USER MANUAL

Contents

Chapter 1: Introduction

5

Scope

5

Registration

5

Useful Links

5

Chapter 2: Safety Notications

7

Safety Warning

7

Safety Caution

7

Chapter 3: Warranty

8

Warranty Conditions

8

What is Not Covered Under this Limited Warranty

8

How to Make a Warranty Claim

9

Minor Repairs

9

Major Repairs

9

Chapter 4: Overview and part list

10

This is How Your Me-Mover FIT is Packaged in the Box

10

The Me-Mover FIT Box Contains the Following Pieces

10

An Overview of the Main Parts of the Me-Mover FIT

11

Chapter 5: Technical Terms

12

Chapter 6: How to Use Quick Releases

15

Chapter 7: Assembly

16

Chapter 8: Checklist Before You Get On

27

Chapter 9: Rules to Ride Safely

28

Know and Obey Local Road Laws

28

Wear Safety Gear

29

2

Make Sure You Are Clearly Visible

29

Maximum Load

30

Think About Safety When You Ride

30

Chapter 10: Safeguarding

31

Lock Your Me-Mover FIT

31

Packaging When You Ship Your Me-Mover FIT

31

Chapter 11: Riding Instructions

32

Chapter 12: Maintanance

35

Suggested Tools List

35

About Mechanical Work

35

Incorrect Mechanical Work Can Make Your Me-Mover FIT Unsafe

35

Modications to Your Me-Mover FIT Can Make it Unsafe

36

Neccessary Regular Maintenance

36

Lubrication

36

Every Day, or Before Getting on Your Me-Mover FIT

37

Every Week

37

Lubricating the Locking Bolt

38

Lubricating the Wheel Chain

39

Ever y Year

39

Chapter 13: Repairs and adjustments

41

A Word About Torque Specications

41

Handlebar

42

Handlebar Adjustment

42

Steering

43

Steering Height Adjustment

43

Brake

44

How Does a Brake Disc Work?

44

Parking Brake

44

Brake Check

44

Brake Adjustment

45

3

Brake Handle Angle

46

Brake Cable Specications and Replacement

47

Instructions to Replace the Brake Cable

48

Changing Which Brake Handles Operate the Front and Rear Brake

52

Centre Block

54

Locking bolt

54

Centre Block Screw

55

Carving Fastener

56

Wheels, Tyres and Tubes

57

Tyre Pressure

57

Inspection of Wheels

57

Flat Tyres

57

Use the Correct Size

57

Replacing a Tube

58

Replacing a Tyre

59

Transmission Screws

60

Pedal Arms and Pedals

61

Pedal Arms (Rodbase Screws)

61

Pedal Straps

61

Pedal Axle

62

Anti-Slip Stickers

62

Chapter 14: Accessories

63

Front Rack

63

Reectors / Lights

64

Adapter for Rear Light

64

Straps

66

Cushions for Foot Strap

67

Chapter 15: Troubleshooting

68

4

Introduction

1

Scope

This user manual is an extremely important document for getting the most

out of your Me-Mover FIT. It contains important safety, performance and main-

tenance information. Please read through this user manual before using your

Me-Mover FIT for the rst time. This is an online manual and in case of updates

keep it handy.

This manual explains how to perform basic maintenance and repair work. Some

tasks should only be done by a Me-Mover FIT selected repair shop, and this

manual identies them.

Parents must explain important information to their child, especially regarding

safety issues such as the use of brakes and safety gear.

Registration

When you rst purchase your Me-Mover FIT you must register it online.

Each Me-Mover FIT has a serial number. By registering your Me-Mover FIT serial

number it will allow us to identify exactly which Me-Mover FIT belongs to you in

case of theft. It will also help in making warranty claims. Register here

https://me-mover.com/me-mover-t-registration/

We have a forum on our website specially created for you to engage in our

active community. You can share your thoughts and ideas, ask questions and

talk to fellow Me-Movers:

www.me-mover.com/forums.

Useful Links

If you have any troubles with your Me-Mover FIT, if you nd some parts

particularly cumbersome, or you face frequent problems we encourage you to

get in contact with us. We want to hear from you.

If you cannot nd an answer in the User Manual, please ask us on our

online forum at:

1 Introduction

5Chapter

www.me-mover.com/forums/forum/technical-support-discussion.

We recommend you to check our Youtube channel for Instruction videos at

http://bit.ly/1voMnNQ.

If you have any further questions or doubts contact us and we will get back to

you as soon as possible:

support@me-mover.com

Thank you for purchasing a Me-Mover FIT. We hope you enjoy the ride!

We are looking forward to talking to you!

1 Introduction

6Chapter

Safety Notications

2

To highlight some of the most important safety concerns, this User Manual

contains safety warnings. These warnings are featured throughout this guide.

Safety Warning

The following symbol: WARNING!

Calls attention to a potential hazard that, if not properly addressed or avoided,

could cause serious injury or death.

Safety Caution

The following symbol: CAUTION!

Calls attention to a potential hazard that, if not properly addressed or avoided,

could cause property damage to your Me-Mover FIT and/or void your warranty.

The Me-Mover FIT is not a toy.

Children must only ride the Me-Mover FIT with adult supervision.

When riding the Me-Mover FIT you must always hold on with both hands.

Do not attempt to ride with one hand.

Do not ride on roads or in trac unless you have ensured it is legal to do so

in the area in which you are located.

Me-Mover is not liable for any legal infringements. It is up to the individual

rider to stay up to date with the laws in their respective area.

Do not ride the Me-Mover FIT before going through the Checklist Before

You Get On on page 27.

2 Safety notications

7Chapter

Warranty

3

Warranty Conditions

Every Me-Mover FIT has a limited two-year warranty on the frame and

main parts: rear frame, front fork, steering column, transmission, pedal

arms, and pedals. This warranty, however, excludes wear and tear parts.

This warranty applies only to original owners and is not transferrable. This

warranty expires two years from the date of delivery and is conditioned on the

Me-Mover FIT being operated under normal conditions and use and with

proper maintenance.

What is Not Covered Under this Limited Warranty

Your Me-Mover FIT has been designed for general transportation and recre-

ational use, but has not been designed to withstand abuse associated with

stunting and jumping. This warranty ceases when you rent, sell or give away the

Me-Mover FIT, or ride with more than one person. This warranty does not cover

ordinary wear and tear or anything you break accidentally or deliberately. This

warranty does not apply to malfunctions or failures that result from abuse,

neglect, improper assembly, improper maintenance, alteration, collision, crash,

accident or misuse. Nor does the warranty apply if the original owner uses the

Me-Mover FIT in other than its intended and customary manner.

This warranty does not apply to paint, nish and component parts such as

brake grips, brake cables, brakes (caliper, pads, and brake disc) brake handles,

tyres, chains, anti-slip stickers, plastic covers, and mud guards.

It is the responsibility of the individual consumer purchaser to assure that all

parts included in the shipment box are adjusted properly and fully functional,

and subsequent normal maintenance services and adjustments necessary are

done to keep the Me-Mover FIT in good operating condition.

3 Warranty

8Chapter

How to Make a Warranty Claim

The contact person for the warranty claims is the dealer from whom the

Me-Mover FIT was purchased. If purchased in the web-shop you must contact

Me-Mover directly at support@me-mover.com. If a fault or defect covered

by the warranty occurs in a Me-Mover FIT within the warranty period, please

contact either your respective dealer or Me-Mover to arrange the next steps for

you.

Minor Repairs

Customers can use this User Manual as an instruction guide for minor repair

work. To get a list of repairs that you can do at home, please nd the relevant

section in the Contents on page 2. If there is something you cannot x,

please get in contact with either Me-Mover at support@me-mover.com or your

deale r.

Major Repairs

In the case of major breakage or damage to the frame or main parts, you must

contact us at support@me-mover.com or your local dealer for further

instruction and direction. We will handle each repair individually.

CAUTION!

Any unapproved modication to the Me-Mover FIT can make it unsafe

to use and voids your warranty. A component that is not approved or

assembly that is not correct can put high stress on your Me-Mover

FIT or components. A frame, fork, or component with modications could

decrease your control and cause you tu fall. Do not sand, drill, le, remove

secondary retention devices, install incompatible forks, or make other

modications. Before you add an accessory to your Me-Mover FIT or change a

part of your Me-Mover FIT, consult your dealer to conrm that it is compatible

and safe.

