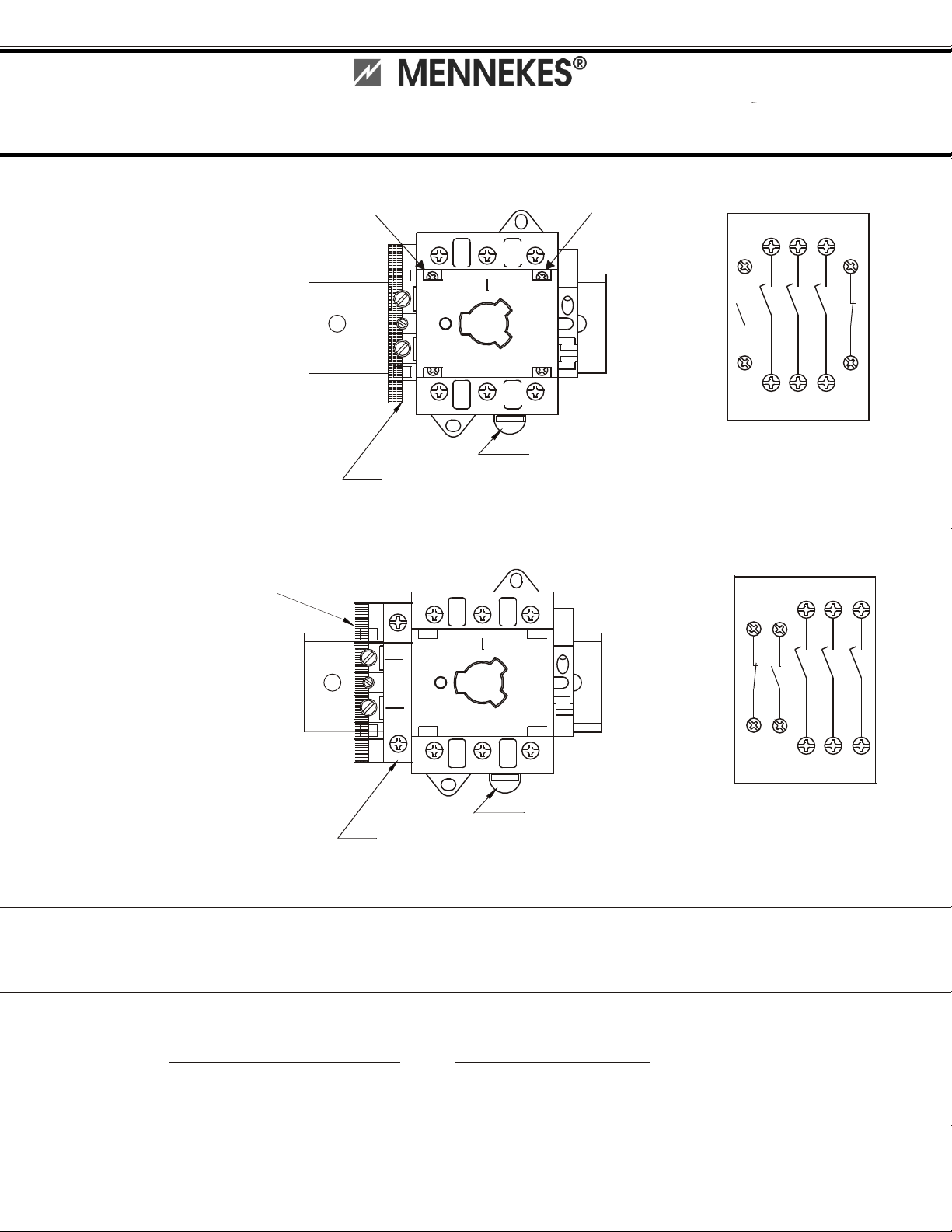

Mennekes Electrical Products HDI DISCONNECT SWITCHES WIRING DIAGRAM

WIRING DIAGRAM

HDI DISCONNECT SWITCHES

FOR: ME 20MS1A-M2

ME 30MS1A-M2

ME 32MS1A-M2

ME 40MS1A-M2

ME 20MS4A-M2

ME 30MS4A-M2

ME 20MS5A-M2

ME 30MS5A-M2

ME 40MS5A-M2

ME 60MS5A-M2

*If needed - pull down with screwdriver in slot. Tilt upward on load side of switch.

