Fire Brigade Key Safe

FSK700-2 / FSK700-2SX

User Manual

Description

Installation - Connection – Commissioning - Maintenance

VdS Approval: G 199055

© by MEP-Gefahrenmeldetechnik GmbH

User Manual FSK700-2 / FSK700-2SX 3

Contents

1 Introduction................................................................................................................................... 5

1.1 General............................................................................................................................................5

1.2 Description of the Series FSK700 Key Safe...................................................................................5

1.2.1 Main features of the Series FSK700 Key Safe............................................................................. 6

1.3 Types of signs................................................................................................................................. 7

1.4 Outline of the manual......................................................................................................................7

1.5 Abbreviations..................................................................................................................................7

1.6 Important advice for the operator and specialist installer................................................................7

1.7 Cleaning the Series FSK700 Fire Brigade Key Safe.......................................................................8

1.8 Product contents.............................................................................................................................. 8

1.9 Product overview............................................................................................................................ 9

1.10 Special terms................................................................................................................................. 10

1.11 Standards, Guidelines, CE marking..............................................................................................11

1.12 Warranty.......................................................................................................................................11

2 Function........................................................................................................................................ 12

2.1 Normal condition.......................................................................................................................... 12

2.2 Fire alarm condition......................................................................................................................12

2.3 Activation of the unblocking device.............................................................................................13

2.4 Fire alarm reset............................................................................................................................. 13

2.5 Sabotage alarm.............................................................................................................................. 13

3

3 Installation....................................................................................................................................14

3.1 General..........................................................................................................................................14

3.2 Installation site.............................................................................................................................. 14

3.3 Installation of Flush Mounting Frame EZ700-2 or Flush Mounting Frame with

Drill Protection EZBS700-2..........................................................................................................15

3.4 Installation of Flush Mounting Frame EZ700-2 or Flush Mounting Frame with

Drill Protection EZBS700-2 in Key Safe Column SDS700-2.......................................................15

3.5 Preparation of the Fire Brigade Key Safe......................................................................................15

3.5.1 Removal of the inner door angle................................................................................................16

3.5.2 Installation of a locking half cylinder in the Locking Cylinder Mounting Bracket.....................16

3.5.3 Installation of additional locking half cylinders in Key Safe FSK700-2SX................................17

3.5.4 Installation of the inner door......................................................................................................18

3.6 Installation of the Fire Brigade Key Safe in the Flush Mounting Frame.......................................19

4 Connection.................................................................................................................................... 20

4.1 Preparation of the connection cables.............................................................................................20

4.2 Inner view of the Fire Brigade Key Safe.......................................................................................21

4.3 Layout of Connection Board APL-4.............................................................................................21

4.4 Connecting....................................................................................................................................22

4.4.1 Complete connection diagram.................................................................................................... 22

4.4.2 Connecting the Flush Mounting Frame with Drill Protection, or the Tamper Switch

of the Key Safe Column............................................................................................................. 24

4.4.3 Heating device of the Series FSK700 Fire Brigade Key Safe.....................................................24

4.5 Connecting the cables of the Key Safe to Connection Board APL-4............................................24

4.5.1 Ribbon cable of the outer door...................................................................................................25

4.5.2 Cable of the closure device.........................................................................................................25

4.5.3 Connecting the cables of the Locking Cylinder Mounting Brackets...........................................25

4.6 Typical connection diagram of a fire detection control panel and the Fire Brigade Key Safe.......26

4.6.1 Connection diagram of a system comprising fire detection control panel,

Series FSK700 Key Safe, Key Safe Controlling and Monitoring Device AD900-1,

and Power Supply Unit NT700-1...............................................................................................26

4.6.2 Connection diagram of a system comprising fire detection control panel,

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D

ZN62163/38/3

4 User Manual FSK700-2 / FSK700-2SX

4

burglar alarm control panel, and Fire Brigade Key Safe.............................................................26

4.6.3 Connection diagram of a system comprising burglar alarm control panel and

Fire Brigade Key Safe, without fire detection control panel.......................................................27

5 Commissioning............................................................................................................................28

5.1 General..........................................................................................................................................28

5.2 Notes on insurance protection....................................................................................................... 28

5.3 Configuration with jumpers..........................................................................................................28

5.3.1 Activation temperature of the outer door heating device............................................................28

5.3.2 Acoustic warning signal when missing master key....................................................................28

5.3.3 Automatic deactivation of the release magnet when outer door is open.....................................29

5.4 Commissioning instructions..........................................................................................................29

6 Inspection, maintenance, service............................................................................................. 32

6.1 Inspection, maintenance................................................................................................................ 32

6.2 Advice on fault correction of electrical parts................................................................................33

7 Technical specifications.............................................................................................................35

7.1 Fire Brigade Key Safe FSK700-2, FSK700-2SX..........................................................................35

7.2 Inner doors.................................................................................................................................... 35

7.2.1 Inner Door for FSK700-2/2SX/PHZ/30.5mm ITA-2..................................................................35

7.2.2 Inner Door for FSK700-2/2SX/PHZ/35.5mm ITA-3..................................................................35

7.2.3 Inner Door for FSK700-2/2SX/DBUS ITB-2.............................................................................36

7.2.4 Inner Door for FSK700-2/2SX/DBUS ITF-2.............................................................................36

7.3 Flush Mounting Frames................................................................................................................36

7.3.1 Flush Mounting Frame EZ700-2................................................................................................36

7.3.2 Flush Mounting Frame with Drill Protection EZBS700-2..........................................................36

7.4 Locking Cylinder Mounting Bracket for FSK700-2SX PHZAW700-2S1....................................36

7.5 Auxiliary Locking Cylinder for FSK700-2/2SX PHZ700-2..........................................................36

7.6 Weather Protection Hood for FSK700-2/2SX WSD-FSK.............................................................36

8 Certifications................................................................................................................................37

8.1 VdS Certificate.............................................................................................................................37

8.2 EC Declaration of Conformity......................................................................................................38

Safety Instructions

Prior to installing, operating, or providing maintenance to the products described herein,

the respective chapters of this manual must strictly be read, and especially the safety

information on page 7 and onwards in chapter 1.6 "Important advice for the operator and

specialist installer" must be implicitly observed and followed.

Furthermore, the pictographs on page 7 in chapter 1.3: "Types of signs" are highly

important – the many passages in this manual marked by these pictographs contain warnings of dangers that can arise from inappropriate usage of the product, as well as other

valuable advice.

Described in this manual is the range of functions of the Fire Brigade Key Safes FSK700-2

and FSK700-2SX (combinedly termed "Series FSK700") with Connection Board APL-4

(version number PN60046V2-H005) and Door Protection Board BOHR-4 (version number PN60047V1-H002). Outer dimensions are applicable from production number

08/06806 onwards. The functionality of units with a different production number can differ from the description in this manual in some points.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/4

User Manual FSK700-2 / FSK700-2SX Chapter 1 • Introduction 5

1 Introduction

1.1 General

Fire Brigade Key Safes serve for the theft-proof, copy-protected safekeeping of master keys, allowing the Fire Brigade to enter a building swiftly and without use of force in the event of fire.

The Fire Brigade Key Safe is installed in the entry area of the respective site. Upon alarm activation of the fire detection system, the outer door is unlocked remotely by the fire brigade, granting

access to the inner door of the Key Safe.

1.2 Description of the Series FSK700 Key Safe

Fire Brigade Key Safes FSK700-2 and FSK700-2SX (combinedly termed "Series FSK700"), as

manufactured by MEP-Gefahrenmeldetechnik GmbH (abbreviated "MEP" hereafter), are distinguished by application of solid, high-quality materials, as well as intelligent details in design,

achieving high security against unauthorised taking of master keys. Furthermore, master keys can

be secured by integrating the electric surveillance devices of the Key Safe in a burglar alarm system.

