Mennekes Electrical Products Plugs Connectors Receptacles & Inlets Wiring Instructions

MENNEKES WIRING INSTRUCTIONS

60A & 100A PowerTop Xtra

Plugs, Connectors, Receptacles & Inlets

Color Coding: All device are color coded to easily identify voltage

GROUND SLEEVE POSITION

RATED VOLTAGE

110V–125V

220V- 250V

440V– 480V

600V

277V

125/250V

415V

ME 4 60 R 7 W

COLOR

Yellow

Blue

Red

Black

Gray

Orange

Red

3W

4

6

7

-

5

-

-

CATALOG NUMBERING SYSTEM

4W

9

7

5

-

12

6

5W

9

7

5

-

6

Mennekes PIN CONFIGURATION AMPERAGE DEVICE TYPE POLARIZATION ENVIRONMENTAL RATING

3-2 POLE + E

4-3 POLE + E

5-3 POLE + N + E

60 100 P-PLUG

C-CONNECTOR

R-RECEPTACLE

B-INLET

CLOCK POSITION OF

FEMALE SLEEVE

(MALE PIN

CORRESPONDS TO

RESPECTED

FEMALE POSITION)

W-WATERTIGHT

(SCREW CAP &

LOCKING RING)

WARNING: BE SURE THE POWER IS OFF BEFORE STARTING INSTALLATION.

READ ENTIRE DIRECTIONS BEFORE STARTING INSTALLATION.

Caution: Check to see that the rating label on the device is correct for the installation.

Select cable/conductor of suitable ampacity, service and temperature. See TABLE I per NEC Article 400.

Notes: Watertight versions have locking rings and locking covers, weatherproof versions do not.

60 Amp and 100 Amp devices do not require use of wire ferrules.

The Following Tables are Referenced in Wiring Instructions for all Devices:

TABLE l

Wire Capacity

Terminal Torque IN-lb

Strip length jacket

Strip length conductor (“hot”, neutral)

Strip length ground 0.60” (conn/recep)

Cord Capacity Round 3W; 4W; 5W:

Strain Relief Nut (4) Torque in lb.

Cable Clamp Screw (11) Torque in lb.

Trade Size Thread of Housing (NPT) 3W; 4W; 5W:

60Amp 100Amp Pilot Contact

#8 to #4 #2 to #1/0 14 AWG

18* 88.5* 7 in/lb.

3.15” 4.33” 3/10”

0.67” 1.06”

0.67” 1.06”

.60 to 1.45 .96 – 1.92

66 66

18 35

1 1/2” 2”

*Each terminal should be torqued at full recommended value for 2 complete cycles: Tighten both screws of each terminal for one

cycle and repeat the process again. 100A = #5 allen headscrew.

TABLE II

TERMINAL IDENTIFICATION USE

G, ⏚ or Green

W, White System ground (neutral conductor)

L1, L2, L3 or X, Y, Z Line (“hot” conductors)

