Page 1

Precision Pressure Indicator

CPG2500

Operating Instructions

Precision Pressure Indicator CPG2500 PN 0018908001B • 11/2014

Page 2

Precision Pressure Indicator

CPG2500

This Warning symbol indicates that danger of injury for

persons and the environment and/or considerable damage

!

Warning

!

Caution

i

Notice

(mortal danger, danger of injury) will occur if the respective

safety precautions are not taken.

This Caution symbol indicates danger for the system and

material if the respective safety precautions are not taken.

This Notice symbol does not indicate safety notices but

information for a better understanding of the facts.

2 Operating Instructions - CPG2500

Page 3

Precision Pressure Indicator

CPG2500

Table of Contents

1. General Information 7

1.1 Warranty 7

1.2 Important Notice 7

1.3 FCC Radio Frequency Emission Notice 7

1.4 Trademarks and Copyrights 8

1.5 Software License Agreement 8

1.6 Mensor Service Plus 8

1.6.1 After the Warranty 8

1.6.2 Calibration Services 8

1.6.3 Certications and Accreditations 8

1.7 Packaging for Shipment 8

2. Safety Notices 9

2.1 User Responsibilities 9

2.2 General Safety Notices 9

2.3 Warnings and Caution Notices 10

3. General Description 11

3.1 Features 11

3.2 Turning On 12

3.3 Front Panel 12

3.4 Display 13

3.5 Chassis Assembly 13

4. Specications 15

4.1 Transducer Specication 15

4.2 Measurement & General Specications 16

5. Installation 17

5.1 Unpacking the Instrument 17

5.2 Dimensions (inches) 18

5.3 Mounting 19

5.4 Rear Panel 19

5.4.1 Pressure Connections 20

5.4.2 Pressure Port 20

5.4.3 Reference Port 20

5.5 Remote Communication Connections 20

5.6 Power Up 20

Operating Instructions - CPG2500 3

Page 4

Precision Pressure Indicator

CPG2500

6. Local Operation and Setup 21

6.1 General Operation 21

6.1.1 Setup Applications 21

6.1.2 Display Screen Features 21

6.2 Initial Setup 22

6.2.1 Contact and Version Information Application 22

6.2.2 Language Selection 22

6.3 Application Selection and parameter inputs 23

6.4 Applications 24

6.4.1 Measure Application 24

6.4.1.1 Pressure Mode / Emulation Mode 25

6.4.1.2 Auxiliary Displays 25

6.4.1.3 Zero Button 26

6.4.1.4 Tare Button 27

6.4.2 Settings Application 28

6.4.2.1 Languages 28

6.4.2.2 Brightness 29

6.4.2.3 Volume 29

6.4.2.4 User base units / Base units multiplier 30

6.4.2.5 Barometer Units 30

6.4.2.6 Conguration 31

6.4.3 Frames Application 32

6.4.3.1 Frame Format 32

6.4.3.2 Frames Channel 33

6.4.4 Transducer Application 34

6.4.4.1 Transducer Channel Selection 34

6.4.4.2 Transducer Delta Emulation 35

6.4.4.3 Transducer Filter 35

6.4.4.4 Transducer Resolution 36

6.4.4.5 Auxiliary Displays 37

6.4.4.6 Cal Function 38

6.4.5 Remote Application 39

6.4.5.1 Remote Command Set 39

6.4.5.2 Remote Communication Settings 40

6.4.6 Info Application 41

6.4.7 Leak Test Application 42

6.4.8 Troubleshooting Application 43

6.4.9 Service Application 44

6.4.10 Unlocked Service Application 45

4 Operating Instructions - CPG2500

Page 5

Precision Pressure Indicator

CPG2500

7. Remote Operation 47

7.1 Command Set 47

7.2 IEEE-488 47

7.2.1 IEEE-488.2 Commands 47

7.3 Ethernet 48

7.4 Serial 49

7.4.1 Serial Cable Requirements 49

7.5 Mensor Command Set 50

7.6 Command and Query Format 50

7.7 Command Set Denitions 50

7.8 Output Formats 51

7.9 CPG2500 Commands and Queries 51

7.9.1 Units Command Syntax for Measurement Units 56

7.9.2 CPG2500 Error Codes 57

7.9.3 SCPI Commands and Queries 57

7.9.4 SCPI Commands Error Messages and Error Codes 59

7.9.5 GPIB Capability Codes 59

7.9.6 Interface Functions 59

8. Options 61

8.1 Barometer 61

8.2 Barometric Reference 61

8.2.1 Absolute Pressure Emulation 61

8.2.2 Emulation Mode Accuracy 62

8.2.3 Barometric Reference Calibration 62

8.2.4 Barometric reference Specications 62

8.3 Delta Channel 62

8.4 External Transducers (CPT6100 and CPT6180) 62

8.4.1 External Pressure Sensor Connection Cable 62

8.5 External Sensor Package (D-Sub) 63

8.6 Analog Output 63

8.6.1 Specications 63

8.7 Rack Mount Kit 63

8.8 Fittings 63

8.9 Remote Calibration 63

8.9.1 Remote Calibration Kit for Internal Transducers. 64

8.9.2 Barometric Reference Calibration Sled 64

8.9.3 External Calibration Procedures 65

8.9.3.1 Transducer Removal 65

8.9.3.2 Barometric Reference Removal 65

Operating Instructions - CPG2500 5

Page 6

Precision Pressure Indicator

CPG2500

9. Maintenance 67

9.1 Beyond the Warranty 67

9.2 Spare Parts 67

10. Calibration 69

10.1 Environment 69

10.2 Pressure Standards 69

10.3 Media 69

10.4 Setup 70

10.5 Service Application 71

10.5.1 Service Application (unlocked) 72

10.6 Calibration Data 73

10.7 One Point Cal Application 73

10.8 Two Point Cal Application 74

10.9 Linearization 75

10.10 Head Pressure 77

11. Appendix 79

11.1 Conversion Factors, PSI 80

11.2 Conversion Factors, Millitorr 81

11.3 Conversion Factors, Pascal 82

6 Operating Instructions - CPG2500

Page 7

Precision Pressure Indicator

CPG2500

1 General Information

1.1 Warranty

All products manufactured by Mensor are warranted to be free of defects in workmanship and materials for

a period of one year from the date of shipment. No other express warranty is given, and no armation of

Seller, by words or actions, shall constitute a warranty. SELLER DISCLAIMS ANY IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSES WHATSOEVER. If any defect

in workmanship or material should develop under conditions of normal use and service within the warranty

period, repairs will be made at no charge to the original purchaser, upon delivery of the product(s) to the

factory, shipping charges prepaid. If inspection by Mensor or its authorized representative reveals that the

product was damaged by accident, alteration, misuse, abuse, faulty installation or other causes beyond the

control of Mensor, this warranty does not apply. The judgment of Mensor will be nal as to all matters concerning condition of the product, the cause and nature of a defect, and the necessity or manner of repair.

Service, repairs or disassembly of the product in any manner, performed without specic factory permission, voids this warranty.

MENSOR MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. Mensor shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

1.2 Important Notice

The product specications and other information contained in this manual are subject to change without

notice.

Mensor has made a concerted eort to provide complete and current information for the proper use of

the equipment. If there are questions regarding this manual or the proper use of the equipment, contact

Mensor at:

Mensor WIKA Alexander Wiegand SE & Co. KG

201 Barnes Drive Alexander-Wiegand-Straße 30

San Marcos, Tx 78666 D-63911 Klingenberg / Germany

Tel: 1.512.396.4200 Tel: (+49) 93 72/132-9986

1.800.984.4200 (USA only) web site: www.wika.de

web site: www.mensor.com fax: (+49) 93 72/132-8767

fax: 512.396.1820 e-mail: testequip@wika.de

e-mail: sales@mensor.com

tech.support@mensor.com

1.3 FCC Radio Frequency Emission Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his or her own expense.

USE SHIELDED CABLES TO CONNECT EXTERNAL DEVICES TO THIS INSTRUMENT TO MINIMIZE

RF RADIATION.

Operating Instructions - CPG2500 7

Page 8

Precision Pressure Indicator

CPG2500

1.4 Trademarks and Copyrights

Mensor is a registered trademark of Mensor, LP. All other brand and product names are trademarks or

registered trademarks of their respective companies. ©2007, Mensor, LP. All rights reserved.

1.5 Software License Agreement

This product contains intellectual property, i.e., software programs, that are licensed for use by the end

user/customer (hereinafter “end user”).

This is not a sale of such intellectual property.

The end user shall not copy, disassemble or reverse compile the software program.

The software programs are provided to the end user “as is” without warranty

i

Notice

Mensor and its suppliers shall not be held to any liability for any damages suered or incurred by the end

user (including, but not limited to, general, special, consequential or incidental damages including dam-

ages for loss of business prots, business interruption, loss of business information and the like), arising

from or in connection with the delivery, use or performance of the software program.

of any kind, either express or implied, including, but not limited to, warranties

ofmerchantabilityandtnessforaparticularpurpose.Theentireriskofthe

quality and performance of the software program is with the end user.

1.6 Mensor Service Plus

If you have problems and you don’t nd the answer in this manual, contact Mensor at 1.800.984.4200

(USA only) or 1.512.396.4200 for personal assistance, or at any of the contact addresses listed on the

rear cover of this manual. We are ready to help.

1.6.1 After the Warranty

Mensor’s concern with the performance of this instrument is not limited to the warranty period. We pro-

vide complete repair, calibration and certication services after the warranty for a nominal fee.

1.6.2 Calibration Services

In addition to servicing our own products Mensor can perform a complete pressure calibration service,

up to 20,000 psi, for all of your pressure instruments. This service includes an accredited calibration.

1.6.3 CerticationsandAccreditations

Mensor is registered to ISO 9001:2008. The calibration program at Mensor is accredited by A2LA, as

complying with both the ISO/IEC 17025:2005 and the ANSI/NCSL Z540-1-1994 standards.

1.7 Packaging for Shipment

If the product must be shipped to a dierent location or returned to Mensor for any reason through a common carrier it must be packaged properly to minimize the risk of damage.

The recommended method of packing is to place the instrument in a container, surrounded on all sides

with at least four inches of shock attenuation material such as styrofoam peanuts.

8 Operating Instructions - CPG2500

Page 9

Precision Pressure Indicator

CPG2500

2 Safety Notices

2.1 User Responsibilities

To ensure safety, the user must make sure that:

• The system is used properly, no dangerous media are used and that all technical specications are

observed.

• The system is operated in perfect operating condition.

• This operation manual is legible and accessible to the user at the system’s location.

• The system is operated, serviced and repaired only by authorized and qualied personnel.

• The operator receives instruction on industrial safety and environmental protection, and is knowledgeable of the operating instructions and the safety notices contained therein.

2.2 General Safety Notices

The system should only be operated by trained personnel who are familiar with

i

Notice

!

Warning

this manual and the operation of the instrument.

WARNING: A condition for trouble-free and safe operation of this system is proper

transport, proper storage, installation, assembly and proper use as well as careful

operation and maintenance.

Any operation not described in the following instructions should be prohibited.

The system must be handled with care required for an electronic precision instru-

ment(protectfromhumidity,impacts,strongmagneticelds,staticelectricityand

extreme temperatures). Do not insert any objects into the instrument.

The system is powered via the power cable with a voltage that can cause physical injury. Even after disconnecting the system from the power supply, dangerous

voltages can temporarily occur due to capacitance.

Extreme care must be taken with pressure connections when using hazardous or

toxic media.

Repairs must only be performed by authorized service personnel.

i

Notice

Operating Instructions - CPG2500 9

Additional safety notices are found throughout this manual.