5

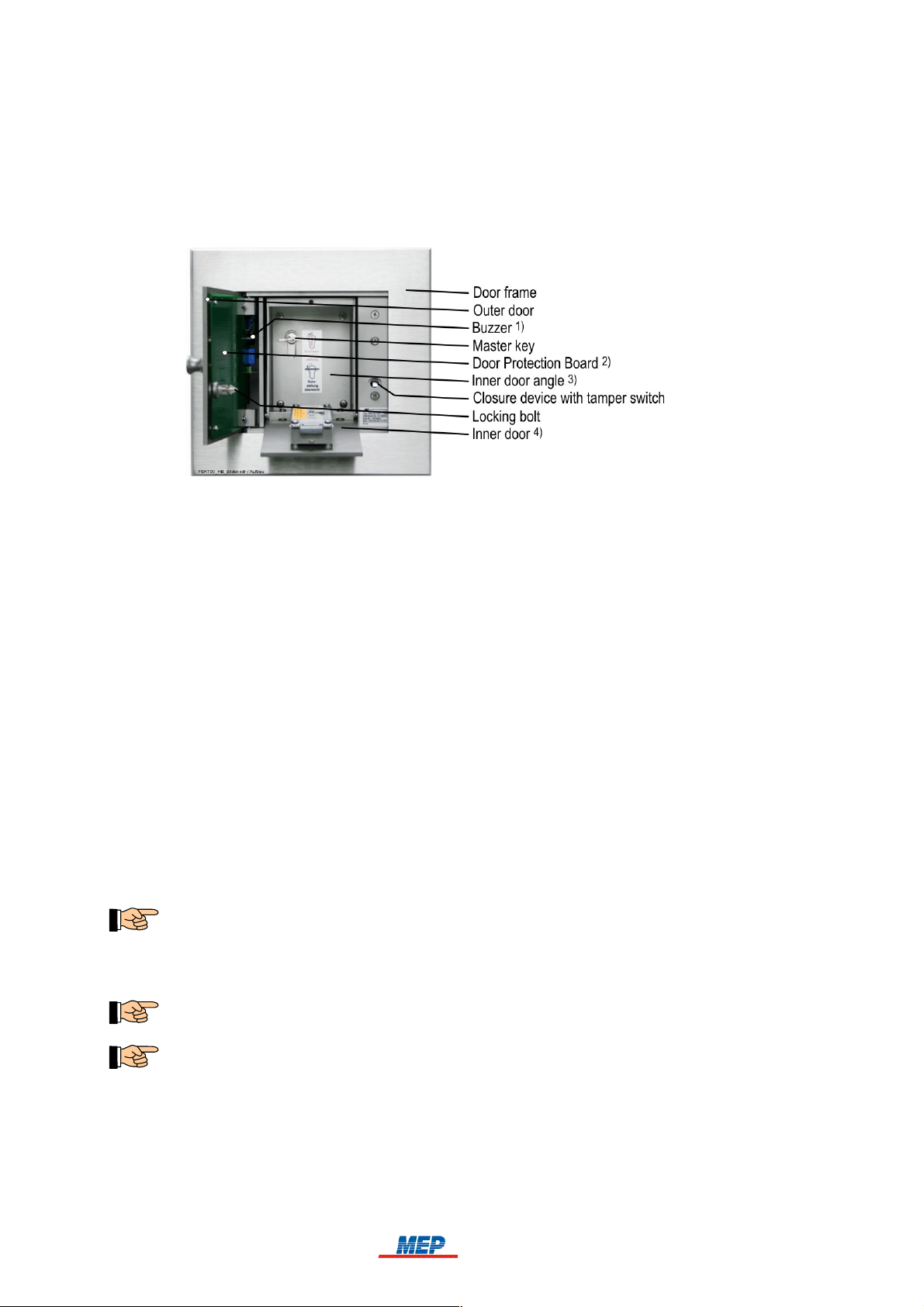

Fig. 1: Series FSK700 Fire Brigade Key Safe – front view

Series FSK700 consists of

Key Safe FSK700-2 (MEP Article No. 265740), in which one master key can be kept,

Key Safe FSK700-2SX (MEP Article No. 265742), of which the basic version can keep up to

two master keys, and can be upgraded with two Locking Cylinder Mounting Brackets to keep a

total of four master keys,

a range of accessory parts, described in chapter 1.9: "Product overview", from page 9 onwards.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/5

6 Chapter 1 • Introduction User Manual FSK700-2 / FSK700-2SX

6

Fig. 2: Series FSK700 Fire Brigade Key Safe

On the left: FSK700-2 with open outer and inner doors, master key inserted, inner door fitted

with a double-bit variable lock

On the right: FSK700-2SX with 4 master keys, open outer and inner doors, inner door fitted with

a lock for a locking half cylinder

1.2.1 Main features of the Series FSK700 Key Safe

The Series FSK700 Key Safe has been tested and certified (Certification No. G 199055) by VdS

Schadenverhütung GmbH (VdS). In combination with a VdS-certified Key Safe controlling and

monitoring device, it can be employed together with most commercially available 12V or 24V fire

detection and burglar alarm systems.

The Series FSK700 Key Safe conforms to DIN 14675 Appendix C – Class 3 (FSD 3, high risk).

Up to four master keys can be stored inside a Fire Brigade Key Safe, thus meeting even complex

organisational requirements.

Due to intelligent details in design – for instance, protected outer door hinges – high security

against unauthorised opening is achieved.

The self-adjusting magnetic closure device automatically assumes the optimal position – therefore,

the closure device is able to function at the highest precision level, even during long-time opera-

tion under unfavourable temperatures or environmental conditions.

To guarantee high corrosion resistance and mechanical stability, all vital mechanical parts are

made from stainless steel.

Installation of the Key Safe is easy and smooth due to the Flush Mounting Frame introduced

many years ago in Germany by MEP.

An acoustic warning signal will sound from the Key Safe if not all master keys have been inserted

correctly.

For application of different locking mechanisms, such as double-bit variable locks or locking half

cylinders, suitable inner doors are available.

To assure unhindered opening of the Key Safe at low outside temperatures, the outer door can be

electrically heated with 12V or 24V AC or DC. Heating is controlled by temperature, operating

only at temperatures below +10°C (at factory default settings).

Adaption of the magnetic closure device and heating device to different voltages (12V or 24V) is

performed automatically by all Series FSK700 units, guaranteeing quick and problem-free commissioning.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/6

User Manual FSK700-2 / FSK700-2SX Chapter 1 • Introduction 7

1.3 Types of signs

Especially important passages in this manual are marked with signs. The following signs are used:

ATTENTION! Disregard of this reference can lead to malfunction or damage to the unit.

TIP! This passage contains notes that will help ease operation.

The country-specific and/or the site-specific requirements of the device and/or system

APPROVALS must be observed.

1.4 Outline of the manual

Following the safety instructions on page 4, and guidelines given in the first chapter, which

should be implicitly observed,

chapter two contains all information required to operate a Series FSK700 Fire Brigade Key

Safe. It is explained how the Fire Brigade Key Safe works in combination with a fire detection

control panel, a controlling and monitoring device, an unblocking device, and a transmitting

device, as well as describing in which situations sabotage alarm is activated.

7

In chapter three, relevant guidelines for the installation of the Fire Brigade Key Safe by a spe-

cialist installer are given.

In chapter four, the specialist installer is provided with an overview of the arrangement of ter-

minals, connectors, and other important elements, as well as information required to connect

the Fire Brigade Key Safe to an MEP Key Safe Controlling and Monitoring Device AD900-1,

and to a fire detection control panel.

In chapter five, commissioning of the Fire Brigade Key Safe is described in detail for the spe-

cialist installer.

In chapter six, notes on inspection and maintenance of the unit are given. Also described in

this chapter are possible causes of malfunction and steps to correct them.

In chapter seven, all essential technical specifications of the unit are presented.

In chapter eight, copies of the VdS-Prüfzertifikat and the EC Declaration of Conformity are

provided.

1.5 Abbreviations

The correct designations for both Key Safe types "Fire Brigade Key Safe FSK700-2" and "Fire Brigade Key Safe FSK700-2SX" are shortened to "Fire Brigade Key Safe", "Key Safe", or "Series

FSK700" for improved readability of the manual. Differences between the two types are noted in

the respective text passages.

1.6 Important advice for the operator and specialist installer

The keeping of keys in a Fire Brigade Key Safe results in an increased level of danger, which the

insurance company must be informed of.

If the key depot is not VdS-certified and/or is not installed, operated and maintained

according to the VdS-Richtlinien für Schlüsseldepots, Planung, Einbau und Instandhaltung

(VdS 2350), it is possible that no insurance protection is available for damages due to burglary, in case the building has been opened using the (real) key taken from the key depot.

The Fire Brigade Key Safe must only be used in combination with components recommended or

certified by the manufacturer, and exclusively for the application described in the manual.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/7

8 Chapter 1 • Introduction User Manual FSK700-2 / FSK700-2SX

8

For the safe operation of the Fire Brigade Key Safe, appropriate transport, storage, installation,

commissioning, inspection, proper maintenance and correction of malfunctions, as well as careful

and competent handling are required.

Fire detection systems and devices must, on principle, be installed by and receive maintenance

from regularly trained technical staff only. Special training for technical staff must be performed by

MEP-Gefahrenmeldetechnik GmbH (MEP) or personnel expressly authorised by MEP. Country-specific standards, rules and regulations, or instructions by MEP must be strictly abided.

For proper functioning of the fire detection system, all devices must be installed according to regulations, and supplied with voltage. It must be ensured that all units are suitable to use under expected environmental conditions.

