Page 1

Operating instructions

Precision Pressure Transducer

Basic Version, Model CPT6020

EN

Precision Pressure Transducer, Model CPT6020

Page 2

EN

Operating instructions model CPT6020

© 12/2017, Mensor, LP. All rights reserved.

Mensor is a registered trademark of Mensor, LP.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Prior to starting any work, read the operating instructions!

Keep for later use!

2

Mensor operating instructions process pressure transducer, Model CPT6020

0020507001A 09/2018 EN

Page 3

Contents

1. General Information 6

1.1 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.2 Radio Frequency Emission Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 FCC Emission Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 CE Emission Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.3 Software License Agreement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Mensor Service Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.1 After the Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.2 Calibration Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.3 Certifications and Accreditations . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Short Overview 8

2.1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Safety 9

3.1 Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Improper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4 Responsibility of the Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.5 Personnel Qualification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Personal Protective Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7 Labeling, Safety Marks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7.1 Product Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7.2 Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.8 Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. Transport, Packaging and Storage 13

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Packaging and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. Installation 14

5.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.1 Pressure Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.2 Safety Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.3 Pressure Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.4 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6. Operation 16

6.1 General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.1 Command and Query Format . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.1.1 RS-485 Command and Query Format . . . . . . . . . . . . . . . . . . . . . . 16

6.1.1.2 RS-232 Command and Query Format . . . . . . . . . . . . . . . . . . . . . . 16

6.1.1.3 Command Error Detection and Debugging . . . . . . . . . . . . . . . . . . . . 16

6.1.2 CPT6020 Commands and Queries. . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.2.1 Default Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.2.2 Setting the Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.2.3 Setting Pressure Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1.2.4 Customer Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1.2.5 Calibration Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1.2.6 Output String Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1.3 MENSOR Legacy Command Set . . . . . . . . . . . . . . . . . . . . . . . . . 22

7. Maintenance and Recalibration 24

0020507001A 08/2018 EN

EN

WIKA operating instructions process pressure transducer, model CPT6020

3

Page 4

EN

Contents

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1.1 Beyond the Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2.1 Calibration Services by Mensor or WIKA worldwide . . . . . . . . . . . . . . . . . . . 24

7.2.2 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.3 Pressure Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.4 Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.5 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.6 Calibration & Communication Software . . . . . . . . . . . . . . . . . . . . . . . 26

8. Dismounting, Return and Disposal 28

8.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.3 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9. Specifications 30

9.1 Measurement Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.2 General Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.3 Approvals and Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.4 Dimensions in mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10. Accessories 33

10.1 Fittings & Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

0020507001A 08/2018 EN

4

WIKA operating instructions process pressure transducer, model CPT6020

Page 5

EN

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

5

Page 6

EN

General information

1. General Information

■

The CPT6020 Precision Pressure Transducer described in the operating instructions has been designed and manufactured

using state-of-the-art technology. All components are subject to stringent quality and environmental criteria during production.

Our management systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's operating range.

■

The operating instructions are part of the instrument and must be kept in the immediate vicinity of the instrument and readily

accessible to skilled personnel at any time. Pass the operating instructions onto the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations are carried out in accordance with international standards.

■

Further information:

Mensor Corporation

- Address 201 Barnes Dr., San Marcos, TX 68666

- Internet address: www.mensor.com

- Relevant data sheet: CT 25.12

- Application consultant: Tel.: (+1) 512-396-4200

(+1) 800-984-4200 (USA only)

Fax: (+1) 512-396-1820

E-Mail: sales@mensor.com

techservices@mensor.com

Importer for Europe

WIKA Alexander Wiengand SE & Co. KG

- Address

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 25.12

- Application consultant: Tel.: (+49) 9372/132-5015

1.1 Warranty

All products manufactured by Mensor are warranted to be free of defects in workmanship and materials for a period of two year

from the date of shipment. No other express warranty is given, and no affirmation of Seller, by words or actions, shall constitute

a warranty. SELLER DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSES WHATSOEVER. If any defect in workmanship or material should develop under conditions of normal use and service

within the warranty period, repairs will be made at no charge to the original purchaser, upon delivery of the product(s) to the

factory, shipping charges prepaid. If inspection by Mensor or its authorized representative reveals that the product was damaged

Alexander Wiegand-Straße

63911 Klingenberg, Germany

Fax: (+49) 9372/132-8767

E-Mail: CTsales@wika.com

0020507001A 08/2018 EN

6

WIKA operating instructions process pressure transducer, model CPT6020

Page 7

General Information

by accident, alteration, misuse, abuse, faulty installation or other causes beyond the control of Mensor, this warranty does not

apply. The judgment of Mensor will be final as to all matters concerning condition of the product, the cause and nature of a defect,

and the necessity or manner of repair. Service, repairs or disassembly of the product in any manner, performed without specific

factory permission, voids this warranty.

MENSOR MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Mensor shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this

material.

1.2 Radio Frequency Emission Notices

USE SHIELDED CABLES TO CONNECT EXTERNAL DEVICES TO THIS INSTRUMENT TO

MINIMIZE RF RADIATION

1.2.1 FCC Emission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a residential environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

1.2.2 CE Emission Notice

This equipment is of the emission class B, intended for operation in industrial, residential or commercial environments.

EN

1.3 Software License Agreement

This product contains intellectual property, i.e. software programs, that are licensed for use by the end user/customer (hereinafter

“end user”).

This is not a sale of such intellectual property.

The end user shall not copy, disassemble or reverse compile the software program.

The software programs are provided to the end user “as is” without warranty of any kind, either express

or implied, including, but not limited to, warranties of merchantability and fitness for a particular purpose.

The entire risk of the quality and performance of the software program is with the end user.

