Page 1

Preliminary

Operating instructions

Betriebsanleitung

Temperature dry-well calibrator, model CTD4000

Temperatur-Blockkalibrator, Typ CTD4000

EN

DE

Temperature dry-well calibrator, model CTD4000

Page 2

ENDEOperating instructions model CTD4000 Page 3 - 34

Betriebsanleitung Typ CTD4000 Seite 35 - 66

Further languages can be found at www.wika.com.

© 05/2020 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 3

Contents

Contents

1. General information 3

2. Short overview 3

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Safety 4

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.4 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Personnel qualification. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.6 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . 6

3.7 Labelling, safety marks . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Design and function 7

4.1 Overview of the different instrument models . . . . . . . . . . . . . . . . . . . 7

4.2 Isometric views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Description of the temperature controller . . . . . . . . . . . . . . . . . . . . 8

4.4 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.5 Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.6 Heating resistance (CTD4000-375 or CTD4000-650) . . . . . . . . . . . . . . . . 10

4.7 Temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.8 Safety thermostat (CTD4000-375 or CTD4000-650). . . . . . . . . . . . . . . . . 10

4.9 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.10 Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5. Transport, packaging and storage 11

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Packaging and storage . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6. Commissioning, operation 11

6.1 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Use at high temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 First commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 Operating position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.5 Switching on the calibrator . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.6 Setting a set temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.7 Testing or calibrating temperature probes . . . . . . . . . . . . . . . . . . . . 12

6.7.1 Testing of temperature probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.7.2 Calibrating temperature probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.7.3 Positioning the temperature probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.7.4 Calibration with one reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.7.5 After the test or the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.8 Switch test function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.9 Cooling down the metal block . . . . . . . . . . . . . . . . . . . . . . . . 15

7. Operating the calibrator 16

7.1 Setting a temporary set temperature (set-point mode) . . . . . . . . . . . . . . . . 16

7.2 Programming (main menu) . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3 Short description of the menu . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3.1 Menu structure, parameter levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.3.2 First menu level - General settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

EN

14366831.01 05/2020 EN/DE

1WIKA operating instructions, model CTD4000

Page 4

Contents

7.3.3 Second menu level - Settings for optimising the control . . . . . . . . . . . . . . . . . . . . . . . 19

7.3.4 Third menu level - Recalibration of the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.3.5 Fourth menu level - Settings of the temperature controller . . . . . . . . . . . . . . . . . . . . . . 21

8. Serial communication 22

8.1 List of the variables and parameters . . . . . . . . . . . . . . . . . . . . . . 22

8.2 Data reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EN

8.3 Data writing (FLOAT VARIABLES) . . . . . . . . . . . . . . . . . . . . . . . 23

9. Faults 24

10. Maintenance, cleaning and recalibration 25

10.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.3 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.3.1 Calibration of the internal probe by the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11. Dismounting, return and disposal 27

11.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12. Specifications 28

13. Accessories 30

Declarations of conformity can be found online at www.wika.com.

2 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 5

1. General information / 2. Short overview

1. General information

■

The model CTD4000 temperature dry-well calibrator

described in the operating instructions has been designed

and manufactured using state-of-the-art technology.

All components are subject to stringent quality and

environmental criteria during production. Our management

systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information

on handling the instrument. Working safely requires that all

safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations

and general safety regulations for the instrument's range

of use.

■

The operating instructions are part of the product and

must be kept in the immediate vicinity of the instrument

and readily accessible to skilled personnel at any time.

Pass the operating instructions on to the next operator or

owner of the instrument.

■

Skilled personnel must have carefully read and

understood the operating instructions prior to beginning

any work.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried

out in accordance with international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 41.10

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

EN

2. Short overview

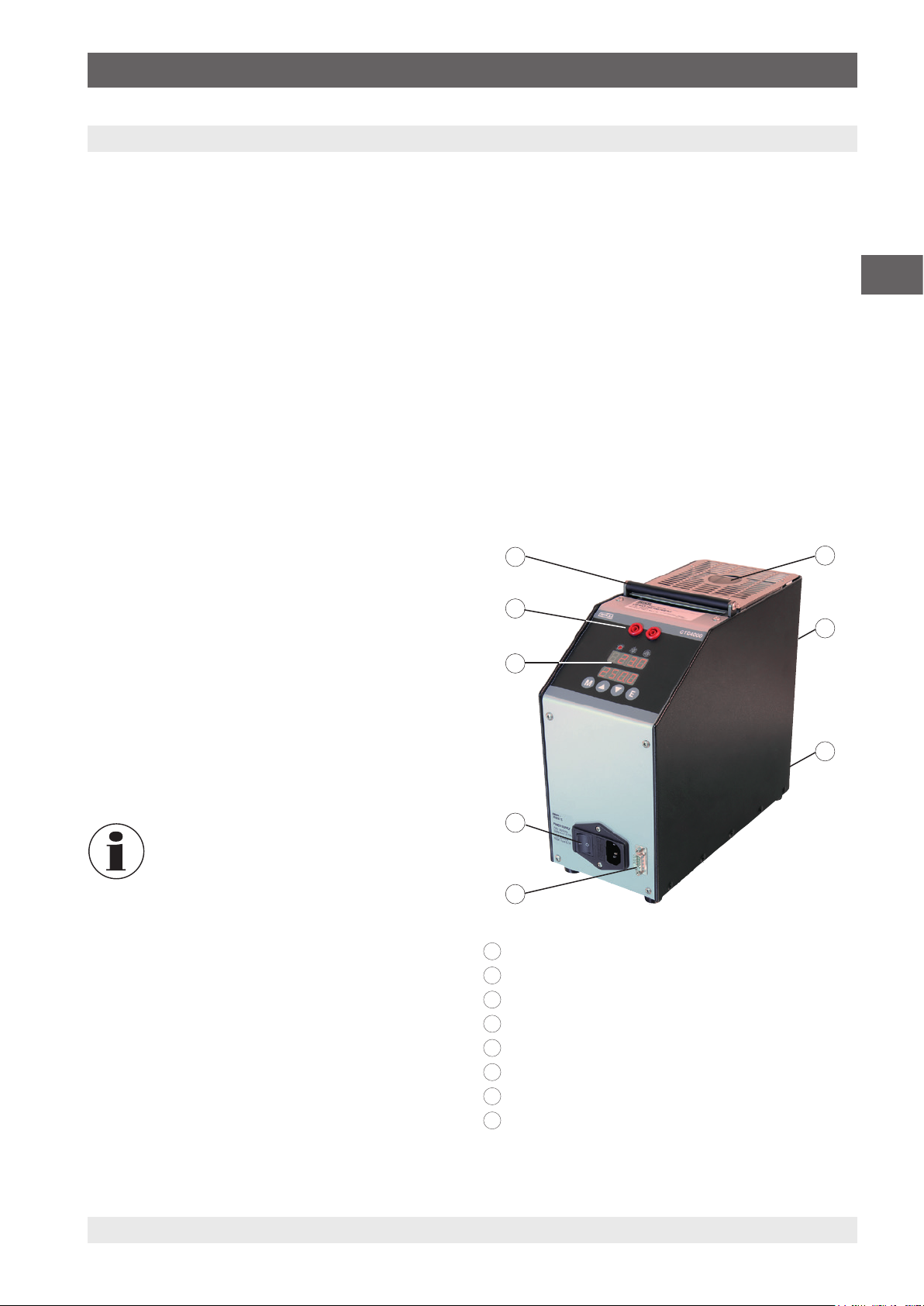

2.1 Overview

8

7

6

5

1

Temperature block

2

1

2

User interface

3

RS-232 interface

4

Power connection

5

Main switch

6

Fuse holder

7

Connections for temperature switch test

8

Carrying handle

2.2 Description

The calibrator has been designed for on-site applications

as well as for the harsh conditions of the naval and marine

3

sectors.

The thermal part of the calibrator is made of a metal block

heated/cooled with resistors or with Peltier thermoelectric

modules. In the metal block there is one bore in which the

interchangeable insert is placed.

14366831.01 05/2020 EN/DE

4

3WIKA operating instructions, model CTD4000

Page 6

2. Short overview / 3. Safety

2.3 Scope of delivery

For model CTD4000-140 temperature dry-well calibrator

■

Calibrator

■

Power cord, 1.5 m [5 ft] with safety plug

■

Replacement tool

■

Operating instructions

■

Drilled insert with 4 bores: 3.3 mm, 4.8 mm and

EN

2 x 6.4 mm [0.13 in, 0.19 in and 2 x 0.25 in]

For model CTD4000-375 temperature dry-well calibrator

■

Calibrator

■

Power cord, 1.5 m [5 ft] with safety plug

■

Replacement tool

■

Operating instructions

■

Drilled insert with 4 bores: 3.2 mm, 4.8 mm, 6.4 mm and

11.1 mm [0.13 in, 0.19 in, 0.25 in and 0.44 in]

3. Safety

For model CTD4000-650 temperature dry-well calibrator

■

Calibrator

■

Power cord, 1.5 m [5 ft] with safety plug

■

Replacement tool

■

Operating instructions

■

Drilled insert with 4 bores: 3.2 mm, 5 mm, 7 mm and

10.5 mm [0.13 in, 0.2 in, 0.28 in and 0.41 in]

Cross-check scope of delivery with delivery note.

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation

that can result in serious injury or death, if not

avoided.

CAUTION!

... indicates a potentially dangerous situation that

can result in light injuries or damage to property

or the environment, if not avoided.

DANGER!

... identifies hazards caused by electric power.

Should the safety instructions not be observed,

there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that

can result in burns, caused by hot surfaces or

liquids, if not avoided.

Information

... points out useful tips, recommendations

and information for efficient and trouble-free

operation.

3.2 Intended use

The model CTD4000 portable temperature dry-well calibrator

is a portable unit that has been designed for on-site

applications as well as for the harsh conditions of the naval

and marine sectors.

The temperature dry-well calibrator is intended for the

calibration of thermometers, temperature switched/

thermostats, resistance thermometers and thermocouples.

The operational safety of the delivered instruments is only

assured if the equipment is employed for its intended use

(verification of temperature sensors). The given limit values

should never be exceeded (see chapter 12 “Specifications”).

Maximum ambient conditions at place of use:

■

Ambient temperature: 5 ... 45 °C [41 ... 113 °F]

■

Humidity: 95 % relative humidity (non-condensing)

This instrument is not permitted to be used in hazardous

areas!

Notes for instruments with EMC and class A

This is class A equipment for emissions and is intended

for use in industrial environments. In other environments,

e.g. residential or commercial installations, it can interfere

with other equipment under certain conditions. In such

circumstances the operator is expected to take the

appropriate measures.

4 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 7

3. Safety

The instrument has been designed and built solely for

the intended use described here, and may only be used

accordingly.

The technical specifications contained in these operating

instructions must be observed. Improper handling or

operation of the instrument outside of its technical

specifications requires the instrument to be taken out of

service immediately and inspected by an authorised WIKA

service engineer.

Handle electronic precision measuring instruments with

the required care (protect from humidity, impacts, strong

magnetic fields, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings).

Plugs and sockets must be protected from contamination.

The manufacturer shall not be liable for claims of any type

based on operation contrary to the intended use.

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to

hazardous situations and injuries or damage to

property.

▶

Refrain from unauthorised modifications to

the instrument.

▶

Do not use the instrument within hazardous

areas.

▶

Do not use the instrument with abrasive or

viscous media.

▶

Only ever use the power cord supplied.

▶

Observe the operating parameters in

accordance with chapter 12 “Specifications”.

To avoid injuries or damage to property observe further

points:

■

Keep clear the area around the calibrator on all sides and

especially behind the calibrator.

■

Do not put anything on the top of the calibrator.

■

Only carry out maintenance on the calibrator when it has

cooled down and been switched off.

■

Before switching off, ensure that the calibrator has

cooled to room temperature (CTD4000-140) or < 100 °C

(CTD4000-375/CTD4000-650).

■

The calibrator must only be stored in the carrying case

once it has cooled down.

■

Do not switch off the calibrator when it is operating at high

temperature because the protective grille and the case

may overheat.

■

Do not use any oil or liquids since these can lead to

damage of the calibrator.

■

Do not put any fuel containers near the calibrator.

Voltage supply

■

The mains socket must be freely accessible at all times!

■

Ensure that the female connector, when connected to the

voltage supply, is properly grounded.

■

With the following points, the temperature dry-well

calibrator must be disconnected by unplugging the power

cord from the mains socket.

▶

Before exchanging the fuse

▶

Before cleaning

▶

Before service/maintenance

▶

In the event of danger

Interface

Do not connect any voltage to the RS-232 input.

Fuse

Remove the fuse from the calibrator only when the power

connection has been disconnected from the mains.

Temperature switch test

■

Do not connect any voltage to the switch test connection.

■

Do not connect any voltage during the test of the

thermostats.

EN

Temperature dry-well calibrator

■

Only operate the calibrator in a defect-free, functioning

condition.

■

Faultless and safe operation of this calibrator requires

proper transport, professional storage, installation,

mounting and use as intended in addition to careful

operation and maintenance.