EQUIPMENT GROUND

TERMINAL BLOCK (GREEN/YELLOW)

FOR:

ME 80MS2A-M2

ME 100MS2A-M2

Auxiliary Contact

LL11 LL22 LL33

1133

OFF

ON

1144

TT11 TT22

EQUIPMENT GROUND TERMINAL BLOCK (GREEN/YELLOW)

LL11 LL22 LL33

43

31

OFF

32

44

TT33

ON

Auxiliary Contact

2211

2222

RELEASE MECHANISM*

CONTACT ARRANGEMENT

LL11

LL22

LL33

1133

1144

3131

TT11

4343

TT22

LL11

TT33

LL22 LL33

2211

2222

AUXILIARY CONTACTS

Rating: 10A 600Vac

Wiring: 13-14 N/O

21-22 N/C

CONTACT ARRANGEMENT

TT11 TT22

AUXILIARY CONTACT BLOCK

*If needed - pull down with screwdriver in slot. Tilt upward on load side of switch.

Connection and Grounding

See separate conduit connection and grounding instructions.

Use above wiring diagram.

Terminal Specifications

Switch

Ground

Auxiliary

25Amp(& 30Amp 10hp) Torque

#10AWG

#12 to #10AWG

#14AWG

13-16 lbs./in.

20 lbs./in.

4 lbs./in.

30, 40 & 60 Amp Torque

#10 to #6AWG

#10 to #8AWG

#12AWG

TT33

RELEASE MECHANISM*

20-24 lbs./in.

20 lbs./in.

7 lbs./in.

4444

3232

TT22

TT33

TT11

AUXILIARY CONTACTS

Rating: 10A 600Vac

Wiring: 43-44 N/O

31-32 N/C

.

80 & 100 Amp Torque

#6 to #2AWG

#8 to #6AWG

#12AWG

22-27 lbs./in.

20 lbs./in.

7 lbs./in.

