Page 1

USB pressure transmitter

With USB adapter and software

Model CPT2500

Applications

■

Calibration service companies and service industry

■

Quality assurance

■

Recording and monitoring of pressure processes

■

Measurement of pressure peaks

Special features

■

Recording interval can be set from 1 ms ... 10 s

■

Measuring ranges from 0 ... 25 mbar to 0 ... 1,000 bar

■

Accuracy: 0.2 %, optional 0.1 % (incl. calibration certicate)

■

No external voltage supply required

■

Software for recording of measured values, calibration and

evaluation

Calibration technology

WIKA data sheet CT 05.01

Model CPT2500 USB pressure transmitter with model

CPA2500 USB adapter

Description

Extensive application possibilities

The CPT2500 USB pressure transmitter is suitable for

connection to any PC with a USB port, via the CPA2500 USB

adapter.

For the USB adapter there are stainless steel pressure

transmitters available with measuring ranges up to 1,000 bar.

The USB adapter automatically detects the measuring range

of the currently connected pressure transmitter and ensures

a highly accurate pressure measurement.

Functionality

The measurement interval for pressure recording can be set

in the range of 1 ms ... 10 s. With a recording interval of more

than 5 ms the following data is recorded in addition to the

current measured value:

■

the mean value over the recording interval

■

the maximum and minimum value during the recording

interval

Thus pressure peaks within the overall recording interval can

be very easily identied.

It is also possible to set start and stop conditions for the

recording. In this way it is possible to detect pressure peaks

with a resolution of up to 1 ms.

The CPT2500 is a thus very well suited to all applications

where, over a limited time span, pressure processes must be

recorded and analysed with high resolution.

Software

The USBsoft2500 and USB ScanSoft software are delivered

as standard with the USB adapter. With it, all settings

for recording the pressure process can be made. The

recorded measured values can be graphically displayed and

evaluated.

In addition to the USBsoft2500 and USB ScanSoft software,

WIKA-CAL calibration software for calibration tasks is also

available. Using this software, the data is automatically

transferred into a printable calibration certicate.

Furthermore, WIKA-CAL also oers, over and above

PC-supported calibration, the management of the calibration

and instrument data in an SQL database. For data transfer, a

USB interface is available.

Data sheets showing similar products and accessories:

Hand-Held pressure indicator; model CPH6200; see data sheet CT 11.01

Hand-Held pressure indicator; model CPH6300; see data sheet CT 12.01

Test pumps, hydraulic; CPP-Series; see data sheet CT 91.05

Hand test pump, pneumatic; model CPP30; see data sheet CT 91.06

Calibration software; WIKA-CAL; see data sheet CT 95.10

Page 1 of 6WIKA data sheet CT 05.01 ∙ 05/2014

Page 2

Complete service case

For easy transport and safe storage, the USB adapter is

delivered in a compact transport case, which can also hold

one or more pressure transmitters.

Certied accuracy

For each reference pressure sensor, the accuracy for the

complete measuring chain is certied by a factory calibration

certicate which accompanies the instrument. On request,

we can provide a DKD/DAkkS calibration certicate for this

instrument.

