Page 1

Operating instructiOns

Waterbaths

WNB 7 - 45

Page 2

1 General notes and safety notes ............................................................................................................3

1.1 Transport .................................................................................................................................3

2 Technical data ..................................................................................................................................... 4

2.1 Material quality .......................................................................................................................5

2.2 Electrical equipment ................................................................................................................5

2.3 Note on EMC (electromagnetic compatibility) ...........................................................................5

2.4 Brief technical description ........................................................................................................5

2.5 Standard equipment ................................................................................................................6

3 Installation ..........................................................................................................................................6

3.1 Initial start-up .......................................................................................................................... 7

3.2 Start-up - waterbath ................................................................................................................7

4 Bath construction and operation ......................................................................................................... 8

4.1 Controls and indications .......................................................................................................... 8

4.2 Switching on ........................................................................................................................... 9

4.3 Setting the parameters ............................................................................................................ 9

4.3.1 Temperature setpoint ..........................................................................................................10

4.3.2 Delayed switch-on .............................................................................................................. 10

4.3.3 Hold time of the setpoint temperature ................................................................................ 11

5 Programming example of a programme sequence ............................................................................. 11

6 Monitoring the programme sequence ...............................................................................................12

7 Temperature monitor and protection devices ..................................................................................... 13

7.1 Mechanical temperature monitor: temperature limiter............................................................13

7.2 Low-level protection .............................................................................................................. 13

7.3 Monitor relay .........................................................................................................................13

8 Use of the cover (special equipment) .................................................................................................14

9 Level control (special equipment) .......................................................................................................14

10 Cooling system (special equipment) ................................................................................................. 15

11 Cleaning and maintenance ..............................................................................................................15

12 Check list for fault rectification ........................................................................................................16

13 Action on supply failure .................................................................................................................. 16

14 Glossary .......................................................................................................................................... 16

15 CE Conformity of Declaration ..........................................................................................................17

16 Address and customer service ..........................................................................................................18

17 Index .............................................................................................................................................. 19

BASIC page 2

Page 3

1 General notes and safety notes

You have purchased a technically fully proven product which has been produced in Germany with the use

of high-grade materials and the application of the latest manufacturing techniques; it has been factory

tested for many hours.

For this waterbath we guarantee spare parts to be available up to 10 years.

Observation of the Operating Instructions is necessary for faultless

operation and for any possible claims under warranty. If these

Instructions are disregarded, all claims under warranty, guarantee

and indemnification are excluded!

This mark on the product means:

Note Operating Instructions

Warning – bath hot when operating

The right to technical modifications is reserved.

Dimensional details are not binding.

1.1 Transport

Always use gloves!

If the units WNB 22 to 45 have to be carried, 2 persons are required.

Place the bath accurately horizontal and

not on an inflammable support!

