Valve, open or short circuit

027 Injectors, open or short circuit.

028 LH Control Module incorrectly coded or open circuit.

029 1GR Start relay module (K29/1), open or short circuit

These codes require special scanners to access.

LH-SFI “Current” Fault Codes

DTC Readout Possible Cause of Failure

001 Injector, cylinder 1 circuit short to positive

002 Injector, cylinder 5 circuit short to positive

003 Injector, cylinder 4 circuit short to positive

004 Injector, cylinder 8 circuit short to positive

005 Injector, cylinder 6 circuit short to positive

006 Injector, cylinder 3 circuit short to positive

007 Injector, cylinder 7 circuit short to positive

008 Injector, cylinder 2 circuit short to positive

009 Injector, cylinder 1 open circuit or short to ground

010 Injector, cylinder 5 open circuit or short to ground

011 Injector, cylinder 4 open circuit or short to ground

18

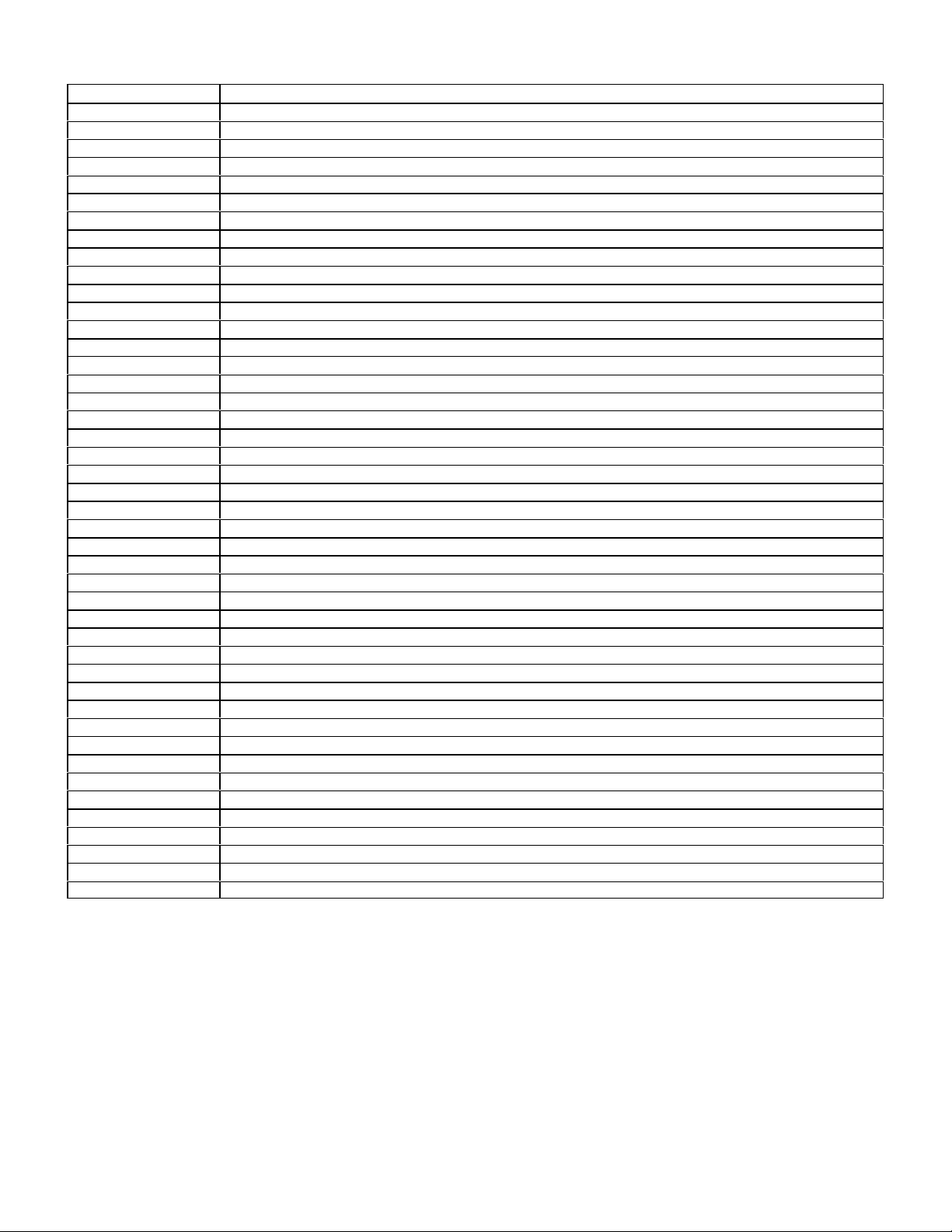

Page 19

DTC Readout Possible Cause of Failure

012 Injector, cylinder 8 open circuit or short to ground

013 Injector, cylinder 6 open circuit or short to ground

014 Injector, cylinder 3 open circuit or short to ground

015 Injector, cylinder 7 open circuit or short to ground

016 Injector, cylinder 2 open circuit or short to ground

017 HFM sensor Voltage too high or too low, may open circuit

018 Engine coolant temperature sensor short or open circuit

019 Engine coolant temperature sensor short or open circuit

020 Engine coolant temperature sensor signal questionable

021 Intake air temperature sensor short or open circuit

022 Exhaust temperature sensor short or open circuit (Japan version only)

023 CO potentiometer open circuit (non KAT)

024 LH-SFI control unit coding plug open circuit (not USA version)

025 Starter signal missing (circuit 50), may short or open circuit

026 Idle speed recognition from Cruise control/Electronic accelerator (CC/EA), circuit short to ground

027 Not used

028 O2S 1 signal, short or open circuit

029-030 Not used

031 O2S 2 signal, short or open circuit

032 Not used

033 CAN communication problem, No communication from LH control unit

034 CAN communication problem, No communication from ASR control unit

035 CAN communication problem, No communication from LH control unit

036 CAN communication problem, No communication from LH control unit

037 CAN communication problem, No communication from EZL/AKR ignition control unit

038 CAN communication problem, No communication from EZL/AKR ignition control unit

038 CAN communication problem, No communication from Cruise control/Electronic accelerator

040 Not used

041 Air injection system short or open circuit

042 Fuel purge switchover valve open or short circuit

043 Transmission switchover valve, circuit open or short

044 EGR switchover valve, circuit open or short

045 Camshaft timing adjust solenoid, circuit open or short

046 Camshaft timing adjust solenoid, circuit open or short

