Page 1

Installation and User Instructions and Systems Log

Menvier Fire System

MF9300

Eight and sixteen zone control panels

Page 2

IMPORTANT

THIS MENVIER FIRE PANEL IS DESIGNED TO BE USED WITH POLARISED AND

SUPPRESSED BELLS. DO NOT USE WITH UNSUPPRESSED BELLS, UNSUPPRESSED

RELAYS OR NON-POLARISED SOUNDERS OR STROBES ETC. DO NOT CONNECT 230V

MAINS DIRECTLY TO THE PCB. ELECTRICAL INSULATION TESTS SHOULD NOT BE

CARRIED OUT WITH THE CABLES CONNECTED TO THE PANEL OR DETECTORS OR

SOUNDERS.

BEFORE MOUNTING THE PANEL PLEASE CARRY OUT THE FOLLOWING TEST:

CONNECT ALL END OF LINE RESISTORS TO ZONE AND ALARM LINE TERMINALS

(SEE FIG. 3 PG. 27). CONNECT A MAINS SUPPLY,THAT IS NOT SWITCHED ON, TO THE

PANEL. SCREW THE CENTRE SECTION INTO PLACE ON THE BACK BOX. CONNECT THE

BATTERIES AND THEN SWITCH ON THE MAINS SUPPLY.

CHECK THAT ALL LIGHTS EXTINGUISH APART FROM THE POWER ON LIGHT. SELECT

LAMP TEST AND CHECK THAT ALL LAMPS LIGHT AND THE INTERNAL BUZZER

SOUNDS. IF ANY FAULT EXISTS THEN PLEASE CONTACT THE MENVIER SALES OFFICE.

ACCESSORIES

MBG913 Flush Mounting Call Point

MBG914 Surface Mounting Call Point

MBG917 Weatherproof Call Points

MMT760 Medium Response Heat Detector

MHT790 High Temp. Response Heat Detector

MFR730 Fast Response Heat Detector

MID710 Ionisation Smoke Detector

MDP720 Photoelectric Smoke Detector

MDB700 Common Detector Base

MBB244 4ins (100mm) Bell

MBM246 6ins (150mm) Bell

MBM248 8ins (200mm) Bell

MWB824 8ins (200mm) Weatherproof Bell

MDS724 Ceiling Sounder

MFS324 Flush Sounder

MWS424/DB Weatherproof Sounder - Deep Base

MWS424/SB Sounder - Shallow Base

MCD524/DB Combined Sounder/Beacon - Deep Base

MCD524/SD Combined Sounder/Beacon - Shallow Base

MXB124/DB Xenon Beacon - Deep Base (1W)

MXB124/SB Xenon Beacon - Shallow Base (1W)

MXB224/DB Xenon Beacon - Deep Base (2W)

MXB224/SB Xenon Beacon - Shallow Base (2W)