BASICpage 3

Page 4

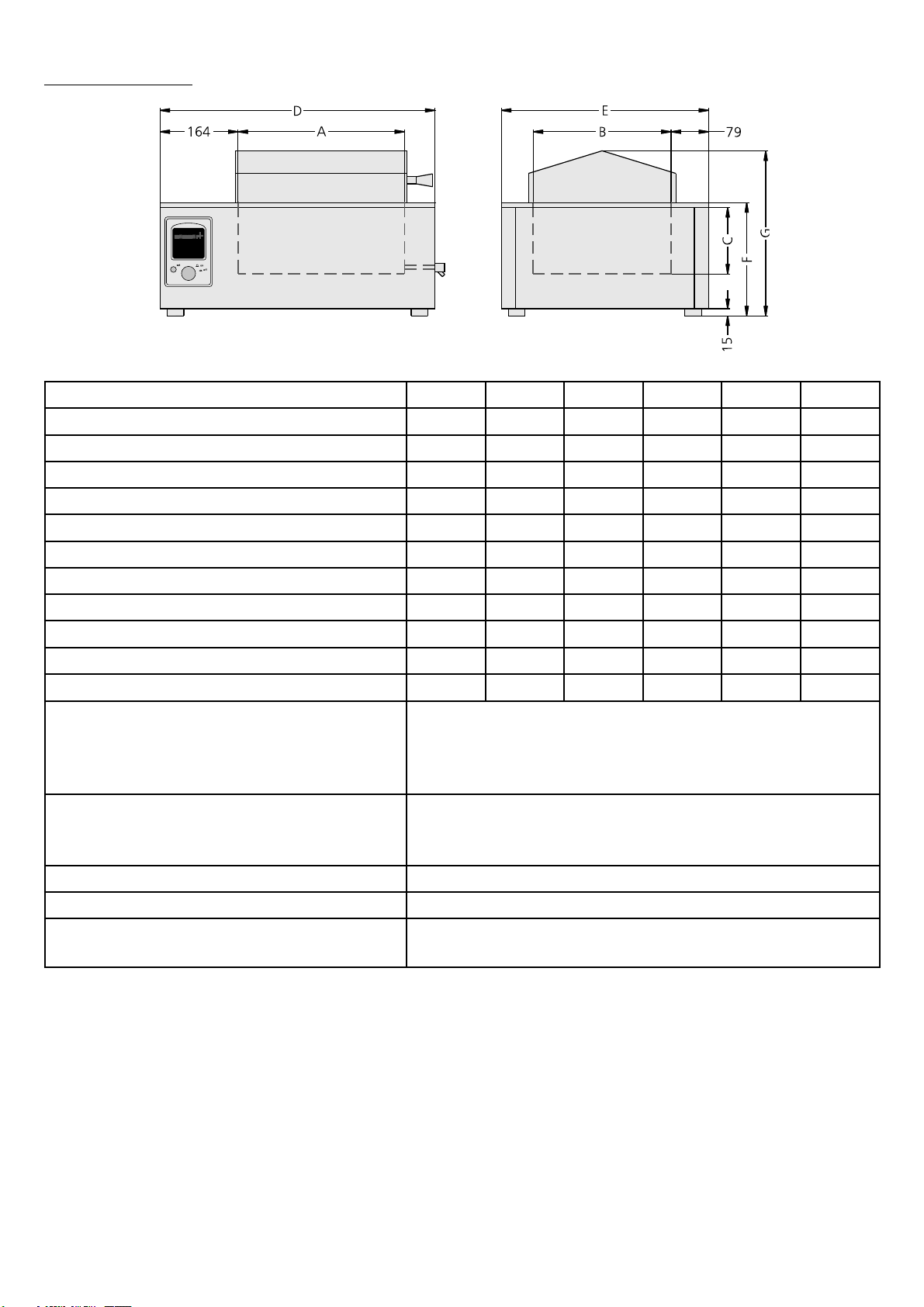

2 Technical data

Model 7 1014222945

Volume [liter] 7 10 14 22 29 45

Usable bath length A [mm] 240 350 350 350 590 590

Usable bath width B [mm] 210 210 290 290 350 350

Usable bath depth C [mm] 140 140 140 220 140 220

Housing length D [mm] 468 578 578 578 818 818

Housing width E [mm] 356 356 436 436 516 516

Housing height (with flat cover) F [mm] 238 238 238 296 238 296

Housing height (with gable cover) G [mm] 337 337 347 405 343 401

Weight [kg] 11 14 16 17 24 26

Current consume [A] 5,2 5,2 7,8 8,7 10,4 12,2

Power [W] 1200 1200 1800 2000 2400 2800

Ambient conditions Ambient temperature 5ºC - 40°C

rh max. 80% (no condensation)

Overvoltage Category: II

Contamination degree: 2

Setting temperature range 10°C to 95°C

with activation of the boiling mode up to 100°C, see

section 4.3.1

Setting accuracy 0,1°C

Indication accuracy 0,1°C

Working temperature range 5ºC above ambient temperature to nominal temperature

= maximum temperature (see rating plate)

BASIC page 4

Page 5

2.1 Material quality

Memmert is using stainless steel ( Mat.Ref. 1.4301) for the external casing as well as for the interior, an

outstanding material because of its high stability, optimum hygienic features and corrosion resistance

against many (not all!) chemical combinations (Attention e.g. at chlorine combinations!).

The load has to be tested for its chemical compatibility with the materials mentioned above.

A material-compatibility table covering all these materials can be requested from MEMMERT.

WARNING! Always pull out the supply plug before

opening the bath cover!

2.2 Electrical equipment

• Operating voltage see rating label, 50/60 Hz

• Protection Class 1, i.e. operating isolation with ground connection to EN 61 010

• Protection IP20 to DIN EN 60 529

• Interference suppression to EN55011 Class B

• Bath protected by a fuse 250V/15A fast blow

• Controller protected by a 80 mA fuse (200 mA on 115 V)

• When connecting a MEMMERT bath to the electrical supply you have to observe any local

regulations which apply (e.g. in Germany DIN VDE 0100 with FI protection circuit)

2.3 Note on EMC ( electromagnetic compatibility)

This product is intended to operate on a supply network with a system impedance Z

at the transfer point

max

(building connection) of 0.292 Ohm max. The user has to ensure that the product is only operated on an

electrical supply network which meets these requirements. If necessary, details of the system impedance

can be obtained from the local electricity supply authority.

Note:

Any work which involves opening up the bath must only be

carried out by a properly qualified electrician!

2.4 Brief technical description

MEMMERT-waterbaths are electrically heated and electronically controlled.

The temperature of the thermostating liquid is continuously controlled by a microprocessor-controller

with pulse package control. Electronic microprocessor-PID-controller with continuous power matching

and autodiagnostic system with fault indicator (see section 12), integral timer for digital programme time

selection.

The temperature is measured using a Pt 100 temperature sensor (4-wire circuit). The accuracy is as

follows:

WNB

Setting accuracy 0,1ºC

Temperature fluctuation ±0,1ºC

The components of temperature control are controlled by integrated malfunction-recognition. The heaters

are installed outside - therefore no problems through dirt or limeresidue.