All work on the componentry of the Fire Brigade Key Safe must be performed without

voltage. Installation must be thoroughly checked prior to supplying voltage.

Regular maintenance based on country-specific standards must be performed on fire detection systems. Required repairs are to be promptly performed.

The locking bolt must only be installed in the outer door after both the Fire Brigade Key

Safe and the connected controlling and monitoring device are fully operational!

Also take note of the advice given from page 15 onwards in chapter 3.5: "Preparation of the

Fire Brigade Key Safe", as well as from page 29 onwards in chapter 5.4: "Commissioning

instructions".

1.7 Cleaning the Series FSK700 Fire Brigade Key Safe

Series FSK700 Key Safes are manufactured from stainless steel, and as such are – apart from

providing high mechanical stability – mostly corrosion-free. Residue of steel or iron (e.g., grit produced by brake discs of motorised vehicles), however, can rust and penetrate the corrosion protection layer of almost any high-grade steel – this can, after prolonged exposure, leave traces of corrosion on the Key Safe itself.

To prevent this, the front side of the Key Safe should regularly be cleaned using a plain, non-abrasive cleaning aid. Afterwards, special products for care of stainless steel should be applied to the

surface.

Under no circumstances use abrasive detergents – this would scratch the finely polished surface

of the Key Safe!

1.8 Product contents

Series FSK700 Key Safes are 100% tested for operation, and are supplied with all materials necessary for installation, as well as a manual.

Outside the scope of delivery are Inner Doors, Flush Mounting Frames, Auxiliary Locking Cylinders, Weather Protection Hood, etc. These are listed in the following chapter 1.9: "Product overview", must be ordered, and will be delivered separately.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/8

User Manual FSK700-2 / FSK700-2SX Chapter 1 • Introduction 9

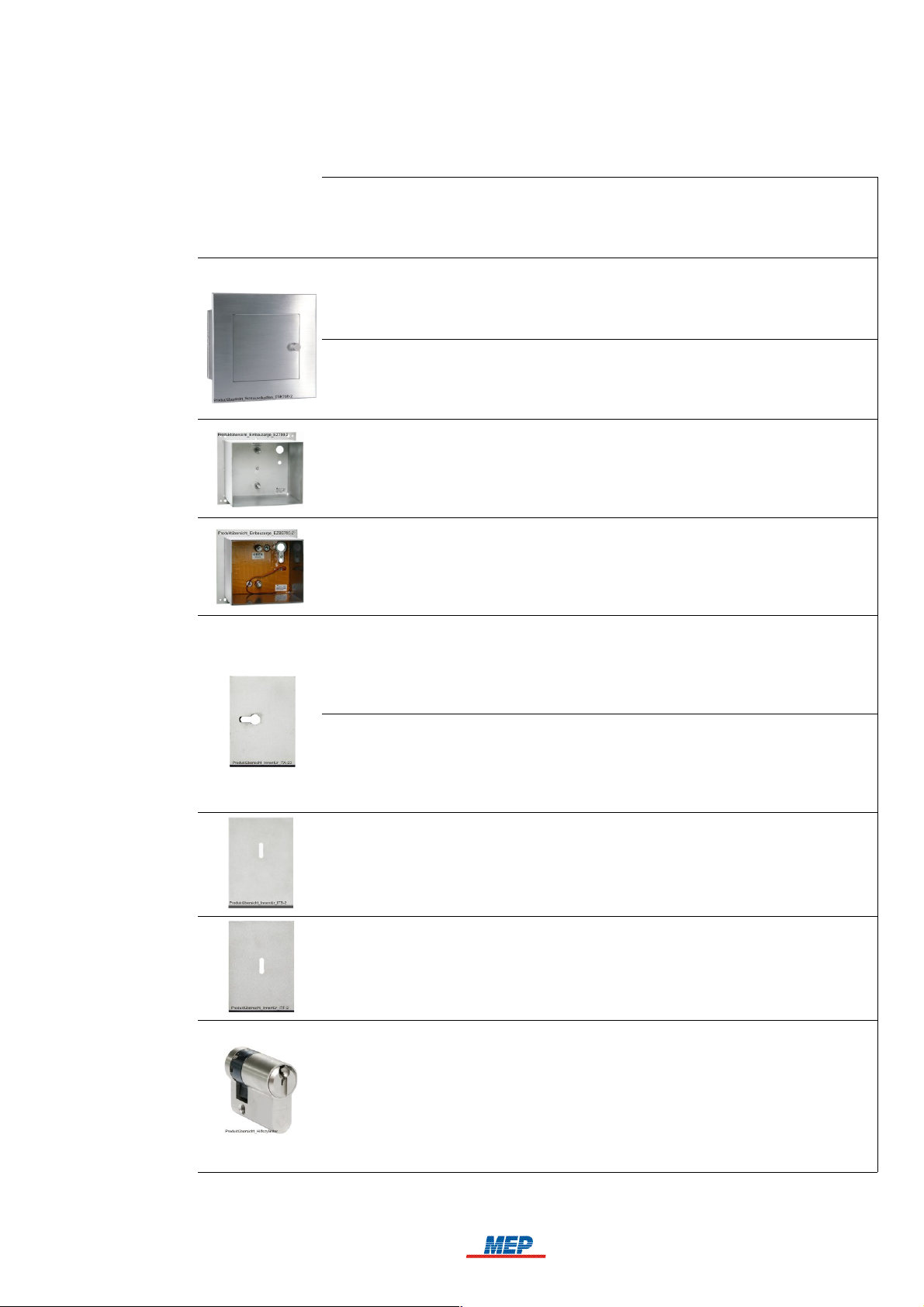

1.9 Product overview

The following table lists all types of Series FSK700 Fire Brigade Key Safes, as well as available

accessory parts.

• MEP Article No.

• Name

• Type

• Notes

• 265740

• Fire Brigade Key Safe

• FSK700-2

• For safekeeping of one master key

• 265742

• Fire Brigade Key Safe

• FSK700-2SX

• For safekeeping of two master keys, with upgrade options for up to four master keys

• 265751

• Flush Mounting Frame

• EZ700-2

• For installation of Key Safe FSK700-2 or FSK700-2SX in a solid wall

9

• 265818

• Flush Mounting Frame with All-Side Drill Protection

• EZBS700-2

• For installation of Key Safe FSK700-2 or FSK700-2SX in the Key Safe Column or

a wall with thermal insulation.

• 265752

• Inner Door for FSK700-2/2SX/PHZ/30.5mm

• ITA-2

• Includes pre-installed lock for locking cylinders compliant with VdS 2156 Class B,

with a length of 30.5mm. Locking cylinder is not included!

• 265748

• Inner Door for FSK700-2/2SX/PHZ/35.5mm

• ITA-3

• Includes pre-installed lock for locking cylinders compliant with VdS 2156 Class B,

with a length of 35.5mm. Locking cylinder is not included!

• 265753

• Inner Door for FSK700-2/2SX/DBUS

• ITB-2

• For double-bit variable lock type 2 or type 2005. Lock is not included!

• 265757

• Inner Door for FSK700-2/2SX/DBUS

• ITF-2

• For double-bit variable lock type Mauer 70091/70092. Lock is not included!

• 265744

• Auxiliary Locking Cylinder for FSK700-2/2SX

• PHZ700-2

• Common key locking cylinder, total length 36.3mm, key bit position of 0°.

An auxiliary locking cylinder is used if special master keys (e.g., electronic keys,

transponders, etc.) are to be kept inside the Key Safe. These are inseparably

attached to the supplied key fitting the auxiliary locking cylinder using the included

quick link.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/9

10 Chapter 1 • Introduction User Manual FSK700-2 / FSK700-2SX

10

• 265743

• Locking Cylinder Mounting Bracket FSK700-2SX

• PHZAW700-2S1

• For upgrading Key Safe FSK700-2SX to be able to keep one additional master key

• 249650

• Weather Protection Hood for FSK700-2/2SX

• WSD-FSK

• Offers further protection of the Fire Brigade Key Safe against humidity if rain hits

the area around the outer door from above or from the sides

Table 1: Available accessory parts for the Series FSK700 Fire Brigade Key Safe

1.10 Special terms

Several of the technical / special terms that appear in this manual are defined herein. Take further

notice of the information given in the manual of the respectively used fire detection control panel.

Unblocking device

A key switch to which public safety services (e.g., fire brigade) possess a key, installed outside

the site, and with which fire alarm can be activated from outside the site. The fire alarm will

activate the transmitting device of the fire detection control panel, thus unlocking the outer door

of the Key Safe in which the master key is kept.