Mensor and its suppliers shall not be held to any liability for any damages suffered or incurred by the end user (including, but

not limited to, general, special, consequential or incidental damages including damages for loss of business profits, business

interruption, loss of business information and the like), arising from or in connection with the delivery, use or performance of the

software program.

1.4 Mensor Service Plus

1.4.1 After the Warranty

Mensor’s concern with the performance of this instrument is not limited to the warranty period. We provide complete repair,

calibration and certification services after the warranty for a nominal fee.

1.4.2 Calibration Services

In addition to servicing our own products Mensor can perform a complete pressure calibration service, up to 30,000 psi, for all of

your pressure instruments. This service includes an accredited calibration.

1.4.3 Certifications and Accreditations

Mensor is registered to ISO 9001:2008. The calibration program at Mensor is accredited by A2LA, as complying with both the ISO/

IEC 17025:2005 and the ANSI/NCSL Z540-1-1994 standards.

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

7

Page 8

EN

Short Overview

2. Short Overview

The CPT6020 pressure transducer is a high accuracy digital output pressure transducer and is available in gauge, absolute and

bidirectional pressure ranges with full scale pressure ranges as low as 10” H2O to as high as 15,015 psia .

Figure 2.1

2.1 Features

Here is a short list of significant features designed into the CPT6020:

■

Accuracy to 0.02% FS

■

Wide voltage power input range

■

IP-67 rating for harsh environments

■

All 316L SS wetted path on ranges >5 psi

■

Command emulation for digital communications

■

User selectable units

■

Compact size

2.2 Scope of Delivery

■

Precision Pressure Transducer model CPT6020

■

Power cord with 1.5 m (5 ft) length

■

Operating instruction

■

Factory calibration certificate

■

Selected fitting

0020507001A 08/2018 EN

8

WIKA operating instructions process pressure transducer, model CPT6020

Page 9

Safety

3. Safety

3.1 Explanation of Symbols

DANGER!

... indicates a directly dangerous situation resulting in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage to property or the environment,

if not avoided.

DANGER!

... identifies hazards caused by electrical power. Should the safety instructions not be observed, there is a risk of

serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused by hot surfaces or liquids, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and trouble-free operation.

EN

3.2 Intended Use

The CPT6020 pressure transducer is designed to measure pressure with extreme accuracy as stand-alone devices or as

incorporated in OEM type applications. It is characterized over a wide temperature range and is designed to be used in

environments that are much more harsh than tolerable by previous generations of Mensor pressure transducers.

3.3 Improper Use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and injuries.

▶

Do not use the transducer within hazardous areas

▶

Do not use the transducer with oxygen as a medium

▶

Do not attempt to disassemble the transducer

Any use beyond or different than the intended use is considered improper use.

3.4 Responsibility of the Operator

The instrument is used in the industrial sector. The operator is therefore responsible for legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety, accident prevention and environmental protection

regulations for the application area must be maintained.

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

9

Page 10

EN

Safety

The operator is obliged to maintain the product label in a legible condition.

The operator must ensure that:

■

Mechanical vibration, mechanical shock are minimized

■

The transducer is installed in areas without soot, vapor, dust and corrosive gases

■

The transducer is not used in hazardous environments, flammable atmospheres

■

The operating personnel are regularly instructed in all topics regarding work safety, first aid and environmental protection and

know the operating instructions and in particular, the safety instructions contained therein

■

The transducer is suitable for the particular application in accordance with its intended use

■

Personal protective equipment is available

3.5 Personnel Qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to equipment.

▶

The activities described in these operating instructions may only be carried out by skilled personnel who have the

qualifications described below.

Skilled personnel

Skilled personnel, authorized by the operator, are understood to be personnel who, based on their technical training, knowledge

of measurement and control technology and on their experience and knowledge of country-specific regulations, current standards

and directives, are capable of carrying out the work described and independently recognizing potential hazards.

Operating personnel

The personnel trained by the operator are understood to be personnel who, based on their education, knowledge and experience,

are capable of carrying out the work described and independently recognizing potential hazards.

Special knowledge for working with instruments for hazardous areas:

The skilled (electrical) personnel must have knowledge of ignition protection types, regulations and provisions for equipment in

hazardous areas.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

10

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 11

Safety

3.6 Personal Protective Equipment

The personal protective equipment is designed to protect the skilled personnel from hazards that could impair their safety or health

during work. When carrying out the various tasks on and with the instrument, the skilled personnel must wear personal protective

equipment.

Follow the instructions displayed in the work area regarding personal protective equipment!

The requisite personal protective equipment must be provided by the operating company.

Wear safety goggles!

Protect eyes from flying particles and liquid splashes.

Wear a protective helmet!

Protects the head from falling objects.

Wear safety shoes!

Protect feet from falling objects or objects lying around, as well as against toxic or hazardous liquids and aggressive

media.

