Page 1

Precision Pressure Indicator

Model CPG2500

Applications

Pressure standard for calibration labs

Transfer standard with remote transducers

Pressure instrument manufacturing

Dierential pressure measurement

Simultaneous three channel pressure monitoring

Features

Pressure ranges from 0.36 to 42,000 psi

Removable / Interchangeable transducers

Accuracy down to 0.008% of IS (IntelliScale)

External pressure ranges from 0.36 to 6,000 psi

Precision 0.004% FS

Two year warranty

Calibration Technology

WIKA data sheet CT 25.02 ∙05/2018

Precision Pressure Indicator CPG2500

Description

Application

The CPG2500 is used in calibration laboratories and manufacturing facilities as a source for precise pressure measurement.

It is used to verify the accuracy of eld pressure indicators/

transmitters or as a laboratory standard and wherever there is

a need for a high level of pressure accuracy in manufacturing,

testing and calibration of pressure instruments or gauges.

Functionality

The CPG2500 can be congured with 1, 2, or 3 pressure

transducers. Two transducers are internal, and the third is

external. The transducer channels are pneumatically isolated

so that one channel can be congured with a sensor as high

as 10,000 psi / 700 bar and another as low as 10 inH2O / 25

mbar. An optional barometric reference sensor can be added

internally to display barometric pressure or used to emulate

gauge or absolute pressure. Pressure ranges for each channel

are specied by the customer. Standard and premium sensors

are available internally. External transducers are Mensor’s

CPT6100 or CPT6180 digital pressure transducers. See trans-

ducer chart on page 3 for ranges and uncertainty specication.

WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018

Advantage of IntelliScale and removable tansducers

With the IntelliScale specication, each sensor is calibrated

to give a percent of reading in the upper portion of the range.

Three transducers can be congured so that the percent

of reading portions of their ranges are contiguous, giving a

percent of reading uncertainty over a wide range. In addition,

each transducer is removable and interchangeable which allows remote recertication and quick transducer range changes while minimising downtime. The CPT6180 or CPT6100

external sensor is also available for remote applications.

Communication

The local user interface is displayed on a 7” color LCD touch-

screen. Navigation within the intuitive menu structure is easily

learned. Recognizable touchscreen icons open screens for

conguration and calibration. Communicating to a remote

computer is achieved through RS-232, IEEE-488, USB or

Ethernet. Communication commands and queries are consistent with previous Mensor digital pressure gauges with added

commands for the third channel.

