Page 1

Portable low-pressure controller

Model CPC2000

Applications

■

Mobile calibration of low-pressure measuring instruments

■

Supply of very low positive or negative pressures

■

Accurate measurement of small overpressures or

dierential pressures

Special features

■

Pressure ranges: 1 ... 1,000 mbar

■

Accuracy: to 0.1 % FS

■

Integrated, automatic pressure generation

■

Portable, also usable without power supply unit due to

Li-Ion battery

■

Simple operation

Calibration

WIKA data sheet CT 27.51

for further approvals

see page 3

Portable low-pressure controller model CPC2000

Description

Application

The main applications for this instrument are in the areas of

heating, ventilation, air-conditioning, ltration, cleanroom,

and medical technology as a calibrator or as highly accurate

measurement equipment and/or precise pressure transducer.

Functionality

The model CPC2000 low-pressure controller is a mains or

battery-operated pressure controller with internal, automatic

pressure generation and pressure reference. The pressure

generation is achieved using an integrated, electric pump,

which makes a positive and/or negative pressure available

on both the tube connections. As soon as the instrument is

switched on, a zero point setting is automatically carried out,

so that a zero-point drift is eliminated.

∙ 07/2019

The subsequent preparation of a calibration requires only a

few settings. First, using the MENU button, select one of the

stored pressure units and the variable pressure change step

in the range of 0 ... 50 %.

Then, once the full scale has been entered in control mode,

the pressure can be easily increased or decreased by the

dened level using the navigation buttons. To check whether

the calibration assembly or the test item has a leak, the LEAK

button can be used. With this, the pressure is locked into the

test assembly and any pressure drop there might be, as well

as the time this takes, is measured and displayed.

Interface

The instrument has an RS-232 and USB interface, enabling

communication and data exchange with a PC.

Page 1 of 8WIKA data sheet CT 27.51

Data sheets showing similar products and accessories:

Industrial pressure controller; model CPC4000; see data sheet CT 27.40

Modular pressure controller; model CPC6050; see data sheet CT 27.62

Precision pressure controller; model CPC8000; see data sheet CT 28.01

Page 2

Software

WIKA-Cal calibration software is available for the CPC2000.

WIKA-Cal also oers, over and above PC-supported

calibration, the management of the calibration and instrument

Certied accuracy

The accuracy of the instrument is certied by a factory

calibration certicate. On request, we can provide a DKD/

DAkkS calibration certicate for this instrument.

data in an SQL database.

