SERVICE MANUAL

INFORMATION FOR USING THE DECK PARTS

(OVD-5)

Parts on the deck of our product are very similar as shown below.

Make sure to use the parts listed by Parts No. in the service manual for

the repair, because the deck or your important tape will be damaged.

S/M CODE NO.: OVD5ASM

DATE OF ISSUE 12/1997

TABLE OF CONTENTS

SPRING, MAIN BRAKE ................................................................................................................................................................

SPRING, TENSION ARM 1 ..........................................................................................................................................................

PINCH ROLLER BLOCK ..............................................................................................................................................................

MODE SWITCH ............................................................................................................................................................................

HOLDER, TENSION .....................................................................................................................................................................

CAM, MAIN ...................................................................................................................................................................................

WORM ASS'Y ...............................................................................................................................................................................

MAIN BRAKE T ASS'Y .................................................................................................................................................................

LEVER, MAIN BRAKE ..................................................................................................................................................................

BRACKET, BRAKE .......................................................................................................................................................................

ARM IDLER ASS'Y .......................................................................................................................................................................

CLUTCH GEAR T ASS'Y..............................................................................................................................................................

CLUTCH GEAR S ASS'Y..............................................................................................................................................................

AHC ASS'Y ...................................................................................................................................................................................

CAM PINCH ROLLER...................................................................................................................................................................

P5 ARM ASS'Y .............................................................................................................................................................................

CATCHER P5 2 ............................................................................................................................................................................

MAIN CHASSIS ASS'Y .................................................................................................................................................................

ROD, MAIN ASS'Y........................................................................................................................................................................

CAM, P5........................................................................................................................................................................................

1

1

1

2

2

3

3

4

4

5

5

6

6

6

7

7

8

8

9

10

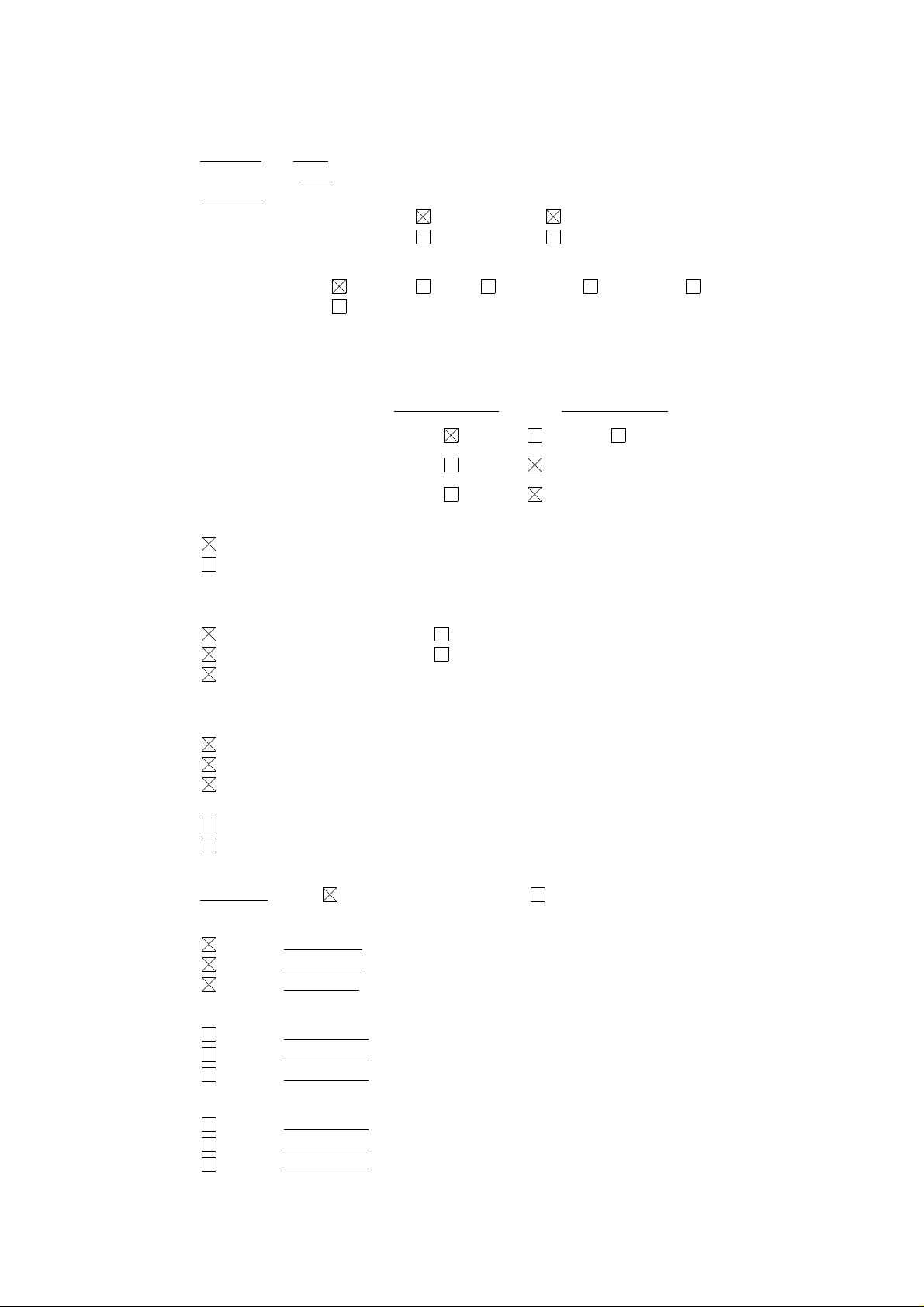

The following parts can not be distinguished by the external appearance.

• SPRING, MAIN BRAKE and SPRING, MAIN BRAKE (VP)

• SPRING, TENSION ARM 1 and SPRING, TENSION ARM (1S)

• PINCH ROLLER BLOCK and PINCH ROLLER (PB) BLOCK

So before repairing, please identify each part by referring to the Parts List and Parts No. of Service Manual.