■

The calibrator has been designed as a controller. With

any operation of the calibrator not expressly provided

for in these operating instructions, additional protective

measures must be taken.

■

The electronic µ processor is factory configured so that all

technical specifications are maintained. These parameters

must not be changed, above all to prevent malfunction or

failure which could lead to damage.

14366831.01 05/2020 EN/DE

Any use beyond or different to the intended use is considered

as improper use.

Do not use this instrument in safety or emergency stop

devices.

5WIKA operating instructions, model CTD4000

Page 8

3. Safety

3.4 Personnel qualification

WARNING!

Risk of injury should qualification be

insufficient!

Improper handling can result in considerable

injury and damage to property.

▶

The activities described in these operating

EN

instructions may only be carried out by

skilled personnel who have the qualifications

described below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood

to be personnel who, based on their technical training,

knowledge of measurement and control technology and

on their experience and knowledge of country-specific

regulations, current standards and directives, are capable

of carrying out the work described and independently

recognising potential hazards.

Special operating conditions require further appropriate

knowledge, e.g. of aggressive media.

3.5 Personal protective equipment

The personal protective equipment is designed to protect the

skilled personnel from hazards that could impair their safety

or health during work. When carrying out the various tasks

on and with the instrument, the skilled personnel must wear

personal protective equipment.

Follow the instructions displayed in the work area

regarding personal protective equipment!

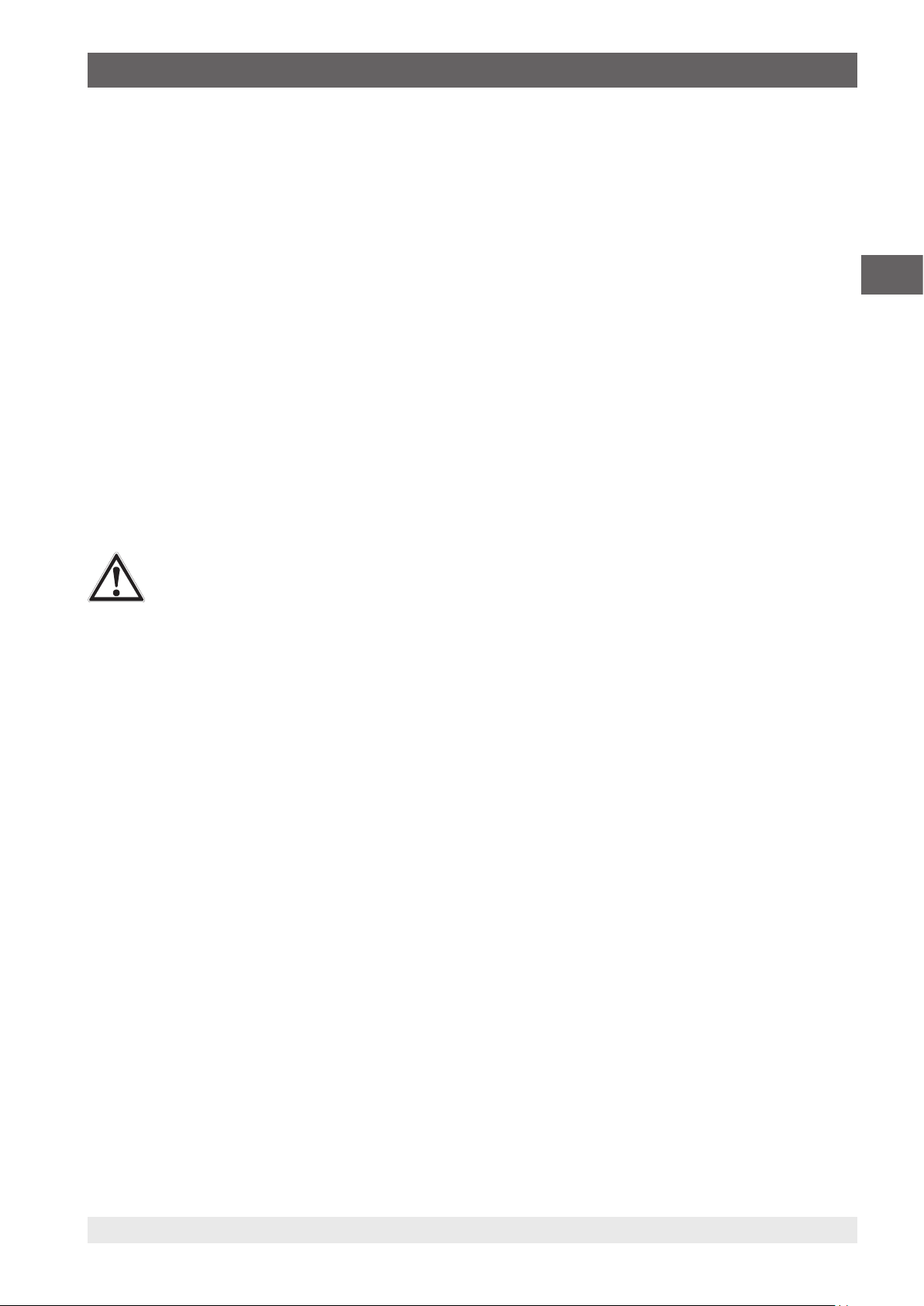

3.6 Labelling, safety marks

The operator is obliged to maintain the product label in a

legible condition.

Product label (example)

The product label is fixed on the rear of the instrument.

Mod.

Matr.

WIKA Alexander W iegand

SE & Co. KG

Alexander-Wiegand Str.30

63911 Klingenberg

Germany

www.wika.de

4

1

Model designation

2

Frequency in Hz

3

Power in W

4

Operating voltage

V

bar

Hz

W

Explanation of symbols

Before mounting and commissioning the

instrument, ensure you read the operating

instructions!

Do not dispose of with household waste. Ensure

a proper disposal in accordance with national

regulations.

1

2

3

The requisite personal protective equipment must be

provided by the operating company.

Wear protective gloves!

Protect hands from contact with hot surfaces and

aggressive media.

14366831.01 05/2020 EN/DE

6 WIKA operating instructions, model CTD4000

Page 9

4. Design and function

4. Design and function

4.1 Overview of the different instrument models

■

CTD4000-140 (cooling and heating)

■

CTD4000-375 (heating)

■

CTD4000-650 (heating)

The temperature dry-well calibrator consists of a robust,

grey-painted steel case, with a carrying handle on top.

The rear part of the case contains a metal block with a

19 x 150 mm or 26 x 150 mm bore in which the inserts can

be placed.

With the help of the inserts temperature probes of different

sizes can then be calibrated.

The heater element heats the block and an electronic µ

controller with static relay output checks and regulates the

temperature.

The metal block is thermally insulated.

A centrally mounted fan generates a constant air flow that

reduces the temperature of the case.

The air flow is divided in two parts: One part of the air flows

from the back of the calibrator, while the second part of the

flow is parallel to the top grid of the calibrator. Thus, the

stem of the sensor is above the insert at the lowest possible

temperature.

The front part of the case contains the complete electronic

unit for controlling the reference temperature.

To control the heating elements, solid-state relays (SSRs) are

used.

On the front panel is the controller, which is fitted with an LED

display (2-line) for the reference and set temperature.

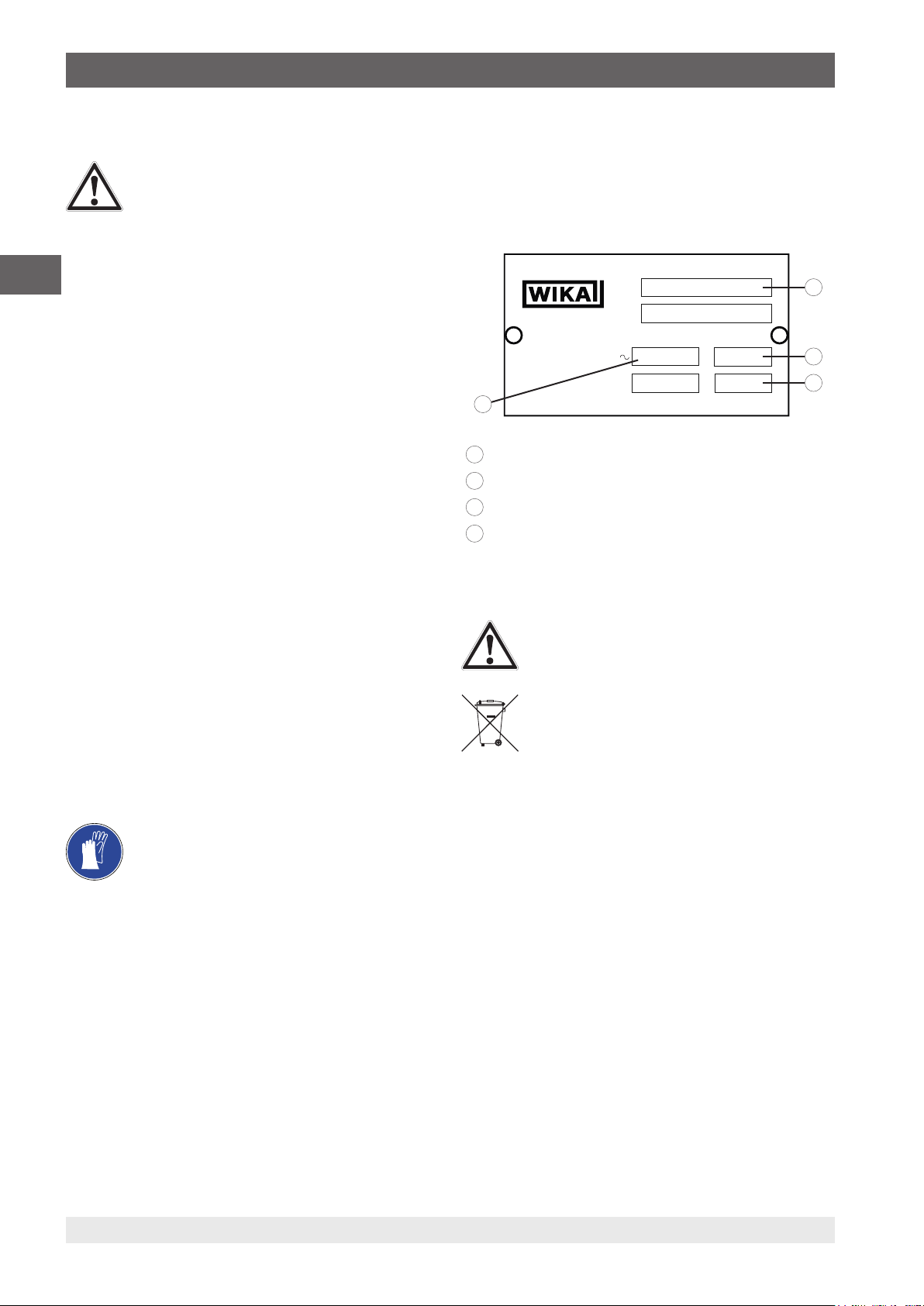

4.2 Isometric views

Front and top

On the top of the temperature dry-well calibrator, you will find

the dry well access opening for inserting the insert.

The controller, with display and controls, is located on the

front of the calibrator.

The temperature switch test is found through the indicator.

In the lower area are the mains connector socket and the

power switch with its fuse holder.

Furthermore, the mains voltage and the fuse rating is given.

On the right hand side, next to the power connection is

located the RS-232 interface.

Rear of the instrument

On the rear of the case are located the product label and the

fan.

This must not be obstructed in any way!

8

7

6

1

2

3

EN

The calibrator is fitted with the following

protective devices to prevent hazards in

operation.