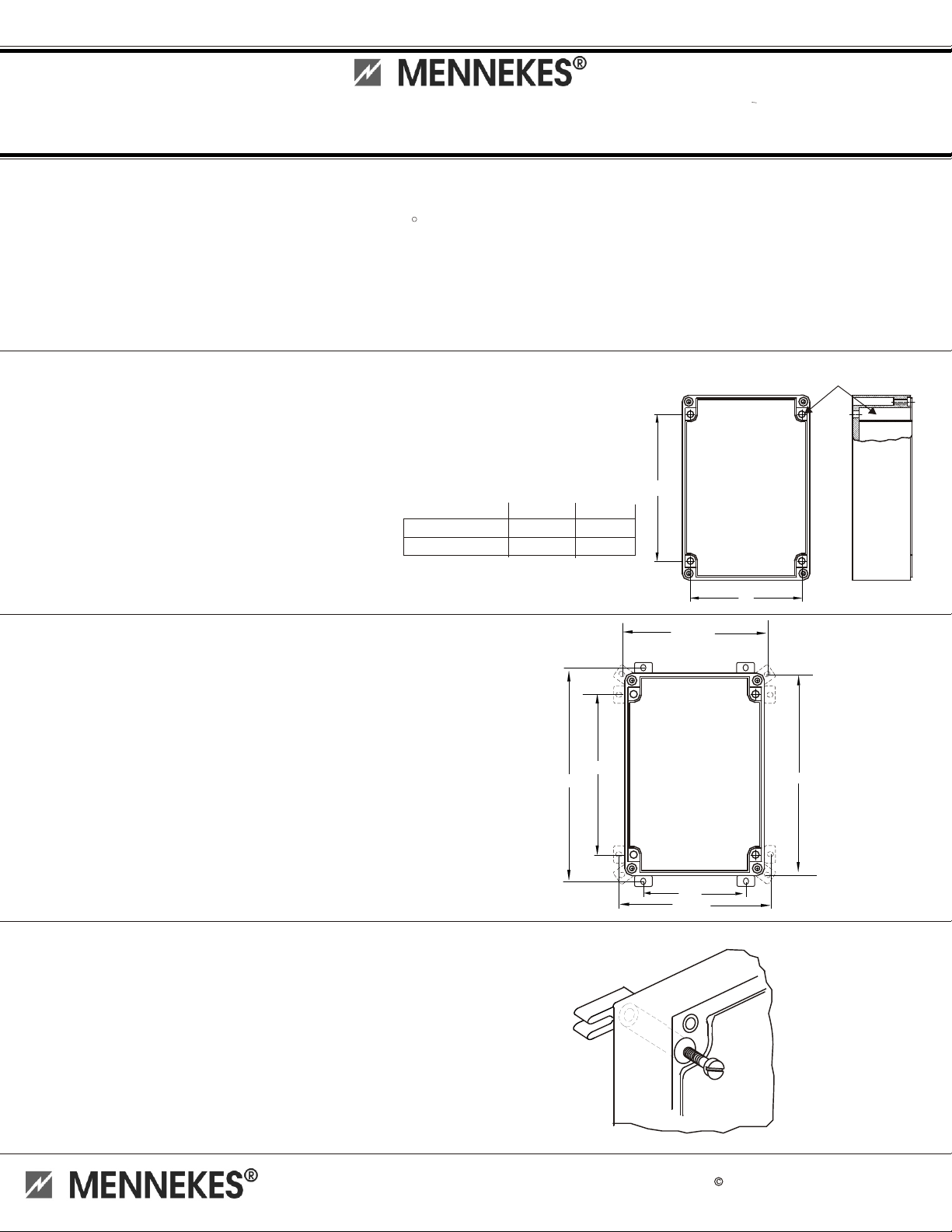

MOUNTING INSTRUCTIONS

HDI DISCONNECT SWITCHES

NOTICE:

1. Turn off power feed to switch before installing or servicing.

2. This unit provides no overcurrent protection.

3. Select conductors in accordance with the 75 C column of

Ampacity Table 310-16 of the National Electrical Code.

To Remove and Replace Front Cover

Fully loosen screws (Do Not Remove) located in four corners of cover. Pull cover away from bottom of enclosure. To replace

cover, reverse above procedure, slight wiggle of cover and switch handle may be needed to position cover. Do not force.

Do not over-torque.

Tighten cover screws to 15 in.lb. for MS1A Enclosure & to 25 in.lb for MS2A Enclosure.

Direct Mount Using Mounting Tubes

For: MS1A/MS4A Enclosures

MS2A/MS5A Enclosures

1. Position Box Upright using ON/OFF as Reference.

2. Drop #10 Screw into each Mounting Tube.

See Fig. 1a Below.

3. Mount Unit on Secure Flat Vertical Surface.

(Hardware not provided)

4. Reinstall Cover.

Mount with External Mounting Feet

For: MS2A/MS5A Enclosures

Order KIT ME MS2A-MF

1. Turn Bottom Box Over to Expose Threaded

Rivets.

2. Screw Mounting Feet into Corner Rivets.

Position Mounting Feet as Required.

See Fig. 2a.

3. Position Box Upright Using ON/OFF as Reference.

4. Mount Unit to Flat Vertical Surface.

(Hardware not provided)

5. Reinstall Cover.

Enclosure A B

MS1A/MS4A 5.26” 4.039”

MS2A/MS5A 8.86” 6.00”

Dimensions +/- 1/32”

MOUNTING DIMENSIONS

Fig. 2a

8.535”

11.654”

Fig. 1a

Fig. 1aFig. 1aFig. 1a

A

DO NOT MOUNT

THROUGH REAR WALL

DO NOT MOUNT

THROUGH REAR WALL

OF BOX

7.016”

TOP

OF BOX

Mounting Tubes

Use #10 Screw

TOP

B

10.736”

Mount with External Mounting Feet

For: MS1A/MS4A Enclosures

Order KIT ME 236MIMF

1. Place Screw (provided in kit) through Mounting Tubes.

See Fig. 3a.

2. Place Mounting Foot Below Hole of Mounting Tube.

Position Horizontally.

3. Tighten Screws 13-17 in. Lb.

4. Position Box Upright using On/Off as Reference.

5. Mount Unit to Flat Vertical Surface.

(Hardware not provided)

6. Reinstall Cover.

277 Fairfield Road

Fairfield, New Jersey 07004

Tel. 973 - 882 - 8333

www.MENNEKES.COM

Fig. 3a

4.815”

7.593”

Copyright 2005 Mennekes Electronics, Inc.

Specifications Subject to Change.

Loading...

Loading...