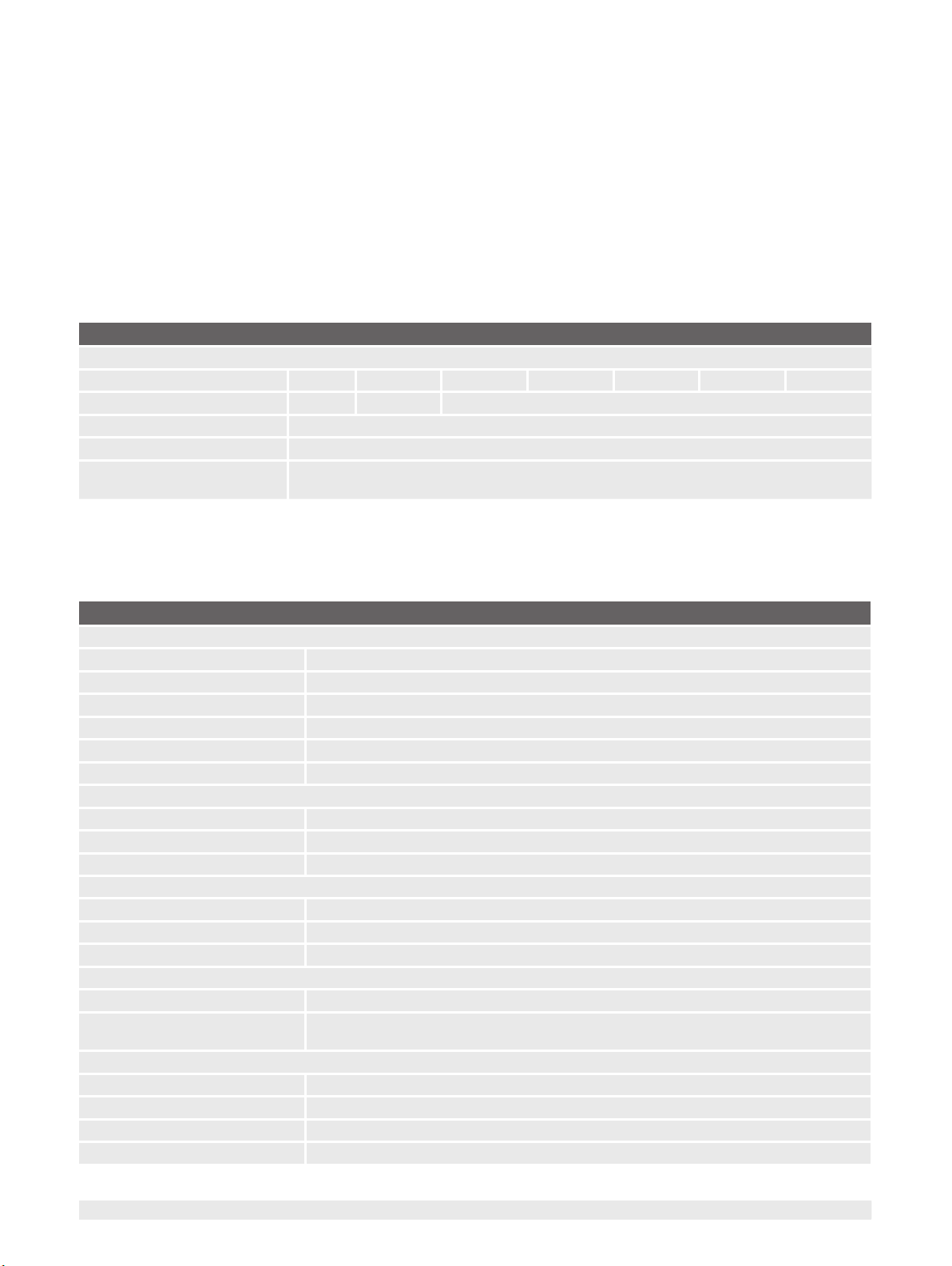

Specications

Model CPC2000

Reference pressure sensor

Pressure range

Gauge pressure mbar 0 ... 1 0 ... 10 0 ... 50 0 ... 100 0 ... 500 0 ... 1,000

Accuracy

Calibration interval 365 days

Pressure units Pa, kPa, hPa, bar, mbar, psi, inH

Overpressure protection 5 times; ≤ 100 mbar

1) It is dened by the total measurement uncertainty, which is expressed with the coverage factor (k = 2) and includes the following factors: the intrinsic performance of the instrument, the

measurement uncertainty of the reference instrument, long-term stability, inuence of ambient conditions, drift and temperature eects over the compensated range during a periodic

zero point correction.

2) FS = Full span = end of measuring range - start of measuring range

1)

2)

% FS

2 times; > 100 mbar ... ≤ 1,000 bar

0.3 0.1

O, inHg, mmHg, Torr

2

Base instrument

Instrument

Instrument version Benchtop instrument with carrying handle

Dimensions 102.6 x 257 x 271 mm (4.04 x 10.12 x 10.67 in) without carrying handle

Weight 4.6 kg (10.14 lbs)

Warm-up time approx. 15 min

Pressure generation internal, electric pump

Ingress protection IP20

Display

Screen backlit, multi-line graphic display

Resolution 4 ... 5 digits depending on range and units

Keyboard Membrane keypad

Connections

Pressure connections 6,6 x 11 mm (0.26 x 0.43 in) (hose diameter D = 6 mm (0.24 in))

Permissible pressure media Ambient air

Wetted parts Ni, Al, CuBe, PUR

Functions

Menu languages German, English, Spanish and French

Zero point setting automatic (at denable time intervals)

manual (ZERO button)

Voltage supply

Supply voltage DC 24 V, 1 A

Power consumption 24 VA

Battery type Li-Ion

Battery life approx. 8 h

WIKA data sheet CT 27.51 ∙ 07/2019 Page 2 of 8

Page 3

Base instrument

Permissible ambient conditions

Operating temperature 10 ... 40 °C (50 ... 104 °F)

Storage temperature -10 ... +70 °C (14 ... +158 °F)

Humidity 30 … 80 % r. h. (non-condensing)

Control parameters

Control steps 0 ... 50 % individually adjustable or 100 %

Control speed approx. 5 s (dependent upon test volume)