Page 10

Precision Pressure Indicator

CPG2500

2.3 Warnings and Caution Notices

WARNING: HIGH PRESSURE! High pressure gases are potentially hazardous.

Energy stored in these gases and liquids can be released suddenly and with

!

Warning

!

Warning

!

Warning

!

Caution

extreme force. High pressure systems should be assembled and operated only by

personnel who have been trained in proper safety practices.

WARNING: NOT EXPLOSION PROOF! Installation of this instrument in an area

requiring devices rated as intrinsically safe is not recommended.

WARNING: POSSIBLE INJURY! The tubing, valves, and other apparatus attached

to the gauge must be adequate for the maximum pressure which will be applied,

otherwise physical injury to the operator or bystanders is possible.

CAUTION: USE THE PROPER PRESSURE MEDIUM! Use only clean, dry, non-corro-

sivegasesunlessotherwisespeciedbyMensor.Thisinstrumentisnotdesigned

for oxygen use.

CAUTION: As with most sensitive electronic equipment, switch the power switch

!

Caution

Additional Warning and Caution notices are found throughout this manual.

obeforeconnectingordisconnectingtoapowersourcetopreventdataloss.Do

notpositiontheequipmentsothatitisdiculttodisconnecttheDCpowerjack.

CAUTION: ESD PROTECTION REQUIRED. The proper use of grounded work

surfaces and personal wrist straps are required when coming into contact with

exposed circuits (printed circuit boards) to prevent static discharge to sensitive

electronic components.

10 Operating Instructions - CPG2500

Page 11

Precision Pressure Indicator

CPG2500

3 General Description

The CPG2500 Precision Pressure Indicator is a multi-channel pressure indicator designed to test and

calibrate a variety of pressure devices in either absolute or gauge pressure modes. The CPG2500 can

have two independent internal transducers, an optional barometric reference and an external remote

pressure transducer.

Figure 3.1 - Desk top version

3.1 Features

Here is a short list of signicant features designed into the CPG2500:

• Up to two removable / interchangeable, highly stable, temperature compensated, internal pressure

transducers. (Option to connect two external transducers via a rear mounted RS-232 port in place of

the two internal transducers)

• An optional remote transducer in addition to the two internal transducers.

• An optional removable / interchangeable internal high accuracy barometric reference transducer

providing gauge pressure emulation for absolute ranges and absolute pressure emulation for gauge

ranges.

• Optional Analog output for each internal sensor.

• 7” Color LCD display with touch screen

• Delta function when two or more transducers are installed

• Multiple languages; change the language for on-screen text and number/date formats by simply

touching one of the “national ag” icons available in the setup screen.

• Desk top or rack mount

• Local Operation, or command and read remotely.

Operating Instructions - CPG2500 11

Page 12

Precision Pressure Indicator

CPG2500

3.2 Turning On

You can conrm that your CPG2500 is operational right now. Apply power to the power connector on

the rear of the instrument with the included power adapter, remove any plastic plugs from the rear panel

pressure ports, and press the power switch to ON. The system will go through an initialization process,

which takes about 45 seconds, and then a display will appear similar to the screen shown below.

Power Switch

ON/OFF

To see information about the conguration of your new CPG2500, touch the Information Application

(App) icon on the menu and a window will appear listing the Mensor customer service contact, model

number and the sensors that are installed. Press the Measure App [

] to return to the main screen.

Information Application

3.3 Front Panel

The CPG2500 front panel includes a 7” color LCD display with touch screen. Operator input is accom-

plished by pressing the words or App icons presented on the display. There is a single discrete on/o

button and a USB on the right hand side. The front panel also shows the model number designation and

brand logos.

12 Operating Instructions - CPG2500

Page 13

Precision Pressure Indicator

CPG2500

3.4 Display

The display is made up of two sections. In the main screen (“Measure Application”), the left two thirds

shows the transducer channels that are congured for display, along with the pressure reading, units,

mode (absolute or gauge), channel label, an auto zero or tare button (if enabled) and any auxiliary indications that have been chosen. The right one third of the screen has Application Icons (“Apps”) for setting

viewing options, sensor settings, communication settings plus a “Page Down” button [

pressed, shows a second and third page of icons for calibration, remote communication error checking

and a leak test application.

] that, when

Channel label

Page Down

and range

Auto Zero

Reading

Units and Mode

Auxiliary Indications

Transducer Channels Settings Apps

Buttons, Labels and Windows: The CPG2500 touch screen has many buttons with relevant graphic

icons or text which, when pressed, will open a related window where changes can be made or information viewed. Some of these buttons will toggle from one state to another, others present choices or display a numerical data entry screen. Text or icons that are displayed, but do not respond to being touched,

are called labels or windows. Operators will quickly become accustomed to the particular characteristics

of the frequently used buttons.

Main Screen: The main screen or “Measure Application”, appears after power-up. This screen contains

the channel frames and settings button. It will remain as congured after a power cycle.

Transducer Channel Frame(s): The transducer channel frames (left 2/3 of the screen) contain informa-

tion specic to a channel. Up to three channels can be displayed at once, two are shown in the picture

above. The channel frames are color coded with channel A - green, channel B - blue and the remote

channel - red. The optional barometer channel is sky-blue and the delta channel is yellow. If only one

channel is installed, a full frame will be displayed in the color of the channel connected. The channel

frame contains the pressure reading, units, and mode(absolute or gauge) plus any auxiliary displays that

have been chosen.

3.5 Chassis Assembly

The chassis assembly is the housing for the system and the removable transducers. The system has no

user-serviceable parts, and therefore the chassis should not be opened except by qualied repair personnel at Mensor or certied service locations for any reason except to change the removable transduc-

ers.

Operating Instructions - CPG2500 13

Page 14

Precision Pressure Indicator

CPG2500

NOTES

14 Operating Instructions - CPG2500

Page 15

Precision Pressure Indicator

CPG2500

4 Specications

Accuracy specications presented herein are obtained by comparison with primary standards traceable

to a national metrology institute or recognized international standard organization. These specications

are obtained in accordance with the ISO Guide to the Expression of Uncertainty in Measurement (GUM).

The calibration program at Mensor is accredited by the American Association of Laboratory Accreditation

(A2LA) as complying with both the ISO/IEC 17025:2005 and the ANSI/NCSL Z540-1-1994 standards. If

there is an exception to the requirements and recommendations of Z540 during a calibration the excep-

tion is noted on the individual calibration certicate.

Mensor reserves the right to change specications without notice.

4.1 TransducerSpecication

Standard Reference Transducers, Model CPR2550

Accuracy

Gauge Pressure 0 ... .36 to 0 ... <1 psi 0... 1 to 0 ... 10,000 psi 0 ...14.5 to 0 ... 6000 psi

Bi-Directional Pressure -0.18 to 0.18 to >-0.5 ... <0.5 -0.5 ... 0.5 to -15.5 ... 10,000 psi -14.5 ... 145 to -14.5 ... 6000 psi

Absolute Pressure — 0 ... 7.5 to 0 ... 10,000 psia 0 ... 14.5 to 0 ...6015 psia

Calibration Interval 180 days 365 days

Media Compatibility

Metals in contact with media 6000/7000 series Aluminum, 316 SS, brass

Non-metals in contact with media PTFE (Teon®), Urethane, Silicone, RTV, Silicone grease, PVC, Epoxy, Buna-N, uoroelastomers

Sensor

Reading rate 33 readings/second

Calibration adjustments Internal zero adder and span multiplier, up to 11 point linearization for each sensor

(1)

0.03%Full Span 0.01%Full Span 0.01%IS-50

(3)

(Viton®)

365 days

(2)

Premium Reference Transducers, Model CPR2580

Accuracy

Gauge

Pressure

Absolute

Pressure

Calibration

Interval

(1)

0.008% IS-33

0 ... 12 to 0 ...16.5 psig

0 ... 17.5 to 0 ... 33 psig

0 ... 80 to 0 ... 110 psig

0 ... 120 to 0 ... 220 psig

0 ... 12 to 0 ...16.5 psia

0 ... 18.4 to 0 ... 33 psia

0 ... 36 to 0 ... 50 psia

0 ... 80 to 0 ... 110 psia

0 ... 160 to 0 ... 220 psia

0 ... 240 to 0 ... 500 psia

365 days 365 days 365 days 365 days

Media Compatibility

Metals in contact with media 6000/7000 series aluminum, 316 SS, brass, inconel

Non-metals in contact with media PTFE (Teon®), Urethane, Silicone, RTV, Silicone grease, PVC, Epoxy, Buna-N, uoro-

Sensor

Reading rate 10 readings/second

Calibration adjustment Internal Zero adder and Span multiplier, up to 11 point linearization for each sensor

(1)

Accuracy is dened by total measurement uncertainty with the coverage factor (k=2) and includes the intrinsic performance of the instrument (linearity, hysteresis, repeatability), the measure-

ment uncertainty of the reference instrument, long term stability, inuences of ambient conditions, drift and temperature eects over the calibrated range, with periodic zero point adjustment.

(2)

The Intelliscale (IS) specication is a percent of reading specication combined with a percent of full scale specication. For example the designation “0.01% IS-50”, simply means that the

uncertainty of the sensor is 0.01% of reading above 50% of Full Scale, and 0.01% of 50% of Full Scale below 50% of the Full Scale. The 0.008% IS-33 specication is the same except the

uncertainty is 0.008% and the break over from percent of reading to percent of Full Scale is at 33% of Full Scale. Same rules apply for bidirectional ranges.

(3)

Gauge and Bidirectional ranges with full scale or full span range less than 14.5 psi have a calibration interval of 180 days, otherwise the calibration interval is 365 days.

(2)

0.008% IS-50

0 ... 700 to 0 ... 1100 psia

0 ... 1400 to 0 ... 3300 psia

0 ... 4200 to 0 ... 6015 psia

(2)

0.01% FS 0.014% FS

— — —

0 ... 8000 to 0 ... 11,000 psia 0 ... 12,000 to 0 ... 22,000 psia

0 ... 24,000 to 0 ... 31,500 psia

0 ... 32,000 to 0 ... 42,000 psia

elastomers (Viton®)

Operating Instructions - CPG2500 15

Page 16

Precision Pressure Indicator

CPG2500

4.2 Measurement&GeneralSpecications

Basic Instrument

Instrument

Instrument version Standard: Table top with tilt feet

Option:

-19” rack-mounting for single instrument mount.

-19” rack-mounting for dual instrument mount.

Dimensions See technical drawing

Weight 12.5 lbs./ 5.7 kg (with all internal options)

Warm-up time Approximately 15 minutes

Display

Screen 7” color LCD display

Resolution Selectable from 4 to 6 digits, depending on range and units

Data entry Touch screen keypad

Measurement Units psi, psf, osi, atm, inH20@4C, inH20@20C, inH20@60F, mbar, bar, Dy/cm2, pascal,

hPa, kPa, MPa, inHg@0C, inHg@60F, mTorr, Torr, mmHg@0C, cmHg@0C, mHg@0C,

mmH20@4C, cmH20@4C, mH20@4C, mmH20@20C, cmH20@20C, mH20@20C,

mSW, ftH20@4C, ftH20@20C, ftH20@60F, inSW, ftSW, tsi, tsf, g/cm

Range, + plus 2 user dened units (multiplier from psi, bar or pascal)

Rate Units /sec., /min., /hr., /3-hr

Languages English, German, Spanish, French, Italian, Portuguese, Polish, Russian, Chinese,

Japanese, Korean

Measurement lters O, Low, Normal (default), High

Connections

Number of integrated transducer

(selectable)

Pressure connections Ranges ≤ 6015 psi: 7/16 - 20 female SAE/MS (adapters provided)

Pressure adaptors Standard: 1/8 in. FNPT

Overpressure limits 110 % FS typical, optional external relief valves are available

Voltage supply

Power input requirements 100-120 or 200-240 VAC, 50-60Hz, 24VA max

Switching power supply Output: 12 VDC, 1.7 A (includes 4 region specic plugs adapters)

Permissible ambient conditions

Storage temperature range 0 to 70 deg C

Operating environment 0 ... 95 % RH (relative humidity, non-condensing)

Operating temperature range 15 ... 45 deg C

Operating Altitude <3048 meters (10,000 ft)

Communications

Remote interface IEEE 488, RS-232, USB and Ethernet

Command sets Mensor, WIKA SCPI

Standard: 1 reference transducer

Optional: 2nd reference transducers, external transducer, internal barometric reference

Ranges > 6015 psi: Autoclave F250C/HIP HF4

Optional: 1/4 inch tube, 6 mm tube, 1/4 in FNPT, 1/8 in. FBSP.

