I. Introduction

Merax Pipe Benders are designed to bend Schedule 40 pipes with diameters of

½” to 3” and ½” to 4”, in accordance with Standards DIN2441. They are versatile

and easy to use and are sold in two versions: Pneumatic - Hydraulic Pipe

Bender and Electric-Hydraulic Pipe Bender.

Pipe Benders in two versions.

1

Before using your Merax Pipe Bender, check:

1) Electric-Hydraulic Model (220V): Oil level in tank must be filled (Hydraul i c

system oil 68; not included).

2) Pneumatic - Hydraulic Model: Oil already stored in machine. Check only

compressed air pressur e. (KG/PSI) 8/120.

Oil tank

(Electric-Hydraulic)

Use a

funnel to fill tank

with oil.

Use only Hydraulic System Lubricant 68.

3) The amount and level of oil (± 8 liters) can be monitored by the level opposite

the manometer. The level must be full when equipment is off and the bender

cylinder ram retracted.

2

II. Installation

Installing the Pipe Bender;

1) Tighten the cylinder ram to the lower plate using the screws supplied with machine.

(Fig. 2).

Fig. 1 Fig. 2

Area for installation

of cylinder ram

Lower

plate.

Cylinder ram

installed on

lower plate.

2) Tighten upper plate (Fig. 3) on top of the cylinder ram. (Fig. 4).

Upper plate

Fig. 3 Fig. 4

Plates attached

to cylinder ram.

3

3) Pneumatic-Hydraulic model: Install compressed air hose into the

trigger of the pneumatic motor (Fig. 7).

4) Electric-Hydraulic Model: Install compressed air hose into electric-hydraulic

pump (Fig. 6), and then, on hydraulic cylinder ram (Fig. 5).

Fig. 5 Fig. 6

Hoses.

Hoses

attached to

piston.

Electric-

Hydraul

ic Pump

Fig. 7

Compressed air fitting.

5) Fit degrees plate, according to pipe size. Then fit swaging blocks, checking

the markings on the top of the bender. (Fig. 8). (Fig. 9).

Fig. 8 Fig. 9

3-face swaging

blocks to be used

according to pipe

diameter.

4

4

6) Define the position of the swaging blocks and place them on the same

position. Them install the pipe between the swaging blocks and lower the

upper plate. (Fig. 10). (Fig. 11)

Pipe

installed.

Fig. 10 Fig. 11

Upper plate lowered.

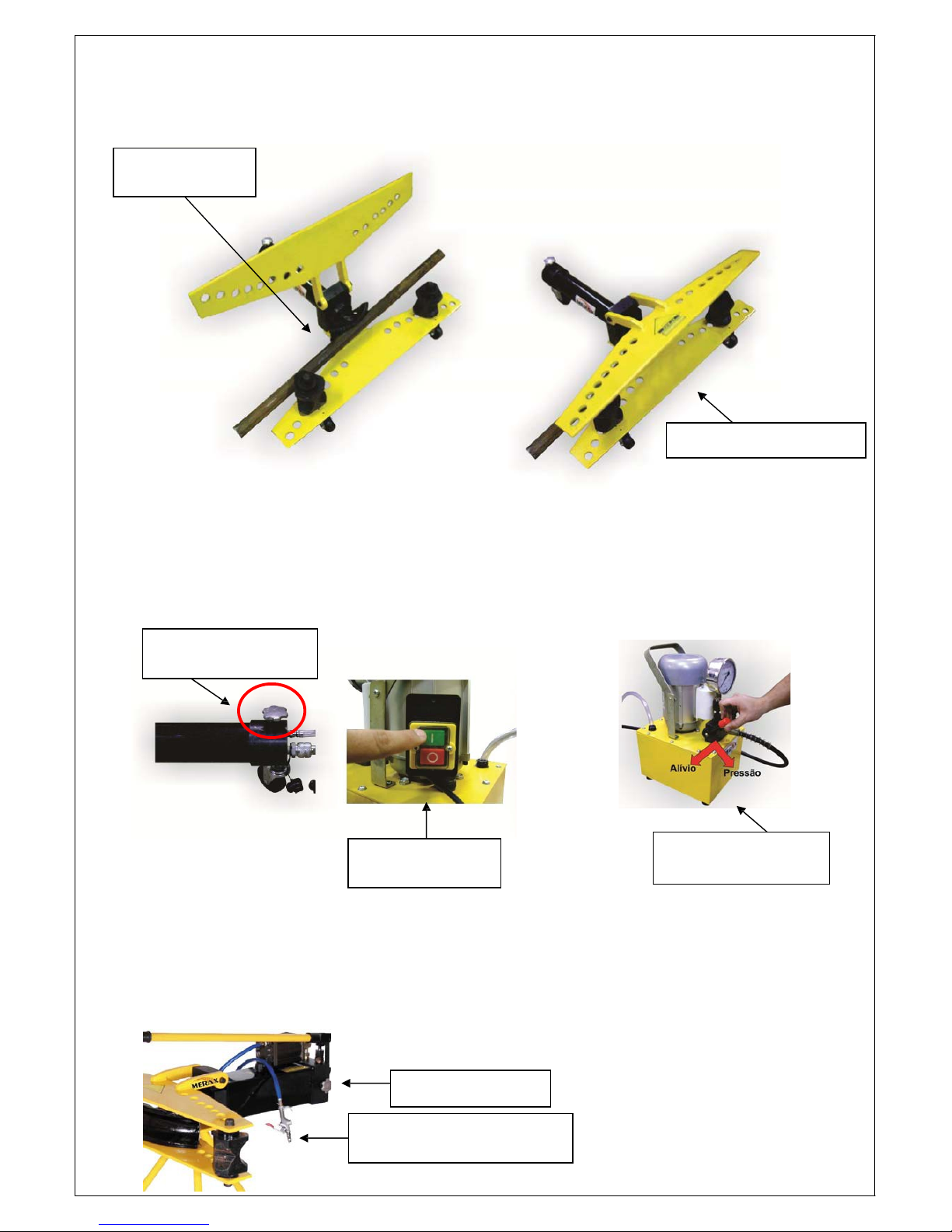

7) Electric-Hydraulic Model: Close the piston relief valve (Fig. 12), turn motor on

(Fig. 13). Turn valve to “pressure”, making hydraulic cylinder move towards the

pipe. (Fig. 14). To stop cylinder motion, turn valve back to initial position and open

relief valve.

Fig. 12 Fig. 13 Fig. 14

Piston relief valve.

Motor On/Off

switch

Pressure Valve

control switch.

8) Pneumatic-Hydraulic model: Loosen the nut beside the pneumatic motor,

close relief valve and pull the pneum ati c motor trigger (Fig. 15), making cylinder

ram move forward; to move back use relief valve.

Fig. 15

Relief valve

Pneumatic drive trigger

5

Merax Pipe Benders DO NOT bend very sharp angles in a single

process.

WARRANTY

MERAX Pipe Bend ing Machines are guarantee d for 6 months in Brazil from the date of issue of

invoice or delivery of the product to the final consumer.

This warranty applies to manufacturing, materials, parts and workmanship defects, when

adequately proven.

This warranty does not ap pl y to dam ages pro voked b y inadequate transportati on, ac cidents of an y

type, misuse, electrical installation oscillations, use of wro ng voltage, bad quality of compres sed

air, the removal or alteration of the series number of the machine, and the non-compliance with the

instructions herein contained. This warranty does not apply to any component that deteriorates

under normal use.

Check parts listing and their codes in our website: www.merax.com.br

6

Loading...

Loading...