047 First gear start relay, circuit open or short

048 Not used

049 Air injection system circuit short or open

050 Fuel purge switchover valve circuit short or open

051 Transmission switchover valve relay or solenoid, circuit short or open

052 EGR switchover valve circuit short or open

053 camshaft timing Adjust solenoid circuit short or open

054 camshaft timing Adjust solenoid circuit short or open

055 First gear start relay circuit short or open

056 Not used

19

Page 20

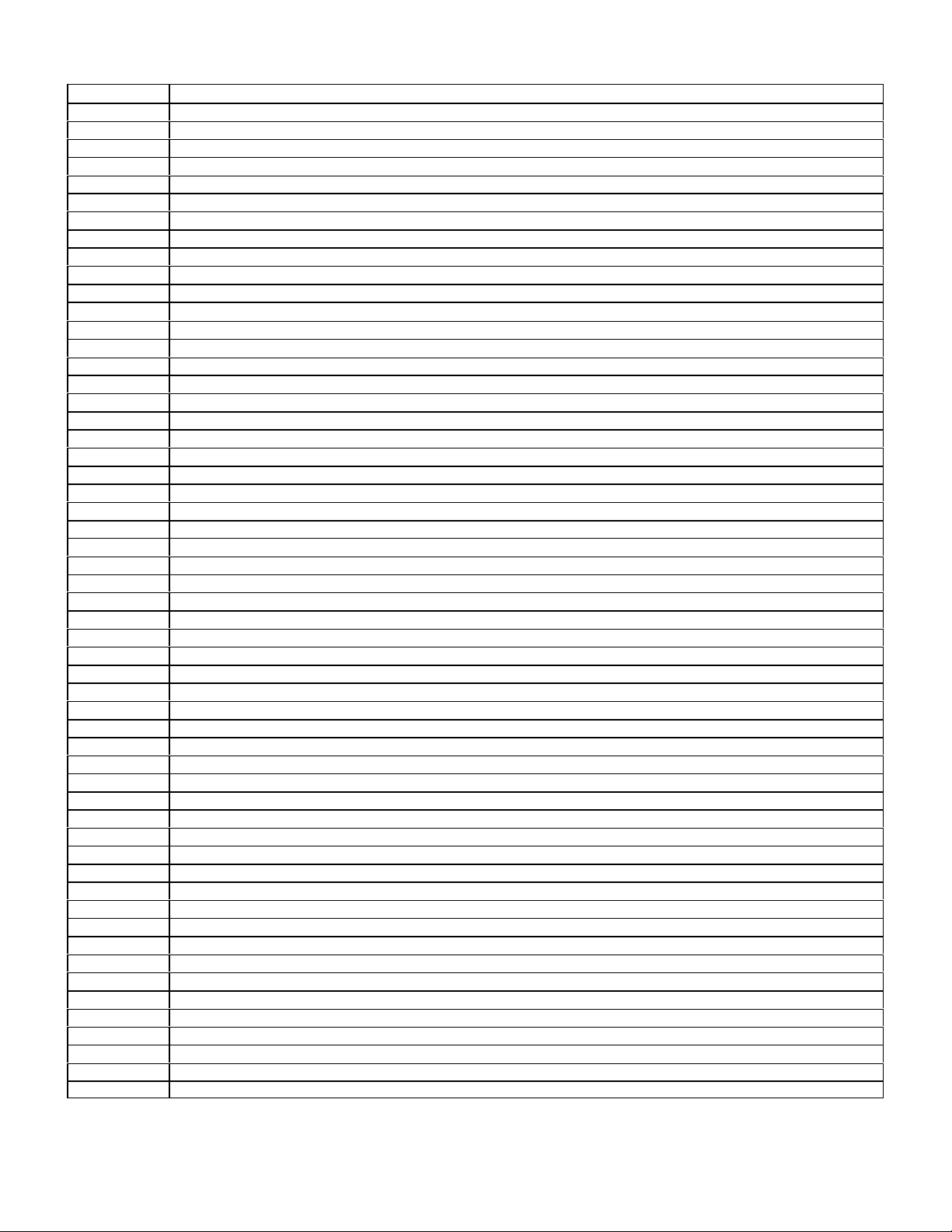

HFM Sequential Multiport Fuel Injection - Analog

Engines Model Year

104 111 1993

See digital HFM injection section page 22 for models 3/93 and later.

Also check for codes in the Diagnostic Module (DM page 41 and 43) and the Electronic Accelerator/Cruise Control (EA/CC/ISC

pages 50 and 49).

FAULT CODE TABLE

DTC Readout Possible Cause of Failure

1 No fault found

2 Engine Coolant temperature sensor

3 Intake air temperature sensor

4 Hot film mass air flow sensor

5 CTP switch

6-7 Not used

8 Idle speed control (ISC) system at upper or lower control stop or CC or EA indicates "limp home" mode.

9 O2S 1 (before TWC) - voltage too high, circuit open or voltage implausible

10 O2S 2 (after TWC)voltage too high, circuit open or voltage implausible

11 O2S 1 heater (before TWC) - Current too high/low or short circuit.

12 O2S 2 heater (after TWC) - Current too high/low or short circuit.

13 O2S (Lambda) control system operating at rich or lean limit

14 Injector, cylinder 1

15 Injector, cylinder 2

16 Injector, cylinder 3

17 Injector, cylinder 4

18 Injector, cylinder 5

19 Injector, cylinder 6

20 Self-adaptation at idle speed or upper/lower partial load at rich or lean limit

21 Ignition output 3 or ignition coil for cylinder 1 and 6

22 Ignition output 1 or ignition coil for cylinder 2 and 5 (Engine 111, cylinder 1 and 4)

23 Ignition output 2 or ignition coil for cylinder 3 and 4 (Engine 111, cylinder 2 and 3)

24 CKP sensor or magnet for position sensor not recognized

25 CMP sensor not recognized or implausible

26 Not used

27 TN-signal (rpm signal ) - open or short to ground

28 VSS - open circuit

29 Not used

30 Fuel pump relay module - open or short circuit

31 Not used

32 Knock sensors 1 and /or 2

33 Maximum retard setting on at least one cylinder has been reached or the ignition angle deviation between the

individual cylinders is greater than 6 degrees crankshaft angle

34 Knock control-output switch in engine control module faulty Momentary fault in self-adaptation closed throttle

speed/partial load

35 Model 124,129 and 140 AIR pump switchover valve and/or electromagnetic AIR pump clutch.

Model 202 AIR pump switchover valve and/or AIR relay module

36 Purge control valve - open/short to ground or B+

37 Transmission Upshift delay switchover valve (Y3/3) without function (Logic Chain) - Check vacuum and

adjust Bowden cable.