Specications

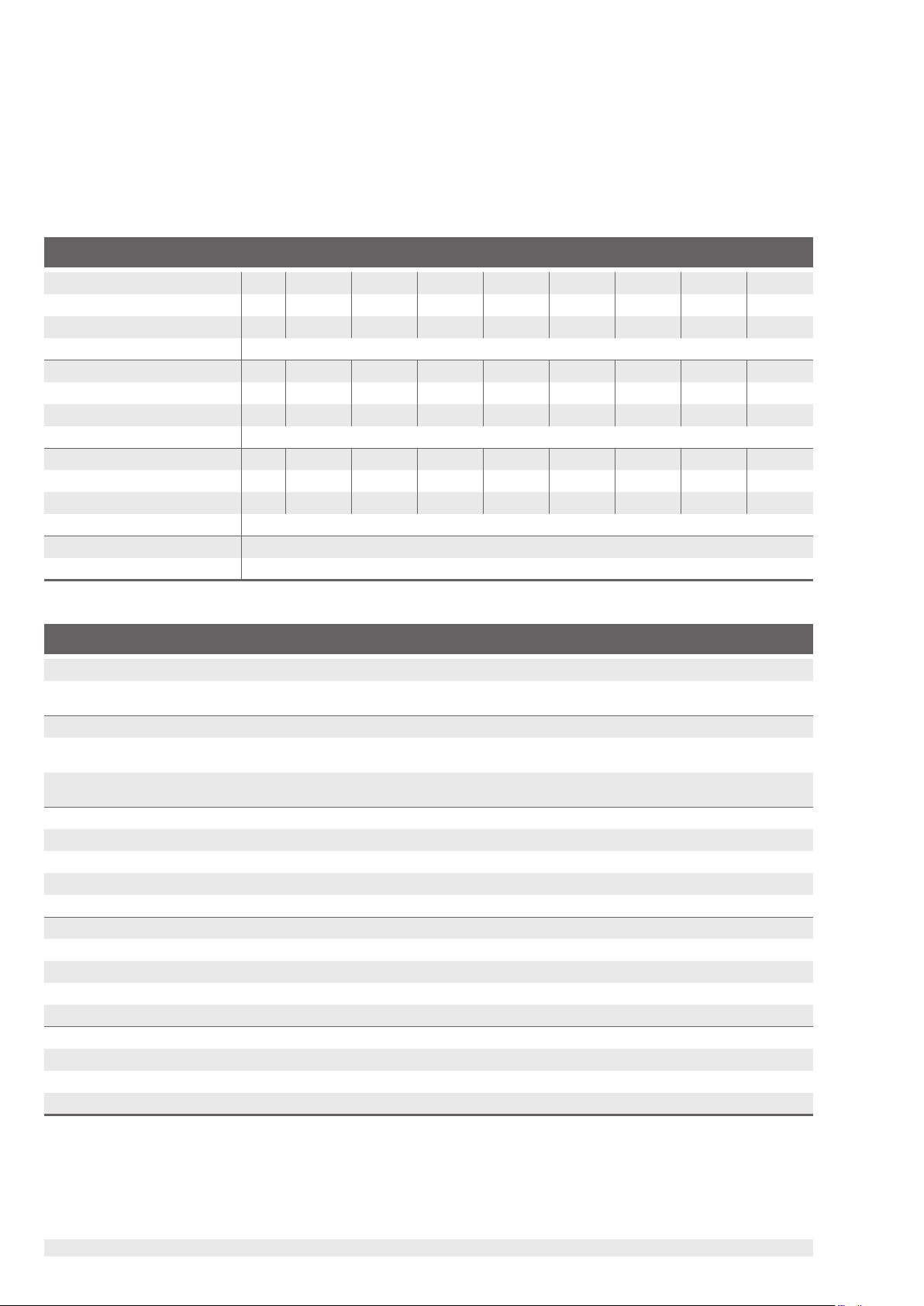

USB pressure transmitter model CPT2500 (complete measuring chain)

Measuring range mbar 0 ... 25 0 ... 40 0 ... 60 0 ... 100 0 ... 160 0 ... 250 0 ... 400 0 ... 600

Overpressure limit mbar 500 500 500 1,000 1,500 2,000 2,000 4,000

Burst pressure mbar 1,000 1,000 1,000 2,000 2,000 2,400 2,400 4,800

Resolution dependant on pressure range (max. 4 1/2-digit)

Measuring range bar 0 ... 1 0 ... 1.6 0 ... 2.5 0 ... 4 0 ... 6 0 ... 10 0 ... 16 0 ... 25

Overpressure limit bar 5 10 10 17 35 35 80 50

Burst pressure bar 6 12 12 20.5 42 42 96 96

Resolution dependant on pressure range (max. 4 1/2-digit)

Measuring range bar 0 ... 40 0 ... 60 0 ... 100 0 ... 160 0 ... 250 0 ... 400 0 ... 600 0 ... 1,000

Overpressure limit bar 80 120 200 320 500 800 1,200 1,500

Burst pressure bar 400 550 800 1,000 1,200 1,700 2,400 3,000

Resolution dependant on pressure range (max. 4 1/2-digit)

Type of pressure Relative pressure, {absolute pressure from 0 ... 25 bar abs. and vacuum from -1 ... +24 bar}

Accuracy of the measuring chain 0.2 % FS (resolution 4-digit); {optional: 0.1 % FS (resolution 4 1/2-digit)}

{ } Items in curved brackets are optional extras for an additional price.