14366831.01 05/2020 EN/DE

■

Temperature controller that recognises any

possible break in the temperature sensor and

disconnects the heating

■

Maximum temperature safety thermostat to

disconnect the heating system

■

Protective grille to prevent any contact with

the metal block

■

Protective fuses

5

4

1

Temperature block with insert

2

Fan

3

Product label

4

RS-232 interface

5

Mains connector socket with power switch and fuse

6

Temperature controller

7

Temperature switch test

8

Carrying handle, retractable

7WIKA operating instructions, model CTD4000

Page 10

4. Design and function

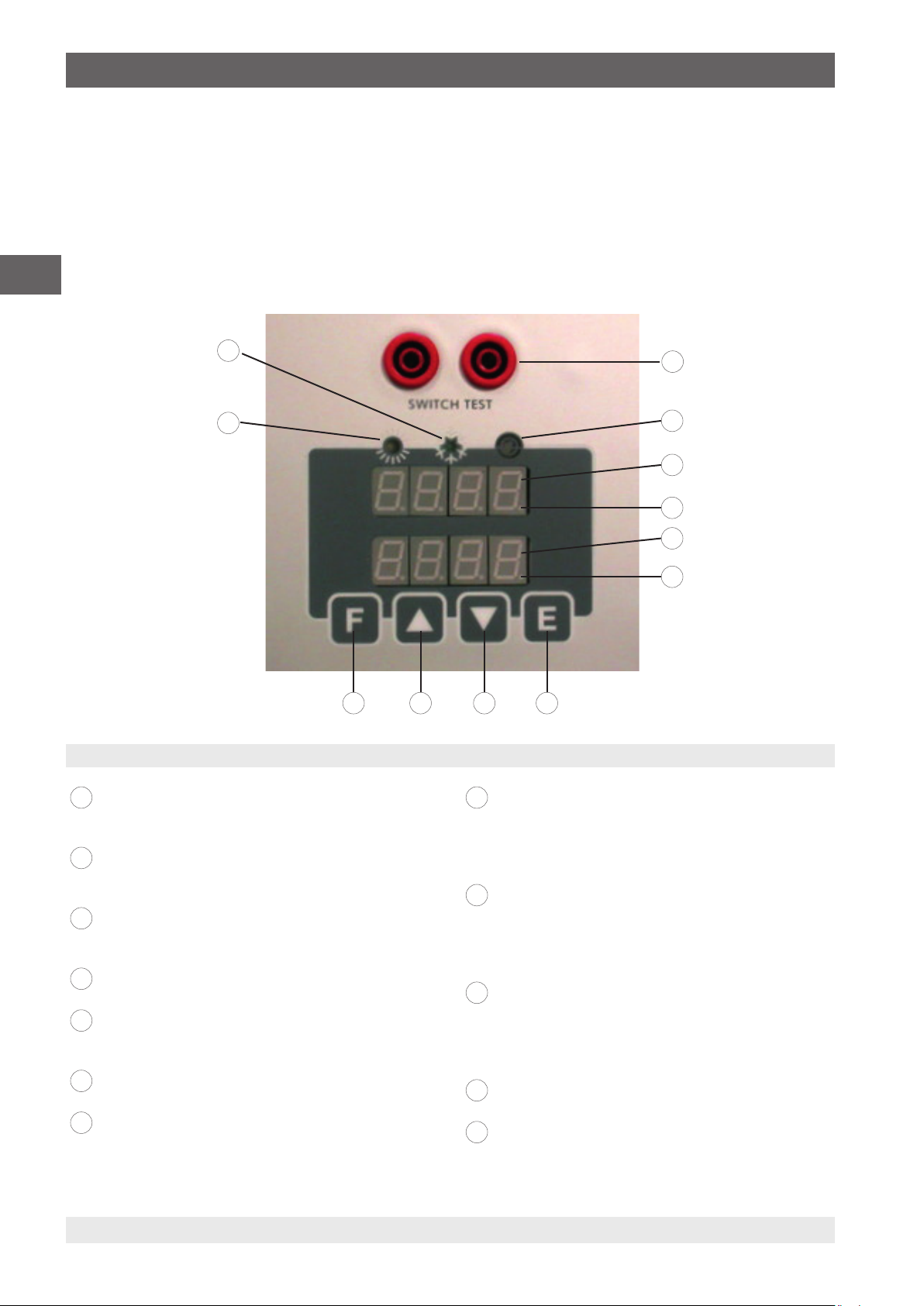

4.3 Description of the temperature controller

The temperature controller is a PID microprocessor, which

can be set from -30 ... 140 °C, 0 ... 375 °C and 0 ... 650 °C

[-22 ... 284 °F, 32 ... 707 °F or 32 ... 1,202 °F]. The display

indicates the current temperature and the set point.

EN

Controls

12

11

89 710

Overview of the operating elements of the temperature controller

Connections for temperature switch test

1

8

For further information, see chapter 6.8 “Switch test

function”.

Switch test LED

2

Lights up when the temperature switch contact is

closed.

Display 1

3

9

Displays the value of the actual temperature or the

value of the function selected.

Stability LED

4

When the LED is flashing, the temperature is stable.

Display 2

5

10

Set temperature display

The parameters are displayed in the function menu.

Switch test

6

When the LED is flashing, the function is active.

Button [E]

7

Confirms the selected values or the selected function.

11

12

1

2

3

4

5

6

Button [▼]

Lowers the value which is shown on display 1 or

display 2.

By holding the [▼] button down, the speed is

increased.

Button [▲]

Increases the value which is shown on display 1 or

display 2.

By holding the [▲] button down, the speed is

increased.

Function menu button [F]

By pressing both the [F] and [▲] buttons at the same

time, the 2nd level menu is accessed.

With the [F] button, the function is called up and can

be browsed in the menu level.

Heating LED

Lights up when the calibrator is heating.

Cooling LED

Lights up when the calibrator is cooling.

8 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 11

4. Design and function

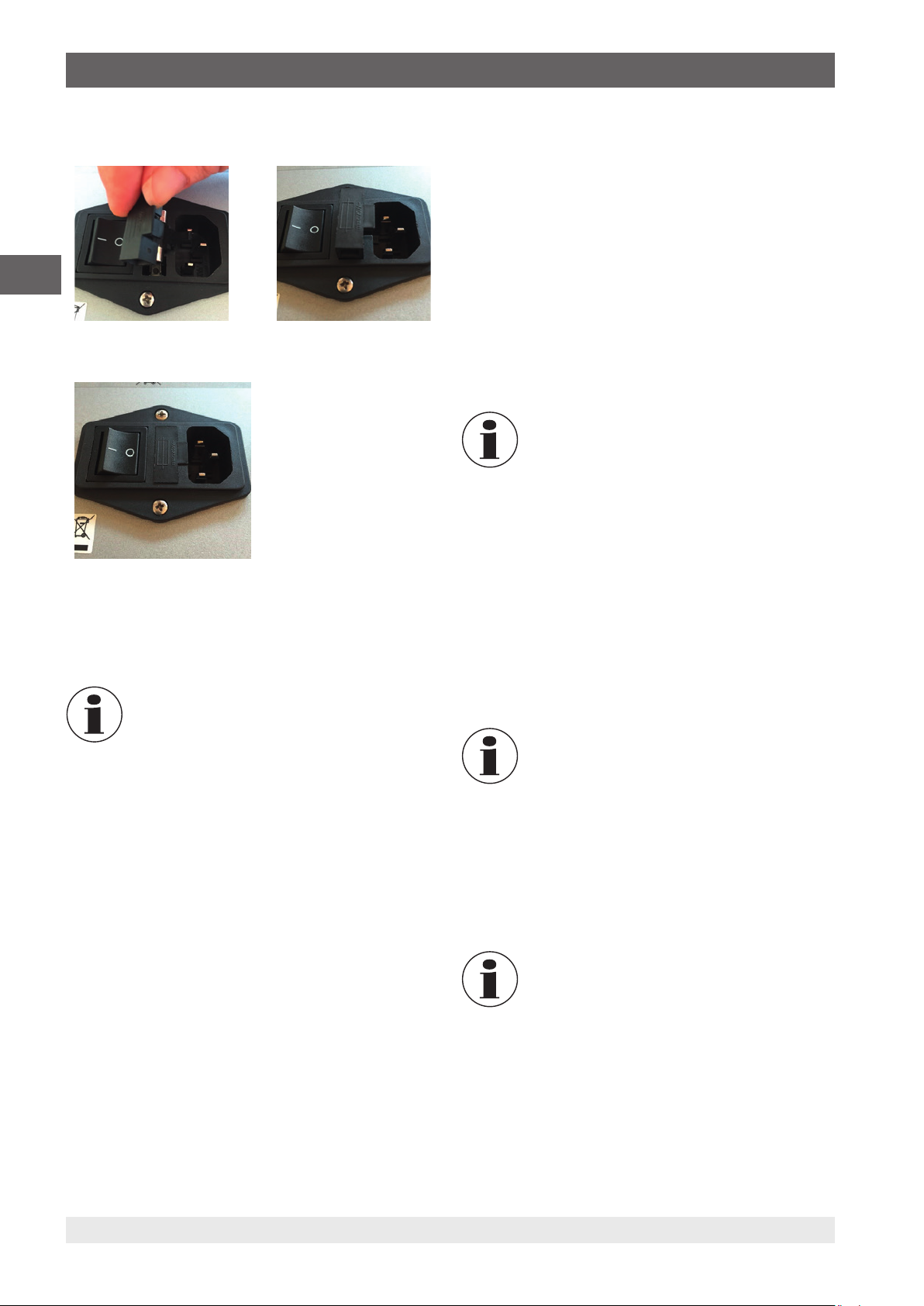

4.4 Voltage supply

13 14 15 16 17

Information about the calibrator

13

Main switch

14

Fuse

15

Power connection

16

RS-232 interface

17

For further information, see chapter 8 “Serial

communication”.

4.5 Fuse

The calibrators are fitted with the following fuses, in

accordance with the table:

Operating

voltage

AC 100 ... 240 V 2.5 A slow blow

AC 100/115 V - 6.3 A slow blow

AC 230 V - 3.15 A slow blow

Only use type F 5 x 20 mm fuses. All the

electrical components are found below the main

switch.

Changing of the fuse

1. Open the fuse container, using a screwdriver for example,

and pull it out.

CTD4000-140 CTD4000-375

CTD4000-650

-

fuse

fuse

fuse

EN

Voltage supply for CTD4000-140

The CTD4000-140 calibrator operates with an operating

voltage of AC 100 ... 240 V, 50/60 Hz.

Voltage supply for CTD4000-375 and CTD4000-650

The calibrator runs on a voltage of AC 230 V or AC 115 V,

50/60 Hz.

The calibrator automatically sets the supply voltage to a

voltage of AC 115 V or AC 230 V.

The instruments can be supplied with voltage of AC 115 V or

AC 230 V (50/60 Hz).

The fuse must be changed, if the supply voltage changes

from AC 230 V to AC 115 V.

Voltage Fuse

AC 230 V 3.15 A (factory delivery)

AC 115 V 6.3 A (included in standard scope of delivery, in

a bag)

For both calibrators, in total 4 fuses are included in the

standard scope of delivery. One is already built-in; the

remaining are placed in labelled plastic bags.

⇒

2. Remove the fuse from the clamp.

3. Place new fuse into the clamp.

14366831.01 05/2020 EN/DE

9WIKA operating instructions, model CTD4000

Page 12

4. Design and function

4. Insert the clamp into the fuse container.

⇒

EN

5. Press in the fuse container fully.

4.6 Heating resistance (CTD4000-375 or CTD4000-650)

The resistance is made from stainless steel; the max power

is 630 W and it can become very hot.

The use of the calibrator at continuous high

temperatures reduces the service life of the

resistor. Limit the number of hours at which the

resistance is used at maximum temperatures

to the time required by the calibrator in order to

prolong the life of the resistance.

4.8 Safety thermostat (CTD4000-375 or CTD4000-650)

The calibrator is fitted with a thermal fuse for the highest

temperature, which has a manual reset button. The thermal

fuse switches off the heating system as soon as there is an

error.

If Ht is showing on the display means, that the temperature

has exceeded the upper limit.

If Ht is on the display:

1. Cool the temperature calibrator

The temperature must fall to at least 60 ... 80 °C

⇒

[140 ... 176 °F] under the high set value (standard).

2. Switch off the calibrator then switch on again a few

second later.

The thermostat has been factory set to 660 °C

±10 °C [1,220 °F ±10 °F] with the CTD4000-650

and to 385 °C ±10 °C [725 °F ±10 °F] with the

CTD4000-375.

If the problem persists, disconnect the calibrator from the

voltage supply and rectify the possible fault.

4.9 Fan

A fan is installed in the calibrator. The fan works with two

different speeds: the control system switches on the fan

at minimum speed with increasing temperature, and at

maximum speed for decreasing the temperature. The fan

keeps the case of the calibrator at a low temperature when

the temperature increases and assist the cooling process.

Every hole at the bottom and at the back of

CTD4000 must be kept free in order to let the air

flow properly.

The equalising block has an opening of 26 mm into which

the inserts for almost any temperature probe size can be

inserted. The function of this block is to make the temperature

in the calibration zone uniform.

The bores are dependent on the temperature probes.

For further information, see 6.7 “Testing or calibrating

temperature probes”. Through this, any problems, which

might arise if the wrong tolerances are used, will be avoided.

4.7 Temperature sensors

The temperature sensor used for the reading and

thermoregulation is inserted directly into the equalising block

to display the real temperature value.

10 WIKA operating instructions, model CTD4000

4.10 Inserts

In order to achieve the greatest possible accuracy, the use of

exactly matched inserts is necessary. For this, the diameter

of the test item must be accurately determined. The bore for

the insert is obtained by adding approx. +1 mm [+0.04 in],

depending on the temperature range.

Following use, the inserts should be removed

using the replacement tools and then the insert

and block should be cleaned. This prevents the

sleeves becoming jammed in the heating block.

14366831.01 05/2020 EN/DE

Page 13

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the temperature dry-well calibrator for any damage

that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage

to property can occur.

▶

When unloading packed goods upon delivery

as well as during internal transport, proceed

carefully and observe the symbols on the

packaging.

▶

With internal transport, observe the

instructions in chapter 5.2 “Packaging and

storage”.

If the instrument is transported from a cold into a warm

environment, the formation of condensation may result

in instrument malfunction. Before putting it back into

operation, wait for the instrument temperature and the room

temperature to equalise.

5.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection

during transport (e.g. change in installation site, sending for

repair).

Permissible conditions at the place of storage:

■

Storage temperature: -10 ... +60 °C [14 ... 140 °F]

■

Humidity: 30 ... 95 % relative humidity (non-condensing)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down

hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

Store the temperature dry-well calibrator in its original

packaging in a location that fulfils the conditions listed above.