MAS175 Discrete Sounder/Indicator

MAR724 Heavy Duty Replay

Page 3

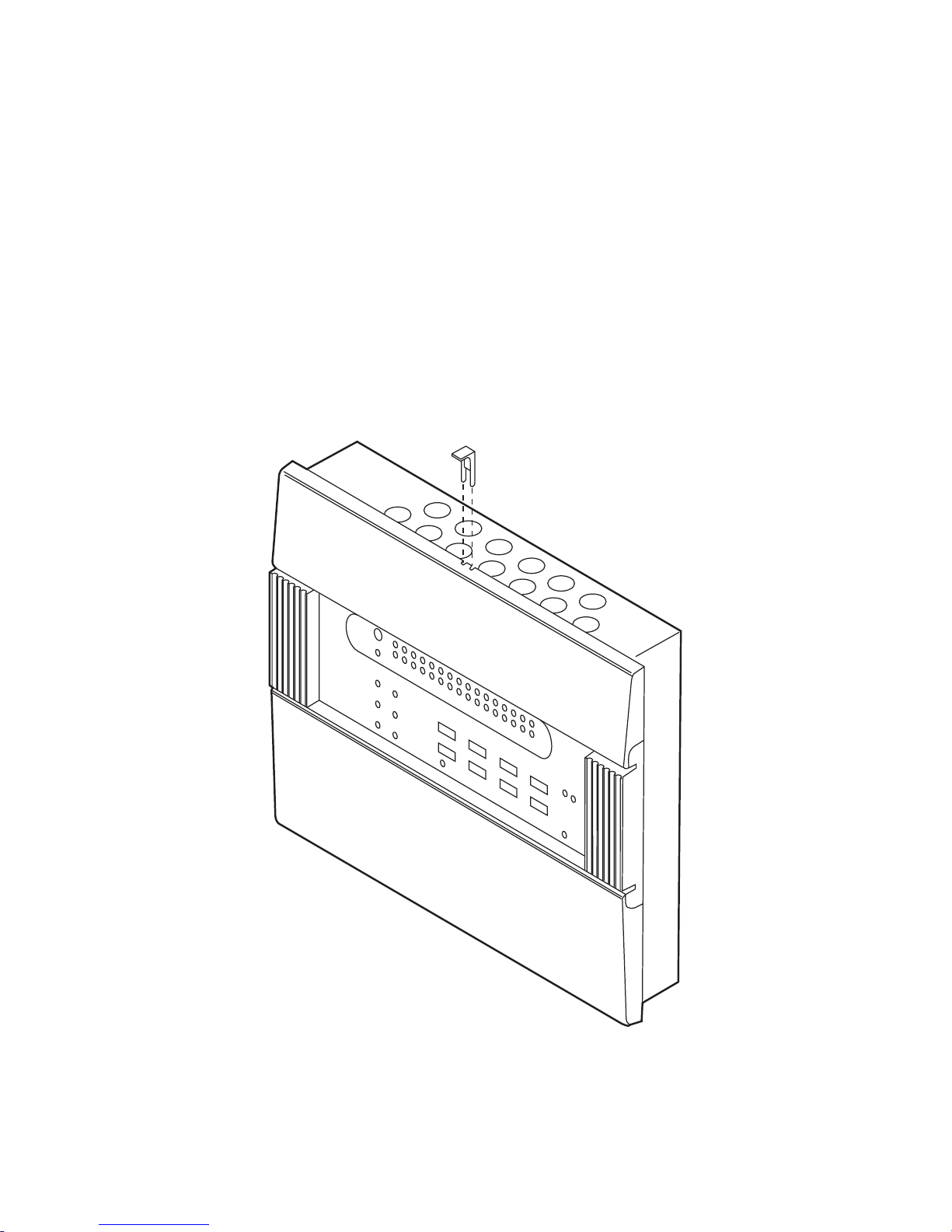

IMPORTANT NOTICE RELATING TO INSTALLING AND

SER VICING THE P ANEL

WHENEVER POWERING UP THE PANEL FROM A COMPLETELY POWERED

DOWN STATE,

I.E. NO MAINS OR BATTERY SUPPLY CONNECTED, THE SYSTEM RESET

BUTTON MUST BE PRESSED - SEE FIG. 2 FOR THE LOCATION OF THIS

PUSH BUTTON.

PLEASE ALSO NOTE THAT ACCESS TO THE SERVICE AREA, BEHIND THE

UPPER DOOR, SHOULD BE GAINED BY USING THE SPECIAL FORKED KEY

PROVIDED. INSERT THE KEY AS SHOWN BELOW, PRESS DOWN AND THE

DOOR LATCH WILL CLEAR ALLOWING THE DOOR TO BE OPENED.

ATTEMPTING TO GAIN ENTRY TO THE SERVICE AREA WITH-

OUT USE OF THE KEY MAY DAMAGE THE PANEL.

Page 4

TABLE OF CONTENTS

ACCESSORIES 1

OVERVIEW 4

SYSTEM OPERATION 4

OPERATING THE PANEL 5

SPECIALISED OPTIONS 8

APPENDIX A

Fire Alarm Log 9

Details Of Installation 18

Details Of Modifications 19

APPENDIX B

Faults - How To Recognise Them & What Action To Take 20

Fires - How To Recognise Them 20

APPENDIX C

Installation Of The MF9308 Control Panels 21

Using The Panel Interfaces 22

Setting System Parameters 24

APPENDIX D

Assembly Drawing 25

Positional Layout of Components 26

Wiring Diagram 27

Technical Specifications 28

PAGE 3

Page 5

OVERVIEW

This document gives details of how to install, test, use and maintain operation of your MF9300 fire

alarm panel.

SYSTEM OPERATION

What To Do At A Glance

The following information tells you what the various indicators, visible on the front panel, mean and

how you should react to them.

INDICATOR STATUS ACTION

GENERAL FIRE ON Fire detected alarms not sounded.

FLASHING Fire detected alarms sounded.