Page 1 of 8

Page 2

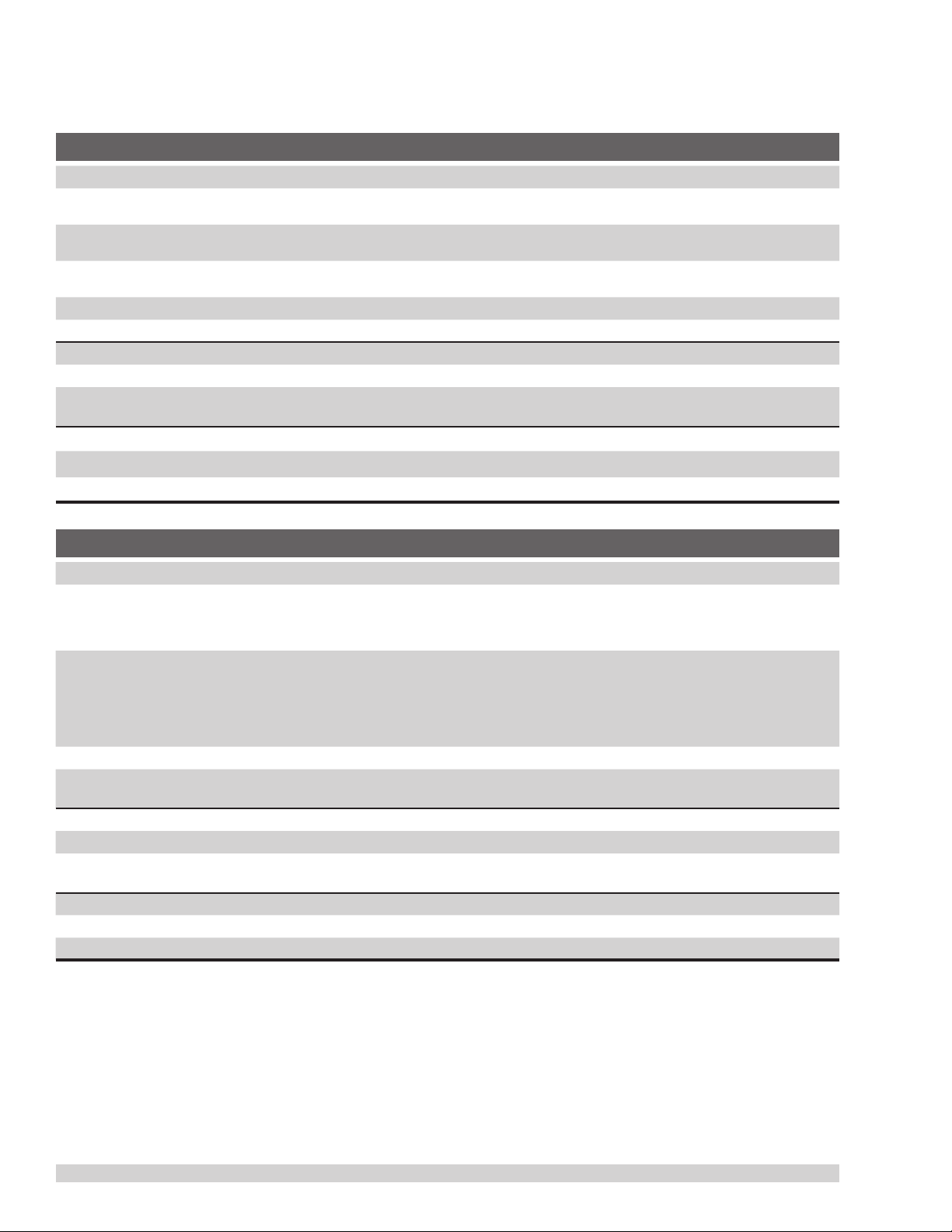

Specications

Model CPG2500

Standard Reference Transducers, Model CPR2550

Accuracy

Gauge Pressure

(1)

0.01%FS

0 ... 0.36 up to 10,000 psi

0 ... 25 mbar up to 700 bar

Bi-Directional Pressure

-0.18. ... 0.18 to -14.5 ... 10,000 psi

-12.5 ... 12.5 mbar to -1 ... 700 bar

Absolute Pressure

(4)

0 ... 7.5 up to 10,015 psi

0 ... 0.5 up to 701 bar

Precision

(5)

0.004%FS 0.004%FS

Calibration Interval 365 days

Media Compatibility

Metals in contact with media 6000/7000 series Aluminum, 316 SS, brass

Non-metals in contact with

media

PTFE (Teon®), Urethane, Silicone, RTV, Silicone grease, PVC, Epoxy, Buna-N, uoroelastomers (Viton®)

Sensor

Reading rate 33 readings/second

Calibration adjustments Internal zero adder and span multiplier, up to 11 point linearization for each sensor

(3)

0.01%IS-50

(2)

0 ...14.5 up to 6000 psi

0 ... 1 up to 400 bar

-14.5 ... 145 to -14.5 ... 6000 psi

-1 ... 10 to -1 ... 400 bar

0 ... 14.5 up to 6015 psi

0 ... 1 up to 401 bar

(6)

365 days

Premium Reference Transducers, Model CPR2580

Accuracy

Gauge

Pressure

(1)