Auxiliary locking cylinder

An auxiliary locking cylinder is used if special master keys inapplicable for use with a locking

cylinder (e.g., electronic keys, transponders, etc.) are to be kept inside the Fire Brigade Key

Safe. The master keys are inseparably attached to the supplied key fitting the auxiliary locking

cylinder using the included quick link.

Key depot, termed "Key Safe" in the manual

Solid two-door container, which can be unlocked remotely, used for the safekeeping of master

keys. A key depot consists of a mechanically stable case, of which the outer door can be electromagnetically unlocked by an unlocking device. Located inside the key depot is an inner door, to

which the key is in the possession of, e.g., the fire brigade or a security company alone. The

master keys are kept behind the inner door. The key depot, as well as the keys kept inside are

under electronic surveillance. The keys are thus protected from unauthorised access, yet quickly

reachable by the fire brigade in case of emergency.

Definition from VdS-Richtlinie 2105: "4.2.4. Key depot 3 (SD3) – equal to DIN 14675 – FSD 3.

A container installed in a solid outer wall of a building. The keys kept inside the container enable

entry to secured areas. Monitoring of the key depot is required. The key depot is connected to an

alarm detection control panel."

Key depot control

Key depot control incorporates all functions required for controlling and monitoring of a key

depot. It can be available as part of an external device (e.g., fire detection control panel), a discrete module (e.g., circuit board), or a separate device.

Key depot controlling and monitoring device

Key depot control variant, available as a separate device or discrete module (e.g., a slide-in

module for an alarm system).

Transmitting device for alarm transmission

Transmitting devices receive messages from alarm systems, process them for transmission via

transmission paths, and serve as interface for these transmission paths. Furthermore, transmitting devices process the commands given by the alarm receiving device and transmit them to the

connected alarm system.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/10

User Manual FSK700-2 / FSK700-2SX Chapter 1 • Introduction 11

Confirmation signal

11

Signal transmitted to the fire detection control panel by the transmitting device, serving as confirmation of the successful activation of the transmitting device.

Variable lock

Lock that can be converted to use a new key code without replacing the tumblers.

1.11 Standards, Guidelines, CE marking

This manual contains dated and undated references to relevant standards. These references appear

in the appropriate sections of the manual, the titles of these standards are listed below. The latest

version of the respective standards are in effect.

DIN 14675 / App. C Fire detection and fire alarm systems - Design and operation

VdS 2105 Schlüsseldepots (SD) - Anforderungen an Anlagenteile

VdS 2350 Schlüsseldepots (SD) - Planung, Einbau und Instandhaltung

DIN 1053 Masonry

DIN 106 Calcium silicate units with specific properties

DIN 1045 Concrete, reinforced and prestressed concrete structures

DIN 49020 Conduit for Electrical Wiring; Screwed Steel Conduit, Plain Conduit,

Couplers

The CE marking on the Series FSK700 Fire Brigade Key Safe is done in accordance with Directive

2004/108/EC of the European Parliament and of the Council regarding Electromagnetic Compatibility (EMC). With the CE marking, see page 38 in chapter 8.2: "EC Declaration of Conformity", the

manufacturer confirms that the product conforms to EMC Directive 2004/108/EC.

1.12 Warranty

All parts of the Series FSK700 Fire Brigade Key Safe by MEP are manufactured with highest precision and utmost care. Nonetheless, the occurrence of malfunctions during operation cannot be

ruled out entirely. To register a complaint, please contact the company responsible for installation

of your system.

While the warranty period is in effect, all parts that become defective because of a demonstrable

flaw in their manufacture or in material will be either replaced or repaired free of charge. In such

cases, the time period of the original warranty will not be extended, nor will a new warranty period

be set for the replaced or repaired parts. All further claims are excluded, especially those regarding

reductions of the purchase price, cancellation of contract, compensatory damages or replacement

due to secondary damages of any type. Beyond these regulations, the current regulations of the

"General Terms of Delivery" that are issued by the Austrian Electrical and Electronics Industry

Association are in effect.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/11

12 Chapter 2 • Function User Manual FSK700-2 / FSK700-2SX

12

2 Function

The Series FSK700 Key Safe features independently operating sensors and actuators. The logical

operations between the signals of the sensors and actuators are made by the corresponding monitoring equipment (such as Key Safe Controlling and Monitoring Device AD900-1, MEP Article No.

265900), which acts as intelligent interface between the Key Safe and the fire detection control

panel or burglar alarm system.

1)

See page 13 onwards in chapter 2.4: "Fire alarm reset"

2)

With integrated temperature-controlled panel heating

3)

With one master key

4)

With double-bit variable lock and inserted key

Fig. 3: Fire Brigade Key Safe FSK700-2, displayed with doors open

2.1 Normal condition

The Fire Brigade Key Safe is in normal condition if:

the master key/all master keys are inserted correctly,

the inner door is closed,

the key to the inner door has been removed,

the outer door is closed, and

the unlocking device of the Key Safe has not been activated.

In normal condition, the electromagnet of the outer door closure device is rendered currentless.

2.2 Fire alarm condition

Fire alarm is reported to the fire brigade by the fire detection control panel using a transmitting

device. The fire brigade will transmit the confirmation signal, which, via the controlling and monitoring device, electromagnetically unlocks the outer door of the Key Safe – the outer door is thereby

cleared for opening.

The outer door does not open automatically after unlocking.

After opening the outer door, the inner door can be accessed. Using the key in possession of the fire

brigade, the inner door can be opened, and the master key(s) obtained.

In this state, monitoring of opening or sabotage of the Key Safe, as well as – if available – monitoring of the Flush Mounting Frame with Drill Protection and the Key Safe Column is disabled.

In special application cases, unlocking of the outer door must only be performed when, supplementary to the confirmation signal, the fire detection control panel is in fire alarm condition. The

Key Safe Controlling and Monitoring Device AD900-1 by MEP is equipped for this special

application, featuring two unlocking inputs, which can be connected via a logical AND operation

(AD900-1 / S2-1 switched "ON").

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/12

User Manual FSK700-2 / FSK700-2SX Chapter 2 • Function 13

13

2.3 Activation of the unblocking device

The unblocking device (a specially realised key switch – see, for example, Unblocking Device

FSE/PHZ900-1, MEP Article No. 265662) is connected to the fire detection control panel in the

same way as a manual call point. Upon activation of the unblocking device, fire alarm will be

activated, thus unlocking the outer door of the Fire Brigade Key Safe via the confirmation signal of

the transmitting device connected to the fire brigade.

Activation of the fire detection control panel by the unblocking device must not affect Fire Control procedures of the fire detection control panel.

2.4 Fire alarm reset

The outer door of the Key Safe will only lock again after the fire detection control panel is reset,

thereby terminating the confirmation signal, the/all master keys have been reinserted, and the inner

and outer door have been closed. Successful locking can be confirmed by pulling the outer door.

By locking the outer door, monitoring of opening or sabotage of the Key Safe, as well as – if

available – monitoring of the Flush Mounting Frame with Drill Protection and the Key Safe

Column will be reactivated.

Should a master key not have been inserted correctly after resetting the fire detection control panel,

a sustained buzzing tone generated by the Key Safe's integrated buzzer will sound upon closing the

outer door.

This function is only available if the Key Safe is connected to the Key Safe Controlling and

Monitoring Device AD900-1 by MEP (also see page 28 and onwards in chapter 5.3.2: "Acoustic

warning signal when missing master key").

If the Key Safe remains unopened during fire alarm, the outer door will be automatically locked

again upon termination of the confirmation signal, and monitoring of opening or sabotage of the

Key Safe, as well as – if available – monitoring of the Flush Mounting Frame with Drill Protection

and the Key Safe Column will be reactivated.

2.5 Sabotage alarm

The following states are constantly monitored by the Key Safe Controlling and Monitoring Device

AD900-1:

Outer door closed,

Drill Protection Board undamaged,

master keys correctly inserted,

Drill Protection of the Flush Mounting Frame undamaged (if available),

Tamper Switch of the Key Safe Column closed (if available).

The Key Safe Controlling and Monitoring Device AD900-1 will generate an alarm signal if – e.g.,

by forcefully breaking into the Key Safe – one of these monitored states is violated insofar as causing the monitor loop's resistance to deviate more than 40% from normal condition.

DIN 14675 / chapter C.2.2.3: The report (sabotage report) must, under application according to

Class FSD 3 (high risk), be forwarded to an office or authority that is available at all times, such

as a police department or security company.

If the Key Safe has been unlocked by the confirmation signal, sabotage monitoring is disabled

until a reset is performed correctly (see page 13 and onwards in chapter 2.4: "Fire alarm reset").