1

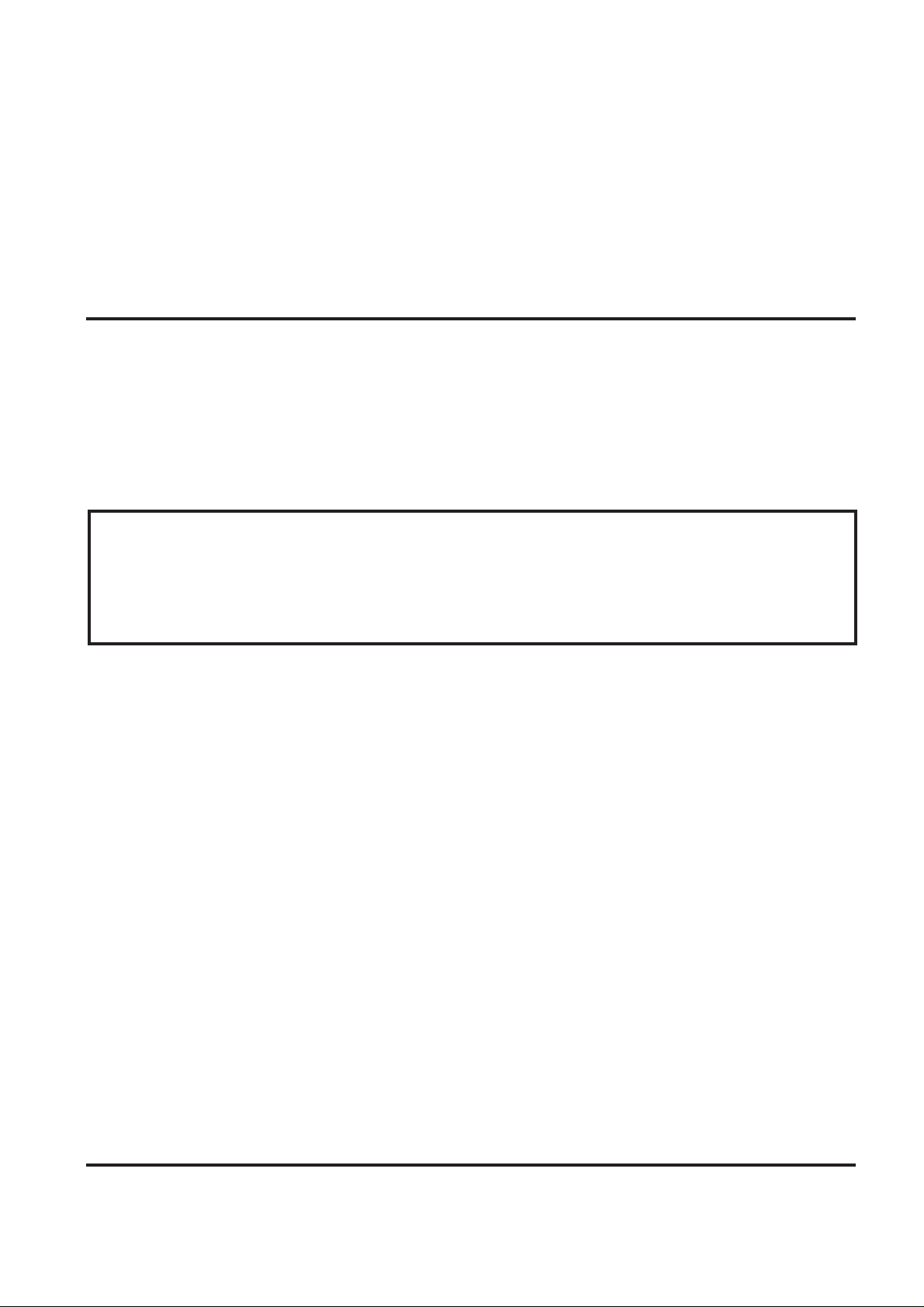

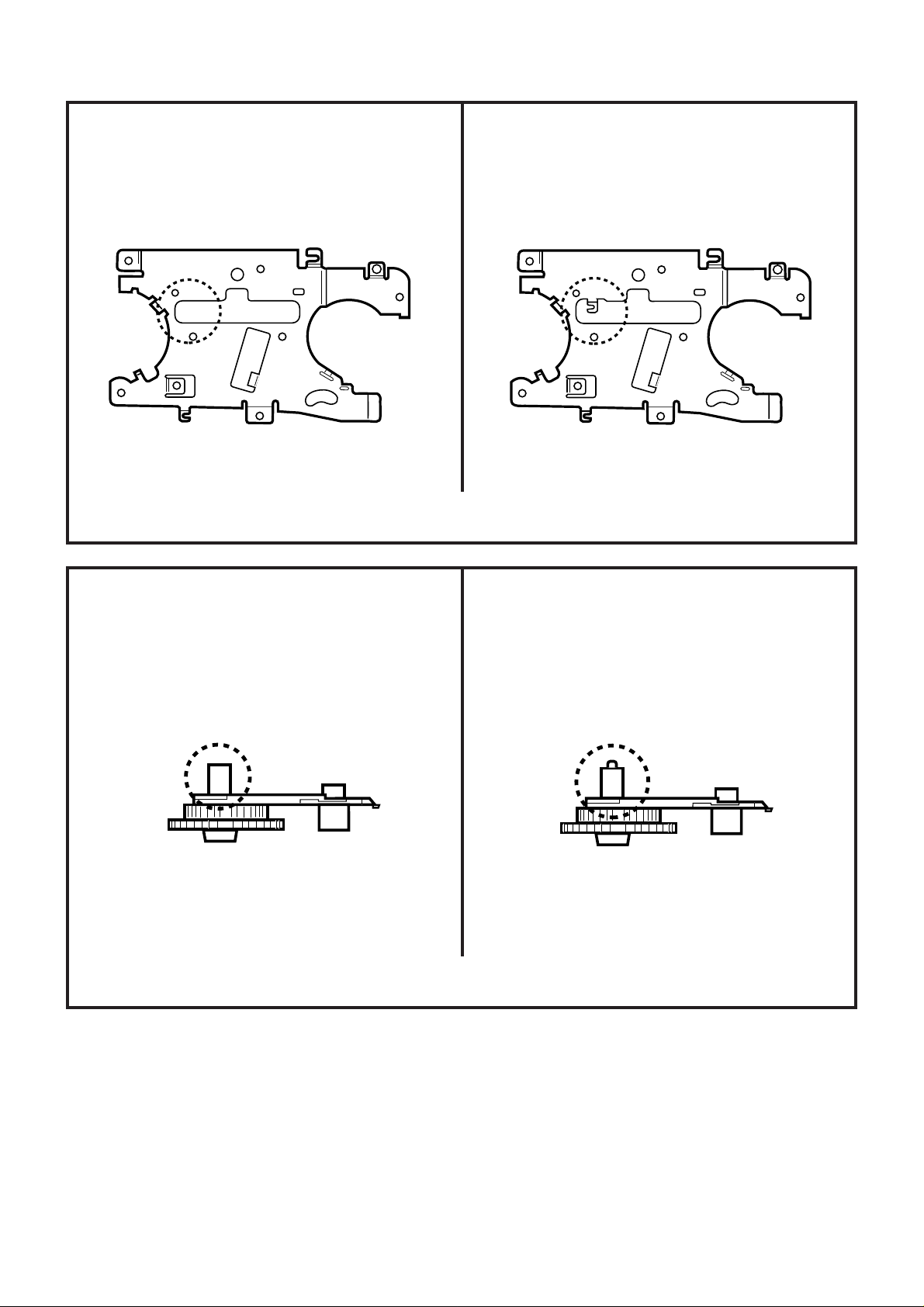

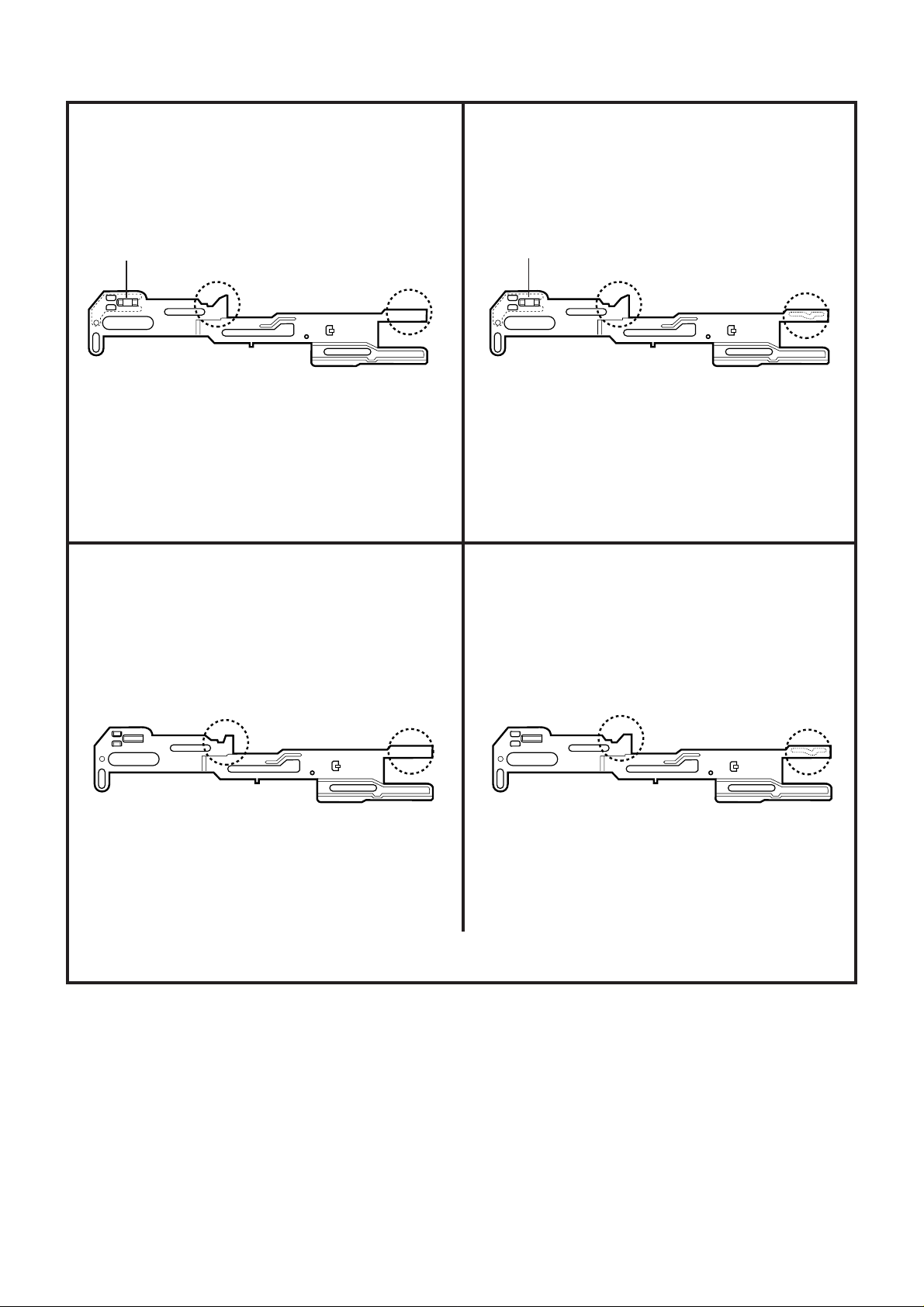

NAME: MODE SWITCH

PART NO.: 0520244003 or 0520244006

Distinction: You can distinguish by the cut part.

NAME: MODE SWITCH

PART NO.: 0520244005 or 0520244007

Cut part

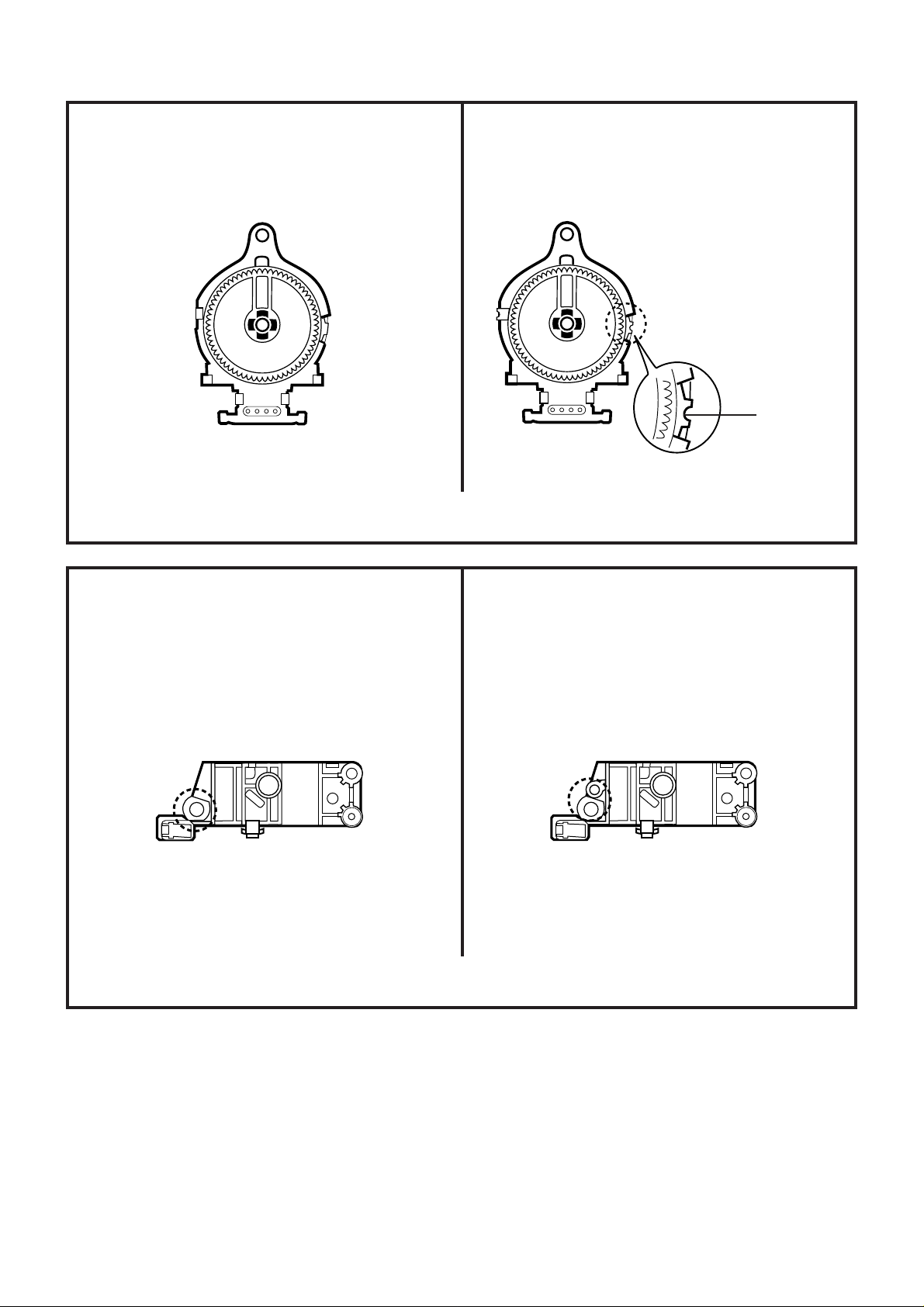

NAME: HOLDER, TENSION

PART NO.: 85OP400359

NAME: HOLDER, TENSION (S)

PART NO.: 85OP400452

Distinction: You can distinguish by the shape in the dotted circle.