Communication

Interface RS-232 and USB

Response time 1 value/s

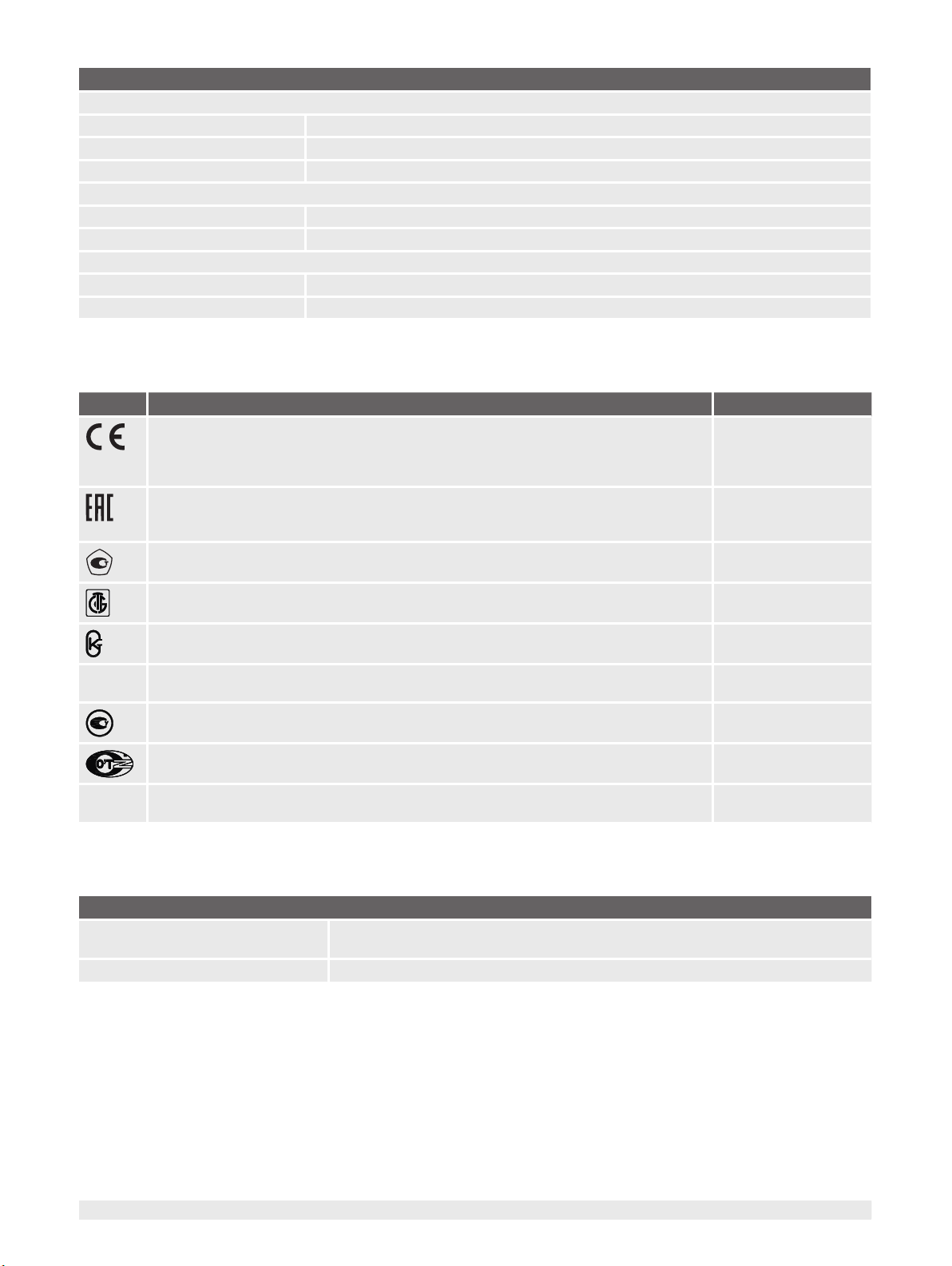

Approvals

Logo Description Country

EU declaration of conformity

■

EMC directive

EN 61326-1 emission (group 1, Class B) and immunity (industrial application)

■

RoHS directive

EAC (option)

■

EMC directive

■

Low voltage directive

GOST (option)

Metrology, measurement technology

BelGIM (option)

Metrology, measurement technology

KazInMetr (option)

Metrology, measurement technology

- MTSCHS (option)

Permission for commissioning

UkrSEPRO (option)

Metrology, measurement technology

Uzstandard (option)

Metrology, measurement technology

- CPA (option)

Metrology, measurement technology

European Union

Eurasian Economic

Community

Russia

Belarus

Kazakhstan

Kazakhstan

Ukraine

Uzbekistan

China

Certicates

Certicate

Calibration

Recommended recalibration interval 1 year (dependent on conditions of use)

3) Calibration in a horizontal position.