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/13

14 Chapter 3 • Installation User Manual FSK700-2 / FSK700-2SX

14

3 Installation

3.1 General

Installation and commissioning of the Series FSK700 Fire Brigade Key Safe is to be performed by

a specialist company trained and authorised by MEP-Gefahrenmeldetechnik GmbH or their local

representative. All relevant standards and regulations must thereby be observed (see page 11 and

onwards in chapter 1.11: "Standards, Guidelines, CE marking").

1)

Optional Weather Protection Hood WSD-FSK

Fig. 4: Dimensions of the Series FSK700 Key Safe, starting from production number 08/06806

The Key Safe is to be inserted in the Flush Mounting Frame EZ700-2, MEP Article No. 265751,

which must be tightly grounded in the wall. Should the wall not be sufficiently solid (see page 14

and onwards in chapter 3.2: "Installation site"), the Flush Mounting Frame with Drill Protection

EZBS700-2, MEP Article No. 265818 must be utilised instead.

Instructions for installation of the Key Safe in the Key Safe Column SDS700-2 are provided in

the manual "Key Safe Column SDS700-2" by MEP-Gefahrenmeldetechnik GmbH.

Controlling and monitoring of the Key Safe must be performed using a VdS-certified controlling

and monitoring device (such as Key Safe Controlling and Monitoring Device AD900-1, MEP Article No. 265900).

Instructions for installation of the controlling and monitoring device are provided in the manual

of the respectively used device.

3.2 Installation site

The Key Safe is to be installed in accordance with the local fire brigade, preferably in a weatherproof location (i.e., in an alcove, passageway, or under a canopy), flush mounted in the wall. The

bottom edge of the Key Safe should be located about 1.2m (at least 0.8m) above the floor.

The wall in which the Key Safe (i.e., Flush Mounting Frame EZ700-2) is to be installed in must be

made from stone work according to DIN 1053, bricks according to DIN 105, lime-sand bricks

according to DIN 106, or from reinforced concrete (minimum B 25 according to DIN 1045). The

wall must be at least 80mm thicker than the installation depth of the Key Safe.

Should no adequately solid wall suitable for installation of the Key Safe be available (e.g., only

walls with thermal insulation), the Flush Mounting Frame with Drill Protection EZBS700-2 must

be utilised to improve security and protect against sabotage.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/14

User Manual FSK700-2 / FSK700-2SX Chapter 3 • Installation 15

15

3.3 Installation of Flush Mounting Frame EZ700-2 or Flush Mounting Frame with

Drill Protection EZBS700-2

1)

The front edge of the Flush Mounting Frame must not protrude from the wall

Fig. 5: Dimensions of Flush Mounting Frames EZ700-2 and EZBS700-2

The front edge of the Flush Mounting Frame must be flush-mounted to the wall surface (under no

circumstances must it protrude!) as best as possible. The bottom edge of the Key Safe should be

located about 1.2m (at least 0.8m) above the floor.

Installation of Flush Mounting Frames EZ700-2 and EZBS700-2 is to be performed according to

the manual provided with the Flush Mounting Frames.

Insert the Flush Mounting Frame into the prepared opening in the wall, and insert the conduits

for the connection cables, as well as for the protective earth into the Flush Mounting Frame

from behind.

Notice the required installation position (labelled: "OBEN / TOP SIDE – Einbauzarge

putzbündig einmauern!").

Fix the Flush Mounting Frame onto the installation surface.

Fill the remaining openings in the Flush Mounting Frame, as well as the inner space with suit-

able materials, to prevent mortar, cement, or similar from entering while setting the Flush

Mounting Frame into the wall.

Protect the drill protection film inlaid in the Flush Mounting Frame with Drill Protection EZB-

S700-2, and the connection cable from damage while setting the Flush Mounting Frame into the

wall.

Fix the Flush Mounting Frame in the wall.

3.4 Installation of Flush Mounting Frame EZ700-2 or Flush Mounting Frame with

Drill Protection EZBS700-2 in Key Safe Column SDS700-2

Instructions for installation in the Key Safe Column SDS700-2, with or without cement grouting

according to VdS guidelines 2105 and 2350, are found in the manual "Key Safe Column

SDS700-2" by MEP-Gefahrenmeldetechnik GmbH.

3.5 Preparation of the Fire Brigade Key Safe

The Series FSK700 Fire Brigade Key Safe must be fitted with the appropriate inner door, as well as

the locking cylinder(s) for the master key(s) or auxiliary locking cylinder(s). Installation of additional Locking Cylinder Mounting Brackets PHZAW700-2S1 along with appropriate locking cylinders is required for the Series FSK700-2SX Key Safe if more than two master keys are to be kept.

It is possible to perform the following tasks on an already installed Key Safe – however, it is

recommended to complete preparation of the Key Safe before installation in the Flush Mounting

Frame.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/15

16 Chapter 3 • Installation User Manual FSK700-2 / FSK700-2SX

16

The locking bolt supplied in the accessory kit must only be installed in the outer door after

both the Fire Brigade Key Safe and the connected controlling and monitoring device are

fully operational! Should the electrical unlocking device not be fully operational upon closing the outer door with installed locking bolt, the Key Safe can only be opened again by

means leading to the destruction of some of its componentry (e.g., outer door, Drill Protection Board). Additional advice can be found on page 29 and onwards in chapter 5.4: "Commissioning instructions".

3.5.1 Removal of the inner door angle

For the tasks of installing the Fire Brigade Key Safe in the Flush Mounting Frame, setting up cable

connections, as well as for the installation of the locking cylinder(s) for the master key(s), the inner

door angle must be removed.

Removal of the inner door angle is to be performed as follows:

Open the outer and inner doors.

Remove all master keys.

Remove the 4 mounting screws on the inner door angle (see Fig. 6 below).

Pull out the inner door angle in a forward direction.

Fig. 6: Location of the mounting screws for the inner door angle

The figure shows an already installed locking cylinder for the master key, as well as an inner

door including lock – these parts are not pre-installed in a newly shipped Key Safe!

Reinstallation of the inner door after completion of the planned tasks is to be performed with the

steps in reverse order.

3.5.2 Installation of a locking half cylinder in the Locking Cylinder Mounting Bracket

Depending on the case of application, either a locking half cylinder identical to the locking mechanisms used on-site, or alternatively, an auxiliary locking cylinder (see page 10 and onwards in

chapter 1.10: "Special terms") must be installed.

Locking cylinders that meet the requirements listed in the technical specifications on page 35 and

onwards in chapter 7.1: "Fire Brigade Key Safe FSK700-2, FSK700-2SX" are to be used exclusively.

Remove the inner door angle, see page 16 and onwards in chapter 3.5.1: "Removal of the inner

door angle".

Adjust the locking cam of the locking half cylinder so that it points downwards when assuming

the key removal position, see Fig. 7 below.

Fig. 7: Position of the locking cam with key removed

Insert the locking half cylinder into the Locking Cylinder Mounting Bracket and fix it in place

using the M5×12mm hex head screw included in the accessory kit.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/16

User Manual FSK700-2 / FSK700-2SX Chapter 3 • Installation 17

Check the detent and proper triggering of the micro switch by the locking cam.

Check if the label showing the key removal position, found on the inner door angle, conforms

17

with the installed locking half cylinder for the master key. An alternative label showing a horizontal key removal position is included in the accessory kit of the Key Safe, see Fig. 8 below.

Fig. 8: Label showing key removal position of the locking half cylinder designated for the master key

(key removal position on top)

On the left: factory default label

On the right: alternative label showing horizontal key removal position

3.5.3 Installation of additional locking half cylinders in Key Safe FSK700-2SX

Fire Brigade Key Safe FSK700-2SX is factory-equipped with two Locking Cylinder Mounting

Brackets. Using the supplementary Locking Cylinder Mounting Brackets PHZAW700-2S1, Key

Safe FSK700-2SX can be upgraded to up to four locking half cylinders.

A Locking Cylinder Mounting Bracket PHZAW700-2S1 is required for every additional locking

half cylinder.

Key Safe type FSK700-2 is not applicable for installation of additional locking half cylinders.

Installation is to be performed as follows:

Remove the inner door angle, see page 16 and onwards in chapter 3.5.1: "Removal of the inner

door angle".

Adjust the locking cam of the locking half cylinder so that it points downwards when assuming

the key removal position, see Fig. 7 above.

Insert the locking half cylinder into the Locking Cylinder Mounting Bracket and fix it in place

using the M5×12mm hex head screw included in the accessory kit.

Install the Locking Cylinder Mounting Bracket including locking half cylinder in the next avail-

able install position, see Fig. 9 below, left-hand picture. The required M4 nuts are included in

the accessory kit of the Locking Cylinder Mounting Bracket.

The cables leading from the Locking Cylinder Mounting Brackets should only be connected to

the Connection Board after all cables leading from the controlling and monitoring device have

been connected. See page 25 and onwards in chapter 4.5.3: "Connecting the cables of the Locking Cylinder Mounting Brackets".