2

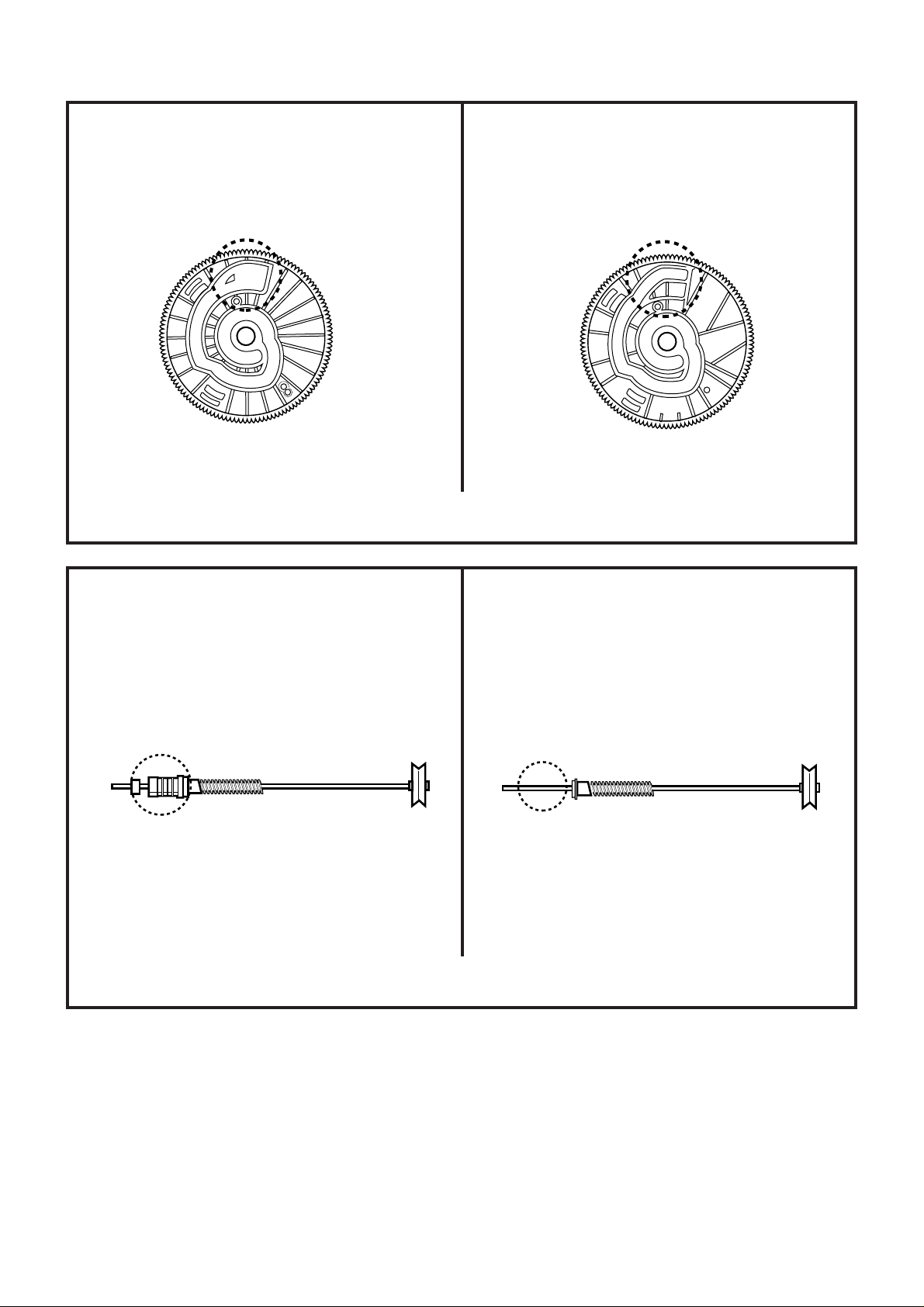

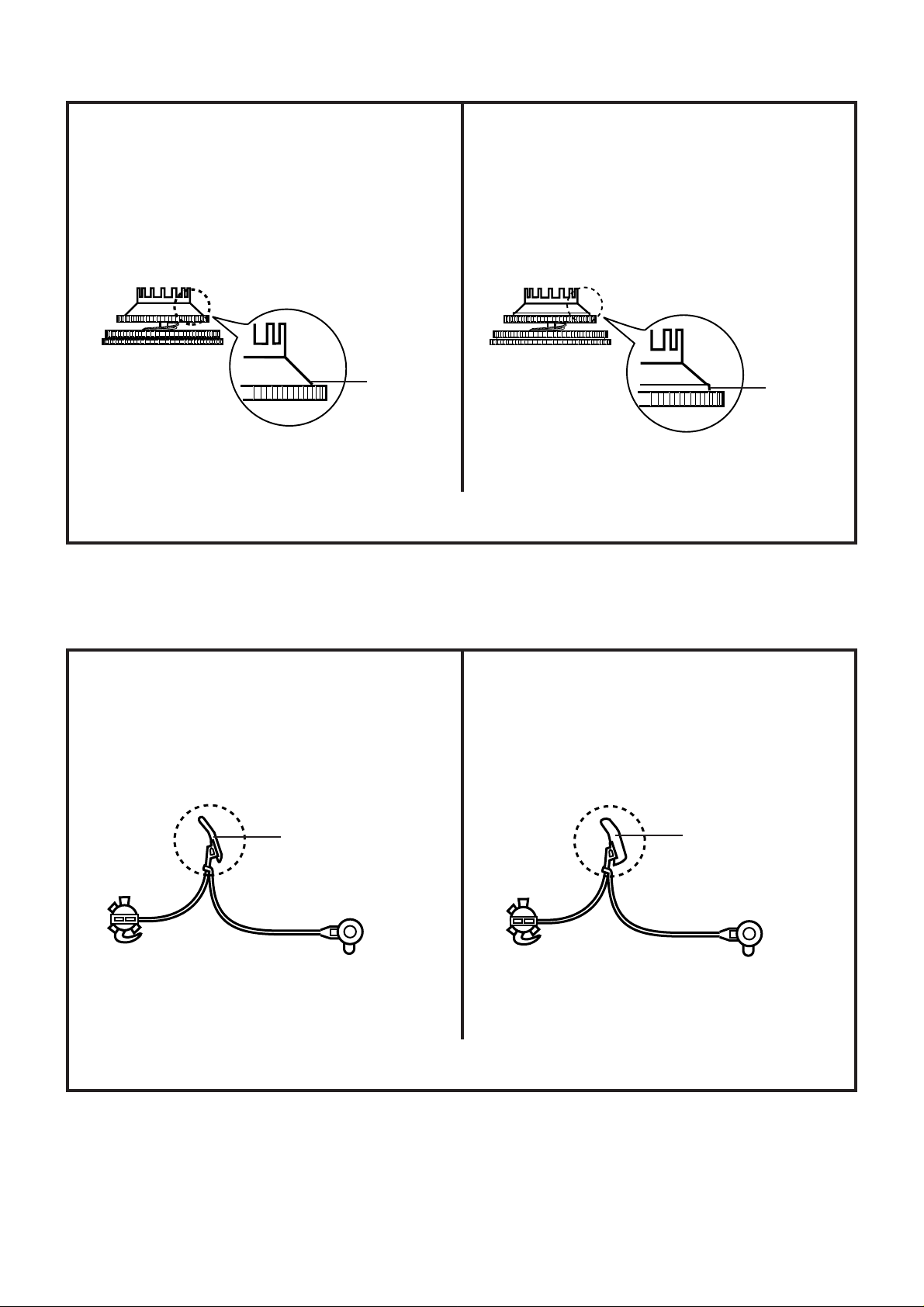

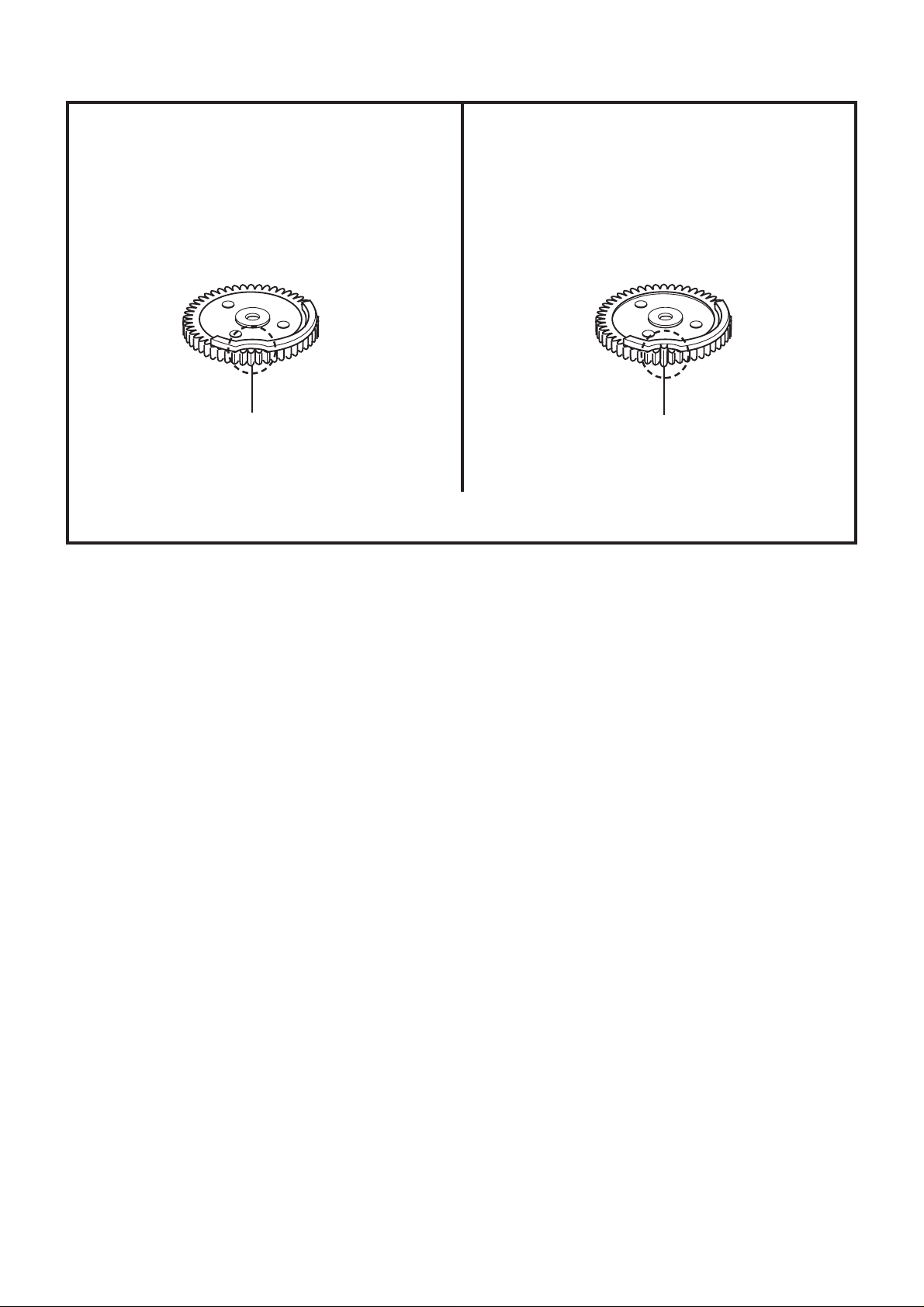

NAME: CAM, MAIN

PART NO.: 85OP600535

NAME: CAM, MAIN (VP)

PART NO.: 85OP600529

Distinction: You can distinguish by the shape in the dotted circle.

NAME: WORM ASS'Y

PART NO.: 85OA600159

NAME: WORM (VP) ASS'Y

PART NO.: 85OA600179

Distinction: You can distinguish by the shape in the dotted circle.

3

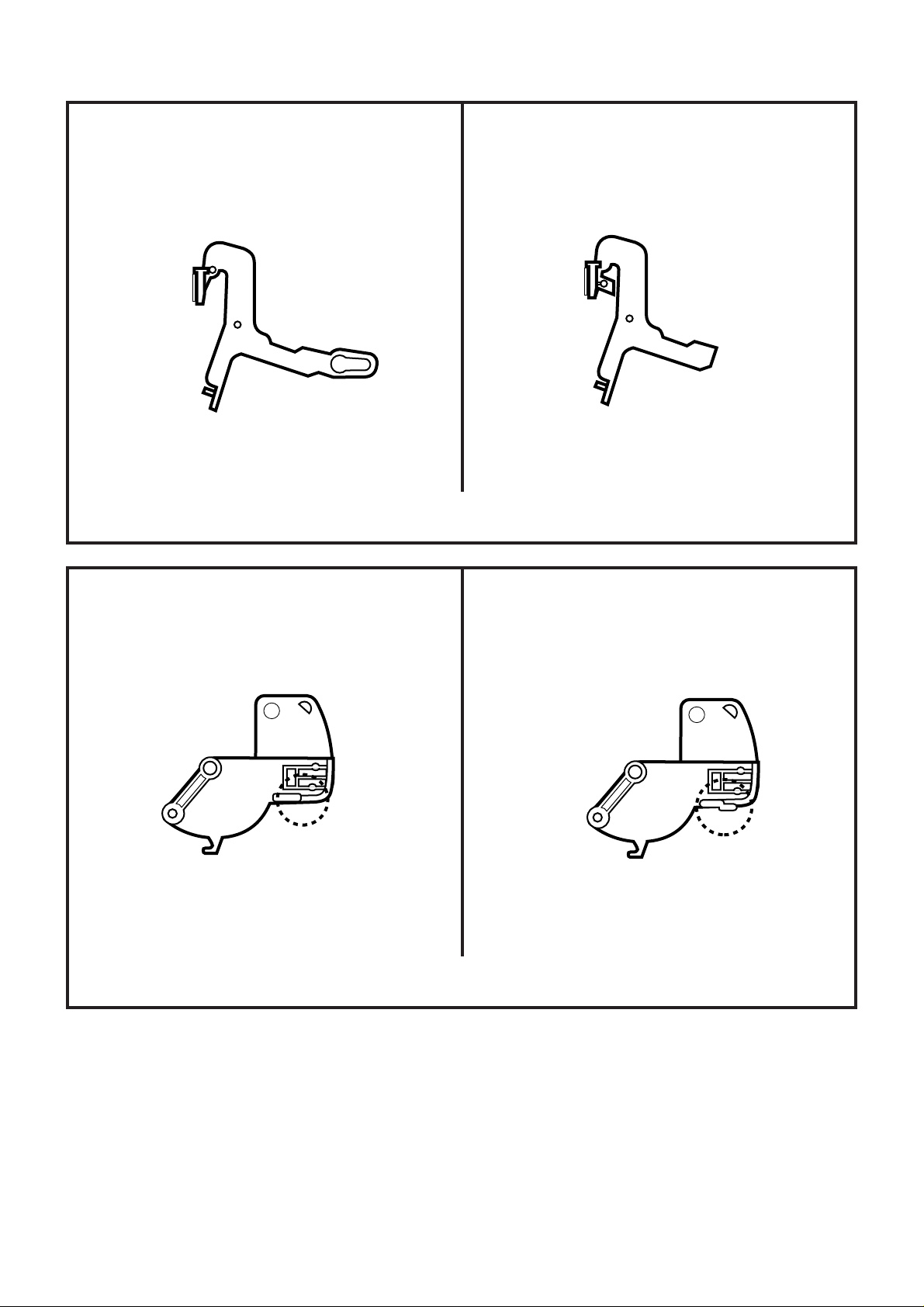

NAME: MAIN BRAKE T ASS'Y

PART NO.: 85OA600156

NAME: MAIN BRAKE T (VP) ASS'Y

PART NO.: 85OA600178

Distinction: You can distinguish by the shape.

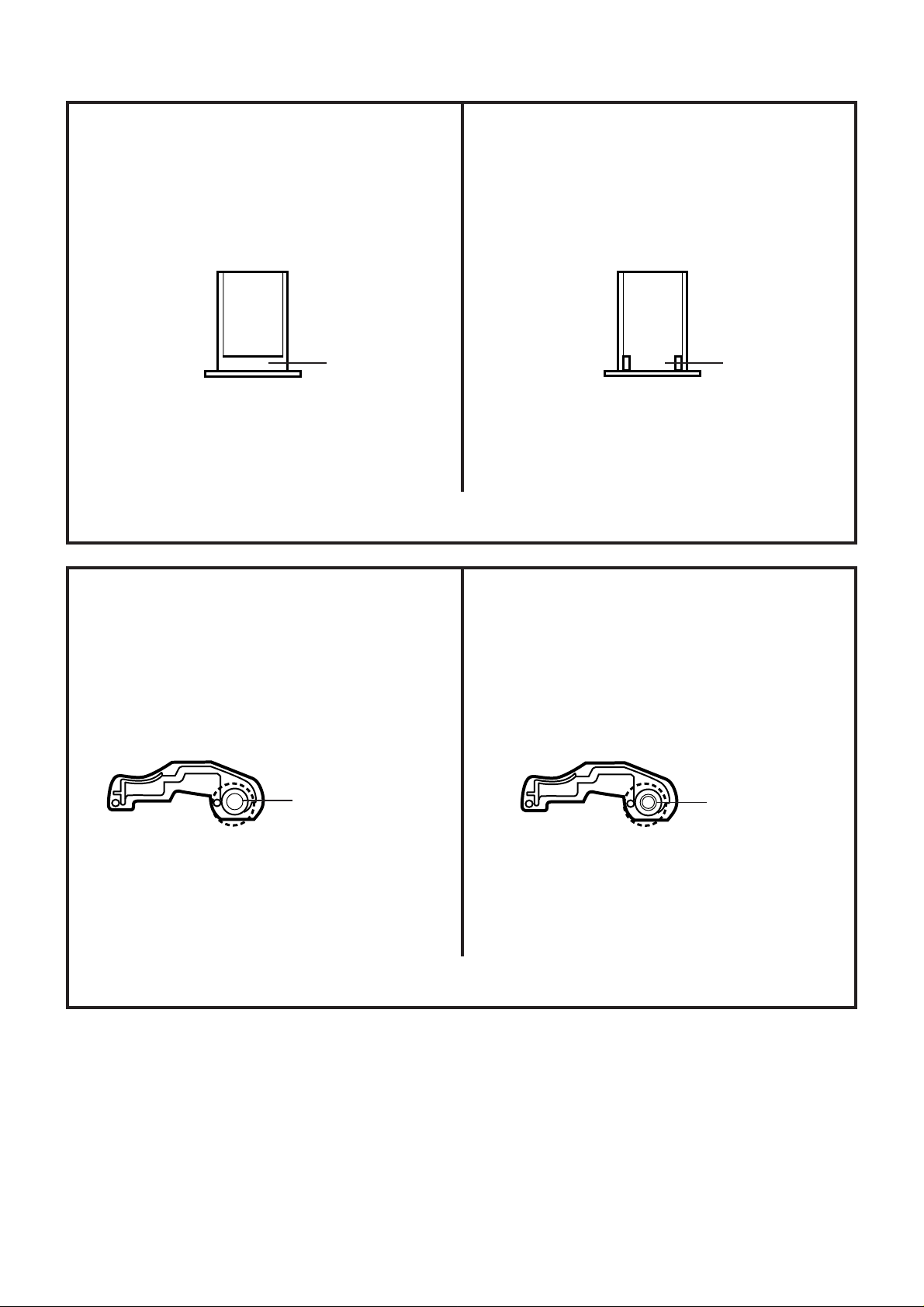

NAME: LEVER, MAIN BRAKE

PART NO.: 85OP600468

NAME: LEVER, MAIN BRAKE (VP)

PART NO.: 85OP600530

Distinction: You can distinguish by the shape in the dotted circle.

4

NAME: BRACKET, BRAKE

PART NO.: 85OP600471

NAME: BRACKET, BRAKE (VP)

PART NO.: 85OP600531

Distinction: You can distinguish by the shape in the dotted circle.

NAME: ARM IDLER ASS'Y

PART NO.: 85OA200065

NAME: ARM IDLER (VP) ASS'Y

PART NO.: 85OA200067

Distinction: You can distinguish by the shape in the dotted circle.