ALARM LINE DELAY ON No action. Alarm line delays are set

up.

FLASHING Fire has been detected. Alarm delay

is in action, check for fire.

SYSTEM FAULT ON Refer to service provider (see front of

this manual for telephone number)

DISABLEMENT FLASHING No action. Zone(s) disabled.

TEST FLASHING Zone in test. If service provider is on

site take no action. Else refer to

service provider (see front of this

manual for telephone number).

REMOTE SIGNAL ISOLATE ON No action. Remote signal output is

isolated.

SUPERVISOR MODE ON No action - you are in Supervisor

mode - see section on `Operating

The Panel`.

FLASHING No action. System is self-checking.

Indicator should go out within 25

seconds.

GENERAL FAULT FLASHING Refer to Appendix B

PAGE 4

Page 6

OPERA TING THE P ANEL

General

The panel operates in 1 of 2 modes - Normal mode or Supervisor mode. In Normal mode the

Supervisor mode LED is extinguished. In Supervisor mode the Supervisor LED is continuously ON.

Control of the facilities at the panel is available via the keyboard. Akey press is acknowledged by a

blip of the internal panel buzzer. All keys that are active in the Normal mode have their legend actually on the key itself, whereas all those facilities that are active once in the Supervisor mode have their

legends above the corresponding key. For example, in Normal mode pressing the SILENCE BUZZER

key will silence the internal panel buzzer. However, if in the Supervisor mode pressing the same key

will perform a Lamp Test.

Normal Mode

This is the condition the panel is generally to be found in. From the Normal mode the user may:

Silence Buzzer:

The user can silence the panel buzzer by pressing the SILENCE BUZZER button on the

keyboard. The buzzer will then only sound approximately once every 10 seconds. NOTE

that this does not silence any alarms, only the buzzer within the panel.

Entering the Supervisor mode:

By entering a 4 digit access code the user may get into the Supervisor mode. The access

code for this panel is 2214. By pressing the numbered keys in the correct order, and then by

hitting the ENTER key, the user will see the Supervisor mode indicator come on. Note that

the buzzer will sound when it has recognised each key press. You are then in the Supervisor

mode and may carry out additional facilities at the panel (see below).

Supervisor Mode

When in this mode a number of extra features are available to the user.

Silence/Resound Alarms:

When in the Supervisor mode this key can be used to either turn the alarms on or to silence

them. It is a toggle action. So, for example, to initiate an evacuation of a site you could

press the Silence/resound alarm button to cause the alarms to sound. You could then silence

the alarm at a later time by pressing the same button again. Note that if the alarms are

silenced but there is still a Fire condition then the internal panel buzzer will buzz every 10

seconds. Also, if the alarms are silenced then this will not prevent subsequent new fire

conditions from automatically resounding the alarms.

PAGE 5

Page 7

PAGE 6

Reset:

This facility allows you to reset the panel. When hit, all panel indicators will light and the

internal panel buzzer will sound. On the MF9304 the Fault relay output will also activate.

On releasing the button the lights will extinguish, the buzzer will silence and the relay output

will deactivate. For a period of approximately 25 seconds after pressing the Reset button the

Supervisor mode indicator will flash. This is indicating that the panel is 'self testing'. Once the

panel is ready the Supervisor mode indicator will extinguish and you can continue using the

panel as you like.

Disable/Enable:

The panel allows a supervisor to disable individual zones and/or the alarm lines. A zone

which has been disabled will not be monitored for faults or for fires. Similarly, if the

alarm lines are put into disablement then they will not be monitored for faults, nor

would they be activated in a fire condition on a zone. (Note alarm lines are disabled in

pairs i.e. lines 1/2 and/or lines 3/4).

To actually disable zone/alarm lines you have to be in the Supervisor mode. Once there,

press the Right Arrow key and a flashing 'cursor' will appear in the Alarm Line indicators.

By repeatedly pressing the Right Arrow key you can step this 'cursor' through the Alarm Line

indicators, onto the Zone Fault indicators. Keep pressing the same key and you will step

through the zones, one at a time, until eventually it returns to the Alarm line indicators, and so

on. When the indicator is at the zone or alarm lines that you wish to disable/re-enable then

by simply pressing the Disable/Enable button in zone/alarm lines will be toggled accordingly.

The Disablement indicator will flash, the internal buzzer will sound every 10 seconds and the

corresponding Fault indicator(s) will light continuously for any zone or alarm line that is

disabled. You may then use the Right Arrow key to move on and disable/re-enable further

zones/alarm lines as required.

