Memorex MT1191V Schematic

Service Manual

MT1191V

19” Color Television

THIS SERVICE MANUAL IS FOR MT1191V SUFFIX A , B ,

C, D AND E CRT USAGE

V451 5721-015ST51N

DY501 4993-118

SUFFIX A SUFFIX B SUFFIX C SUFFIX D SUFFIX E

(51GGD95X)

5721-51CN020T

(510UEB22DY)

4993-060 4993-122 4993-119 4993-123

5721-028TT48N

(A48LRH93X (W))

5721-029NT48N

(A48LSD095X)

5721-031ZT48N

(A48LGS30X)

FEATURES

w On-screen graphics guide you through setup features and operations

w Automatic programming of channels allows easy selection of stations available in your viewing

area

w Sleep timer programs the TV to turn itself off at a preset time

w One day timer programs the TV to come on once at a preset time

w Weekly timer programs the TV to come on at a preset time every day

w 26 button infrared remote control allows remote operation

w VHF/UHF/CATV tuning allows reception of standard broadcasts or cable TV channels

w Closed caption decoder displays captions or half-screen text

w V-Block function

SPECIFICATIONS

AC Power Input: 120V, 60Hz

AC Power Consumption: 98Watts

Chassis Construction: IC Solid State

Picture Tube: 19” ( measured diagonally )

Speaker: 3.5 x 2 in (90 x 50 mm) Oval, 8 ohms

Tuner: 181 Channel, Freq. Synthesized

Remote Control: Infrared, Direct Access

26 Key, 2 “AA” batteries

Receiving Channels:

VHF 2 - 13

UHF 14 - 69

CATV

Mid Band 14 - 22

Super Band 23 - 36

Hyper Band 37 - 65

Ultra Band 66 - 94, 100 - 125

Sub Mid Band 1, 95 - 99

Cabinet: Monitor Style

Antenna Input Impedance 75 ohm (VHF/UHF) Coaxial Input

CAUTION:TO PREVENT ELECTRIC SHOCK, MATCH WI DE BLADE OF PLUG TO WIDE

SLOT, FULLY INSERT.

- 1 -

IMPORTANT SERVICE SAFETY INFORMATION

Operation of receiver outside of cabinet or with back remov ed involv es

a shock hazard. Work on these models should only be performed by

those who are thoroughly familiar with precautions necessary when

working on high voltage equipment.

Exercise care when servicing this chassis with power applied. Many

B plus and high voltage RF terminals are exposed which, if carelessly

contacted, can cause serious shock or result in damage to the chassis.

Maintain connecting ground lead connections between chassis,

escutcheon, picture tube dag and tuner cluster when operating

chassis.

These receivers have a “Polarized” AC line cord. The AC plug is

designed to fit into standard AC outlets in one direction only. The

wide blade connects to the “ground side” and the narrow blade

connects to the “hot side” of the AC line. This assures that the TV

receiver is properly grounded to the house wiring. If an extension

cord must be used, make sure it is of the “polarized” type.

When it is necessary to make measurements or tests with AC power

applied to the receiver chassis, an Isolation T ransf ormer must be used

as a safety precaution and to prev ent possible damage to transistors.

The Isolation Transformer should be connected between the TV line

cord plug and the AC power outlet.

Certain HV failures can increase X-ray radiation. Receivers should

not be operated with HV levels exceeding the specified r ating for their

chassis type. The maximum operating HV specified for the chassis

used in these receivers is 25 KV ± 1.0KV at zero beam current with a

line voltage of 120V AC. Higher voltage may also increase possibility

of failure in HV supply.

It is important to maintain specified values of all components in the

horizontal and high voltage circuits and anywhere else in the receiver

that could cause a rise in high voltage, or operating supply voltages.

No changes should be made to the original design of the receiver.

PROTECT YOUR CUSTOMER

1. Inspect all lead dress to make certain that leads are not pinched

or that hardware is not lodged between the chassis and other

metal parts in the receiver.

2. Replace all protective devices such as non-metallic control knobs,

insulating fishpapers, cabinet backs, adjustment and compartment covers or shields, isolation resistor capacitor networks,

mechanical insulators, etc.