2

, kg/cm2, kg/m2, % of

CE conformity and certicates

CE compliance EN61326-1:2013 electromagnetic compliance

EN61010-1:2010 safety/CB scheme

Calibration Calibration certicate per ISO/IEC 17025:2005. Accreditation is by the American

Association for Laboratory Accreditation (A2LA).

16 Operating Instructions - CPG2500

Page 17

Precision Pressure Indicator

CPG2500

5 Installation

5.1 Unpacking the Instrument

In addition to functional testing, each unit is inspected for appearance prior to leaving the factory. Upon

receipt, please examine the instrument for shipping damage. Report any apparent damage to the carrier

immediately.

In addition to this manual you should have:

• CPG2500 Precision Pressure Indicator;

• Power Supply;

• Fitting adapters ordered;

• Any accessories ordered;

• An envelope containing the calibration certicate.

Operating Instructions - CPG2500 17

Page 18

Precision Pressure Indicator

CPG2500

5.2 Dimensions (inches)

Desk top case

Front view

Single mount - Front view

Side view

19” rack mount

Dual mount - Front view

Rear Panel

Remote Transducer

connection

RS-232

USB (device)

USB (host)

Ethernet port

IEEE-488

Power

Measure port

Channel B

(7/16-20 UNF)

Baro ref port

(baro ref option)

Measure port

Channel A

(7/16-20 UNF)

18 Operating Instructions - CPG2500

Page 19

Precision Pressure Indicator

CPG2500

5.3 Mounting

The instrument can be set up on a desk top or it can be rack-mounted. Rack mount hardware is optional

on the CPG2500 (see Section 5.2 Dimensions and Section 8, Options).

The special sensors used in the CPG2500 are relatively insensitive to tilt and vibration. However to further assure stability and accuracy, avoid mounting the instrument on surfaces subject to excessive motor

or machinery vibration.

5.4 Rear Panel

Two slots are available on the rear of the CPG2500. These slots can be lled with a removable transducer

or a remote transducer interface connection. Gauge Transducers will have a reference and a pressure

port. Absolute transducers will have a plug in the reference port. If a barometer is installed a hose barb

tting will be installed in the upper right. Transducers with analog output will have an electrical connection. Positioned on the left side is a remote transducer connection, the RS-232, Ethernet, IEEE-488, USB

device connections for communication, the USB host connection and the 12 VDC power input.

Figure 5.4 A - Two removable gauge transducers installed

Figure 5.4 B - Two remote transducer interface connections installed

Operating Instructions - CPG2500 19

Page 20

Precision Pressure Indicator

CPG2500

5.4.1 Pressure Connections

Whenmakingupaconnectiontoano-ringadapterttingportuseaback-up

wrench to prevent over-stressing the threads in the manifold block.

i

Notice

For pressure range less than 6015 psi, the pressure ports on the rear are female 7/16 - 20 SAE/MS

straight threads per MS16142 and SAE J514 table 14. Connected adaptors require a tube tting boss

seal with an o-ring per MS33656. Mensor can provide a variety of adapter ttings (see Section 8 Options) with the instrument. Do not use sealant on ttings sealed with an o-ring. The integrity of each seal

is particularly important since even microscopic leaks can cause errors in pressure measurements. For a

pressure range greater than 6015 psi, a xed Autoclave F250C/HIP HF4 tting is attached

5.4.2 Pressure Port

The CPG2500 will precisely measure the pressure connected to the pressure port up to the full scale

range of the transducer installed.

5.4.3 Reference Port

The reference port is available on gauge units that have sensors that are not sealed gauge units. For

these units this port is available to connect to the reference side of the sensor. This port is normally left

open to atmosphere but may be connected to a stable reference pressure. In an absolute pressure transducer this port is plugged.

5.5 Remote Communication Connections

See Section 7, Remote Operation, for connections and commands for operation over IEEE-488, Ethernet, USB or RS-232 ports.

5.6 Power Up

Apply power to the power connector on the rear of the instrument using the power adaptor included, and

switch the power switch on the front of the unit ON. The instrument will go through an initialization process and system check. As soon as the system check is completed the system will default to a screen

similar to the one shown in Section 6.1.2 - Display Screen Features. The main measurement screen may

be congured in many dierent ways but initially it will be in a default conguration. Subsequently, the unit

will power up in the conguration that it was in when last powered o. Allow at least 15 minutes of warm

up before performing critical pressure measurements.

20 Operating Instructions - CPG2500

Page 21

Precision Pressure Indicator

CPG2500

6 Local Operation and Setup

6.1 General Operation

This section describes the procedures for operating the CPG2500 from the front panel. Instructions for

operating the device remotely from an external computer are covered in Section 7, Remote Operation. By

following the procedures provided in these two sections and Section 10, Calibration, you can expect your

CPG2500 to deliver maximum accuracy and dependability for many years of useful service.

6.1.1 Setup Applications

Conguration of the CPG2500 is achieved by changing settings accessed through the Application (“App”)

buttons. Local operation is accomplished by observing the data presented in the display. The appearance

and functionality of the display can be changed by pressing the App button for the related function. After

an app has been chosen, a set of related parameters will appear on the left. After choosing one of these

parameters, a set of selections related to that parameter will appear on the right or a data entry keypad.

The desired selection or data can be entered here.