3 Warranty

9Chapter

Overview and Part List

4

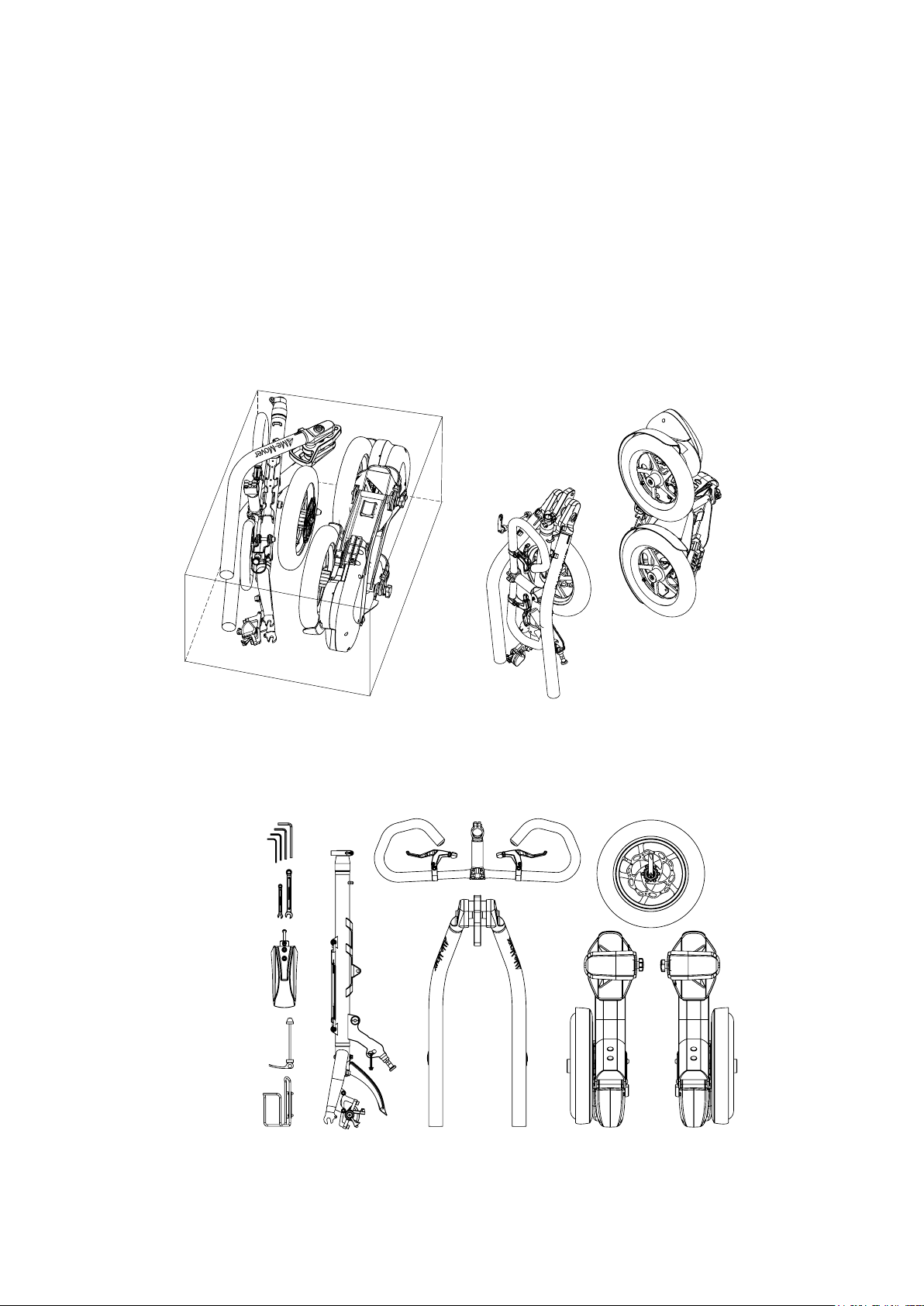

This is How Your Me-Mover FIT is Packaged in the Box

There are two boxes inside: one with the transmission and the other with all

remaining parts.

Rear part

Front part

The Me-Mover FIT Box Contains the Following Pieces and

Sub-Assemblies:

Too ls:

3 mm hex key

4 mm hex key

5 mm hex key

6 mm hex key

10mm open-end

wrench

7 mm open-end

wrench

Mudguard

Front wheel

quick release

Water bottle

holder

Steering column

Handlebar

Rear frame

Front wheel

Transmissions with wheels

4 Overview and Part List

10Chapter

An overview of the main parts of the Me-Mover FIT

Brake cables

Brake handles

Inner steerer

Steering

column

Fixtures for

accessories

Handlebar

Handlebar stem

Bottle

holder

Fixture

Centre block

screw

Steering column quick

2

release

Transmissions

Front fork

Front wheel

Locking bolt

Safet y pin

Front wheel quick release

Front brake disc

4 Overview and Part List

Pedal

Foot strap screw

1

Foot strap

Rear brake disc

Rear wheel

11Chapter

Technical Terms

5

Adjustment screw

Lock nut

Brake cable housing This is the black plastic casing that

Brake cable The inner wire inside the brake cable

Brake caliper This is a part of the brake system. The

Brake disc This is the silver disc on the front wheel

This, together with the lock nut, allows

you to adjust the tightness of the brakes.

This, together with the adjustment screw,

allows you to adjust the tightness of the

brakes. The lock nut “locks” the tension of

the brake cable in place.

protects your brake cable (inner wire).

housing.

caliper is the black attachment on the

brake disc. It houses the brake pads.

and the rear left wheel. The brake pads

grip on to the brake disc to increase

friction and slow down your Me-Mover

FIT.

Brake handle

Parking brake

Brake pads They are two little pads located inside

5 Tech nical Terms

These are the handles located on the

handlebar. They are what control the

front and rear brakes.

It is located by the brake handle.

the brake caliper. When the brake handle

is pulled, the brake pads grip on to the

brake disc to increase friction in order to

slow down your Me-Mover FIT.

12Chapter

Brake washer This is the washer that holds the brake

cable in place on the brake caliper arm.

It has unique “hooks” keeping the brake

cable from moving around.

Carving fastener The carving fasteners connect the in-

dividual tubes of the rear frame to the

centre block. With these the Me-Mover

FIT can make its unique carving motion.

See page 56

Centre block This is the area where the rear frame and

the steering column come together. It is

also the folding point of the Me-Mover

FIT. See page 54

Centre block screw This is the screw located on the centre

block and connects the steering column

to the centre block. See page 55

End anchor This is the metal cap at the end of the

inner wire. It secures the brake cable in

the brake handle. See page 45

Hex key Also known as allen key. It is the tool with

a hexagonal cross-section. This is one of

the tools required to assemble and

maintain your Me-Mover FIT. See page

35

Locking bolt This is the black knob underneath the

centre block. It is a part of the folding

mechanism and must click into place

when unfolding. See page 54

Open-end wrench This is one of the tools required to as-

semble and maintain your Me-Mover FIT.

See page 35

Quick release This is a two-part locking system

consisting of a clamp and a nut. The

Me-Mover FIT has two quick releases.

5 Tech nical Terms

See page 15

13Chapter

Rodbase screw These screws are located in the pedal

arms, protected by rubber plugs.

See page 61

Torque This is a measure of the tightness of

a screw or bolt. For every screw you

can fasten there is a torque specica-

tion. These specications are listed in

Maintenance on page 35.

Transmission This is the “brain” of the Me-

Mover FIT. It is located beside the

rear wheels. This should not be ad-

justed or repaired by customers as it

is a complex

mechanism. However the chains

must be lubricated on a regular basis.

Please consult us or your dealer

when facing troubles with the

transmission.

Transmission screws These screws connect the trans-

mission to the individual rear frame

‘tubes’. See page 60

5 Tech nical Terms

14Chapter

How to Use Quick Releases

6

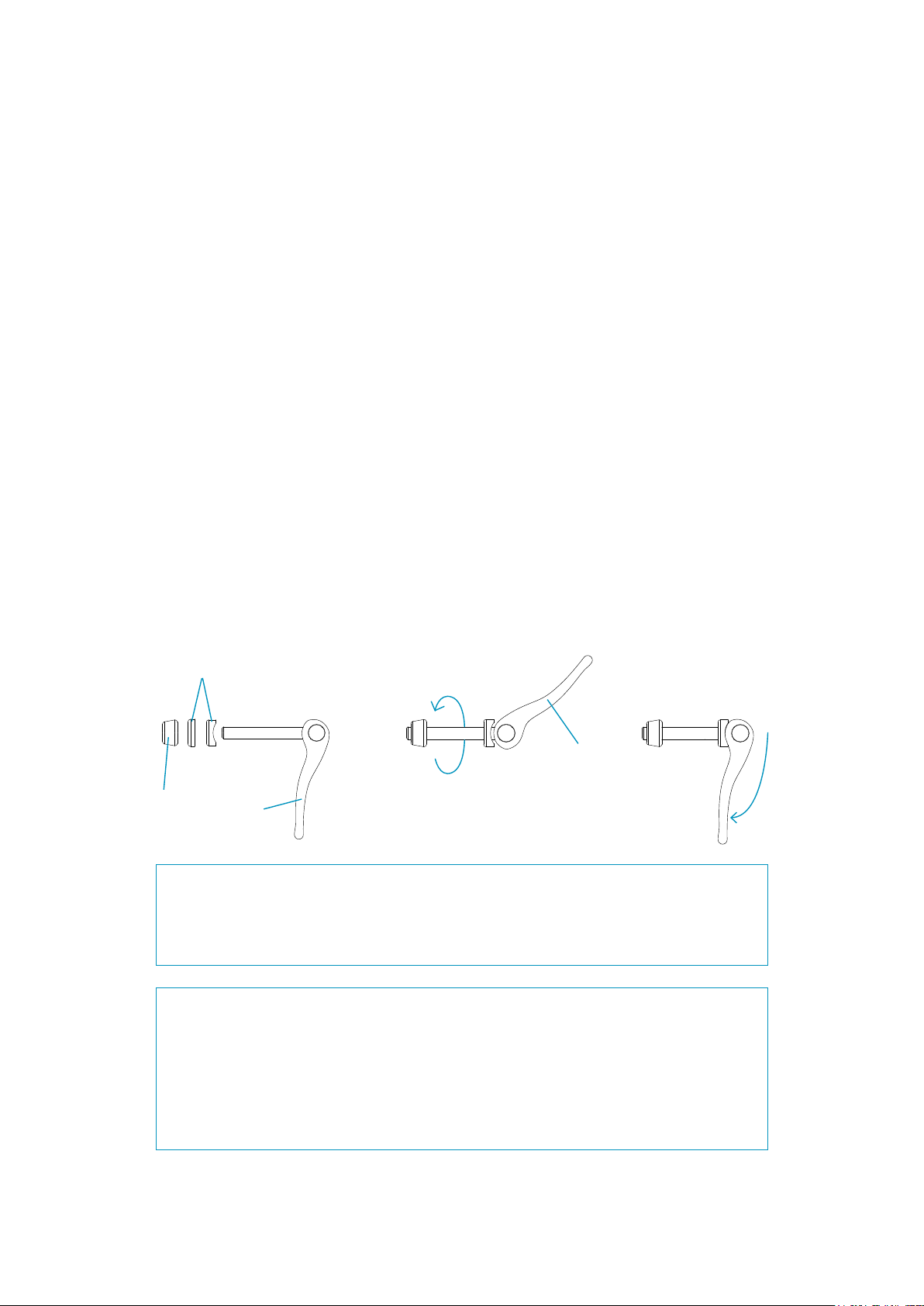

The Me-Mover FIT has two quick releases. It is extremely important that

these quick releases are tightened securely before you use your Me-Mover

FIT.

