Page 1

ICO

OPERATING MANUAL

CO2 INCUBATOR ICO

Page 2

Manufacturer and customer service

MEMMERT GmbH + Co. KG

Willi-Memmert-Straße 90-96

91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

E-mail: sales@memmert.com

Internet: www.memmert.com

Customer service:

Service hotline: +49 (0)9171 9792 911

Service fax: +49 (0)9171 9792 979

E-mail: service@memmert.com

For service enquiries, please always specify the appliance number on the nameplate (see page

12).

Shipping address for repairs:

Memmert GmbH + Co. KG

Customer service

Willi-Memmert-Str. 90-96

DE-91186 Büchenbach

Germany

Please contact our customer service before sending appliances for repair or before returning

equipment, otherwise, we have to refuse acceptance of the shipment.

© 2016 MEMMERT GmbH + Co. KG

D33451 | Edition 11/2016

Changes reserved

Page 3

About this manual

About this manual

Purpose and target audience

This manual describes the design, function, transport, putting into operation, the actual operation and maintenance of CO

the owner, who have the task of operating and/or maintaining the respective appliance.

If you are asked to work on the appliance, read this manual carefully before starting. Familiarise yourself with the safety regulations. Only perform work that is described in this manual. If

there is something you do not understand, or certain information is missing, ask your manager or contact the manufacturer. Do not do anything without authorisation.

Versions

The appliances are available in different configurations and sizes. If specific equipment features or functions are available only for certain configurations, this is indicated at the relevant

points in this manual.

The functions described in this manual refer to the latest firmware version.

Due to individual configurations and sizes, illustrations in this manual may be slightly different

from the actual appearance. Function and operation are identical.

Other documents that have to be observed

When operating the appliance with the MEMMERT AtmoCONTROL PC software, observe the

separate software manual. To open the AtmoCONTROL software manual, click on “Help” in

the AtmoCONTROL menu bar.

Storage and resale

This instruction manual belongs with the appliance and should always be stored where

persons working on the appliance have access to it. It is the responsibility of the owner to

ensure that persons who are working or will work on the appliance are informed as to the

whereabouts of this instruction manual. We recommend that it is always stored in a protected

location close to the appliance. Make sure that the instruction manual is not damaged by heat

or humidity. If the appliance is resold or transported and then set up again at a different location, the operating instructions must go with it.

For the current version of this operating manual in pdf format, please go to http://www.memmert.com/en/service/downloads/user-manual/ .

incubators ICO. It is intended for use by trained personnel of

2

D33451 | Edition 02/2017 3

Page 4

Contents

Contents

1. For your safety 6

1.1 Terms and signs used........................................................................................................... 6

1.2 Product safety and dangers ................................................................................................ 7

1.3 Requirements of the operating personnel .......................................................................... 8

1.4 Responsibility of the owner ................................................................................................. 8

1.5 Intended use ........................................................................................................................ 8

1.6 Changes and conversions ....................................................................................................9

1.7 Behaviour in case of malfunctions and irregularities ..........................................................9

1.8 What to do in case of accidents .......................................................................................... 9

1.9 Switching off the appliance in an

emergency ........................................................................................................................... 9

2. Construction and description 10

2.1 Construction ...................................................................................................................... 10

2.2 Description and function ................................................................................................... 10

2.3 Material.............................................................................................................................. 11

2.4 Electrical equipment .......................................................................................................... 11

2.5 Connections and interfaces ...............................................................................................11

2.6 Designation (nameplate) ................................................................................................... 12

2.7 Technical data .................................................................................................................... 13

2.8 Applied directives and standards ...................................................................................... 14

2.9 Declaration of conformity ................................................................................................. 14

2.10 Ambient conditions ........................................................................................................... 15

2.11 Scope of delivery ...............................................................................................................15

2.12 Optional accessories .......................................................................................................... 15

3. Delivery, transport and setting up 16

3.1 For your safety ...................................................................................................................16

3.2 Delivery .............................................................................................................................. 17

3.3 Transport ............................................................................................................................ 17

3.4 Unpacking ......................................................................................................................... 17

3.5 Storage after delivery ........................................................................................................17

3.6 Setting up .......................................................................................................................... 18

4. Putting into operation 20

4.1 Connect the appliance to the power supply ..................................................................... 20

4.2 Establishing water supply .................................................................................................. 20

4.3 CO

4.4 Switching on ...................................................................................................................... 22

5. Operation and control 23

5.1 For your safety ...................................................................................................................23

5.2 Operating personnel.......................................................................................................... 23

5.3 Opening the door .............................................................................................................. 24

5.4 Loading the appliance .......................................................................................................25

5.5 Operating the appliance .................................................................................................... 25

5.6 Monitoring function .......................................................................................................... 32

5.7 Graph ................................................................................................................................. 38

5.8 Sterilising the appliance ...................................................................................................40

5.9 Ending operation ...............................................................................................................40

and N2 connection ...................................................................................................... 21