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/17

18 Chapter 3 • Installation User Manual FSK700-2 / FSK700-2SX

18

Fig. 9: Arrangement of locking half cylinders for master keys in Key Safe FSK700-2SX

On the left: install positions for 4 Locking Cylinder Mounting Brackets in Key Safe

FSK700-2SX

On the right: breaking points for locking half cylinders 3 and 4 on the inner door angle

The appropriate breaking point for every additional locking half cylinder must be opened up on

the inner door angle, for example, using a flat chisel and applying a few soft hammer blows.

3.5.4 Installation of the inner door

All installation materials required for installation are included in the accessory kit provided with

the respective inner door.

Installation of the inner door can be performed more easily after removing the inner door angle

(see page 16 and onwards in chapter 3.5.1: "Removal of the inner door angle").

The locking mechanism to be used in the inner door (i.e., locking half cylinder, variable lock) is

to be determined by local authorities.

Install the variable lock in the inner door, or, with inner doors ITA-2 an ITA-3, insert the lock-

ing half cylinder into the lock and fix it using an M5×65mm countersunk head screw, see Fig.

10 below, right-hand picture (detail "A").

Fix the inner door on the inner door angle using two M4×6mm screws, see Fig. 10 below, left-

hand picture (detail "B"). The shaped recesses in the door bearings must face the inner door.

Fig. 10: Installation of the inner door

On the left: detail "A": Screw fixing the locking half cylinder in Inner Doors ITA-2 and ITA-3

detail "B": Fixing the inner door to the door bearings

detail "C": Screw used for limiting the angle of rotation

On the right: View of the inner door angle from behind/above. The clearance of the locked inner

door is adjusted with the M5 grub screw on the door stop bar. Fix the adjustment setting using

the M5 counter nut.

Insert the M5 grub screw in the upper door stop bar of the inner door angle, but tighten it only

as much so that sufficient clearance is guaranteed when the inner door is closed (see Fig. 10

above, right-hand picture).

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/18

User Manual FSK700-2 / FSK700-2SX Chapter 3 • Installation 19

Fix the position of the grub screw using the M5 nut included in the accessory kit.

For inner doors equipped with a locking half cylinder (ITA-2 and ITA-3), an M3×20 screw

19

must be used after installing the locking cylinder to limit the angle of rotation (see Fig. 10

above, right-hand picture, detail "C"), so the key cannot be removed when in unlocked position.

Afterwards, verify the proper functioning of the locking mechanism.

3.6 Installation of the Fire Brigade Key Safe in the Flush Mounting Frame

Connect the protective earth to the spot marked by the earthing symbol on Flush Mounting

Frame EZ700-2 or EZBS700-2.

Insert the cable lead-throughs included in the accessory kit of the Key Safe in the two desig-

nated openings in the back wall of the Key Safe.

Remove the inner door angle from the Key Safe (see page 16 and onwards in chapter 3.5.1:

"Removal of the inner door angle").

Insert the Key Safe into the Flush Mounting Frame, at the same time insert the cable leading

from the controlling and monitoring device through the upper cable lead-through, and – if available – insert the cable connecting the Drill Protection of Flush Mounting Frame EZBS700-2, as

well as the Tamper Switch of the Key Safe Column through the lower cable lead-through in the

back wall of the Key Safe.

Be careful that

- the cable(s) do not get crushed between the back wall of the Key Safe and the Flush Mounting

Frame, and

- the componentry inside the Key Safe does not get damaged during inserting the cables!

Fix the Key Safe in the Flush Mounting Frame using the M10 nuts, washers, and toothed lock

washers included in the accessory kit of the Flush Mounting Frame.

Tighten the nuts only as much so that the Key Safe is properly secured to the installation wall,

without deforming the base of the Flush Mounting Frame.

If the application of the Weather Protection Hood is indicated by weather conditions, the

Weather Protection Hood must be installed before fixing the Key Safe to the wall. Insert the

Weather Protection Hood from above, between the wall, or Key Safe Column, respectively, and

the door frame of the Key Safe, and fix it using M10 nuts. Be careful not to damage the cellular

rubber strips attached to the back sides of the Weather Protection Hood and the door frame.

Fig. 11: Fixing the Key Safe (example: FSK700-2SX, able to keep four master keys) into the Flush

Mounting Frame

Detail "A": Nuts for fixing the Locking Cylinder Mounting Bracket in Key Safe FSK700-2, or the

L-bracket with Locking Cylinder Mounting Brackets in Key Safe FSK700-2SX, respectively. See

page 22 and onwards in chapter 4.4: "Connecting".

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/19

20 Chapter 4 • Connection User Manual FSK700-2 / FSK700-2SX

20

4 Connection

The locking bolt supplied in the accessory kit must only be installed in the outer door after

both the Fire Brigade Key Safe and the connected controlling and monitoring device are

fully operational! Should the electrical unlocking device not be fully operational upon closing the outer door with installed locking bolt, the Key Safe can only be opened again by

means leading to the destruction of some of its componentry (e.g., outer door, Drill Protection Board). Additional advice can be found on page 29 and onwards in chapter 5.4: "Commissioning instructions".

The connection between the controlling and monitoring device and the Fire Brigade Key Safe is to

be made continuously, as well as preferably in-wall, or protected by other means.

Before beginning to make the connections, disconnect the cables connected to Connection Board

APL-4 (closure device, Locking Cylinder Mounting Bracket, etc.), to gain additional working

space.

4.1 Preparation of the connection cables

The cables inserted through the back side of the Fire Brigade Key Safe are to be prepared as follows:

Trim the connection cable leading from the controlling and monitoring device to a length of

approximately 60cm (measured from the cable insertion opening).

The cables leading from the Drill Protection of Flush Mounting Frame EZBS700-2, as well as

those leading from the Tamper Switch of the Key Safe Column are not to be trimmed. The

excess length of these cables can be housed in the hollow space between the Flush Mounting

Frame and the Key Safe (approx. 17mm).

Strip off 15cm of the insulation of the cable leading from the controlling and monitoring device.

The cables leading from the Drill Protection of Flush Mounting Frame EZBS700-2, as well as

those leading from the Tamper Switch of the Key Safe Column have already been prepared

accordingly.

If a cable with a large outer diameter is used to connect the controlling and monitoring device,

it is suggested to strip the insulation off the cable (starting at the cable insertion opening), to

ensure the small bending radius required inside the Key Safe can be achieved.

Insert the cables into the Key Safe according to Fig. 12 below, and fix the cables in place using

the nylon cable clamp located right below the Connection Board.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/20

User Manual FSK700-2 / FSK700-2SX Chapter 4 • Connection 21

21

4.2 Inner view of the Fire Brigade Key Safe

Fig. 12 below pictures the inner view of Fire Brigade Key Safe FSK700-2SX, with the inner door

angle removed.

Fig. 12: Inner view of the Fire Brigade Key Safe, using the example of Key Safe FSK700-2SX

All connectors on Connection Board APL-4 have been disconnected for easier handling.

The cable leading from the controlling and monitoring device has been inserted with excess

length, fixed in place using the nylon cable clamp, and connected to the terminals.

The space pictured in Fig. 12 is sufficient to house cables of type J-Y(St)Y8×2×0.8. If a cable with

a thicker insulation diameter (e.g., functional endurance cable, earth cable) is used, the insulation

should be stripped off the cable (starting at the cable insertion opening), to ensure the small bending radius required inside the Key Safe can be achieved.

With Key Safe FSK700-2SX, the terminals on the Connection Board can be made more access-

ible by removing Locking Cylinder Mounting Bracket No. 1 (see Fig. 11, detail "A" on page 19),

by which the L-bracket can be removed as well. Be careful that no cables get crushed during

reassembly.

4.3 Layout of Connection Board APL-4

Fig. 13: Location of the terminals, connectors, and jumpers on Connection Board APL-4

Connecting the cables leading from the outer door, closure device, and Locking Cylinder Mounting

Brackets is described on page 24 and onwards in chapter 4.5: "Connecting the cables of the Key

Safe to Connection Board APL-4".

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/21

22 Chapter 4 • Connection User Manual FSK700-2 / FSK700-2SX

22

With Jumper JP1, it is possible to adjust whether the buzzer installed in the Key Safe should

activate in the event that the Key Safe is closed without the master key(s) having been inserted correctly (see page 28 and onwards in chapter 5.3.2: "Acoustic warning signal when missing master

key").

JP1 connected (factory default setting): the buzzer will activate if the master key(s) have not

been inserted correctly.

JP1 disconnected: the buzzer will not activate.

This function is only available if Key Safe Controlling and Monitoring Device AD900-1 is utilised as controlling and monitoring device.