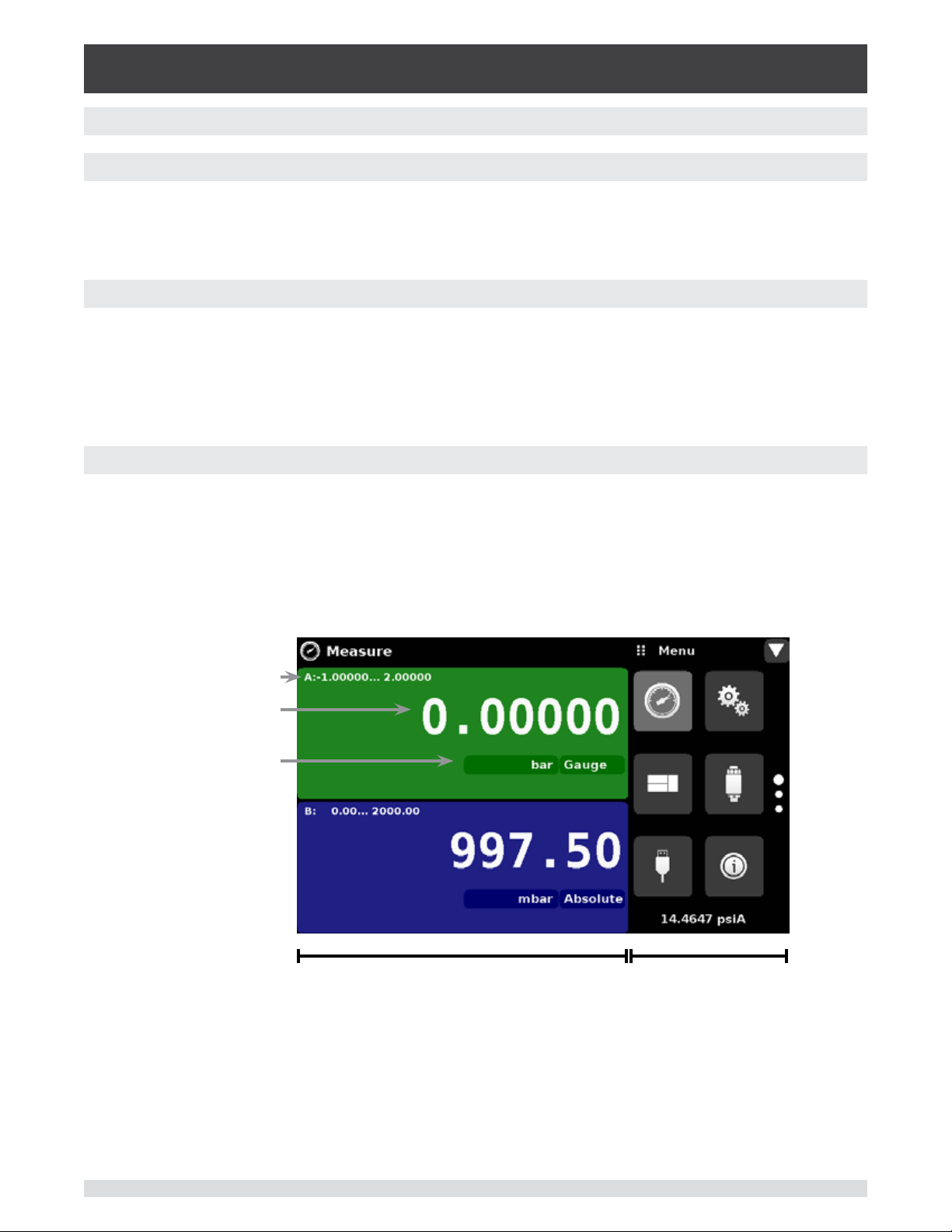

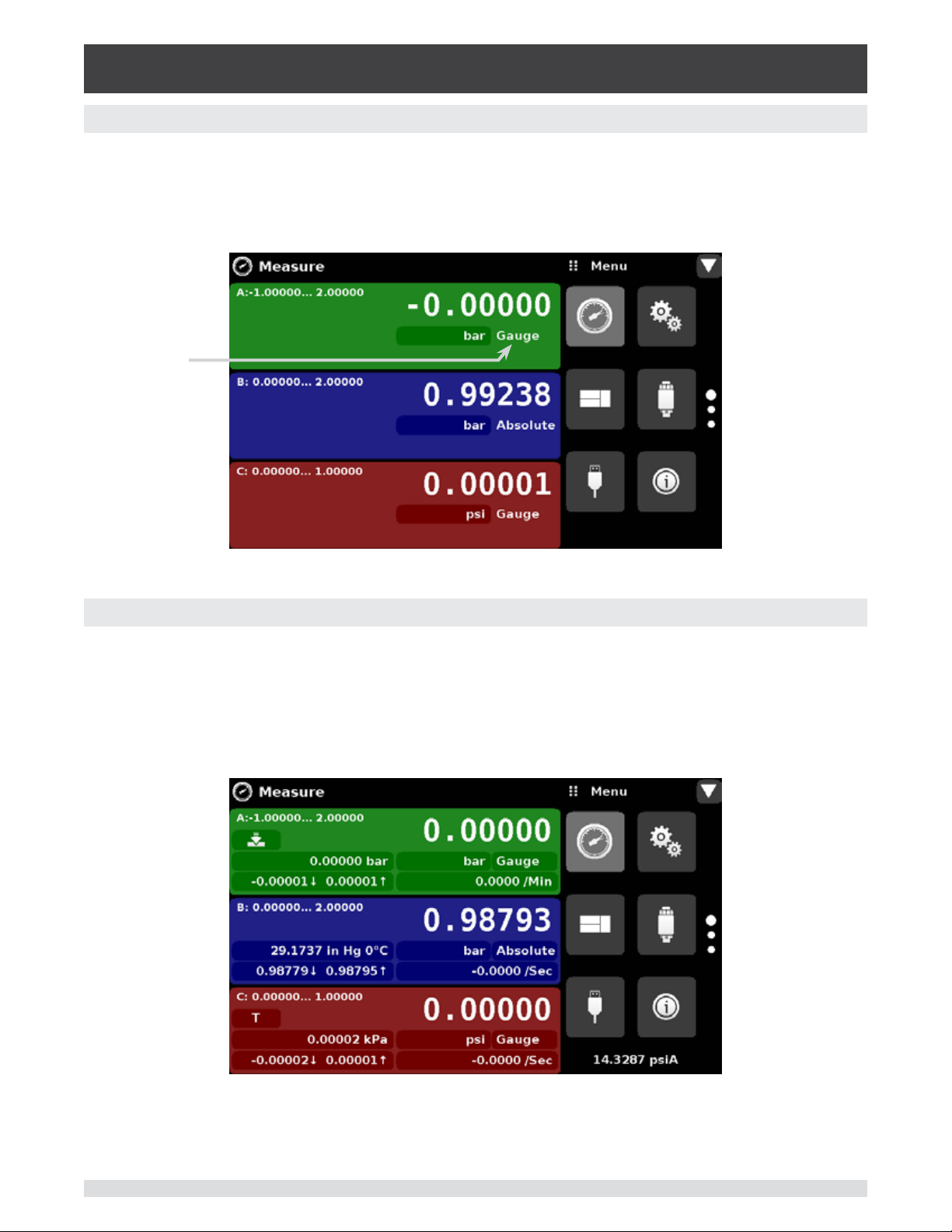

6.1.2 Display Screen Features

The screen shown below provides a brief description of the features shown on a 2 channel display after

initialization. The left two thirds of the display contains the area where information is displayed (in this

case the Measure Application) and the right one third contains the selection icons for each application.

Channels are color coded: Channel A is green, B is blue, C (remote) is red and the barometer is sky-blue.

Color coding persists throughout all channel-specic screens. A zero or tare button and auxiliary displays

(auxiliary units, rate and peak) will appear in the Measure App if activated. All of the CPG2500 screen

features are described in more detail throughout this manual.

Range

Reading

Pressure Units

and Mode

App Display / Parameter Selection

Figure 6.1.2 - Display Screen Features

App Selection /

Data Entry

Operating Instructions - CPG2500 21

Page 22

Precision Pressure Indicator

CPG2500

6.2 Initial Setup

Section 6.3.1 and 6.3.2 are provided rst so that the operator can initially check the information screen to

verify the installed components and to change the language if needed.

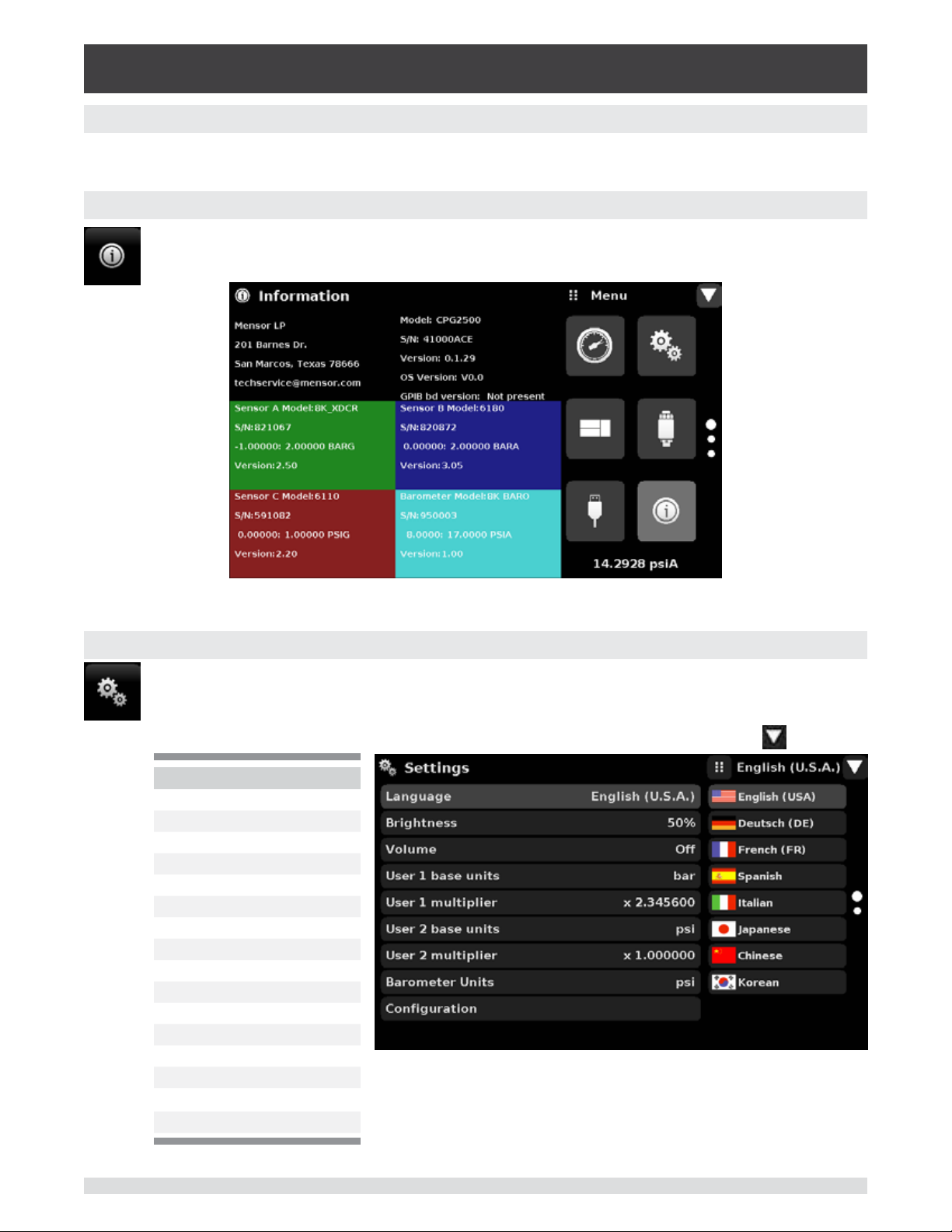

6.2.1 Contact and Version Information Application

Press this application button to display Mensor contact, installed sensor, instrument and

software version information.

6.2.2 Language Selection

Pressing the settings application button will open a screen where the language, display

brightness, volume, user base units/multiplier and conguration loading/saving, can be

changed. The current language selections available are shown in the table below. Additional

language choices will appear on the screen after pushing the Page Down button [

Language Country

English USA

German Germany

French France

Spanish Spain

Italian Italy

Chinese China

English Great Britain

German Switzerland

French Switzerland

Spanish Mexico

Russian Russia

Korean Korea

English Canada

French Canada

Polish Poland

Japanese Japan

Figure 6.2.1 - Information

]:

22 Operating Instructions - CPG2500

Page 23

Precision Pressure Indicator

CPG2500

6.3 Application Selection and parameter inputs

The application selection area on the right one third of the screen (see Figure 6.1.2 - Display Screen Features) is the area where setup, information and calibration Apps can be chosen. A second and third page

of application selections can be accessed by pressing the page down button [ ]. A series of vertically

placed circles on the center right indicates the active page by a larger circle. As each App is chosen,

related application parameters will appear on the left two thirds of the screen along with the name of the

application, and a reduced size icon in the top title section . When a parameter is chosen, related selections, sliding scales or a data entry key pad will appear in the input area on the right where the application

selection buttons were previously displayed. An example of each type of input is shown below. To return

to the App selection menu, simply press the menu button [

use of each selection and menu is intuitively apparent and will become second nature with minimal exposure to the menu structure.

] above the input area. The purpose and

App Title

Page Down

Menu Button

Input Title

Operating Instructions - CPG2500 23

Page 24

Precision Pressure Indicator

CPG2500

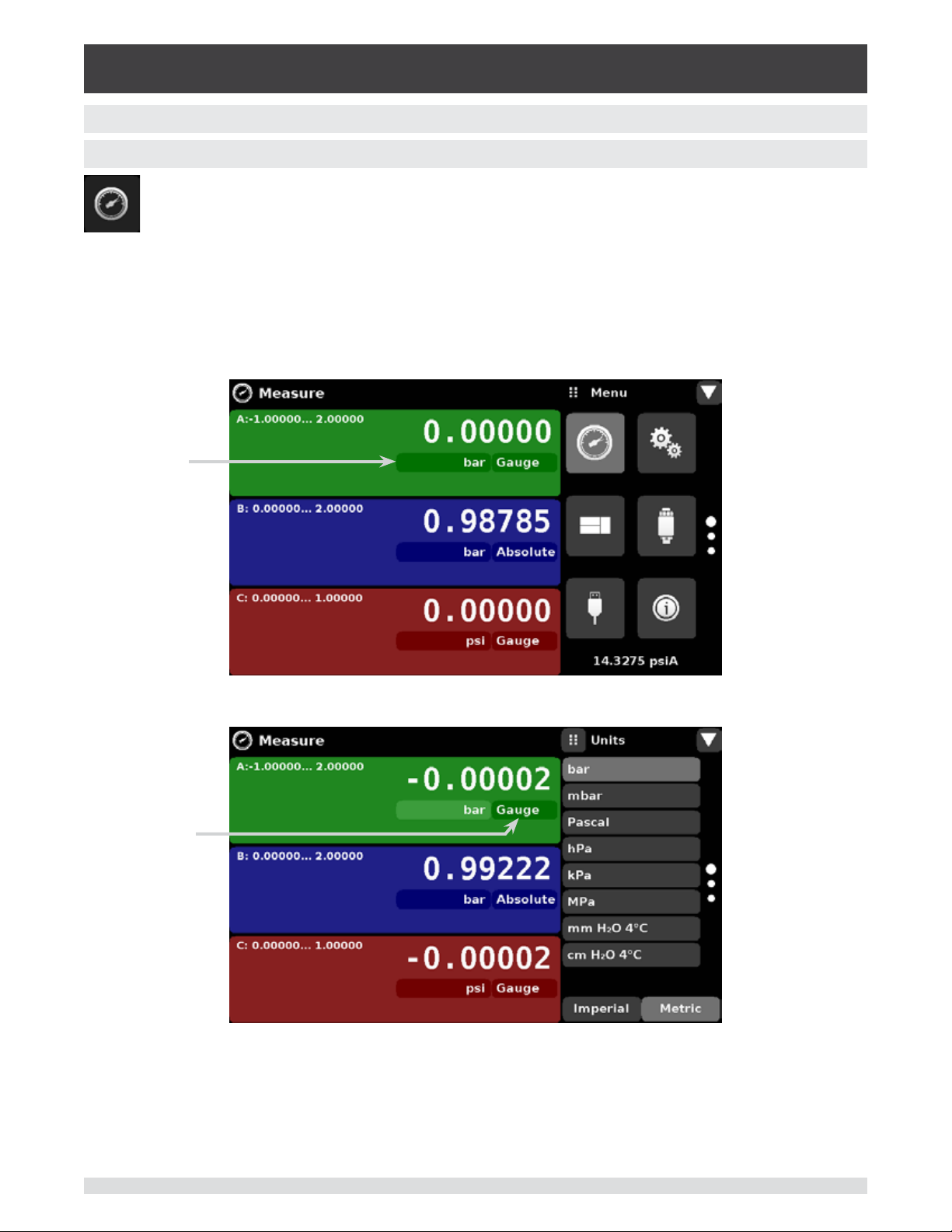

6.4 Applications:

6.4.1 Measure Application

The Measure App is the normal operation screen referred to in previous instruments as the

‘main screen’. This application is dierent from the others in that it is not use to setup the conguration but is used to monitor the pressure applied to the installed transducers.