Front wheel quick release

Steering column quick release

column. It can be adjusted to suit a child or an adult.

To ensure the tightness of a quick release you need to:

1. Hold the clamp OPEN while you rotate the nut in a clockwise direction.

2. Rotate the nut until you cannot close the clamp anymore. Then release the

nut slightly so you can JUST close the clamp.

3. To close the clamp push it rmly inwards.

1

: used to secure the front wheel to the front fork.

2

: used to adjust the height of the steering

OPEN position

washers

hold the clamp

nut

clamp

WARNING!

To close the clamp you must use a fair amount of force, otherwise it may be

too loose.

CAUTION!

Always ensure that the quick releases are securely tightened. If they come

loose you must re-adjust the quick release to make it tighter. Never drive

rotate the nut clockwise

CLOSED position

the Me-Mover FIT without having tested that your quick releases are

correctly mounted and secured.

6 How to Use Ouick Releases

15Chapter

Assembly

7

TO ASSEMBLE YOUR ME-MOVER FIT, FOLLOW THESE STEPS OR WATCH OUR

ASSEMBLY VIDEO.

1. Place the cardboard box on the oor and use this as an underlay during

assembly. Keep the box for future shipping/transportation.

2. Open the steering column quick release and pull out the inner steerer

from the steering column. Pull the inner steerer out by 10cm. Tighten the quick

release clamp again so the inner steerer does not slide back down. Pull out the

end plug.

End plug

10 cm

Steering column

quick release OPEN

NOTE: Lubricate the inner steerer with oil or grease.

3. Mount the handlebar stem on the inner steerer and tighten the two screws

using a 4mm hex key. Re-insert the end plug.

Handlebar stem

Inner steerer

Steering column

quick release CLOSED

End plug

7 Assembly

Inner steerer

16Chapter

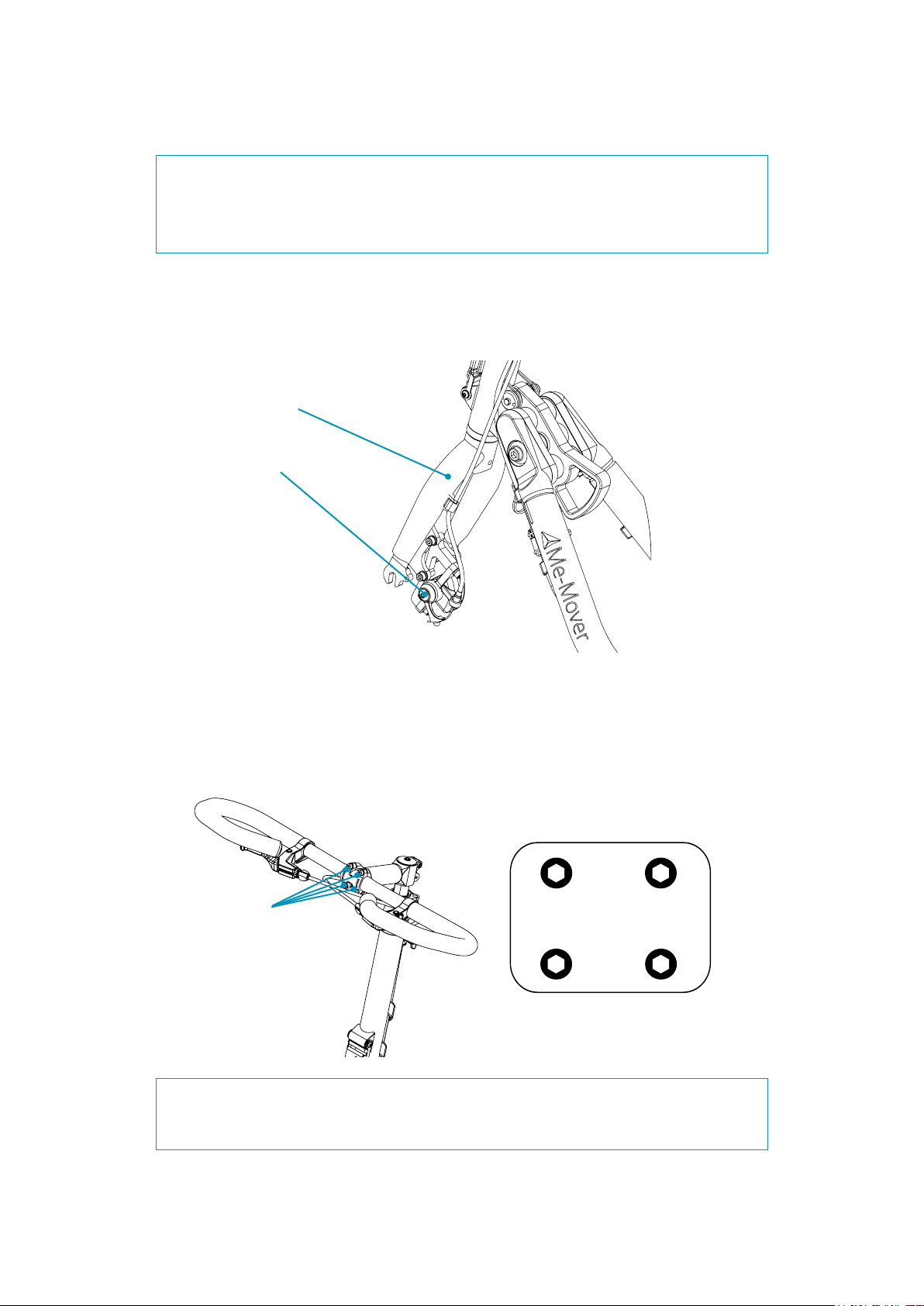

WARNING!

Do not tighten the screws with more than 5Nm. 5Nm corresponds to a 20cm

wrench with a force of 2,5 kg.

NOTE: Ensure the front fork is pointing in the right direction. The front fork

needs to be bending slightly forward. The brake caliper has to be on the left

side.

Front fork

Brake caliper

4. Loosen all four screws on the handlebar with a 4mm hex key and adjust

the angle of the handlebar to your liking. After alignment, screw all four screws

in halfway. Then use this tightening sequence to tighten them in place:

Screws to

loosen / fasten

1

4

Cross-fastening sequence

3

2

WARNING!

Do not tighten the screws with more than 5Nm.

17Chapter 7 Assembly

5. Connect the brake cables to the brake handles. Pull the brake handle and

insert the end anchor into the slot in the brake handle.

Brake

handle

Slot

End anchor

Brake

cable

End anchor in the slot

6. Align the lock nut and adjustment screw and slide the cable into the

groove. If necessary, pull the brake cable housing so more cable is exposed.

Screw the lock nut and adjustment screw tight.

NOTE: Please take note of which cable operates the front and the rear brake

when doing this step. There may be local laws regulating how your brakes need

to function.

Adjustment

screw

Lock nut

Groove

7 Assembly

18Chapter

7. Mount the front wheel to the front fork. Ensure that the front fork is

pointing forward. Slide the front wheel into the front fork so that the brake disc

is placed between the brake pads in the caliper.

Front wheel

Brake caliper

Brake disc

8. Fasten the front wheel to the front fork using the front wheel quick

release. Hold the clamp OPEN while you rotate the nut in a clockwise direction.

Rotate the nut until you cannot close the clamp anymore. At this point release

the nut slightly so you can JUST close the clamp.

Hold the clamp in

OPEN position

Rotate the nut in

clockwise direction

WARNING!

Always ensure that the front wheel quick release is fastened securely.For

detailed instructions see How to Use Quick Releases on page 15.

7 Assembly

19Chapter

9. Remove the safety pin and unscrew the steering column screw using a

6mm hex key.

Steering

column screw

Safet y pin

10. Connect the steering column to the rear frame. Press the frame in

between the anges at the steering column at a slightly downward angle.

Then adjust until the two holes are aligned.

Steering column

Rear frame

Align the holes

7 Assembly

20Chapter

Steering column and rear frame in

aligned position

11. Screw in the steering column screw using a 6mm hex key and then

re-insert the safety pin.

Steering column screw

Safet y pin

7 Assembly

21Chapter

12. Mount the right transmission and wheel onto the right rear frame tube.

Lift the pedal arm and slide the transmission onto the tube. Align the small

bracket “A” with the slot “A” in the frame tube. Press the transmission in until the

end of rear tube is aligned with the end of the transmission.