EN

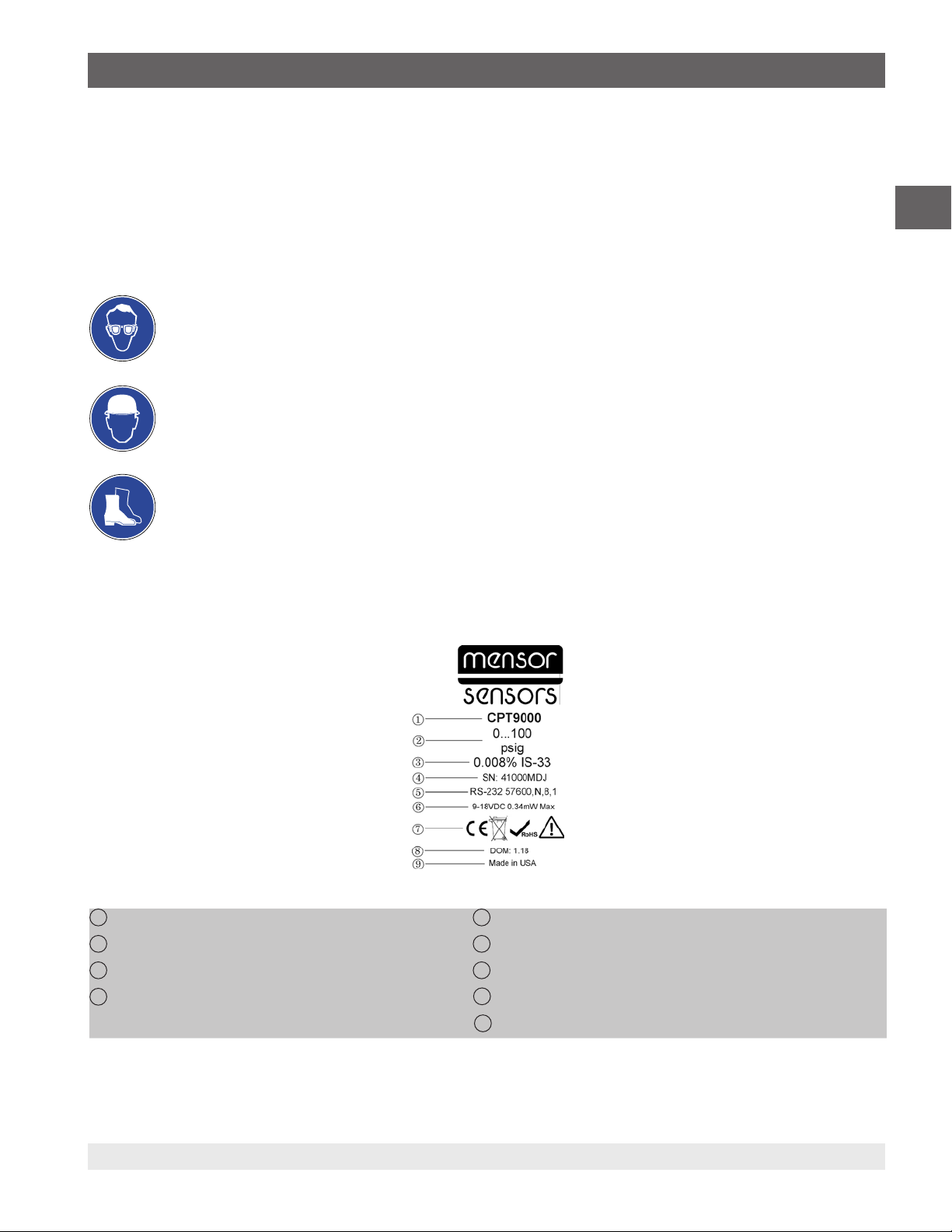

3.7 Labeling, Safety Marks

3.7.1 Product Label

1

Model

2

Range

3

Accuracy

4

Serial Number Date of Manufacture

5

Communications

6

Power Requirements

7

Symbols

8

9

Origin

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

11

Page 12

EN

Safety

3.7.2 Symbols

Before mounting and commissioning the instrument, ensure you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

This marking on the instruments indicates that they must not be disposed of in domestic waste. The disposal is

carried out by return to the manufacturer or by the corresponding municipal authorities (see EU directive 2012/19/

EU).

3.8 Warnings and Cautions

WARNING!

HIGH PRESSURE! High pressure gases are potentially hazardous. Energy stored in these gases and liquids can

be released suddenly and with extreme force. High pressure systems should be assembled and operated only by

personnel who have been trained in proper safety practices.

WARNING!

NOT EXPLOSION PROOF! Installation of this instrument in an area requiring devices rated as intrinsically safe is not

recommended.

WARNING!

POSSIBLE INJURY! The tubing, valves, and other apparatus attached to the gauge must be adequate for the

maximum pressure which will be applied, otherwise physical injury to the operator or bystanders is possible.

CAUTION

USE THE PROPER PRESSURE MEDIUM! Only use media compatible with materials of construction as specified .

This transducer is not designed for oxygen use.

CAUTION

As with most sensitive electronic equipment, switch the power switch off before connecting or disconnecting to a

power source to prevent data loss. Do not position the equipment so that it is difficult to disconnect the AC power

cord.

WARNING!

Detachable main power supply cord with inadequate ratings should not be used. See Section 9.2 Specifications for

power ratings.

Additional Warning and Caution notices are found throughout this manual.

12

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 13

Transport, Packaging and Storage

4. Transport, Packaging and Storage

4.1 Transport

Check the CPT6020 for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

■

While unlikely, with improper transport, damage can occur. When unloading packed goods upon delivery as well

as during internal transport, proceed carefully and observe the symbols on the packaging.

■

If the instrument is transported from a cold into a warm environment, the formation of condensation may result in

instrument malfunction. Before putting it back into operation, wait for the instrument temperature and the room

temperature to equalize.

4.2 Packaging and storage

Permissible conditions at the place of storage

■

Storage Temperature: -40 … 85˚C

■

Humidity: 5 … 95% relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, excessive mechanical shock

■

Soot, vapor, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

EN

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

13

Page 14

Installation

5. Installation

Personnel: Skilled electrical personnel

EN

WARNING!

READ THESE INSTRUCTIONS BEFORE INSTALLATION!

Only use original parts (see Chapter 10 “Accessories”).

WARNING!

Physical injuries and damage to property and the environment caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable or toxic substances), harmful media (e.g.

corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compressors, there is a danger of

physical injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high temperature and under high pressure or vacuum may

be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate existing codes or regulations must also be

followed.