With Jumper JP2, it is possible to adjust whether the current supplied to the closure device should

be cut when the outer door of the Key Safe is opened.

JP2 connected: the current supplied to the closure device will be cut while the outer door is

open.

JP2 disconnected (factory default setting): the closure device will remain activated until the Fire

Brigade Key Safe is switched back to normal condition.

4.4 Connecting

4.4.1 Complete connection diagram

In the connection diagram, Fig. 14 below, the typical interconnection of a

Series FSK700 Fire Brigade Key Safe together with

Key Safe Controlling and Monitoring Device AD900-1, a

fire detection control panel, a

transmitting device, an

unblocking device, as well as the

Drill Protection of Flush Mounting Frame EZBS700-1, or

Tamper Switch DK700-2 of the Key Safe Column, respectively,

among other devices

is pictured as an example. If, instead of Key Safe Controlling and Monitoring Device AD900-1, a

different approved product is utilised, connections must be adapted accordingly.

With Key Safe FSK700-2SX, the terminals on the Connection Board can be made more accessible by removing Locking Cylinder Mounting Bracket No. 1 (see Fig. 11, detail "A" on page 19),

by which the L-bracket can be removed as well. Be careful that no cables get crushed during

reassembly.

Key to Fig. 14 on page 23:

1)

An additional common alarm signal by the fire detection control panel is necessary on terminals 17/18

on the controlling and monitoring device if the first signal (terminals 9/10 on the controlling and monitoring device) is not available as a static signal, or if a second signal is required. When using Key Safe

Controlling and Monitoring Device AD900-1, the DIL switch S2-1 is to be switched from "OFF" to

"ON" in this case.

2)

With an appropriate transmitting device, it is possible to forward the report of sabotage alarm directly.

The sabotage contact "Relay contact 1" should be used to forward the sabotage alarm report to the fire

detection control panel as well, to activate the display "Sabotage Schlüsselkasten" (Key Safe sabotage),

and create an entry in the event log accordingly.

3)

Only one Locking Cylinder Mounting Bracket is installed in Key Safe FSK700-2.

4)

Use of the additional 2.2kΩ resistor is only permitted and required when connecting the Flush Mounting

Frame with Drill Protection EZBS700-2. This resistor is included in the accessory kit of Flush Mounting

Frame EZBS700-2.

5)

The sabotage circuit of the Key Safe is closed by a jumper on terminals 12 and 15 at factory default settings. This jumper must be removed when connecting Tamper Switch DK700-2 of the Key Safe Column

and/or the Flush Mounting Frame with Drill Protection EZBS700-2.

6)

Connecting optional unblocking devices must always be performed under line surveillance.

7)

Alternatively, the heating device of Key Safe FSK700 can be powered with nominal voltages of 12VAC

or DC, or with 24VDC. The heating device for Unblocking Device FSE/PHZ900-1 by MEP is designated for 24VAC or DC exclusively!

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/22

User Manual FSK700-2 / FSK700-2SX Chapter 4 • Connection 23

23

The key to notes 1) through 7) can be found on page 22.

Fig. 14: Interconnection of Key Safe FSK700-2 / FSK700-2SX and Key Safe Controlling and Monitoring

Device AD900-1, fire detection control panel, transmitting device, unblocking device, Power

Supply Unit for Heating Device NT700-1, as well as Flush Mounting Frame EZBS700-1, or

Tamper Switch DK700-2 of the Key Safe Column, respectively

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/23

24 Chapter 4 • Connection User Manual FSK700-2 / FSK700-2SX

24

Variant "A": Drill protection of Flush Mounting Frame EZB700-2 and Tamper Switch of the

Key Safe Column are connected instead of jumper wire 5).

Variant "B": Drill protection of Flush Mounting Frame EZB700-2 is connected instead of

jumper wire 5).

The drawn positions of the switches become effective if

- the outer door of the Key Safe is closed and all master keys have been inserted correctly

- the AD900-1 is not signalling sabotage alert and its case door is closed

- the fire detection control panel is not signalling the common alarm signal and is not receiving

the confirmation signal

- the transmitting device is not transmitting the confirmation signal

- the top cover of the Key Safe Column has not been lifted

If an unblocking device with locking half cylinder is to be used, it is recommended to use the

Unblocking Device FSE/PHZ900-1 by MEP, Article No. 265662, which shares the design of the

Series FSK700 Key Safe. This unblocking device is standardly equipped with a heating device

(24V/1W), which can be powered by the Power Supply Unit for Heating Device 24VNT700-1.

Additional information is provided in the documentation of Unblocking Device FSE/PHZ900-1.

4.4.2 Connecting the Flush Mounting Frame with Drill Protection, or the Tamper Switch of the Key Safe Column

At factory default settings, terminals 12 and 15 on Connection Board APL-4 are connected by a

jumper. This jumper must be removed if the Flush Mounting Frame with Drill Protection EZBS700-2, or the Tamper Switch of the Key Safe Column are to be integrated in the sabotage monitoring.

Should Flush Mounting Frame EZBS700-2 be utilised without the Tamper Switch of the Key Safe

Column, the Drill Protection of the Flush Mounting Frame is to be connected to terminals 12 and

15 on the Connection Board, as well as the 2.2kΩ resistor (colour code: red/red/red), included in

the accessory kit of the Flush Mounting Frame, connected to terminals 3 and 4.

Should, in addition to Flush Mounting Frame EZBS700-2, the Tamper Switch of the Key Safe

Column be utilised, the Drill Protection of the Flush Mounting Frame is to be connected to terminals 12 and 13, as well as the Tamper Switch connected as N/C contact to terminals 14 and 15. See

variants "A" and "B" in Fig. 14 above. The 2.2kΩ resistor (colour code: red/red/red) included in the

accessory kit of the Flush Mounting Frame must be connected to terminals 3 and 4 on the Connection Board.

4.4.3 Heating device of the Series FSK700 Fire Brigade Key Safe

The heating resistors are designed for voltages of

12VAC or DC, and

24VAC or DC

Adaption to the actual voltage is performed automatically.

The heating device is controlled by temperature. The temperature at which it will activate is

adjustable in stages (see page 28 and onwards in chapter 5.3.1: "Activation temperature of the outer

door heating device").

The heating device can also be powered by 12VDC or 24VDC from a fire detection control panel

(provided the power supply unit is sufficient). In this case, it is recommended to switch off the

heater voltage during a power blackout, so the emergency battery does not get overloaded.

4.5 Connecting the cables of the Key Safe to Connection Board APL-4

Connect the internal cables of the Key Safe to the Connection Board only after all external cables

have been placed inside the Key Safe, secured in place using the nylon cable clamp (see page 21

and onwards in chapter 4.2: "Inner view of the Fire Brigade Key Safe"), and connected to the corresponding terminals.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/24

User Manual FSK700-2 / FSK700-2SX Chapter 4 • Connection 25

1)

See page 25 and onwards in chapter 4.5.3: "Connecting the cables of the Locking Cylinder Mounting

Brackets"

25

Fig. 15: Connecting the closure device, ribbon cable of the outer door, and cables of the Locking Cylin-

der Mounting Brackets to Connection Board APL-4. Example pictures Key Safe FSK700-2SX,

upgraded to keep 4 master keys.

4.5.1 Ribbon cable of the outer door

Following connecting the terminals, connect the ribbon cable of the outer door to connector ST7 on

Connection Board APL-4. Place the ribbon cable inside the Key Safe in a way that operating the

locking half cylinder(s) does not damage the cable.

4.5.2 Cable of the closure device

Connect the cable of the closure device to connector ST6 on Connection Board APL-4. Ensure that

the two red connecting wires are on the bottom side (see Fig. 15 above).

Adaption of the closure device to the voltage of the fire detection control panel (12VDC or

24VDC) is performed automatically.

Should the cable of the closure device not be properly connected to connector ST6 on Connection Board APL-4, the closure device cannot function properly – as a result, the outer door of the

Key Safe cannot be opened anymore.

Should the cable of the closure device be connected to connector ST6 with wrong polarity,

this can lead to the Connection Board APL-4 becoming defective!

4.5.3 Connecting the cables of the Locking Cylinder Mounting Brackets

1)

Install positions for the Locking Cylinder Mounting Bracket are pictured in Fig. 9 on page 18.

Fig. 16: Connecting positions of the Locking Cylinder Mounting Brackets on Connection Board APL-4

throughout the upgrade stages of the Series FSK700 Key Safe

The cable leading from the Locking Cylinder Mounting Bracket in Key Safe FSK700-2 is the

only cable to be connected to connector ST1 on Connection Board APL-4! When using Key Safe

FSK700-2SX, it is imperative that nothing is connected to connector ST1.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/25

26 Chapter 4 • Connection User Manual FSK700-2 / FSK700-2SX

26

Place the cables inside the Key Safe in a way that operating the locking half cylinder(s) does not

damage the cables. Fix the cables to the Connection Board using the cable tie included in the

accessory kit of the Key Safe, see Fig. 15 above.