38 Adjustable camshaft timing solenoid - open/short to ground or B+

39 Exhaust gas recirculation switchover valve - open/short to ground or B+

40 Transmission overload protection switch - open/short to ground or B+ or open or closed or implausible

41 CAN communication from engine control module faulty

20

Page 21

DTC Readout Possible Cause of Failure

42 CAN communication from ASR, EA/CC/ISC module or diagnostic module (OBD II) faulty

43 Starter signal (circuit 50) not present

44 Not used

45 Fuel safety shut-off of electronic accelerator or cruise control active

46 Resonance intake manifold switchover valve - open/short to ground or B+

48 O2S 2 (after TWC) heating circuit relay module - open/short to ground or B+

49 Voltage supply at engine control module implausible/low volts.

50 Engine control module faulty or not coded.

21

Page 22

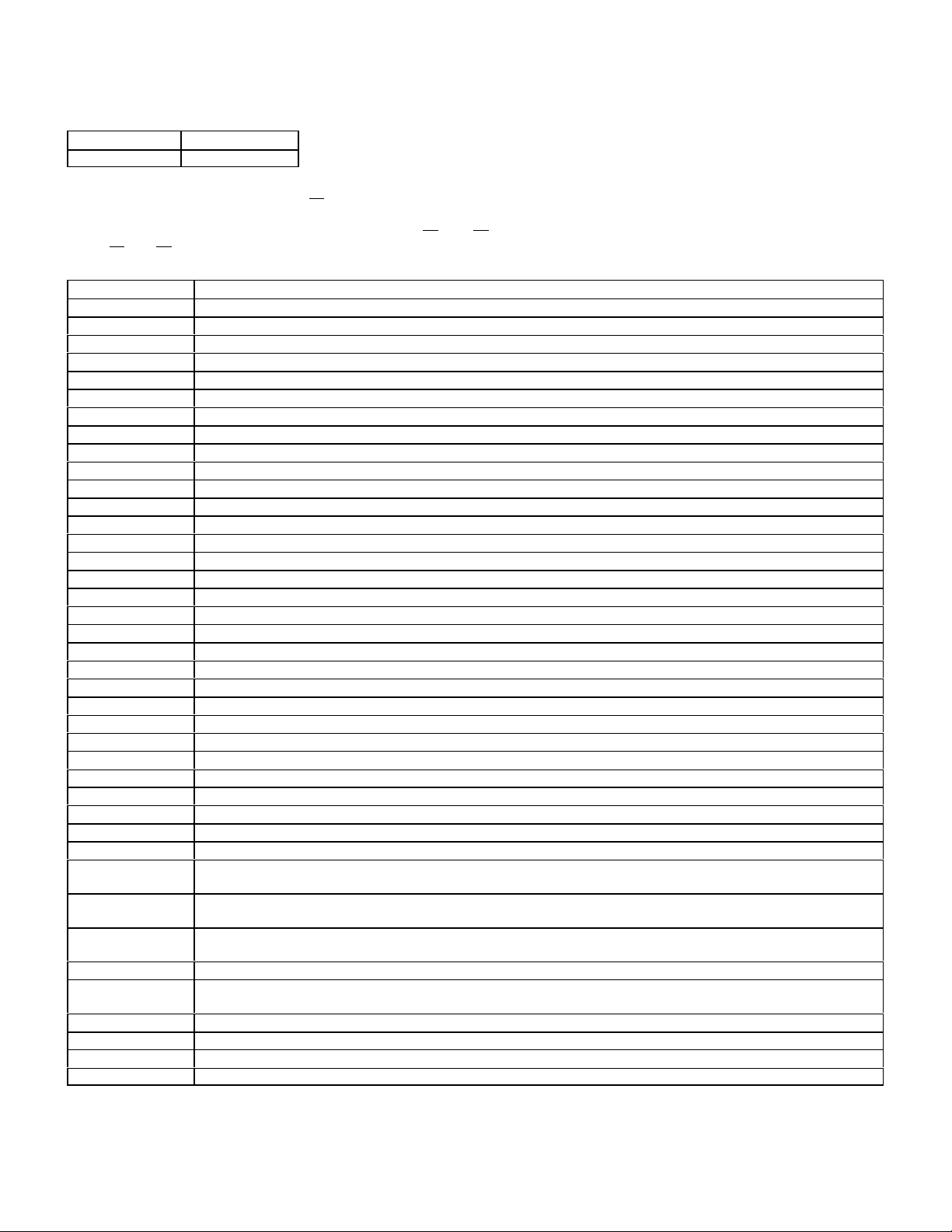

HFM Sequential Multiport Fuel Injection - Digital

Engines Model Years

111 (4 cylinder, 2.2/2.3L engine) 1994-97

104 (6 cylinder, 2.8/3.2L engine) 1994-97

Also check for codes in the Diagnostic Module (DM page 43) and the Electronic Accelerator/Cruise Control (EA/CC/ISC pages 50

and 49).

HFM-SFI Stored Fault Codes

Only Stored Fault Codes illuminate the Check Engine Light. (Code Scanner will display the fault code numbers listed under OB15,

Mercedes factory numbers are listed under MB for referral to factory literature.)