▶

Wear the requisite protective equipment (see Chapter 3.6 “Personal Protective Equipment”).

CAUTION

Damage to the Instrument

When working on open electrical circuits (printed circuit boards) there is a risk of damaging sensitive electronic

components through electrostatic discharge.

▶

The correct use of grounded working surfaces and personal armbands is required.

5.1 Mounting

The transducer may be mounted via its process connection or with any ring clamps along its body. Having the sensor oriented in a

position other than vertical (with the port down) might cause a slight zero shift than can be removed by re-zeroing the transducer.

5.1.1 Pressure Connections

The CPT6020 has a JIC4 type female connection. When installing a mating connector, do not torque the connector with more than

13 ft-lbs or galling might occur. The transducer is supplied with a crush washer that can be used to further eliminate leaks.

5.1.2 Safety Relief Valves

Mensor recommends that an appropriately sized relief valve be placed in line with the pressure port of the transducer.

5.1.3 Pressure Media

A media comparable with the wetted parts of the transducer must be used.

14

CAUTION

USE THE PROPER PRESSURE MEDIUM! Only use media compatible with materials of construction as specified .

This transducer is not designed for oxygen use.

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 15

RS-232

RS-485

Installation

5.1.4 Electrical Connections

Note: Power supply should be

The pinouts on the six pin connector and RS-232 and RS-485 Cable connections are:

HOST

DB9

9 to 18 VDC (12 VDC nominal).

Pin

1 RS-485 TX- White

2 +9-18V Brown

3 Ground Gray

4 RS-485 RX+ or RS-232 RX Black

5 RS-485 RX- Blue

6 RS-485 TX+ or RS-232 TX Pink

External Connector Pinouts

Function Pigtail Color

EN

COM

COM

Female

PWR

HOST

DB9

9

Female

PWR

2

3

5

GND

12 VDC

1

2

3

5

GND

12 VDC

PINK

BLACK

GR AY

BROWN

WHITE

BLACK

BLUE

PINK

GR AY

BROWN

0020507001A 08/2018 EN

Figure 5.1.2 COM Connection Pin-out and RS-232 / RS-485 cable connections

WIKA operating instructions process pressure transducer, model CPT6020

15

Page 16

EN

Operation

6. Operation

6.1 General Operation

The CPT6020 transducer can be ordered with either an RS-232 or RS-485 full duplex output. The communications protocol is

defaulted to 57600,N,8,1. The baud rate can be changed via remote commands. Connector pinouts and RS-232 and RS 485

cable connections are shown in Figure 5.1.2. The transducer has multiple command sets with which it can communicate with the

host. These are set through the CMD_SET command.

6.1.1 Command and Query Format

Commands must be sent in ASCII format and terminated with a carriage return (<CR>) followed by a linefeed (<LF>). Commands

are not case sensitive. Query strings are terminated with a “?” prior to the termination character(s). If the transducer is put in a

burst output mode, the output of the transducer is in a binary output mode. The host communications program must synchronize

with the output of the transducer. The transducer’s output to a pressure value query is programmable depending on what the user

wants in the output string.

6.1.1.1 RS-485 Command and Query Format

On RS-485 versions of the CPT6020, the commands must be preceded by a “#”, an address or a “*”, and a space. In RS-485 the

ADDRESS command sets the address in ranges from “0” to “9” and “A” to “Z”. The global address character is the “*”. When data

is required for a command, a space (only) should delimit command and data fields.

6.1.1.2 RS-232 Command and Query Format

On RS-232 versions of the CPT6020, the “#” or address character is not necessary to precede the command for the Sensor

command set. But, the Mensor Legacy command set still requires a proceeding “#” and address character. With the default

sensor command set in RS-232, the start character and address character are not required.

6.1.1.3 Command Error Detection and Debugging

The CPT6020 has built in responses to correct and incorrect data. The responses can be used to help debug the software. In the

Sensor command set, the device will return “Ready” in response to a valid data command. If the device is in the Mensor Legacy

command set, an “R” will be returned in response to valid data. If the data is determined to be invalid, the Sensor command set

will return “Invalid Data”. The Mensor Legacy command set will still return an “R” character when invalid data is sent. This is a

limitation of the Mensor Legacy command set. The Sensor command set will return “Unknown command” if the command is not

found, while the Mensor Legacy command set will ignore it and not respond. This paragraph is summarized below in the following

table:

Mensor Legacy Command Set

Case Return Value

Valid data command “R”

Invalid data command “R”

Invalid command Nothing

Sensor Default Command Set

Case Return Value

Valid data command “Ready”

Invalid data command “Invalid Data”

Invalid command “Unknown Command”

Query Customer password protected command “User Password Needed”

Table 7.1.1 Command set returns for given cases

Also, it is important to note that when sent data is determined to be valid, the value will be stored in RAM. Only after the SAVE

command is sent is the data saved permanently. This applies to all command sets.

16

WIKA operating instructions process pressure transducer, model CPT6020

0020507001A 08/2018 EN

Page 17

Operation

6.1.2 CPT6020 Commands and Queries

Commands with complex outputs are explained In tables following the command set.

The following convention is used for the following command set tables:

n – 1 placeholder for digits and decimal point

C – 1 character placeholder for alpha character A-Z

<cr> - carriage return – ASCII 13

<lf> - line feed – ASCII 10

± - 1 place holder for a + or – sign, or blank which implies +

¬<sp> - 1 place holder for a space

X – address placeholder or ‘*’ for universal queries to be sent to all instruments

Y(1,2,3…) – strings as defined in description

<yy,mm,dd> - Last two digits of year, month, day.