3. T o be sure that no shoc k hazard e xists, a chec k f or the presence

of leakage current should be made at each exposed metal part

having a return path to the chassis (antenna, cabinet metal, screw

heads, knobs and/or shafts, escutcheon, etc.) in the following

manner.

Plug the AC line cord directly into a 120V AC receptacle . (Do not use

an Isolation Transformer during these checks) All checks must be

repeated with the AC line cord plug connection rev ersed. (If necessary,

a non-polarized adapter plug must be used only for the purpose of

completing these checks.)

If available , measure current using an accurate leakage current tester.

(Use Standard Item No. 25086,21641) Any reading of 0.4 mA or more

is excessive and indicates a potential shock hazard which must be

corrected before returning the receiver to the owner.

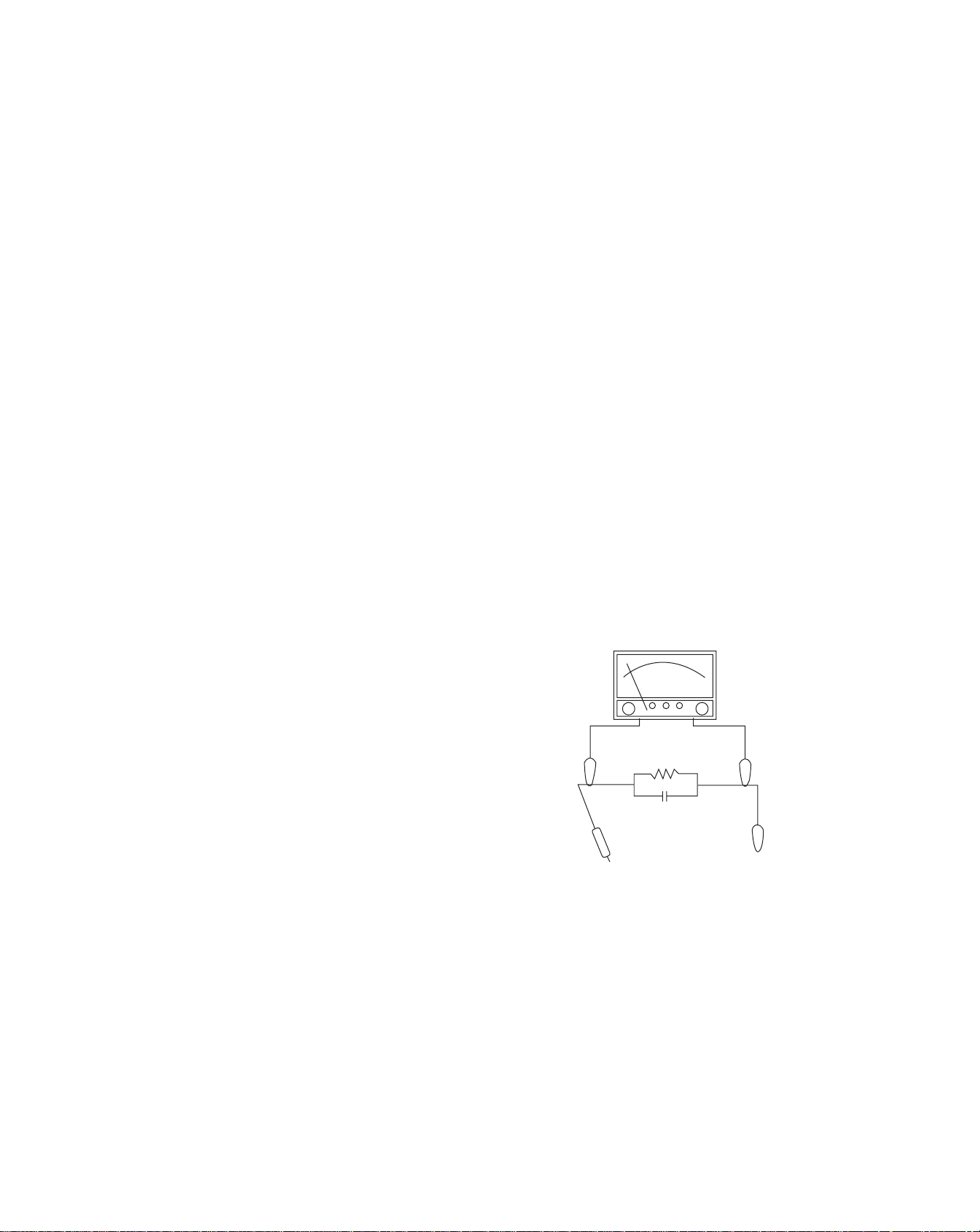

If a reliable leakage current tester is not availab le, this alternate method

of measurement should be used. Using tw o clip leads, connect a 1500

ohm, 10 watt resistor paralleled by a 0.15 MF capacitor in series with

a known earth ground, such as a water pipe or conduit and the metal

part to be checked. Use a VTVM or VOM with 1000 ohms per volt, or

higher sensitivity to measure this AC voltage drop across the resistor .

Any reading of 0.61 volt RMS or more is excessive and indicates a

potential shock hazard which must be corrected before returning the

receiver to the owner .

Components shown in the shaded areas on the schematic diagram

or identified by the safety mark in the replacement parts list should

be replaced only with exact Factory recommended replacement parts.

The use of unauthorized substitute parts may create shock, fire,