4.6 Typical connection diagram of a fire detection control panel and the Fire Brigade Key Safe

The connection between the controlling and monitoring device and the Fire Brigade Key Safe is to

be made continuously, as well as preferably in-wall, or protected by other means. Also see the

advice on page 20 and onwards in chapter 4: "Connection".

4.6.1 Connection diagram of a system comprising fire detection control panel, Series FSK700 Key Safe, Key Safe Controlling and Monitoring Device AD900-1, and Power Supply Unit NT700-1

Fig. 17: Typical example connection diagram for connecting a fire detection control panel to

- Series FSK700 Fire Brigade Key Safe,

- Key Safe Controlling and Monitoring Device AD900-1,

- transmitting device,

as well as optional devices

- Unblocking Device FSE/PHZ900-1,

- Power Supply Unit for Heating Device NT700-1

- burglar alarm control panel

Cables such as fire detector cables J-Y(St)Y n×2×0.8 or functional endurance cables JE-H(St)H

n×2×0.8 E30 can be utilised. The actual dimensioning of the cables is to be determined by

on-site requirements.

4.6.2 Connection diagram of a system comprising fire detection control panel, burglar alarm control panel, and Fire Brigade Key Safe

The example shows

the unlocking of the Fire Brigade Key Safe by the confirmation signal from the corresponding

transmitting device, activated by fire alarm, as well as

sabotage alarm by the Key Safe Controlling and Monitoring Device AD900-1, either via the

burglar alarm control panel, or alternatively, directly alerting the security company.

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/26

User Manual FSK700-2 / FSK700-2SX Chapter 4 • Connection 27

1)

Should no burglar alarm control panel be utilised, sabotage alarm by the AD900-1 is transmitted directly

to the security company via the transmitting device. In this case, all devices must meet the requirements

specified for the fire alarm control system.

2)

Instead of two separate transmitting devices, it is possible to utilise a transmitting device that is able to

transmit both signals. This combined transmitting device must meet the requirements specified for the

burglar alarm system.

27

Fig. 18: Typical interconnection of Fire Brigade Key Safe, burglar alarm control panel, and fire detec-

tion control panel

4.6.3 Connection diagram of a system comprising burglar alarm control panel and Fire Brigade Key Safe, without fire detection control panel

The example shows

the burglar and sabotage alarm by the Key Safe or the Key Safe Controlling and Monitoring

Device AD900-1, transmitted to the transmitting device for the security company via the burglar

alarm control panel, as well as

the unlocking of the Fire Brigade Key Safe by the confirmation signal from the transmitting

device, and/or due to additional inputs (e.g., by a control point or local code input)

1)

Activation by a fire detection control panel is not permitted in this case!

Fig. 19: Typical interconnection of Fire Brigade Key Safe and burglar alarm control panel, without fire

detection control panel

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/27

28 Chapter 5 • Commissioning User Manual FSK700-2 / FSK700-2SX

28

5 Commissioning

The locking bolt supplied in the accessory kit must only be installed in the outer door after

both the Fire Brigade Key Safe and the connected controlling and monitoring device are

fully operational! Should the electrical unlocking device not be fully operational upon closing the outer door with installed locking bolt, the Key Safe can only be opened again by

means leading to the destruction of some of its componentry (e.g., outer door, Drill Protection Board). Additional advice can be found on page 29 and onwards in chapter 5.4: "Commissioning instructions".

5.1 General

Commissioning, inspection, and maintenance of the Series FSK700 Fire Brigade Key Safe is to be

performed by a specialist company trained and authorised by MEP-Gefahrenmeldetechnik GmbH

or their local representative (see page 7 and onwards in chapter 1.6: "Important advice for the operator and specialist installer").

All tasks performed are to be entered in the report book of the corresponding alarm system.

5.2 Notes on insurance protection

The keeping of keys in a Fire Brigade Key Safe results in an increased level of danger, which

the insurance company must be informed of.

If the key depot is not VdS-certified and/or is not installed, operated and maintained

according to the VdS-Richtlinien für Schlüsseldepots, Planung, Einbau und Instandhaltung

(VdS 2350), it is possible that no insurance protection is available for damages due to burglary, in case the building has been opened using the (real) key taken from the key depot.

5.3 Configuration with jumpers

5.3.1 Activation temperature of the outer door heating device

The heating device for the outer door can be set to activate at a temperature of +10°C or +5°C, as

well as set to continuous operation by moving or removing the jumper on the Door Protection

Board, as pictured in Fig. 20 below. At factory default settings, the heating device is set to activate

at a temperature of +10°C.

Fig. 20: Setting the activation temperature of the heating device on the Door Protection Board

To be able to move the jumper, the Door Protection Board must be removed from the outer

door. It is essential that the Key Safe is rendered currentless (e.g., by switching off the

voltage of the controlling and monitoring device and the heating device) prior to this!

5.3.2 Acoustic warning signal when missing master key

If the Series FSK700 Key Safe is closed after the fire alarm has been reset, and not all master keys

have been inserted correctly, the Key Safe's integrated buzzer will sound as warning.

This function is only available if the Key Safe is connected to the Key Safe Controlling and

Monitoring Device AD900-1 by MEP-Gefahrenmeldetechnik GmbH.

Should this function be undesired, Jumper JP1 must be removed from Connection Board APL-4

(see Fig. 13 on page 21).

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/28

User Manual FSK700-2 / FSK700-2SX Chapter 5 • Commissioning 29

29

5.3.3 Automatic deactivation of the release magnet when outer door is open

The electromagnetic unlocking device of the outer door is designed for a duty cycle of 100%. During emergency operation, the release magnet is activated, and will only be deactivated again once

normal condition is restored (at factory default settings).

To conserve energy (drawn from the emergency battery during a power blackout) during emergency operation, it is possible to automatically deactivate the release magnet upon opening the

outer door. When the outer door is closed hereafter, – provided fire alarm is still active – the release

magnet will be reactivated, and the door can be opened again. To enable this energy conservation

function, Jumper JP2 must be connected to both pins (the jumper is connected only to one pin at

factory default settings) on Connection Board APL-4 (see Fig. 13 on page 21).

5.4 Commissioning instructions

The following instructions for commissioning require that, before starting,

the locking bolt has not been installed yet,

all locking cylinders, as well as the inner door have been installed, and the corresponding keys

are readily available. Should this not be possible at the time of commissioning, fitting substitute

locking cylinders or locks that will be replaced at a later time must be utilised instead.

Key Safe FSK700-2, or FSK700-2SX, respectively, has been connected to a VdS-certified con-

trolling and monitoring device,

If the Key Safe is connected not to the Key Safe Controlling and Monitoring Device AD900-1 by

MEP, but to a controlling and monitoring device by another manufacturer, some of its functionality can differ from the way described herein.

the Flush Mounting Frame with Drill Protection has been connected (if applicable),

the Tamper Switch of the Key Safe Column has been connected, and the top cover has been

properly installed (if applicable),

ample supply voltage for operation of the Key Safe is available and has been properly connec-

ted.

The controlling and monitoring device must not necessarily be connected to a fire detection control panel or a burglar alarm control panel during commissioning. However, a suitable power

supply must be available.

During commissioning, the steps listed below must be followed in order!

1 Checking the functioning of the closure device

With the outer door open and without locking bolt, verify the proper functioning of the closure device by repeatedly activating it using the controlling and monitoring device. The locking angle must thereby move upwards.

If Jumper JP2 is connected to both pins on Connection Board APL-4, the closure device is

only activated while the outer door is closed. In this case, the closed state must be simulated

by triggering the outer door closing contact.

Should any problems that limit the proper functioning of the closure device arise, it is imperative that these problems are resolved before the installation of the locking bolt!

2 Installing the locking bolt in the outer door

Fig. 21: Inserting the locking bolt along with the steel ball in the outer door

HB_FSK700_1020_9161690_Englisch_D.odt / 1022 D / AN9161690

ZN62163/38/29

30 Chapter 5 • Commissioning User Manual FSK700-2 / FSK700-2SX

30

Place the steel ball included in the accessory kit of the Key Safe – serving to increase security

against drilling – into the threaded hole designated for the locking bolt in the outer door, then insert

the locking bolt (see Fig. 21 above) and fix it in the outer door.

Two types of locking bolts, with and without undetachable washer are in use. Both

types are equal in function. However, the washer should never be removed from a

locking bolt with undetachable washer, and neither should a washer be attached to

a locking bolt without washer!