Page 1

042.920.000

13.11.07

Betriebsanleitung

Operating Instructions

Instructions de service

Instrucciones de uso

Istruzioni per l’uso

Kullanma Kýlavuzu

Instruções de utilização

操作手冊 MLT WESCO

/ 1

m

deutschenglishfrançaisespañolitaliano

türkçe

português

中文

Page 2

18

Preface / Index

Preface

We are pleased that you selected a MEMMINGER-IRO product. The more familiar you make yourself with this product,

the better the results that you achieve will be.

We therefore strongly recommend the following:

Please read these operating instructions carefully before putting the device into operation. It contains important information and notes that must be observed when using the device.

Index

Preface......................................................................................................................................................................18

Index .........................................................................................................................................................................18

Safety Notes .............................................................................................................................................................19

Accessories Supplied .............................................................................................................................................20

Function ...................................................................................................................................................................20

Unit Components .....................................................................................................................................................21

Settings ....................................................................................................................................................................22

Initial Commissioning of the MLT WESCO ................................................................................................................ 22

m/min oder yd/min auswählen ................................................................................................................................... 22

Switching the MLT WESCO on .................................................................................................................................. 22

Switching the MLT WESCO off .................................................................................................................................. 22

Mounting ..................................................................................................................................................................23

Installing the revolution sensor and magnet holders .................................................................................................23

Connecting the MLT WESCO to the revolution sensor .............................................................................................23

Operation ..................................................................................................................................................................24

Threading ..................................................................................................................................................................24

Starting the measuring process ................................................................................................................................. 24

Measuring the machine speed ..................................................................................................................................25

Displaying the last or the penultimate measured value ............................................................................................. 25

Measuring the yarn length ......................................................................................................................................... 26

Setting the number of machine revolutions to be measured ....................................................................................26

Displaying the last or the penultimate measured value ............................................................................................. 26

Selecting the Yarn Tension measuring modes........................................................................................................... 27

Measuring the yarn tension .......................................................................................................................................28

Displaying the last or the penultimate measured value ............................................................................................. 28

Measuring the yarn speed ......................................................................................................................................... 29

Displaying the last or the penultimate measured value ............................................................................................. 29

Calibration .................................................................................................................................................................30

Maintenance ............................................................................................................................................................. 31

Charging the batteries ...............................................................................................................................................31

Cleaning the MLT WESCO ........................................................................................................................................31

Replacing the batteries .............................................................................................................................................. 32

Inserting the batteries ................................................................................................................................................ 32

Dimension Drawing ................................................................................................................................................. 33

Technical Data .........................................................................................................................................................33

Declaration of Conformity ......................................................................................................................................34

Page 3

19

english

Safety Notes

The MLT WESCO yarn meter has exclusively been designed for measuring the yarn infeed and the yarn tension in textile machines.

We would like to point out that we cannot be held liable for any damage or operating failures arising due to

an incorrect operation or improper device handling.

The metering roller must be able to rotate freely, without any obstruction.

The MLT WESCO contains electronic components which can be destroyed by electrostatic discharge when touched. Therefore, all measures to avoid such discharge, e.g. by means of touching

an earthed object (machine or earth contact of a plug, etc.), must be taken prior to opening the

device.

All contained components may only be replaced by original MEMMINGER-IRO spare parts.

NOTE!

Before using the MLT WESCO for the rst time, or if it hasn't been used for a while, the unit has to be

charged.

i

Page 4

20

Accessories Supplied / Function

Accessories Supplied

The MLT WESCO yarn meter is supplied together with

the following components:

1 - MLT WESCO yarn meter

2 - Carry case

3 - Battery charger with US plug and EU,

UK, AUST. adapter

4 - Revolution sensor with cable and plug

5 - Data transmission cable with plug

6 - Holder for revolution sensor

7 - Magnet with holder

8 - Calibration set

Function

The MLT WESCO yarn meter is a stand alone, electronic

hand-held measuring device for the measurement and

digital display of the machine speed, yarn consumption,

yarn tension and yarn speed in circular and at knitting

machines as well as in body, stocking, hosiery and sock

machines.

Application advantages of the MLT WESCO yarn

meter:

Measurement of the yarn consumption in meters or

yards per machine revolution.

Measurement of the yarn infeed in any knitting system,

with and without positive yarn infeed.