BASICpage 5

Page 6

2.5 Standard equipment

• Electronic fuzzy-supported PID process controller with delayed programme start and programmable

hold time. The controller has permanent power matchinig and an autodiagnostic system for rapid

fault finding

• Recessing push/turn control for simple operation of bath

• Visual alarm indication

• Mechanical temperature limiter (TB Class 1)

• Monitor relay to switch off heating in case of fault

• High-grade stainless-steel Pt100-temperature sensor (Mat.Ref. 1.4571) Class A in 4-wire circuit

• Boiling mode for temperatures above 95°C

Special equipment (to be ordered separately as accessory): flat cover with concentric ring sets, gable cover

to drain condensate, cooling device, various racks for test tubes, bottles etc

3 Installation

min.

750mm

space for

air circula-

tion

min.

80mm

space for

air circula-

tion

min.

80mm

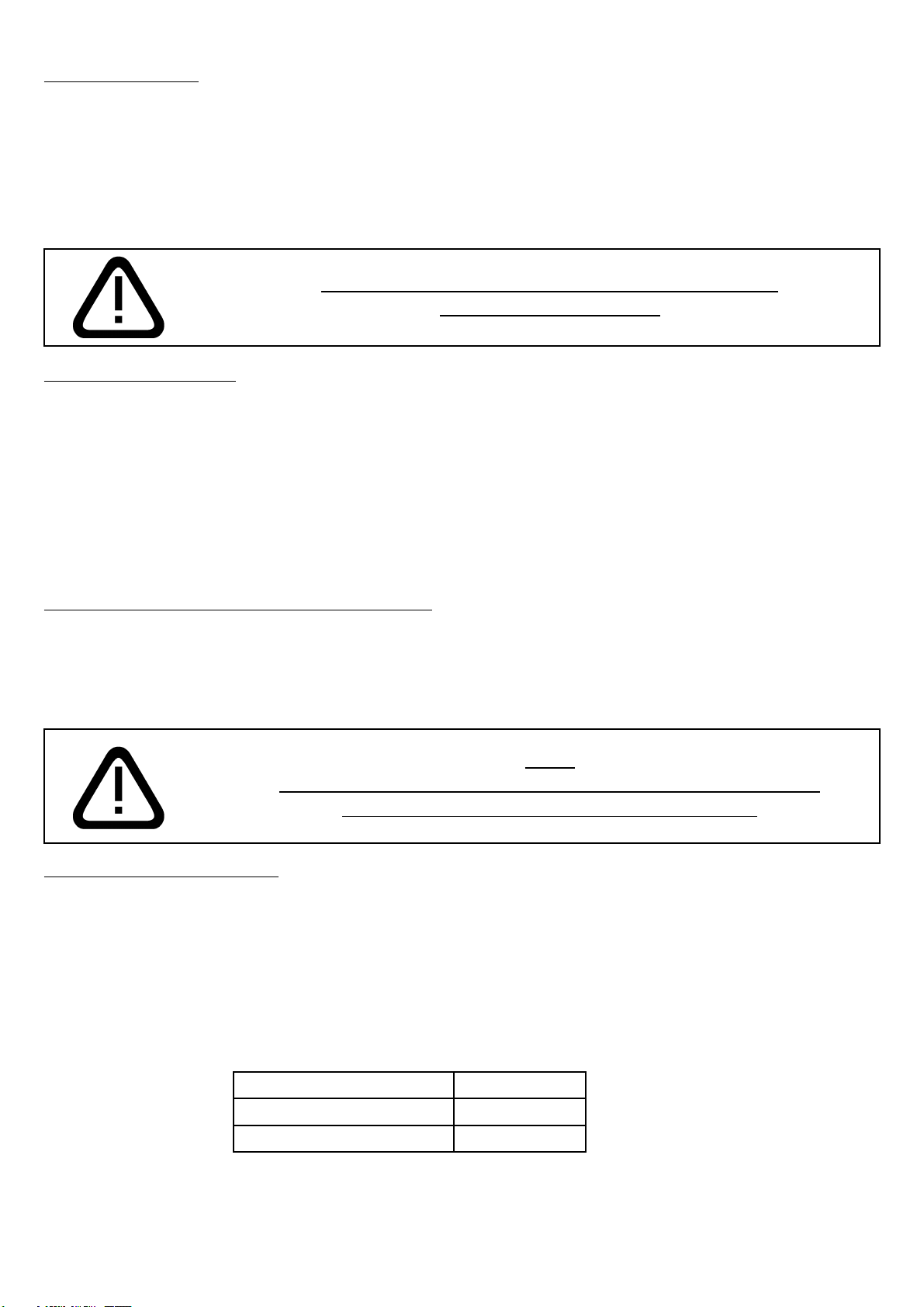

The unit must be placed on a horizontal, non-flammable surface which cannot tilt.