EN

6. Commissioning, operation

Personnel: Skilled personnel

Protective equipment: Protective gloves

Only use original parts (see chapter 13 “Accessories”).

WARNING!

Physical injuries and damage to property

and the environment caused by hazardous

media

Upon contact with hazardous media (e.g. with

flammable or toxic substances) and also harmful

media (e.g. corrosive, toxic, carcinogenic,

radioactive), there is a danger of physical injuries

and damage to property and the environment.

Should a failure occur, aggressive media and/

or with high temperature may be present at the

instrument.

▶

For these media, in addition to all standard

regulations, the appropriate existing codes or

regulations must also be followed.

▶

Wear the requisite protective equipment (see

chapter 3.5 “Personal protective equipment”").

6.1 Voltage supply

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct

danger to life.

▶

Only ever use the supplied power cord (see

chapter 4.4 “Voltage supply”).

▶

Ensure that the correct operating voltage is

present when doing this.

6.2 Use at high temperatures

WARNING!

Fire hazard!

The calibrator is suitable for operating at high

temperatures with the consequent danger of fire.

▶

Keep inflammable material away.

▶

Do not pour any liquids into the interior of the

block.

14366831.01 05/2020 EN/DE

11WIKA operating instructions, model CTD4000

Page 14

6. Commissioning, operation

6.3 First commissioning

To avoid any smell in the room it is better to switch on the

calibrator outside the room for the first time.

6.4 Operating position

The operating position of the temperature dry-well calibrator

is in the vertical orientation, since this guarantees an optimal

EN

temperature distribution in the metal block.

▶

Place the temperature dry-well calibrator on a clean and

even surface so that the fan on the bottom is not blocked

and sufficient fresh air can be drawn in.

Insufficient ventilation can lead to damage to

the calibrator. Therefore, make sure that there is

enough space around the temperature dry-well

calibrator and that the air can circulate.

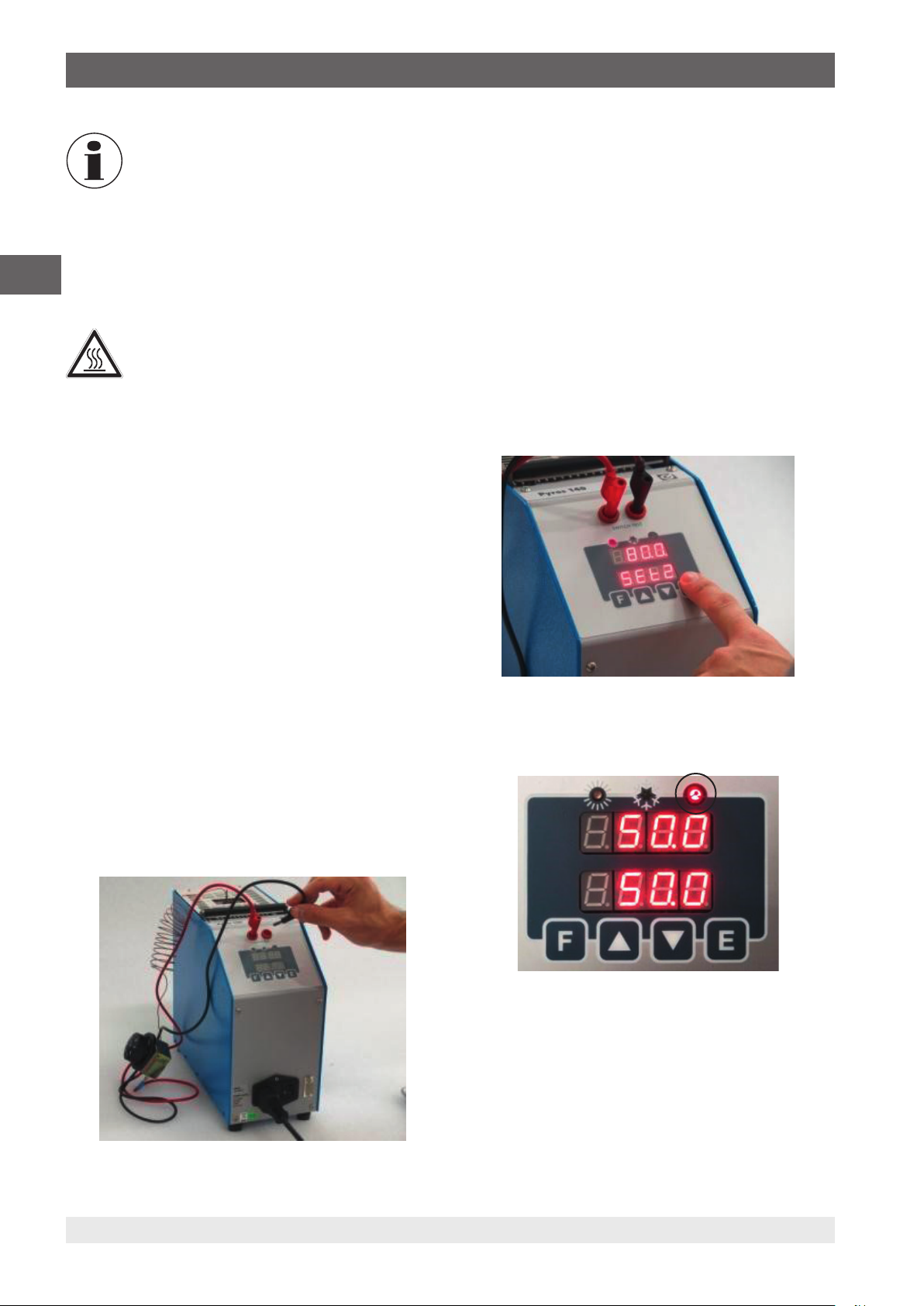

6.5 Switching on the calibrator

1. Connect to the mains using the mains connector supplied.

Ensure that the correct voltage is present when doing

⇒

this.

Make sure that the instrument has been correctly

⇒

grounded.

2. Switch on the mains switch.

The controller will be initialised. After approx. 5 secs, the

initialisation will be complete and the calibration mode will

automatically be displayed.

The lower display will show Stby.

6.6 Setting a set temperature

1. Insert the insert into the equalising block

Make sure that it does not get caught.

⇒

2. Insert the thermometer to be tested into the sleeve.

Here, also ensure that this doesn't get caught.

⇒

3. With the [▲] or [▼] button, enter the set point.

4. Confirm the entry with the [E] button.

The built-in heating or cooling elements will temper the metal

block automatically from room temperature to the controller's

set temperature.

If the temperature has stabilised, this will be shown by the

STABILITY-LED blinking in the lower right of display 1.

6.7 Testing or calibrating temperature probes

WARNING!

Risk of burns!

Touching the hot metal block or the test item can

lead to acute burns.

▶

During the use of the calibrator, do not touch

the upper grille, the inserts or temperature

probes because they may be very hot.

6.7.1 Testing of temperature probes

To test temperature probes, connect a separate temperature

measuring instrument to the test item. By comparing the

temperature displayed on the external measuring instrument

with the reference temperature, there is evidence of the

status of the test item. Here, pay attention to the fact that the

test item requires a short time until it reaches the temperature

of the metal block.

At the end of the test, DO NOT remove the probe while it is

still at high temperature. First. cool the calibrator while the

probes are still inserted, see chapter 6.9 “Cooling down the

metal block”.

Before returning the calibrator to its case make sure that,

the temperature of the block is almost the same as ambient

temperature.

6.7.2 Calibrating temperature probes

Calibrations with a temperature dry-well calibrator can be

performed with the internal reference of the calibrator. Should

a better accuracy need to be achieved, working with an

external reference is required. With the second option the

external reference and the test item should be located on the

same height and near together.

6.7.3 Positioning the temperature probe

Insert the temperature probe, together with the matching

insert, into the temperature dry-well calibrator.

The insert is manufactured from aluminium or brass and has

one or more holes so that a large number of temperature

probes can be calibrated in this insert. This insert has the

function of distributing the temperature evenly.

It is therefore also possible to calibrate temperature probes

with different lengths so long as the depth of the holes has

been adjusted.

▶

After setting up the calibrator, insert the insert carefully

into the holder.

Ensure that no dirt or other foreign materials can get

⇒

between the block and the insert.

12 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 15

6. Commissioning, operation

The insert replacement tool is a curved pair of pliers that can

be hooked into the holes provided in the top of the insert. The

insert must be aligned in such a way, so that the grooves sit

directly over the controlling and monitoring thermometers.

In order to achieve the best result from the calibration, the

following points must be observed:

■

Diameter of the temperature probe being checked

■

The bore diameter of the insert should be larger than the

that of the temperature probe to be calibrated

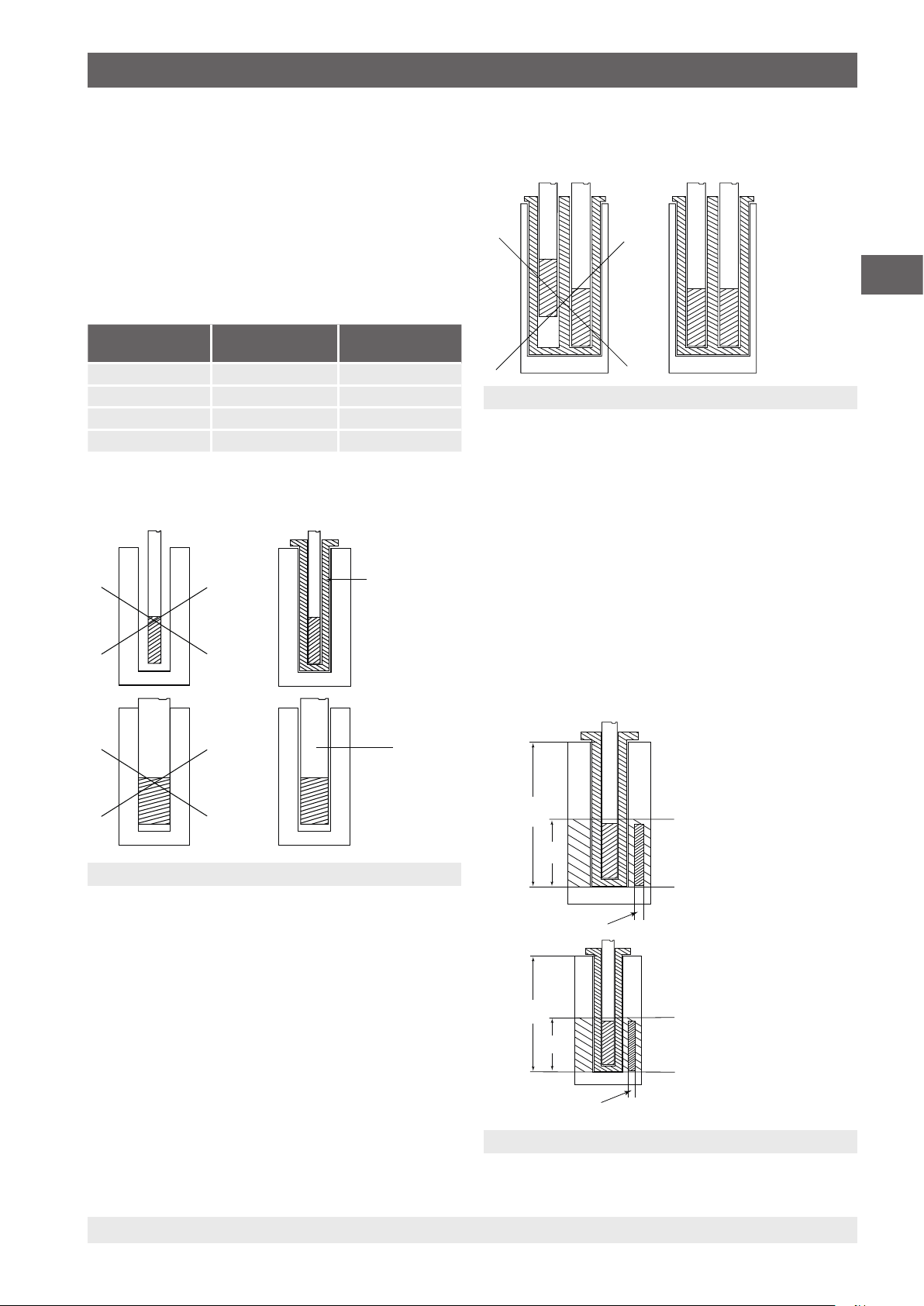

Max.

temperature

600 °C 4.5 ... 8 mm 0.5 mm

600 °C 8 ... 12 mm 0.7 mm

600 °C 12 ... 17 mm 1 mm

< 300 °C 4.5 ... 14 mm 0.3 mm

If this is not possible, use reducing blocks with the abovementioned tolerances (see figure 1).

Probe diameter Tolerances of

No

the bores

Reducing

block

Yes

The sensitive element of the temperature probe is oriented

optimally when it sits on the bottom (see figure 2).

YesNo

Figure 2

6.7.4 Calibration with one reference

If the length of the temperature probe is shorter than the

depth of the bore, then the reference should also be placed

at the height of the test item.