2

4 D33451 | Edition 11/2016

Page 5

Contents

6. Malfunctions, warning and error messages 41

6.1 Warning messages of the monitoring function ................................................................ 41

6.2 Malfunctions, operating problems and appliance errors ................................................ 43

6.3 Power failure ...................................................................................................................... 45

7. Menu mode 46

7.1 Overview ............................................................................................................................ 46

7.2 Basic operation in menu mode using the example of language selection ....................... 47

7.3 Setup.................................................................................................................................. 48

7.4 Date and time .................................................................................................................... 51

7.5 Calibration ......................................................................................................................... 52

7.6 Programme ........................................................................................................................ 58

7.7 Sounds ............................................................................................................................... 59

7.8 Protocol ............................................................................................................................. 60

7.9 USER ID .............................................................................................................................. 61

8. Maintenance and Servicing 63

8.1 Regular maintenance.........................................................................................................63

8.2 Cleaning ............................................................................................................................. 63

8.3 Repairs and Service ............................................................................................................ 63

9. Storage and disposal 64

9.1 Storage .............................................................................................................................. 64

9.2 Disposal ............................................................................................................................. 64

Index 65

D33451 | Edition 11/2016 5

Page 6

For your safety

1. For your safety

1.1 Terms and signs used

In this manual and on the appliance itself, certain common terms and signs are used to warn

you of possible dangers or to give you hints that are important in avoiding injury or damage.

Observe and follow these notes and regulations to avoid accidents and damage. These terms

and signs are explained below.

1.1.1 Terms used

WARNING

CAUTION

NOTICE

1.1.2 Signs used

Danger of elec-

trocution

Do not tilt Disconnect the

Information on

first aid

Fire hazard

mains plug

First aid:

Rinse eyes out

Warns about a dangerous situation that might lead to death

or serious injuries

Warns about a dangerous situation that might lead to moderate or minor injuries

Warns about material damage

Gases / vapours Danger of frost-

bite/

cold burns

Wear gloves Wear safety

boots

Important or

useful

additional infor-

mation

Warning about

gas bottles

Observe informa-

tion in separate

manual

6 D33451 | Edition 11/2016

Page 7

For your safety

1.2 Product safety and dangers

The appliances described in this manual are technically sophisticated, manufactured using

high-quality materials and subject to many hours of testing in the factory. They reflect the

state of the art and comply with recognised technical safety regulations. However, there are

still risks involved, even when the appliances are used as intended. These are described below.

WARNING

After removing covers, live parts may be exposed. You may receive

an electric shock if you touch these parts. Disconnect the mains plug

before removing any covers. Only electrical engineers may work on

the electrical equipment of the appliances.

WARNING

When loading the appliance with an unsuitable load, poisonous or

explosive vapours or gases may be produced. This could cause the

appliance to explode, and people could be severely injured or poisoned. The appliance may not be loaded with materials / test objects

that release toxic or explosive vapours when heated up (see also

chapter Intended use on page 8).

WARNING

Leaving the door open during operation can cause the appliance to

overheat or pose a fi re hazard. Do not leave the door open during

operation.

WARNING

Gas bottles may burst or explode at high temperatures. Keep the

gas bottles away from open fl ames. Store gas bottles below 50 °C

and ensure that the location is always well ventilated. Prevent water

from penetrating as well as backfl ow into the gas bottles. It is es-

sential that you read the safety notes and instructions of the gas

supplier.

CAUTION

Danger of suffocation. CO2 and N2 can have a suffocating effect

in high concentrations. In normal mode, the appliance emits small

amounts of CO2 and N2 to its surroundings. You should therefore

ensure that the room in which it is installed is properly ventilated.

Always close the stop valve or pressure reducer on the gas bottles if

the appliance is not in operation.

CAUTION

High concentrations of CO2 can cause cold burns or frostbite. Avoid

contact with CO2 gas to the eyes and skin.

D33451 | Edition 11/2016 7

Page 8

For your safety

CO2 and N2 are not dangerous substances in terms of the German Hazardous Substances

Ordinance (GefStoffV). You should nevertheless familiarise yourself with the applicable safety

regulations prior to handling such gas bottles.

1.3 Requirements of the operating personnel

The appliance may only be operated and maintained by persons who are of legal age and

have been instructed accordingly. Personnel who are to be trained, instructed or who are undergoing general training may only work with the appliance under the continuous supervision

of an experienced person.

Repairs may only be performed by qualified electricians. The regulations in the separate service

manual must be observed.

1.4 Responsibility of the owner

The owner of the appliance

► is responsible for the flawless condition of the appliance and for it being operated in ac-

cordance with its intended use (see chapter 1.5);

► is responsible for ensuring that persons who are to operate or service the appliance are

qualified to do this, have been instructed accordingly and are familiar with the operating

instructions at hand;

► must know about the applicable guidelines, requirements and operational safety regula-

tions, and train staff accordingly;

► is responsible for ensuring that unauthorised persons have no access to the appliance;

► is responsible for ensuring that the maintenance plan is adhered to and that maintenance

work is carried out properly (see page 63);

► has to ensure that the appliance and its surroundings are kept clean and tidy, for example

through corresponding instructions and inspections;

► is responsible for ensuring that personal protective clothing is worn by operating person-

nel, e.g. work clothes and safety shoes.