5

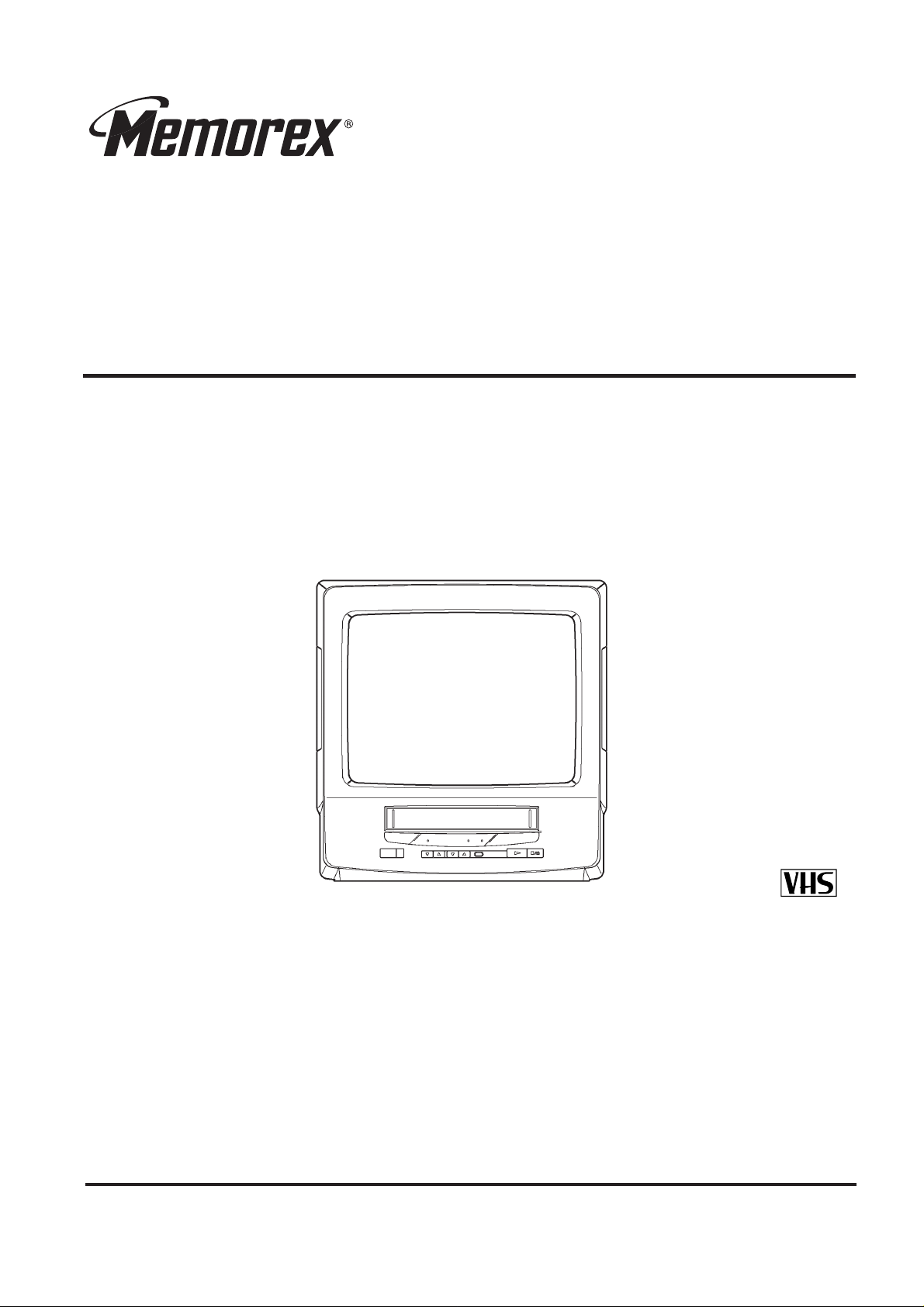

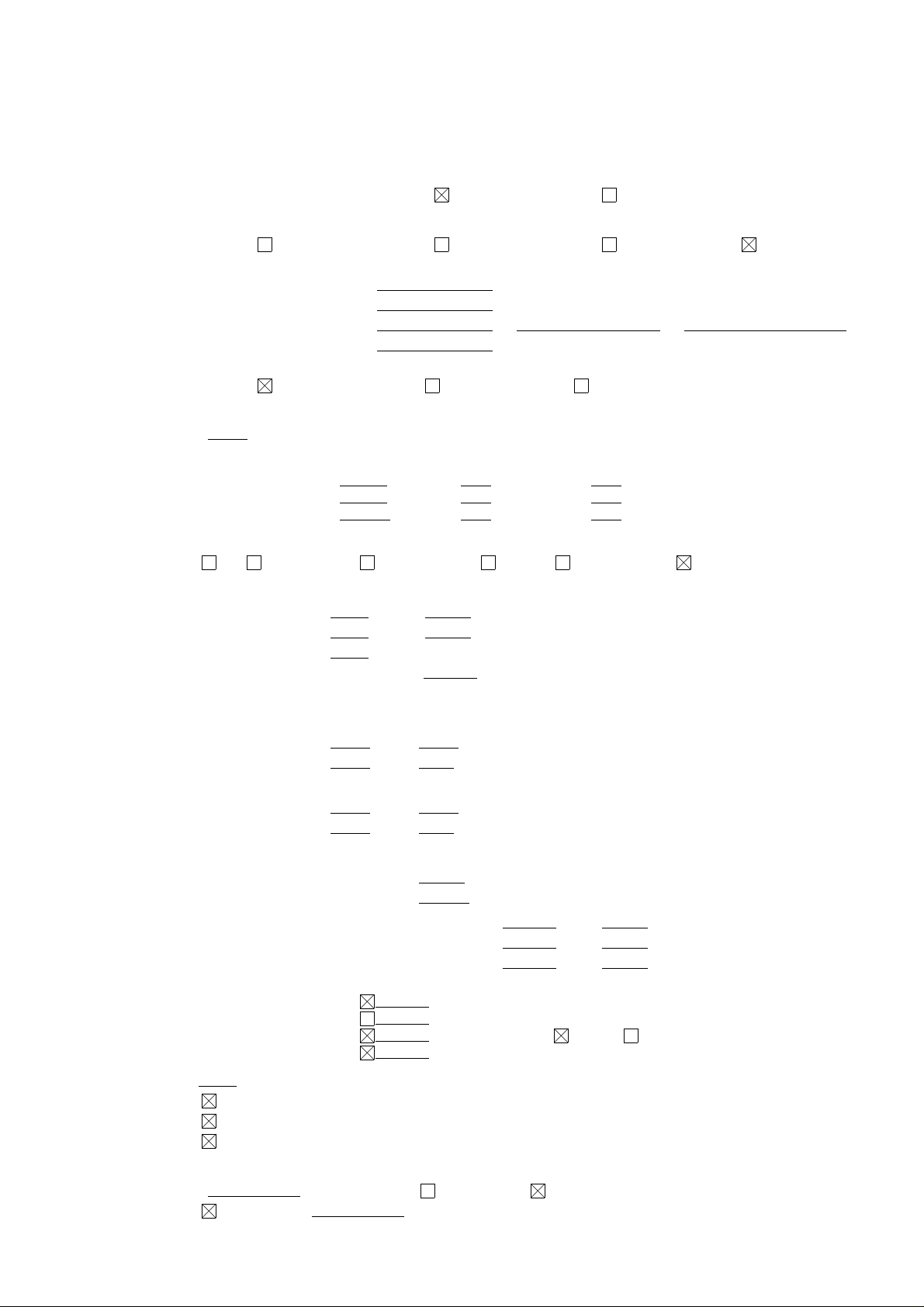

NAME: CLUTCH GEAR T ASS'Y

PART NO.: 85OA200064

NAME: CLUTCH GEAR S ASS'Y

PART NO.: 85OA200063

NAME: CLUTCH GEAR S (S) ASS'Y

PART NO.: 85OA200070

NAME: CLUTCH GEAR T (VP) ASS'Y

PART NO.: 85OA200069

NAME: CLUTCH GEAR S (VP) ASS'Y

PART NO.: 85OA200068

NAME: CLUTCH GEAR S (VPS) ASS'Y

PART NO.: 85OA200071

NOTE:

The following parts can't be distinguished by the external appearance.

• CLUTCH GEAR S ASS'Y and CLUTCH GEAR S (S) ASS'Y

• CLUTCH GEAR S (VP) ASS'Y and CLUTCH GEAR S (VPS) ASS'Y

So before repairing, please identify each parts by referring to the Parts List and Parts No. of Service Manual.

NAME: AHC ASS'Y

PART NO.: 85OA500013

MATERIAL COLOR: WHITE

There is no

step.

Distinction: You can distinguish by the existence of the step.

NAME: AHC ASS'Y (2)

PART NO.: 85OA500020

MATERIAL COLOR: GRAY

There is a

step.

Width: Approx. 2.5mm

Distinction: You can distinguish by the material color and shape in the dotted circle.

6

Width: Approx. 4.5mm

NAME: CAM PINCH ROLLER

PART NO.: 85OP400433

MATERIAL COLOR: WHITE

NAME: CAM PINCH ROLLER (PB)

PART NO.: 85OP400430

MATERIAL COLOR: GRAY

Cross Section

NAME: P5 ARM ASS'Y

PART NO.: 85OA400120

Cross Section

No Dent

Distinction: You can distinguish by the material color and the dent.

NAME: P5 ARM ASS'Y (PB)

PART NO.: 85OA400168

Dent

Without a brass sleeve

Distinction: You can distinguish by the shape in the dotted circle.

7

With a brass sleeve

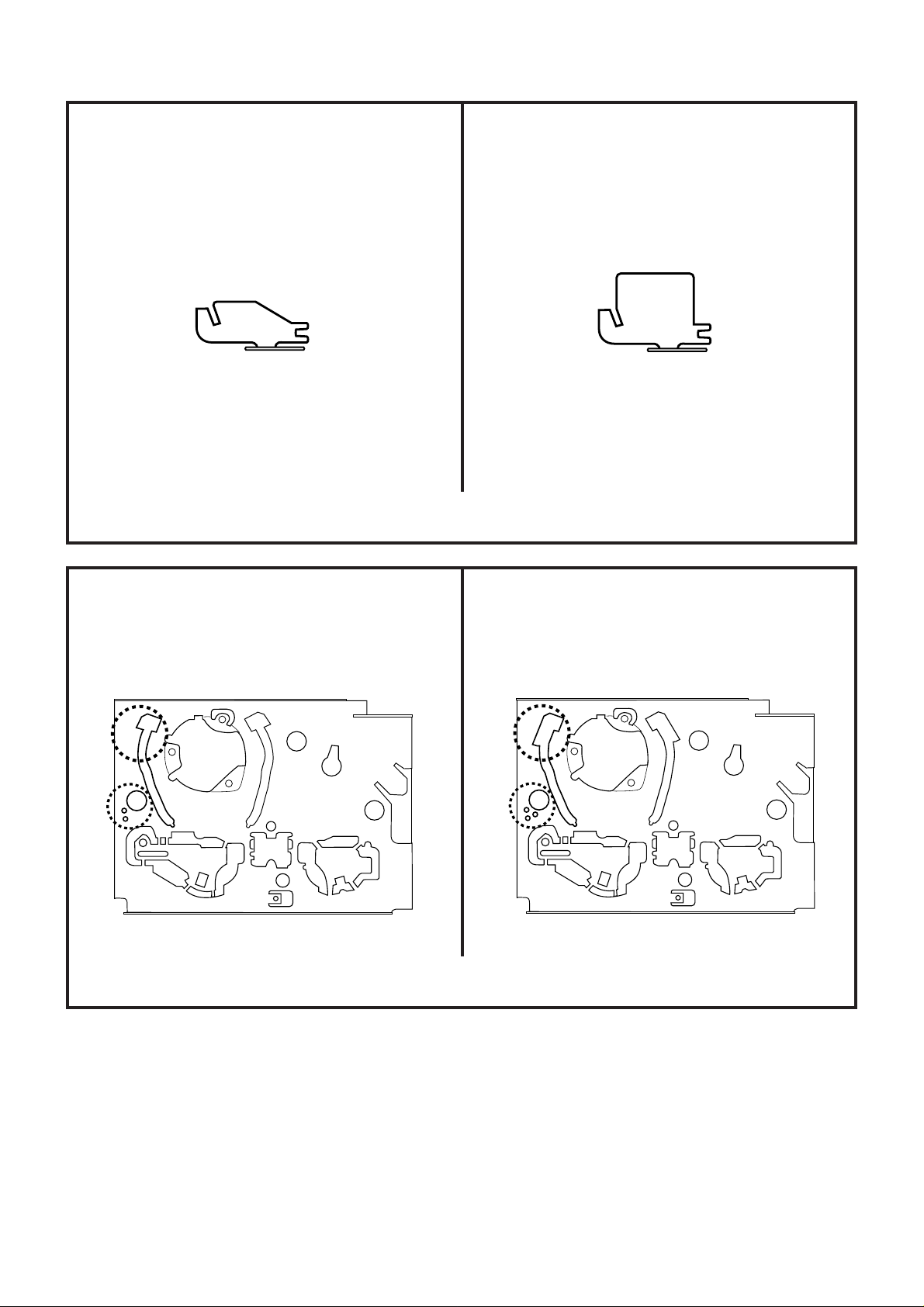

NAME: CATCHER P5 2

PART NO.: 85OP400402

NAME: CATCHER P5 (VP)

PART NO.: 85OP400446

Distinction: You can distinguish by the shape.

NAME: MAIN CHASSIS ASS'Y

PART NO.:

85OA000173, 85OA000221, 85OA000222,

85OA000229 or 85OA000231

NAME: MAIN CHASSIS ASS'Y

PART NO.:

Distinction: You can distinguish by the shape in the dotted circle.

85OA000227, 85OA000226 or 85OA000230

8

NAME: ROD, MAIN ASS'Y

PART NO.: 85OA600176

NAME: ROD, MAIN (S)

PART NO.: 85OA600181

RATCHET PLATE (Back Side)

NAME: ROD, MAIN (VP)

PART NO.: 85OP600527

RATCHET PLATE (Back Side)

NAME: ROD, MAIN (VPS)

PART NO.: 85OP600538

Distinction: You can distinguish by the shape in the dotted circle.

9

NAME: CAM, P5

PART NO.: 85OP400344

NAME: CAM, P5

PART NO.: 85OP400450

All teeth are the same height.

Distinction: You can distinguish by the tooth height of circled section.

Only one tooth is high.

10

MVT2138

SERVICE MANUAL

COLOR TELEVISION/VIDEO CASSETTE RECORDER

ORIGINAL

MFR’S VERSION C

Design and specifications are subject to change without notice.

SERVICING NOTICES ON CHECKING

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathoderay tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

6. AVOID AN X-RAY1. KEEP THE NOTICES

Safety is secured against an X-ray by considering about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage peripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathoderay tube.

PERFORM A SAFETY CHECK AFTER

7.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

3.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

Earphone jack

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

A1-1

CONTENTS

SERVICING NOTICES ON CHECKING .....................................................................

HOW TO ORDER PARTS..........................................................................................

CONTENTS ................................................................................................................

GENERAL SPECIFICATIONS...................................................................................

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS AND P.C. BOARDS ..............................

2. REMOVAL OF DECK PARTS .............................................................................

3. REMOVAL OF ANODE CAP ...............................................................................

KEY TO ABBREVIATIONS ......................................................................................

PREVENTIVE CHECKS AND SERVICE INTERVALS ..............................................

NOTE FOR THE REPLACING OF MEMORY IC .......................................................

DECK PARTS LOCATIONS ......................................................................................

SERVICING FIXTURES AND TOOLS........................................................................

PREPARATION FOR SERVICING .............................................................................

MECHANICAL ADJUSTMENTS ................................................................................

ELECTRICAL ADJUSTMENTS .................................................................................

MAJOR COMPONENTS LOCATION GUIDE ............................................................

BLOCK DIAGRAMS

TV BLOCK DIAGRAM ............................................................................................

Y/C/AUDIO/HEAD AMP..........................................................................................

SYSTEM CONTROL/SERVO.................................................................................

IN/OUT ....................................................................................................................

PRINTED CIRCUIT BOARDS

MAIN/CRT...............................................................................................................

SYSCON .................................................................................................................

OPERATION...........................................................................................................

SCHEMATIC DIAGRAMS

TIMER MICON........................................................................................................

IF/CHROMA............................................................................................................

SOUND AMP ..........................................................................................................

DEFLECTION .........................................................................................................

CRT.........................................................................................................................

POWER (TV) ..........................................................................................................

OPERATION(2) ......................................................................................................

Y/C/AUDIO..............................................................................................................

HEAD AMP .............................................................................................................

IN/OUT ....................................................................................................................