X-radiation or other hazard.

To deter mine the presence of high voltage, use an accurate high

impedance HV meter connected between second anode lead and

the CRT dag grounding device. When servicing the High Voltage

System remove static charge from it by connecting 10K ohm resistor

in series with an insulated wire (such as a test probe) between picture

tube dag and 2nd anode lead (AC line cord disconnected from AC

supply).

The picture tube used in this receiver employs integral implosion

protection. Replace with tube of the same type number f or continued

safety. Do not lift picture tube by the neck. Handle the picture tube

only when wearing shatter-proof goggles and after discharging the

high voltage completely. Keep others without shatter-proof goggles

away .

When removing springs or spring mounting parts from tuner, tuner

cluster or chassis, shatter-proof goggles must be worn. Keep others

without shatter-proof goggles away.

SAFETY INSPECTION

Before returning the receiver to the user, perform the following safety

checks:

AC

VOLTMETER

1500 OHMS

0.15 µF

TEST

PROBE

TO EXPOSED

METAL PARTS

TO KNOWN

EARTH GROUND

X-RAY PROTECTOR CIRCUIT CHECK

PERFORM WHENEVER HIGH VOLTAGE CIRCUITRY OR POWER

SUPPLY CIRCUITRY IS SERVICED.

1. Plug the AC Line Cord (P1) into a AC 120V, 60Hz receptacle.

2. Turn the Power Switch (S101) on and wait for about 10 minutes.

3. Connect the antenna leads to the EXT. Antenna Terminal (TE1)

and select a broadcasting station.

4. Connect DC Digital Voltmeter to TP11 (positive lead) and TP4

(negative lead).

5. Apply DC 11V between TP11 and TP9 from external equipment.

6. If picture and sound do not disappear, check IC301, D552, D553,

D554, R554, R555, R556, R557, C555 and C556.