All commands, queries, and responses will be terminated with a <cr><lf>.

All commands that are password protected are designated with “(Password Protected)” in the Query column below.

Global Commands

Query Command Data Description

N/A ADDRESS<sp><C> (RS-485 only) C Transducer address 0-9,

A-Z

*IDN?/ID? N/A Manu,Model,SN,SW Version Manufacturer, Model,

SN, SW Version

N/A SAV E Saves Data to EEPROM

TYPE? N/A C Pressure type - 1 char

FILTER? FILTER<sp><n> n Filter percentage 1 to 99

WINDOW? WINDOW<sp><nn> n

BAUD? BAUD<sp><n> n Baud Rate - 9600,

N/A CERR Clears Error stack

N/A DEFAULT Defaults parameters per

CMD_SET? CMD_SET<sp><n> n Selects command set

N/A PWD_CHANGE<sp><n,n> nnnn,nnnn Change password <n,n>

N/A PWD<sp><n> nnnn Send password

Set 0 ... 99 to correspond

to a filter window of

0 ... 0.099%FS

19200, 57600, 115200

Table 6.1.3.2

per Table 2.1 (This

command is included in

all command sets.)

= <old,new>

Pressure Related Commands

PRESS? N/A Returns configurable

output from active

channel in current units

see Table 6.1.2.10

& Output Control

Commands section.

EN

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

17

Page 18

EN

Operation

RANGE_MIN? N/A +n.nnnnnnnE+nn Minimum range in

current units.

RANGE_MAX? N/A +n.nnnnnnnE+nn Maximum range in

current units

UNIT_INDEX? UNIT_INDEX<sp><n> n Mensor unit index: 1-39

or 99 for CUST_UNIT.

See Table 6.1.2.5

UNIT? N/A cccccccccc Unit text 10 char -

mmHg, psi, kPa…

CUST_UNIT? CUST_UNIT<sp><n> +n.nnnnnnnE+nn Sets custom unit

multiplication (xx/psi).

See Section 6.1.2.6

Calibration Related Commands

CAL_DATE? CAL_DATE<sp><yy,mm,dd>

(Password Protected)

SPAN? CAL_SPAN<sp><n>

(Password Protected)

ZERO? CAL_ZERO<sp><n>

(Password Protected)

N/A TARE<sp><n> n Turns tare on/off - 1/0

Temperature Related Command

TEMP? N/A +nnn.n Temperature in deg. C.

Output Control Commands

OUTPUT_MASK? OUTPUT_MASK<sp><n> n Configures output for

nn,nn,nn Calibration date

+n.nnnnnnnE+nn Customer span multipler

- 0.99 to 1.01. See

Section 6.1.2.7

+n.nnnnnnnE+nn Customer zero adder.

See Section 6.1.2.7

PRESS? Query and

Continuous Output– see

6.1.2.10

Table 6.1.2 – Sensor Command Set

Password Protection

In the Sensor Command Set, data that affects calibration is protected by a user settable 4 character password (designated as

“Password Protected”). The default password is “0000”. This is changed using the PWD_CHANGE command. It should be

changed once the user receives the device. The factory password will override the user’s password in the case that the user loses

their password.

Filter & Window

The filter is a percentage of the previous reading averaged with the current reading - as long as the current reading is within the

window of the previous reading. The window is set as a %FS of the transducer’s range. If the current reading is outside of the

window from the previous reading, the filter is unused and the current reading is displayed without manipulation. This scheme

allows the user to tune the transducer’s response as they like. It also allows the transducer to respond to rapid pressure changes

without having to change the filter. The default values are 0.01% FS for the window and a filter of 90%.

18

WIKA operating instructions process pressure transducer, model CPT6020

0020507001A 08/2018 EN

Page 19

Operation

6.1.2.1 Default Command

DEFAULT - This will default the following parameters to the shown settings:

Parameter Setting

Filter 90

Window 10

Baud 57600

CMD_SET 0

CUST_UNIT 1

Table 6.1.2.2 - Default Settings

6.1.2.2 Setting the Command Set

CMD_SET - This will set the transducer to communicate using different command sets:

Command Set Description

0 Sensor Default Command Set

1 Mensor Legacy

EN

Table 6.1.2.3 – Command Set List

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

19

Page 20

EN

Operation

6.1.2.3 Setting Pressure Units

UNIT_INDEX - This command sets the output units per the following table:

Unit Index Units Unit Index Units

1 psi 21 Torr

2 inHg 0C 22 kPa

3 inHg 60F 23 Pa

4 inH2O 4C 24 dy/cm2

5 inH2O 20C 25 g/cm2

6 inH2O 60F 26 kg/cm2

7 ftH2O 4C 27 MSW 0C

8 ftH2O 20C 28 osi

9 ftH2O 60F 29 psf

10 mTorr 30 tsf

11 inSW 0C 31 Not Used

12 ftSW 0C 32 uHg 0C

13 atm 33 tsi

14 bar 34 mHg 0C

15 mbar 35 hPa

16 mmH2O 4C 36 Mpa

17 cmH2O 4C 37 mmH2O 20C

18 MH2O 4C 38 cmH2O 20C

19 mmHg 0C 39 mH2O 20C

20 cmHg 0C 99 CUST_UNIT

Table 6.1.2.5 - Available Unit Codes and Units

6.1.2.4 Customer Units

The CUST_UNIT multiplier in conjunction with UNIT_INDEX 99 allows the user to set their own units. The CUST_UNIT is a

multiplier times psi to achieve the customer’s unit value.

6.1.2.5 Calibration Adjustments

SPAN & ZERO - These are calibration multipliers and offset respectively. The zero is an offset applied to all output pressure values.

The span is a multiplier times all pressure output values..