SYSTEM CONTROL/SERVO.................................................................................

POWER (VCR) .......................................................................................................

OPERATION(1) ......................................................................................................

INTERCONNECTION DIAGRAM ...............................................................................

WAVEFORMS ............................................................................................................

MECHANICAL EXPLODED VIEWS ...........................................................................

CHASSIS EXPLODED VIEW.....................................................................................

FRONT LOADING UNIT 15 EXPLODED VIEW .........................................................

MECHANICAL REPLACEMENT PARTS LIST..........................................................

CHASSIS/FRONT LOADING UNIT 15 REPLACEMENT PARTS LIST ....................

ELECTRICAL REPLACEMENT PARTS LIST ...........................................................

A1-1

A1-1

A2-1

A3-1~A3-6

B1-1, B1-2

B2-1~B2-5

B3-1

C1-1, C1-2

C2-1

C3-1

C4-1, C4-2

C5-1

C5-1

D1-1~D1-3

D2-1~D3-1

D4-1, D4-2

E-1, E-2

E-3, E-4

E-5, E-6

E-7, E-8

F-1, F-2

F-3~F-6

F-7, F-8

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

G-11, G-12

G-13, G-14

G-15, G-16

G-17, G-18

G-19, G-20

G-21, G-22

G-23, G-24

G-25, G-26

G-27, G-28

H-1~H-4

I-1, I-2

I-3, I-4

I-5

J1-1

J2-1

J3-1~J3-3

A2-1

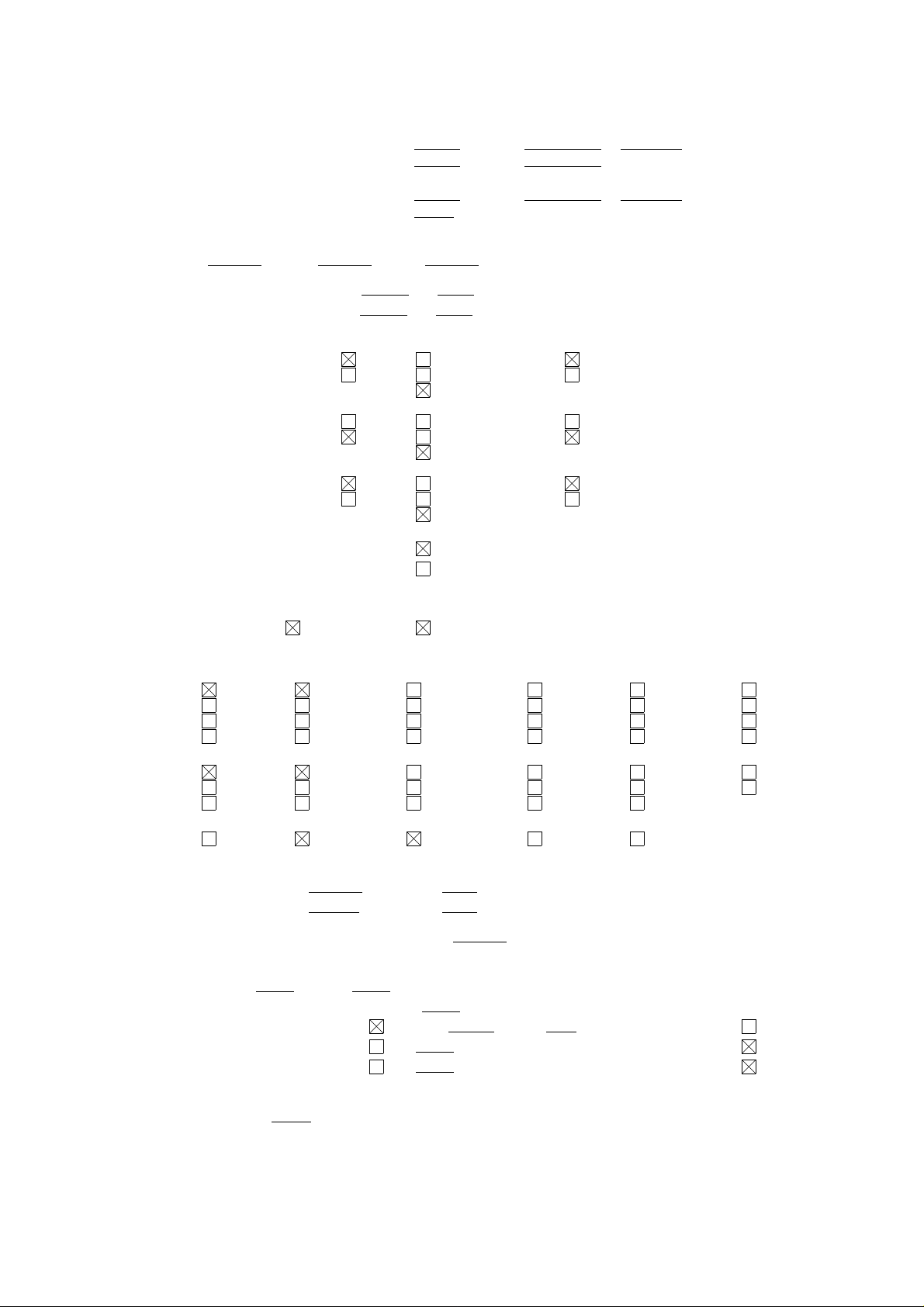

G E N E R A L S P E C I F I C A T I O N S

G-1.Outline of the Product

13 inch(335.4mmV):Measured diagonally

Color CRT 90 degree deflection

3 -Speed 1/2" Video Cassette Recorder

VHS Recorder/Player

VHS-C Player

G-2.VCR Format

VHS Standard NTSC PAL SECAM PAL-M PAL-N

VHS Hi-Fi Audio System

G-3.Video Recording System :Rotary,slant azimuth two head helical scan system

Luminance Component :FM recording

Chrominance Component :Low frequency converted direct recording

G-4.Broadcasting System US System M

G-5.Color System NTSC PAL SECAM or Monochrome signal

G-6.NTSC Playback(PAL 60Hz) Yes No

G-7.MESECAM Yes No

G-8.Cassette Tape

VHS type video cassette tape Width 12.65mm (1/2 Inch)

VHS-C type video cassette tape Width 12.65mm (1/2 Inch)

G-9.Tape Speed

NTSC or PAL-M PAL or SECAM

S P 33.35 mm/sec S P 23.39 mm/sec

LP 16.67 mm/sec LP 11.69 mm/sec

SL P 11.12 mm/sec

G-10.Recording/Playback Time

NTSC or PAL-M

at SP Mode Max. 210 min. (with T-210 cassette)

at LP Mode Max. 420 min. (with T-210 cassette)

at SLP Mode Max. 630 min. (with T-210 cassette)

PAL or SECAM

at SP Mode Max. 300 min. (with E-300 cassette)

at LP Mode Max. 600 min. (with E-300 cassette)

G-11.Rewind/Fast Forward Time(Approx.)

2' 30" (with T-120 cassette) (with E-180 cassette)

G-12.Search Speed

SP 3 and 5 Times

LP 7 and 9 Times

SLP 9 and 15 Times

G-13.Slow Speed

SP Times

LP Times

SLP Times

G-14.Frame Advance

SP Times

LP Times

SLP Times

A 3 - 1

G E N E R A L S P E C I F I C A T I O N S

G-15.Antenna Input Impedance

VHF/UHF 75 ohm unbalanced

G-16.Tuner and Receiving channel 1Tuner Syatem 2Tuner System

Tuner : Contactless Electric tuner

Oscar(W/O HYPER) Oscar(W/ HYPER) France CATV) Others

Receiving channel

VH F (LOW) 2 ch~ 6 ch

(HIGH) 7 ch~ 13 ch

(CATV) A5 ch~ I ch J ch~ W+ 29 ch GGG ch~ W+84 ch

UHF 14 ch~ 69 ch

Tuning System

Frequency syn. Voltage syn. Others

G-17.Preset Channel

-- channels

G-18.Intermediate Frequency

Picture(FP) 45.75 MHz MHz MHz

Sound (FS) 41.25 MHz MHz MHz

FP-FS 4.50 MHz MHz MHz

G-19. Stereo/Dual TV Sound

Yes( NICAM GERMAN USA JAPAN) No

G-20.Video Signal

Input Level 1 Vp-p / 75 ohm

Output Level 1 Vp-p / 75 ohm

S/N Ratio 50 dB (Weighted)

Horizontal Resolution at SP Mode 230 Lines

G-21.Audio Signal

Input Level

Output Level

S/N Ratio at SP Mode 42 dB

Harmonic Distortion : 1.5 % (1KHz)

Frequency Response : at SP Mode 120 Hz ~ 10 KHz

G-22.Heads

Video 2 Rotary Heads

FM Audio Rotary Heads

Audio / Control 1 Stationary Head ( Mono Stereo(L,R) )

Erase 1 Full Track Erase

Line -- dB / -- Kohm

RCA - 8 dB / 50 Kohm

Line -- dB / -- Kohm

RCA - 6 dB / 1 Kohm

(0dB=0.775 V rms)

at LP Mode 120 Hz ~ 6 KHz

at SLP Mode 120 Hz ~ 4 KHz

G-23.Motor: 3 Motors

Tape/Cassette Loading

Cylinder (Dire c t Drive)

Capstan (Direct Drive)

G-24.Power Source

120 V AC 50Hz AC 60Hz

EXT DC Jack 12 V

A 3 - 2

G E N E R A L S P E C I F I C A T I O N S

G-25.Power Consumption: 88 W at AC 120 V 60 Hz

54 W at DC 12 V

(at TV and VCR ON)

Stand by: 10 W at AC 120 V 60 Hz

Per Year: -- kWh / Year

G-26.Dimensions(Approx.)

365 mm(W) 370 mm(D) 382 mm(H)

G-27.Weight(Approx.) Net : 12.5 Kg ( 27.6 lbs)

Gross: 14.5 Kg ( 32.2 lbs)

G-28.Cabinet Material

Cabinet Front: PS 94HB DECABROM

ABS 94V2 NON-DECA

94V0

Cabinet Rear: PS 94HB DECABROM

ABS 94V2 NON-DECA

94V0

Jack Panel: PS 94HB DECABROM

ABS 94V2 NON-DECA

94V0

G-29.Cassette Loading System: Front Cassette Loading System

Top Loading System

G-30.Tape Counter: Linear Time Tape Counter

G-31.Protector: Power Fuse Dew Sensor

G-32.Regulation

Safety

UL CSA SAA SI CE SEV

BS NF NEMKO FEMKO DEMKO IEC65

SEMKO NZ HOMOLO SABS CNS SISIR

NOM AS3159 DENTORI UNE GOST NONE

Radiation

FCC DOC FTZ PTT CE SEV

SABA SI NF NZ HOMOLO UNE

CNS CISPR13 DENTORI AS/NZS NONE

X-Radiation

PTB DHHS HWC DENTORI NONE

G-33.Temperature

Operation 5 ºC~ 40 ºC

Storage -20 ºC~ 60 ºC

G-34.Operating Humidity Less than 80 %RH

G-35.Clockand Timer

Built-in 1 Month 7 Events Programmable Timer

One Touch Recording : Max Time 5 Hours

Sleep Timer Yes Max 120 Min.( 10 Min. Step) No

On/Off Timer Yes Programs No

Wake Up Timer Yes Programs No

G-36.Timer back up Time

More than 1/12 Minutes (at Power Off Mode)

A 3 - 3

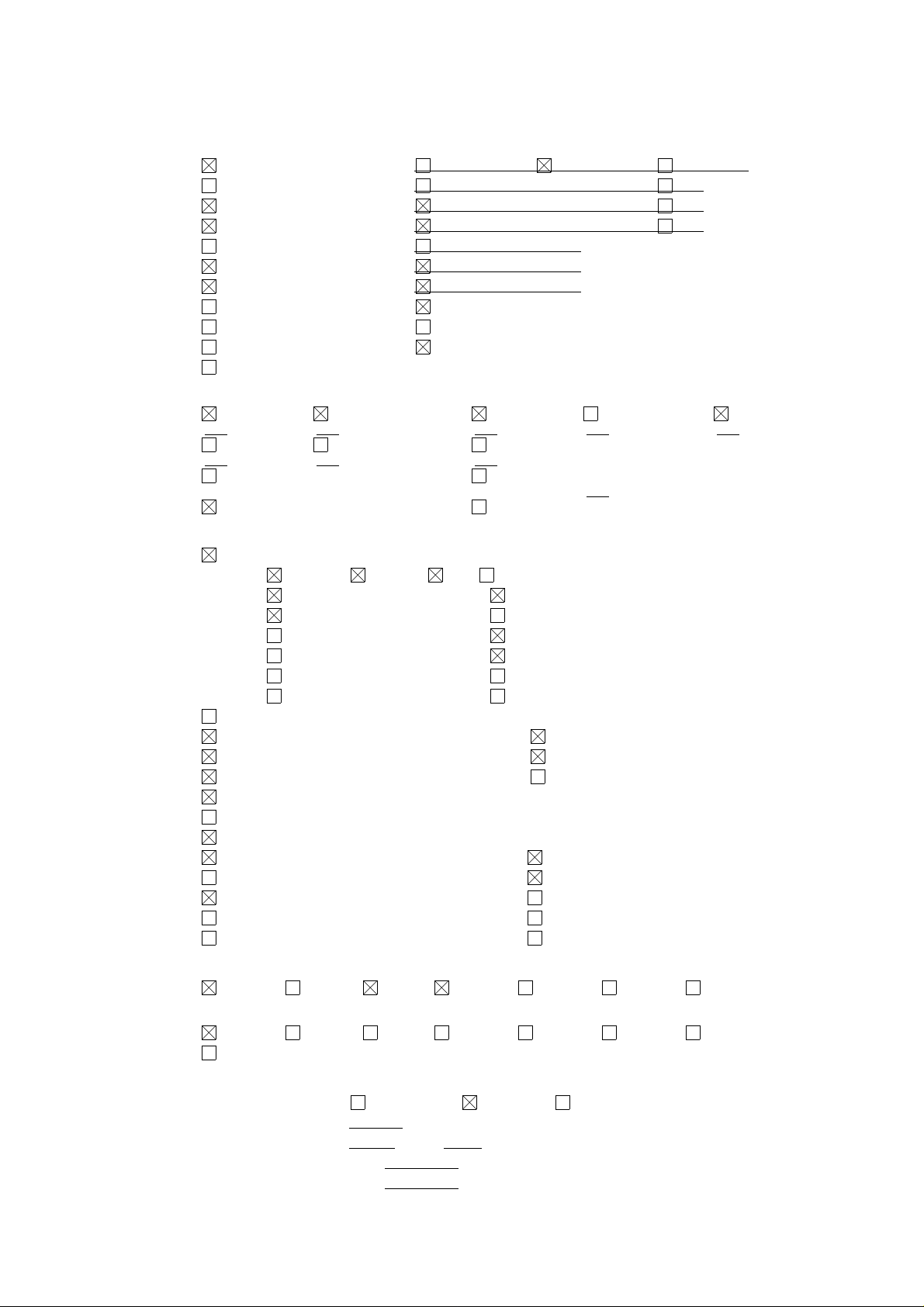

G-37.Terminals

VHF/UHF Antenna Din Type F-Type France Type

Video Input(Front) Phono Jack (RCA ø8.3) BNC

Video Input(Rear) Phono Jack (RCA ø8.3) BNC

Video Output(Rear) Phono Jack (RCA ø8.3) BNC

Audio Input(Front) Phono Jack (RCA ø8.3)

