Page 1

Industrial Pressure Controller

Model CPC4000

Applications

■

Oil & gas industry

■

Industry (laboratory, workshop and production)

■

Transmitter and pressure gauge manufacturers

■

Calibration service companies and service industry

Special Features

■

Pressure ranges -1 ... 210 bar (-15 ... 3,045 psi)

■

Control speed of 10 s

■

Control stability < 0.005 % FS

■

Accuracy down to 0.02 % IS (IntelliScale)

Description

Design

The CPC4000 offers a broad pressure range from -1 …

210 bar (-15 … 3,045 psi). This instrument can be

specified as a desktop or as a 19” rack-mounted device.

It can have up to two reference pressure sensors and

an optional barometer for displaying barometric

pressure or used to emulate gauge or absolute

pressure.

Application

Since the controller offers a measurement accuracy of

up to 0.02 %IS-50, and controls pressure with a high

stability, it is particularly suited as a production tool for

transmitter manufacturing, a calibration and

maintenance tool for pressure measuring devices or a

factory/working standard for the calibration of all types of

pressure measuring devices. The contamination

prevention accessories like the coalescing filter and

block and bleed valve make the CPC4000 an ideal

solution in oil and gas plants.

Functionality

The touchscreen, along with an intuitive user interface,

provide maximum ease-of-use. In addition, the large

number of menu languages add to its operability. The

device can have up to two internal pressure transducers

and the ranges for each unit are determined by the

customer within the allowable range.

Calibration Technology

Calibration technology

WIKA data sheet CT 27.40

Industrial Pressure Controller

Model CPC4000

Depending on the application, the operator can choose

between three methods of pressure control:

1) Direct numeric entry via keypad for the precise input of

the pressure value (set point) which will be controlled.

2) Define steps to reach the desired pressure value by

either defining fixed pressure increments or a

percentage of span value.

3) Program and store individual test sequences based on

users’ application.

Software

The WIKA-CAL calibration software enables the convenient

calibration of pressure measuring instruments and the

generation of test certificates. Additionally the device can

also be remotely controlled using the serial command

formats, the Mensor standard, SCPI or further optional

command sets are available.

Complete Test and Calibration Systems

On request, complete mobile or stationary test systems can

be manufactured. There is an IEEE-488.2, RS-232, USB

(along with an optional USB-WiFi adapter) and an Ethernet

interface for communication with other instruments, and

thus the instrument can be integrated into existing systems.

WIKA data sheet CT 27.40 ∙ 04/2015

Data sheets showing similar products and accessories:

Pneumatic precision pressure controller; model CPC6000; see data sheet CT 27.61 High-end

pressure controller; model CPC8000; see data sheet 28.01

WIKA-CAL calibration software; see data sheet CT 95.10

Page 1 of 8

Page 2

Specifications

CPC4000

Reference Pressure Sensors

Pressure range Standard Optional

Accuracy

Gauge pressure 0 ... 0.35 up to 0 ... 210 bar

Bi-directional -0.35 ... 0.35 up to -1 ... 210 bar

Absolute pressure 0 ... 1 up to 0 ... 211 bar abs.

1)

0.02 % FS 0.02 % IS-50

2)

0 ... 1 up to 0 ... 210 bar

(0 ... 5 up to 0 ... 3,045 psi)

(0 ... 15 up to 0 ... 3,045 psi)

-1 ... 10 up to -1 ... 210 bar

(-5 ... 5 up to -15 ... 3,045 psi)

(-15 ... 145 up to -15 ... 3,045 psi)

0 ... 1 up to 0 ... 211 bar abs.

(0 ... 15 up to 0 ... 3,060 psi abs.)

(0 ... 15 up to 0 ... 3,060 psi abs.)

Calibration interval 365 days 365 days

Optional barometric reference

Function The barometric reference can be used to switch pressure types 3), absolute <=> gauge. With gauge

pressure sensors, the measuring range of the sensors must begin with -1 bar (-15 psi) in order to carry

out an absolute pressure emulation.

Measuring range 552 ... 1,172 mbar abs. (8 ... 17 psi abs.)

Accuracy

1)

0.02 % of reading

Pressure units 38 and two freely programmable

1) It is defined by the total measurement uncertainty, which is expressed with the coverage factor (k=2) and includes the following factors: the intrinsic performance of the instrument, the

measurement uncertainty of the reference instrument, long-term stability, influence of ambient conditions, drift and temperature effects over the compensated range during a periodic zero

point adjustment.