Enables quick and easy adjustments, to repeat the

same fabric quality on different machines with identical

gauge but differing cylinder diameters.

Measurement of the yarn tension.

Measurement of the yarn speed.

Option for determining the yarn consumption of indi-

vidual fabric qualities.

The values can be measured and displayed without

having to switch the machine off.

The device is stand alone and transportable.

All required accessories are included in the carry

case.

MEMMINGER-IROGMBH

D-72277DORNSTETTEN

7

1

2

3

4

5

6

8

Page 5

21

english

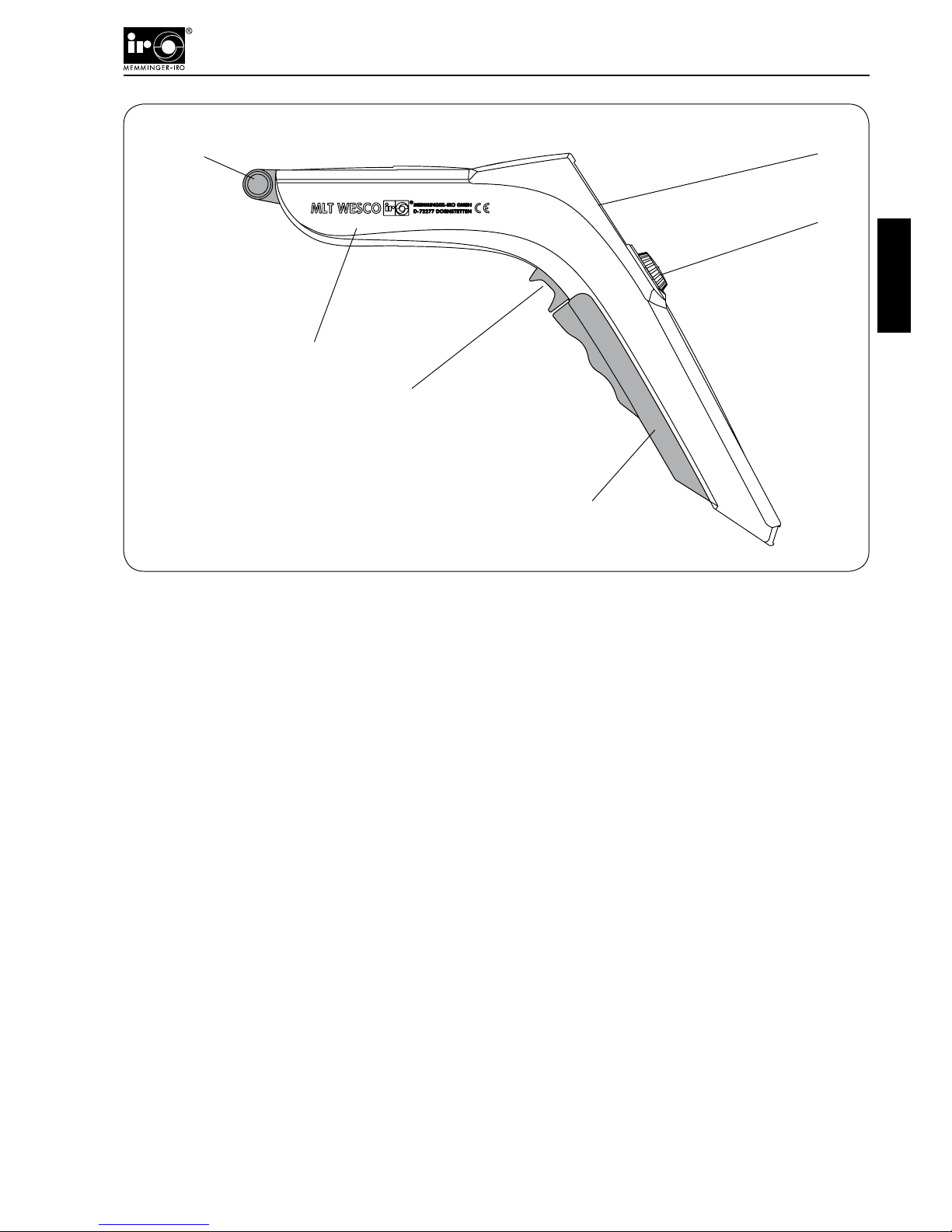

Unit Components

1

6

5

4

3

2

Unit Components

The MLT WESCO offers four selectable MEASURING MODES:

MACHINE SPEED

YARN LENGTH

YARN TENSION

YARN SPEED

The YARN LENGTH mode can be set between:

1 to 100 machine revolutions

The YARN TENSION mode can be set to:

Normal = current yarn tension

Average = average yarn tension

Peak = maximum yarn tension

Yarn tension range: 0 to 50 cN

1 - Housing

2 - Yarn engagement swivel arm

3 - Display

4 - Rotary knob

5 - Swivel arm release handle

6 - Locking knob

Page 6

22

Switching the MLT WESCO off

Press the rotary knob (4) for approx. 2 seconds.

"OFF" is shown on the display.

The MLT WESCO is switched off.

NOTE!

The MLT WESCO is automatically switched off

after approx. 5 minutes of disuse.

NOTE!

The MLT WESCO is automatically switched

off after approx. 15 minutes of a continuous

measuring process.

Settings

Switching the MLT WESCO on

Switch the MLT WESCO on by a short press of the

rotary knob (4).

The previously set measuring mode, e.g. "YARN

LENGTH", is shown on the display.

"MEASURE" ashes on the display.

Initial Commissioning of the MLT

WESCO

For measuring yarn lengths, the MLT WESCO can both

be set to a metrical length unit (m/min) as well as to an

English length unit (yd/min).

m/min oder yd/min auswählen

Switch the MLT WESCO on by pressing the rotary

knob for at least 2 seconds.

The software version is shortly shown on the display.

Then, "SET mode" is displayed.

"m/min m" or "yd/min inch" ashes on the display.

Select the desired "m/min m" or "yd/min inch" setting

by turning the rotary knob to the left or the right.

Conrm your selection by a short press of the rotary

knob.

i

i

Page 7

23

english

max. 5 mm

NOTE!

The Symbol is shortly shown in the display

at each machine revolution, when the magnet

passes the revolution sensor.

Connecting the MLT WESCO to the

revolution sensor

Plug the revolution sensor (4) into the socket of the

MLT WESCO.

NOTE!

Press the release knob on the bottom when

unplugging the revolution sensor.

4

6

7

Installing the revolution sensor and

magnet holders

Mount the revolution sensor holder (6) to the machine

frame.

Mount the magnet holder (7) to the take-down or the

cylinder drive ring together with the magnet.

NOTE!

The maximum clearance between the magnet

and the revolution sensor must not exceed 5

mm.

Mounting

i

i

i

Page 8

24

NOTE!

During the measuring process, the MLT WESCO

must be held still and straight.

ATTENTION!

The measuring process is stopped as soon

as the swivel arm release handle is released

or no longer pressed.

NOTE!

The measuring process must be repeated for

further measurements.

Operation

Threading

Engage the yarn on the roller with the help of the swivel

arm.

Starting the measuring process

Press the swivel arm release handle. The arm then

swivels into the measuring position together with the

yarn. In this position the yarn is automatically positioned

over the tension force sensor.

Press the swivel arm release handle to the limit stop

and keep it pressed. The measurement is started.

The measured value in units of the preset system of

measurement (e.g. m or inch per revolution) is shown

on the display.

i

i

!

Page 9

25

english

Measuring the machine speed

Connect the MLT WESCO to the revolution sensor.

Apply a short press to the rotary knob to access the

"selection menu":

MACHINE SPEED

YARN LENGTH

YARN TENSION

YARN SPEED

Turn the rotary knob to the right or left until "MACHINE

SPEED" ashes on the display.

Press the rotary knob. The "MACHINE SPEED" menu

is selected.

"MEASURE" ashes on the display.

Press the swivel arm release handle and keep it

pressed. The measurement is started.

"MEASURE" ashes on the display and the " " symbol

ashes upon each machine revolution.

Furthermore, the display shows dots running from the

left to the right during the measuring process until the

machine speed is displayed.

Operation

The machine speed is shown in "rpm" on the dis-

play.

Displaying the last or the penultimate

measured value

Turn the rotary knob to select "MEM" on the display.

The last measured value is automatically displayed.

Press the swivel arm release handle again and keep

it pressed. The penultimate value is displayed.

Page 10

26

Operation

Measuring the yarn length

Connecting the MLT WESCO to the revolution sen-

sor.