Audio Input(Rear) Phono Jack (RCA ø8.3)

Audio Output(Rear) Phono Jack (RCA ø8.3)

21 Pin DC Jack 12V (Center +)

AC Inlet Ext Speaker

Diversity Ear Phone

Head Phone

G-38.Indicator

Power Rec/OTR Play Tape-In Timer Rec

(Red) (Red) (Red)( ) (Red)

Stand By On Timer Rental Mode(or Clear Picture)

( ) ( )( )

One Touch Playback(Button Lights) Charge

Dew Sensor(Play LED F lush) NONE

G-39.On Screen Display

Menu

G-CODE(or SHOWVIEW or PLUSCODE)No. Entry

Clock CH

Tape Counter/Memory Tape Speed

Sleep Time EXT.Input

Control Level (Vol,Bright,Cont,Color,Tint,Sharpness)

Control Level (Vol,Bright,Cont,Color,Sharpness)

Play/Stop/FF/Rew/Rec/OTR/T-Rec/Pause

Auto Tracking/Manual Tracking Caption 1/2

Index Sound Mute

Add/Delete Auto Wide On/Off

Wide Select Picture Position

Tone 1/2 Stereo

G E N E R A L S P E C I F I C A T I O N S

( )

Clock Set( Calendar 12H 24H)

Timer Rec Set Language

Auto Repeat On/Off Area Code

On/Off Timer Set Channel Se t

Guide CH Set Picture

ATS System Select

Protect On/Off User Registration

G-40.OSD Language

Eng Ger Fre Spa Ita Por Jan

OSD Language Setting

Eng Ger Fre Spa Ita Por Jan

Not Applicable

G-41.Speaker

P o s i t i o n Front Side Bottom

Size 3 inches

Imp 8 ohm x 1 pcs

Power Max 1.0 W (Typical)

10% 0.7 W (Typical)

A 3 - 4

G E N E R A L S P E C I F I C A T I O N S

G-42.EXT Speaker : Yes -- W Imp -- ohm

G-43.Carton

Master Carton: Need N o Need

Content: ---- Set

Material: ---- / ---- Corrugated Carton

Dimensions: ---- mm(W) ---- mm(D) ---- mm(H)

Description of Origin Yes No

Gift Box

Material AB Double/Brown Corrugated Carton ( with Photo Label)

AB Double/White Corrugated Carton ( with Photo Label)

AB Double Full Color Carton W/Photo

Dimensions: 447 mm(W) 423 mm(D) 443 mm(H)

Design: As Per BUYER 's

Description of Origin: Yes No

Drop Test Natural Dropping At 1 Corner / 3 Edges / 6 Surfaces

Height 25cm 31cm 46cm 62cm 80cm

Container Stuffing: 700 Sets / 40' container

G-44.Accessories

Channel Film Dew Caution Sheet

Owner's Manual ( W/Guarantee Card) [English/French]

Remote Control Unit AC Plug Adaptor

Rod Antenna ( One Pole Two Pole/ F-Type DIN Type France Type)

Loop Antenna( F-Type DIN Type France Type)

U/V Mixer Quick Set-up Sheet

DC Car Cord (Center+) Battery (UM- 4 x 2 )

Guarantee Card A C Cord

Warning Sheet A V Cord (2Pin-1Pin)

Circuit Diagram Registration Card

Antenna Change Plug PTB Sheet

Service Facility List 300 ohm to 75 ohm Antenna Plug

Euro Warranty Information Sheet

G-45.Other Features

Auto Head Cleaning Index Search

Auto Tracking Auto Search

CH Auto Set-Up/Auto Clock ATS

VIDEO PLUS+(SHOWVIEW,G-CODE) PDC

HQ (VHS Standard High Quality) VPS

Auto Power On, Auto Play, Auto Rewind, Auto Eject,Auto Repeat System

Forward / Reverse Picture Search SQPB

One Touch Playback CATV(181CH)

Auto CH Memory Anti-Theft

Just Clock Function Rental Mode

Closed Caption Fastext

Toptext Unitext

TV Auto Shutt off Function TV Monitor

NTSC Playback PAL TV (PAL 60Hz) TV/Rec Monitor

One Touch Automatic Channel Programing

A 3 - 5

G E N E R A L S P E C I F I C A T I O N S

G-46.Switch

Front Power(Tact) Channel Up Volume Up

Play Channel Down Volume Down

Pause/Still F.FWD/Cue Rew/Rev

System Select Eject/Stop Rec/OTR

One Touch Playback Main Power SW

Rear Color On/Off (SECAM only) Degauss

Main Power SW AC/DC

G-47.Magnetic Field

BV : +0.45G BV : +0.35G BV : +0.25G

BH : 0.18G BH : 0.30G BH : 0.30G

BV : -0.15G BV : -0.25G BV : -0.50G

BH : 0.15G BH : 0.15G BH : 0.30G

G-48.Remote Control Unit: RC-BH

Power Source: D.C 3 V Battery UM - 4 x 2

0 Power Prog.CFM

1 Rec/OTR Enter

2 Play Set +

3 F.Fwd Set 4 Rew Auto Ch Memory

5 Pause/Still Delete

6 Stop Add

7 Eject Tracking Auto

8 Slow Tracking Up

9 Clock/Counter Tracking Down

10 Counter Memory Call

11 Counter Reset TV/Caption/Text

12 TV/VCR Caption On/Off

Ch Up Speed Ch.1/2

Ch Down Index Caption 1/2

Volume Up Sleep Timer Mute

Volume Down Repeat Preset (Ch Set)

Quick View Bar Select AFT

Clock/Prog Normalize Select

Menu Cancel Timer Rec

Search Up TV Monitor Ch.Set

Search Down Mute/Normal Daily

Fine Tuning Up/Tracking Up Rental Mode

Fine Tuning Down/Tracking Down Input Select

Tuning Select (Auto Search On/Off) Once

One Touch Playback VIDEO PLUS+ (SHOWVIEW,G-CODE)

Weekly F/T/B Text/Mix/TV

Red Cyan Yellow

Green Status Reset

A 3 - 6

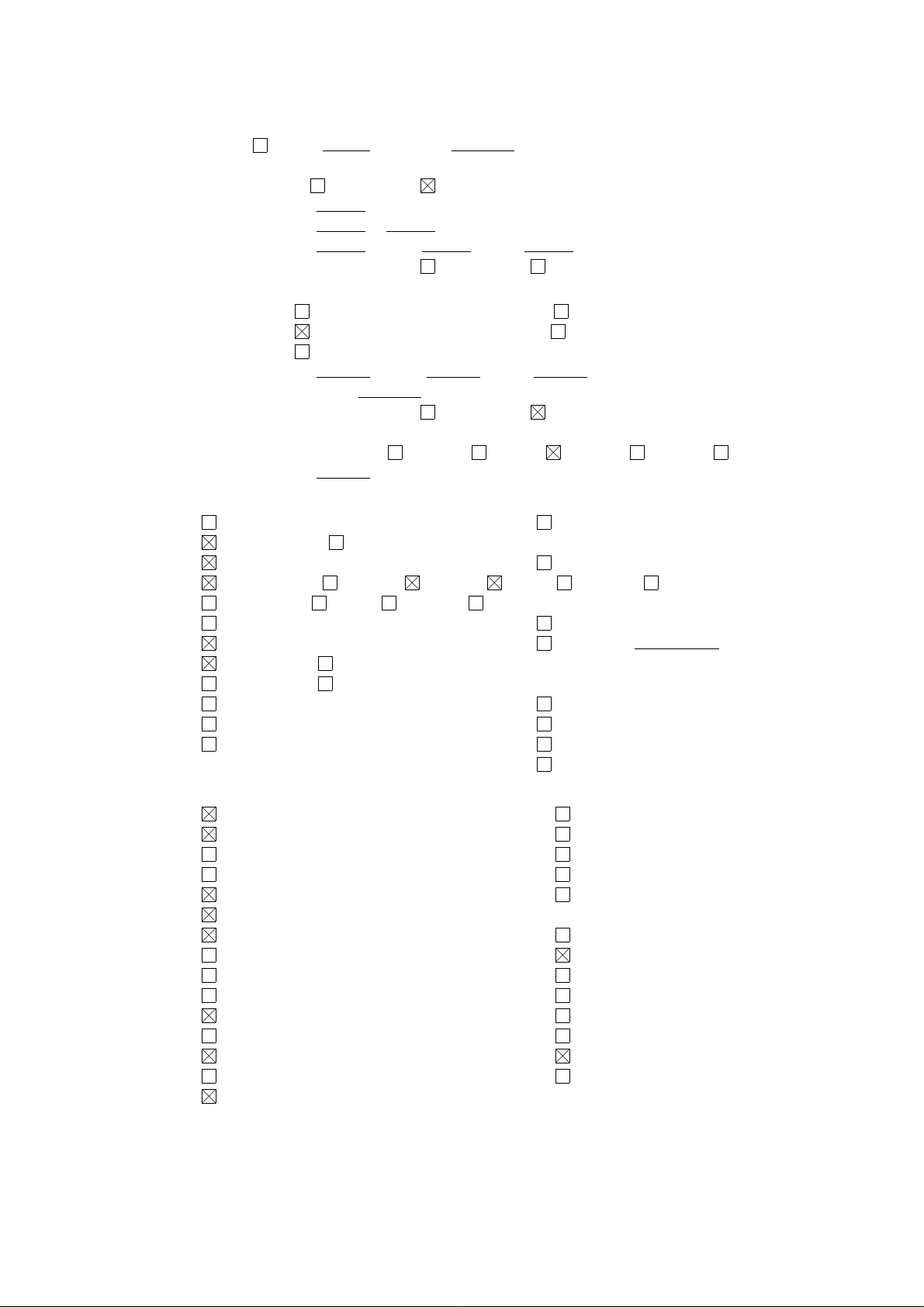

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 4 screws 1.

2.

Remove the 2 screws 2.

3.

Remove the screw 3.

4.

Remove the Back Cabinet in the direction of arrow.

Front Cabinet

1

1

1

2

2

3

1

CAUTION: BEFORE REMOVING THE ANODE CAP,

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1-2: TV BLOCK (Refer to Fig. 1-2)

1.

Remove the CRT PCB in the direction of arrow (A), then

unplug the following connector: (CP801).

2.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

3.

Disconnect the following connectors:

(CP820, CP810, CD850, CP401, CD840 and CP502 ).

4

Slide out the TV Block in the direction of arrow (B).

Front Cabinet

Back Cabinet

Fig. 1-1

1-3: VCR BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws 1.

2.

Disconnect the following connector: (CP351).

3.

Unlock the support 2.

4.

Remove the VCR Block in the direction of arrow.

Front Cabinet

1

2

VCR Block

1

1-4: MAIN PCB (Refer to Fig. 1-4)

1.

Remove the 5 screws 1.

2.

Remove the screw 2.

3.

Unlock the 2 supports 3 and remove the Main PCB in

the direction of the arrow.

1

1

3

1

1

1

3

TV PCB Holder

2

Main PCB

Fig. 1-3

Fig. 1-4

CRT PCB

(A)

(B)

TV Block

Fig. 1-2

1-5: DECK SHIELD PLATE (Refer to Fig. 1-5)

1.2.Remove the 4 screws 1.

Remove the Deck Shield Plate in the direction of arrow.

1

1

Deck Shield

Plate

B1-1

1

1

Syscon PCB

Fig. 1-5

DISASSEMBLY INSTRUCTIONS

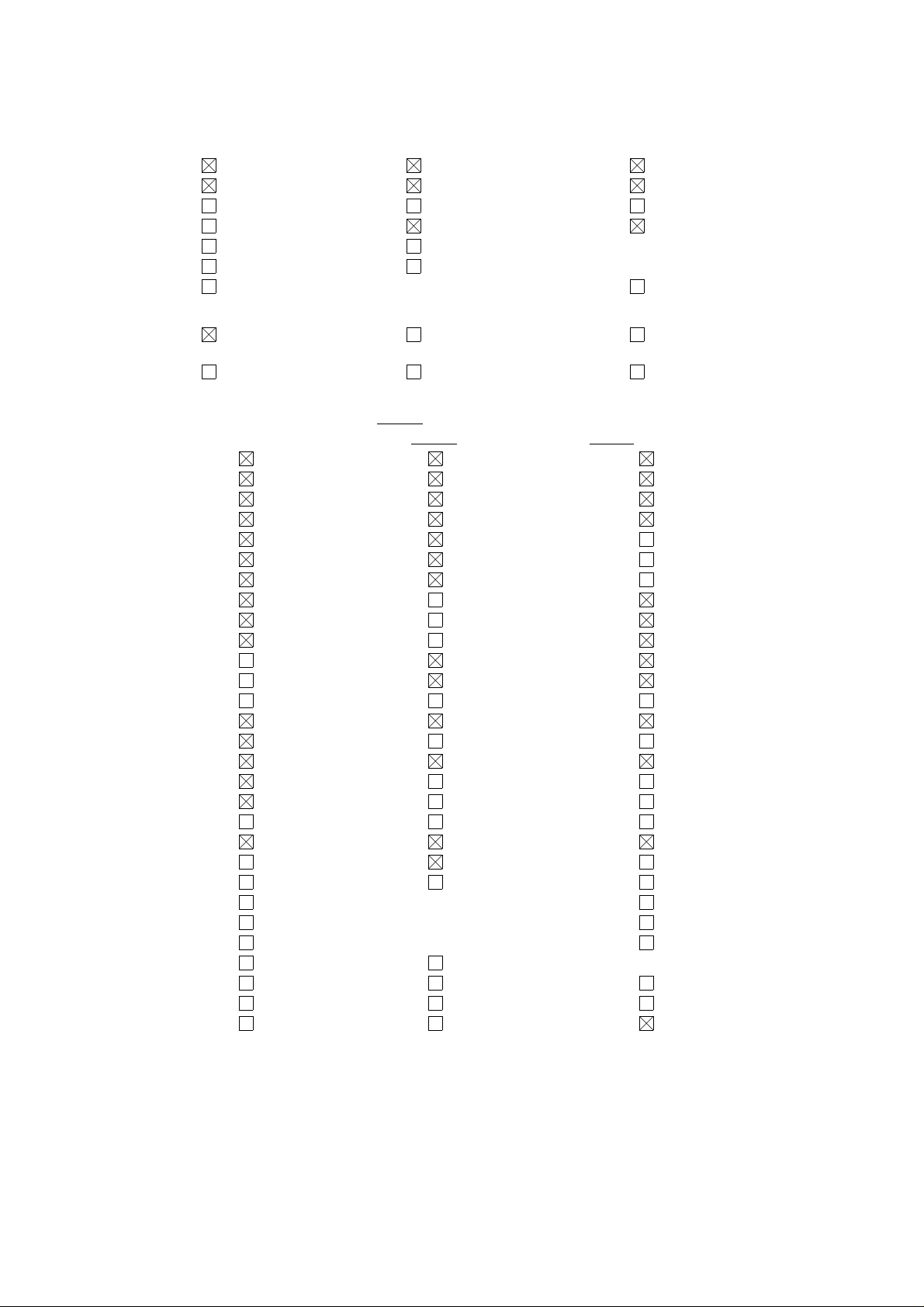

1-6: FRONT LOADING UNIT 15, CHASSIS SECTION

AND CASE SHIELD (Refer to Fig. 1-6-A)

1.