OB15 MB Description

0 No Fault Found

1 (002) Engine Coolant Temperature Sensor - Short Circuit

2 (003) Engine Coolant Temperature Sensor - Open Circuit

3 (004) Engine Coolant Temperature Sensor - Signal Incorrect

(005) Engine Coolant Temperature Sensor - Intermittent Contact

4 (006) Intake Air Temperature Sensor, Short Circuit

5 (007) Intake Air Temperature Sensor, Open Circuit

(008) Intake Air Temperature Sensor - Intermittent Contact

6 (009) Hot Film Air Mass Sensor - Signal Too High

7 (010) Hot Film Air Mass Sensor - Open Circuit

8 (011) Engine idle speed contact Throttle valve position too large

9 Not used

10 (012) Engine idle speed contact air mass too large

11 (113) HFM-SFI control unit not coded

12 (014) Throttle valve potentiometer actual value too high.

13 (015) Throttle valve potentiometer actual value too low.

14 (017) Throttle valve potentiometer drive value implausibly high.

15 (018) Throttle valve potentiometer drive value implausibly low.

16 (020) ISC (Idle speed control) at lower control stop area, malfunction.

17 (021) ISC (Idle speed control) at upper control stop area, malfunction.

18 (022) CC,EFP actuator signals in limp home mode (emergency mode).

19 (023) O2 sensor (before/upstream of Cat. Conv.), voltage too large.

20 (024) O2 sensor (before/upstream of Cat. Conv.), open circuit

21 (025) O2 sensor (before/upstream of Cat. Conv.), signal incorrect

22 (026) O2 sensor (after/downstream of Cat. Conv.), voltage too large

23 (027) O2 sensor (after/downstream of Cat. Conv.), open circuit

24 (028) O2 sensor (after/downstream of Cat. Conv.), signal incorrect

25 (029) O2 sensor heater (before/upstream of Cat. Conv.), heater current (amp) too small

26 (030) O2 sensor heater (before/upstream of Cat. Conv.), heater current (amp) too large

27 (031) O2 sensor heater (before/upstream of Cat. Conv.), heater current, short circuit

28 (032) O2 sensor heater (after/downstream of Cat. Conv.), heating current (amp) too small

29 (033) O2 sensor heater (after/downstream of Cat. Conv.), heating current (amp) too large

30 (034) O2 sensor heater (after/downstream of Cat. Conv.), heating current, short circuit

31 (035) Fuel adaptation (lambda) control, mixture too lean (rich stop)

(Intake air leak, fuel injectors, diaphragm pressure regulator)

32 (036) Fuel adaptation (lambda) control, mixture too rich (lean stop)

(Intake air leak, fuel injectors, diaphragm pressure regulator)

33 (037) Injection valve cylinder 1, short to positive

34 (038) Injection valve cylinder 1, open circuit or short to ground

35 (039) Injection valve cylinder 2, short to positive

36 (040) Injection valve cylinder 2, open circuit or short to ground

37 (041) Injection valve cylinder 3, short to positive

38 (042) Injection valve cylinder 3, open circuit or short to ground

22

Page 23

OB15 MB Description

39 (043) Injection valve cylinder 4, short to positive

40 (044) Injection valve cylinder 4, open circuit or short to ground

41 (045) Injection valve cylinder 5, short to positive

42 (046) Injection valve cylinder 5, open circuit or short to ground

43 (047) Injection valve cylinder 6, short to positive

44 (048) Injection valve cylinder 6, open circuit or short to ground

45 (049) Self-adjustment too rich at Idle

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

46 (050) Self-adjustment too lean at Idle

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

47 (051) Self-adjustment too rich at Lower part load

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

48 (052) Self-adjustment too lean at Lower part load

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

49 (053) Self-adjustment too rich at Upper part load

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

50 (054) Self-adjustment too lean at Upper part load

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

51 (061) Ignition system output stage 3, Cylinder 1 misfires

52 (062) Ignition system output stage 3, Cylinder 6 misfires

53 (063) Ignition system output stage 3, Current value not reached

54 (055) Ignition system output stage 1, Cylinder 2 misfires

55 (056) Ignition system output stage 1, Cylinder 5 misfires

56 (057) Ignition system output stage 1, Current value not reached

57 (058) Ignition system output stage 2, Cylinder 3 misfires

58 (059) Ignition system output stage 2, Cylinder 4 misfires

59 (060) Ignition system output stage 2, Current value not reached

60 (064) Crankshaft signal incorrect

61 (065) Crankshaft signal Magnet missing or Number of teeth incorrect

62 (066) Crankshaft signal Speed incorrect, too high

63 (067) Camshaft signal incorrect/not recognized

64 (068) HFM circuit/trimming plug short to ground

65 (069) HFM circuit/trimming plug open circuit or short to positive

66 (070) TN speed signal (rpm) Output short to ground

67 (071) TN speed signal (rpm) Output short to positive

68 (072) Vehicle speed signal not recognized, short circuit

69 (073) Vehicle speed signal implausibly high, short circuit

70 (074) PSV relay K3/1 circuit short to positive

71 Not used

72 (076) Fuel pump relay open circuit or short circuit

73 Not used

74 (077) CO potentiometer Input short to positive

75 (079) Knock sensor 1 signal open circuit

76 (080) Knock sensor 2 signal open circuit

77 (081) Ignition timing max retardation reached at least one cylinder

78 (082) Ignition angle deviation between the individual cylinders too high

79 (083) Knock control analysis, HFM control unit defective

80 (084) Short-term self-adjustment Idle/Part-load fault

81 (085) Air pump relay-module/switch-valve output, open circuit or short circuit

82-83 Not used

84 (086) Fuel purge switch-valve, open circuit/short circuit

85 (087) Fuel purge switch-valve, short to positive

86 (088) Transmission Upshift delay switchover valve (Y3/3) without function (Logic Chain)

87-88 Not used

89 (089) Camshaft timing adjust actuator circuit short to positive

90 (090) Camshaft timing adjust actuator open circuit or short to ground

23

Page 24

OB15 MB Description

91 (091) EGR switch-valve short to positive

92 (092) EGR switch-valve open circuit or short to ground

93 (093) Transmission overload protection switch short to ground

94 (094) Transmission overload protection switch, circuit short or open

95 (095) Transmission overload protection switch, circuit short or open

96 (096) Transmission overload protection switch signal implausible

97 (097) CAN problem Transmission communication from HFM control system faulty

98 (098) CAN problem No data reception from ASR

99 (116) CAN problem No data reception from IRCL. ( if equip with IRCL) Voltage supply at Circuit 87M, low

voltage or implausible (Starting 06/93)