NOTE: The right transmission does not have the brake caliper.

Right transmission

and wheel

Right rear frame tube

A

WARNING!

Slide the transmission in slowly and gently. The slot in the rear frame tube

could break if too much force is used.

7 Assembly

22Chapter

Transmission screws

13. Do the same for the left transmission.

NOTE: The left wheel has the brake caliper.

14. Attach the two brake cables at the cable splitter. Screw the splitter

together using your hands. Rotate one in a clockwise and the other in a

counterclockwise direction simultaneously.

Brake splitter

7 Assembly

23Chapter

15. Attach the brake cable to the brake caliper. Flip the Me-Mover FIT over and

let it rest on the handlebar. Loosen the screw using a 5mm hex key.

Screw to loosen

Pull the cable through the cable adjustment screw and underneath the small

bracket. Then pull the brake caliper arm until the wheel is blocked. Then,

release it until the wheel is JUST able to rotate. Then tighten the screw.

Cable adjustment screw

Brake cable

Brake caliper

arm

7 Assembly

24Chapter

If the brake disc still touches the brake pads, loosen the two screws holding the

entire brake in place and slightly adjust its position so the brake disc is

positioned exactly between the two brake pads. Same procedure for the front

brake if it needs adjustment.

Screws

Tyre

16. Mount the mudguard. Place the washers between the mudguard and the

front fork as shown. Use a 10mm open-end wrench to hold the nut in place

while you rotate the screw with a 5mm hex key.

Front fork

Washer

Nut

Washer

Mudguard

Screw

7 Assembly

25Chapter

17. Brakes check: Please test the brakes are functioning properly.

Conduct a security test before riding. Test both the front and the rear brakes

before getting on your Me-Mover FIT. Walk alongside your Me-Mover FIT and try

to brake with each brake individually. You should be able to stop the Me-Mover

FIT when in motion with each brake. The rear brake will bring you to a gradual

halt.

WARNING!

The front brake will bring you to a sudden halt, so please use it cautiously. In

wet or slippery conditions, and when carving around corners, please be very

cautious with the front brake.

WARNING!

Do not use the Me-Mover FIT if the brakes do not work properly. If they are

not working properly, please refer to the User Manual for instructions on how

to adjust the brakes.

18. Mount the bottle holder. Align the bottle holder with the xtures and screw

them in using a 4mm hex key.

Screws

26Chapter

Checklist Before You Get On

8

You should run through this checklist every time you are about to use your

Me-Mover FIT:

1. Ensure the locking bolt has clicked in place, when unfolding, see page 54

2. Ensure all Quick Releases are fastened tightly, see page 15

3. Ensure both the front and rear brakes function properly and they are not

being overstretched, see page 44

4. Ensure the parking brake is not engaged, see page 44

5. Ensure the centre block screw is securely tightened, see page 55

6. Ensure the tyre pressure is sucient, and check for wear and/or damage

to tyres, see page 57

7. Ensure both carving fasteners are securely tightened, see page 56

8. Ensure transmission screws are secure. Stand on the pedals, lift them and

lean side to side. If the rear wheels do not move in the direction you are

leaning the transmission is not secure enough, see page 60

9. Ensure each of the wheels run freely. Tilt the Me-Mover FIT to one side, life

the pedal arm and let it drop. The wheels should rotate with no scratching

sounds, see page 57

10. Ensure the carry straps are secured in place, see page 66

3, 4

2

5

10

6

10

6, 9

2

8 Checklist Before You Get On

7

1

8

27Chapter

Rules to Ride Safely

9

Know and Obey Local Road Laws

Most state and local areas have specic road laws. Obey these laws. The

necessary items such as lights and reectors change between areas. To learn

what is necessary, consult your local council or the Department of

Transportation (or the equivalent). It is the responsibility of the rider to remain

up-to-date with road laws. Me-Mover is not liable for infringements while riding

a Me-Mover FIT.

RESPECT

TRAFFIC LAW

These are examples of some important trac rules. Please note that these are

only a small number of rules - you must familiarise yourself fully with your local

road laws.

• When riding the Me-Mover FIT always hold on with both hands. Do not at-

tempt to ride with one hand.

• Mount a horn or bell on your Me-Mover FIT to tell people you are near

• Ride one at a time (single le) when you ride with other road users

• Ride on the correct side of the road; Do not ride in the opposite direction of

trac

• Ride defensively: be prepared for all situations

• Take care when riding over road curbs and/or uneven or badly maintained

roads.

• Use correct hand signals. Be careful when doing so, so you do not loose

balance.

9 Rules to Ride Safely

28Chapter

Wear Safety Gear

Wear a helmet that complies with your country’s legal safety standards. A

helmet can decrease or prevent injury.

It is advised that you also wear protective gear such as knee pads and elbow

pads.

Make Sure You Are Clearly Visible

You must ensure your Me-Mover FIT has a full set of reectors and lights that

are leaglly appropriate according to your country’s road laws. Make sure the

reectors are clean and in the correct position, and that your clothing or acces-

sories do not obstruct them.

Wear bright, and reective clothing to make it easier for others to spot you,

especially at night. If you ride at dusk, at night, or in low-visibility conditions,

consult your dealer to nd equipment or materials that help your vision and

that meet local requirements.

9 Rules to Ride Safely

29Chapter

Maximum Load

The Me-Mover FIT is suitable for both children and adults, however there are

weight restrictions. The pedal arms are pressed down by your body weight, thus

a certain amount of weight is needed. Anyone weighing less than 30kg could

have problems with applying enough force to lower the pedals, and could make

riding a challenge

The maximum load of a Me-Mover FIT is 100kg / 220lbs. Persons heavier than

100kg will risk damaging the Me-Mover FIT by bending the rear frame.

.

100 kg / 220 lbs

Think About Safety When You Ride

You can prevent many accidents if you use common sense and think about

safety. Here are some examples:

• Check your Me-Mover FIT before every ride

• Do not ride ‘no hands’ or with one hand

• Do not ride with a loose object or pet (or its leash) attached to the

handlebar or other part of your Me-Mover FIT

• Do not ride while intoxicated or while you use medication that can make you

drowsy

• Do not ‘ride double.’ The Me-Mover FIT is designed for only one rider

• Do not ride above your skill level

• Do not ride abusively

• Ride carefully when o-road. Ride only on the trails. Do not ride over rocks,

branches, or depressions. When you approach a descent use your rear

brake to decrease your speed

• Do not ride too fast. Higher speed causes higher risk. Higher speed results

in higher forces if a crash occurs. The Me-Mover FIT can reach speeds as

fast as 40 km/h, however only do this if you are an advanced rider. Children

should not ride fast and never without adult supervision

9 Rules to Ride Safely

30Chapter

Safeguarding

10

Lock your Me-Mover FIT

Safeguarding your Me-Mover FIT is essential in everyday use. Therefore always

use a secure, tough lock. Use a lock that resists bolt cutters and saws. Do not

park your Me-Mover FIT unless it is locked.

Loop the chain through the centreblock and the front wheel, and then secure it

to an immovable object. Engage the parking brake.

Packaging When You Ship Your Me-Mover FIT

If you need to package your Me-Mover FIT for travel, always use a hard case or

carton that will protect your Me-Mover FIT. Attach pads to all the frame and

fork tubes, and use a rigid block to protect the fork tips and maintain structural

support of the fork blades. If the Me-Mover FIT is not packaged correctly it could

be easily damaged in transit.

It is a good idea to save the box your Me-Mover FIT was shipped in for future

use.

10 Safeguarding

31Chapter

Riding Instructions

11

WARNING!

Do not try the Me-Mover FIT in a crowded or high-trac area for the rst time.

WARNING!

Never attempt to ride with one hand, always hold on with both hands.

The Me-Mover FIT oers a totally unique riding feel that requires only minutes

to learn. Follow these simple instructions to start riding your new Me-Mover FIT.

You can also watch our video : bit.ly/1ryQn71

1. Find an area without trac to practice in.

Ensure that it is a at, straight, safe stretch with at surface.

2. Make sure both pedals are in the bottom position.

3. Adjust the foot straps: place one foot fully onto the pedal - not just the ball of

the foot. Gently tighten the foot strap until it ts comfortably around your foot.

Repeat on the other foot.

4. Stand next to your Me-Mover FIT. Ensure the parking brakes are not engaged.

5. Grab the handlebar and hold the brake(s) tight.

Place one foot into the pedals at a time – for stability purposes place your foot

closest to the Me-Mover FIT in the pedal rst.

6. Keep holding the brake(s) tight and lean gently to either side to nd your

balance, and to get the feeling of the unique carving motion the Me-Mover FIT

oers.

11 Riding Instructions

32Chapter

7. Lift one leg to the highest comfortable point .

8. Let go of the brake(s). You will move slightly forward, and at this point you

have to lift your other foot. Only concentrate on lifting your feet. Alternate

lifting them as though you are walking up a ight of stairs. Eventually you will lift

your second foot before the rst foot will reach the bottom of the pedal stroke.

There is no need to forcibly push the pedal downwards, because your body

weight will automatically push the pedal down when the other pedal is being

lifted.

9. The higher the pedal rises, the lower the gear is. The position of the stroke

determines the gear.

10. Enjoy!

light gear

heavy gear

Use this area for

acceleration and

uphill riding

WARNING!

Due to the very compact design and short wheel-base it is possible to do an

unintended ‘wheelie’.

Always lean forwards when riding the Me-Mover FIT. Keep your centre of

gravity between the front wheel and the rear wheels at all times.