Apply a short press to the rotary knob to access the

"selection menu":

MACHINE SPEED

YARN LENGTH

YARN TENSION

YARN SPEED

In the "selection menu", turn the rotary knob to select

"YARN LENGTH" on the display.

Apply a short press to the rotary knob, the "YARN

LENGTH" selection is conrmed.

Catch the yarn with the help of the swivel arm.

Press the swivel arm release handle and keep it

pressed. The measurement is started.

The yarn length is shown on the display, e.g. in "m/1

machine revolution".

NOTE!

The yarn length to be measured can be

measured within the range of 1 - 100 machine

revolutions.

Setting the number of machine revolutions to be measured

Access the "SETUP" menu by turning the rotary knob.

Conrm your selection (by pressing the rotary knob).

"REVS", "SETUP" and the number of revolutions to

be measured is displayed within the ashing.

Select the number of machine revolutions to be

measured (e.g. 3) by turning the rotary knob.

Apply a short press to the rotary knob to conrm your

selection.

The measuring process can now be started.

Displaying the last or the penultimate

measured value

Turn the rotary knob to select "MEM" on the display.

The last measuring value is automatically displayed.

Press the swivel arm release handle again and keep

it pressed. The penultimate value is displayed.

i

Page 11

27

english

Operation

Selecting the Yarn Tension measuring modes

Apply a short press to the rotary knob to access the

"selection menu":

MACHINE SPEED

YARN LENGTH

YARN TENSION

YARN SPEED

In the "selection menu", turn the rotary knob to select

"YARN TENSION" on the display.

Apply a short press to the rotary knob.

In the "selection menu", turn the rotary knob to select

"SETUP" on the display.

Apply a short press to the rotary knob.

The selection menu is displayed:

normal

average

peak

The set mode, e.g. "normal", ashes on the dis-

play.

normal = The currently measured yarn tension is

displayed.

average = The average yarn tension value throug

hout the entire measuring time is display ed.

peak = The highest measured yarn tension (peak

value), which is displayed. The peak

tension display value will alter according

to peak values measured.

Select the respective setting by turning the rotary knob.

The setting, e.g. "normal", ashes on the display.

Apply a short press to the rotary knob to conrm your

selection.

Page 12

28

Operation

Displaying the last or the penultimate

measured value

Turn the rotary knob to select "MEM" on the display.

The last measuring value is automatically displayed.

Press the swivel arm release handle again and keep

it pressed. The penultimate value is displayed.

Measuring the yarn tension

Catch the yarn with the help of the swivel arm.

Press the swivel arm release handle and keep it

pressed. The measurement is started.

Furthermore, the display shows dots running from the

left to the right during the measuring process until the

yarn tension is displayed.

The yarn tension is shown in "cN" on the display.

Page 13

29

english

Operation

Measuring the yarn speed

Apply a short press to the rotary knob to access the

"selection menu":

MACHINE SPEED

YARN LENGTH

YARN TENSION

YARN SPEED

In the "selection menu", turn the rotary knob to select

"YARN SPEED" on the display.

"YARN SPEED" ashes on the display.

Conrm your selection by a short press of the rotary

knob.

Catch the yarn with the help of the swivel arm.

Press the swivel arm release handle and keep it

pressed. The measuring process is started.

Furthermore, the display shows dots running from the

left to the right during the measuring process until the

yarn speed is displayed.

The display is refreshed every 6 seconds.

Displaying the last or the penultimate

measured value

Select "MEM" by turning the rotary knob. The last

measuring value is automatically displayed.

Apply a short press to the swivel arm release handle

and keep it pressed. The penultimate measuring value

is displayed.

The yarn speed is shown in (m/min) or (yd/min) on

the display.