- 2 -

te Control to select the

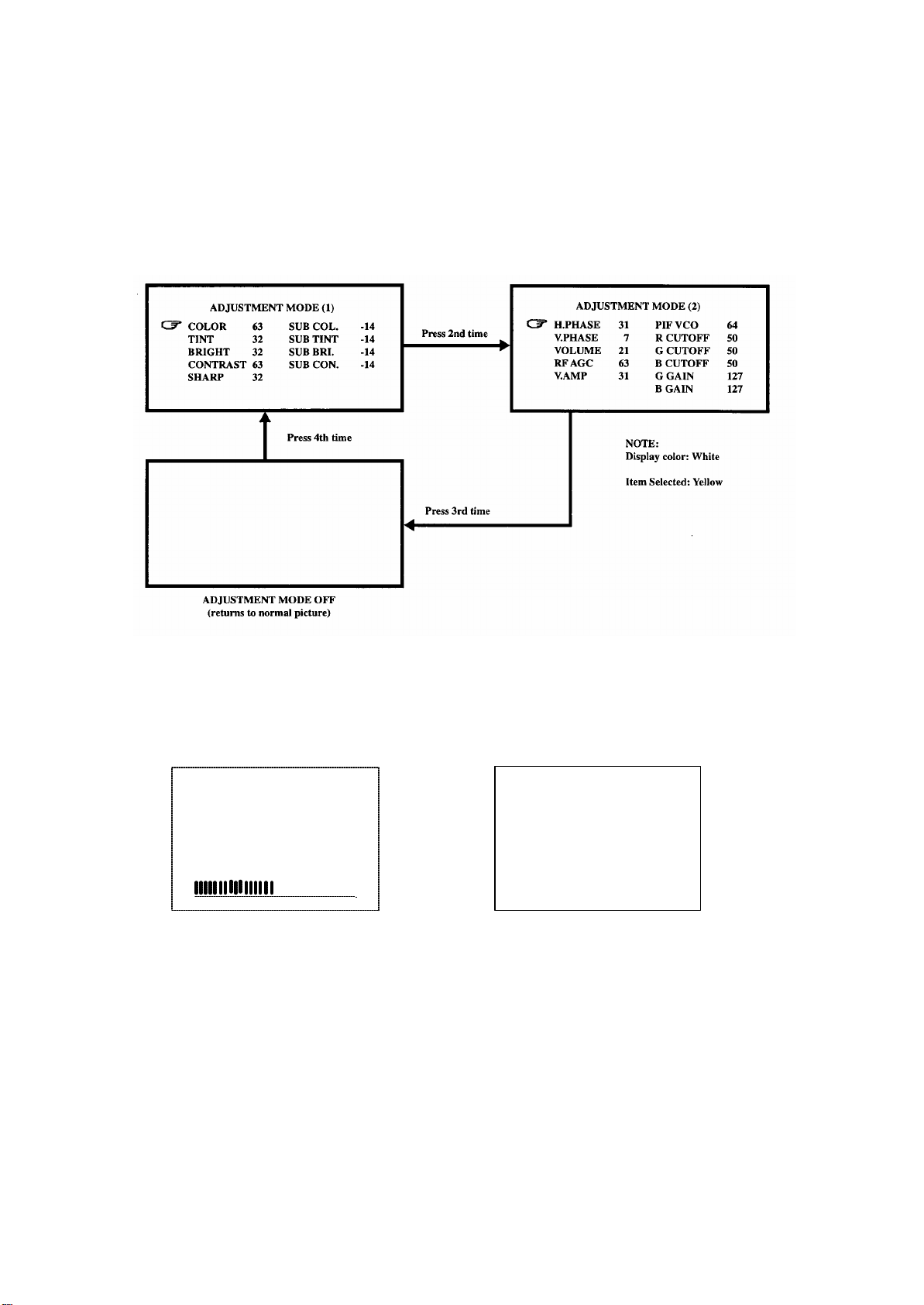

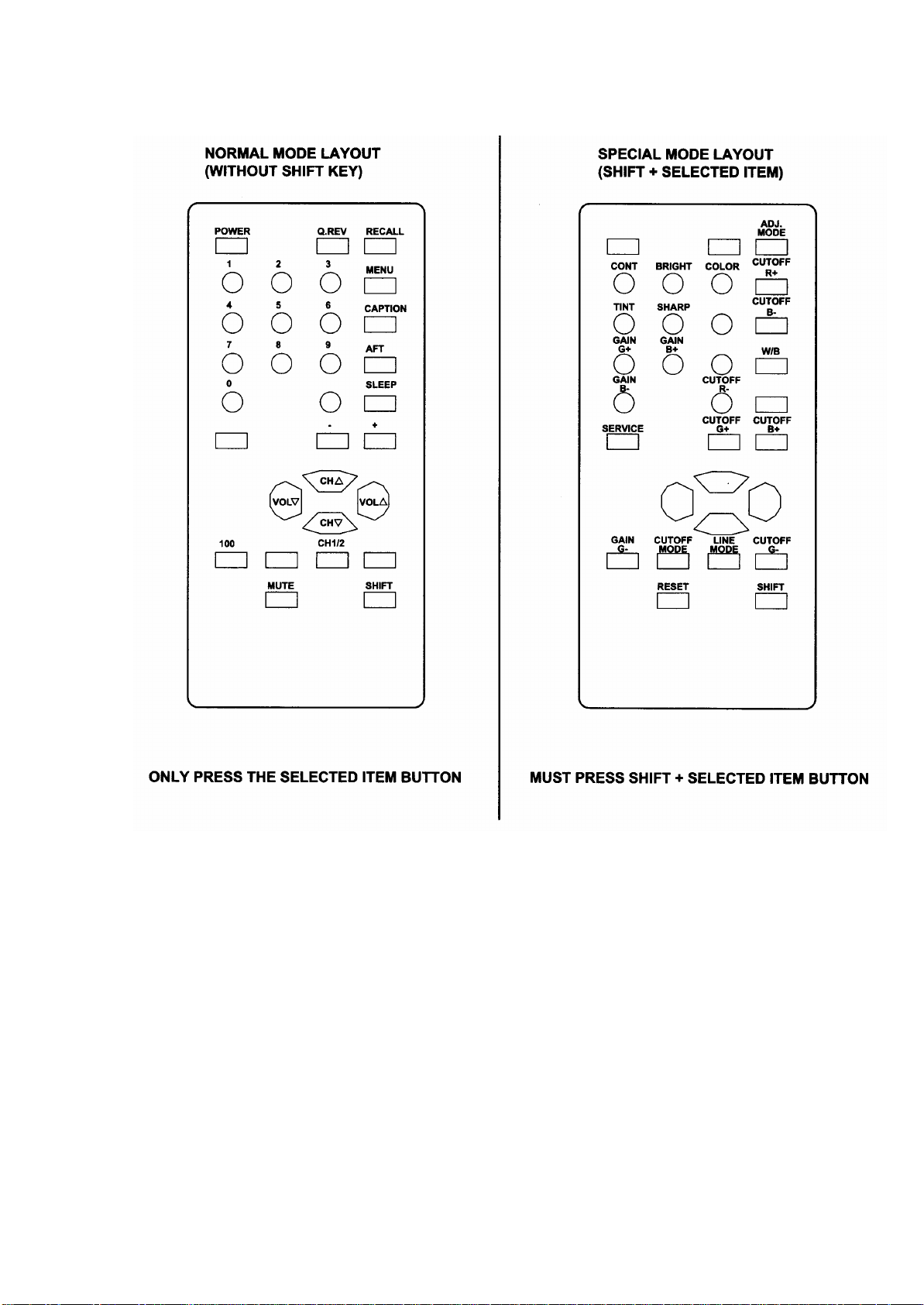

( ADJUSTMENT BY REMOTE CONTROL )

ADJUSTMENT MODE

The following adjustment items can be performed from menus by Remote Control as shown

below :

NOTE: The button combination and position on the Remo

adjustment items is given on page 4.

1. Press the SHIFT + ADJ. MODE buttons on the Remote Control simultaneously to bring up

the adjustment mode menu screens shown below.

2. From the menu screen, press the + or - button on the Remote Control to select the item to

be adjusted.

3. Press the MENU button on the Remote Control to enter adjustment mode for the item

selected, and the display shown below appears :

OR

COLOR 32

RED CUTOFF 127

Example:

4. Use the + or - button on the Remote Control to adjust the data for the item selected.

5. When adjustment has been completed, press the SHIFT + ADJ. MODE buttons on the

Remote Control simultaneously to return to the main menu.