The vent openings in the left and back side must remain unobstructed. Minimum wall spacing on all sides

is 80 mm. The minimum spacing from the top of the bath to the next ceiling (rack, etc.) is 750 mm.

BASIC page 6

Page 7

3.1 Initial start-up

When the bath is started up for the first time, it should be supervised continuously until steady conditions

have been reached.

3.2 Start-up - waterbath

Mains

connection

Filling

The mains connection cable must be placed away from any hot surface.

max water level

min water level

drain valve

In order to garant the high quality of the stainless steel it is recommended by the

steel producer to fill the waterbath with deionised water.

IMPORTANT! The bath has to be filled up to a level between the

two markings at the right side of the tub!

Waterbaths can be fitted with a

level control system (see section 9).

Draining

The tank can be drained through the drain valve. The thermostating fluid must be cooled

to room temperature before draining. Drain the fluid either directly into an appropriate

container or connect an appropriate hose to the drain valve.

NOTE: Polluted fluids may not be drained directly into the public

wastewater system! If the thermostating fluid is polluted, please

make sure that it will be properly filtered or dumped according to

the applicable regulations!

Operation with non-flammable thermostating liquids only!

BASICpage 7

Page 8

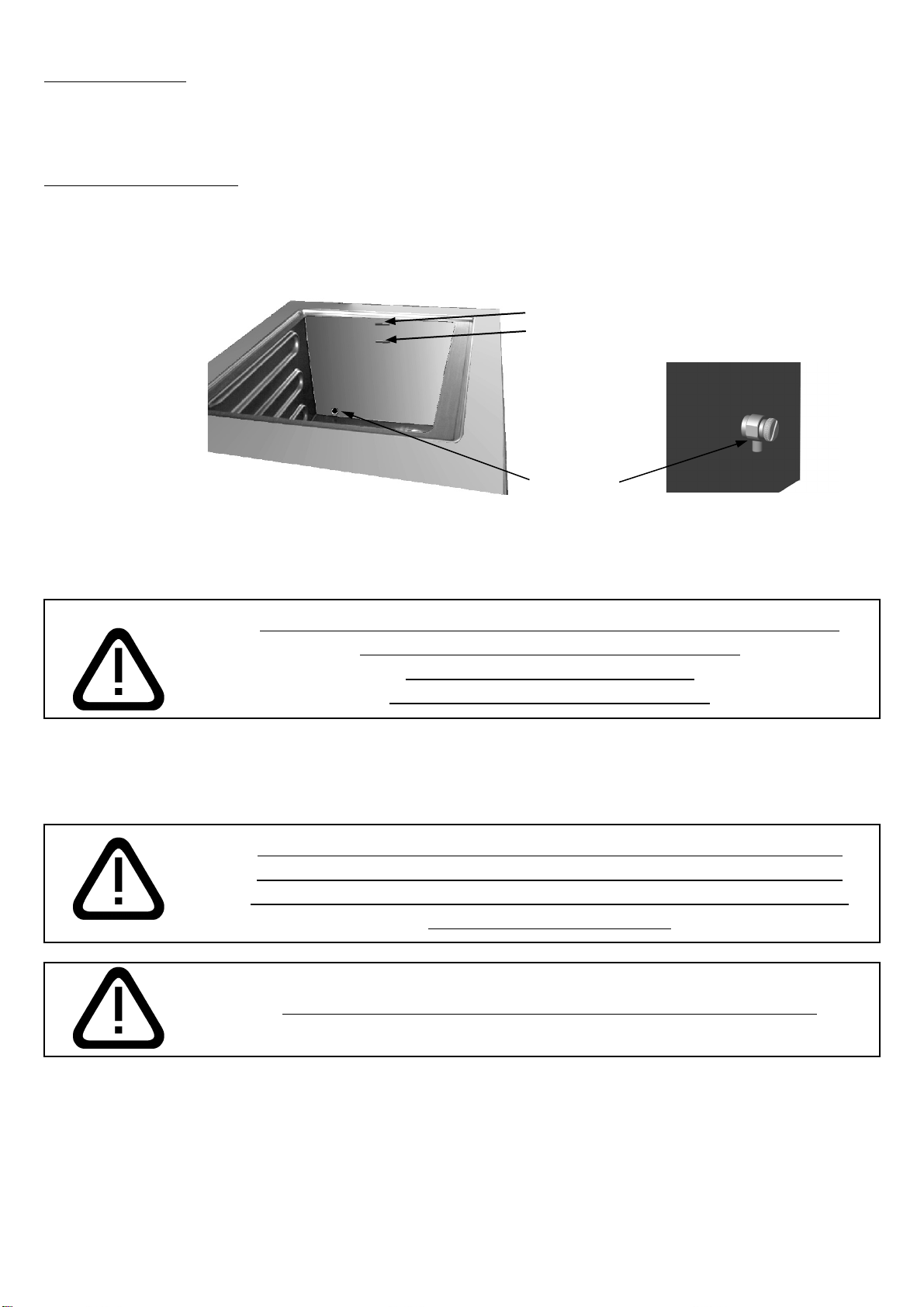

4 Bath construction and operation

relatively largest heat loss (since

furthest away from the heated ribs)

minimum heat loss (since

very close to the heated ribs)

bath

Insulation

heating elements

The heating positioned on three sides around the tank ensures a natural water circulation of the liquid

inside, thus securing an optimal uniform temperature distribution.