Page 14

30

Operation

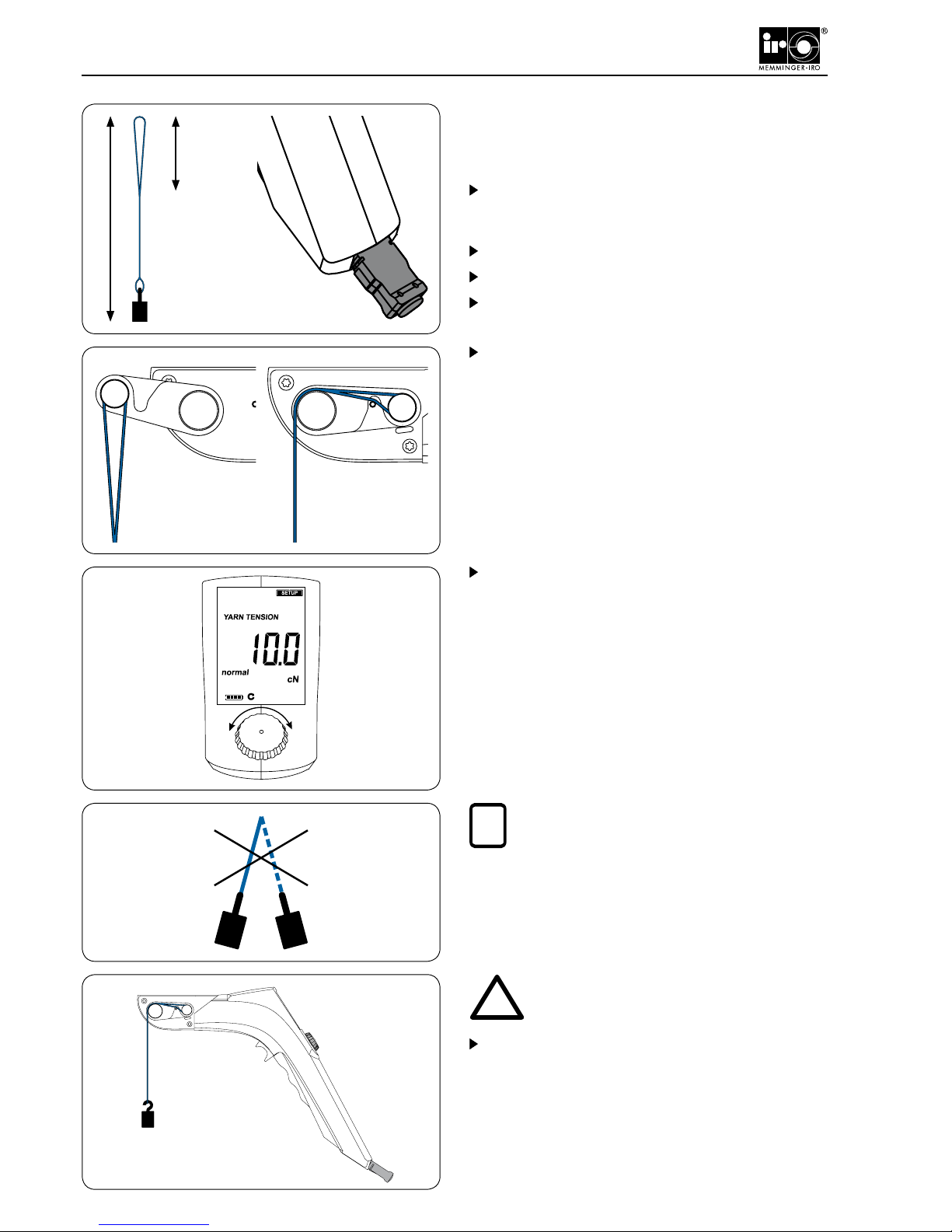

Calibration

The calibration set is used to check the correct yarn

tension and to correct it if necessary.

For calibration purposes take the thread and form

a loop on each side. Attach the weight at the lower

loop.

The device is switched off.

Insert the calibration plug in the MLT WESCO.

Switch on the MLT WESCO and select YARN TEN-

SION.

Place the upper loop over the roller of the swivel arm.

Trigger the swivel arm release handle and keep it

pressed.

If the MLT WESCO does not show 10.0 cN the value

has to be corrected by turning the rotary knob.

ATTENTION!

In order to get an exact calibration the procedure has to be repeated several times.

To store the values unplug the calibration plug and

switch off the MLT WESCO.

!

ca. 30 cm

ca. 8 cm

NOTE!

The weight is not allowed to swing during

calibration.

i

Page 15

31

english

Maintenance

The following instructions must be observed:

The batteries must not be opened or thrown into

a re.

Replaced batteries must be appropriately disposed

of.

The rechargeable batteries must exclusively be

charged with the supplied original charger unit.

Depending on the local supply voltage, only the

supplied charger (110 to 230 V) may be used for

charging the batteries.