20

WIKA operating instructions process pressure transducer, model CPT6020

0020507001A 08/2018 EN

Page 21

Operation

6.1.2.6 Output String Setting

PRESS? & OUTPUT_MASK - PRESS? is a programmable output query that returns an ASCII string based on the selections set by

the OUTPUT_MASK variable. The selected parameters will populate the output string with commas separating the variables in the

order in which they appear in the following table:

Parameter Description Weight Format Max Length (plus 1 comma

between fields)

Pressure Pressure in current units Fixed +n.nnnnnnnE+nn 14

Units Unit Description 1 CCCCCCCCCC 10

Stable 0/1 – unstable/stable 16 n 1

Error 0/1 – no errors, error(s) in stack 32 n 1

Checksum Checksum of output string 64 n 2

Table 6.1.2.10 - Query Mode Mask Description

EN

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

21

Page 22

EN

Operation

6.1.3 MENSOR Legacy Command Set

This command and query set replicates the communications with legacy Mensor products – the 61xx, CPT61xx, 6000, CPT6010

and most of the removable sensors from Mensor pressure calibrators (PCS400M, PCS 6000, CPC6000, CPC8000). The

command set enabled and stored sets the power-on command set for the transducer. From any command set, the CMD_SET

command can select which one is used.

Command Set 1 – Mensor Legacy

P/W Command Command String Return String Description

None ? #X? X<sp>±Y Basic query to return

readings. Pressure in

native units are returned

None A<x> #X<sp>Y R Sets address of sensor X

to Y (0-9,A-Z)

None CMD_SET<Y> #XCMD_SET<sp>Y R Change CPT6020 into

different command sets.

1 is Mensor Legacy. 0 is

Sensor command set

None DC? #XDC? X<sp>DC<sp>Y Returns the date of

calibration where Y is

mmddyy

Cust DC<Y> #XDC<sp>Y R Loads the date of

calibration where Y is

mmddyy

None DT? #XDT? X<sp>DT<sp>NNN Returns the temperature

a/d DAC offset

None FL? #XFL? X<sp>FL<sp>NN Returns the filter – it is the

percentage of old reading

added to new reading: 0

to 99

None FL<X> #XFL<sp>NN R Sets the filter percentage

None FS? #XFS? X<sp>FS<sp>NN Returns the % FS

uncertainty

None ID? #XID? X<sp> ID <sp> AAAAAAAA,

<sp>BBBBBBBB,

<sp>CCCCCCCC,

<sp>VD.DD

None M? #XM? X<sp>M<sp> Y Returns the operation

None R-? #XR-? X<sp>R-<sp>Y Returns range floor value

None R+? #XR+? X<sp>R+<sp>Y Returns range ceiling

None SAVE #XSAVE R Saves all data to

Returns transducer id.

‘AA…’ is an id string,

‘BB….’ is a model string,

‘CC…’ is the serial

number string, D.DD is the

firmware version

mode

value

EEPROM. Ready char

is sent when save is

complete

22

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 23

Operation

None SC? #XSC? X<sp>SC<>Y Returns the customer

span correction multiplier

Cust SC<X> #XSC<sp>Y R Loads a customer span

correction multiplier

None T? #XT? X<sp>T<sp>C Returns pressure type

None W? #XW? X<sp>W<sp>NN Returns the filter window

in %FS.

Mens W<NN> #XW<sp>NN R Sets the filter window in

counts. Readings inside

this window are filtered.

None ZC? #XZC? X<sp>ZC<sp>Y Returns customer zero

correction value in current

units.

Cust ZC<X> #XZC<sp>Y R Sets customer zero

correction value in current

units.

Table 6.1.3 – Mensor Legacy Command Set

EN

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

23

Page 24

EN

Operation

7. Maintenance and Recalibration

For contact details, please see Chapter 1 “General information” or the back page of the operating instructions.

7.1 Maintenance

The CPT6020 was designed for maintenance-free operation. User maintenance is not recommended. If you have questions not

covered by this manual, call 1-800-984-4200 (USA only), or 1-512-396-4200 for assistance, or send an email to techservices@

mensor.com.

7.1.1 Beyond the Warranty

Take advantage of Mensor’s expert product care. Mensor provides complete maintenance and calibration services, available for

a nominal fee. Our service staff is knowledgeable in the innermost details of all of our transducers. We maintain units that are in

operation in many different industries and in a variety of applications, and by users with a wide range of requirements. Returning

your transducer to Mensor for service benefits you in several ways:

• Our extensive knowledge of the transducer assures you that it will receive expert care.

• Repair or replacement of the CPT6020 transducers will be available up to 7 years after the production life cycle of the product,

pending external vendor parts or equivalent parts availability. The production life cycle is defined as the time from the product

series launch to the announcement of discontinuation (typically 8 to 10 years).

• All repairs should be performed by Mensor due to the complexity of performing these repairs.

7.2 Recalibration

The CPT6020 automatically calculates the pressure reading for all effects of temperature and non-linearity within the compensated

temperature range. The Process is referred to as dynamic compensation because each reading is adjusted before it is output.

Thus, a calibrated CPT6020 operated within its temperature band, and with proper zero and span adjustments, will provide

accurate pressure measurements.

The CPT6020 should have the calibration verified periodically to ensure stability. The recommended calibration interval for this

instrument is given in the Specifications section under “Calibration Interval” in Section 9.1.

.

7.2.1 Calibration Services by Mensor or WIKA worldwide

Mensor and WIKA worldwide have extensive experience and knowledge of Mensor products. Calibration of the transducers can be

performed at the addresses below or by competent internal or external labs using the procedures in this section.