Approvals and certicates, see website

WIKA data sheet CT 27.51 ∙ 07/2019 Page 3 of 8

3)

Standard: 3.1 calibration certicate per DIN EN 10204

Option: DKD/DAkkS calibration certicate

Page 4

Dimensions in mm (in)

Front view

Side view

Electrical connections on the rear

1

2

3

1

USB interface

2

RS-232 interface

3

Connection for power supply unit

WIKA data sheet CT 27.51 ∙ 07/2019 Page 4 of 8

Page 5

Keyboard and display

User interface

10

Possible modes and screen displays

1 2 3 4

7 689

1

In control mode: Starts the leak

measurement, otherwise without

function

2

During the control process → Vent,

otherwise select SETUP

3

Increase set point by x %

4

5

Set set point to 100 %

5

On/O button

6

SELECT to conrm the entry

7

Decrease set point by x %

8

Set set point to 0 %

9

Zero point setting

10

Pressure connections

Measuring

1

5

MEAS

+10.000

mbar

+00.002

4

In measuring mode, the pressure at the pressure ports is

measured with great precision.

Leak test

5

LEAK

+ 0% +0.002

7

+10.000

mbar

+10.100

10 s

+ 1% +0.100

9

Control

1

2

3

5

CTRL

+10.000

mbar

+04.999

4

+ 50% +5.000

6

2

3

In control mode, pressures are supplied to the pressure ports

with high precision.

A set-point change (in a selectable step size) is made via the

/ buttons.

1

Full scale

2

Pressure unit

3

Measured value

4

2

3

810

Battery status

5

Operating mode

6

Set point in % of full scale

7

Starting value for the leakage measurement

8

Pressure drop

9

Pressure drop in % of the starting value

10

Measurement duration

In test mode, the pressure drop/time in the connected test

assembly is determined.

WIKA data sheet CT 27.51 ∙ 07/2019 Page 5 of 8

Page 6

P

t

Menu and calibration procedure

I) General conguration via SETUP menu

SETUP menu items

■

Select measuring range

■

Select pressure unit (Pa, kPa, hPa, bar, mbar, psi, inH2O,

inHg, mmHg, Torr)

■

Step size, freely selectable between 0 … 50 % or 100 %

■

Select the operating mode (MEAS, CTRL, AUTO)

II) Calibration sequence example

Full scale

Step size

■

Select language (DE, EN, ES, FR)

■

Controller settings (zero point setting, interface, display,

auto mode, info)

1. Dening the calibration cycle full scale (span)

MENU

-------------------------

RANGE.....: +10.000

UNIT......:

STEPS.....: 50%

MODE......: CTRL

LANGUAGE..: EN

SETTINGS -->

2. Go back to the main screen and run through the calibration cycle in the dened step size (x %)

CTRL

+10.000

mbar

mbar

+04.999

To congure the full scale (span):

Select the digit via

Change the digit via

Change set point to x %

Pressure change in % via

Change pressure to 100 % via

buttons

/ buttons

/ buttons

button

+ 50% +5.000

Change pressure back to 0 % via

button

The newly selected pressure step will be controlled immediately after the set-point change.

⇒

WIKA data sheet CT 27.51 ∙ 07/2019 Page 6 of 8

Page 7

WIKA-Cal calibration software

Easy and fast creation of a high-quality calibration certicate

The WIKA-Cal calibration software is used for generating

calibration certicates or logger protocols for pressure

measuring instruments and is available as a demo version for

a cost-free download.

A template helps the user and guides him through the

creation process of a document.

In order to switch from the demo version to a full version of

the respective template, a USB stick with the template must

be purchased.

The pre-installed demo version automatically changes to

the selected full version when the USB stick is inserted and

remains available as long as the USB stick is connected to

the computer.