2) 0.02 % IS-50 accuracy: 0.02 % of reading in the upper half of the measuring range.

3) For a pressure type emulation, we recommend a native absolute pressure sensor, since the zero point drift can be eliminated through a zero point adjustment.

Base Instrument

Instrument

Instrument version Standard: desktop case

Option: 19" mounting with rack-mounting kit

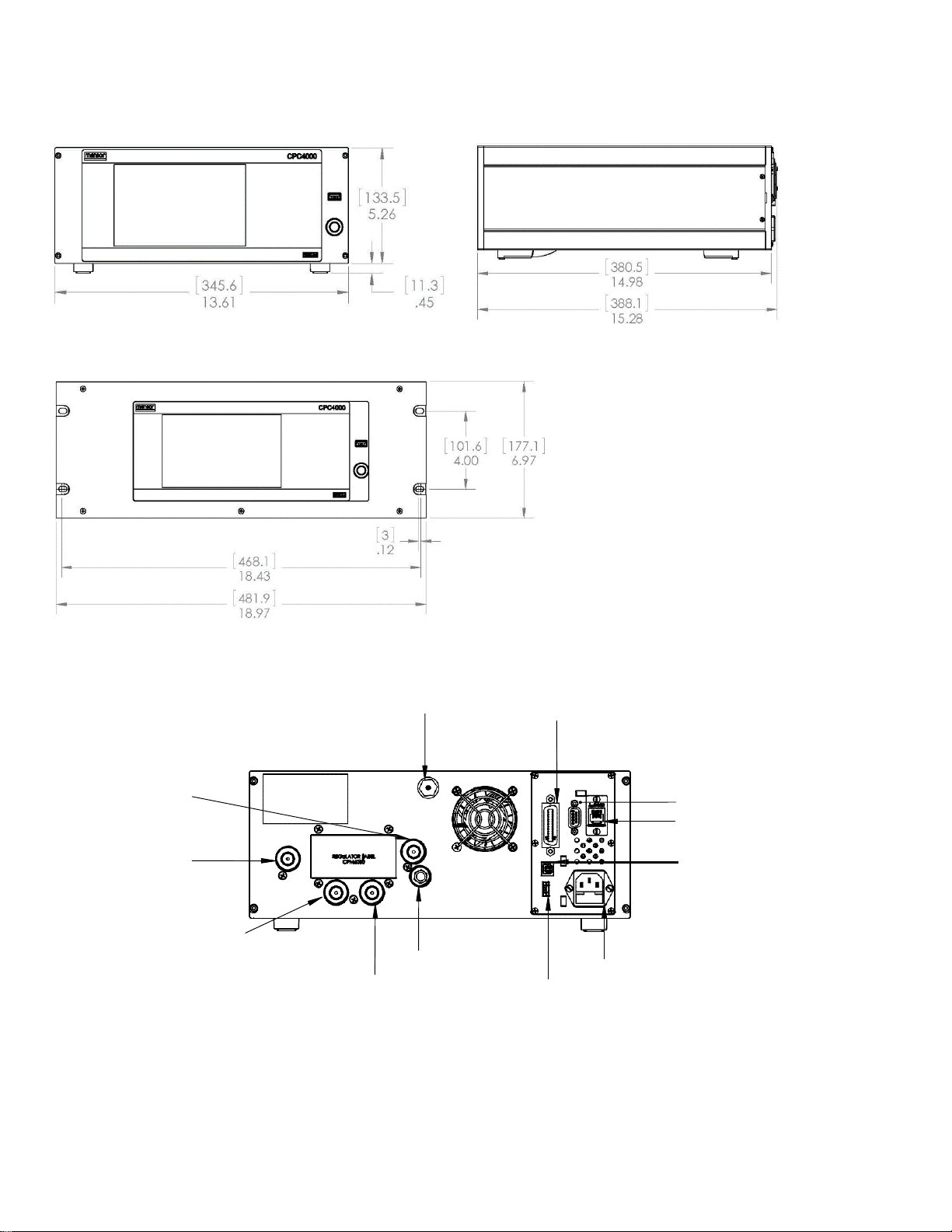

Dimensions in mm see technical drawings

Weight approx. 12.7 kg (28 lbs.) with all internal options

Warm-up time approx.. 15 min

Display

Screen 7.0" color LCD display

Resolution 4 ... 6 digits depending on range and units

Input methods Resistive touchscreen

Connections

Pressure connections 4 ports with 7/16”- 20 F SAE and 1 port with 1/8” F NPT

Optional Barometer: 1 port with barb fitting

Filter elements Filter element (40 micron) included in each pressure port

Pressure port adapters Standard: without

Option: 6 mm tube fitting, 1/4" tube fitting, 1/4" NPT female, 1/8" NPT female or 1/8" BSPG female