Equipment grounding conductor

PLUGS / CONNECTORS

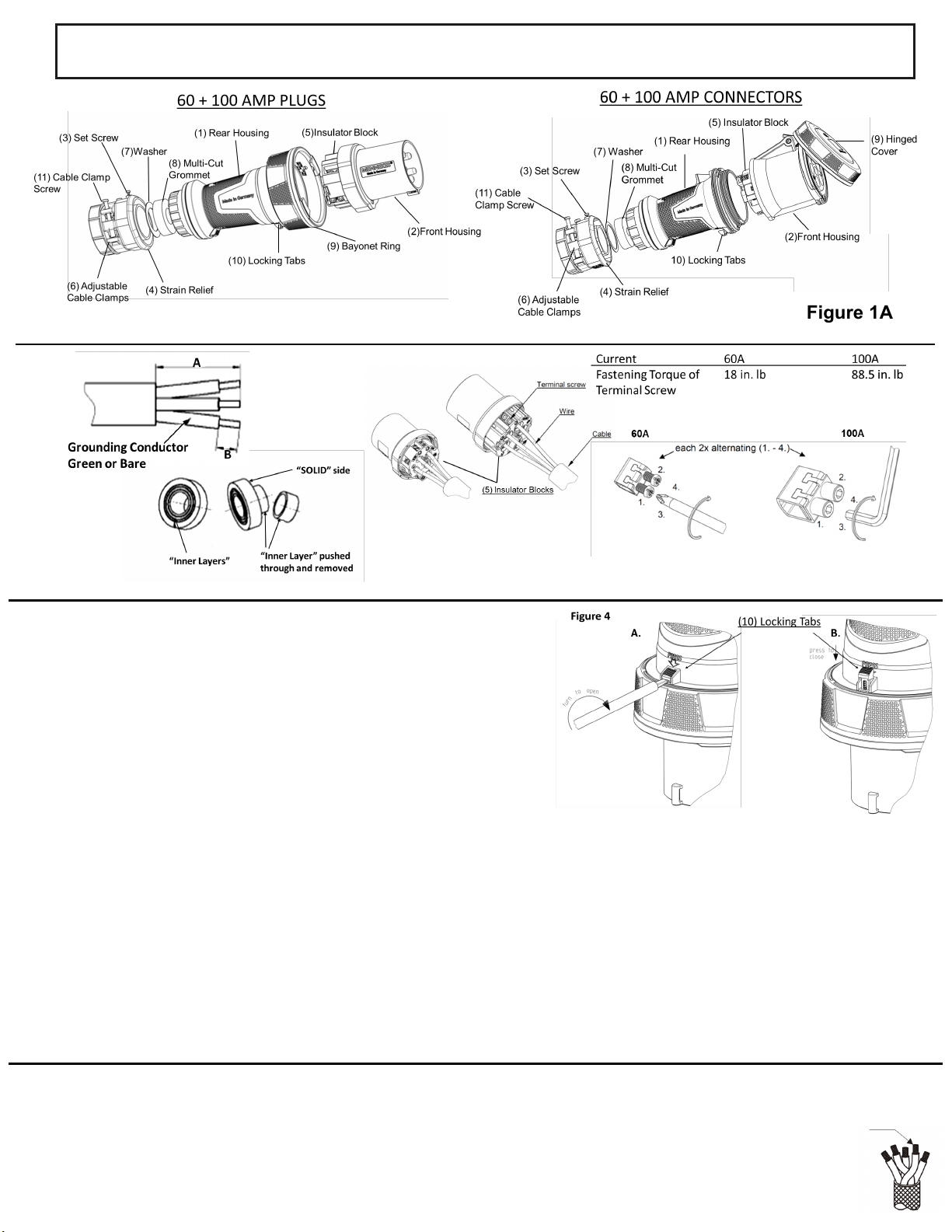

Figure 1 Figure 1A

Figure 2

For Copper

Figure 3

#5 Allen Head screw

Conductors ONLY!

1. Choose the correct end of the cable for plug or connector so that conductor

color coding corresponds to terminal location.

2. Disassemble device as shown in Figure 1A by unscrewing the rear housing (1)

from the front housing (2), loosening set screw (3) and unscrewing strain relief

(4). Do not attempt to disassemble the insulator block from the front housing.

Note – If locking tab (10) is in “Closed’ position, open as shown in Figure 4.

3. Strip the cable jacket and individual conductors per TABLE I. As seen in Figure

2, select cable/conductor of suitable ampacity, service type and temperature.

4. Slide strain relief (4) with adjustable cable clamps (6) and washer (7) over

prepared cable.

5. Remove "inner layers" from multi-cut grommet (8) until it slips over power

cable. Be sure not to remove any more than necessary. Remove one layer at a

time, by pushing through to solid side and tearing off. See Figure 2.

6. Slide cable through threaded opening of rear housing (1).

CAUTION Apply the next steps with care. Otherwise the device terminations and/or the cable grip will not be correct.

Risk of serious/fatal injuries due to electrocution could occur if steps are not completed properly.

7. Insert wires into proper terminals of insulator block according to the established wiring pattern. See TABLE II. Conductors must

bottom in contact terminal well. When stripped according to TABLE I, the uninsulated conductor will remain below the surface of

insulator block (within the metal terminal cavity). Tighten terminal pressure screws to the torque value listed in TABLE I. See Figure 3.

8. Thread rear housing (1) into front housing and align locking tab (10) with receiving piece on front housing (2). Press Close tab (10) as

arrow directs to secure rear and front housing together. See Figure 4A.

9. Slide multi-cut grommet (8) and washer (7) into threaded entry of rear housing (1) Screw strain relief (4) into rear housing (1) and

torque per TABLE I. The torque value is also located on the strain relief (4). Secure set screw in place so strain relief cannot turn.

10. Tighten cable clamp screws (11) around power cable to the torque in TABLE I. Alternate tightening sequence from side to side as

needed to prevent binding.

NOTES:

1. The devices will work with Hard Service, Junior Hard Service and Portable Power cable/cord per NEC 400 5(A)(1) or Canadian

Electrical Code Table 12.

2. The respected cord diameter must be within the range specified in TABLE I.

3. The conductor size of the cord must be within the range specified in TABLE I.

4. The cable opening of the rear housings are NPT threaded. A UL Listed trade

fitting with compatible threading can be utilized in place of the provided external strain relief fitting.

One ungrounded conductor

over grounded conductor

Loading...

Loading...