Service Center USA Service Center Europe

Mensor

website: www.mensor.com

tel: 1-512-396-4200

1-800-984-4200

fax: 1-512-396-1820

email: tech.support@mensor.com

Service Center China

WIKA China

website: www.wika.cn

contact: Baggio Li

tel: (+86) 512 6878 8000

fax: (+86) 512 6809 2321

email: baggio.li@wika.com

WIKA Alexander Wiegand SE & Co. KG

website: www.wika.de / www.wika.com

tel: (+49) 9372 132-0

fax: (+49) 9372 132-406

email: CTServiceTeam@wika.com

24

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 25

Transducer

Maintenance and Recalibration

7.2.2 Environment

For maximum accuracy, allow the CPT6020 to warm up a minimum of 15 minutes in ambient temperature within the compensated

range prior to a calibration. In addition, the instrument should be at rest on a stable platform that is free of excessive vibration,

shock and with minimal temperature change.

7.2.3 Pressure Standards

Mensor recommends the use of appropriately accurate primary pressure standards when calibrating this instrument. Such

standards should be sufficient so that when the techniques of the ISO Guide to the Expression of Uncertainty in Measurement

(GUM) are applied, the instrument meets its accuracy statements as required by ISO/IEC 17025:2005, or other applicable

standards.

7.2.4 Media

The recommended calibration medium is dry nitrogen or clean dry instrument air. For ranges above 5 psi any liquid media

compatible with 316L SS is acceptable. A reference height variation between the standard and the CPT6020 can cause errors. A

calculation should be made to compensate for this difference.

7.2.5 Setup

The schematic in Figure 7.2.5 shows a typical setup used to calibrate the CPT6020.

Power

Supply

Communication

EN

Absolute

Under Test

Diaphragm

Capacitance

Gauge

Deadweight

Tester or

Primary

Standard

Supply

Vent

P - V

Controller

Objects in the dashed preimeter are only needed

for sub atmoshheric pressure points.

Figure 7.2.5 - Calibration Setup

When calibrating absolute transducers and approaching very low absolute pressures, you must use a needle valve or controlled

leak to maintain a small pressure (600 mTorr, 80 Pa recommended) throughout the system. If you try to run calibration points

below that pressure, the system will have significant pressure gradients in it unless left to stabilize for an extended period of time.

Needle

Valve

Vacuum

Pump

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

25

Page 26

Maintenance and Recalibration

7.2.6 Calibration & Communication Software

The Operation and Calibration software utility is available on the Mensor.com website from the main menu select Service/

Calibration then Download Software then PC Software.

EN

The purpose of this software is to communicate with the CPT6020 transducer. Calibration of the transducer output and

configuration of various parameters can be accomplished. It has many features that allow you to read and adjust the rich feature

set including:

• Changing filter settings

• Modifying the output format of the sensor

• Changing the pressure units output

It also has many features to adjust various calibration parameters after the appropriate password is sent:

• Setting the calibration date

• Setting the calibration interval

• Setting custom pressure units

• Setting Zero and Span

• Resetting the calibration password

• Restoring the factory calibration

26

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 27

Maintenance and Recalibration

EN

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

27

Page 28

EN

Dismounting, Return and Disposal

8. Dismounting, Return and Disposal

WARNING!

Physical injuries and damage to property and the environment through residual media

Residual media in the dismounted instrument can result in a risk to persons, the environment and equipment.

▶

Wear the requisite protective equipment (see Chapter 3.6 “Personal protective equipment”).

▶

Observe the information in the material safety data sheet for the corresponding medium.

▶

Wash or clean the dismounted instrument, in order to protect persons and the environment from exposure to

residual media.

8.1 Dismounting

WARNING!

Physical injuries and damage to property and the environment through residual media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable or toxic substances), harmful media (e.g.

corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compressors, there is a danger of

physical injuries and damage to property and the environment.

▶

Before storage of the dismounted instrument (following use) wash or clean it, in order to protect persons and the

environment from exposure to residual media.

▶

Wear the requisite protective equipment (see Chapter 3.6 “Personal protective equipment”).

▶

Observe the information in the material safety data sheet for the corresponding medium.

WARNING!

Risk of burns

During dismounting there is a risk of dangerously hot media escaping.

▶

Let the instrument cool down sufficiently before dismounting it!

WARNING!

▶

Power should switched off before disconnecting the device.

WARNING!

Physical injury

When dismounting, there is a danger from aggressive media and high pressures.

▶

Wear the requisite protective equipment (see Chapter 3.6 “Personal protective equipment”).

▶

Observe the information in the material safety data sheet for the corresponding medium.

▶

Only disconnect the pressure measuring instrument/measuring assembly/test and calibration installations once

the system has been de-pressurised.

28

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 29

Dismounting, Return and Disposal

8.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA or Mensor must be free from any kind of hazardous substances (acids, bases, solutions, etc.)

and must be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment through residual media

Residual media in the dismounted instrument can result in a risk to persons, the environment and equipment.

▶

With hazardous substances, include the material safety data sheet for the corresponding medium.

When returning the instrument, use the original packaging or a suitable transport packaging.

To avoid damage:

1. Wrap the instrument in an anti-static plastic film.

2. Place the instrument along with shock-absorbent material in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our local website.

EN

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally compatible way and in accordance with the

country-specific waste disposal regulations.

This marking on the instruments indicates that they must not be disposed of in domestic waste. The disposal is

carried out by return to the manufacturer or by the corresponding municipal authorities.