- 3 -

REMOTE CONTROL LAYOUT

VIDEO

VIDEO

- 4 -

IC, TRANSISTOR AND CRT COMPLEMENT

INTEGRATED CIRCUITS

IC101 TA87C-B2 Microcomputer

IC102 M24CO2B EEPROM

IC301 TA1268N IF/Video/Chroma/Deflection

IC311 NJ7809FA Voltage Regulator

IC501 AN5512 Vertical Deflection Output

IC601 STR30130 AVR

IC671 NJ7805LD Voltage Regulator and Reset

TRANSISTORS

Q101 DTC143ZS Vertical Synchronizing

Q102 2SC945(P) Horizontal Synchronizing

Q173 2SC945(P) SD Signal Buffer

Q301 2SC945(P) SIF Signal Buffer

Q302 2SA733(P) Video Buffer Amplifier

Q303 2SC945(P) Video Out

Q351 DTC143ZS Service Mode Switching

Q451 2SC1573A(R) Red Color Driver

Q452 2SC1573A(R) Blue Color Driver

Q453 2SC1573A(R) Green Color Driver

Q551 2SC1473A(R) Horizontal Driver

Q552 2SD1877 Horizontal Driver

Q601 2SC945(P) Power On/Off Relay Driver

Q801 2SC945(P) Audio Amplifier

Q802 2SA950(0) Audio Amplifier

Q803 2SC2120(0) Audio Amplifier

PICTURE TUBE

V451 51GGD95X CRT (SUFFIX A) V451 A48LRH93X(W) CRT (SUFFIX C)

V451 510UEB22(DY) CRT (SUFFIX B) V451 A48LS D095X CRT (SUFFIX D)

V451 A48LGS30X CRT (SUFFIX E)

CHASSIS REMOVAL

1. Remove 4 screws (177) from Cabinet Back (AB) and remove Cabinet Back from rear.

2. Discharge anode lead at CRT chassis ground through a 10kohm resistor.

3. Disconnect anode lead from CRT.

4. Disconnect CRT Socket P.C. board (PCB -2) from CRT(V451).

5. Disconnect 3 connectors (CN501 (DY501), CN601 (L601) and LCN801) from Main P.C.

board (PCB -1).

6. When replacing chassis, reverse the above procedure making certain that all leads are

fastened in their original places.

CRT REMOVAL

CAUTION: Wear shatterproof goggles and exercise proper handling precautions when working

around high vacuum picture tubes.

1. Remove chassis per instructions under CHASSIS REMOVAL.

2. Remove Convergence Magnet Assembly (MG451) from neck of CRT.

3. Remove Deflection Yoke (DY501) from neck of CRT

4. Remove 3 wedges (142) from CRT

5. Remove Degaussing Coil (L601) from CRT

6. Remove braid wire (331) and spring (158) from CRT

7. Lay cabinet face down on some protective material.

8. Remove 4 CRT mounting screws (156).

9. Remove CRT from Cabinet Front (AA).

10. To install new CRT, reverse above procedure.

11. Perform purity and convergence adjustments.

- 5 -

INSTALLATION AND SERVICE INSTRUCTION

CAUTION: Use an isolation transformer when performing any service on this chassis.

SHUTDOWN CIRCUIT: When the high voltage rises, there are simultaneous voltage increase

developed at terminal 6 of the Horizontal Output Transformer ( T671 ) and applied to pin 29 of IC301. If

excessive high voltage is produced, the increased voltage developed exceeds the rating of zener diode

D552 causing the Horizontal Oscillator to stop functioning and the high voltage system to shut down.

AFT ( AUTOMATIC FINE TUNING ) ADJUSTMENT

1. Remove JP200. (See Figure 1 for positioning)

2. Connect positive wire of TV signal Generator (NTSC signal, 45.75MHz, 80dBu ) to JP199 and

negative wire of TV Signal Generator to TP4.