Permissible pressure and media

Permissible pressure media Dry, clean air or nitrogen (ISO8573-1:2010 Class 5.5.4 or better)

Wetted parts Aluminum, bras s, 316 and 316L stainless steel, Buna N, FKM/FPM, PCTFE, PEEK, PTFE, PPS,

glass-filled epoxy, RTV, ceramic, silicone, silicone grease, Urethane

Overpressure protection Safety relief valve adjusted to specific customized pressure range

Supply Port ~ 110 % FS

Measure/Control Port max. 105 % FS

Page 3

Base Instrument

Power supply

Power supply AC 100 ... 240 V, 50 Hz / 60 Hz

Power consumption max. 120 VA

Permissible ambient conditions

Storage temperature 0 ... 70 °C (32 ... 158 °F)

Humidity 5 … 95 % r. h. (relative humidity, non-condensing)

Compensated temperature range 15 … 45 °C (59 ... 113 °F)

Mounting position horizontal

Control parameter

Control stability < 0.005 % FS of active range

Control mode Slow, normal, fast and variable

Control time 10 s (with a 10% pressure increase in a 50cc test volume)

Control range 0.05% FS or 0.0017 bar (0.025 psi) over exhaust pressure to 100% FS

Overshoots < 0.3% FS in fast control mode (typical <0.1% FS in slow control mode)

Test volume 50 ... 1,000 ccm

Communication

Interface Standard: Ethernet, IEEE-488, USB, RS-232.

Command sets Mensor, WIKA SCPI, others optional

Response time 100 ms

Optional: WiFi (with a USB-WiFi adapter)

Approvals and Certificates

CE conformity

EMC directive

Low voltage directive 2006/95/EC, EN 61010-1:2010

Approvals

GOST Metrology/measuring technology, Russia

Certificate

Calibration

4) Warning! This is class A equipment for emissions and is intended for use in industrial environments. In other environments, e.g. residential or commercial installations, it can interfere with

other equipment under certain conditions. In such circumstances the operator is expected to take the appropriate measures.

5) Calibration in a horizontal position.

5)

6)

2004/108/EC, EN 61326-1: 2013 emission (group 1, class A) and interference immunity (industrial

application)

Standard: A2LA calibration certificate (standard on factory)

Option: DKD/DAkkS calibration certificate

Approvals and certificates, see website

Page 4

LPSVR MODULE ±0.175 bar (±2.5 psi)

2)

MPSVR MODULE ±0.7 bar (± 5 psi)

2)

HPSVR 3) MODULE -1… 5.2 bar (-15 … 75 psi)

2)

EPSVR

3)

MODULE -1 ... 10 bar (-15 … 150 psi)

2)

LPSVR MODULE 0 … 0.5 bar (0 … 7.5 psi)

2)

MPSVR MODULE 0 … 1 bar (0 … 15 psi)

2)

HPSVR 3) MODULE 0 … 5.2 bar (0 … 75 psi)

2)

EPSVR

3)

MODULE 0 ... 11 bar (0 … 165 psi)

2)

Working Ranges of the Controller Modules

Bi-directional or gauge pressure [bar (psi)]

-1 (-15) 0 3.4 (50) 10 (150) 100 (1,500) 210 (3,045)

Absolute pressure [bar (psi)]

0 4.4 (65) 11 (165) 101 (1,515) 211 (3,060)

1)

1)

1) Mixing of absolute pressure and gauge pressure sensors in a module is not possible.

2) Smallest recommendable sensor range

For controlling absolute pressure a vacuum pump connected at the Exhaust port is required.

Easy Operation via Touchscreen

Home Screen

Shortly after power-up, the standard home screen (see following picture) is displayed. In this menu screen, one can switch

between the operating modes using the buttons “MEASURE” / “CONTROL” / “VENT” at the bottom of the screen.

Set point selection

Selection of the active sensor

or auto-range

Range of sensors

Optional zero/ tare function

Current measuring value

Optional bar graph

Current pressure unit

Auxiliary displays with either

Pressure mode, peak, rate or

alternate units

MEASURE

In measure mode, the pressure

present at the Measure/Control port

is measured with high accuracy (if

you switch directly from

“CONTROL” to “MEASURE” mode,

the last controlled pressure in the

connected test assembly will be

maintained/locked).