Note that a disablement is not cancelled by a reset or a removal of power to the panel.

Test:

The fire panel will allow the supervisor to put any zone into a test mode. To do this go into

the Supervisor mode. Then press the Right Arrow key once and a flashing 'cursor' will

appear in the Alarm indicators. Continue pressing the Right Arrow key until the 'cursor'

reaches the zone that you want to put into test. Then press the Test button. The Test

indicator will begin to flash, the internal panel buzzer will buzz at 10 second intervals and the

Fault indicator of the zone concerned will light continuously. That particular zone is now in

the Test mode.

When in test mode a detector/manual call point can be put into fire on that particular zone.

The panel will recognise the fire condition and sound the alarms for 2 seconds. Then the

panel will automatically reset the zone, in order to try and clear the fire condition. If the zone

resets successfully then the alarms will sound again for 2 seconds. You can then go on and

test the next detector/manual call point on the zone. If the zone fails to reset successfully,

maybe due to a faulty detector or such like, then the panel will keep on trying to reset the

zone for 2 minutes. If it has still failed at the end of this period then that zone immediately

goes into fire.

Note that the alarm lines cannot be put into the test condition.

Page 8

The fact that a zone is in test will not prevent the panel from recognising and acting upon

fires or faults in other zones.

To take a zone out of the test mode you must go into the Supervisor mode and then press

Reset.

Remote Signal Isolate:

To isolate the Remote Signal output press the Remote Signal Isolate button, whilst in

Supervisor mode. The Remote Signal Isolate indicator will light, the Disablement indicator

will flash and the internal panel buzzer will buzz every 10 seconds. To re-enable the Remote

signal again at a later time simply press the Remote Signal Isolate button again.

The corresponding indicators will extinguish and the panel buzzer will silence itself. Note that

the remote signal isolate facility is not cancelled by a system reset.

Lamp Test Facility:

It is possible to test the indicators and the internal panel buzzer manually. To do this from

within the Supervisor mode the Lamp Test button should be pressed. For the period that the

button is kept depressed all panel indicators should light and the internal buzzer should

sound. Once the button is released the panel will return to the condition it was in prior to the

lamp test.

Exiting from the Supervisor Mode:

This mode will automatically exit if no key press is detected for a period of greater than 15

seconds. Alternatively, if you have finished in the Supervisor mode you may simply press

ENTER. In either case the Supervisor mode indicator will extinguish and the panel will be

back in the Normal mode.

PAGE 7

Page 9

SPECIALISED OPTIONS

Certain additional features may be set up by the service provider at the commissioning stage.

They are as follow:

Non-latching Zone

This feature is available on zone 1 and is selectable at commissioning by use of a switch in the panel

(see Appendix C for selecting this feature). Note that this facility is additional to the requirements of

EN54.

When activated any fire condition on zone 1 will not be latched i.e. once the condition has cleared, by

whatever means, at the detecting device, the panel will automatically come out of the fire state for

zone 1 - no user intervention would be required at the panel.

Further details of this interface are available on request.

Coincidence Detection

This feature is available on zone 2 and is selectable at commissioning by use of a switch in the panel

(see Appendix C for selecting this feature).

On the first detector going into fire the panel indicates the event by sounding the buzzer and by having a double flash followed by a pause on the zonal fire indicator. Once the second detector goes into

fire the full fire condition is initiated by the panel.

Using coincidence detection on zone 2 does not affect the way in which fires are recognised or acted

upon from other zones in the system.

Note also that a manual call point pressed on any zone will put the panel into the fire condition

immediately, irrespective of whether coincidence detection is active.

Alarm Line Delays

Delays can be introduced between the panel recognising a detector fire signal and the alarms being

sounded. That delay is selectable at commissioning by use of switches in the panel (see Appendix

C). The length of the delay can be set anywhere between 0 minutes i.e. no delay, and 7 minutes, in 1

minute intervals.

When the panel has alarm line delays set up the ALARM LINE DELAY indicator will be permanently

ON. When a fire is detected on a zone the ALARM LINE DELAY indicator will flash, the buzzer will

sound intermittently and the appropriate zonal fire indicator will flash. After the set delay period the

panel will switch the alarms ON, unless the panel is reset.

Note that, delays do not affect fire signals from manual call points. These signals are acted upon

immediately.