0.008% IS-33

0 ... 12 to 0 ...16.5 psig

0 ... 17.5 to 0 ... 33 psig

0 ... 80 to 0 ... 110 psig

0 ... 120 to 0 ... 220 psig

Absolute

Pressure

0 ... 12 to 0 ...16.5 psia

(4)

0 ... 18.4 to 0 ... 33 psia

0 ... 36 to 0 ... 50 psia

0 ... 80 to 0 ... 110 psia

0 ... 160 to 0 ... 220 psia

0 ... 240 to 0 ... 500 psia

Precision

Calibration

(5)

0.004% FS 0.004%FS 0.004%FS 0.004%FS

365 days 365 days 365 days 365 days

Interval

Media Compatibility

Metals in contact with media 6000/7000 series aluminum, 316 SS, brass, inconel

Non-metals in contact with media PTFE (Teon®), Urethane, Silicone, RTV, Silicone grease, PVC, Epoxy, Buna-N,

Sensor

Reading rate 10 readings/second

Calibration adjustment Internal Zero adder and Span multiplier, up to 11 point linearization for each sensor

(1)

It is dened by the total measurement uncertainty, with the coverage factor (k = 2) and includes the intrinsic performance of the instrument, the measurement uncertainty of the reference

instrument, long-term stability, inuence of ambient conditions, drift and temperature eects over the compensated range with recommended zero point adjustment every 30 days

(2)

0.01 % IS-50 accuracy: Between 0 ... 50 % of the full scale, the accuracy is 0.01% of half of the full scale value and between 50 ... 100 % of the full scale, the accuracy is 0.01 % of reading

(3)

FS = full span.

(4)

The minimum calibrated range of absolute transducer(s) is 600 mTorr

(5)

It is dened as the combined eects of linearity, repeatability and hysteresis throughout the stated compensated temperature range.

(6)

180 days for pressure ranges below 1 bar (15 psi) and above 400 bar (6,000 psi) gauge or absolute, and -1...1 bar (-15 ...14.5 psi) bidirectional. 365 days for the remainder of the specied

ranges.

(7)

0.008 % IS-33 accuracy: Between 0 ... 33 % of the full scale, the accuracy is 0.008% of one third of the full scale value and between 33 ... 100 % of the full scale, the accuracy is 0.008 % of

reading

.

(8)

0.008 % IS-50 accuracy: Between 0 ... 50 % of the full scale, the accuracy is 0.008% of half of the full scale value and between 50 ... 100 % of the full scale, the accuracy is 0.008 % of reading.

(7)

0.008% IS-50

(8)

0.01% FS

(3)

0.014% FS

(3)

— — —

0 ... 700 to 0 ... 1100 psia

0 ... 1400 to 0 ... 3300 psia

0 ... 4200 to 0 ... 6600 psia

0 ... 8000 to 0 ... 11,000 psia 0 ... 12,000 to 0 ... 22,000 psia

0 ... 24,000 to 0 ... 31,500 psia

0 ... 32,000 to 0 ... 42,000 psia

uoroelastomers (Viton®)

.

.

.

WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018 Page 2 of 8

Page 3

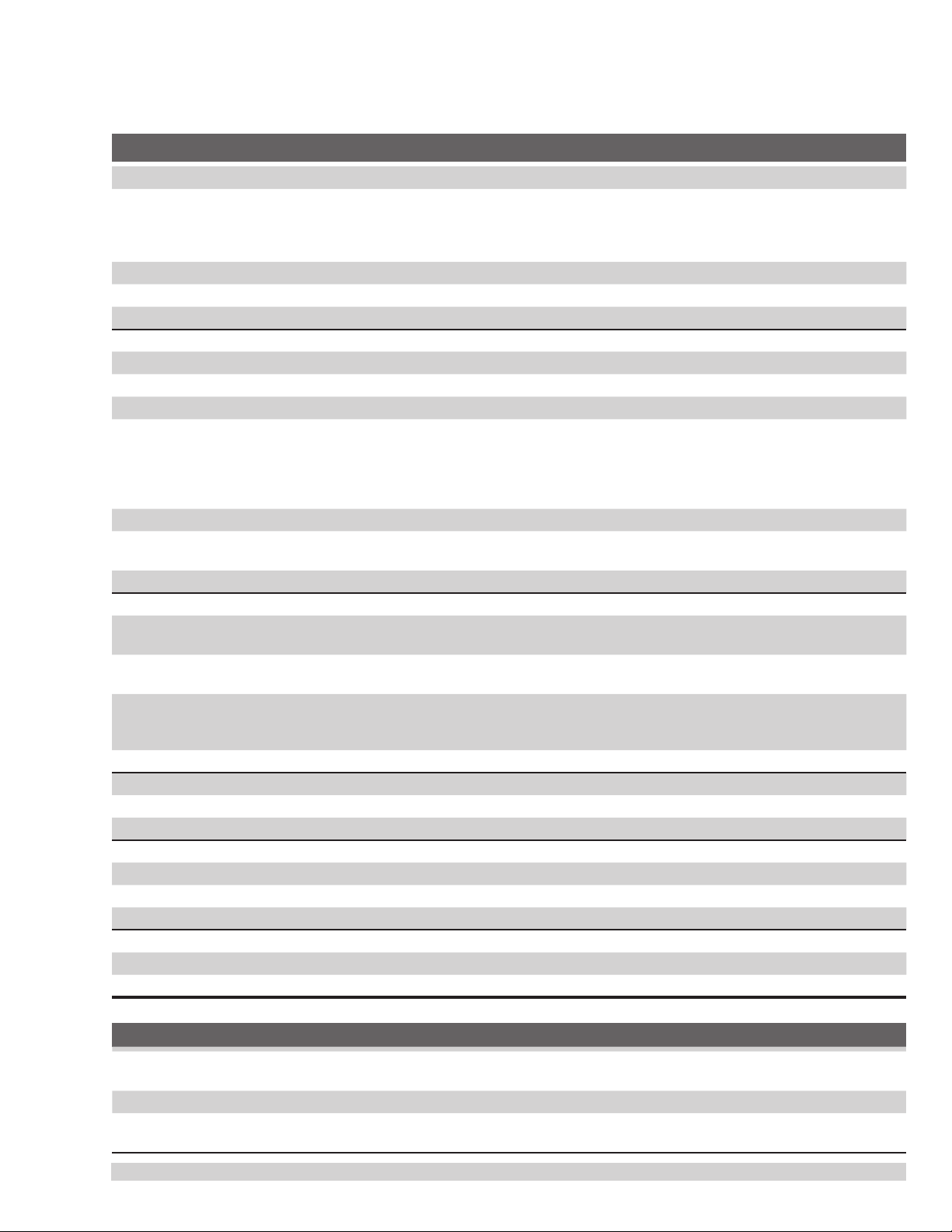

Specications (Continued)

Model CPG2500

Basic Instrument

Instrument

Instrument version Standard: Table top with tilt feet

Option:

-19” rack-mounting with side panels incl. rack-mounting kit for single instrument mount.

-19” rack-mounting with side panels incl. rack-mounting kit for dual instrument mount.

Dimensions See technical drawing

Weight 12.5 lbs./ 5.7 kg (with all internal options)

Warm-up time Approximately 15 minutes

Display

Screen 7” color LCD

Resolution Selectable from 4 to 7 digits, depending on range and units

Data entry Touch screen keypad

Measurement Units psi, psf, osi, atm, inH20@4C, inH20@20C, inH20@60F, mbar, bar, Dy/cm2, pascal,

hPa, kPa, MPa, inHg@0C, inHg@60F, mTorr, Torr, mmHg@0C, cmHg@0C, mHg@0C,

mmH20@4C, cmH20@4C, mH20@4C, mmH20@20C, cmH20@20C, mH20@20C, mSW,

ftH20@4C, ftH20@20C, ftH20@60F, inSW, ftSW, tsi, tsf, g/cm2, kg/cm2, kg/m2, % of Range,

+ plus 2 user dened units (multiplier from psi, bar or pascal)

Rate Units /sec., /min., /hr., /3-hr

Languages English, German, Spanish, French, Italian, Portuguese, Polish, Russian, Chinese,

Japanese, Korean

Measurement lters O, Low, Normal (default), High

Connections

Number of integrated transducer

(selectable)

Pressure connections To 6000 psi: 7/16 - 20 female SAE/MS. 1/8” FNPT adapters provided.