4.1 Controls and indications

time-symbol

delay-symbol

(delayed switch-on)

alarm-symbol

SET key

temperature display

7 5. 0

heater-symbol

hold-symbol

(hold time)

push/turn control

BASIC page 8

Page 9

4.2 Switching on

The bath is switched on by pressing the push/turn control

and can be operated in connection with the

SET-key.

Bath switched off: The push/turn control is

pushed in and protected against damage.

4.3 Setting the parameters

A parameter can be selected by rotating the push/turn control; all other parameters are then dimmed.

The selected parameter flashes brightly and can now be altered with the push/turn control while holding

down the SET key (protection against unintentional alteration).

If the push/turn control is rotated quickly the setpoint is altered in large steps; with slow operation it is

altered in single steps.

After the SET key has been released the newly set value is stored.

Further rotation of the push/turn control selects the next parameter.

Rotation of the push/turn control selects the following parameters (in the order indicated), to be altered

as described above:

1. Temperature setpoint

2. Delayed switch-on

3. Hold time of the setpoint temperature

BASICpage 9

Page 10

4.3.1 Temperature setpoint

*

*

90°C

Adjustment range:

10°C to 95°C or ca. 100°C with

activation of the boiling mode

Setting and indication accuracy:

The bath starts to heat up immediately

0,1°C

to the set temperature.

Rotate the push/turn control until the °C symbol flashes.

The setpoint temperature can then be selected with the SET key depressed, as

described in section 4.3. After releasing the SET key the display briefly flashes the

setpoint. The display then changes to the actual temperature and the controller

starts to control to the selected setpoint temperature.

°C

During heating the

symbol flashes in proportion to the actual heater power.

In order to reach water temperatures above 95°C (boiling point), waterbaths are

provided with the boiling mode. If this is selected, the heating is switched on

permanently.

Activating the boiling mode by rotating the push/turn control beyond the

maximum value until the display shows “ CCC“

The setting “boiling mode“ is not stored permanently. After the bath is switched

off and on again, the controller shows again the previously selected setpoint.

4.3.2 Delayed switch-on

Adjustment range:

90°C

1 min bis 99.59 hrs

Setting accuracy:

1 min

delay 12h

The bath starts to heat up to the previously

selected temperature only after the time of

Indication accuracy:

<10 hrs: 1 min

≥10 hrs: 1 hr

the switch-on delay has elapsed.

°C

Rotate the push/turn control until the (delay) and the symbol flashes.

The duration of the delayed switch-on can then be set with the SET key depressed

as described in section 4.3. After the SET key has been released the bath briefly

flashes the setting of the switch-on delay.

The delayed switch-on is then activated and the display alternates between the

actual temperature and the running time of the switch-on delay. The time is

shown with a negative sign and runs down. In this way it is possible to determine

at any time how much longer the bath waits until it begins to heat up.

If no delayed switch-on is required, it can be de-activated by the setting “OFF“.

BASIC page 10

°C

°C

°C

Page 11

4.3.3 Hold time of the setpoint temperature

*

t

90°C

1 min bis 99.59 hrs

Setting accuracy:

Adjustment range:

hold 6h

The bath switches off the heating after

the end of the selected hold time. In this

case the hold time includes the heating-

1 min

Indication accuracy:

<10 hrs: 1 min

≥10 hrs: 1 hr

up time.

Rotate the push/turn control until the (hold) and the symbol flashes.

The duration of the hold time can then be selected with the SET key depressed,

as described in section 4.3. After the SET key has been released the bath briefly

flashes the hold time setting.

If no hold time has been programmed, the hold time is activated immediately

and the display alternates between the actual temperature and the running time

of the hold time. As with switch-on delay, the residual time is shown with a

negative sign and runs down.

If no hold time is required, it can be de-activated by the setting “OFF“

°C

°C

°C

5 Programming example of a programme sequence

1. Setpoint temperature setting

Rotate the push/turn control until the °C symbol flashes. With the SET key

depressed, use the push/turn control to set the temperature setpoint to f.ex.

90.0 °C.

2. Delayed switch-on setting

Rotate the push/turn control until the (delay) and the symbol flashes. With

the SET key depressed, use the push/turn control to set the time f.ex. 6.00 hours.

3. Hold time setting

Rotate the push/turn control until the (hold) and the symbol flashes. With

the SET key depressed, use the push/turn control to set the time f.ex. 4.00 hours.