Rererence pressure sensor model CPT2500

Process connection

Pressure units mbar, bar, Pa, kPa, MPa, mmHg, psi, inHg (0 °C), inHg (60 °F), mWs; (depending on the measuring

Material

Wetted parts Stainless steel or Elgiloy

Internal transmission uid Synthetic oil (only for measuring ranges up to 16 bar or ush diaphragm)

Sensor specication

Accuracy per year ≤ 0.2 % of span at reference conditions

Compensated range 0 ... 80 °C

Mean temperature coecient ≤ 0.2 % of span/10 K (outside of reference conditions)

Measuring rate 1,000 measurements/s

Permissible ambient conditions

Medium temperature -25 ... +100 °C

Operating temperature -20 ... +80 °C

Storage temperature -40 ... +100 °C

Relative humidity 0 ... 95 % r. h. (non-condensing)

Case

Material Stainless steel

Dimensions see technical drawings

Weight approx. 220 g

{ } Items in curved brackets are optional extras for an additional price.

1) As an oxygen version, a ush diaphragm model is not available. In an oxygen version, the model CPT2500 is only available in gauge pressure ranges ≥ 0.25 bar, with media tempera-

tures between -10 … +50 °C and using stainless steel or Elgiloy® wetted parts.

2) For pressure measuring ranges 0 ... 25 mbar, 0 ... 40 mbar and 0 ... 60 mbar all wetted parts are made of stainless steel, silicium, aluminium, gold, silicone.

3) Reference conditions: 15 ... 25 °C

4) For pressure measuring ranges 0 ... 25 mbar, 0 ... 40 mbar and 0 ... 60 mbar the medium temperature and storage temperature are limited to +80 °C.

1)

G ½ B; {ush diaphragm (G 1 for 0.1 up to 1.6 bar) or various connection adapters on request}

range, selectable)

®

, (> 25 bar with additional NBR seal)

2)

Flush diaphragm version: stainless steel {Hastelloy C4}; O-ring: NBR {FKM/FPM or EPDM}

{Halocarbon oil for oxygen applications}; {Listed by FDA for food industry}

3)

4)

4)

Page 2 of 6 WIKA data sheet CT 05.01 ∙ 05/2014

Page 3

USB adapter model CPA2500

Communication

PC connection Standard USB connector (type A)

Electrical sensor connection Circular connector, 7-pin, M16 x 0.75

Recording interval 1 ms ... 10 s, adjustable via software

Recording options selectable start/stop conditions, pre-trigger, stop-delay

Voltage supply

Power supply Supply via USB port

Permissible ambient conditions

Operating temperature -25 ... +50 °C

Storage temperature -25 ... +70 °C

Relative humidity 0 ... 95 % r. h. (non-condensing)

Case

Dimensions see technical drawings

Weight approx. 120 g

CE conformity, approvals, certicates

CE conformity for the model CPT2500 USB pressure transmitter

Pressure equipment directive 97/23/EC, module A, pressure accessory

EMC directive 2004/108/EC, EN 61326 Emission (group 1, class B) and interference immunity (commercial

applications, laboratories, service centres and workshops)

CE conformity for the model CPA2500 USB adapter

EMC directive 2004/108/EC, EN 61326 Emission (group 1, class B) and interference immunity (controlled

electromagnetic environment)

Approvals

GOST-R Import certicate, Russia

Certicates

Calibration Standard: 3.1 calibration certicate per DIN EN 10204

Option: DKD/DAkkS calibration certicate

Approvals and certicates, see website

Dimensions in mm

USB adapter model CPA2500

Lumberg KV 70 USB connector type A

Page 3 of 6WIKA data sheet CT 05.01 ∙ 05/2014

Page 4

Dimensions in mm

USB pressure transmitter model CPT2500

USBsoft2500 and USB ScanSoft conguration and evaluation software

The USBsoft2500 software is required for the operation of the

model CPT2500 USB pressure transmitter in connection with

the model CPA2500 USB adapter. This enables the conguration of the pressure transmitter as well as the selection of

the various recording settings.