3. Connect wire (+) of DC Digital Voltmeter to TP6 and wire (-) to TP4.

4. Adjust T202 so that the DC Digital Voltmeter reading is 2. 5V ± 0.2V.

5. Re insert JP200 and put solder.

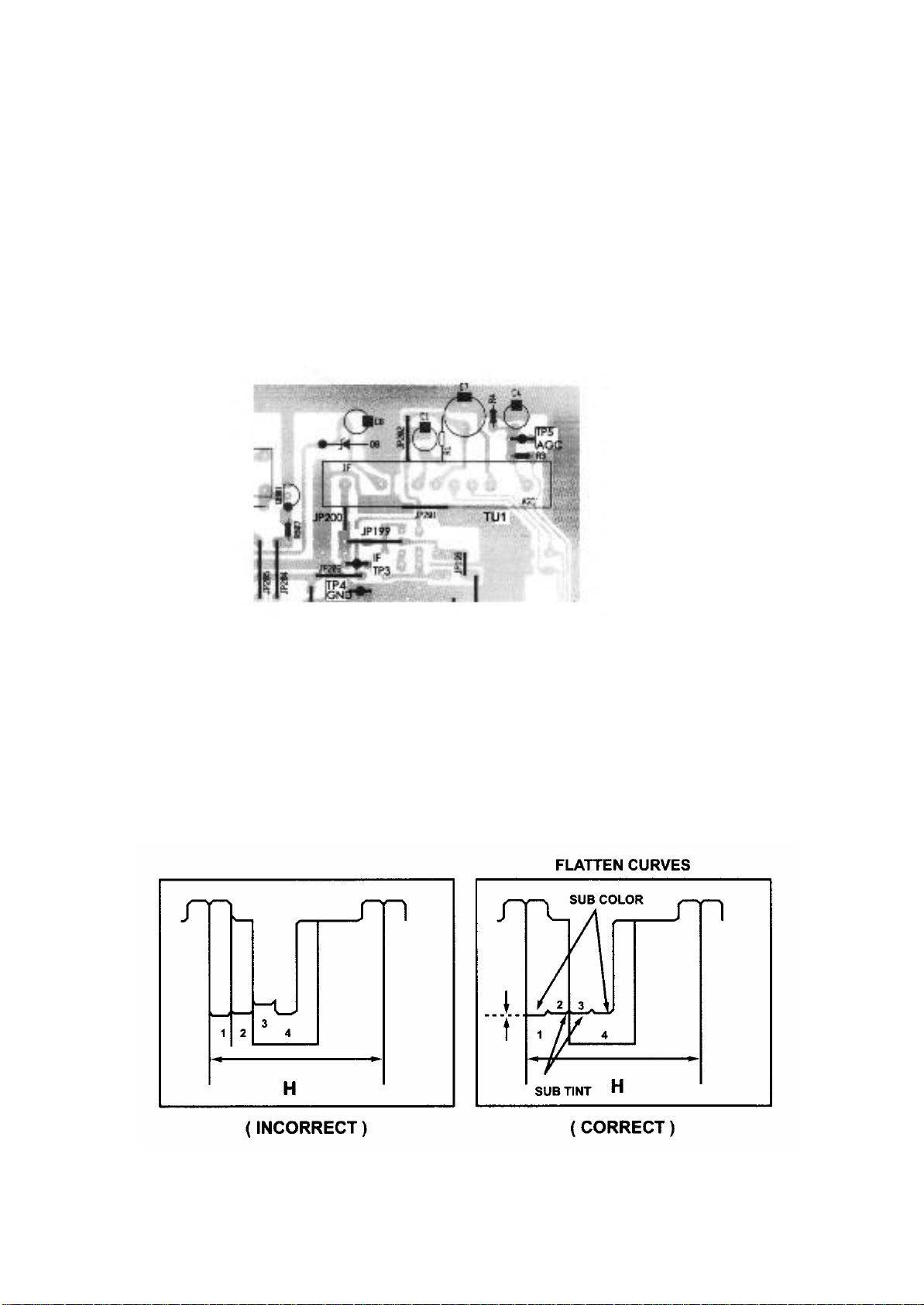

FIG. 1

SUB TINT ADJUSTMENT

1. Connect TV Test Pattern Generator (NTSC signal, Color Bar signal, 70dB u , channel 6) to EXT.

Antenna Terminal (TE1) through TV Channel Signal Generator.

2. Connect positive lead of Oscilloscope to TP14 and negat ive lead to TP10.

3. Connect EXT. trigger of Oscilloscope to R463.

4. Set Tint control to center position. (by Remote Control).

( NOTE: For steps 5, 6 and 7 below, refer to page 3 for Adjustment By Remote Control Method).

5. Go to Adjustment Mode (1) by remote control.

6. Select SUB TINT from Adjustment Mode (1) menu screen.

7. Adjust SUB TINT level (by using + or - button on remote control) so that waveform is the same as

shown in Figure 2.

FIG. 2

- 6 -

Loading...

Loading...