Page 1

Temperature dry-well calibrator

Model CTD4000

Applications

■

Testing and calibration of temperature measuring

instruments

■

Reference instrument for easy and quick measurements

■

Suitable for on-site use

Special features

■

High stability

■

Possibility to check temperature switches

■

Low weight and compact design

■

Simple operation

Calibration

WIKA data sheet CT 41.10

Description

These innovative calibrators have been designed for on-site

applications as well as for the severe conditions of the naval

and marine sectors.

Their ease of use and their compact and practical design

make them unbeatable in industrial processes where the

calibration of the temperature measurement systems is

essential for the control of the process and the quality of the

nal product.

Special attention is paid to reduce weight, size and to

reinforce robustness by using an aluminium body as well as

aluminium and stainless steel for many internal parts.

Each calibrator is tested in our laboratory and calibrated with

our references in accordance with the international standard.

At this stage all the functions are checked against reference

parameters and a calibration protocol is issued.

Temperature dry-well calibrator CTD4000

The thermal part of these calibrators is made of a metal

block heated with resistors or with Peltier thermoelectric

modules. In the metal block there is one bore in which the

interchangeable insert is placed.

With the available standard inserts, the calibrators are

versatile and can be easily adapted for the calibration of

temperature probes with the most common diameters.

Customer-specic inserts and bores are available on request.

WIKA data sheet CT 41.10

Data sheets showing similar products:

Temperature dry-well calibrator; models CTD9100-COOL, CTD9100-165, CTD9100-450, CTD9100-650; see data sheet CT 41.28