The software also allows dierent start/stop conditions to

be dened, in order to easily identify, for example, a single

pressure peak.

Graphical evaluation of the measured data (including mean,

min- and max-values), in addition the measured data can

also be exported to other software.

Several series of measurements can be displayed in a single

chart.

Using software USB ScanSoft, several CPT2500 in combination with model CPA2500 USB adapter can be run parallel.

For each CPT2500 one CPA2500 is required.

Performance data

■

Recording interval of 1 ms ... 10 s

■

Data export to other programs e.g. Excel

■

Languages: German, English, Spanish and Czech

®

System requirements for USBsoft2500

■

CPU with at least 1 GHz

■

At least 20 MB free hard disc space

■

CD-ROM drive

■

At least 256 MB RAM

■

Windows® operating system 95, 98, NT 4.0 (with Service

Pack 3.0 or higher), 2000, XP, Vista or 7

■

USB port

System requirements for USB ScanSoft

■

CPU with at least 1.2 GHz

■

At least 100 MB free hard disc space

■

CD-ROM drive

■

At least 1 GB RAM

■

Windows® operating system XP (SP 3), Vista (SP2) or 7

(SP1)

■

USB port

Windows® is a registered trademark of Microsoft Corporation in the United States and other countries.

Page 4 of 6 WIKA data sheet CT 05.01 ∙ 05/2014

Page 5

WIKA-CAL calibration software

Easy and fast creation of a high-quality calibration

certicate

The WIKA-CAL calibration software is used for generating

calibration certicates or logger protocols for pressure

measuring instruments and is available as a demo version for

a cost-free download.

A template helps the user and guides him through the

creation process of a document.

In order to switch from the demo version to a full version of

the respective template, a USB key with the template has to

be purchased.

The pre-installed demo version automatically changes to

the selected full version when the USB key is inserted and

is available as long as the USB key is connected to the

computer.

■

Creation of calibration certicates for mechanical and

electronic pressure measuring instruments

■

A calibration assistant guides you through the calibration

■

Automatic generation of the calibration steps

■

Generation of 3.1 certicates in accordance with

DIN EN 10204

■

Creation of logger protocols

■

User-friendly interface

■

Languages: German, English, Italian and more due with

software updates

For further information see data sheet CT 95.10

Calibration certicates can be created with the Cal-Template and logger protocols can be created with the Log-Template.

Cal Demo

Generation of calibration certicates limited to 2 measuring

points, with automatic initiation of pressures via a pressure

controller.

Cal Light

Generation of calibration certicates with no limitations on

measuring points, without automatic initiation of pressures

via a pressure controller.

Log Demo

Creation of data logger test reports, limited to 5 measured

values.

Log

Creation of data logger test reports without limiting the

measured values.

Page 5 of 6WIKA data sheet CT 05.01 ∙ 05/2014

Page 6

Scope of delivery

■

USB pressure transmitter model CPT2500

■

USB adapter model CPA2500

■

Software USBsoft2500 and USB ScanSoft

■

Transport case

■

Operating instructions

■

3.1 calibration certicate per DIN EN 10204

Options

■

DKD/DAkkS certied accuracy

■

Sensors for oxygen applications

Accessories

Connection adapters

■

Various pressure adapters

■

MINIMESS® quick-connect process connection system

Pressure generation

■

Pneumatic test pumps

■

Hydraulic test pumps

Software

■

WIKA-CAL calibration software

Transport case with USB pressure transmitter and

USB adapter

Ordering information

Model / Unit / Measuring range / Accuracy / Process connection / Extension cable / Type of certicate / Accessories /

Additional order information

© 2008 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

Page 6 of 6 WIKA data sheet CT 05.01 ∙ 05/2014

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

05/2014 GB

Loading...

Loading...