NOTE: AUX contacts are also delayed when this facility is active.

PAGE 8

Page 10

PAGE 9

Date Zone Event Action required Signed

FIRE ALARM SYSTEM LOG APPENDIX A

It is recommended that this book is maintained by a responsible executive and that every ‘event’ affecting the installation should be recorded.

An ‘event’ should include false alarms, failures, tests, temporary disconnections, the dates of installing engineer’s visits and a note of any out-

standing work or conditions.

Page 11

PAGE 10

Date Zone Event Action required Signed

Page 12

PAGE 11

Date Zone Event Action required Signed

Page 13

PAGE 12

Date Zone Event Action required Signed

Page 14

Date Zone Event Action required Signed

PAGE 13

Page 15

PAGE 14

Date Zone Event Action required Signed

Page 16

PAGE 15

Date Zone Event Action required Signed

Page 17

PAGE 16

Date Zone Event Action required Signed

Page 18

PAGE 17

Date Zone Event Action required Signed

Page 19

PAGE 18

DETAILS OF INSTALLATION

Zone No.

No. of Call

Points

No. of Smoke

Detectors

No. of Heat

Detectors

Location

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

TOTAL

CURRENT

No. OF SOUNDER BELLS

ELECTRONIC

OTHER

TOTALALARM LOAD:

OTHER DETAILS OF EQUIPMENT:

THIS SYSTEM HAS BEEN INSTALLED IN ACCORDANCE WITH THE REQUIREMENTS OF EN54

SIGNED DATE

FOR

THIS SYSTEM HAS BEEN COMMISSIONED IN ACCORDANCE WITH THE REQUIREMENTS OF

EN54

SIGNED DATE

FOR

Page 20

PAGE 20

APPENDIX B

Faults - How To Recognise Them And What Action To Take

All fault conditions on the fire alarm panel will be indicated by the flashing of the general fault

indicator (positioned immediately below the large red fire indicator) and the activation of at least one

other fault-specific indicator. By determining which fault-specific indicator is active and by referring to

the table shown you can decide on what action to take.

INDICATOR FLASH RATE CONDITION ACTION

ACTIVE COMP ARED T O

GENERAL FAULT

INDICATOR (G.F.I.)

POWER FAULT flashing Faster than G.F.I. Battery Fault. Refer to service provider.

Short flash, long pause. Mains fail. Check mains supply to

panel is switched on.

ZONAL FAULT Flashing Slower than G.F.I. Zone open circuit. Refer to service provider.

Faster than G.F.I. Zone short circuit. Refer to service provider.

Same as G.F.I. Detector Check detectors

removed from in zone are

base correctly fitted

in their bases.

ALARM FAULT flashing Slower than G.F.I. Alarm open circuit Refer to service provider.

Faster than G.F.I. Alarm short circuit. Refer to service provider.

EARTH FAULT on Earth Fault in Refer to service

System provider

SYSTEM FAULT on System fault Refer to service

occurred provider

Fires - How to Recognise Them

All fire conditions on the fire panel will be indicated by the flashing of the Main Fire Indicator (large

red indicator) and the activation of at least one Zone Fire Indicator.

Main Fire Indicator on Fire detection but alarms not sounded

but not flashing (due to delay or coincidence detection)

Main Fire Indicator Fire detected and alarms sounded

flashing

Zone Fire Indicator on Call Point Fire

but not flashing

Zone Fire Indicator Detector Fire

flashing

Zone Fire Indicator 1st stage coincidence detection

'double flash'

Page 21

APPENDIX C

Installation Of The MF9300 Control Panels

General Points:

Before actually installing your MF9300 panel please note the following points about the system:

The wiring for each of the zones and alarm lines is to be a 2 core parallel circuit with the end of line

resistor fitted to the end of the circuit. No 'spurs' or 'tee offs' are permitted. The wiring diagram (Fig.3)

gives more details.

If a zone is not to be used at all then the end of line resistor must be left in the relevant zone terminal

blocks in the panel.

All equipment used must be of the open circuit type.

Manual call points used in the system (MBG913/MBG914) are polarised. Use the connection details

accompanying the manual call points in order to ensure that the correct polarity of connections is

observed at all times. Also, make sure that the 'MF9300' terminals are used on the manual call

points.

All cables should be tested for Earth fault before connection to the panel. Do not use a MEGGER on

any cable after connection to any equipment including the fire panel.