100 Not used

101 (099) CAN problem No data reception from EFP,TPM

102 (100) CAN problem No data reception from Diagnosis Module

103 Not used

104 (117) Attempt to start with IRCL locked

105 (101) No starter signal (Terminal 50), open or short circuit

106 (102) Thermocouple CAT B16/6 Temperature too high

107 (103) Thermocouple CAT B16/6 Temperature too low

108 (104) Fuel safety cut-off settled

109 Not used

110 (105) Resonance intake manifold switchover valve, short to positive

111 (106) Resonance intake manifold switchover valve, open circuit/short to ground

112 (107) Ignition dwell angle control output stage, short to ground

113 (114) HFM control unit identification illogical

114 (108) Oxygen sensor heater (after/downstream of Cat. Conv.), short to positive

115 (109) Oxygen sensor heater (after/downstream of Cat. Conv.), open circuit or short to ground

116 (115) HFM-SFI control unit N3/4 coding bytes illogical

117 Not used

118 (110) Voltage supply to HFM-SFI control unit, incorrect

119 (111) Voltage supply at HFM-SFI control unit, voltage too low

120 (112) HFM control unit faulty

121 (005) Coolant temperature sensor, Loose contact

122 (008) Intake air temperature sensor, Loose contact

123 (013) Idle speed contact, Loose contact

124 (016) Potentiometer throttle valve, Loose contact

125 (019) Potentiometer throttle valve drive, Loose contact

126 (078) CO potentiometer R33 Loose contact

127-128 Not used

24

Page 25

PMS (PEC) Fuel Injection - Digital

Engines Model Years

111 (4 cylinders, 1.8/2.0L engine) 1994-97

PMS Stored Fault Codes

Only Stored Fault Codes illuminate the Check Engine Light.(Code Scanner will display the fault code numbers listed under OB15,

Mercedes factory numbers are listed under MB.)

OB15 MB Description

001 (002) Coolant temperature sensor, short circuit

002 (003) Coolant temperature sensor, open circuit

003 (004) Coolant temperature sensor, incorrect

004 (006) Intake air temperature sensor, short circuit

005 (007) Intake air temperature sensor, open circuit

006 (009) PMS Control unit, Intake manifold pressure implausible

007 (010) PMS Control unit, No Intake manifold pressure

008 (011) Idle speed contact closed signal incorrect

009 (068) Idle speed contact open circuit

010-011 Not used

012 (013) Potentiometer throttle valve, value too high

013 (014) Potentiometer throttle valve, value too low

014 (016) Potentiometer throttle valve drive value too high/incorrect

015 (017) Potentiometer throttle valve drive value too low/incorrect

016 (019) Idle speed control at lower control stop area, malfunction

017 (020) Idle speed control at upper control stop area, malfunction

018 (021) Idle speed control in limp home-mode (emergency operation)

019 (022) O2 sensor voltage too large

020 (023) O2 sensor, open circuit

021 (024) O2 sensor signal illogical

022 (069) Exhaust flap short to positive

023 (070) Exhaust flap open circuit or short to ground

024 Not used

025 (025) O2 sensor heater current (amps) too small

026 (026) O2 sensor heater current (amps) too large

027 (027) O2 sensor heater, short circuit

028-030 Not used

031 (028) Fuel adaptation (lambda) control mixture too lean (Intake air leak, fuel injectors, diaphragm

pressure regulator)

032 (029) Fuel adaptation (lambda) control mixture too rich (Intake air leak, fuel injectors, diaphragm

pressure regulator)

033 (030) Injection valve cylinder 1/4 short to positive

034 (031) Injection valve cylinder 1/4 open circuit or short to ground

035 (032) Injection valve cylinder 2/3 short to positive

036 (033) Injection valve cylinder 2/3 open circuit or short to ground

037 (064) Input signal from IFZ, open circuit or short to positive

038 (065) Input signal from IFZ, short to ground

039 (066) IFZ system unresponsive

040 (067) Input signal from IFZ incorrect

041-044 Not used

045 (034) Self-adjustment too rich at Idle

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

046 (035) Self-adjustment too lean at Idle

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

047 (036) Self-adjustment too rich at Part load (Intake air leak, fuel injectors, diaphragm pressure

regulator, wear engine)

25

Page 26

OB15 MB Description

048 (037) Self-adjustment too lean at Part load

(Intake air leak, fuel injectors, diaphragm pressure regulator, wear engine)

049-050 Not used

051 (038) Ignition system output stage 1, short to positive

052 (039) Ignition system output stage 1, Cylinder 1/4 misfires

053 (040) Ignition system output stage 1, Amperage not achieved

054 (041) Ignition system output stage 2, short to positive

055 (042) Ignition system output stage 2, Cylinder 2/3 misfires

056 (043) Ignition system output stage 2, Amperage not achieved

057-059 Not used

060 (044) Crankshaft signal incorrect

061 (045) Crankshaft signal Magnet missing or Numbers of teeth incorrect

062 (046) Crankshaft signal Speed incorrect, too high

063 Not used

064 (047) PMS circuit/trimming plug short to ground

065 (048) PMS circuit/trimming plug open circuit or short to positive

066 (049) TN speed signal (rpm) Output short to ground

067 (050) TN speed signal (rpm) Output short to positive

068 (051) Vehicle speed signal not recognized, short circuit

069 (052) Vehicle speed signal too high, short circuit

070 (053) PSV relay open circuit or short to positive

071 (054) PSV relay short to ground

072 (055) Fuel pump relay open circuit or short to positive

073 (056) Fuel pump relay short to ground

074 (057) CO potentiometer Input circuit short to positive

075 ~079 Not used

080 (061) Short-term self-adjustment faulty at idle speed or part load

081 (071) Rear axle ratio was changed

082 (072) Rear axle ratio signal incorrect

083 Not used

084 (059) Fuel purge switch-valve open circuit or short to positive

085 (060) Fuel purge switch-valve short to ground

086 (062) Transmission shifting delay/smooth switch-valve, open circuit or short circuit