■

Creation of calibration certicates for mechanical and

electronic pressure measuring instruments

■

Fully automatic calibration with pressure controllers

■

Calibration of gauge pressure measuring instruments with

absolute pressure references and vice versa

■

A calibration assistant guides you through the calibration

■

Automatic generation of the calibration steps

■

Generation of 3.1 certicates per DIN EN 10204

■

Creation of logger protocols

■

User-friendly interface

■

Languages: German, English, Italian and more due with

software updates

For further information see data sheet CT 95.10

Calibration certicates can be created with the Cal-Template and logger protocols can be created with the Log-Template.

Cal Demo

Generation of calibration certicates limited to 2 measuring points, with

automatic initiation of pressures via a pressure controller.

Cal Light

Generation of calibration certicates with no limitations on measuring

points, without automatic initiation of pressures via a pressure controller.

Calibration certificate

Kalibrierzeugnis

General

Allgemein

Calibration certificate

Kalibrierschein

Customer Demo customer

Kunde

Demo street

DE-12345 Demo city

Customer order No.

Kundenbestellnummer

Order date

Bestelldatum

Date of calibration 01/02/2017

Datum der Kalibrierung

Operator Demo User

Bearbeiter

Environmental conditions

Umgebungsbedingungen

Temperature (20,0 ± 0,1) °C

Temperatur

Atmospheric pressure (1013,0 ± 0,1) hPa

Atmosphärischer Luftdruck

Rel. humidity (40 ± 1) %

Rel. Luftfeuchte

Measurement conditions

Messbedingungen

Working standard (WS) Pressure controller

Gebrauchsnormal (GN) Druckcontroller

Model Demo CPC

Typ

Calibration mark Demo 12345

Kalibrierzeichen

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.02 % FS

Genauigkeit

Demo laboratory

Tel.: 01234/56789

Demo street 123

Fax: 01234/56789

12345 Demo city

E-Mail: demo@demo.com

Demo country

www.demo.com

Certificate No. 00000122

Zeugnis-Nr.

Device under test (DUT)

Kalibriergegenstand (KG)

Electrical gauge

Elektrisches Druckmessgerät

Model D-10

Typ

Serial number demo1234

Seriennummer

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.05 % FS

Genauigkeit

Resolution (scale division) 0.0001 bar

Auflösung (Skalenwert)

Measuring point No. demo tag

Messstellen-Nr

Place of calibration

Ort der Kalibrierung

g = (9.80946 ± 0.01) m/s²

Demo place

Musterort

Calibration certificate

Kalibrierzeugnis

Certificate No. 00000122

Zeugnis-Nr.

Measurement results

Messergebnisse

Reference value WS Reading DUT

Referenzwert GN Ablesung KG

bar bar

↑ ↓

0.00000 0.0000 0.0010

10.00000 10.0010 10.0020

Statement of compliance

Konformitätsaussage

Object keeps the specifications!

Der Kalibriergegenstand hält die Herstellerspezifikationen ein!

Page 1 / 2

Demo laboratory

Seite

Tel.: 01234/56789

Demo street 123

Fax: 01234/56789

12345 Demo city

E-Mail: demo@demo.com

Demo country

www.demo.com

Cal

Generation of calibration certicates with no limitations on measuring

points, with automatic initiation of pressures via a pressure controller.

Log Demo

Creation of data logger test reports, limited to 5 measured values.

Page 2 / 2

Seite

Log

Creation of data logger test reports without limiting the measured values.

WIKA data sheet CT 27.51 ∙ 07/2019 Page 7 of 8

Page 8

Accessories for CPC2000 Order code

Description CPX-A-C2

Spare power supply unit -P-

Transport case

Robust

Easy -E-

Interface cable

RS-232

-C-

-9-

Ordering information for your enquiry:

1. Order code: CPX-A-C2

2. Option:

⇓

[ ]

Scope of delivery

■

Portable low-pressure controller model CPC2000

■

Power supply unit

■

Operating instructions

■

3.1 calibration certicate per DIN EN 10204

Options

■

DKD/DAkkS calibration certicate

Ordering information

Model / Measuring range / Accuracy / Type of certicate / Power cord / Further approvals / Additional ordering information

© 03/2010 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

WIKA data sheet CT 27.51 ∙ 07/2019 Page 8 of 8

07/2019 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Loading...

Loading...