The maximum load permitted on each of the 4 alarm sounder circuits is specified in the Technical

Specification (Appendix D, fig.4). The load should be spread equally across the circuits. All sounders

must be polarised, with the correct polarity of connections being observed at all times. Refer to the

wiring diagram (Appendix D, fig.3) and the instructions with the relevant sounders for the appropriate

connection details.

All cables entering or leaving the panels must do so via the 'knock-out' positions provided.

Additional Instructions for Electromagnetic Compatibility

When used as intended this product complies with EMC Directive (89/336/EEC) and the UK EMC

regulations 1992 (SI 2372/1992) by meeting the limits set by the standards BS 5406 (Pts 2 & 3)

1988, EN50082-1 1991 and EN50081-1 1992. The following installation guidelines must be followed.

1. External cables must be connected using the cable entries or knockouts provided.

2. When routing external cables inside the product they must be

a) Kept as short as possible

b) Routed close to the housing

c) Kept as far as possible from the electronics

Any modifications other than those stated in this manual, or any other use of this product may

cause interference and it is the responsibility of the user to comply with the EMC and Low

Voltage Directives.

Installing The Panel:

Follow the steps shown here, in conjunction with the assembly diagram shown in this manual (Fig.1):

1. Unscrew the battery cover plate and the centre section from the back box and place the centre

section somewhere safe. Take the back box and remove/drill any knockouts that are to be used,

either on the top or rear of the enclosure. Note that specific knockout positions should be used

for the AC mains supply. These positions are indicated both on the back box itself and on the

assemly diagram (Fig 1) Note also that the cables should only enter or leave the enclosure via

positions indicated by the knockouts. Do not drill additional holes in the enclosure. Fix the back

box to the wall. Use the 4 fixing holes in the back of the enclosure if it is to be mounted proud of the

wall. Alternatively, for flush fixing, use the 5mm mounting holes 4 off around the lip of the erar

enclosure to mount the panel.

PAGE 21

Page 22

PAGE 22

2. Connect the batteries together using the battery connectors contained in the accessories bag -

note the polarity of the connections on the assembly diagram (Fig.1). Fit the batteries into the battery

compartment of the rear enclosure.

3. Ensure that all external wiring that is to be used is available within the back box and connect them

to the correct terminal blocks on the interface board (use Fig.3 for guidance). Connect the inter board

connections (one 8 way connector from the power supply board to TB2 on the main board, one 14

way connector from the interface board to TB1 on the main board and one 26 way ribbon connector

from the interface board to the main board) (Fig 2). Wire the AC mains input to the mains terminal

block within the rear enclosure. Connect the battery connector to the Power Supply PCB (ensure that

the clip on the connector socket fits with the catch on the connector plug on the PCB). Asmall spark

may be seen at the connector when this is done - this is quite normal. The internal buzzer should

sound and the green POWER LED should flash (other LEDs may also be lit - this too is quite normal

at this stage). Fix the central section to the rear enclosure using the 4mm screws provided (4 off).

Apply the AC mains supply and press the system reset button (see Fig 2). If all is well the green

POWER LED should now be permanently ON.

4. Fix the battery cover plate to the rear enclosure using the 3mm screws provided (6 off).

5. Fit the lower door.

6. Carry out the testing of the system. NOTE that all manual call points (MBG913/MBG914) used in

the system must be individually tested for correct operation. Then when satisfied that all is working

correctly fit the upper door - ensure that the door clicks into place and locks there.

WARNING: Operating up of a panel after installation should only be carried out by a suitably

qualified/trained person. Live parts are exposed by this operation so ensure that the mains supply is

switched off before attempting to service any of the parts inside the panel.

Routine testing of the system should be carried out as recommended in BS5839 part 1: 1988

(Clause 29).

Using The Panel Interfaces:

The panels provide the following interfaces options. Fig.2 shows the location of the interface

terminal blocks on the circuit board. Note that these features are in addition to the

requirements of EN54.

Auxiliary DC Output

A 24 VDC output is provided. This output may be switched via the auxiliary relays or used to drive

external relays via the auxiliary zone/common outputs. This output is fused to protect against wiring

faults but is UNMONITORED by the panel i.e. if this fuse ruptures the panel will not register a fault.

Page 23

Class Change

A pair of contacts are provided for a class change facility. By short circuiting these contacts via a

switch, pulse unit, time clock or by other means, the alarms will sound without illuminating the fire

lights. The alarms will cancel when the short circuit is removed. No voltage should be applied to

these terminals.