Remove the 3 screws 1.

2.

Remove the Case Shield.

3.

Remove the screw 2.

4.

Remove the screw 3.

5.

Remove the Front Loading Unit 15 in the direction of

arrow (A).

6.

Remove the 3 screws 4.

7.

Remove the 2 screws 5.

8.

Disconnect the following connector: (CP4101 ,

CD1002, CD4002, CP1004 and CP4106 ).

9.

Remove Chassis Section in the direction of arrow (B).

2

3

Front Loading Unit 15

Case Shield

(A)

4

Chassis Section

1

1

1

5

4

5

4

1-7: JACK PLATE AND SYSCON PCB (Refer to Fig. 1-7)

1.

Remove the screw 1.

2.

Remove the Syscon PCB in the direction of arrow (A).

3.

Remove the screw 2.

4.

Remove the Nut 3.

5.

Unlock the 2 support 4 and remove the Jack Plate in

the direction of arrow (B).

Jack Plate

(B)

3

Syscon PCB

4

1

(A)

Deck Holder

2

4

Fig. 1-7

Syscon PCB

(B)

Fig. 1-6-A

NOTE

When installing the Front Loading Unit 15, align the

timing marks and pull the Cassette Holder Ass'y in the

direction of arrow (C). (Refer to Fig. 1-6-B)

Marker

(C)

Cassette Holder Ass'y

Fig. 1-6-B

B1-2

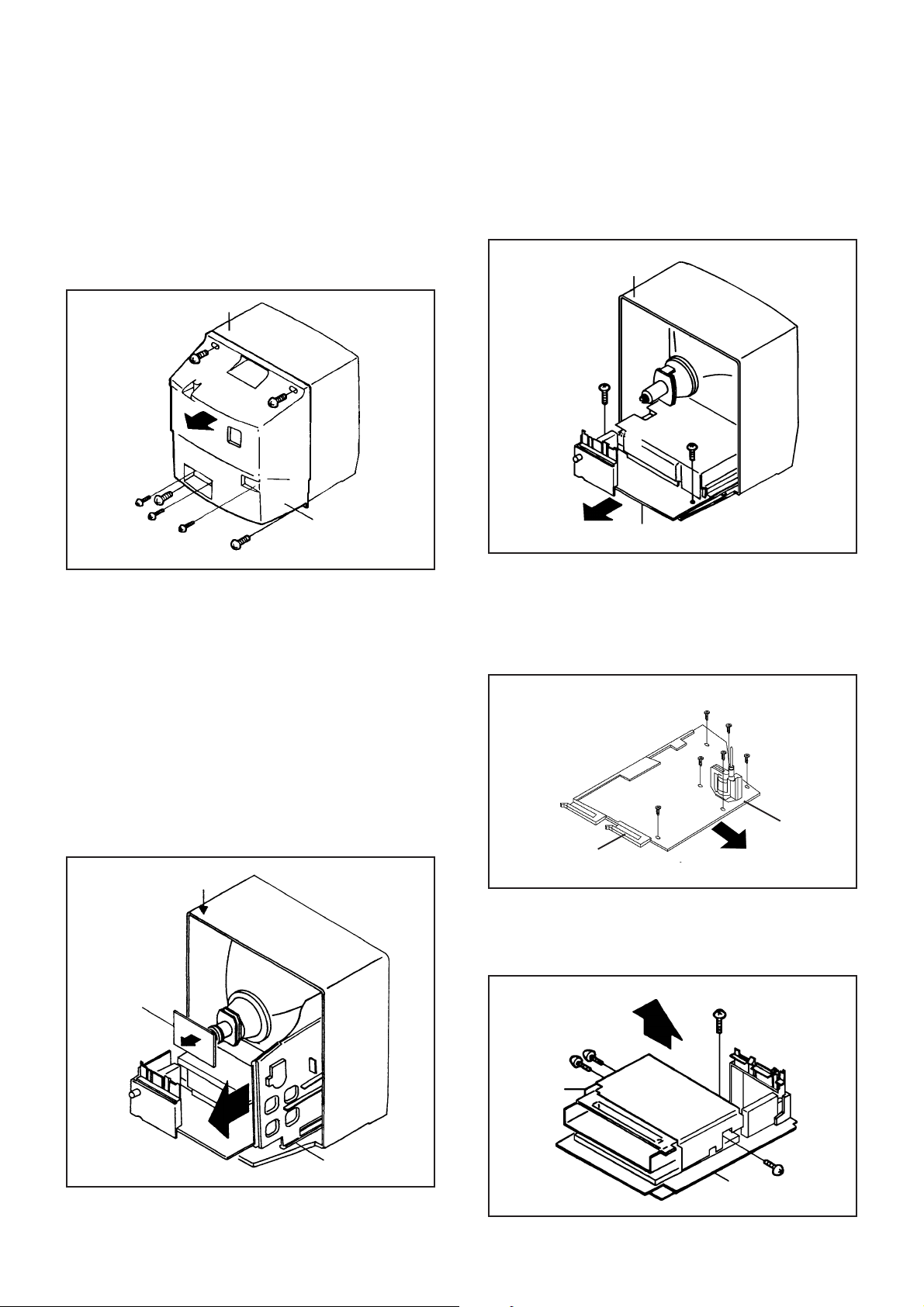

DISASSEMBLY INSTRUCTIONS

2.

REMOVAL OF DECK PARTS

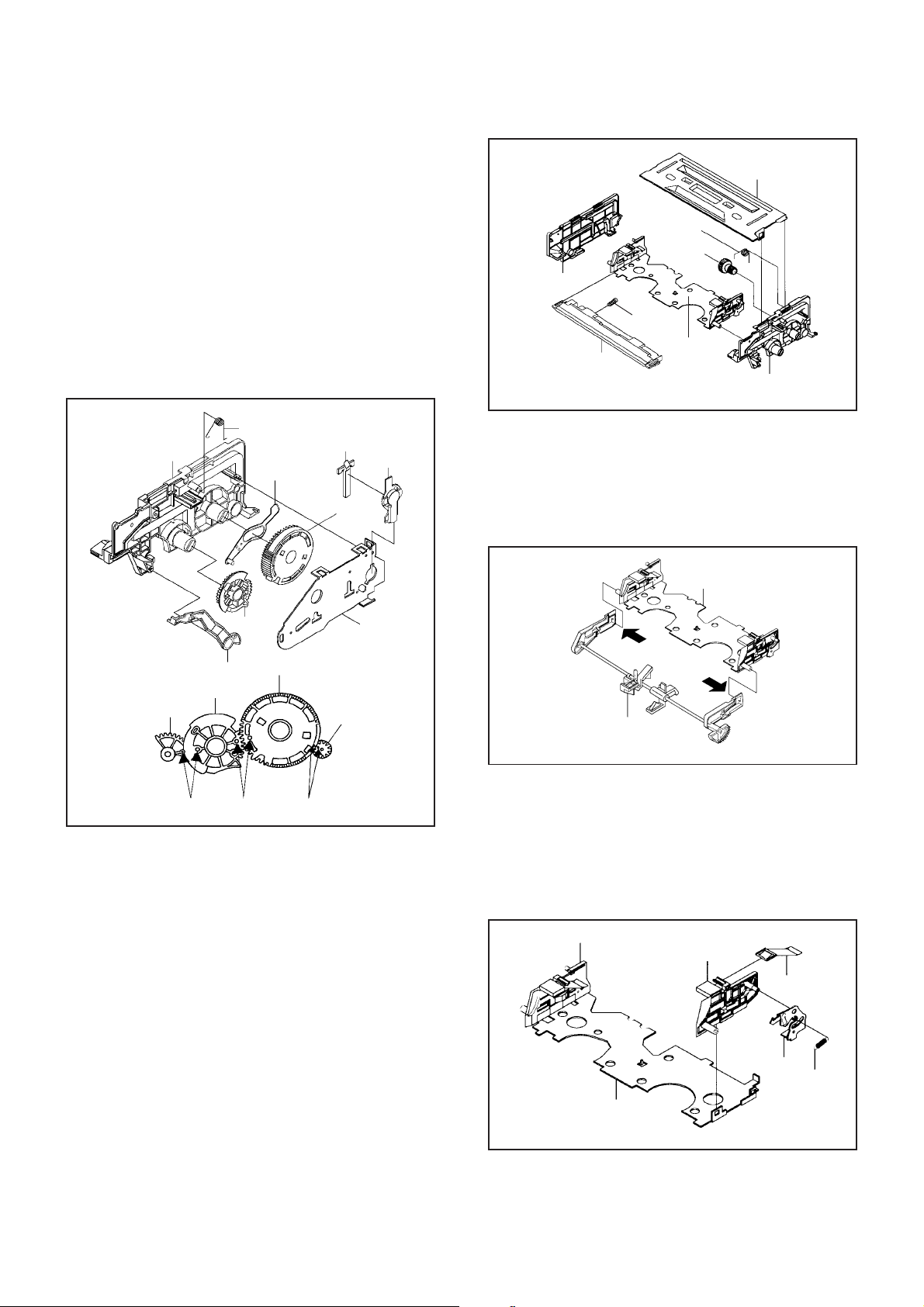

2-1: LINK GEAR (R) / CAM GEAR (Refer to Fig. 2-1)

1.

Unlock the support 1.

2.

Remove the BOT Sensor Cover and BOT Reflector.

3.

Unlock the 3 supports 2.

4.

Remove the Side Bracket R2 and Spring Earth.

5.

Remove the Flap Lever, Link Gear (R) , Cam Gear Ass'y

and BOT Lever.

NOTES

When installing the BOT Lever, insert the BOSS into the

1.

hole of Link Gear (R).

When installing the Link Ass'y 3 and Link Gear (R), align

2.

the timing Marks.

2

Side Bracket L

1

Tape Piece

Guide

2

Bracket R Spring

Joint Gear

Rec Lever

Spring

Cassette

Holder Ass'y

1

Top Bracket

3

2

Side Bracket R1

2

Fig. 2-2

Spring Earth

Side Bracket R1

Link Ass'y 3

Marker

Link Gear (R)

Flap Lever

Link Gear (R)

Marker

BOT Reflector

BOT Lever

Cam Gear Ass'y

Cam Gear Ass'y

Marker

BOT Sensor

Cover

2

2

Side Bracket R2

Joint Gear

2

2-2:TOP BRACKET / TAPE PIECE GUIDE

(Refer to Fig. 2-2)

1. Remove the Rec Lever Spring.

2. Unlock the 2 supports 1.

3. Remove the Tape Piece Guide.

4. Unlock the 4 supports 2.

5. Remove the Top Bracket.

6. Remove the Side Bracket R1 and Side Bracket L.

7. Unlock the support 3.

8. Remove the Joint Gear.

9. Remove the Bracket R Spring.

1

Fig. 2-1

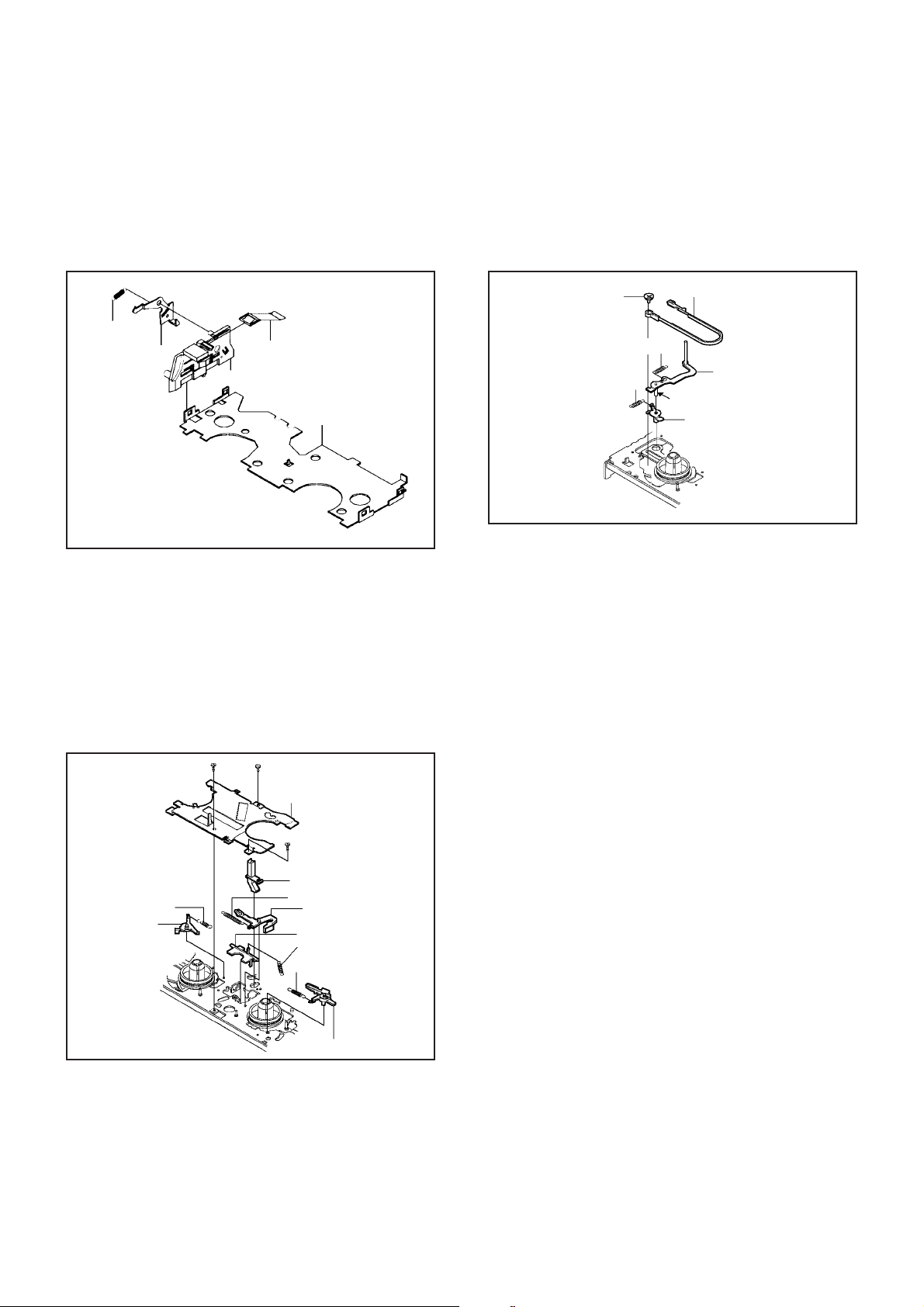

2-3: LINK ASS'Y 3 (Refer to Fig. 2-3)

1. After removing in the direction (A) of Link Ass'y 3,

remove the Link Ass'y 3 in the direction (B).