The screen in gure 6.4.1-A shows the basic Measure App in a three channel instrument. The units but-

ton is always present in each channel. When the units button is pressed a selection of imperial and metric

units will be displayed on the right (gure 6.4.1-B); notice that the Units button has a lighter background

when the selection menu is active. Any unit of measure can be selected for any channel. If a barometric

reference is installed, the Mode button, described below, will toggle from Gauge to Absolute mode when

pressed.

Units Button

Mode Button

Figure 6.4.1-A Basic Measure App

Figure 6.4.1-B - Units Change

24 Operating Instructions - CPG2500

Page 25

Precision Pressure Indicator

CPG2500

6.4.1.1 Pressure Mode / Emulation Mode

The Mode button is only active if there is an optional Barometric reference installed. Otherwise, the mode

button becomes a label (gure 6.4.1.1) indicating the native mode of the transducer (absolute or gauge).

When an optional barometric reference is installed, a native gauge transducer can emulate absolute

pressure using the barometric reference. Alternatively, a native absolute transducer can emulate gauge

pressure. Emulation can be activated simply by pressing the Mode button.

Without a

Barometer the

Mode button

becomes a label

Figure 6.4.1.1 - Mode Label

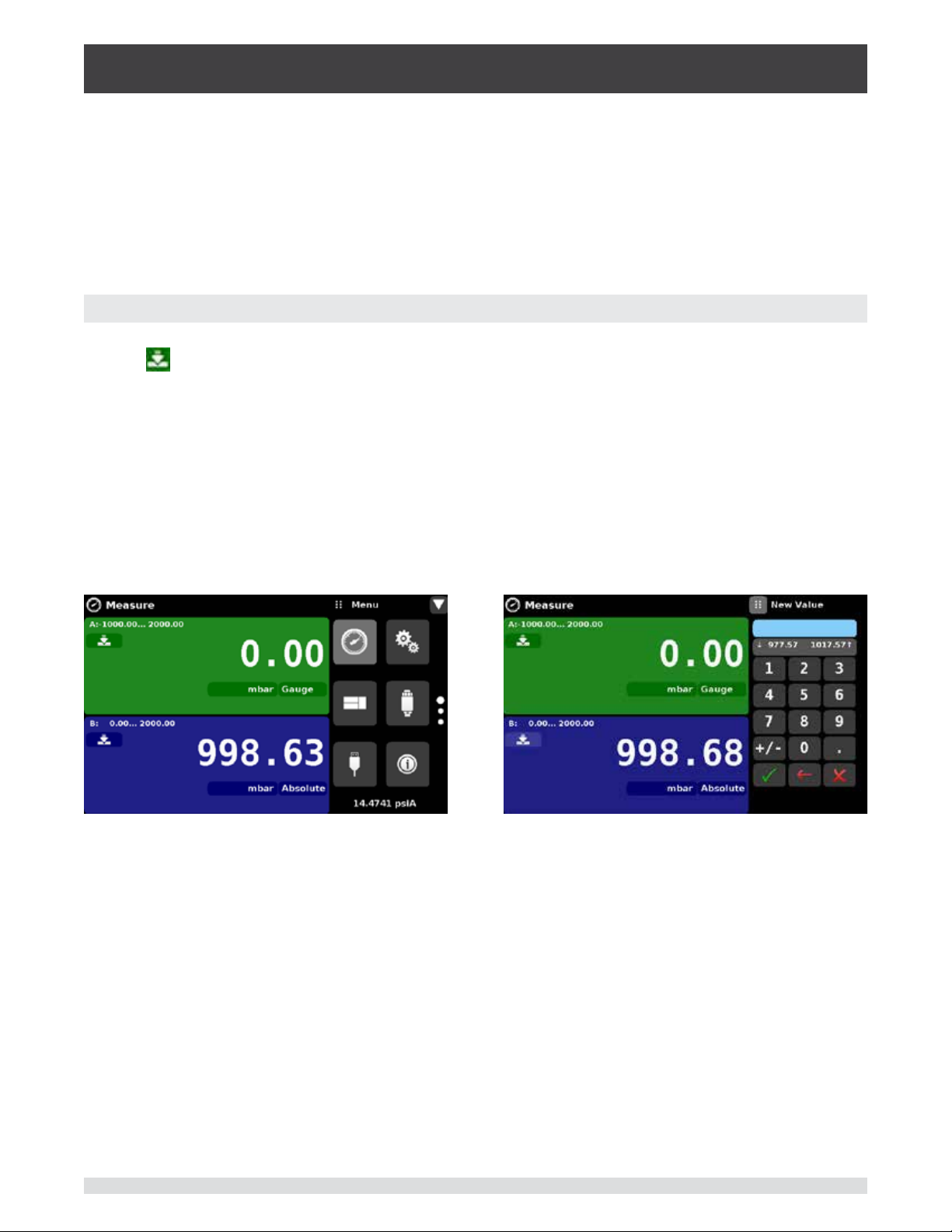

6.4.1.2 Auxiliary Displays

The screen in gure 6.4.1.2 shows all of the possible auxiliary display items that can be included in the

Measure App, in addition, each channel can contain one of two possible calibration functions. The auxiliary display item includes “Alternate Units”, “Peak” and “Rate”. Calibration functions are either a “Zero”

button or a “Tare” button. These auxiliary features will appear in the Measure App when selected from the

Transducer App (section 6.4.4.4).

Figure 6.4.1.2 - Three channel Measure App with auxiliary displays

Operating Instructions - CPG2500 25

Page 26

Precision Pressure Indicator

CPG2500

Auxiliary buttons can be placed in three dierent parts of the screen depending on how they are set in the

Transducer Application. Each auxiliary display can be modied by pressing the displayed button.

Peak: Pressing the Peak button will reset the upper and lower peak value to the current reading, subsequent negative or positive divergence from that reading will be recorded in the button.

Rate: Pressing the Rate button will display a choice of time rate units for the rate denominator.

Units: Pressing the Auxiliary Units button will display the same set of units available for the primary units.

Pressing any of these units will change the auxiliary units to that chosen unit.

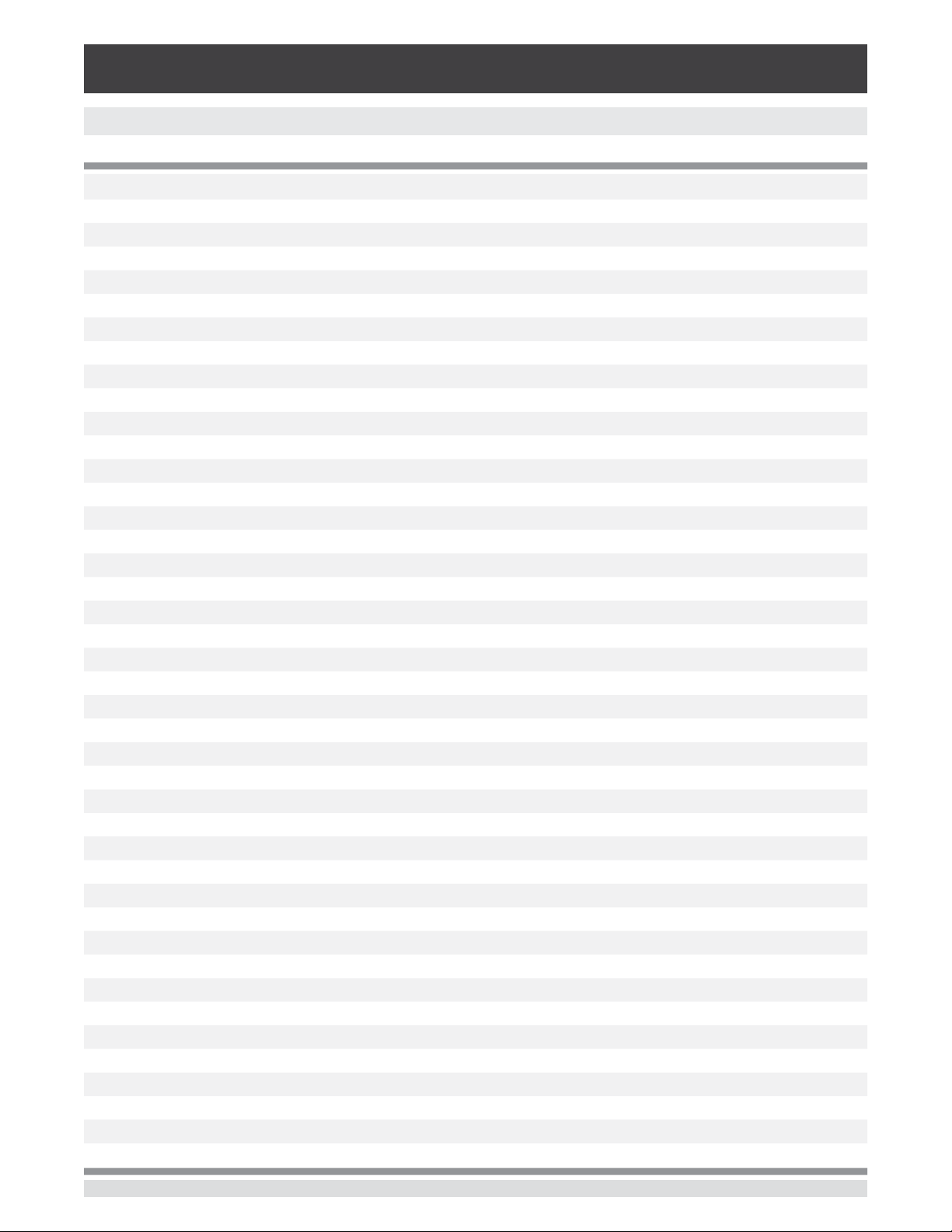

6.4.1.3 Zero Button

If the Zero Calibration function has been chosen in the Transducer App (section 6.4.4), then the Zero Cal

Button [

Cal Button is pressed, a keyboard will appear to allow a single point calibration. If the channel is measuring gauge pressure, pressing the button will set the current reading to zero. If the channel is in emulation

mode (absolute or gauge) then the value will not be saved to the sensor but only as a temporary adjustment while in emulation mode. After exiting the emulation mode or after a power cycle, the temporary

adjustment will be cleared. The zero adjustment for a channel not in emulation mode will be saved to the

sensor as if single point calibration had been performed.

] will appear in the Measure App. If the channel is measuring absolute pressure, and the Zero

Figure 6.4.1.4 shows two channels displayed, the zero cal function has been enabled for both channels.

The screen on the left shows both channels with zero buttons. The screen on the right shows the same

two channels, but the zero button on the absolute channel has been pressed, showing the keypad enabled to accept a new single point calibration value.

Figure 6.4.1.3 - Zero Button, Gauge - Absolute

The background color of the zero button will momentarily change to a lighter color as the zero calibration

is performed then will revert back to a darker color when complete.

26 Operating Instructions - CPG2500

Page 27

Precision Pressure Indicator

CPG2500

6.4.1.4 Tare Button

If the Tare calibration function has been chosen in the Transducer App (section 6.4.4), then the Tare Button [

screen at the same time, in the same channel. When the Tare button is pressed, the instrument will subtract the current pressure reading (the tare pressure) so that the indicator will display zero. Subsequent

deviations in pressure will be relative to the tare pressure. Notice in the gure below that, when active, the

back ground of the tare button is lighter than the channel background, when not active the button background is darker than the channel background.