Temperature dry-well calibrator; model CTD9100-ZERO; see data sheet CT 41.30

Temperature dry-well calibrator; model CTD9100-375; see data sheet CT 41.32

∙ 03/2020

Page 1 of 6

Page 2

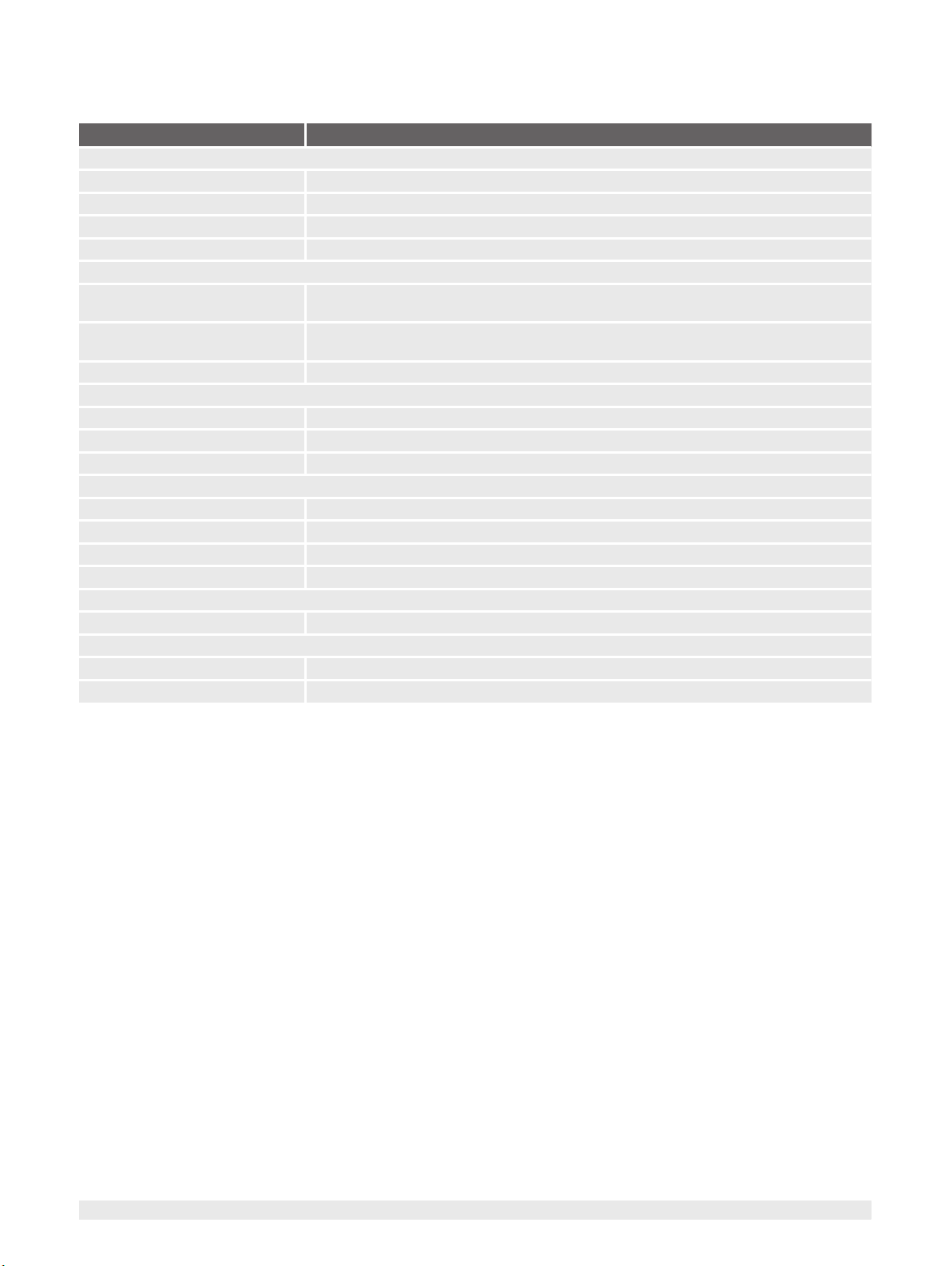

Specications

CTD4000 series

Specications Model CTD4000-140

Display

Temperature range -24 ... +140 °C [-11 ... +284 °F]

Accuracy

Stability

1)

2)

Resolution 0.1 °C

Temperature control

Heating time approx. 20 min from 20 to 120 °C

Cooling time approx. 17 min from +20 to -20 °C

Stabilisation time

3)

Insert

Immersion depth 104 mm [4.09 in]

Insert dimensions Ø 19 x 104 mm [Ø 0.75 x 4.09 in]

Insert material Aluminium

Voltage supply

Operating voltage AC 100 ... 240 V ±10 %, 50/60 Hz

Power consumption 80 W

Fuse 2.5 A slow blow fuse

Power cord for Europe

Communication

Interface RS-232

Case

Dimensions (W x D x H) 130 x 260 x 280 mm [5.12 x 10.24 x 11.02 in]

Weight 4.9 kg [10.81 lbs]

1) Is dened as the measuring deviation between the measured value and the reference value.

2) Maximum temperature dierence at a stable temperature over 30 minutes.

3) Time before reaching a stable value.

0.25 K at 100 °C [212 °F]

±0.1 K

[from 68 °F to 248 °F]

[from +68 °F to -4 °F]

dependent on temperature and temperature probe

The measurement uncertainty is dened as the total measurement uncertainty (k = 2), which contains the following shares:

accuracy, measurement uncertainty of reference, stability and homogeneity.

WIKA data sheet CT 41.10 ∙ 03/2020 Page 2 of 6

Page 3

Specications Model CTD4000-375 Model CTD4000-650

Display

Temperature range t

Accuracy

Stability

1)

2)

+ 15 °C ... 375 °C [t

amb

0.35 K 0.5 K

±0.1 K ±0.3 K

Resolution 0.1 °C

Temperature control

Heating time approx. 20 min from 30 to 375 °C

[from 86 °F to 707 °F]

Cooling time approx. 40 min from 375 to 100 °C

[from 707 °F to 212 °F]

Stabilisation time

3)

dependent on temperature and temperature probe

Insert

Immersion depth 150 mm [5.91 in]

Insert dimensions Ø 26 x 150 mm [Ø 1.02 x 5.91 in]

Insert material Brass

Voltage supply

Operating voltage AC 115/230 V ±10 %, 50/60 Hz

Automatic switchable

Power consumption 600 W

Fuse 6.3 A slow blow fuse (at AC 115 V)

3.15 A slow blow fuse (at AC 230 V)

Power cord AC 230 V; for Europe

Communication

Interface RS-232

Case

Dimensions (W x D x H) 130 x 260 x 280 mm [5.12 x 10.24 x 11.02 in]

Weight 5.4 kg [11.9 lbs] 6 kg [13.2 lbs]

1) Is dened as the measuring deviation between the measured value and the reference value.

2) Maximum temperature dierence at a stable temperature over 30 minutes.

3) Time before reaching a stable value.

+ 15 °F ... 707 °F] t

amb

+ 15 °C ... 650 °C [t

amb

approx. 35 min from 50 to 650 °C

[from 122 °F to 1,202 °F]

approx. 60 min from 650 to 100 °C

[from 1,202 °F to 212 °F]

+ 15 °F ... 1,202 °F]

amb

The measurement uncertainty is dened as the total measurement uncertainty (k = 2), which contains the following shares:

accuracy, measurement uncertainty of reference, stability and homogeneity.

WIKA data sheet CT 41.10 ∙ 03/2020 Page 3 of 6

Page 4

Approvals

Logo Description Country

EU declaration of conformity

■

EMC directive

EN 61326 emission (group 1, class A) and immunity (industrial application)

■

Low voltage directive

EN 61010, safety requirements for electrical equipment for measurement, control and laboratory

use

■

RoHS directive

DNV GL (only valid for CTD4000-375 and CTD4000-650)

Ships, shipbuilding (e.g. oshore)

1) Warning! This is class A equipment for emissions and is intended for use in industrial environments. In other environments, e.g. residential or commercial installations, it can interfere

with other equipment under certain conditions. In such circumstances the operator is expected to take the appropriate measures.