Pressure adaptors Standard: None

Overpressure limits 110 % FS typical, optional external relief valves are available

Voltage supply

Power input requirements 100-120 or 200-240 VAC, 50-60Hz, 24VA max

Switching power supply Output: 12 VDC, 1.67 A (includes 4 region specic plugs adapters)

Permissible ambient conditions

Storage temperature range 0 to 70 deg C

Operating environment 0 ... 95 % RH (relative humidity, non-condensing)

Operating temperature range 15 ... 40 deg C

Communications

Remote interface IEEE 488, RS--232, USB and Ethernet

Command sets Mensor, WIKA SCPI

Standard: 1 reference transducer

Optional: 2nd reference transducers, external transducer, internal barometric reference

Ranges >6000 psi: Autoclave F250C/HIP HF4

Optional: 1/4 inch Swagelok® tube ttings, 6 mm Swagelok® tube ttings, 1/8 in. female

NPT ttings or 1/8 in. female BSP ttings.

CE conformity and certicates

CE compliance EN61326-1:2013 electromagnetic compliance

EN61010-1:2010 safety/CB scheme

RoHS directive 2011/65/EU, aticle 4

Calibration Calibration certicate per ISO/IEC 17025:2005. Accreditation is by the American

Association for Laboratory Accreditation (A2LA).

Page 3 of 8 WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018

Page 4

Dimensions in inches

Desk top case

Front view

Single mount - Front view

Side view

19” rack mount

Dual mount - Front view

Remote Transducer

connection

RS-232

USB (device)

USB (host)

Ethernet port

IEEE-488

Power Supply

Rear Panel

Measure port

Channel B

(7/16-20 UNF)

Baro ref port

(baro ref option)

Measure port

Channel A

(7/16-20 UNF)

Page 4 of 8 WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018

Page 5

Operator Interface

Single frame Channel “A”

with auxiliary display of Alternate Units, Peak and Rate. Barometer units set to psi.

Reading for optional barometer

Dual frame Channel “A” and “B”

without auxiliary display of Alternate Units, Peak and Rate.

Barometer units set to inHg 0oC.

Local Operation:

The intuitive operator interface of the CPG2500 provides

visibility of one, two or three channels, each with, or without

the auxiliary display of “Alternate Units”, “Peak”, and/or “Rate”.

Readings from the optional barometer can also be displayed

in the lower right hand corner. Pressure units for each channel

and the barometer can be selected from a list of 38 metric and

imperial units. The setup “apps” are continuously visible for fast

conguration for various applications.

Remote Operation:

Remote control of the CPG2500 is achieved through the use

of the IEEE-488, RS-232, Ethernet or USB communication

interface.

Triple frame Channel “A”, “B” and “Remote”

with auxiliary display of Alternate Units, Peak and Rate, plus

Zero button displayed. Barometer units set to psi.

RS-232 connection

to remote transducer

RS-232

communication

Ethernet

communication

Communication Panel

IEEE-488

communication

USB Device

USB Host

12 VDC Power

WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018 Page 5 of 8

Page 6

Transducer versatility

One or two transducers can be chosen from the list provided

in the “Transducers” section of the specications on page 3. In

addition, a remote transducer range (Max Range ≤ 6015 psi)

can be chosen from the “Standard Range” section. Remote

transducers are Mensor CPT6100 or CPT6180 models set to

communicate via RS-232 with a baud rate that can be chosen

from four selectable baud rates.

All internal transducers are removable and interchangeable.