] will appear in the channel screen. The Tare button and the Zero Button cannot appear on the

Tare button,

active.

Tare button,

inactive.

Figure 6.4.1.4 - Tare Button

Pressing the tare button again will deactivate the tare and change the pressure indication back to the

reading corresponding to the calibrated output of the transducer. An active tare will revert to a deactivated state after a power cycle.

Operating Instructions - CPG2500 27

Page 28

Precision Pressure Indicator

CPG2500

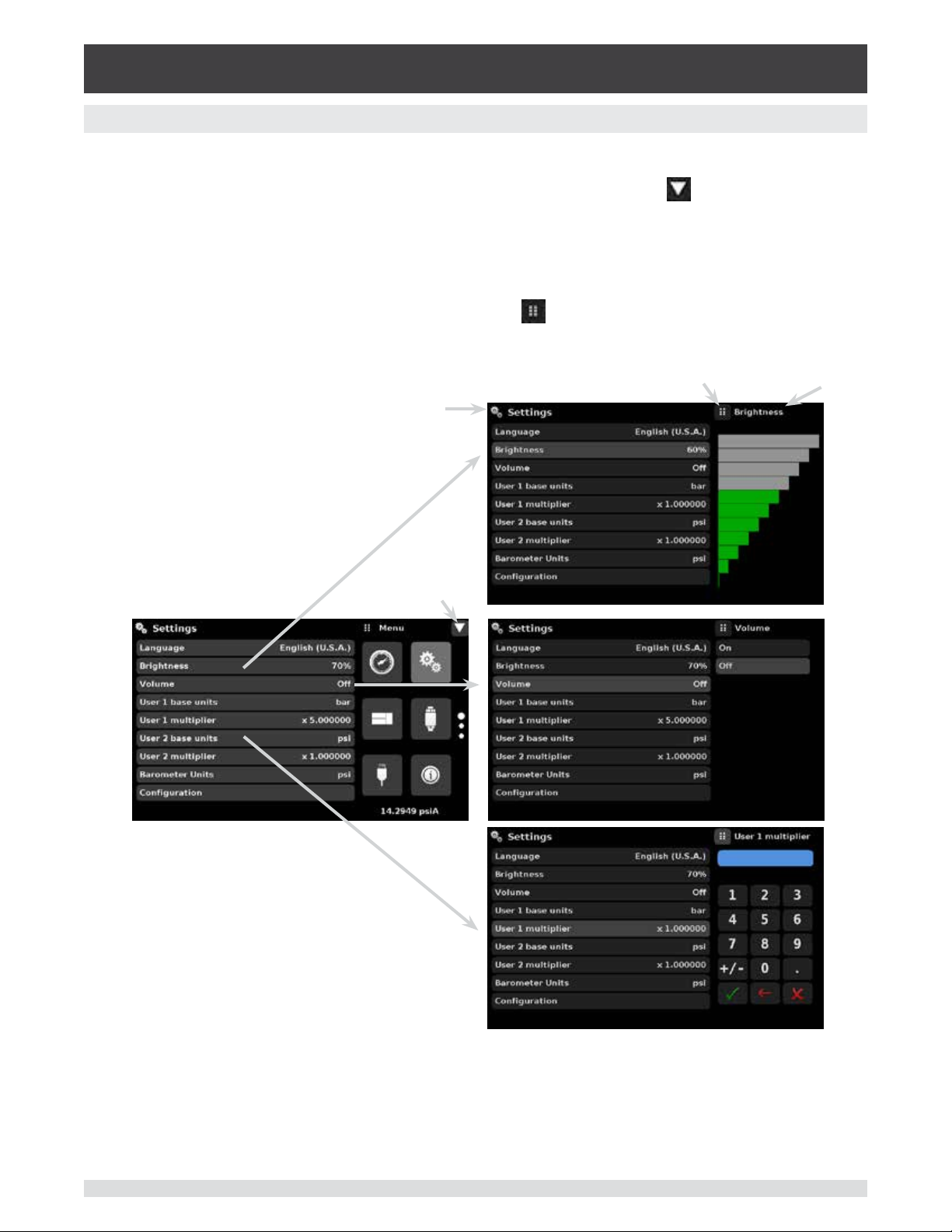

6.4.2 Settings Application

The Settings App is used to set up general settings for the display. Settings parameters include

Language, Brightness, Volume, User 1 base units, User 1 multiplier, User 2 base units, User 2

multiplier, Barometer units, and Conguration. Figure 6.4.2 shows these parameters as indicated when the Settings App has been chosen. As each parameter is pressed, an input screen will

appear on the right where selections can be made.

The Settings App provides a place to change the language, display brightness, volume, user units, and

barometer units. Conguration settings of the unit can also be saved within this application plus the default conguration can be activated.

Figure 6.4.2 - Settings application

6.4.2.1 Languages

The Language parameter provides a selection of dierent languages. Once a language is chosen all

words within all menus will appear in the chosen language and the radix character (decimal mark) will

change from a dot (.) to a comma (,) depending on the language chosen.

Figure 6.4.2.1 - Languages

28 Operating Instructions - CPG2500

Page 29

Precision Pressure Indicator

CPG2500

6.4.2.2 Brightness

The Brightness setting provides a sliding scale to increment the screen brightness in all screens. Sliding

your nger along the bar graph or touching anywhere in the bar graph will change the brightness of the

screen. After the setting is made and your nger is removed from the screen the menu will revert back to

the basic settings menu.

Figure 6.4.2.2 - Brightness

6.4.2.3 Volume

The Volume setting provides a way to turn on or o the touch screen audio feedback.

Figure 6.4.2.3 - Volume

Operating Instructions - CPG2500 29

Page 30

Precision Pressure Indicator

CPG2500

6.4.2.4 User base units / Base units multiplier

When choosing a unit of measure from the Measure Application (main screen), standard units can be

chosen in addition to two user dened units. User units 1 and 2 are dened in the Settings App using

“User 1 base units”, “User 1 multiplier” and / or “User 2 base units”, “User 2 multiplier”. For example, if the

display of one atmosphere (atm) was needed, then psi could be chosen as the “User 1 base unit” and

the “User 1 multiplier”, in this case, would be 0.068045. When set this way and the user 1 unit has been

chosen, the user 1 unit will now display the pressure in atm.

Figure 6.4.2.4 - User base units / Base units multiplier

6.4.2.5 Barometer Units

When the Barometer Units Parameter has been chosen, a list of Imperial or Metric units is presented on

the right side of the screen. Any of these units can be chosen from this list for the barometric readout that

can be seen on the bottom right of the Measure App.

Figure 6.4.2.5 - Barometer units

30 Operating Instructions - CPG2500

Page 31

Precision Pressure Indicator

CPG2500

6.4.2.6 Conguration

Conguration is the last parameter in the Settings App. It allows the operator to save instrument settings

and load them, as needed, in the future. Parameters that are set in the Settings App, the Frames App, the

Transducer App, and the Remote App can be saved using the Conguration “Save” button and recalled

using the Conguration “Load” button. Simply set all desired parameters then go to Settings-Conguration, press one of the numbered Conguration buttons then press the “Save” button. This will save the

current conguration in that button. To reload a saved conguration at a later time, go to Settings-Conguration and press the numbered conguration button corresponding to the saved conguration and then

press the “Load” button.

Figure 6.4.2.6 - Conguration

The instrument default conguration can be activated simply by pressing the “Default” Button.

Operating Instructions - CPG2500 31

Page 32

Precision Pressure Indicator

CPG2500

6.4.3 Frames Application

The Frame App allows the user to select the number and order of the transducer channels

displayed in the Measure Application. A total of three channels can be displayed at a time. Typically, if two internal transducers and one external transducer are installed the display will include

three channels: A, B and Remote, in order form top to bottom. The order and number of channels displayed can be dened in the Frames Application. In addition the optional barometric reference transducer can be displayed as a channel as well as an emulated Delta channel. Figure

6.4.3 shows the unit in dual frame format with the Frame Format set to display the readings from

two transducers (A & B in a dual frame mode).

Figure 6.4.3 - Frames Application

6.4.3.1 Frame Format

The Frame format button sets the display in the Measure Application to Single Frame, Dual Frame or

Triple Frame. Figure 6.4.3.1 shows the available selections for the Frame Format parameter.

Figure 6.4.3.1 - Frame Format

32 Operating Instructions - CPG2500

Page 33

Precision Pressure Indicator

CPG2500

6.4.3.2 Frames Channel

The channel setting in the Frames application provides a way to choose which channel(s) appears and in

what order within the Measure Application (Main Screen). Any installed transducer channel or the emu-

lated Delta channel can be displayed in the Measure Application. In gure 6.4.3.2, the Dual Frame format

is set in the Frames format parameter, channel A is set as the top frame and Channel B is set as the bottom frame. Channels A, B, Remote or Barometer could be placed in any available position. If the Single

or Triple frame format is chosen then the channels will appear as shown in each of the respective frame

position sets.

Frame

positions sets:

Single Frame

Dual Frame

Triple Frame

Resulting view in the Measure Application

Figure 6.4.3.2 - Frames Channel

In Figure 6.4.3.2-A, the Channels have been set in order for each frame format and the frame format has

been set to “Frame triple”. In the Measure App the resulting channel position will be: channel “A’ on top,

Channel “B” in the middle and the “Delta” channel on the bottom. The barometer reading (if installed) will

appear as a selectable channel and will always be in the bottom right under the application menu.

Figure 6.4.3.2-A - Example channel frame settings

Operating Instructions - CPG2500 33

Page 34

Precision Pressure Indicator

CPG2500

6.4.4 Transducer Application

For each transducer, the Transducer Application provides a way to set the lter for the reading to

reduce uctuations due to electrical noise, and to set the resolution of the reading. In addition,

the auxiliary display functions and calibration function can be specied here.

Figure 6.4.4 - Transducer Application

6.4.4.1 Transducer Channel Selection

To set the transducer parameters, the transducer channel must be selected. Transducer parameters are

identical for all channels but can be set dierently in each channel. Figure 6.4.4.1 shows two displays

where channel “A” and “B” have been selected.

Figure 6.4.4.1 - Transducer Channel Selection

34 Operating Instructions - CPG2500

Page 35

Precision Pressure Indicator

CPG2500

6.4.4.2 Transducer Delta Emulation

If there is more than one transducer installed, the Delta Channel option will appear as a selection in the

Transducer App. The Delta channel has all of the regular transducer parameters in addition to the Delta

Function shown at the bottom of Figure 6.4.4.2. When the Delta Function is selected settings will appear

that dene the delta display (in the Measure App). All discrete combinations for adding or subtracting

one channel from another are available as a selection. These combinations are shown below in Figure

6.4.4.2.

Figure 6.4.4.2 - Transducer Delta Emulation

6.4.4.3 Transducer Filter

The Filter is an electronic lter to smooth out the pressure readings. Because of dierences in resolution,

greater ltering may display a more stable reading for some pressure units. Turn o the Filter by selecting

“O”, select varying degrees of ltering for the current units by selecting “Low”, “Normal” or “High”.

Figure 6.4.4.3 - Transducer Filter

Operating Instructions - CPG2500 35

Page 36

Precision Pressure Indicator

CPG2500

6.4.4.4 Transducer resolution

The Resolution of each transducer Channel can be set in the Transducer Application using the resolution

Parameter. The resolution can be set to 4, 5 or 6 digits.

Figure 6.4.4.4 - Transducer Resolution

36 Operating Instructions - CPG2500

Page 37

Precision Pressure Indicator

CPG2500

6.4.4.5 Auxiliary Displays

The Transducer Channel Auxiliary Display(s) can be set in the Transducer App by selecting Auxiliary Display 1, 2 or 3 and selecting from, None, Peak, Rate or Units. Figure 6.4.4.5-A shows auxiliary display 1, 2

and 3 set for units, peak and rate respectively. Auxiliary displays will appear in the Measure App as seen

in Figure 6.4.4.5-B.