°C

°C

°C

BASICpage 11

Page 12

6 Monitoring the programme sequence

*

t

*

t

*

t

*

t

90°C

delay 6h

hold 4h

Bath does not heat up

90°C

delay 6h

hold 4h

Bath heats up

90°C

delay 6h

hold 4h

Bath holds setpoint

temperature

During the delayed switch-on the

symbol

flashes and the display alternates between

residual time and actual temperature

After the end of the delayed switch-on the

symbol goes dark and the bath heats up to

the selected setpoint temperature. Heating is

indicated by the

symbol.

During the hold time the symbol flashes

and the display alternates between the residual

time and the actual temperature.

°C

°C

°C

°C

°C

90°C

delay 6h

hold 4h

Heating is switched off

After the hold time has elapsed the symbol

goes dark, the heating is switched off, and

the display alternates between the actual

temperature and “end“.

°C

°C

BASIC page 12

Page 13

7 Temperature monitor and protection devices

7.1 Mechanical temperature monitor: temperature limiter

All waterbaths are fitted with a mechanical temperature limiter (TB) Protection Class 1 to DIN 12880.

If the electronic control unit should fail during operation and the fixed factory-set maximum temperature is

exceeded by approx. 30°C the temperature limiter switches off the heating permanently as a final protective

measure. The

7.2 Low-level protection

In addition to its function as overtemperature protection the TB also operates as low-level protection,

i.e. the heating is switched off permanently if the liquid drops below a certain level. As a warning the

symbol lights up continuously.

Fault rectification after the TB cut-out has been activated:

1. Switch off the bath and allow it to cool down

2. Rectify the fault (e.g. top up the liquid, replace temperature probe) and where appropriate contact

customer service

3. The bath is again ready for operation only after it has cooled down and after the fault has been

rectified

symbol lights up continuously as warning.

7.3 Monitor relay

In addition the bath is equipped with an electronic monitor relay.

If a fault occurs during operation or if the selected setpoint temperature is exceeded by 10°C, then the

monitor relay continues control of the heating at this temperature in emergency operation.

The symbol flashes as warning.

Fault rectification after the monitor relay may been activated:

Check the controller for error messages (see section 12) and where appropriate contact customer service.

Example:

With a setpoint temperature of 80°C, if a fault occurs in the power unit (faulty triac) the bath continues to

operate in emergency operation at approx. 90°C.

BASICpage 13

Page 14

8 Use of the cover (special equipment)

Gable cover The gable cover (may be ordered as already mounted special equipment) should always

be closed in order to prevent evaporation of thermostating liquid and to obtain optimal

temperature distribution. The gable shape of the cover makes sure that condensed water

will not drop down into the loads.

Flat cover For positioning of test flasks on top of the bath, a flat cover (special equipment) may be

used. The size of the holes in this cover can be adapted to the flasks with ring inserts. The

rings may therefore only be inserted or taken off, if the bath is cooled down.

Note that during operation the flat cover and the gable cover

heat up to the temperature of the thermofluid!

9 Level control (special equipment)

2 different filling levels can be maintained constant if the unit is fitted with a level control system. When

using water as thermostating liquid, connect the feed pipe with tubing to the mains water supply. The

drain must be connected with tubing to an appropriate container or sink.

Make sure, that the tubing cannot be clogged or bended, and that it continually runs downhill.

Please note, that the outflowing water may be hot!

Supply and drain are indentified by arrows. Use temperature

resistant material for the tubing.

If the second overflow is not required, it must be closed with

a sealing cap.

The evaporation loss can be compensated through a slightly

open water supply (dripping) and can be monitored through

the “observation window“.

The level control system cannot be retrofitted!

Warning – bath hot when operating

observation

window

supply

drain

drain

BASIC page 14

Page 15

10 Cooling system (special equipment)

If the waterbath is fitted with a cooling device

for quicker cooling of the bath liquid, the “water

supply“ has to be connected by a hose f.ex. to a

cold water supply line. The “discharge“ has to

be lead into a drain.

(Use temperature resistant material for the

tubing)

discharge

water supply

Please note, that the outflowing water may be hot!

The discharge must be connected with tubing to an appropriate container or sink. Make sure, that the

tubing cannot be clogged or bended, and that it continually runs downhill.

11 Cleaning and maintenance

By regular cleaning of the easy to clean the tank, residues are

avoided which at continuous influence can impair the outfit and

function of the waterbath.

Please use only detergents and antiliming agents appropriate for

stainless steel for the cleaning of the tank and the housing (stainless

steel detergents usual in the trade)!

After cleaning and after draining the water the

stainless steel tank must be rinsed thoroughly with clear water

and dried carefully!

It is important to ensure that no rusting objects come into contact with the stainless steel bath tank or the

stainless steel housing. Rust sediments lead to contamination.

If rust stains caused by contamination occur on the tank surface, the affected areas must be cleaned and

polished immediately.