CONTROL

In control mode, the

instrument provides a highly

accurate pressure to the

Measure/Control port,

corresponding to the desired

set point.

VENT

Immediately vents the system, incl.

the test assembly connected to the

Measure/Control port, to

atmosphere.

Page 5

Simple Instrument Configurations

A) General Settings of the Instrument

Instrument language, screen brightness and

volume settings

User defined measurement units

Units for the optional barometer

Multiple user specific configurations created

and saved for ease of access

B) Control Settings of the Instrument

The maximum and minimum limits for the

desired control can be set

The stability of the control can be defined by the

user by setting the Stable Window as “% of set

point” and by setting the Stable Delay

The control rate parameters can be adjusted by

setting the Rate Stable Window & Delay. The

actual rate can be set using the Rate Setpoint.

The vent rate of the instrument can be set

C) Display Settings of the Instrument

Electronic filter to smooth the readings

The resolution of the reading

can be changed

Bar graph can be turned on or off

Easy zeroing and tare features

Page 6

Reference Port

(7/16-20 UNF)

Baro Ref Port

(10-32 UNF)

IEEE-4888

RS-232

Ethernet Port

USB (device)

Power Supply

USB (host)

Vent (ATM)

Measure/ Control Port

(7/16-20 UNF)

Vent (ATM)

Supply Port

(7/16-20 UNF)

Exhaust Port

(7/16-20 UNF)

Dimensions in [mm]/ inch

Front view Side view

19” Rack Mount

Electrical and Pressure Connections – Rear

Page 7

WIKA-CAL Calibration Software

Easy and fast creation of a high-quality calibration

certificate

The WIKA-CAL calibration software is used for generating

calibration certificates or logger protocols for pressure

measuring instruments and is available as a demo version for a

cost-free download.

A template helps the user and guides him through the creation

process of a document.

In order to switch from the demo version to a full version of the

respective template, a USB key with the template has to be

purchased.

The pre-installed demo version automatically changes to the

selected full version when the USB key is inserted and is available as long as the USB key is connected to the computer.

■

Creation of calibration certificates for mechanical and

electronic pressure measuring instruments

■

Fully automatic calibration with pressure controllers

■

Calibration of relative pressure measuring instruments

with absolute pressure references and vice versa

■

A calibration assistant guides you through the calibration

■

Automatic generation of the calibration steps

■

Generation of 3.1 certificates per DIN EN 10204

■

Creation of logger protocols

■

User-friendly interface

■

Languages: German, English, Italian and more due with

software updates

For further information see data sheet CT 95.10

Calibration certificates can be created with the Cal-Template and logger protocols can be created with the Log-Template.

Cal Demo

Generation of calibration certificates limited to 2 measuring

points, with automatic initiation of pressures via a pressure

controller.

Cal Light

Generation of calibration certificates with no limitations on

measuring points, without automatic initiation of pressures via

a pressure controller.

Cal

Generation of calibration certificates with no limitations on

measuring points, with automatic initiation of pressures via a

pressure controller.

Log Demo

Creation of data logger test reports, limited to 5

measured values.

Log

Creation of data logger test reports without limiting

the measured values.

Page 8

06/2015

Scope of Delivery

■

Model CPC4000 industrial pressure controller (desktop case)

■

1.5 m / 5 ft power cord

■

Operating instructions

■

A2LA calibration certificate (standard on factory)

Options

■

DKD/DAkkS Calibration certificate

■

Barometric reference

■

Second reference pressure sensor

■

19" rack mounting kit

■

Customer-specific sy stem

■

Adapters & fittings for pressure connections

Accessories

■

Pressure adapters

■

Interface cable

■

Coalescing filter

■

Block & bleed valve

■

Pressure booster

■

WIKA-CAL calibration software

Ordering information

Model / Housing / Pressure range transducers / Pressure unit / Pressure type / Minimum pressure range / Maximum pressure

range / Accuracy / Type of calibration certificate / Barometric reference / Type of certificate for barometric reference / Digital

interface / Pressure port adapters / Power cord / Additional order details

© 2008 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing. We

reserve the right to make modifications to the specifications and materials.

Page 8 of 8

Represented by:

Mensor

Email: sales@mensor.com

WIKA data sheet CT 27.40 ∙ 04/2015

201 Barnes Drive

San Marcos, Texas 78666 Toll

Free: 800-984-4200

Tel: 512-396-4200

Fax: 512-396-1820

Loading...

Loading...