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

29

Page 30

EN

Specifications

9. Specifications

Accuracy specications presented herein are obtained by comparison with primary standards traceable to a national metrology

institute or recognized international standard organization. These specications are obtained in accordance with the ISO Guide to

the Expression of Uncertainty in Measurement (GUM). The calibration program at Mensor is accredited by the American Association of Laboratory Accreditation (A2LA) as complying with both the ISO/IEC 17025:2005 and the ANSI/NCSL Z540-1-1994

standards. If there is an exception to the requirements and recommendations of Z540 during a calibration the exception is noted on

the individual calibration certicate.

Mensor reserves the right to change specications without notice.

9.1 Measurement Specification

Accuracy

Measuring ranges

Gauge pressure 0 ... 0.36 to 0 ... 1500 psig

Bi-directional pressure

Absolute pressure 0 ... 5 psia to 0 ... 15,015 psia

Calibration interval 185 days

Pressure units 39 and 1 user defined

CPT6020 as barometric reference

Measuring range 8 ... 17 psi abs. (552 ... 1,172 mbar abs.)

Accuracy

1) It is dened by the total measurement uncertainty, with the coverage factor (k = 2) and includes the intrinsic performance of the instrument, the measurement uncertainty of the reference

2) The negative portion of a bidirectional range has the same accuracy as the equivalent positive range.

1)

2)

1)

instrument, long-term stability, inuence of ambient conditions, drift and temperature eects over the compensated range with recommended zero point adjustment every 30 days.

0.020% FS

(0 ... 25 mbar to 0 ... 100 bar)

± 0.18 to -15 ... 1500 psig

(± 12.5 mbar to -1 ... 100 bar)

(0 ... 350 mbar to 0 ... 1001 bar abs.)

0.020% of reading

30

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

Page 31

Specifications

9.2 General Specification

Case

Orientation effects Negligible – completely removable with re-zeroing

Dimensions See technical drawings

Weight ~250 g (depending on range)

Display

Resolution

Warm-up time 15 min.

Connections

Pressure connections SAE J514/JIC or Autoclave® F250C (for pressure ranges > 6000 psi)

Overpressure limit 2X proof, 3X burst; static pressure < 50 psig

Materials, wetted parts Ranges ≤ 5 psi Silicon, 316 SS, glass filled resins, epoxy

Pressure media Ranges ≤ 5 psi – clean, dry, non-corrosive gases

Voltage supply

Power supply 9 to 18 VDC (12 VDC nominal)

Power consumption < 26 mA at 12 VDC +/-5%

Permissible ambient conditions

Compensated temperature range

Operating temperature range

Storage temperature range -40 to 85 oC

Humidity 0 ... 95% r.h. (non -condensing)

Operating altitude <3000 meters (10,000 feet)

Operating environment IP-67

Measure port internal volume <1 cc

Reference port internal olume ~ 40 cc

Communication

Interface RS-232 or RS-485

Baud rate

Measuring rate 50 values/second, default - (factory adjustable)

100 ppb or better

Ranges > 5 to 1500 psi 316 SS

Ranges >1500 psi 316 SS, Fluorocarbon Rubber

Ranges > 5 psi – media compatible with the listed wetted parts.

-20 to 75 oC (-4 to 167 oF)

-40 to 85 oC

Default 57,600 baud - 9600, 19200 and 115200 user selectable

(-40 to 185 oF)

(-40 to 185 oF)

EN

9.3 Approvals and Certificates

Compliance CISPR 11 & A1, IEC 61000-4-2, 3, 4, 5, 6, 11, IEC 61000 A1, A2, IEC 61010-1

Calibration

3) Calibration in a vertical position.

0020507001A 08/2018 EN

3)

A2LA calibration certicate

WIKA operating instructions process pressure transducer, model CPT6020

31

Page 32

Specifications

9.4 Dimensions in mm (in)

Note: Reference port is for gauge type sensors only; for absolute type, and sealed gauge type, the port is plugged.)

EN

108.9mm

4.29in

6 PIN M8 CONNECTOR

1/16" BARBED

REFERENCE PORT

31.8mm

1.25in

85.7mm

3.37in

6 PIN M8 CONNECTOR

117.6mm

4.63in

SEAL SCREW

31.8mm

1.25in

85.7mm

3.37in

122.9mm

4.84in

6 PIN M8 CONNECTOR

SEAL SCREW

31.8mm

1.25in

95.0mm

3.74in

32

18.9mm

.74in

SAE J514 37° FLARE PORT

7/16-20 THREAD

≤1500 psi

18.8mm

.74in

SAE J514 37° FLARE PORT

7/16-20 THREAD

1500 to 6000 psi

6000 to 15000 psi

25.3mm

1.00in

AUTOCLAVE F250C

FEMALE PORT

WIKA operating instructions process pressure transducer, model CPT6020

0020507001A 08/2018 EN

Page 33

Accessories

10. Accessories

10.1 Fittings & Gaskets

Mensor supplies a customer specified fitting with each transducer. Available fittings to connect to the transducer have the following

Mensor Part numbers:

Part Number Description

6000604023 ¼”Male NPT

6000604024 7/16-20 SAE

6000604025 ¼ BSPP

4250040006 Copper gasket washer

Many other fittings are available, consult the factory if you need assistance.

10.2 Accessories

Part Number Description

4050060017 Communication Cable

0020528001 Power Supply & Communication Cable

EN

0020507001A 08/2018 EN

WIKA operating instructions process pressure transducer, model CPT6020

33

Page 34

WIKA subsidiaries worldwide can be found online at www.wika.com.

Mensor LP

201 Barnes Drive

San Marcos, TX 78666 • USA

Tel. (+1) 512 3964200-15

Fax (+1) 512 3961820

E-Mail sales@mensor.com

www.mensor.com

Imported to Europe by:

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

34

34 Mensor operating instructions process pressure transducer, model CPT6020

0020507001A 09/2018 EN

Loading...

Loading...