087 ~092 Not used

093 (073) Transmission protection short to ground or active too long

094-095 Not used

096 (074) Transmission protection open circuit or short to positive

097 ~ 118 Not used

119 (063) PMS control unit voltage supply too low

120 Not used

121 (005) Coolant temperature sensor, Loose contact

122 (008) Intake air temperature sensor, Loose contact

123 (012) Idle speed contact, Loose contact

124 (015) Potentiometer throttle valve, Loose contact

125 (018) potentiometer throttle valve drive value, Loose contact

126 (058) CO potentiometer circuit, Loose contact

127-128 Not used

26

Page 27

ME Sequential Multiport Fuel Injection (ME-SFI)

Engines Model Years

104 (6 cylinders, 2.8/3.2L engine) 8/96111 (4 cylinder 2.0, 2.2, 2.3L) 8/96112 (V6 engine, 2.4/2.8/3.2L) 8/97113 (V8 engine, 4.3, 5.0L) 8/98119 (V8 engine 4.2/5.0L) 8/95-1998

120 (12 cylinder engine) 8/95-2000

ME-SFI ME Injection incorporates EA/CC/ISC, DM, DI and BM codes.

MB ME Code Description

P00XX Fuel and Air Metering and Auxiliary Emission Controls

P0010 A Camshaft Position Actuator Circuit (Bank 1)

P0011 A Camshaft Position - Timing Over-Advanced or System Performance (Bank 1)

P0012 A Camshaft Position - Timing Over-Retarded (Bank 1)

P0013 B Camshaft Position - Actuator Circuit (Bank 1)

P0014 B Camshaft Position - Timing Over-Advanced or System Performance (Bank 1)

P0015 B Camshaft Position - Timing Over-Retarded (Bank 1)

P0020 A Camshaft Position Actuator Circuit (Bank 2)

P0021 A Camshaft Position - Timing Over-Advanced or System Performance (Bank 2)

P0022 A Camshaft Position - Timing Over-Retarded (Bank 2)

P0023 B Camshaft Position - Actuator Circuit (Bank 2)

P0024 B Camshaft Position - Timing Over-Advanced or System Performance (Bank 2)

P0025 B Camshaft Position - Timing Over-Retarded (Bank 2)

P0030 H02S Heater Control Circuit (Bank 1) Sensor 1)

P0031 H02S Heater Control Circuit Low (Bank 1 Sensor 1)

P0032 H02S Heater Control Circuit High (Bank 1 Sensor 1)

P0033 Turbo Charger Bypass Valve Control Circuit

P0034 Turbo Charger Bypass Valve Control Circuit Low

P0035 Turbo Charger Bypass Valve Control Circuit High

P0036 H02S Heater Control Circuit (Bank 1 Sensor 2)

P0037 H02S Heater Control Circuit Low (Bank 1 Sensor 2)

P0038 H02S Heater Control Circuit High (Bank 1 Sensor 2)

P0042 H02S Heater Control Circuit (Bank 1 Sensor 3)

P0043 H02S Heater Control Circuit Low (Bank 1 Sensor 3)

P0044 H02S Heater Control Circuit High (Bank 1 Sensor 3)

P0050 H02S Heater Control Circuit (Bank 2 Sensor 1)

P0051 H02S Heater Control Circuit Low (Bank 2 Sensor 1)

P0052 H02S Heater Control Circuit High (Bank 2 Sensor 1)

P0056 H02S Heater Control Circuit (Bank 2 Sensor 2)

P0057 H02S Heater Control Circuit Low (Bank 2 Sensor 2)

P0058 H02S Heater Control Circuit High (Bank 2 Sensor 2)

P0062 H02S Heater Control Circuit (Bank 2 Sensor 3)

P0063 H02S Heater Control Circuit Low (Bank 2 Sensor 3)

P0064 H02S Heater Control Circuit High (Bank 2 Sensor 3)

P0065 Air Assisted Injector Control Range/Performance

P0066 Air Assisted Injector Control Circuit or Circuit Low

P0067 Air Assisted Injector Control Circuit High

P0070 Ambient Air Temperature Sensor Circuit

P0071 Ambient Air Temperature Sensor Range/Performance

P0072 Ambient Air Temperature Sensor Circuit Low Input

P0073 Ambient Air Temperature Sensor Circuit High Input

P0074 Ambient Air Temperature Sensor Circuit Intermittent

P0075 Intake Valve Control Solenoid Circuit (Bank 1)

27

Page 28

MB ME Code Description

P0076 Intake Valve Control Solenoid Circuit Low (Bank 1)

P0077 Intake Valve Control Solenoid Circuit High (Bank 1)

P0078 Exhaust Valve Control Solenoid Circuit (Bank 1)

P0079 Exhaust Valve Control Solenoid Circuit Low (Bank 1)

P0080 Exhaust Valve Control Solenoid Circuit High (Bank 1)

P0081 Intake valve Control Solenoid Circuit (Bank 2)

P0082 Intake Valve Control Solenoid Circuit Low (Bank 2)

P0083 Intake Valve Control Solenoid Circuit High (Bank 2)

P0084 Exhaust Valve Control Solenoid Circuit (Bank 2)

P0085 Exhaust Valve Control Solenoid Circuit Low (Bank 2)

P0086 Exhaust Valve Control Solenoid Circuit High (Bank 2)

P01XX Fuel and Air Metering

P0100 Mass or Volume Air Flow Circuit

P0101 Mass or Volume Air Flow Circuit Range/Performance Problem

P0102 Mass or Volume Air Flow Circuit Low Input

P0103 Mass or Volume Air Flow Circuit High Input

P0104 Mass or Volume Air Flow Circuit Intermittent

P0105 Manifold Absolute Pressure/Barometric Pressure Circuit

P0106 Manifold Absolute Pressure/Barometric Pressure Circuit Range/Performance Problem