Figure 6.4.4.5-A - Transducer channel aux displays set to Units, Peak and Rate

Figure 6.4.4.5-B - Auxiliary displays as seen in the Measure App

Operating Instructions - CPG2500 37

Page 38

Precision Pressure Indicator

CPG2500

6.4.4.6 Cal Function

The Transducer Cal Function presents a choice of None, Tare or Zero. Choosing Zero will enable the Zero

Cal Button [

App. The Tare button and the Zero Button cannot appear on the screen at the same time, in the same

channel. See section 6.4.1.3 and 6.4.1.4 for operation of the Zero and Tare buttons in the Measure App

(main screen).

] in the Measure App. Choosing Tare will enable the Tare Button [ ] in the Measure

Figure 6.4.4.6 - Cal Function

38 Operating Instructions - CPG2500

Page 39

Precision Pressure Indicator

CPG2500

6.4.5 Remote Application

With the remote application you can select the remote command set for all interfaces. The GPIB address,

Ethernet network parameters and Serial parameters can also be set here.

Details about the Remote Operation (command sets, cable requirements, etc.) can be found in Section 7,

Remote Operation.

IEEE-488

Ethernet

Serial

RS-232 or

USB

Figure 6.4.5 - Remote Application

6.4.5.1 Remote Command Set

The remote command set parameter provides a choice of the Mensor command set or the WIKA SCPI

command set. Both sets of commands are listed in Section 7, Remote Operation.

Figure 6.4.5.1 - Remote Command Set

Operating Instructions - CPG2500 39

Page 40

Precision Pressure Indicator

CPG2500

6.4.5.2 Remote Communication Settings

The remainder of the Parameters in the Remote Application present the choice of a numeric entry, a

numeric address entry, or a radio button selection. The parameters that require a numeric entry will

present a numeric keypad with min and max limits for the variable. The parameters that require a numeric

address (for example an IP address) will also present a keypad. Address entries should conform to the

format of the parameter selected. The three screens below show examples of each type.

Numeric entry

Numeric address entry

Radio button selection

Setting the Ethernet DHCP to

yes will have a short delay while

i

an error will be indicated. If DHCP is

enabled, the IP address, Netmask and

Gateway are greyed out and locked, these

are controlled by the DHCP server.

the DHCP server is contacted.

If a DHCP server is not found,

Figure 6.4.5.2 - Remote Communication Settings

40 Operating Instructions - CPG2500

Page 41

Precision Pressure Indicator

CPG2500

6.4.6 Info Application

The Info application displays information about the instrument, including:

• Mensor address, and email

• Model number, serial number and operating software version.

• Sensor model number, serial number, range, software version

Figure 6.4.6 - Info Application

Operating Instructions - CPG2500 41

Page 42

Precision Pressure Indicator

CPG2500

6.4.7 Leak Test Application

The Leak Test application provides a way to check the system for leaks into or out of the system.

This App is found on the second page of the Apps menu accessed by pressing the page down

button [

The operator denes a leak by setting the Time parameter and the Delta parameter. With the system

pressurized to a predetermined amount, the leak test is initiated by pressing the Start button. If the

change in pressure exceeds the Delta parameter before the allotted time in the Time parameter, then

the Leak Test App will return a red status indication showing the actual dierence (delta) in pressure

recorded during time period set in the leak test, indicating a “failed” test. Otherwise it will return a green

status indication showing that the delta was not exceeded for the time period, indicating a “passed” test.

See Figure 6.4.7-A for examples of a failed and a passed test.

].

Figure 6.4.7 - Leak Test

Figure 6.4.7-A - Leak test fail (left) & Leak test pass (right)

42 Operating Instructions - CPG2500

Page 43

Precision Pressure Indicator

CPG2500

6.4.8 Troubleshooting Application

The Troubleshoot Application will display information about error conditions and remote com-

munications. Within the troubleshoot screen (Figure 6.4.8-B), push the Error button to display

any errors that have occurred in the instrument due to a communication or network error. Push

the Remote button to show commands and responses that have been sent over the remote

communication connection.

If there are any errors in the error queue an error symbol [

] will appear in all screens (Figure 6.4.8A) of the instrument. Pressing this error button from any screen will open the Troubleshoot application

where the error can be viewed.

Figure 6.4.8-A - Error indication

Figure 6.4.8-B - Troubleshoot error and remote

Operating Instructions - CPG2500 43

Page 44

Precision Pressure Indicator

CPG2500

6.4.9 Service Application

The service application is a password protected area where calibration of all connected sen-

sors can be accomplished. In addition, this is where the password for entering this area can be

changed.

Figure 6.4.9-A - Service Application (locked)

Press the Enter button to show the numeric keypad to enter a password. This will unlock other applications. Default password is 123456. Enter 123456 and press the check mark [

Application.

Figure 6.4.9-B - Service Application (Enter Password)

] to unlock the Service

Note: The default Password is 123456. After entering this for the rst time, the password can

i

44 Operating Instructions - CPG2500

be changed.

Page 45

Precision Pressure Indicator

CPG2500

6.4.10 Unlocked Service Application

After the Password has been entered, the unlocked Service Application will appear (Figure 6.4.10). To

re-lock this screen, press the lock button.

Figure 6.4.10 - Unlocked Service Application

From the Unlocked Service Application, the Password can be changed by pressing the Enter button next

to the Change Password label. This will open a keypad where a new password can be entered and accepted by pressing the Check Mark [

Note: Please make note of a password change and save the new password in a secure

i

The Unlocked Service Application is the access point to all calibration screens described in Section 10 of

this manual.

i

location.

Note: Recommended calibration setup and explanation of calibration screen applica-

tions is covered in Section 10 of this manual.

].

Operating Instructions - CPG2500 45

Page 46

Precision Pressure Indicator

CPG2500

NOTES

46 Operating Instructions - CPG2500

Page 47

Precision Pressure Indicator

CPG2500

7 Remote Operation

Use the screens in Section 6.4.5 Remote Application to set the operating parameters for the instrument

command set, Ethernet, Serial (RS-232) and IEEE-488 (GPIB) information.

7.1 Command Set

Command Set button – Users’ can select which model remote protocol they would like to emulate for

simulation and testing purposes. Selections may include the following or may be added per customers’

specications:

• Mensor (default)

• SCPI WIKA (The SCPI WIKA mode emulates the WIKA command set in SCPI format.)

7.2 IEEE-488

IEEE-488 address button – Allows the user to set the GPIB address by inputting a numeric value utilizing

the touch screen.

7.2.1 IEEE-488.2 Commands

Command or Query Response / Function

*IDN? Returns identication string

*RST Reset to known state (default+psi)

*TST? Returns 1

*OPC Operation completed

*WAI Returns operation completed state

*CLS Clear status and error queue

*ESE Enable status event

*ESE? Returns enable status even value

*ESR Event status register

*ESR? Returns even status register value

*SRE Service request enable

*SRE? Returns service request enable value

*STB? Returns status byte

Operating Instructions - CPG2500 47

Page 48

Precision Pressure Indicator

CPG2500

7.3 Ethernet

The Ethernet function allows the user to set the following by inputting a numeric value in each separate

eld:

• IP

• Netmask

• Gateway

• Port

• DHCP settings

Set the Ethernet communication parameters as described in Section 6.4.5.

!

Caution

!

Caution

The Ethernet communication port allows the CPG2500 to communicate with computers using

10/100Based-T specications.

Before using Ethernet communication, four parameters must be set up: IP, Netmask, Gateway, and Port.

CAUTION: Please contact your network administrator for

proper settings.

CAUTION: Please consult your computer resources department prior to connect-

ingthisinstrumenttoyournetworktoverifytherearenoconictswithexistingIP

addresses.

48 Operating Instructions - CPG2500

Page 49

Precision Pressure Indicator

CPG2500

7.4 Serial

Set the Serial communication parameters as shown in Section 6.4.5 Remote Application. The serial communication port allows the CPG2500 to communicate in RS-232 format with computers, terminals, PDAs,

or similar hosts.

These parameters should be set to match your host computer. Default settings are: 9600 baud, 8 data

bits, 1 stop bit, no parity, and no echo.

If echo is ON, the CPG2500 will immediately echo back characters sent over the serial port. The Serial

function allows the user to set the RS-232 serial port settings by selecting from the choices provided:

• Baud

9600

19200

38400

57600

115200

• Data Bits

7

8

• Stop Bits

1

2

• Parity

Even

Odd

None

• Echo settings

On

O

7.4.1 Serial Cable Requirements

RS-232 communications are transmitted over a three conductor, shielded cable terminated in a standard

DB9 connector on the instrument end, and a dierent gender connector on the host end. The proper pin-

outs are shown in the following illustration.

CAUTION: When replacing an older model DPG 2100, the serial cable should be

replaced with a straight cable or a null-modem inserted in the line.

!

Caution

Operating Instructions - CPG2500 49

Page 50

Precision Pressure Indicator

CPG2500

7.5 Mensor Command Set

This Mensor command set is the default on the CPG2500. For queries (ending with a ?), the Data column

represents the response of the CPG2500. All response strings begin with a space character or an “E”

representing that there is an error in the error queue. All response strings are terminated with a <CR>

and a <LF>. The error queue holds the last 10 errors identied.

For all commands (no ?), the data column represents the required parameters to be sent to the CPG2500

following the string in the command column. For any command that requires multiple parameters to be

sent, the parameters must be separated by commas.

7.6 Command and Query Format

Commands must be sent in ASCII format and terminated with either a carriage return (<cr>), linefeed

(<lf>), or both. Commands are not case sensitive. Each query returns a response. If an error is detected

the response will include an error ag.

CommandorQueryeld: Unless otherwise specied, commands are typically converted to queries

by appending a question mark to the command. Table 7.9 lists all of the CPG2500 command or query

keywords.

Dataeld:The data eld is either in ASCII {string} or numeric {value} form. In the case of multiple data

elds, commas are required to separate the elds. Queries do not have a data eld. String (text) or value

(numeric) data are acceptable in any of the following formats:

Examples of {string} data: ON, OFF, mBar, inHg

Examples of {value} data: 1, 1.0, -5.678, 25.68324e-5

7.7 CommandSetDenitions

In this manual a data entry made up of alpha characters is dened as a string, as opposed to data

containing only numbers, such as “Enter 1 for ON or 0 for OFF” where 1 and 0 are dened as values.

Command: Any command or query listed in Table 7.9. For commands that take boolean data the following strings are acceptable:

0 1

False True

No Yes

O On

Separator: Space (SP).

Data: ASCII representations of numbers, {value}, or alpha characters, {string}, data as dened above.

When sending code a literal variable replaces the brackets and the enclosed character(s) shown in the

following examples.

Termination: Linefeed (LF) or carriage return (CR) is used to signal the end of a command statement.

For IEEE-488.2 operation “EOI” is an acceptable alternative.

Always send commands in one of the following formats:

1. [Command] [Termination];

2. [Command] [Separator] [Data] [Termination];

3. Queries are special instructions in the form: [Command?] [Termination] where the question mark, “?”,

immediately precedes the terminator.

When a valid query is received, the CPG2500 will return {data} terminated by CR and LF. Floating point

data is returned in the current engineering units in exponential format.

50 Operating Instructions - CPG2500

Page 51

Precision Pressure Indicator

CPG2500

7.8 Output Formats

Pressure readings are returned in exponential notation in a format according to the OUTFORM command

as follows. Outform applies to both pressure channels.