Further preconditions for the calibration of references:

■

The maximum temperature of the temperature probe

should be higher than the temperature of the calibrator,

otherwise the temperature probe could be destroyed.

■

Insert the test item into the insert before reaching the

target temperature, otherwise instabilities and sensor

break could result.

■

Both temperature probes must be as close to each other

as possible (see figure 3).

EN

> 0.5

No

Figure 1

▶

Avoid using bores which are too accurate and do not

press the temperature probes into the block.

▶

Clean the block and the insert before use.

▶

Only insert the temperature probe or the insert into the

block at ambient temperature using the insert replacement

tool.

14366831.01 05/2020 EN/DE

Yes

190

40

Reference probe

140

90

Reference probe

Figure 3

Calibration zone

Calibration zone

13WIKA operating instructions, model CTD4000

Page 16

6. Commissioning, operation

The temperature difference is proportional to the

diameter of the test item and the diameter of the

bore in the insert.

The time the probes take to reach the set point is

much higher as the difference in diameter from

the probes and the holes is bigger.

EN

6.7.5 After the test or the calibration

WARNING!

Risk of burns!

High temperatures can lead to acute burns.

At the end of the calibration, do not pulled out

the temperature probe from the calibrator at high

temperatures.

▶

Cool down the calibrator, including the

temperature probe, so that thermal shock

is prevented, as described in chapter 6.9

“Cooling down the metal block”.

▶

Before the calibrator is switched off, check

whether the temperature is almost the same

as the ambient temperature.

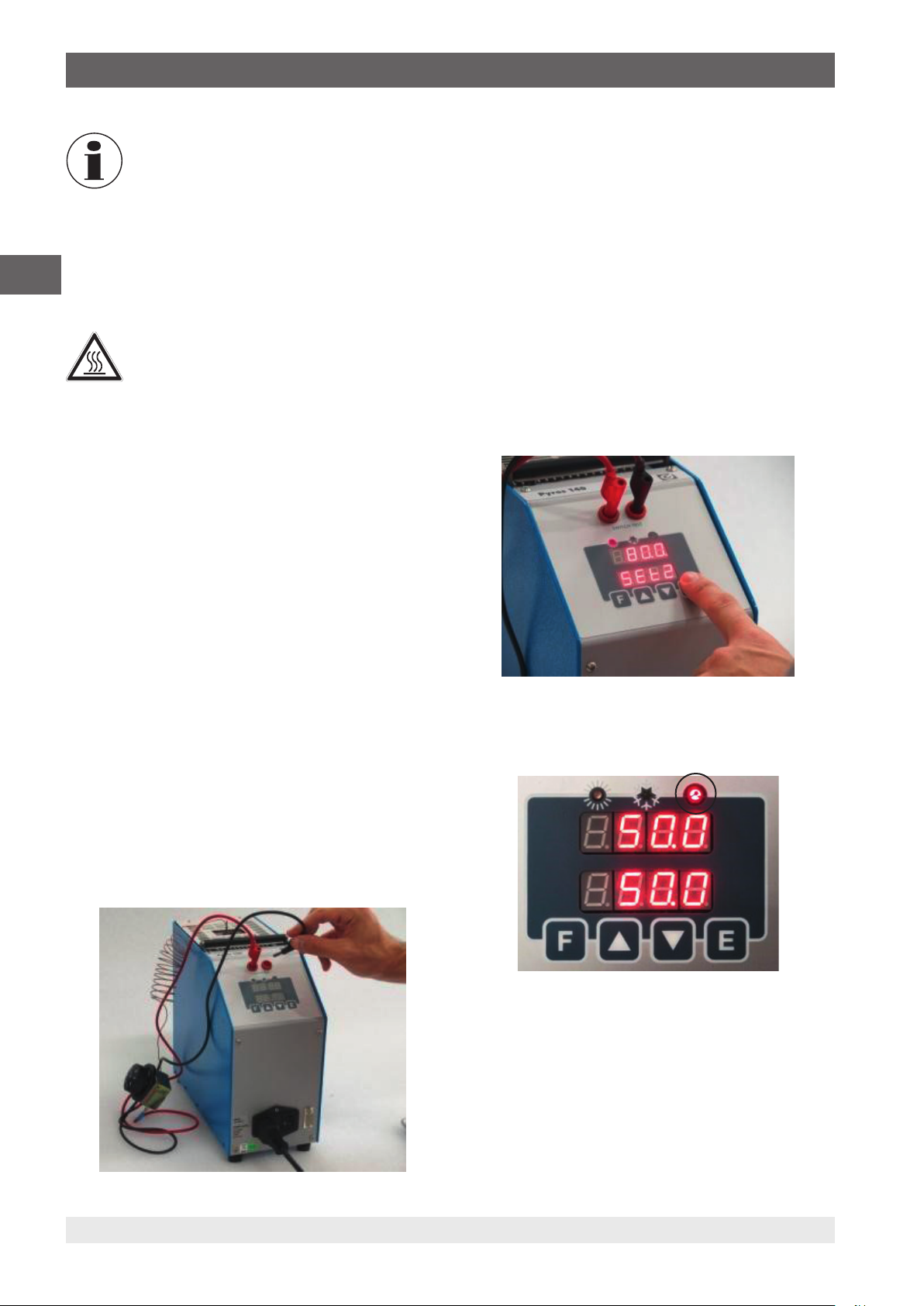

3. Switch on instrument.

4. With the [▲] or [▼] button, enter the set point, which

corresponds to T

5. Confirm the entry with the [E] button.

6. With the [F] button, select the function SEt2.

7. With the [▲] or [▼] button, enter the set point T

8. Confirm the entry with the [E] button.

The temperature of the thermostat switch should be

⇒

between T

9. With the [F] button, call the Grd (degrees per minute)

function.

10. With the [▲] or [▼] button, enter the value for the heating

rate of change.

Low values are preferable for a more accurate test

⇒

(e.g. values less than 1 °C per minute).

11. Confirm the entry with the [E] button.

min

.

min

and T

max

.

max

.

1. With the [▲] or [▼] button, enter the room temperature.

2. Confirm the entry with the [E] button.

Remove the insert from the calibrator after the use. Humidity

may cause verdigris to build up on the inside of the insert

within the metal block

In this case, the insert can become stuck.

⇒

6.8 Switch test function

With the "SWITCH TEST" function, it is possible to control

the open and close temperature of the thermostat:

1. Insert the thermostat sensor into a suitable bore in the

insert.

2. Connect the thermostat to the switch test input.

The switch test LED will indicate the status of the switch:

The LED is lit = LED ON with switch closed

14 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 17

6. Commissioning, operation

The LED isn't lit = LED OFF with switch open

1. With the [F] button, select the function run.

2. With the [▲] or [▼] button, set to ON.

■

By entering run OFF, the switch test is ended.

6.9 Cooling down the metal block

WARNING!

Risk of burns!

High temperatures at the metal block or at the

temperature probe can lead to acute burns.

▶

Before transporting or touching the metal

block and/or calibration instruments, make

sure that they have cooled down sufficiently.

▶

In order that the calibration instruments can

be brought quickly from a higher to a lower

temperature, set the set temperature to a

lower temperature (e.g. room temperature).

▶

In order to cool down the metal block, set the

set temperature to a low temperature, e.g.

room temperature.

EN

When the LED in this function flashes, this indicates that the

process is active.

■

The thermostat’s release values are recorded in the

parameters SOn and SOFF.

■

Temperature runs between T

function is switched off. The SOn and SOFF values are

continuously updated during each run.

max

and T

until the

min

1. With the [▲] or [▼] button, enter the room temperature.

2. Confirm the entry with the [E] button.

The installed fan gently and automatically switches to a

higher speed thus providing more cooling air.

After switching off or removing the mains

connection, no cooling air will be provided by

the built-in ventilator. If the voltage supply is

interrupted during the cooling process, sufficient

thermal decoupling is still guaranteed between

the metal block and the case.

14366831.01 05/2020 EN/DE

15WIKA operating instructions, model CTD4000

Page 18

7. Operating the calibrator

7. Operating the calibrator

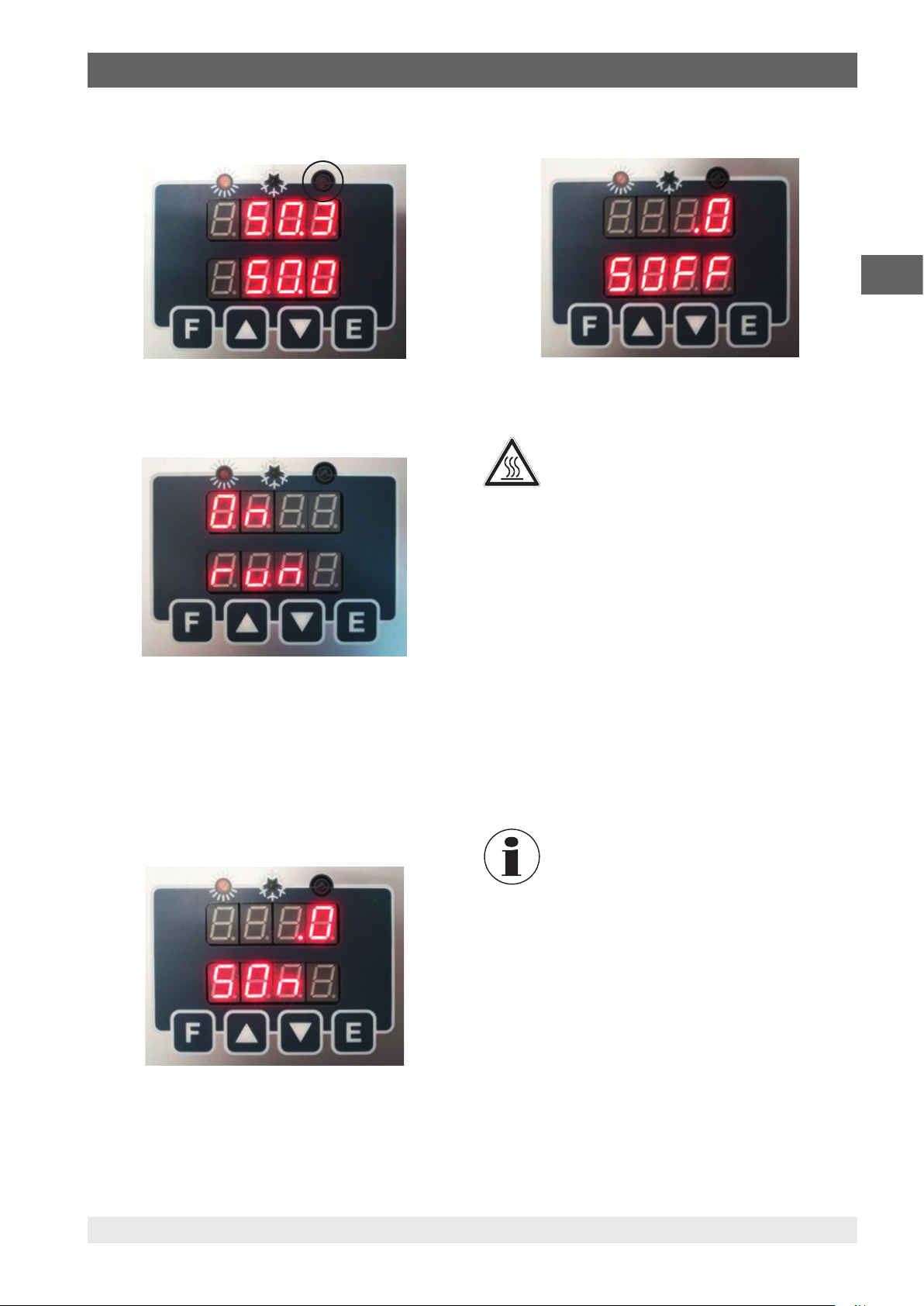

7.1 Setting a temporary set temperature (set-point

mode)

Setting the set temperature:

■

Pressing the [▲] button increases the set point.

■

Pressing the [▼] button lowers the set point.

■

EN

The button [E] confirms the entry.

Before each calibration, you must wait until a stable set point

is reached.

7.2 Programming (main menu)

All the settings can be carried out in this menu structure.

1. Press button [F].

This opens the main menu.

⇒

2. With the button [F] select the desired entry in the main

menu (see overview).