P0107 Manifold Absolute Pressure/Barometric Pressure Circuit Low Input

P0108 Manifold Absolute Pressure/Barometric Pressure Circuit High Input

P0109 Manifold Absolute Pressure/Barometric Pressure Circuit Intermittent

P0110 Intake Air Temperature Circuit

P0111 Intake Air Temperature Circuit Range/Performance Problem

P0112 Intake Air Temperature Circuit Low Input

P0113 Intake Air Temperature Circuit High Input

P0114 Intake Air Temperature Circuit Intermittent

P0115 Engine Coolant Temperature Circuit

P0116 Engine Coolant Temperature Circuit Range/Performance Problem

P0117 Engine Coolant Temperature Circuit Low Input

P0118 Engine Coolant Temperature Circuit High Input

P0119 Engine Coolant Temperature Circuit Intermittent

P0120 Throttle/Pedal Position Sensor/Switch A Circuit, EA/CC/ISC Actuator

P0121 Throttle/Pedal Position Sensor/Switch A Circuit Range/Performance Problem

P0122 Throttle/Pedal Position Sensor/Switch A Circuit Low Input

P0123 Throttle/Pedal Position Sensor/Switch A Circuit High Input

P0124 Throttle/Pedal Position Sensor/Switch A Circuit Intermittent

P0125 Insufficient Coolant Temperature for Closed Loop Fuel Control

P0126 Insufficient Coolant Temperature for Stable Operation

P0127 Intake Air Temperature Too High

P0128 Coolant Thermostat (Coolant Temperature Below Thermostat Regulating Temperature)

P0130 02 Sensor Circuit (Bank 1 Sensor 1)

P0131 02 Sensor Circuit Low Voltage (Bank 1 Sensor 1)

P0132 02 Sensor Circuit High Voltage (Bank 1 Sensor 1)

P0133 02 Sensor Circuit Slow Response (Bank 1 Sensor 1)

P0134 02 Sensor Circuit No Activity Detected (Bank 1 Sensor 1)

P0135 02 Sensor Heater Circuit (Bank 1 Sensor 1)

P0136 02 Sensor Circuit Malfunction (Bank 1 Sensor 2)

P0137 02 Sensor Circuit Low Voltage (Bank 1 Sensor 2)

P0138 02 Sensor Circuit High Voltage (Bank 1 Sensor 2)

P0139 02 Sensor Circuit Slow Response (Bank 1 Sensor 2)

P0140 02 Sensor Circuit No Activity Detected (Bank 1 Sensor 2)

P0141 02 Sensor Heater Circuit (Bank 1 Sensor 2)

P0142 02 Sensor Circuit Malfunction (Bank 1 Sensor 3)

P0143 02 Sensor Circuit Low Voltage (Bank 1 Sensor 3)

28

Page 29

MB ME Code Description

P0144 02 Sensor Circuit High Voltage (Bank 1 Sensor 3)

P0145 02 Sensor Circuit Slow Response (Bank 1 Sensor 3)

P0146 02 Sensor Circuit No Activity Detected (Bank 1 Sensor 3)

P0147 02 Sensor Heater Circuit (Bank 1 Sensor 3)

P0148 Fuel Delivery Error

P0149 Fuel Timing Error

P0150 02 Sensor Circuit (Bank 2 Sensor 1)

P0151 02 Sensor Circuit Low Voltage (Bank 2 Sensor 1)

P0152 02 Sensor Circuit High Voltage (Bank 2 Sensor 1)

P0153 02 Sensor Circuit Slow Response (Bank 2 Sensor 1)

P0154 02 Sensor Circuit No Activity Detected (Bank 2 Sensor 1)

P0155 02 Sensor Heater Circuit (Bank 2 Sensor 1)

P0156 02 Sensor Circuit Malfunction (Bank 2 Sensor 2)

P0157 02 Sensor Circuit Low Voltage (Bank 2 Sensor 2)

P0158 02 Sensor Circuit High Voltage (Bank 2 Sensor 2)

P0159 02 Sensor Circuit Slow Response (Bank 2 Sensor 2)

P0160 02 Sensor Circuit No Activity Detected (Bank 2 Sensor 2)

P0161 02 Sensor Heater Circuit (Bank 2 Sensor 2)

P0162 02 Sensor Circuit Malfunction (Bank 2 Sensor 3)

P0163 02 Sensor Circuit Low Voltage (Bank 2 Sensor 3)

P0164 02 Sensor Circuit High Voltage (Bank 2 Sensor 3)

P0165 02 Sensor Circuit Slow Response (Bank 2 Sensor 3)

P0166 02 Sensor Circuit No Activity Detected (Bank 2 Sensor 3)

P0167 02 Sensor Heater Circuit (Bank 2 Sensor 3)

P0168 Fuel Temperature Too High

P0169 Incorrect Fuel Composition

P0170 Fuel Trim (Bank 1)

P0171 System too Lean (Bank 1)

P0172 System too Rich (Bank 1)

P0173 Fuel Trim Malfunction (Bank 2)

P0174 System too Lean (Bank 2)

P0175 System too Rich (Bank 2)