Simply remove the 4 slotted screws on the rear panel, slide

the transducer out and remove the communication cable. An

optional removable internal barometric reference can also be

ordered.

All CPG2500 transducers can be calibrated while in the

instrument using the instrument rmware. They can also be

calibrated externally with an optional communication / power

cable, calibration sled (needed for barometer only) and remote

calibration software.

Removable / Replaceable Transducer

Application

Precision Pressure Indicator CPG2500

There are a variety of applications for the CPG2500:

Transfer standard to verify the accuracy of eld or factory

transducers, digital or dial pressure gauges

Laboratory pressure standard

High accuracy pressure indicator

Dierential pressure indication, for verication or calibra-

tion

Precision barometer

Component in an OEM application that requires pressure

indication and precision pressure output

Precision ow meter pressure monitoring

Leak testing

Remote indication of pressure in manufacturing pro-

cesses

Remote Transducer

Communication

RS-232

Communication

RS-232

IEEE-488

USB

Ethernet

Removable / Replaceable

Barometric Reference

CPT6100 or CPT6180

Remote Transducer

Remote communication to PC

Page 6 of 8 WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018

Page 7

WIKA-CAL calibration software

Easy and fast creation of a high-quality calibration certicate

The WIKA-CAL calibration software is used for generating

calibration certicates or logger protocols for pressure measuring

instruments and is available as a demo version for a cost-free

download.

A template helps the user and guides him through the creation

process of a document.

In order to switch from the demo version to a full version of the

respective template, a USB key with the template has to be

purchased.

The pre-installed demo version automatically changes to the

selected full version when the USB key is inserted and is available

as long as the USB key is connected to the computer.

■

Creation of calibration certicates for mechanical and electronic

pressure measuring instruments

■

Fully automatic calibration with pressure controllers

■

Calibration of gauge pressure measuring instruments with

absolute pressure references and vice versa

■

A calibration assistant guides you through the calibration

■

Automatic generation of the calibration steps

■

Generation of 3.1 certicates per DIN EN 10204

■

Creation of logger protocols

■

User-friendly interface

■

Languages: German, English, Italian and more due with

software updates

For further information see data sheet CT 95.10

Calibration certicates can be created with the Cal-Template and logger protocols can be created with the Log-Template.

Cal Demo

Generation of calibration certicates limited to 2 measuring points,

with automatic initiation of pressures via a pressure controller.

Cal Light

Generation of calibration certicates with no limitations on measuring

points, without automatic initiation of pressures via a pressure

controller.

Cal

Generation of calibration certicates with no limitations on measuring

points, with automatic initiation of pressures via a pressure controller.

Log Demo

Creation of data logger test reports, limited to 5 measured values.

Log

Creation of data logger test reports without limiting the measured

values.

WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018 Page 7 of 8

Page 8

Scope of delivery

Accessories

Precision Pressure Indicator CPG2500

Switching power supply with 5 ft / 1.5 m power cord

Operating instructions

ISO/IEC 17025:2005, A2LA accredited calibration certi-

cate

Options

DKD/DAkkS calibration certicate

19” rack mount kits

Second internal sensor

External pressure sensor (CPT6100 or CPT6180)

Barometric reference

Analog output

Single range barometer

Pressure relief valve kit (up to 6000 psi (400 bar))

Robust transport case

Pressure adapters

Interface cable

WIKA-CAL calibration software

Barometer calibration sled

Ordering information

Model / Case type / Reference pressure sensor channel A / Reference pressure sensor channel B / External pressure sensor

connection cable / Barometric reference / Type of certicate for barometric reference / Additional ordering information

© 2015 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

Page 8 of 8

WIKA data sheet CT 25.02 ∙ PN 0019642001D ∙ 05/2018

Mensor

201 Barnes Drive

San Marcos, TX 78666

Tel. (512) 396-4200

Fax (512) 396-1820

sales@mensor.com

www.mensor.com

Loading...

Loading...