3. Confirm the entry with the [E] button.

7.3 Short description of the menu

The calibrator has four menu levels:

■

First menu level: General settings

■

Second menu level: Settings for optimising the control

■

Third menu level: Recalibration of the instrument

■

Fourth menu level: Settings of the temperature controller

16 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 19

7. Operating the calibrator

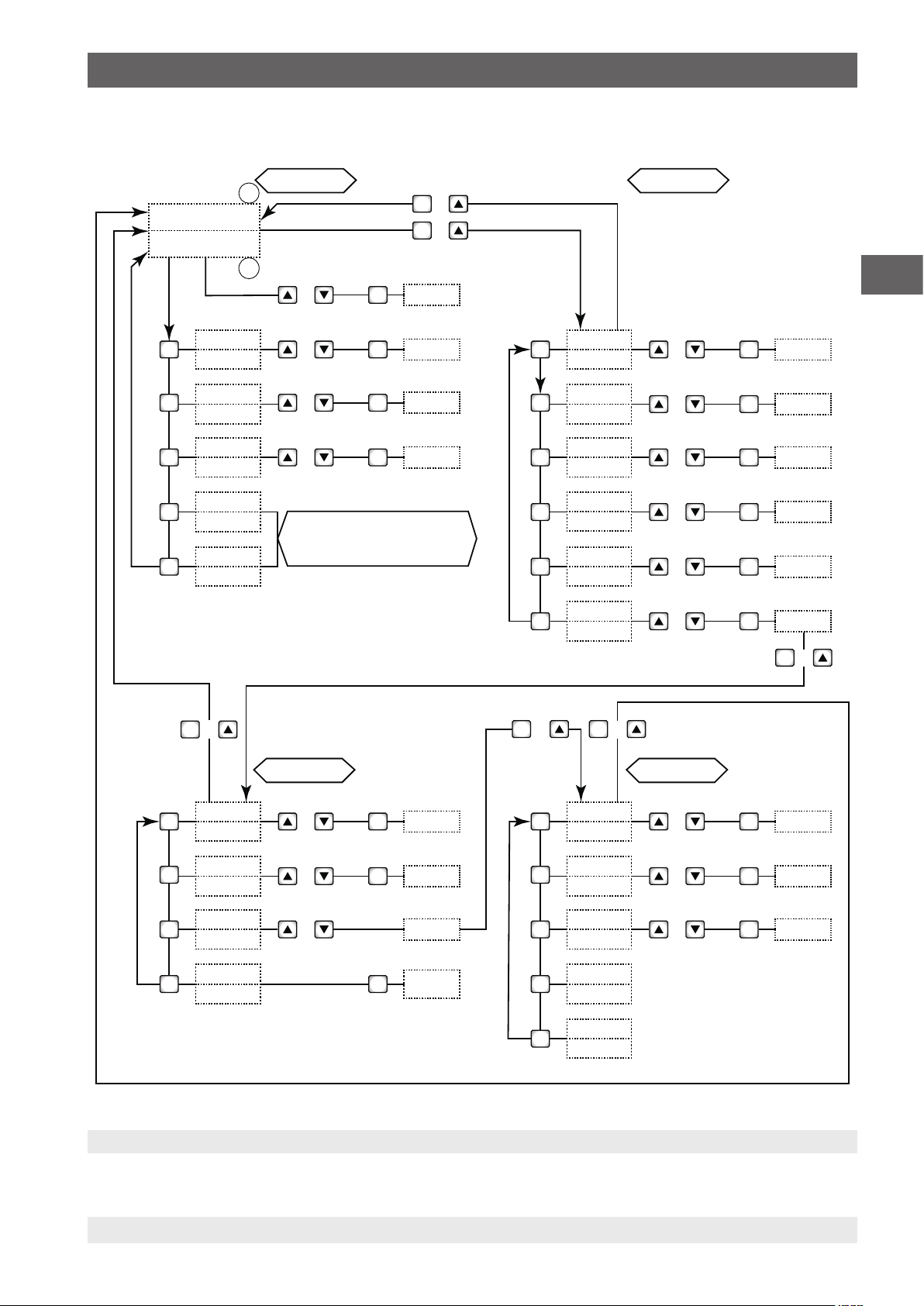

7.3.1 Menu structure, parameter levels

LEVEL 1 LEVEL 2

1

TEMPERATURE VALUE

SET POINT

2

or

E

+

F

+

F

NEW VALUE

EN

VALUE

F

F

F

F

F

F

SEt2

VALUE

Grd

VALUE

run

VALUE

SOn

VALUE

SOFF

+

or

or

or

CLOSING THERMOSTAT

TEMPERATURE

(IF CONNECTED)

E

E

E

NEW VALUE

NEW VALUE

NEW VALUE

F

VALUE

F

F

F

F

F

F

+

Pb

VALUE

td

VALUE

ti

VALUE

dEG

VALUE

dEF

VALUE

CodE

F

+

or

or

or

or

or

or

E

E

E

E

E

E

NEW VALUE

NEW VALUE

NEW VALUE

NEW VALUE

NEW VALUE

Code = 2

+

F

LEVEL 3 LEVEL 4

F

F

F

F

Menu structure

14366831.01 05/2020 EN/DE

VALUE

Pc

VALUE

SEtH

VALUE

CodE

clt

tbl

or

or

or

E

E

E

NEW VALUE

NEW VALUE

Code = 3

Clearing

Table

VALUE

F

F

F

F

F

tSEt

VALUE

Hy

VALUE

Stby

VALUE

Cod1

VALUE

Cod2

or

or

or

E

E

E

NEW VALUE

NEW VALUE

on / off

17WIKA operating instructions, model CTD4000

Page 20

7. Operating the calibrator

7.3.2 First menu level - General settings

▶

By pressing the [F] button, menu level 1 is accessed.

▶

With the [F] button, the menu functions can be scrolled through.

Function Meaning

SP Set point

Setting the set temperature.

EN

SEt2 Set point 2

Grd Gradient

1. With the [▲] or [▼] button, set the set point.

2. Confirm the entry with the [E] button.

Setting of set temperature 2, which the calibrator should approach with a certain gradient within a ramp.

1. With the [▲] or [▼] button, set the set point 2.

2. Confirm the entry with the [E] button.

The value of SEt2 must be always higher than SP.

Heating or cooling change rate during the change of the temperature value SP to SEt2 or SEt2 to SP.

1. With the [▲] or [▼] button, set the gradient.

2. Confirm the entry with the [E] button.

The gradient must be smaller than the maximum specified value in the technical specifications (max.

15 °C/min).

run Switch test

1. With the [▲] or [▼] button, select ON or OFF.

2. With the [E] button, start or stop the switch test.

The temperature dry-well calibrator reaches temperature SP2 from SP with the selected heating rate of

change. The basis is the same temperature with which the ramp was confirmed. If the value of SP2 is lower

than the SP, the calibrator will not accept the run and the instrument will display “Err”. The LED will flash to

indicate that the function is active. The set point will change the value following the selected slope rate. When

the internal temperature reaches the SEt2 set point, the internal temperature will decrease with the cooling

slope rate; the SP value will be considered as the new set point. During the ramp program, the derivative

parameter will not be considered. During the ramp program, the LED on the right of the set point flashes and

the set point increases or decreases the value.

18 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 21

7. Operating the calibrator

Function Meaning

Example for a ramp program

A thermostat with an expected switch range between 120 and 100 °C will be tested.

SP = 100 °C; SP2 = 120 °C; gradient = 2 °C/min.

1. With the [▲] or [▼] button, set SP to 100 °C.

2. Confirm the entry with the [E] button.

3. Press button [F].

4. With the [▲] or [▼] button, set SP2 to 120 °C.

5. Confirm the entry with the [E] button.

6. Press button [F].

7. With the [▲] or [▼] button, set GRD to 2 °C/min.

8. Confirm the entry with the [E] button.

9. Press button [F].

10. With the [▲] or [▼] button, set run to ON.

11. Confirm the entry with the [E] button.

After pressing the [E] button to confirm the start of the ramp, the oven temperature will ascend with the

⇒

heating slope rate. The temperature oscillates between 100 and 120 °C until run OFF is selected. Of

course, there will be some oscillations at the beginning since the ramp slope will not be suitable, but

these only last a short time and then the oven temperature will follow the ramp’s set point.

SOn Switch on

Displays the temperature at which the temperature switch contact closes.

Displays the temperature at which the thermostat would be connected to the terminals.

“SWITCH TEST” has been closed.

SOFF Switch off

Displays the temperature at which the temperature switch opens.

Displays the temperature at which the thermostat would be connected to the terminals.

“SWITCH TEST” has been opened.

The values of SOn and SOFF will change at each loop or each time you select “run OFF”.

EN

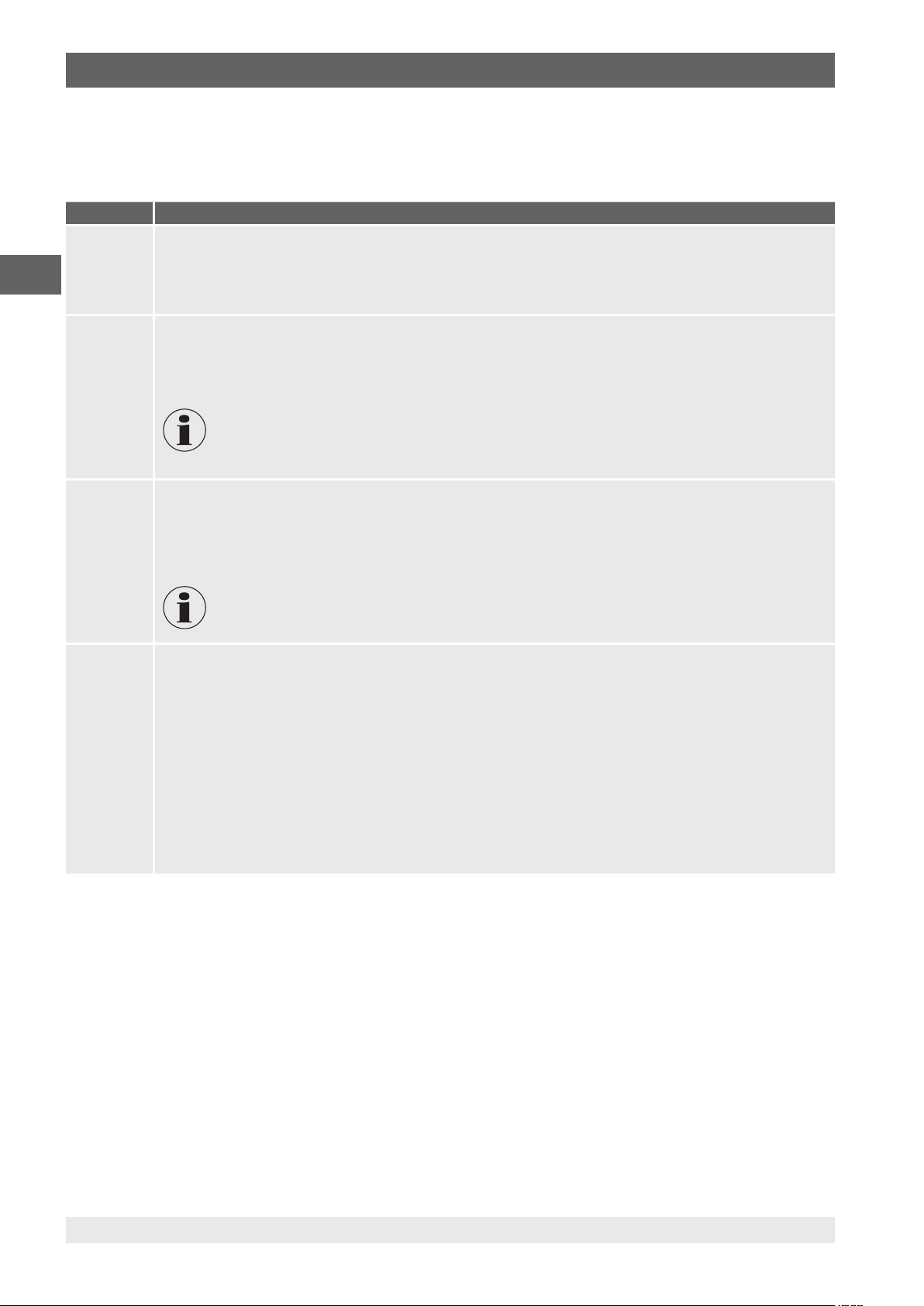

7.3.3 Second menu level - Settings for optimising the control

▶

By pressing the [F] and [▲] buttons at the same time, the 2nd level menu is accessed.

▶

With the [F] button, the menu functions can be scrolled through.

▶

By pressing the [F] and [▲] buttons at the same time or waiting for 20 seconds, you return to the main menu.

Function Meaning

Pb Value of the Proportional band in percentage of the end value.

1. With the [▲] or [▼] button, set the proportional band.

2. Confirm the entry with the [E] button.

Proportional band means the length of time in the measurement field within which there is the variation of the

regulation probe output alarm and therefore the adjustment of the heating element power.

td Derivative time in seconds

1. With the [▲] or [▼] button, set the derivative time in seconds.

2. Confirm the entry with the [E] button.

When there is a step variation of temperature, the derivative action induces a greater initial adjustment, so that

the oven will have a greater power than it usually has due to the proportional and integral action only. Since

the error persists, the derivative action reduces the impact giving the integral action the task of reducing the

error.

14366831.01 05/2020 EN/DE

19WIKA operating instructions, model CTD4000

Page 22

7. Operating the calibrator

Function Meaning

ti Integral time in seconds

1. With the [▲] or [▼] button, set the integral term in seconds.

2. Confirm the entry with the [E] button.

The integral action eliminates the error between the selected set point and the temperature reached through

EN

dEG Selection of the unit in which the temperature should be shown on the display.

dEF Factory setting (default parameters)

the proportional action alone. Integral time means the length of time the integral action needs to double the

proportional term, where the default parameters will be maintained.

1. With the [▲] or [▼] button, select the unit.

The selection is between °C and °F

⇒

2. Press the [E] button to accept the unit.

The controller can be operated with factory-set or customer specific control parameters for P.B./T.I./T.D..