P0176 Fuel Composition Sensor Circuit

P0177 Fuel Composition Sensor Circuit Range/Performance

P0178 Fuel Composition Sensor Circuit Low Input

P0179 Fuel Composition Sensor Circuit High Input

P0180 Fuel Temperature Sensor A Circuit

P0181 Fuel Temperature Sensor A Circuit Range/Performance

P0182 Fuel Temperature Sensor A Circuit Low Input

P0183 Fuel Temperature Sensor A Circuit High Input

P0184 Fuel Temperature Sensor A Circuit Intermittent

P0185 Fuel Temperature Sensor B Circuit

P0186 Fuel Temperature Sensor B Circuit Range/Performance

P0187 Fuel Temperature Sensor B Circuit Low Input

P0188 Fuel Temperature Sensor B Circuit High Input

P0189 Fuel Temperature Sensor B Circuit Intermittent

P0190 Fuel Rail Pressure Sensor Circuit

P0191 Fuel Rail Pressure Sensor Circuit Range/Performance

P0192 Fuel Rail Pressure Sensor Circuit Low Input

P0193 Fuel Rail Pressure Sensor Circuit High Input

P0194 Fuel Rail Pressure Sensor Circuit Intermittent

P0195 Engine Oil Temperature Sensor

P0196 Engine Oil Temperature Sensor Range/Performance

P0197 Engine Oil Temperature Sensor Low

P0198 Engine Oil Temperature Sensor High

29

Page 30

MB ME Code Description

P0199 Engine Oil Temperature Sensor Intermittent

P02XX Fuel and Air Metering

P0200 Injector Circuit

P0201 Injector Circuit - Cylinder 1

P0202 Injector Circuit - Cylinder 2

P0203 Injector Circuit - Cylinder 3

P0204 Injector Circuit - Cylinder 4

P0205 Injector Circuit - Cylinder 5

P0206 Injector Circuit - Cylinder 6

P0207 Injector Circuit - Cylinder 7

P0208 Injector Circuit - Cylinder 8

P0209 Injector Circuit - Cylinder 9

P0210 Injector Circuit - Cylinder 10

P0211 Injector Circuit - Cylinder 11

P0212 Injector Circuit - Cylinder 12

P0213 Cold Start Injector 1

P0214 Cold Start Injector 2

P0215 Engine Shutoff Solenoid

P0216 Injector/Injection Timing Control Circuit

P0217 Engine Coolant Over Temperature Condition

P0218 Transmission Fluid Over Temperature Condition

P0219 Engine Overspeed Condition

P0220 Throttle/Pedal Position Sensor/Switch "B" Circuit

P0221 Throttle/Pedal Position Sensor/Switch "B" Circuit Range/Performance Problem

P0222 Throttle/Pedal Position Sensor/Switch "B" Circuit Low Input

P0223 Throttle/Pedal Position Sensor/Switch "B" Circuit High Input

P0224 Throttle/Pedal Position Sensor/Switch "B" Circuit Intermittent

P0225 Throttle/Pedal Position Sensor/Switch "C" Circuit

P0226 Throttle/Pedal Position Sensor/Switch "C" Circuit Range/Performance Problem

P0227 Throttle/Pedal Position Sensor/Switch "C" Circuit Low Input

P0228 Throttle/Pedal Position Sensor/Switch "C" Circuit High Input

P0229 Throttle/Pedal Position Sensor/Switch "C" Circuit Intermittent

P0230 Fuel Pump Primary Circuit

P0231 Fuel Pump Secondary Circuit Low

P0232 Fuel Pump Secondary Circuit High

P0233 Fuel Pump Secondary Circuit Intermittent

P0234 Turbo/Super Charger Overboost Condition

P0235 Turbo/Super Charger Boost Sensor "A" Circuit

P0236 Turbo/Super Charger Boost Sensor "A" Circuit Range/Performance

P0237 Turbo/Super Charger Boost Sensor "A" Circuit Low

P0238 Turbo/Super Charger Boost Sensor "A" Circuit High

P0239 Turbo/Super Charger Boost Sensor "B" Circuit

P0240 Turbo/Super Charger Boost Sensor "B" Circuit Range/Performance

P0241 Turbo/Super Charger Boost Sensor "B" Circuit Low

P0242 Turbo/Super Charger Boost Sensor "B" Circuit High

P0243 Turbo/Super Charger Wastegate Solenoid "A"

P0244 Turbo/Super Charger Wastegate Solenoid "A" Range/Performance

P0245 Turbo/Super Charger Wastegate Solenoid "A" Low

P0246 Turbo/Super Charger Wastegate Solenoid "A" High

P0247 Turbo/Super Charger Wastegate Solenoid "B"

P0248 Turbo/Super Charger Wastegate Solenoid "B" Range/Performance

P0249 Turbo/Super Charger Wastegate Solenoid "B" Low

P0250 Turbo/Super Charger Wastegate Solenoid "B" High

P0251 Injection Pump Fuel Metering Control "A" (Cam/Rotor/injector)

P0252 Injection Pump Fuel Metering Control "A" Range/Performance (Cam/Rotor/Injector)

30

Page 31

MB ME Code Description

P0253 Injection Pump Fuel Metering Control "A" Low (Cam/Rotor/Injector)

P0254 Injection Pump Fuel Metering Control "A" High (Cam/Rotor/Injector)

P0255 Injection Pump Fuel Metering Control "A" Intermittent (Cam/Rotor/Injector)

P0256 Injection Pump Fuel Metering Control "B" (Cam/Rotor/Injector)

P0257 Injection Pump Fuel Metering Control "B" Range/Performance (Cam/Rotor/Injector)

P0258 Injection Pump Fuel Metering Control "B" Low (Cam/Rotor/Injector)

P0259 Injection Pump Fuel Metering Control "B" High (Cam/Rotor/Injector)

P0260 Injection Pump Fuel Metering Control "B" Intermittent (Cam/Rotor/Injector)

P0261 Cylinder 1 Injector Circuit Low

P0262 Cylinder 1 Injector Circuit High

P0263 Cylinder 1 Contribution/Balance

P0264 Cylinder 2 Injector Circuit Low

P0265 Cylinder 2 Injector Circuit High

P0266 Cylinder 2 Contribution/Balance

P0267 Cylinder 3 Injector Circuit Low

P0268 Cylinder 3 Injector Circuit High

P0269 Cylinder 3 Contribution/Balance

P0270 Cylinder 4 Injector Circuit Low

P0271 Cylinder 4 Injector Circuit High

P0272 Cylinder 4 Contribution/Balance

P0273 Cylinder 5 Injector Circuit Low

P0274 Cylinder 5 Injector Circuit High

P0275 Cylinder 5 Contribution/Balance

P0276 Cylinder 6 Injector Circuit Low

P0277 Cylinder 6 Injector Circuit High

P0278 Cylinder 6 Contribution/Balance

P0279 Cylinder 7 Injector Circuit Low

P0280 Cylinder 7 Injector Circuit High

P0281 Cylinder 7 Contribution/Balance

P0282 Cylinder 8 Injector Circuit Low

P0283 Cylinder 8 Injector Circuit High

P0284 Cylinder 8 Contribution/Balance

P0285 Cylinder 9 Injector Circuit Low

P0286 Cylinder 9 Injector Circuit High

P0287 Cylinder 9 Contribution/Balance

P0288 Cylinder 10 Injector Circuit Low

P0289 Cylinder 10 Injector Circuit High

P0290 Cylinder 10 Contribution/Balance

P0291 Cylinder 11 Injector Circuit Low

P0292 Cylinder 11 Injector Circuit High

P0293 Cylinder 11 Contribution/Balance

P0294 Cylinder 12 Injector Circuit Low

P0295 Cylinder 12 Injector Circuit High

P0296 Cylinder 12 Contribution/Balance

P0298 Engine Oil Over Temperature