Auxiliary Common Output

This is a 'solid state' semiconductor switch which operates on the activation of a fire on any latching

zone by 'pulling down' this output to 'zero volts' (Note, the activation does not occur for fires on

non-latching zones). This makes the output suitable for driving an external 24V relay with a coil

current of 10mA, maximum, which can be used for operating door release units etc. This output is not

activated by Sound Alarms or Class Change.

Auxiliary Fault Relay

A1 Amp (max), 24 VDC (resistive) voltage free single pole changeover relay is provided. The relay

will operate on the activation of any fault registered by the panel. 240V MUST NOT BE SWITCHED

WITH THIS RELAY.

Remote Signal Relay

A1 Amp (max), 24VDC (resistive) voltage free single pole changeover relay is provided, operating

on the activation of any zone, after any delays are taken into account on that zone. The relay is for

signalling to a remote location, of for operation of an autodialler. Where it is required to signal to a

control station an interface unit, supplied by the control station operator, will be required. This relay is

not activated during Sound Alarms, nor during Class Change. 240V MUST NOT BE SWITCHED

WITH THIS RELAY.

An isolate facility is provided to enable the panel to be tested without operating the remote signal

relay. This facility is available in the supervisor mode from the front panel. When pushed the Remote

Signal Isolate LED will light and the internal buzzer will sound every 10 seconds. Note that doing a

system Reset will not cancel the isolate facility.

Repeater Output

A2 wire serial link interface is provided for connecting to a repeater panel. Further details of this

interface are available on request.

Do not exceed the maximum output current rating stated in the Technical Specification

(Appendix D)

PAGE 23

Page 24

Setting System Parameters

Certain facilities that can be set up by the service provider at commissioning. They are as follows:

Non-latching Zone

To enable this facility gain access to the service area of the panel and push the Non-latching zone

switch down (Fig.2). Then press the SYSTEM RESET switch. The panel will reset and the

non-latching zone feature will be available on zone 1.

Coincidence Detection

To enable this facility gain access to the service area of the panel. On the bit-switch (see Fig.2) move

switch 4 to the ON position. Then press the SYSTEM RESET button. The panel will reset and the

coincidence detection feature will then be available for use on zone 2.

Alarm Line Delays

Again, to enable alarm line delays gain access to the service area. The delay period is set by

adjusting the positions of the bit switches (see Fig.2) as follows:

SWITCH POSITION

123

DELAY

(MINS)

0OFFOFFOFF

1ON OFFOFF

2OFFON OFF

3ON ONOFF

4OFFOFFON

5ON OFFON

6OFFON ON

7ON ONON

After the delay period is selected press the SYSTEM RESET switch. The panel will reset, the ALARM

LINE DELAY indicator will light and the delays will be used when appropriate.

PAGE 24

Page 25

PAGE 25

Large door

Middle moulding Battery cover plate

Small door

Back box

Battery compartment

only

Batteries 2 x 12V, 12Ah

Mains conduit entry

Mains Terminal block

Transformer

Transformer wires

colour coded

Battery -ve (black)

Battery link wire

Battery +ve (red)

Battery connector

(polarised)

Transformer

connector

Zone connector

Cable clamp

Alarm connector

Interface board

Battery connector

Power connector

Power supply board

APPENDIX D

Assembly drawing for MF9308 &

MF9316

FIG 1

Page 26

PAGE26

SYSTEM FAULT

FIRE

NE

L

GENERAL FAULT

DISABLEMENT

TEST

POWER

POWER FAULT SUPERVISOR MODE REMOTE SIGNAL ISOLATE

ALARM LINE DELAY

RIBBON

26 WAY CONNECTION TO

TERMINAL BLOCK BOARD

8 WAY CONNECTION TO

POWER SUPPLY BOARD

(TB2)

14 WAY CONNECTION TO

TERMINAL BLOCK BOARD

(TB1)