1)

European Union

International

Certicates

Certicate

Calibration Option: 3.1 calibration certicate per DIN EN 10204

Option: DKD/DAkkS calibration certicate

Recommended recalibration interval 1 year (dependent on conditions of use)

Approvals and certicates, see website

Accessories

Inserts for model CTD4000-140 Order code

Description CTA9I-2O

Insert undrilled

Ø 19 x 104 mm [Ø 0.75 x 4.09 in]

Material: Aluminium

Insert drilled

Ø 19 x 104 mm [Ø 0.75 x 4.09 in]

Drilling depth: 100 mm [3.94 in]

Material: Aluminium

Bore diameter:

1 x 3.3 mm, 1 x 4.8 mm and 2 x 6.4 mm [1 x 0.13 in, 1 x 0.19 in and 2 x 0.25 in]

Insert replacement tool -J-

Ordering information for your enquiry:

1. Order code: CTA9I-2O

2. Option:

Inserts for model CTD4000-375 Order code

Description CTA9I-2P

Insert undrilled

Ø 26 x 150 mm [Ø 1.02 x 5.91 in]

Material: Brass

-N-

-W-

⇓

[ ]

-N-

Insert drilled

Ø 26 x 150 mm [Ø 1.02 x 5.91 in]

Drilling depth: 145 mm [5.71 in]

Material: Brass

WIKA data sheet CT 41.10 ∙ 03/2020 Page 4 of 6

Page 5

Inserts for model CTD4000-375 Order code

Description CTA9I-2P

Bore diameter:

1 x 12.7 mm and 1 x 6.4 mm

[1 x 0.50 in and 1 x 0.25 in]

-O-

Bore diameter:

1 x 3.2 mm, 1 x 4.8 mm, 1 x 6.4 mm and 1 x 11.1 mm

[1 x 0.13 in, 1 x 0.19 in, 1 x 0.25 in and 1 x 0.44 in]

Insert replacement tool -J-

-P-

Ordering information for your enquiry:

1. Order code: CTA9I-2P

2. Option:

⇓

[ ]

Inserts for model CTD4000-650 Order code

Description CTA9I-2Q

Insert undrilled

Ø 26 x 150 mm [Ø 1.02 x 5.91 in]

Material: Brass

Insert drilled

Ø 26 x 150 mm [Ø 1.02 x 5.91 in]

Drilling depth: 145 mm [5.71 in]

Material: Brass

Bore diameter:

1 x 15.7 mm [0.62 in]

Bore diameter:

1 x 17.5 mm [0.69 in]

Bore diameter:

1 x 6.5 mm and 1 x 12.7 mm

[1 x 0.26 in and 1 x 0.50 in]

-N-

-Q-

-R-

-S-

Bore diameter:

1 x 4.5 mm, 1 x 6.5 mm and 1 x 10.5 mm

[1 x 0.18 in, 1 x 0.26 in and 1 x 0.41 in]

Bore diameter:

1 x 3.2 mm, 1 x 5 mm, 1 x 6.5 mm and 1 x 9.5 mm

[1 x 0.13 in, 1 x 0.20 in, 1 x 0.26 in and 1 x 0.37 in]

Bore diameter:

1 x 3.2 mm, 1 x 5 mm, 1 x 7 mm and 1 x 9.5 mm

[1 x 0.13 in, 1 x 0.20 in, 1 x 0.28 in and 1 x 0.41 in]

Insert replacement tool -J-

-T-

-U-

-V-

Ordering information for your enquiry:

1. Order code: CTA9I-2Q

2. Option:

WIKA data sheet CT 41.10 ∙ 03/2020 Page 5 of 6

⇓

[ ]

Page 6

Order code

Description CTX-A-KB

Transport case -CC-

Ordering information for your enquiry:

1. Order code: CTX-A-KB

2. Option:

⇓

[ ]

Scope of delivery

■

Temperature dry-well calibrator model CTD4000

■

Power cord, 1.5 m [5 ft] with safety plug

■

Drilled standard insert, depends on instrument version

• for CTD4000-140 3.3 mm, 4.8 mm and 2 x 6.4 mm

[0.13 in, 0.19 in and 2 x 0.25 in]

• for CTD4000-375 3.2 mm, 4.8 mm, 6.4 mm and

11.1 mm

[0.13 in, 0.19 in, 0.25 in and 0.44 in]

• for CTD4000-650 3.2 mm, 5 mm, 7 mm and 10.5 mm

[0.13 in, 0.2 in, 0.28 in and 0.41 in]

■

Replacement tools

■

Operating instructions

Options

■

3.1 calibration certicate per DIN EN 10204

■

DKD/DAkkS calibration certicate

Ordering information

Model / Type of application / Temperature range / Calibration / Insert / Transport case / Power cord / Further approvals /

Additional ordering information

© 01/2020 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

WIKA data sheet CT 41.10 ∙ 03/2020 Page 6 of 6

03/2020 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax. +49 9372 132-406

info@wika.de

www.wika.de

Loading...

Loading...