1. <sp> pressure value <cr><lf>

2. <sp> pressure, units number,STANDBY <cr><lf>

3. <sp> pressure, pressure rate <cr><lf>

4. <sp> pressure, minimum peak, maximum peak <cr><lf>

7.9 CPG2500 Commands and Queries

Table 7.9 lists all of the current CPG2500 commands and queries.

Channelspeciccommandsaresenttoonlytheactivechannel.

i

Notice

Optional emulation modes are available in which a CPG2500 can emulate remote functions of dierent

brands of pressure gauges. Please contact Mensor for more details.

See ‘CHAN’ command.

Table 7.9 - CPG2500 Commands and Queries

Command Data Response/Function

? See Table Below Returns data per the current output

format

A? <sp>n.nnnnne+nn<cr><lf> Returns the A channel pressure read-

ing

AR? <sp>n.nnnnne+nn<cr><lf> Returns the A channel rate

Acquire? 15 char string.

Ex:

Acquire? Test_stand_1

Returns:

<sp>(YES or NO), CCC…

CCC<cr><lf>

Address 1-31 Sets the GPIB Address

Address? <sp>nn<cr><lf> Returns the GPIB Address

Asset_tag 16 char string General purpose string for customer

Asset_tag? <sp>sssssssss<cr><lf> Return customer asset tag string

This command is used when multiple

computers would like to control the

instrument.

Yes if acquisition is successful.

No if instrument is being controlled

with another computer.

See: Release? and Unlock

use.

B? <sp>n.nnnnnE+nn<cr><lf> Returns the B channel pressure read-

ing

BR? <sp>n.nnnnnE+nn<cr><lf> Returns the B channel rate.

Baro? <sp>+n.nnnnnE+nn<cr><lf> Returns reading from barometric sen-

sor or “NO BAROMETER” if one isn’t

installed

Operating Instructions - CPG2500 51

Page 52

Precision Pressure Indicator

CPG2500

C? <sp>n.nnnnnE+nn<cr><lf> Returns the C channel pressure read-

ing

CR? <sp>n.nnnnnE+nn<cr><lf> Returns the C channel rate

Calculate_as_found_lin-

earity

Caldisable YES,NO Sets whether or not the ability to cali-

Caldisable? <sp>(YES or NO)<cr><lf> Returns whether or not the ability to

Cerr None Clears the error queue

Chan A, B, C, D Sets the active channel

Chan? <sp>X<cr><lf> Returns the active channel

Chanfunc n, func<cr><lf> Sets the auxiliary display function

Chanfunc? <n> <sp>CCCCC…<cr><lf> Returns the auxiliary display function

Cmdset Mensor, SCPI Activates remote command set for

Cmdset? <sp><CCCCC...<cr><lf> Returns active command set identier

Calculate linearity slopes and inter-

cepts from true/actual pressures

brate the sensors is disabled

calibrate the sensors is disabled

where “n” is the auxiliary display to be

set (1,2, or 3) and “func” is the function

(none, peak, rate, units)

specied by “n” for the active channel

instrument emulation modes

D? <sp>n.nnnnne+nn<cr><lf> Returns the D channel pressure read-

ing

DR? <sp>n.nnnnne+nn<cr><lf> Returns the D channel rate

Decpt? <sp>n<cr><lf> Returns the number of decimal points

(see Resolution)

Default None Sets the default values

Deltafunc A+B, A+C, B+C, A-B, A-C, B-A, B-C,

C-A, C-B

Sets the delta to be the result of the

specied function

Deltafunc? <sp>CCC<cr><lf> Returns the delta function

DHCP ON or OFF Reserved for DHCP setup

DHCP? <sp>(YES or NO)<cr><lf> Reserved for DHCP setup

DOC mm/dd/yyyy Sets the date of cal for the active

channel’s sensor

DOC? <sp>mm/dd/yyyy<cr><lf> Returns the date of cal for the active

channel’s sensor

DOM? <sp>mm/dd/yyyy<cr><lf> Returns the date of manufacture

Error? <sp> text description <cr><lf> Returns the next error in the error

queue

Filter OFF, LOW, NORMAL, HIGH Sets the reading lter 0, 80%, 92%,

95%

Filter? <sp> (lter)<cr><lf> Returns the reading lter

Gasdensity Value in lb/cuft, or “NITROGEN” or

“DRYAIR”

Sets the head pressure gas density in

lb/cuft

52 Operating Instructions - CPG2500

Page 53

Precision Pressure Indicator

CPG2500

Gasdensity? <sp>+n.nnnnnE+nn<cr><lf> Gets the head pressure gas density in

lb/cuft

Gastemp Value in degrees F Sets the head pressure gas tempera-

ture

Gastemp? <sp>+n.nnnnnE+nn<cr><lf> Gets the head pressure gas tempera-

ture

Gateway nnn.nnn.nnn.nnn Sets the Ethernet gateway address

Gateway? <sp>nnn.nnn.nnn.nnn<cr><lf> Gets the Ethernet gateway address

Height Value in inches Sets the head pressure height in

inches

Height? <sp>+n.nnnnnE+nn<cr><lf> Gets the head pressure height in

inches

Id? <sp>MENSOR,

CPG2500, ssssss,

v.v.vv<cr><lf>

IP nnn.nnn.nnn.nnn Sets the IP address of the instrument

IP? <sp>nnn.nnn.nnn.nnn<cr><lf> Returns the IP address of the instru-

Keylock YES or NO Locks or unlocks the entire touch

Keylock? <sp>(YES or NO)<cr><lf> Returns Yes or No

List? <sp>PRI,1<cr><lf> Legacy query

Listcal? <sp>PRI, {sn},1,{mmddyy}<cr><lf> Returns the calibration date of the ac-

Listrange? <sp>PRI,1,min,max<cr><lf> Returns the range of the active sensor

Localgravity Value in ft/s^2 Sets the local gravity in feet/sec^2

Localgravity? <sp>+n.nnnnnE+nn<cr><lf> Returns the local gravity in feet/sec^2

Netmask nnn.nnn.nnn.nnn Sets the Ethernet network mask

Netmask? <sp>nnn.nnn.nnn.nnn<cr><lf> Gets the Ethernet network mask

Outform 1 to 4 – see Section 7.9 Sets the output format

Outform? <sp>X<cr><lf> Returns the output format – see table

Peakmax? <sp>n.nnnnnE+nn<cr><lf> Returns the maximum pressure since

Peakmin? <sp>n.nnnnnE+nn<cr><lf> Returns the minimum pressure since

Peakreset None Resets the peak values.

Port nnnnn Sets the Ethernet port of the instru-

Port? <sp>nnnnn<cr><lf> Returns the Ethernet port of the instru-

Ptype Absolute or Gauge Sets the instrument pressure type –

ssssss is the serial number,v.v.vv is

the CPG2500 software version

ment

screen

tive sensor

below

peakreset was sent

peakreset was sent

ment

ment

emulation only works if the optional

barometric sensor is installed

Operating Instructions - CPG2500 53

Page 54

Precision Pressure Indicator

CPG2500

Ptype? <sp>CCCCC<cr><lf> Returns “Absolute” or “Gauge” for the

pressure type

RangeMax? <sp>n.nnnnnE+nn<cr><lf> Returns the maximum range of the ac-

tive transducer in the current units

RangeMin? <sp>n.nnnnnE+nn<cr><lf> Returns the minimum range of the ac-

tive transducer in the current units

Rate? <sp>n.nnnnnE+nn<cr><lf> Returns the rate reading of the instru-

ment in current units/current time unit

(see: Runits)

Rdecpt? <sp>n<cr><lf> Returns the number of rate decimal

points (see: Resolution)

Release? 15 char string.

Ex:

Release? Test stand 1

Returns:

<sp>(YES or NO), CCC…

CCC<cr><lf>

Resolution <n> Sets the number of signicant digits

Resolution? <sp>n<cr><lf> Returns the number of signicant dig-

Rlter Value in % Sets the % of the rate lter

Rlter? <sp>n.nnnnnE+nn<cr>

<lf>

Runits Sec, min, hr Sets the rate time unit

Runits? <sp>XXXX<cr><lf> Returns the rate time unit

Save_cal Save calibration values

Save_linearity Save linearity values

Sbaud 9600, 19200, 38400, 57600, 115200 Sets the serial baud rate

Sbaud? <sp>XXXX<cr><lf> Returns the serial baud data

Sdata 7 or 8 Sets the serial data bits

Sdata? <sp>n<cr><lf> Returns the serial data bits number

Sensorid? <sp>Mensor,SN XXXXXX, VN.NN Returns the active sensor’s serial

Span desired pressure or ? Sets span on active transducer or for

Span? <sp>XXXXXXX<cr><lf> Returns span scale factor for active

Sparity Even, ODD, NONE Sets the serial parity

Sparity? <sp>CCCC<cr><lf> Returns the serial parity

This command is used to release

control of the instrument in a multiple

computer environment.

Yes if release is successful

No if instrument is being controlled

with another computer

CCC… = name of controlling computer or AVAILABLE

See: Acquire? and Unlock

(see: decpt)

its (see: decpt)

Returns the rate lter

number and rmware version

?, clears previous value, must be >

50% FS and has a 1% limit. CALDISABLE must be OFF/NO.

transducer

54 Operating Instructions - CPG2500

Page 55

Precision Pressure Indicator

CPG2500

Sstop 1 or 2 Sets the serial stop bits

Sstop? <sp>X<cr><lf> Returns the serial stop bits

Ta r e ON / OFF Tares the reading to zero

Tare? <sp> n.nnnnnE+nn <cr><lf> Returns value of Tare

Transfer_factory_to_lin-

earity

Units units code or text in table below Sets the instrument engineering units

Units? <sp>CCCC<cr><lf> Returns the instrument units in a text

Unlock None Releases Acquire locks (see: Acquire? )

Window Value in current units Sets the exponential lter window for

Window? <sp>n.nnnnnE+nn

<cr><lf>

Zero desired pressure or ? Sets zero to set pressure or for ?,

Zero? <sp>n.nnnnnE+nn

<cr><lf>

Copy factory linearity coecients to

customer

string

or (see: Release?)

the active sensor

Returns the exponential lter window

for the active sensor

clears previous value. CALDISABLE

must be OFF/NO

Returns zero oset for active transducer

Note:

Except for the engineering units selection, the numeric sux selects the applicable channel/sensor:

1 = Channel A

2 = Channel B

3 = Channel C

4 = Channel D

5 = baro (if installed)

This numeric sux always defaults to 1 and is designated by [C] (channel)

Operating Instructions - CPG2500 55

Page 56

Precision Pressure Indicator

CPG2500

7.9.1 Units Command Syntax for Measurement Units

n Description Output Format Type

1 pounds per square inch PSI Imperial

2 inches of mercury @ 0°C INHG Imperial

3 inches of mercury @ 60°F INHG Imperial

4 inches of water @ 4°C INH2O Imperial

5 inches of water @ 20°C INH2O Imperial

6 inches of water @ 60°F INH2O Imperial

7 feet of water @ 4°C FTH2O Imperial

8 feet of water @ 20°C FTH2O Imperial

9 feet of water @ 60°F FTH2O Imperial

10 millitorr MTORR Metric

11 inches of sea water @ 0°C INSW Imperial

12 feet of sea water @ 0°C FTSW Imperial

13 atmospheres ATM Imperial

14 bars BAR Metric

15 millibars MBAR Metric

16 millimeters of water @ 4°C MMH2O Metric

17 centimeters of water @ 4°C CMH2O Metric

18 meters of water @ 4°C MH2O Metric

19 millimeters of mercury @ 0°C MMHG Metric

20 centimeters of mercury @ 0°C CMHG Metric

21 torr TORR Metric