■

OFF = customer-specific control parameter

■

ON = factory setting

The controller has been tuned optimally in the factory. For any other requirements, please contact

WIKA directly.

By selecting the “OFF” parameter and confirming with the [E] button, the setting parameters can be changed,

which then remain active even if the calibrator is turned off. By selecting the “ON” button (followed by

confirmation by pressing the [E] button) the setting values will be set to the factory default ones specified by

the manufacturer, and these can no longer be changed. By switching the calibrator off, the parameter will set

to OFF, but the factory default parameters will be maintained.

CodE Access code for the functions in the third menu level (default = 2)

1. With the [▲] or [▼] buttons, input the password (default = 2).

2. Press the [F] and [▲] buttons at the same time.

The third menu level will be accessed.

⇒

The access code in the fourth menu level, is changed via the serial interface in the parameter

"Cod1".

If the access code is lost, this can be read via register 13.

7.3.4 Third menu level - Recalibration of the instrument

▶

Via the second menu level and the "CodE" function, one can access the third menu level.

▶

With the [F] button, the menu functions can be scrolled through.

▶

By pressing the [F] and [▲] buttons at the same time or waiting for 20 seconds, you return to the main menu.

Function Meaning

Pc Calibration point

1. With the [▲] or [▼] button, set the value read with the standard thermometer.

2. Confirm the entry with the [E] button.

SetH Maximum temperature setting of the set point

(not adjustable)

20 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 23

7. Operating the calibrator

Function Meaning

CodE Access code for the functions in the fourth menu level (default = 3)

1. With the [▲] or [▼] buttons, input the password (default = 3).

2. Press the [F] and [▲] buttons at the same time.

The fourth menu level will be accessed.

⇒

The access code in the fourth menu level, is changed via the serial interface in the parameter

"Cod2".

If the access code is lost, this can be read via register 20.

Tbl Clearing of the calibration table

In the display Clr will be shown.

▶

With the [E] button, delete the calibration points entered with the Pc function.

7.3.5 Fourth menu level - Settings of the temperature controller

▶

Via the third menu level and the "CodE" function, one can access the fourth menu level.

▶

With the [F] button, the menu functions can be scrolled through.

▶

By pressing the [F] and [▲] buttons at the same time or waiting for 20 seconds, you return to the main menu.

Function Meaning

tSET Set point of the temperature controller

1. With the [▲] or [▼] button, set the set point.

2. Confirm the entry with the [E] button.

The value has been preset by the manufacturer.

EN

Hy Hysteresis of the temperature controller

1. With the [▲] or [▼] button, set the hysteresis.

2. Confirm the entry with the [E] button.

The value has been preset by the manufacturer.

Stby Initial delay time

If the value “OFF” is set in commissioning, the calibrator immediately calls up the last set point selected

prior to turning off. If the value “ON” is set in commissioning, the calibrator enters the waiting setting and

SP flashes. It is necessary to press any button in order to move it from the waiting position and to choose

the desired set point.

Cod1 Access code for the third menu level

(default = 2)

Cod1 can only be changed over the serial interface.

Cod2 Access code for the fourth menu level

(default = 3)

Cod2 can only be changed over the serial interface.

14366831.01 05/2020 EN/DE

21WIKA operating instructions, model CTD4000

Page 24

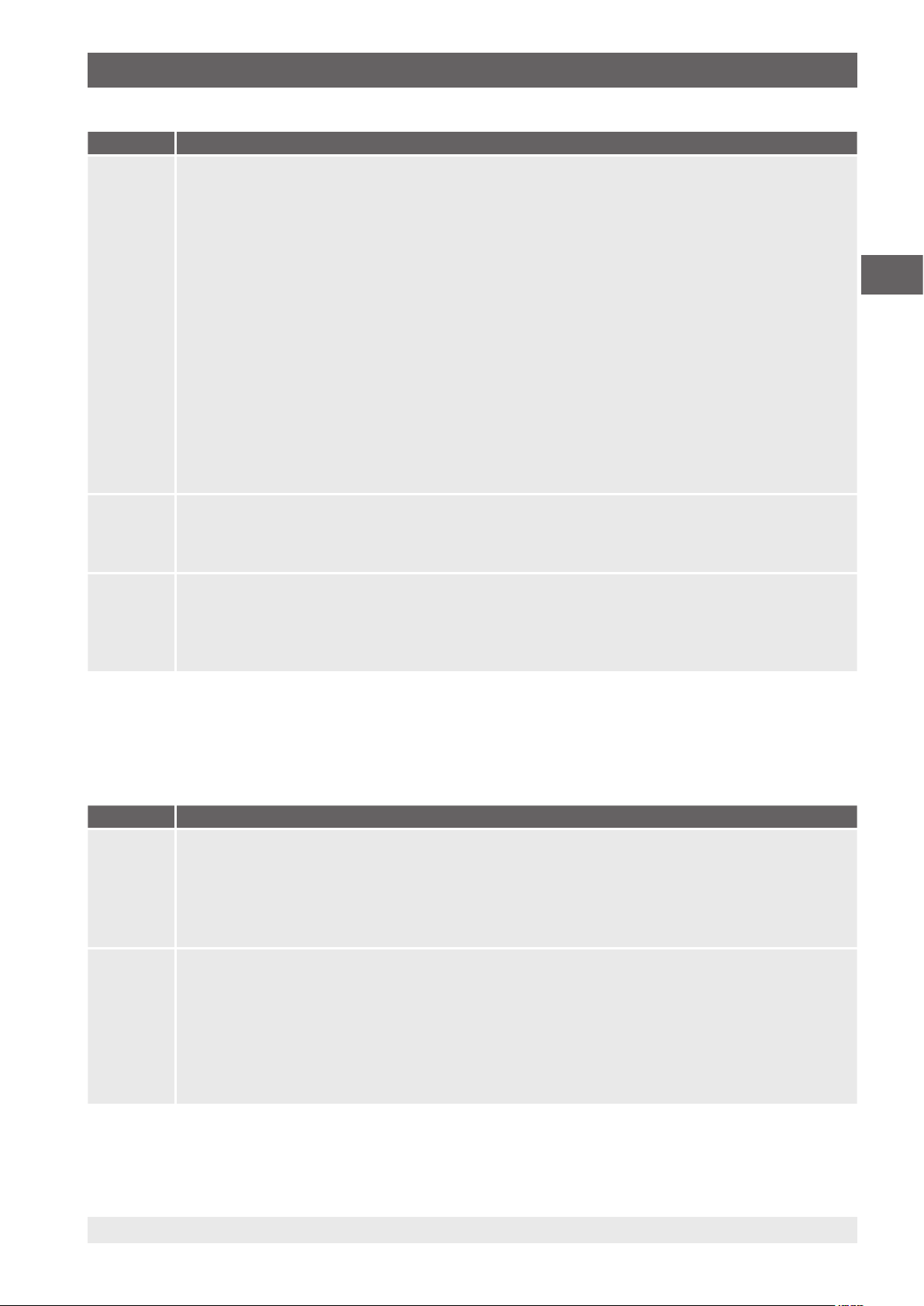

8. Serial communication

8. Serial communication

On the front of the calibrator there is a 9-pole socket

connected to the temperature controller, which enables the

calibrator to be completely controlled by a PC (see figure) by

the RS-232 input.

EN

4

21

6

5

3

7

8 9

Rx

Tx

Pin assignment, front view

The external PC must comply with the IEC 950

standard.

▶

After switching the calibrator on and connecting the serial

interface, wait until the system has booted up.

▶

To activate the serial communication, press the [E] button

on the display.

General characteristics

Baud rate 9600

N. Bit 8

Parity No

Stop bit 1

The communication operates in half-duplex format which

means that transmission and reception cannot happen

simultaneously.

The controller replies only after receiving a command; it

never replies by itself.

Variable Designation Parameters

Adjustable Readable

7 Derivative time in

seconds

10 Units 0 = °C

13 Cod1 (access key)

2 = preset

14 Baud rate

9600 (preset)

15 Address

16 Serial number

19 Min. set point -

20 Cod2

3 = preset

21 Delay ON

22 Switch-on temperature -

23 Switch-off temperature -

24 Firmware version -

27 Internal sensor type - 0 = Pt100

28 Stability range -

29 Stability symbol - 0 = no

31 Alarm setting -

33 Offset of ambient

temperature

xxx

1 = °F

- 2400

- 3

OFF

-

0 = °C

1 = °F

4800

9600

19200

2 = type K

1 = yes

Each commands string is ASCII character succession.

First is $ character; the next must indicate the instrument

address (default 1) and then is the command (4 characters).

The command and reply are ASCII character strings, as

detailed below. The communication program will be able

to convert ASCII to decimal to extract numeric values. The

default address is 1.

8.1 List of the variables and parameters

Possibility

RVAR = Data reading

WVAR = Data writing

The final part of string depends on the type of command. The

character <cr> concludes the sequence.

Variable Designation Parameters

Adjustable Readable

0 Set point x ... 9999

1 Ramp 1 = On

0 = Off

2 Set point 2 x ... 9999

3 Gradient x ... 9999

5 Proportional band 0 ... 100 %

6 Integral time in seconds xxx

1 = On

0 = Off

22 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 25

8. Serial communication

8.2 Data reading

For reading, use the command RVAR.

Example:

Read the current set point (variable 0):

The command string is $1RVAR0_<cr>

Meaning of the command character string

$ = Start of message

1 = Instrument address

RVAR = Read command

0 = Number of the variable to read (see table)

_ = Space

<cr> = End of message

Response (example for 110.0 °C/°F)

The response string is: *1_110.0

The character <cr> concludes the message.

Meaning of the response character string

* = Start of the response

1 = Instrument address

_ = Space

110.0 = Numerical value of data with the character [.]

in order to separate the decimal part of the

number

<cr> = End of message

The response does not include the measure unit. To read the

unit read the variable 10:

The command string is $1RVAR10_<cr>

The response string is *1_0 for °C

The response string is *1_1 for °F

At reception of the command, the answer of the instrument is:

*1<cr>

This string shows the recognition of the command.

If the unit of the temperature is not °C, the

variable 10 for "Units" must first be set to "0".

EN

The command string for this is: $1WVAR10_0<cr>

Integers as variables

We have just shown the procedure for the writing of a float

data.

The variables 1 and 10 have two or more states (for example,

the unit) and to activate them it is necessary to assign these

variables the number corresponding to the one which should

be set, according to the table indicated below:

Variable Designation Parameters

1 Ramp 1 = ON 0 = OFF

10 Units 0 = °C 1 = °F

Example

The variable 1 corresponds to the activation of the ramp. If

you want to set it to ON in order to activate the ramp, you

should assign the value 0, otherwise the value 1.

The command string is: $1WVAR1_1<cr>

Do likewise for the other variables.

8.3 Data writing (FLOAT VARIABLES)

For reading, use the command WVAR.

Example:

Writing the set point to 132.4 °C (variable 0):

If the unit of the temperature is already °C, it is

sufficient to write the set point

The command string is: $1WVAR0_132.4<cr>

Meaning of the command character string

$ = Start of message

1 = Instrument address

WVAR = Writing command

0 = Number of the settable variable (see table)

_ = Space

132.4 = Numerical value of data with the character [.]

in order to separate the decimal part of the

number

<cr> = End of message

14366831.01 05/2020 EN/DE

23WIKA operating instructions, model CTD4000

Page 26

9. Faults

9. Faults

Personnel: Skilled personnel

Protective equipment: Protective gloves

For contact details see chapter 1 “General

information” or the back page of the operating

EN

instructions.

WARNING!

Physical injuries and damage to property

and the environment caused by high

temperatures

In the event of a defect, extreme temperatures

can be present at the instrument.

▶

Wear the requisite protective equipment.

Error Causes Measures

No function

The calibrator does not respond

when the power cord is

connected and the switch is on.

The fuse tripped as the

instrument was switched on

The voltage supply is not established correctly Check voltage supply

The fuse is defective Replacing the fuse

The power cord is defective Replace the power cord with an equivalent

The main switch is faulty Send in for repair

The fuse is wrong Check that the proper fuse is inserted for

CAUTION!

Physical injuries and damage to property

and the environment

If faults cannot be eliminated by means of the

listed measures, the instrument must be taken

out of operation immediately.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the

instructions given in chapter 11.2 “Return”.

the supply voltage and replace the fuse, if

necessary.

The main switch is faulty Send in for repair

Short-circuit in the heating element

Final temperature is not reached The solid-state relay or the heating element is

faulty

The overtemperature switch has tripped

The display is working properly

but the temperature does not

increase and the calibrator

displays error code Ht.

The display is working properly

but the temperature does not

increase and the calibrator

indicate Err after few seconds.

The display shows a different

temperature than is present in the

block

The temperature exceeds the set

point

The calibrator is barely cooling

down

The safety thermostat has been triggered for

over temperature

The heater is faulty Press any button to see if restore the heating.

The temperature controller is faulty Replace the temperature controller

The internal probe is not calibrated Return the temperature dry-well calibrator for

The controller is defective Send in for repair

The control circuit board is defective Send in for repair

The controller is defective Send in for repair

Fan is defective

Send in for repair

Verify the set point of the safety thermostat Set:

Ref to the level 4 of the menu.