ALARMS

1

2 34

EARTH FAULT

ZONE LED'S

1234 5 6 7 8 9 10 11 12 13 14 15 16

AUX DC FUSE 1A

NON LATCH ZONE

ALARM 4 FUSE 3.15A

ALARM 3 FUSE 3.15A

ALARM 1 FUSE 3.15A

FUSED MAINS

CONNECTOR

ALARM 2 FUSE 3.15A

ALARM DELAY

COIN DETN

SYSTEM RESET

Positional layout of components for MF9308 & MF9316 panels

FIG 2

Page 27

PAGE 27

Zone

1

Zone

2

Zone

3

Zone

4

Zone

5

Zone

6

Zone

7

Zone

8

Zone

9

Zone

10

End of line 12K

resistor

End of line 12K

resistor

- +- +-+-+-+- +-+-+-+-+

Zone

11

-+

Zone

12

-+

Zone

13

-+

Zone

14

-+

Zone

15

-+

Zone

16

-+

Alarm

1

-+

Alarm

2

-+

Alarm

3

-+

Alarm

4

- +

+

-

- +

C6

C5

C6

C5

L1

L1

L1

L1

C6

C5

C6

C5

L1

L1

L1

L1

C6

C5

MDB700

+ OUT

+ IN

- 9300 OUT

MBG 913/914

Break Glass

Units

MDB700

Detector

Bases

- 9300 IN

(note 3)

L1

L1

+

+

+

Alarm

sounders

(Note 1)

And subsequent

Alarm lines

+

+

+

Earth

Auxiliary 24v DC output

Auxiliary common output (note 2)

Class change (note 2)

Repeater Transmit

Repeater Ground

Fault

Relay

Remote

Signal

Relay

NC

C

NO

NC

C

NO

To volt free contacts

To REPEATER

PANEL

(NOTE 4)

NC

NC

C

C

-

+

230v AC

+/- 10%

50/60Hz

Heavy

duty

relay

MAR724

24v 10mA

coil

To door release units

(note 4)

To applications

requiring relay with

isolating facility

Fault

And subsequent

Zones

Fire system 9308/9316 wiring diagram

Notes

1. All sounders must be polarised and suppressed.

2. Connection details for door release units when required.

3. Polarity of connections must be observed. Use 9300 negative connections.

4. Connection details for repeater panels when required.

FIG 3

Page 28

PAGE 28

TECHNICAL SPECIFICATIONS

MF9308 MF9316

No. of zones 8 16

No. of alarm circuits 4 4

Mains input voltage 230 VAC +/- 10% 50Hz

System operating voltage 24 VDC

Monitoring

Zones

Alarms

Open, short circuit and detector removed

Open, short circuit and detector removed

End of line elements

Zones

Alarms

12K resistor supplied with panel

12K resistor supplied with panel

Maximum loadings

Zones (per zone)

Break glass units, heat detectors and smoke detectors

(Combined max - 32)

Alarm lines 500mA/line (2A max)

User controls 8 key keypad providing Access level 1 and Access level 2

control - entry to Access level 2 by 4 digit keycode

Fault indications

Power

Mains fail, battery disconnected, battery low/short circuit

Zone Open, short circuit and detector removed

Alarm Open/short circuit

Earth fault

Earth fault in system

System fault

Controller error, code/data/comms error etc

Fire indicators Large common fire LED plus individual zonal LED’s

Auxilliary DC output 24 VDC 350mA max (fused, but unmonitored)

Auxilliary fault relay 1A 24 VDC resistive, single pole c/o contacts

Remote signal relay

1A 24 VDC resistive, single pole c/o contacts - isolate facility

available

Auxilliary common output Active pull-down to 0V

Repeater drive capacity 1 repeater via 2 wire serial link

Class change facility 1 pair terminals - short to sound alarms

Terminal conductor capacity 0.5mm sq. to 2.5mm sq. maximum

Integral charger (mA) 1

Battery capacity (AH) 12

Battery type

2 x 12V Sealed Lead Acid (Supplied)

Recommended replacement period 4 years

Standby on mains failure 72 Hours backup operating in the normal mode followed

by 1/2 hr in the fire condition

Recharge period 24 hours

Dimensions Approx. 395mm(W) x 325mm(H) x 135mm(D)

FIG 4

Page 29

Cooper Lighting and Security Ltd.

Wheatley Hall Road, Doncaster, South Yorkshire, DN2 4NB, United Kingdom

Sales General Export

Tel: +44 (0)1302 - 303303 +44 (0)1302 - 321541 +44 (0)1302 - 303250

Fax: +44 (0)1302 - 367155 +44 (0)1302 - 303220 +44 (0)1302 - 303251

Email: sales@cooper-ls.com info@cooper-ls.com export@cooper-ls.com

PINST FA9308/V

www.cooper-ls.com

For service Tel:

please call:

Service agreement number

Lighting and Security

Loading...

Loading...