The optimum battery charging temperature range

lies between 10° and 35° C. Cooler or higher tem-

peratures would impair the batteries' quality.

The battery poles must not be short-circuited.

The batteries and the charger must be stored in a

cool and dry place.

With longer storage periods, the batteries may be

subject to self-discharge.

The batteries must be recharged when the LO and

BATT is alternatingly displayed.

They must be recharged by means of the supplied

charging unit until Full is shown on the display

and the running display has come to a

halt.

The batteries' duration cannot be guaranteed if the

charging process is interrupted prematurely.

ATTENTION!

Change of batteries only while MLT WESCO

is off.

Plug the DC connection cable into the MLT WES-

CO.

Plug the charger into a Schuko socket by means

of an adapter.

Battery duration:Approx. 50 hours of normal use.

Cleaning the MLT WESCO

The MLT WESCO may only be cleaned with the help

of a moist cloth.

ATTENTION!

No chemical cleaning agents must be

used.

NOTE!

Before using the MLT WESCO for the rst time, or if it hasn't been used for a while, the unit has to be

charged.

i

!

!

Page 16

32

Maintenance

Retain the swivel arm (2).

Disengage the swivel arm release handle (5).

The swivel arm release handle (5) is hinged down, to

provide access to the battery compartment.

The batteries can now be removed and replaced.

2

Inserting the batteries

When inserting the batteries into the MLT WESCO,

the correct polarity must be observed.

-

+

+

+

-

+

+

+

Replacing the batteries

Press the swivel arm (2) to the back.

2

5

Page 17

33

english

Technical Data

Power supply: Rechargeable nickel-metal-hydride battery, 1.2 V, type Mignon AA or

2 dry batteries, type Mignon 1.5 V

Battery charging unit: 100 to 240 V AC, 47-63 Hz,output 5 V, 2 A DC

Digital LCD display: 1 to 9999 meters or inches

Maximum yarn speed: 1000 m/min or 900 yd/min

Measuring range for revolutions: 1 – 100 revolutions

Battery duration: Approx. 50 hours of normal use

Battery charging time: Approx. 6-8 hours for maximum loading result

Machine speed: rpm

Yarn length: m or inch (1 to 100 revolutions can be selected)

Yarn tension: 0 - 50 cN (normal, average or peak value)

Yarn speed: m/min. or yd/min

Dimension Drawing / Technical Data

198

50

260

Page 18

34

Declaration of Conformity

in accordance with the Machinery Directive (98/37/EC), Annex II A

in accordance with the Low Voltage Directive (73/23/EC)

in accordance with the Electromagnetic Compatibility Directive (89/336/EC)

The manufacturer: MEMMINGER-IRO GmbH

Jakob-Mutz-Straße 7

D-72280 Dornstetten, Germany

hereby certies that the following product:

MLT WESCO

conforms to the requirements of the above named directives.

The following harmonised standards were used:

EN ISO 12100 Safety of machinery

EN 61000-4-2 Electromagnetic compatibility (EMC) - Part 4-2: Testing and measurement techniques -

Electrostatic discharge immunity test

EN 61000-4-3 Electromagnetic compatibility (EMC) - Part 4-3: Testing and measurement techniques -

Radiated, radio-frequency, electromagnetic eld immunity test

EN 61000-4-4 Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques -

Electrical fast transient/burst immunity test

EN 61000-4-6 Electromagnetic compatibility (EMC) - Part 4-6: Testing and measurement techniques -

Immunity to conducted disturbances, induced by radio-frequency elds

EN 61000-4-8 Electromagnetic compatibility (EMC) - Part 4-8: Testing and measurement techniques -

Power frequency magnetic eld immunity test

EN 61000-6-2 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards -

Immunity for industrial environments

EN 55022 Information technology equipment - Radio disturbance characteristics -

Limits and methods of measurement

The machine is complete with original operating manuals and technical documentation.

This declaration of conformity becomes null and void if the machine is modied without the manufacturer’s prior written

approval and authorisation.

Declaration of Conformity

Dornstetten, 14.12.2006 M. Kleindorp, Company Management

Distributed by:

ABQ Industrial LP USA

Tel: +1 (281) 516-9292 / (888) 275-5772

eFax: +1 (866) 234-0451

Web: https://www.abqindustrial.net E-mail:

info@abqindustrial.net

Loading...

Loading...