On units with gable cover we recommend that the hinge bolts are oiled from time to time if the bath is

used frequently.

BASICpage 15

Page 16

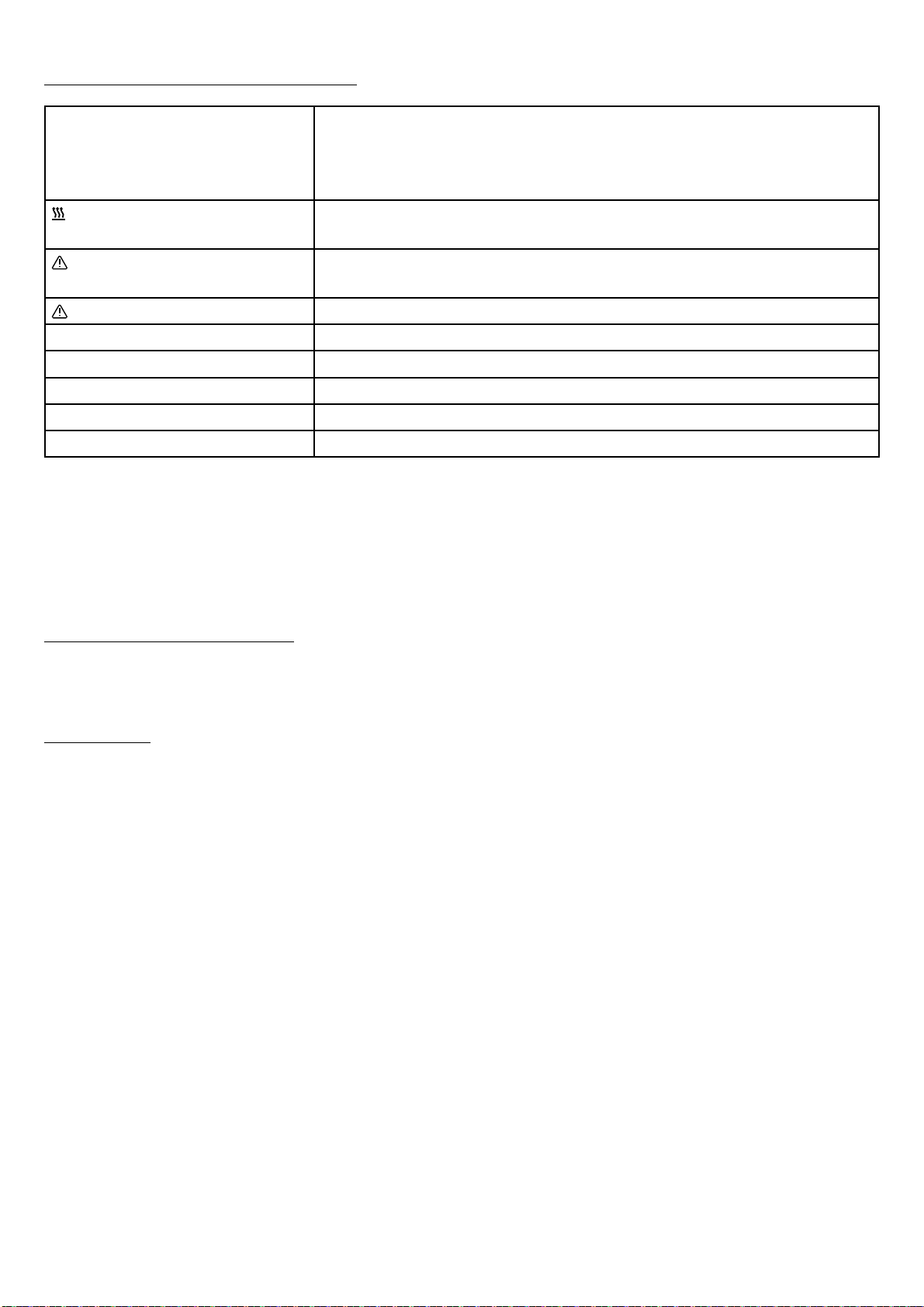

12 Check list for fault rectification

Main switch ON,

no indication on the display

symbol not alight

symbol alight

symbol flashes

C O N F

E - 1

E - 2

E - 3

E - L

In case of a malfunction contact an authorized service station for Memmert equipment or please inform

the Memmert service department (see section 16).

In case of queries always specify model and serial number (on the rating label).

Main fuse 15A or instrument fuse T80mA 250V~ on circuit board

55167.x has blown

Controller faulty

Electrical supply interrupted

Ambient temperature too high

Temperature in bath above the selected setpoint temperaturer

Temperature protection (TB) has operated

Liquid level too low

Monitoring relay has operated

Error on self test

Power module triac faulty

Power module faulty

Pt100-temperature probe faulty

Communication to power unit interrupted

13 Action on supply failure

After a failure of the supply, operation continues with the previously set parameters.