11 Riding Instructions

33Chapter

WARNING!

Although you can learn to ride the Me-Mover FIT in minutes, do not ride on

challenging terrain or in trac areas until you are practiced and have

100% control of the Me-Mover FIT. It is your own responsibility to practice

suciently on the Me-Mover FIT before entering crowded areas. Always wear

protective gear, such as a helmet and protective pads. Never ride the

Me-Mover FIT while intoxicated.

11 Riding Instructions

34Chapter

Maintenance

12

It is important to maintain your Me-Mover FIT properly. This will prolong the

lifespan of your Me-Mover FIT, and will also reduce the likelihood of damage or

breakage.

CAUTION!

Special tools are necessary for the assembly and the adjustment of your

Me-Mover FIT.

Suggested Tools List

• Open-end wrench: 10mm, 7mm

• Hex Key: 8, 6, 5, 4, 2 ½mm

About Mechanical Work

Incorrect Mechanical Work Can Make Your Me-Mover FIT Unsafe

The instructions in this User Manual are for the everyday user and are designed

to help you with assembly and minor repair work. There are some very specic

requirements that must be met when handling the Me-Mover FIT. Something as

simple as an under-tightened screw can, over time, cause a part to break and

lead to an accident.

We recommend you have your Me-Mover FIT professionally serviced every year.

12 Maintenance

35Chapter

Modications to Your Me-Mover FIT Can Make it Unsafe

Each and every part of your new Me-Mover FIT has been carefully selected and

approved. The safety of accessory or replacement parts, and especially how

those parts attach and interface with other parts of the Me-Mover FIT, is not

always apparent. For this reason, you should only replace parts with original

equipment or parts that are approved.

If you are not sure what parts are approved, contact us at:

support@me-mover.com.

Necessary Regular Maintenance

This maintenance schedule is based on normal use. If you ride your Me-Mover

FIT more than average, or in rain, snow, or o- road conditions, do maintenance

on your Me-Mover FIT more frequently than the schedule recommends. If a

part malfunctions, check and service it immediately. If a part has wear or dam-

age, replace it before you ride your Me-Mover FIT again.

After initial use your Me-Mover FIT should be checked. As an example, cables

stretch through use, and this can aect the operation of the brakes.

Even if you do not ride your Me-Mover FIT much, have your Me-Mover FIT fully

serviced each year.

Lubrication

Lubricating the Chains and Locking Bolt

Lubricated Locking Bolt and chains are essential for a safe ride. There are three

chains in the transmission. The chain that rotates with the wheel must be lubri-

cated once a week, while the other two need to be lubricated once a year. An

unlubricated chain can cause accidents and injuries.

We highly recommend you use Cross Country FINISH LINE Wet Lubricant. You

can purchase this at most bicycle shops.

12 Maintenance

36Chapter

Every Day, or Before Getting on Your Me-Mover FIT

1. Check the locking bolt has clicked in place

2. Ensure your foot straps are securely tightened to your foot

3. Check and tighten all Quick Releases securely

4. Examine the brake cables for any problems: kinks, rust, broken strands, or a

frayed end

5. Check the brake calipers are clean so both the front and rear brakes

function properly

6. Tilt the Me-Mover FIT to one side, lift the pedal arm and let it fall freely. The

wheel should spin freely. Repeat on the other wheel. If there is resistance or

a scratching sound, clean the brake discs

7. Ensure the tyre pressure is sucient, if not then inate the tyre further

8. Ensure the front and rear lights and reectors are mounted securely and are

not obstructed

9. Clean your Me-Mover FIT by spraying it down with cold water then wiping it

with a damp cloth if needed

NOTE: Be careful about cleaning your Me-Mover FIT with cold water in the

winter

Every Week

• Check tyre pressure is 5 bars, see page 57

• Check that the centre block screw is tightened properly, see page 55

• Check rear wheel screws are tight, see page 57

• Check the carving fasteners are tight, see page 56

• Check the transmission screws are tight, see page 60

• Check rodbase screws are securely tightened, see page 61

• Lubricate the locking bolt, see page 38

• Lubricate the wheel chain, see page 39

12 Maintenance

37Chapter

Lubricating the Locking bolt

The locking bolt must be lubricated every week. As it is positioned on the

underside of the Me-Mover FIT it can be exposed to water, dirt, sand and other

sediments. The mudguard is in place to prevent this, however even a slight

amount of sediment can jam the locking bolt.

To lubricate the locking bolt:

1. Fold the Me-Mover FIT and stand it upright

2. Apply one drop onto the top of the locking bolt and pull the lever back and

forth to spread the lubrication along the locking bolt.

Locking bolt

12 Maintenance

38Chapter

Lubricating the wheel chain:

1. Place your Me-Mover FIT upside down as shown.

2. Drop 3-4 drops into the little hole on the back of the transmission cover and

pump the pedal up and down to rotate the chain on the inside. This ensures

that the lubricant is distributed along the entire chain.

Hole to apply the

lubricant

Every year you must:

• Complete maintanance by a skilled mechanic

• Remove the transmission covers and lubricate all three chains as shown:

12 Maintenance

39Chapter

1. Remove the transmission covers one at a time: unscrew the six screws on

the inner side of the Me-Mover FIT wheels using a 3mm and 4mm hex key.

3mm hex key

4mm hex key

Transmission

cover

2. Apply the lubricant directly onto the chains as you rotate the individual

wheels. Ensure the wheel makes enough rotations so the oil covers the en-

tire chain suciently.

NOTE: The large chain endures the most force while riding, so it is para-

mount that it gets a good amount of lubrication.

Chains to

lubricate

3. Re-mount the transmission covers and screw the six screws using a 4mm

hex key.

4. Repeat on the other transmission.

CAUTION!

Use EXTREME caution when tightening screws as only a very small amount of

torque is necessary and over-tightening is very easy.

12 Maintenance

40Chapter

Repairs and Adjustments

13

This section provides instructions for repairs and adjustment of the parts of the

Me-Mover FIT. The parts are divided into subsections to make it easier for you

to locate the relevant instructions.

Please note that these repairs and adjustments are only minor. If your

Me-Mover FIT has substantial damage or breakage you must contact Me-Mover

at support@me-mover.com and we will arrange the necessary repairs.

Your warranty only covers the main parts, and excludes any wear-and-tear.

It is extremely important that you follow the given instructions precisely, as

every part of the Me-Mover FIT has specic requirements.

A Word about Torque Specications

Torque is a measure of the tightness of a screw or bolt. For every screw or bolt

you can tighten there is a torque specication. These specications are listed in

the relevant sections in the Repairs and Adjustments on page 41.

Some screws on the Me-Mover FIT are very fragile and only require a little

amount of torque. All of the aluminium screws on the handlebar and all

of the screws securing the transmission covers require only a force of 5

Newton Metres. This is not a lot of force and can easily be exceeded if you are

not careful. Always use the correct tools. There are devices that can measure

the amount of Newton metres.

CAUTION!

Make sure you do not apply too much torque, as this can cause damage or

break the part. However, a screw or bolt that is too loose can also lead to

damage and could cause a part to break.

13 Repair and Adjustments

41Chapter

Handlebar

Handlebar Adjustment

The handlebar is important for control and safety while riding the Me-Mover

FIT.

To fasten the handlebar follow these steps:

1. Using a 4mm hex key rotate the four screws in a clockwise direction.

Torque specications: 5 Newton metres

CAUTION!

These aluminium screws are extremely delicate and do not require a lot of

torque. It is easy to over-tighten so do not exceed the torque specications

given above.

NOTE: you can adjust the angle of the brake handles by adjusting the

handlebar. When you have found the desired position secure the handlebar

screws as indicated.

2. Cross-fasten the screws as shown:

1

4

13 Repair and Adjustments

Handlebar screws

3

2

42Chapter

Steering

Steering Height Adjustment

The steering column can be adjusted to suit people of dierent heights. To

adjust the height, you must use the Quick Release on the steering column.

1. Hold the clamp OPEN while you rotate the nut in a clockwise direction.

2. Rotate the nut until you cannot close the clamp anymore. Then release the

nut slightly so you can JUST close the clamp.

Nut

Clamp

3. To close the clamp push it rmly inwards. Align the clamp with the

centreblock, so the clamp does not stick out of the Me-Mover FIT.

4. Test the tightness of the steering column by trying to push down on it. If it

does not move then it has been fastened securely. If you are able to adjust

the height simply by applying force, you must rotate the nut a few more

rotations and then close the clamp.

CAUTION! WARNING!

Do not heighten past the

mark. If the minimum mark on the steering

column is visible you have heightened it too much. This will weaken the

stability of the steering column and will risk injury and/or damage to your

Me-Mover FIT.

CAUTION!

Do not turn the handlebar more than 90˚ in each direction otherwise the

brake cables will become tangled, which can lead to broken brake cables.

13 Repair and Adjustments

43Chapter

Brakes

The brake system allows you to slow down or stop your Me-Mover FIT. The

Me-Mover FIT is equipped with brake discs. The maintenance and operation

of the brake discs is critical for your safety and driving experience. You should

keep your brake discs clean. lease use caution when wiping them.

How Does a Brake Disc Work?

A cable connects the brake disc with the brake handle. Pulling the brake handle

causes the brake pads to apply pressure to a brake disc attached to the wheel,

thus increasing friction and slowing down your Me-Mover FIT.

WARNING!

The brake disc can get very hot during use and could burn skin. Also, the disc

edges can be sharp and could cut skin. Do not touch the brake disc when hot

or when in motion.