Send in for repair

calibration

810 or 786 appears on the display. Internal probe is faulty Send in for repair

24 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 27

10. Maintenance, cleaning and recalibration

10. Maintenance, cleaning and recalibration

Personnel: Skilled personnel

Protective equipment: Protective gloves

For contact details see chapter 1 “General

information” or the back page of the operating

instructions.

10.1 Maintenance

The instrument described here is maintenance-free.

Repairs must only be carried out by the manufacturer.

This does not apply to the fuse replacement (see chapter

4.5 “Fuse”).

Before replacing the fuse, disconnect the

temperature dry-well calibrator by unplugging the

power cord from the mains socket.

Only use original parts (see chapter 13 “Accessories”).

10.2 Cleaning

CAUTION!

Physical injuries and damage to property

and the environment

Improper cleaning may lead to physical injuries

and damage to property and the environment.

Residual media in the instrument can result in a

risk to persons, the environment and equipment.

▶

Wear the requisite protective equipment.

▶

Carry out the cleaning process as described

below.

▶

Clean the calibrator only when it is cold.

1. Cool down the temperature dry-well calibrator as

described in chapter 6.9 “Cooling down the metal block”.

2. Before cleaning the temperature dry-well calibrator, switch

it off and isolate it by unplugging the power cord from the

mains socket.

3. Clean the instrument with a moist cloth.

Electrical connections must not come into contact with

moisture.

CAUTION!

Damage to the instrument

Improper cleaning may lead to damage to the

instrument!

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects for

cleaning.

Cleaning calibrators with inserts

With calibrators with inserts, during operation, a small

amount of abrasion dust can cause the block and the insert

to become jammed. To prevent this, on a regular basis and

before any long period out of use, remove the insert from

the calibrator heating block. Blow out heating block bores

with compressed air and clean the bore and insert with a dry

cloth.

Liquid or oil inside the block lead to oxides

or verdigris on the insert with use at high

temperature. In this case, the insert could

become stuck.

Liquid which may penetrate the calibrator can

cause damage or lead to the build-up of toxic

fumes.

Cleaning of the fan grille

On the base of each calibrator is a dense air grille, through

which the cooling air is supplied to the calibrator. Depending

on the cleanliness of the air, clean the grille at regular

intervals by vacuuming or brushing.

External cleaning

Clean the outside of the instrument with a damp cloth and

some water, or with a solvent-free light detergent.

10.3 Recalibration

DKD/DAkkS certificate - official certificates:

The temperature dry-well calibrator has been adjusted and

tested before delivery using measuring devices that are

traceable to nationally recognised standards.

On the basis of DIN ISO 10012, the temperature dry-well

calibrator, depending on the application, should be verified at

appropriate periodic intervals.

We recommend that the instrument is regularly recalibrated

by the manufacturer, with time intervals of approx. 12 months

or approximately 500 hours of operation.

The basic settings will be corrected if necessary.

The basis of the recalibration is the guidelines of the German

Calibration Service, DKD R5-4. The measures described

here should be used and followed for recalibration.

EN

4. Clean the instrument, in order to protect persons and the

environment from damage through residual media.

14366831.01 05/2020 EN/DE

25WIKA operating instructions, model CTD4000

Page 28

10. Maintenance, cleaning and recalibration

10.3.1 Calibration of the internal probe by the user

By calibrating yourself, the parameters of the

internal reference probe are re-determined or

adjusted. The accuracy is thus dependent upon

the reference used.

WIKA can thus no longer guarantee the

EN

Calibration can be carried out directly on the keyboard of the

instrument. The calibration is done by adjusting the internal

probe at one or more points of the range using a standard

thermometer.

The calibration is possible only by setting the temperature

unit to “°C”.

The purpose of recalibration is to correct the error between

the temperature indicated and the value of a standard

thermometer.

accuracies specified in the specifications.

As soon as these changes are carried out, the

current calibration certificate (if it was delivered

with it) loses its validity.

To calibrate the internal probe, it is necessary to have a

standard thermometer with a precision greater than the

calibrator to follow the instructions below.

1. Insert the standard thermometer probe in the most

suitable hole of the calibrator.

2. Depending on the measuring range of the instrument

or the external area in which the calibration should be

carried out, define a minimum of 5 calibration points or

several calibration points (max. 10 points).

3. Set the first calibration point and wait for the calibrator to

be stable (see the stability LED).

4. Enter menu level 3 (see 7.3.4 “Third menu level Recalibration of the instrument”) and select PC.

5. With the [▲] or [▼] button, set the value read with the

standard thermometer

6. Confirm the entry with the [E] button.

Confirmation is indicated by a beep.

⇒

7. Repeat the steps 3 ... 6 for the other points.

8. At the end of the operation, wait for approx. 20 seconds to

come back to the main menu.

At the end of the calibration DO NOT remove the standard

thermometer if the calibrator is still at high temperature. First,

cool the calibrator while the probes are still inserted, see

chapter 6.9 “Cooling down the metal block”.

Model Possible calibration points

CTD4000-140 -15, 0, +50, +100 and +125 °C [5, 32, 122, 212 and 257 °F]

CTD4000-375 50, 120, 190, 260 and 340 °C [122, 248, 374, 500 and 644 °F]

CTD4000-650 100, 200, 300, 400, 500 and 600 °C [212, 392, 572, 752, 932 and 1,112°F]

14366831.01 05/2020 EN/DE

26 WIKA operating instructions, model CTD4000

Page 29

11. Dismounting, return and disposal

11. Dismounting, return and disposal

Personnel: Skilled personnel

Protective equipment: Protective gloves

WARNING!

Physical injuries and damage to property

and the environment through residual media

Residual media on or in the instrument can

result in a risk to persons, the environment and

equipment.

▶

Wear the requisite protective equipment.

▶

Observe the information in the material safety

data sheet for the corresponding medium.

▶

Clean the instrument, in order to protect

persons and the environment from damage

through residual media.

11.1 Dismounting

WARNING!

Risk of burns

During dismounting there is a risk of high

temperatures.

▶

Let the instrument cool down sufficiently

before dismounting it!

▶

In order to cool down the metal block, set the

set temperature to a low temperature, e.g.

room temperature.

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct

danger to life.

▶

The dismounting of the instrument may only

be carried out by skilled personnel.

▶

Disconnect test and calibration installations

once the system has been isolated from

power sources.

11.2 Return

Strictly observe the following when shipping the

instrument:

All instruments delivered to WIKA must be free from any

kind of hazardous substances (acids, bases, solutions, etc.)

and must therefore be cleaned before being returned, see

chapter 10.2 “Cleaning”.

When returning the instrument, use the original packaging or

a suitable transport packaging.

To avoid damage:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with the shock-absorbent

material, in the packaging. Place shock-absorbent

material evenly on all sides of the transport packaging.

3. If possible, place a bag, containing a desiccant, inside the

packaging.

4. Label the shipment as transport of a highly sensitive

measuring instrument.

Information on returns can be found under the

heading “Service” on our local website.

11.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials

in an environmentally compatible way and in accordance with

the country-specific waste disposal regulations.

Do not dispose of with household waste. Ensure

a proper disposal in accordance with national

regulations.

EN

1. Cool down the temperature dry-well calibrator as

described in chapter 6.9 “Cooling down the metal block”.

2. Switch off the temperature dry-well calibrator and pull out

the mains plug from the mains socket.

After switching off or after removing the mains

connection, the installed fan can no longer

provide cooling air. If the voltage supply is

interrupted during the cooling process, sufficient

thermal decoupling is still guaranteed between

the metal block and the case.

14366831.01 05/2020 EN/DE

27WIKA operating instructions, model CTD4000

Page 30

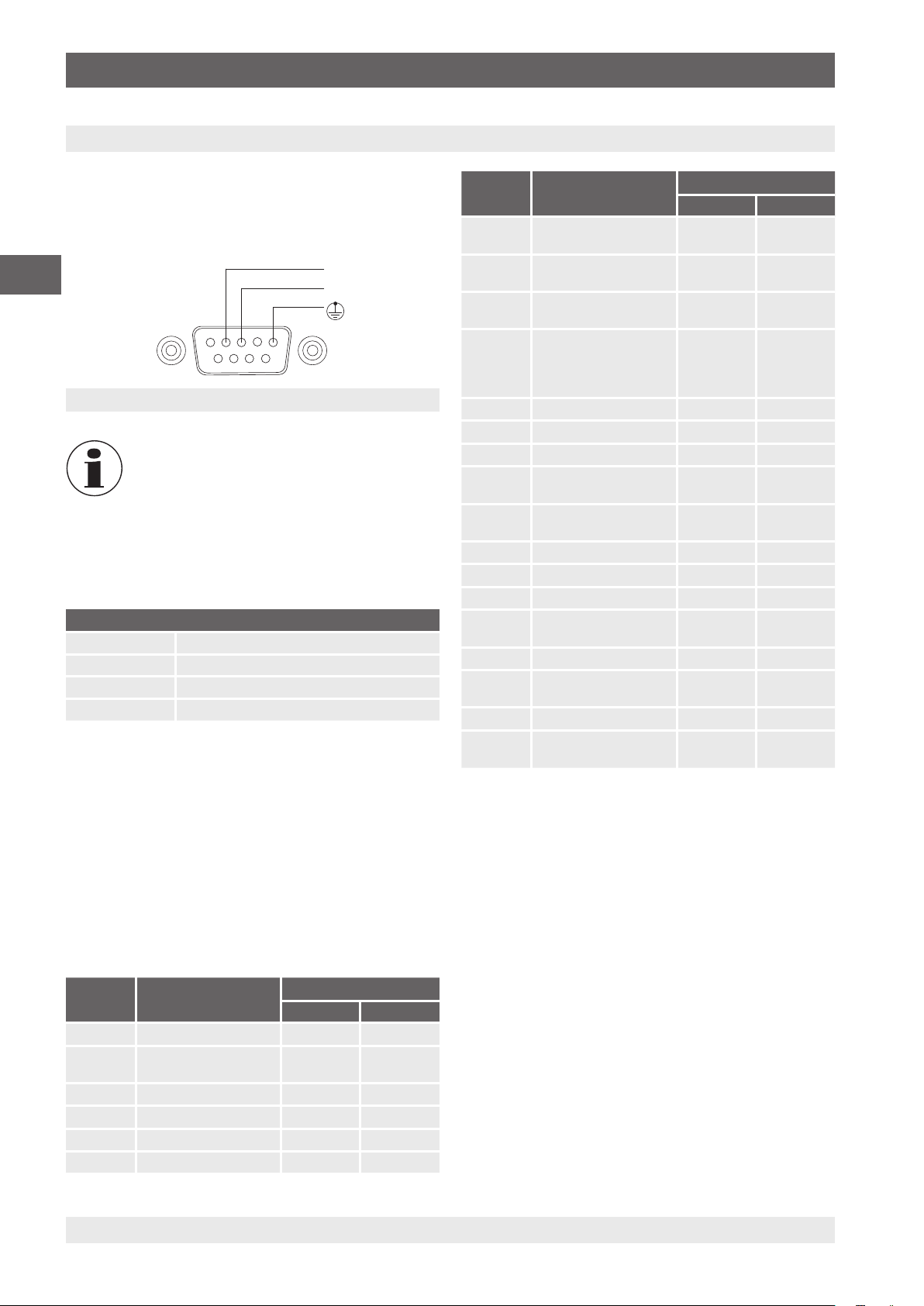

12. Specifications

12. Specifications

Specifications Model CTD4000-140

Display

Temperature range -24 ... +140 °C [-11 ... +284 °F]

Accuracy

EN

Stability

Resolution 0.1 °C

Temperature control

Heating time approx. 20 min from 20 to 120 °C

Cooling time approx. 17 min from +20 to -20 °C

Stabilisation time

Insert

Immersion depth 104 mm [4.09 in]

Insert dimensions Ø 19 x 104 mm [Ø 0.75 x 4.09 in]

Insert material Aluminium

Voltage supply

Operating voltage AC 100 ... 240 V ±10 %, 50/60 Hz

Power consumption 80 W

Fuse 2.5 A slow blow fuse

Power cord AC 230 V; for Europe

Communication

Interface RS-232

Case

Dimensions (W x D x H) 130 x 260 x 280 mm [5.12 x 10.24 x 11.02 in]

Weight 4.9 kg [10.81 lbs]

1) Is defined as the measuring deviation between the measured value and the reference value.

2) Maximum temperature difference at a stable temperature over 30 minutes.

3) Time before reaching a stable value.

1)

2)

3)

0.25 K at 100 °C [212 °F]

±0.1 K

[from 68 °F to 248 °F]

[from +68 °F to -4 °F]

dependent on temperature and temperature probe

The measurement uncertainty is defined as the total measurement uncertainty (k = 2), which contains the following shares:

Accuracy, measurement uncertainty of reference, stability and homogeneity.

28 WIKA operating instructions, model CTD4000

14366831.01 05/2020 EN/DE

Page 31

12. Specifications

Specifications Model CTD4000-375 Model CTD4000-650

Display

Temperature range t

Accuracy

Stability