14 Glossary

• nominal temperature = themaximum adjustable setpoint temperature of the bath.

• ambient temperature = the continuous temperature of the room in which the bath is set up.

BASIC page 16

Page 17

15 CE Conformity of Declaration

EC Declaration of Conformity

Manufacturer´s name and address: MEMMERT GmbH + Co. KG

Product: Waterbath

Type: WNB...

Sizes: 7 / 10 / 14 / 22 / 29 / 45

Nominal voltage: AC 230 V 50/60 Hz

The designated product is in conformity with the European EMC-Directive

Äußere Rittersbacher Straße 38

D-91126 Schwabach

alternative AC 115 V 50/60 Hz

2004/108/EEC

including amendments

Council Directive of 03 May 1989 on the approximation of the laws of the Member States relating to

electromagnetic compatibility.

Full compliance with the standards listed below proves the conformity of the designated product with the essential

protection requirements of the above-mentioned EC Directive:

DIN EN 61326:2004-05 EN 61326:1997

The designated product is in conformity with the European Low Voltage Directive

EN 61326/A1:1998

EN 61326/A2:2001

EN 61326/A2:2003

2006/95/EEC

including amendments

Council Directive on the approximation of the laws of the Member States relating to Electrical

equipment for use within certain voltage limits.

Full compliance with the standards listed below proves the conformity of the designated product with the essential

protection requirements of the above-mentioned EC Directive:

DIN EN 61 010-1 (VDE 0411 part 1):2002-08 EN 61 010-1:2001

DIN EN 61 010-2-010 (VDE 0411 part 2-010):2004-06 EN 61 010-2-010:2003

Schwabach, 03.07.08

______________________________

(Legally binding signature of the issuer)

This declaration certifies compliance with the above mentioned directives but does not include a property assurance. The

safety note given in the product documentation which are part of the supply, must be observed.

BASICpage 17

Page 18

Standard units are safety-approved and bear the test marks:

This product is subject to the Directive 2002/96/EC by the European Parliament

and the EU Council of Ministers which concerns Waste Electrical and Electronic

Equipment (WEEE). This product has been put on the market after 13 August

2005 in countries which have already incorporated this Directive into National

Law. It should not be disposed off as part of domestic refuse. For disposal

please contact your dealer or the manufacturer. Products which are infected,

infectious or contaminated with health-endangering substances are excluded

from return. Please note also all further regulations in this context.

16 Address and customer service

MEMMERT GmbH+Co.KG

PO Box 17 20

91107 Schwabach

Germany

Phone: 00 49 9122 / 925-0

Fax:: 00 49 9122 /14585

E-mail: sales@memmert.com

Internet: www.memmert.com

Customer service:

Phone: 00 49 9122 / 925-143

or 00 49 9122 / 925-126

E-mail: service@memmert.com

In case of queries always specify model and serial number (on the rating label).

© by MEMMERT GmbH+Co.KG

BASIC page 18

Page 19

17 Index

A

address 18

alarm symbol 13

ambient conditions 4

ambient temperature 16

autodiagnostic system 5, 16

B

bath construction 8

boiling mode 4

boiling mode, activate 10

brief technical description 5

C

CCC 10

CE conformity of declaration 17

check list for fault rectification 16

chemical compatibility 5

cleaning 15

contaminations 7, 15

controls 8

cooling system 15

cover, flat 14

cover, gable 14

customer service 18

D

deionised water 7

delayed switch-on 10

DIN 12880 13

disposal 18

draining 7

drain hose 14, 15

drain valve 7

E

electrical equipment 5

electromagnetic compatibility 5

evaporation loss 14

F

fault rectification 16

filling 7

G

H

heating 8

hinge bolts 15

hold time of the setpoint temperature 11

I

indications 8

initial start-up 7

installation 6

L

level control system 7, 14

liquid level 7

low-level protection 13

M

maintenance 15

Mat.Ref. 1.4301 5

material quality 5

monitoring the programme sequence 12

monitor relay 13

monitor unit 13

N

nominal temperature 4, 16

P

parameter settings 9

polluted fluids 7

programming example 11

Protection Class 1 13

Pt 100 temperature sensor 5

R

rust deposits 15

S

safety notes 3

setpoint temperature 16

setpoint temperature, selection 10

standard equipment 6

start-up 7

supply failure 16

switching on the bath 9

T

TB 13

technical data 4

temperature fluctuation 5

temperature limiter (TB) 13

temperature measurement 5

temperature monitor 13

thermofluid 7

transport 3

U

uniform temperature distribution 8

W

water circulation 8

working temperature range 4

glossary 16

BASICpage 19

Page 20

Memmert gmbH + co. Kg | Po. Box 1720 | D-91107 Schwabach | Tel. +49 (0) 9122 / 925 - 0 | Fax +49 (0) 9122 / 145 85 | E-Mail: sales@memmert.com | www.memmert.com

08.06.2009

Waterbath BASIC englisch

D10329

Loading...

Loading...