Parking Brake

Your Me-Mover FIT is equipped with parking brakes to prevent your Me-Mover

FIT from rolling away when parked. To engage the parking brake push the red

tab outward.

Brake Check

Walk alongside your Me-Mover FIT and try to brake with each brake individually.

You should be able to stop the Me-Mover FIT when in motion with each brake.

Pull the brake handle to make sure the brake moves freely and stops your

Me-Mover FIT. If the brake handle can be pulled to the handlebar, the brake is

too loose. If you cannot pull the brake handle at all then the brake is too tight.

Additionally, make the individual wheels spin to listen for friction between the

brake pads and the brake dics. If you hear a scratching sound causing the wheel

rotation to slow down, please adjust your brakes as they are too tight.

When the brake is not applied, the brake-pads should be 0.25-0.75mm away

from the brake disc. If the pads are too near the brake disc, the brake is not in

alignment or the brake is too tight.

13 Repair and Adjustments

44Chapter

WARNING!

The rear brake will bring you to a gradual halt. The front brake can bring you

to a sudden halt, so please use it cautiously. In wet or slippery conditions, and

when carving around corners, please be very cautious with the front brake.

Do not use the Me-Mover FIT if the brakes do not work properly.

CAUTION!

Do not turn the handlebar more than 90˚ in each direction otherwise the

brake cables will become tangled, which can lead to broken brake cables.

Brake Adjustment

Once you have tested your brakes you will know if they are too loose or too

tight.

To adjust your brakes:

1. Release the lock nut.

2. Unscrew the adjustment screw until the tension of the brake handle feels

good.

3. Tighten the lock nut.

Handlebar

Brake handle

Lock nut

Adjustment screw

NOTE: The adjustment screw determines the tension of the brake handle, and

the lock nut secures the position in place.

If the brake handle still touches the handlebar then you must adjust the brake

cable at the brake caliper.

4. Using a 5mm hex key, release the screw at the end of the brake caliper arm.

5. Hold the end of the brake cable and make the wheel spin. Reposition the

brake caliper arm so that there is no scratching sound.

13 Repair and Adjustments

45Chapter

Brake caliper arm

Screw

Brake cable

6. While still holding on to the end of the brake wire, secure the screw at the

end of the brake caliper arm with the 5mm hex key.

7. Fine-tune the brake handle by repeating steps 1 - 3.

Brake Handle Angle

The handle should be mounted at an angle comfortable for your specic

driving style. To adjust you simply adjust the angle of the handlebar. This is a

very simple process.

To adjust the position of the brake handle:

1. Using a 4mm hex key, loosen the four screws 4-5 turns.

2. Rotate the handlebar to your desired position.

Screws

3. Tighten the screws using the same 4mm hex key.

Torque specications: 5 Newton metres

13 Repair and Adjustments

46Chapter

CAUTION!

These aluminium screws are extremely delicate and do not require a lot of

torque. It is easy to over-tighten so do not exceed the torque specications

given above.

Or you can adjust the angle of the individual brake handles.

1. Unscrew the screw on the bottom of the handle using a 5mm hex key

Screws

2. Find the desired position of the brake handle and tighten the screw.

Torque specications: 5 Newton metres

3. Repeat steps 1 and 2 on the other brake handle.

Brake Cable Specications and Replacement

Your Me-Mover FIT is equipped with premium quality brake cables and stainless

steel wire. It is import for safety and drive experience that the brake cables are

intact and without any damage.

Every few weeks you must examine the brake cables and cable housing for any

problems: kinks, rust, broken strands, or a frayed end. If there is a problem with

a brake cable or brake cable housing, do not ride your Me-Mover FIT.

Brake cable type: Mountain bike or road bike NOT RACER BIKE

MEASUREMENTS

Brake cable: 1,5mm 135 c m 75cm 120 cm

Brake cable

housing:

Anchor type: - MTB Road MTB

Width

5mm 120 cm 60cm 105cm

Front cable

length

Rear cable

rear part length

Rear cable

front part length

You can either buy these separately and cut them to the correct length, or buy a

set. You must ensure that if you buy a set you refer to the specications above.

13 Repair and Adjustments

47Chapter

Instructions to Replace the Brake Cables

1. Prepare your new brake cable and brake cable housing.

If you have bought the brake cable as a set then measure the correct length.

If you have bought the brake cable and the brake cable housing separately,

then measure the correct lengths and feed the brake cable through the

brake cable housing. Have your aluminium protective casing ready (this is

typically included when you purchase brake cables).

Brake cable housing

Brake caliper

Brake caliper arm

Screw

Brake cable

Aluminium protective casing

2. Release the Screw on the arm of the brake caliper using a 5mm hex key.

3. Cut o the end of the brake cable and the aluminium protective casing with

a pair of pliers.

4. Pull the brake cable out of the brake caliper.

Brake cable

Aluminium protective casing

5. Put the cables through the bracket for the bottle holder and the top

bracket on the front column.

13 Repair and Adjustments

48Chapter

Top bracket

Fixture for bottle holder

6. Align the lock nut and adjustment screw so you can see the groove.

Adjustment screw

Lock nut

Groove

7. Pull the brake cable out of the brake handle through the groove.

8. Pull the brake handle and unhook the end anchor.

Brake handle

End anchor

Brake cable

13 Repair and Adjustments

49Chapter

9. Install your new brake cable. At the brake caliper, align the brake cable to

the brake washer. Hold it in place and tighten the screw at the end of the

caliper arm using a 5mm hex key.

FRONT BRAKE

Wire

Brake washer

Screw

REAR BRAKE

Brake caliper behind

the left wheel

Screw

Brake cable

10. Apply the aluminium protective casing to the end of your brake cable to

contain any frayed ends. Secure it in place by pressing on it with pliers.

11. Clip the cable to the clips along the front fork and steering column.

12. Pull the brake handle and insert the end anchor into the brake handle.

13 Repair and Adjustments

50Chapter

End anchor

Brake cable

13. Align the lock nut and adjustment screw so you can re-insert the brake ca-

ble into the groove.

Groove

Lock nut

Adjustment screw

14. Adjust the tightness of the brake as outlined in the Brake Adjustment on

page 45.

WARNING!

Always use caution when handling the brake cable as the end can be frayed

and can cut you very easily.

13 Repair and Adjustments

51Chapter

Changing Which Brake Handles Operate the Front and Rear Brake

Every Me-Mover FIT is assembled the same way. The front brake is controlled by

the left brake handle, and the rear brake is controlled by the right brake handle.

This may dier from what you are used to, in which case you can easily switch

the controls around. Follow these steps:

1. Align the lock nut and adjustment screw so you can see the groove.

Lock nut

Adjustment screw

Groove

2. Pull the brake cable out of the brake handle through the groove.

3. Pull the brake handle and unhook the end anchor inside the brake handle.

You will need to manoeuvre the brake cable to feed the end anchor through

the slot in the brake handle.

Brake handle

Slot

End anchor

Brake cable

4. Repeat the same on the other brake handle.

5. Switch the cables around so the front brake is controlled by the right brake

handle, and the rear brake is controlled by the left brake handle.

6. Pull the brake handle and insert the end anchor through the slot in the

brake handle.

13 Repair and Adjustments

52Chapter

Brake handle

Brake cable

7. Align the lock nut and screw and insert the cable into the groove.

Lock nut

Adjustment screw

Groove

8. If necessary, pull the brake cable housing backwards so more cable wiring

appears.

9. Tighten the lock nut and adjustment screw.

Refer to Brake Adjustment on page 45 to ne tune the brake tightness.

13 Repair and Adjustments

53Chapter

Centre block

Locking Bolt

The locking bolt is the little black lever located underneath the centre block. The

locking bolt is part of the folding mechanism. It is the part that clicks into place

when you unfold your Me-Mover FIT.

WARNING!

If the locking bolt does not operate properly do not ride your Me-Mover FIT

under any circumstances.

It is paramount that this locking bolt is maintained and kept clean. Lubricate it

every week. Refer to Lubricating the Locking bolt on page 38.

If it gets too dirty or if sand gets in it could jam the locking bolt. If you ride on

dirty, muddy, sandy, or dusty terrain, ensure you lubricate the locking bolt. This

will decrease the likelihood of your locking bolt jamming.

Lubricate the locking bolt using the Cross Country FINISH LINE Wet Lubricant

and follow the instructions on page 38 .

If your locking bolt jams, please contact us immediately. It is not easy to repair

and is also very costly to do so. Do not attempt to x it or replace it yourself.

13 Repair and Adjustments

54Chapter

Centre Block Screw

The centre block screw is extremely important for your safety. It is what keeps

your steering column and rear frame connected. It is paramount that this centre

block screw remains tightly secured at all times. If it comes loose the Me-Mover

FIT will come apart and you will most likely sustain an injury.

To maintain the centre block screw tightness you must:

Use a 6mm hex key to rotate the screw in a clockwise direction.

WARNING! CAUTION!

It is paramount that you always ensure the centre block screw is tightened.

Centre

block screw

Centre blok

13 Repair and Adjustments

55Chapter

Carving Fastener

There are two carving fasteners on your Me-Mover FIT. They are located on ei-

ther side of the centre block. The carving fasteners connect the individual tubes

of the rear frame to the centre block. The carving fasteners enable the unique

carving motion of the Me-Mover FIT.

In order to maintain exibility and safety while riding, the carving fasteners must

always be securely tightened. When assembled, the fasteners are locked into

place with an engineering adhesive. However, in very rare circumstances they

could come loose.