NOTE

Install the (B) first, then install the (A).

Cassette Holder Ass'y

(A)

(B)

Link Ass'y 3

2-4: CASSETTE SIDE R (Refer to Fig. 2-4)

1. Unlock the 2 supports 1.

2. Remove the Cassette Side R.

3. Remove the Pack Spring.

4. Remove the Locker Spring.

5. Unlock support 2.

6. Remove the Locker R.

Cassette Side L

Cassette Side R

Pack Spring

2

1

1

Fig. 2-3

B2-1

Locker R

Locker Spring

Cassette Holder Ass'y

Fig. 2-4

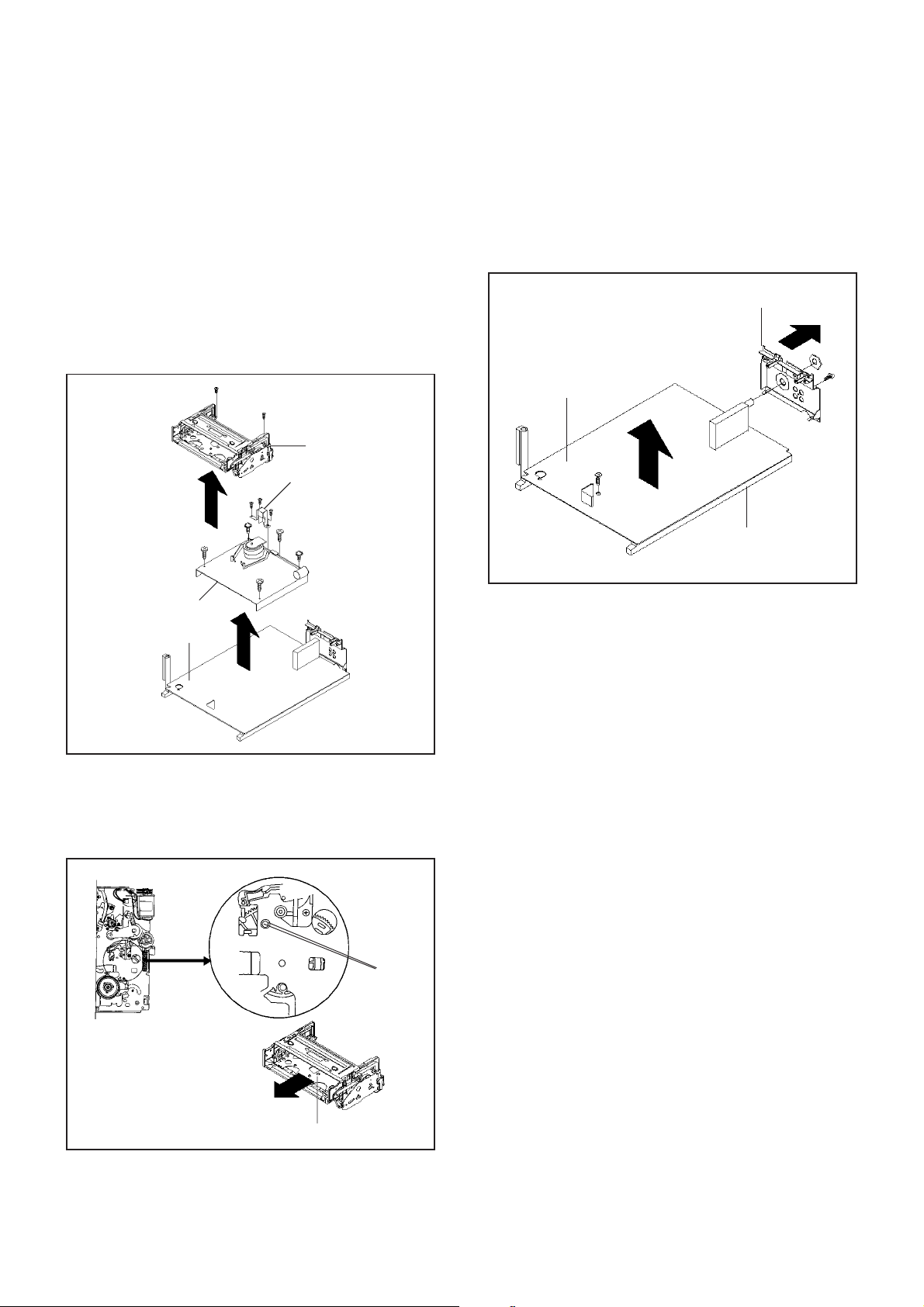

DISASSEMBLY INSTRUCTIONS

2-5: CASSETTE SIDE L (Refer to Fig. 2-5)

1. Unlock the 2 supports 1.

2. Remove the Cassette Side L.

3. Remove the Pack Spring.

4. Remove the Locker Spring.

5. Unlock the support 2.

6. Remove the Locker L.

Locker Spring

Locker L

2

1

1

Pack Spring

Cassette Side L

Cassette Holder Ass'y

Fig. 2-5

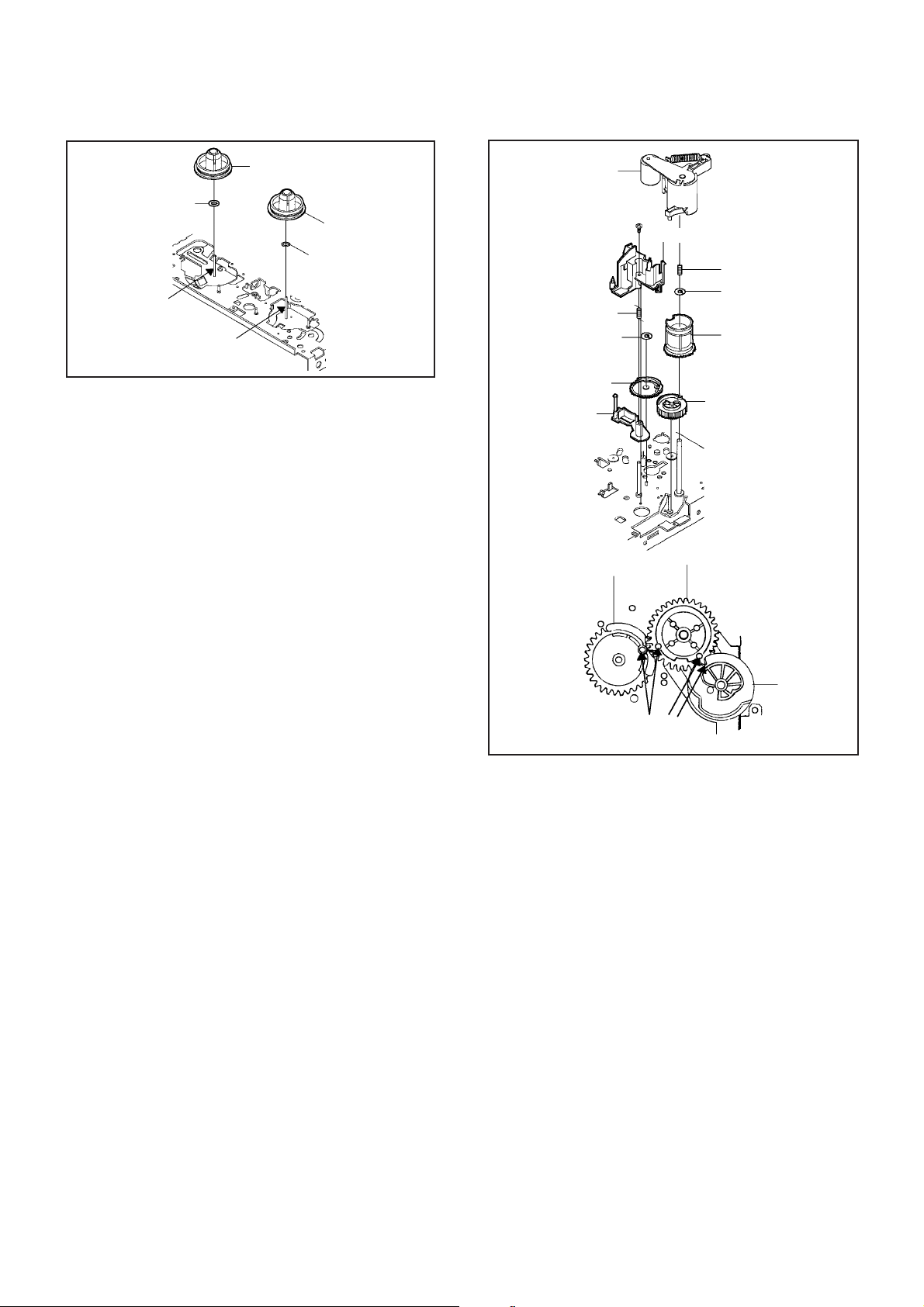

2-6: BRAKE BRACKET (Refer to Fig. 2-6)

1.

Remove the Main Brake Spring, S-S Brake Spring,

Joint Arm Spring and T-S Brake Spring.

2.

Remove the 2 screws 1.

3.

Remove the screw 2.

4.

Remove the Brake Bracket.

5.

Remove the Sub Brake S, Sub Brake T and Main Brake

T Ass'y.

6.

Remove the Joint Arm.

7.

Remove the Reflector LED 2.

1

1

Brake Bracket

2

Reflector LED 2

S-S Brake Spring

Sub Brake S

Main Brake Spring

Main Brake T Ass'y

Joint Arm

Joint Arm Spring

T-S Brake Spring

Sub Brake T

Fig. 2-6

2-7: TENSION BAND (Refer to Fig. 2-7)

1. Remove the Tension Arm Spring 1.

2. Remove the Tension Arm Spring 2.

3. Remove the Tension Adjust.

4. Remove the Tension Arm Ass'y.

5. Remove the Tension Band Ass'y.

6. Remove the Tension Lever 2 Ass'y.

Tension Adjust

Tension Arm Spring 2

Tension Arm Spring 1

Tension Band Ass'y

Tension Arm Ass'y

(A)

Tension Lever 2 Ass'y

Fig. 2-7

NOTE

1.2.Install the Tension Band Ass'y without twisting it.

Turbine Oil (Lubricating Grade #150) the area marked

with A in Fig. 2-7.

EX: KYOUDO Oil Sulaidasu #150

IDEMITSU Oil Super Multi #150

2-8: REEL DISK (Refer to Fig. 2-8)

1. Remove the Reel Disk S and Reel Disk T.

2. Remove the 2 polyslider washers.

NOTES

1.

Installation of Reel Disk after performing step 1, 2 and 3 in

section 2-7 of DISASSEMBLY INSTRUCTIONS.

2.

The Height Adjustment washers are sometimes

attached to the back of the Reel Disk.

3.

Clean the Reel Disk Shaft and put in height adjusting

washers.

4.

Be careful not to damage the Tension Band Ass'y at the

time of removal and installation.

5.

Be careful not to scratch the Reel Disk Shaft with the

polyslider washer or the tool at the time of removal and

installation.

6.

After oiling (Lubricating Grade #150) the Reel Disk Shaft,

install the new Reel Disk S and Reel Disk T again.

EX: KYOUDO Oil Sulaidasu #150

IDEMITSU Oil Super Multi #150

7.8.After installation, adjust the height of the Reel Disk.

(Refer to item 1-1 of MECHANICAL ADJUSTMENTS)

After installation, adjust and confirm the tension post position.

(Refer to item 1-2 of MECHANICAL ADJUSTMENTS)

B2-2

DISASSEMBLY INSTRUCTIONS

Reel Disk S

Polyslider Washer

Reel Disk T

Polyslider Washer

(A)

(A)

Fig. 2-8

PINCH ROLLER / CASSETTE OPENER

2-9:

(Refer to Fig. 2-9)

Unlock the support 1.

1.

Remove the Pinch Roller.

2.

Remove the screw 2.

3.

Unlock the 2 supports 3.

4.

Remove the Cassette Opener.

5.

Remove the Spring P5 and Arm P5 Ass'y.

6.

Remove the Cam Gear, Polyslider Washer 4, Spring

7.

Cam Pinch and Cam Pinch Roller.

Remove the Polyslider Washer 5 and Cam P5.

8.

NOTES

1.2.Do not touch the Pinch Roller. (Use gloves.)

When installing the Cam P5, Cam Pinch Roller and Cam

Gear, align the timing marks.

Pinch Roller

Spring P5

Polyslider Washer 5

Cam P5

Arm P5 Ass'y

Cam P5

2

3

Cassette Opener

1

3

Cam Gear

Cam Pinch Roller

Spring Cam Pinch

Polyslider Washer 4

Cam Pinch Roller

Cam Gear

Marker

Fig. 2-9

2-10: AUDIO CONTROL HEAD (Refer to Fig. 2-10)

1.

Remove the 3 screws 1.

2.

Remove the 3 Audio Control Head Springs.

3.

Remove the Audio Control Head.

NOTES

1.2.Do not touch the head by any means when replacing the

Audio Control Head. (Use gloves.)

After replacement, confirm the following adjustments.

a. MECHANICAL ADJUSTMENTS: ITEM 2-2

b. MECHANICAL ADJUSTMENTS: ITEM 2-3

B2-3

Loading...

Loading...