If the carving fasteners come loose you must tighten them using a 8mm hex

key in a clockwise direction.

Carving fastener

Carving fastener

13 Repair and Adjustments

56Chapter

Wheels, Tyres and Tubes

The wheels are critical for a safe and smooth ride. Their attachment and

integrity are important for your safety.

Tyre Pressure

Since the Me-Mover FIT has small wheels the tyre pressure is extremely import-

ant for smooth riding feel. If the tyre pressure is too low the rolling resistance is

very high. Ensure the tyre pressure is at 5 bars or 72 PSI.

CAUTION!

The wheels and rims are specically approved for the Me-Mover FIT. Do not

use any non-approved parts as this can cause damage to your Me-Mover FIT

and void your warranty.

Inspection of Wheels

Before every ride, check the wheel attachment and tyre ination.

Each month, check tyres for a worn area or damage. Make sure the wheel (hub)

bearings are correctly adjusted and tight.

The rear wheels are secured with an engineering adhesive, so there is a minor

risk to come loose. In case they do you must tighten them using a 6mm

hex key.

Flat Tyres

If you experience a at tyre it is most likely because the tube has been

punctured. In order to x this you must replace the tube or repair it. To replace

a tyre or a tube on your Me-Mover FIT we advise using a tyre repair kit. You can

purchase these at most bicycle shops. We recommend Zefal Kit May Day.

Use the Correct Size

When purchasing spare tyres, tubes, rim strips, or other replacements, always

ensure you are using the correct size of replacement component.

Me-Mover uses a standard tyre where the air inside the tyre is contained in an

inner tube, and the tyre is on a standard rim. This is a very common type of tyre

and is the easiest to repair.

13 Repair and Adjustments

57Chapter

Please consult the chart below for useful information about the Me-Mover FIT

tyre and tube size.

US size (inches) EU size (mm)

Tyre (min) 12 x 1 ¾ 47-203

Tyre (max) 12 ½ x 2 ¼ 62-203

Tube 12 ½ x 2 ¼ 62-203

Valve 45˚ Auto-Valve 45˚ Auto-Valve

Replacing a Tube

Front wheel

Tyre

Tyre

Push to make

space for the

tyre lever

Rim

Quick release

Rim

If you experience a at tyre on your front wheel follow these steps:

1. Release the Quick Release and slide the wheel out of the front fork.

2. Deate the tyre completely.

3. Push the tyre to the centre of the rim to be able to insert the tyre lever. See

illustration.

4. Starting on the opposite side of the valve, insert a tyre lever between the

tyre and the rim. It might be necessary to use two tyre levers simultaneously.

5. Pull the end of the lever towards yourself so the tyre bead pops out of the

rim. Continue around the wheel to lift the bead out until one bead is

completely free.

6. Slot the tube valve through the hole and pull the entire tube out of the rim.

7. Carefully run your hands along the inside of the tyre to check for any

sediments, nails, glass, or anything that could have penetrated the tyre.

Remove any such objects.

8. If the tube has a small puncture you can patch this up with a tube patch.

Check the instructions of your tyre repair kit. If it did not come in your kit,

13 Repair and Adjustments

58Chapter

then you can easily purchase these patches at most bicycle repair shops.

If the tube is unxable then replace the tube.

9. Before you re-insert the tube, inate it a little so it just keeps its shape. This

will ease the positioning of the tube in the rim and tyre.

10. First slot the valve through the hole. Ensure the valve is pointing outside and

not into the wheel. Then place the rest of the tube back in.

11. Insert the tyre bead back into the rim using your hands. When you can no

longer use your ngers to insert the bead, use the tyre lever.

CAUTION!

Do not twist the tube when you are doing this. Twisting can cause the tube to

rupture.

12. When you have reinserted the tyre you must re-inate the tube. Inate it to

MAX 5 bars (maximum 72 PSI).

CAUTION!

Do not pinch the tube between the rim and the tyre.

13. Re-attach the tyre to the front fork and close the Quick Release. Ensure you

slot the brake disc between the brake pads.

14. Rotate the wheel. If you hear a scratching sound you have to reposition the

wheel. To adjust the brakes refer to Brake Adjustment on page 45.

Rear wheels

If you experience a at tyre on your rear wheels lie your Me-Mover FIT on its side

or place a support under the frame and follow steps 3 - 11 above.

Replacing a Tyre

If your tyre has a big puncture you must replace the tyre.

1. Remove one tyre bead completely. Follow steps 5, 6, 7 in Replacing a Tube on

page 58.

2. Deate the inner tube completely.

3. Remove the second tyre bead from the rim.

4. Replace the tyre - refer to the table above for correct the size.

5. Re-insert one tyre bead into the rim.

6. Follow steps 8 onwards in Replacing a Tube on page 59 .

13 Repair and Adjustments

59Chapter

Transmission Screws

The transmission screws fasten the transmission to the rear frame tubes. These

must be securely tightened at all times. If they come loose the

transmission and wheels could tilt inwards and injure your ankles while riding.

To tighten these screws use a 5mm hex key.

WARNING!

Always ensure these screws are securely tightened otherwise you can risk

severe injury to your ankles.

Transmission screws

13 Repair and Adjustments

Transmission screws

5mm hex key

60Chapter

Pedal Arms and Pedals

The pedals and pedal arms connect to the transmission, making you move

forwards. These parts must be maintained in order to have a proper functioning

Me-Mover FIT.

Pedal Arms (Rodbase Screws)

The rodbase screws are located on the pedal arms. There are two screws on each

pedal arm, which are protected by rubber plugs. Always ensure these screws are

tightened securely. NEVER REMOVE THESE SCREWS COMPLETELY, OTHERWISE

YOUR PEDAL ARM WILL DISCONNECT FROM THE TRANSMISSION.

To secure them tightly you must:

1. Remove the rubber plugs

2. Use a 4mm hex key to rotate the screws in a clockwise direction.

Torque specications: 5 Newton metres

3. Re-insert the rubber plugs

Rubber plugs Screws

Pedal arm

Pedal Straps

The pedal straps secure your foot in place when riding. Because the Me-Mover

FIT requires your foot to do a lifting motion it is important to ensure the pedal

straps are securely tightened.

If the pedal straps continuously come loose please see Pedal Axle on

page 62 .

13 Repair and Adjustments

61Chapter

Pedal Axle

The pedal axle must be suciently tightened so the pedal will not rattle while

riding, or rotate while tightening the foot straps. The pedal axle has a self-locking

screw designed to stay in place and not come loose. In the rare circumstance that

it does come loose you must tighten it again.

To tighten the pedal axle:

1. Unscrew the pedal strap screw entirely.

2. Remove the washer.

3. Tighten the screw: Hold the nut in place using a 10mm open-end wrench

while you rotate the screw in a clockwise direction using a 5mm hex key.

Screw

Nut

Pedal axle

Washer

Foot strap

Foot strap screw

If it still comes loose, contact us at support@me-mover.com.

Anti-Slip Stickers

Your Me-Mover FIT pedals are equipped with anti-slip stickers. This is a safety

precaution so you do not slip around on your pedals while you ride. If these

anti-slip stickers wear o you must purchase new ones. Contact us at:

support@me-mover.com for information.

13 Repair and Adjustments

62Chapter

Accessories

14

There is a possibility to equip your dierent Me-Mover FIT with accessories.

All accessories in the webshop are Me-Mover approved. If you choose to use

accessories not sold on the web shop, Me-Mover is not liable for any damage

caused to or by said accessories.

Front Rack

The Me-Mover FIT has xtures on the steering column. These xtures are used

for mounting your front rack.

To mount your front rack follow these steps:

1. Remove the front strap using a 3mm hex key.

2. Starting on the top xture point, place one washer on either side of the front

rack xture points.

3. Slide the screw through the washers and the steering column.

4. Secure it by holding the screw in place with a 6mm hex key. and rotate the

nut using a 13mm open-end wrench.

5. Repeat on the bottom xture points.

14 Accessories

63Chapter

Reectors / Rear light xture

Reectors and lights are important safety features.

Me-Mover FITs should be equipped with reective stickers and front and back

light, especially if you are riding at night. This helps fellow road-users to locate

you, and will make your ride safer.

It is the responsibility of the individual user to ensure reective stickers and

lights are approved by your local authorities.

Adapter for Rear Light

The light can be mounted on either the left or right side of the transmission.

Depending on your trac regulations you should mount it towards the trac

(so that the light is close to the cars).

1. Using a 4mm hex key remove the screw of the transmission cover shown (the

one in the furthest top corner):

14 Accessories

64Chapter

2. Align the parts as shown on the transmission cover.

3. Tighten the screw with a 4mm hex key.

4. Mount your light.

14 Accessories

65Chapter

Straps

Install straps on transmission

Unscrew the two screw on the inner side of the transmission cover using a

4 mm hex key. Mount the carry strap as shown using a 4 mm hex key, remem-

bering to place the washer rst and use a 7mm wrench for the special screw in

the bottom. Repeat on the other side of the transmission.

washer

screw

4mm hex key

7mm wrench

Install straps in front of the Me-Mover FIT

Insert the pin in the top xture and fasten the 2 screws using a 3mm hex key.

Repeat for the bottom xture.

screws

top xture

3mm hex key

bottom xture

14 Accessories

screws

66Chapter

Cushions for Foot Strap

If you wear shoes with thin fabric on top, cushions for foot strap could proect

your foot when you are driving.

14 Accessories

67Chapter

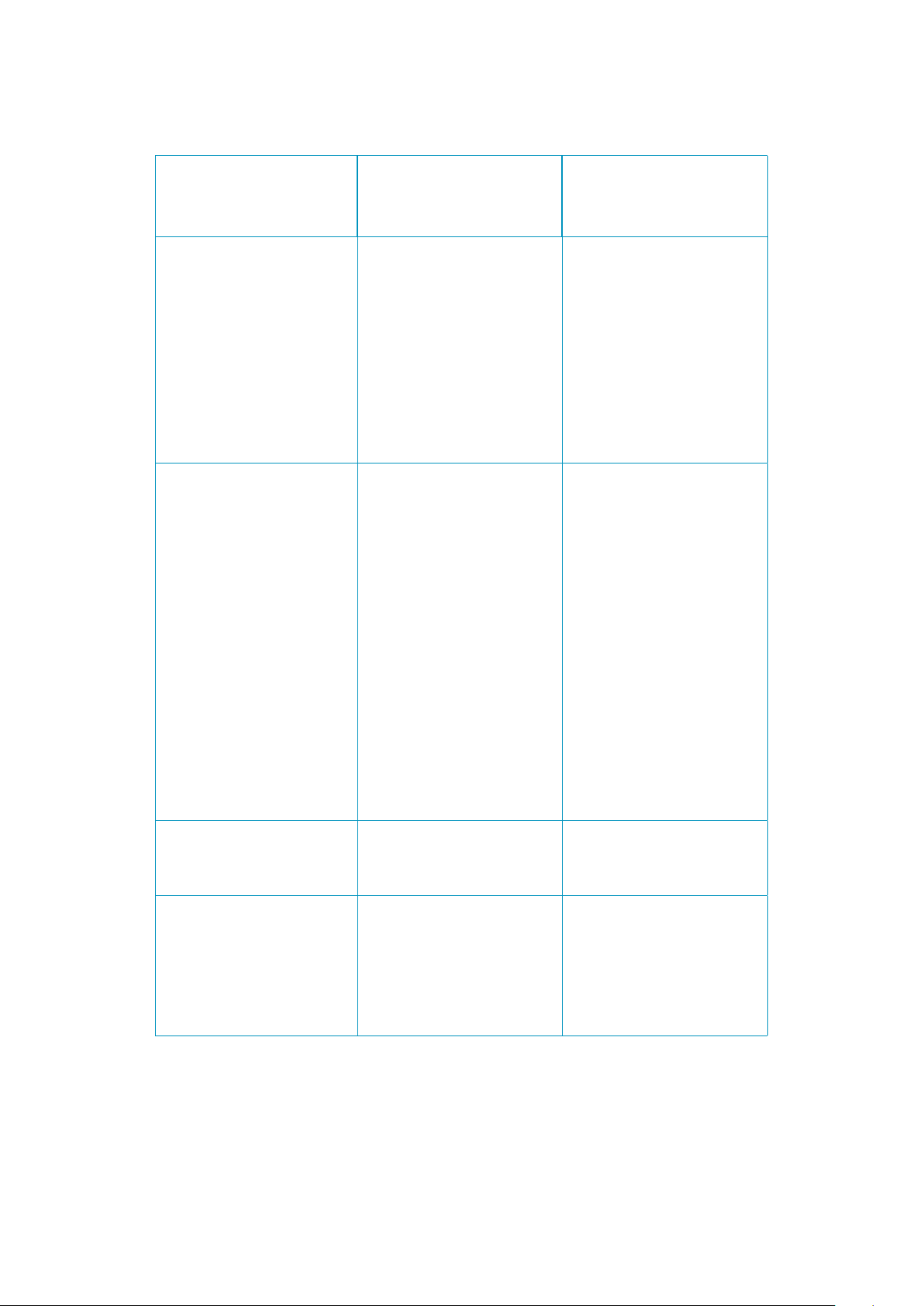

Troubleshooting

PROBLEM POSSIBLE CAUSE SOLUTION

15

The locking bolt does

not click into place

When I brake and come

to a standstil there is a

slight jolt

I can feel the Me-Mover

FIT wiggling while I ride

Jammed locking bolt

Residue stucked inside

the locking bolt

The locking bolt is out of

adjustment

The centre block screw

is loose

The tyre is not mounted

properly

Tyre malfunction

The wheel is out of

aligment

Lubricate the locking

bolt, see page 38

Clean for residue

Contact us or your

dealer

Tighten the centre block

screw according to Cen-

tre Block Screw on page

55

Check that the tyres are

aligned with the rims

Change the tyre if it is

damaged

Contact your dealer or

us to get a new wheel

There is something

wrong with the bearing

Insucient tyre

pressure

The wheels are loose Front wheel

Rear wheels

15 Troubleshooting

Contact us or your local

dealer to get new bearing mounted

Check the Tyre Pressure

on page 57

Tighten the front wheel

quick release

Check that the centre

block screw is properly

tightened

68Chapter

PROBLEM POSSIBLE CAUSE SOLUTION

The brakes are not

functioning adequately

I cannot rotate the

steering column /

handlebar

The brake handle does

not return to original

position after being

pulled

The brakes are too loose

Adjust the brakes, see

Brake Adjustment on

page 45

The brake pads are

worn out

Change the brake pads

- contact us or your

dealer

Twisted brake cables Turn the steering

column to untwist the

cables

The brake cables are

tangled so the outer

casing of the brake

cable prevents the free

movement of the inner

cable

Usually due to the

handlebar being rotated

Re-bend the brake cable

housing to get it to work,

otherwise replace it, see

Instructions to Replace

the Brake Cables on

page 48

Twist the handlebar to

untwist the cables

more than 180 degrees

The transmission slants

inwards (towards each

other)

I can hear a sliding

sound

Corrosion of the outer

casing

The transmission screws

are not securely tightened

There is something

stuck between the

wheel and the fender

Something is stuck

between the brake disc

and the brake

Replace the brake

cables, see Instructions

to Replace the Brake

Cables on page 48

Use a 5mm hex key and

untighten the transmis-

sion bolts. Adjust to ver-

tical position and tighten

the bolts again.

Find the obstacle and

remove it

Find the obstacle and

remove it

15 Troubleshooting

69Chapter

PROBLEM POSSIBLE CAUSE SOLUTION

The foot straps are

coming loose

I can hear a squeaking

sound

The wheels are not running freely

My clothes / hands are

getting dirty when

carrying the Me-Mover

FIT

It feels very heavy to

drive

The foot strap screw is

not adequately tightened

The rubber joints need

lubrication

The carving fastener

need lubrication

The brake pads are

touching the disc

Holding dirty frame /

wheel after rain and

mud

Flat tyre

Unmount the foot strap

and tighten the inner

nut, see page 62

Loosen the carving fas-

tener and lubricate the

housing of the rubber

joints.

Contact us or your local

dealer

Adjust the brakes

according to Brake Ad-

justment on page 45

Use a carry bag / carry

strap

Check the Tyre Pressure

on page 57

There is a lag while

riding fast ( When you

are pressing down the

pedals it takes a second

before the mechanism

is engaged)

Unlubricated transmissions

Worn out bearings

The free wheel hob

inside the gearbox is

probably worn down,

so friction inside is

increased. (This means

the return system is not

fast enough to pull back)

The overall friction

inside the axles need

lubrication

Lubricate the tranmis-

sion according to

page 39

Contact us or your local

dealer

The free wheel needs to

be replaced, contact us

or your local dealer

Contact us or your local

dealer

15 Troubleshooting

70Chapter

PROBLEM POSSIBLE CAUSE SOLUTION

When I lift the pedal it

gets a little stuck at the

bottom

The pedal just falls

down, like it is not connected to the gear box

at all

The rodbase screws

have come loose and

the holes become worn.

The rod will become

jammed in the bottom

position

The rubber stoppers

underneath the pedals

fell o

The Me-Mover FIT has

been left outside during

a very cold night.

Grease on the one way

clutch / free wheel is

sti due to cold temperatures

The mounted bracket

for the 42 teeth sprocket has come loose

Contact us or your local

dealer

The rubber stoppers

need to be replaced,

contact us or your local

dealer

It will stop doing it once

inside has been heated

up (by friction,warmth,

etc.)

The screw has to be

tightened to the brack-

et again. Contact us or

your local dealer

There is a tiny play

when you are pedaling

I feel a sensation that

the chain is loose inside

(when going downhill

fast and you are not

pedalling you can hear

the chain rattling)

15 Troubleshooting

The return spring is

broken

The rod bearings are

worn down

The drive chain (the one

running the wheel axle)

has been worn down so

it has become too loose

The return spring has to

be replaced, contact us

or your local dealer

The rod bearings has to

be replaced, contact us

or your local dealer

The chain has to be

changed or tightened,

contact us or your local

dealer

71Chapter

PROBLEM POSSIBLE CAUSE SOLUTION

There is loss of agility

when carving

When braking the front

brake the steering column gives little play

The pedal arm is re-

stricted in dierent

postions

The carving fastener

needs lubrication

After a small crash the

axle can be bent and

cannot move

The steering column

tting has not been

tightened properly and

just comes loose

The screws inside the

transmission under the

pedal arm are coming

too loose and hitting the

pedal arm

Take it apart and clean

the bearings and the

rubbers relubricate both

bearings and the rubber

Give the rubbers some

chain oil

The axle can be straight-

ened again fairly easily.

Contact us or your local

deale r.

The steering column

tting need to be

tightened and

readjusted, contact us

or your local dealer

Contact us or your local

dealer

15 Troubleshooting

72Chapter

Loading...

Loading...