1.5 Intended use

CO2 incubators ICO are intended for incubation of cell cultures or similar.

The appliance is not explosion-proof (does not comply with the German occupational health

& safety regulation VBG 24). The appliance may only be loaded with materials and substances

which cannot form any toxic or explosive vapours at the set temperature and which cannot

explode, burst or ignite.

The appliance may not be used for the drying, evaporation and baking of paints or similar

materials, the solvents of which could form an explosive mixture when combined with air. If

there is any doubt as to the composition of materials, they must not be loaded into the appliance. Potentially explosive gas-air mixtures must not form, neither in the working chamber nor

in the direct vicinity of the appliance.

Only feed distilled water as well as CO

tions on the rear of the appliance. Introducing other liquids or gases is not permitted.

The incubator may not be used for sterilisation purposes. It is not a steriliser according to the

German Law on Medical Products. Sterilisation programmes (see page 58) that are saved

in the appliance only serve to sterilise the appliance itself. Do not use them to sterilise medical

devices!

8 D33451 | Edition 11/2016

and N2 into the chamber through the media connec-

2

Page 9

For your safety

OONN

N

1.6 Changes and conversions

No unauthorised changes or alterations may be made to the appliance. No parts may be

added or inserted which have not been approved by the manufacturer.

Unauthorised changes or alterations result in the CE declaration of conformity losing its validity, and the appliance may no longer be operated.

The manufacturer is not liable for any damage, danger or injuries that result from unauthorised changes or alterations, or from non-observance of the regulations in this manual.

1.7 Behaviour in case of malfunctions and irregularities

The appliance may only be used in a flawless condition. If you as the operator notice irregularities, malfunctions or damage, immediately take the appliance out of service and inform

your superior.

You can find information on eliminating malfunctions from page 41.

1.8 What to do in case of accidents

1. Keep calm. Act with determination and consideration. Pay attention to your

own safety.

2. Switch off the appliance and close the valves of the gas bottle.

3. Call a doctor.

4. Start first aid measures. If available: Call a trained first aid helper.

In case of contact with CO2 to the eyes and skin:

Rinse eyes out with water for at least 15 minutes. In case of cold burns, rinse with

water for at least 15 minutes. Cover over in a sterile way. Call a doctor.

When breathing in CO2 or N2:

High concentrations can cause suffocation. Symptoms may include a loss of mobility and

unconsciousness. The victim is not aware of suffocating.

Low concentrations of CO

can cause accelerated breathing and headaches.

2

Anyone affected should breathe fresh air, using a breathing device independent of recirculating air. Keep the person warm and calm. Call a doctor. In case of respiratory arrest, use

artificial respiration.

In case of gas leakage:

Leave the room immediately, warn others and ventilate the room. If you re-enter the room,

use a breathing device independent of recirculating air if it has not been established that the

atmosphere is harmless.

1.9 Switching off the appliance in an

emergency

Press the main switch at the ControlCOCKPIT (Fig. 1) and

disconnect the power plug. This disconnects the appliance

from the power supply at all poles.

Fig. 1

Switch off the appliance by pressing the main switch

D33451 | Edition 11/2016 9

ON

Page 10

Construction and description

2. Construction and description

2.1 Construction

1

2

3

4

5

6

Fig. 2 Construction of CO2 incubators ICO

1 ControlCOCKPIT with capacitive function

keys and LCD displays (see page 26)

2 On/Off switch (see page 22)

3 Inner glass door

4 Stainless steel perforated sheet

5 Water tray (passive humidity control)

6 Adjustable feet

7 Nameplate (see page 12)

7

2.2 Description and function

Air is heated inside the appliance by means of large-area all-round heating.

The interior of appliances with passive humidity control is humidified with water that evapo-

rates from a tray that is placed inside. The interior of appliances with active humidity control

is humidified with water evaporating at a set rate from a tank by means of a hot-air generator

on the rear side of the appliance. The sterile hot air is introduced into the interior above the

fan and mixed with the air current. In appliances with water trays, a Peltier humidity trap in

the back of the appliance limits humidity. Appliances with active humidity are dehumidified

with a dosed supply of fresh air provided through a sterile filter.

Carbon dioxide (CO

the interior through sterile filters. Interior ventilation ensures a uniform distribution of the

gases, creating a homogeneous atmosphere. The oxygen concentration is controlled by introducing nitrogen: If nitrogen is introduced, the concentration of oxygen decreases.

) and nitrogen (N2 only for models with O2 module) are also injected into

2

10 D33451 | Edition 11/2016

Page 11

Construction and description

2.3 Material

For the outer housing, MEMMERT uses stainless steel (Mat.No. 1.4016 – ASTM 430) and for

the interior, stainless steel (Mat.No. 1.4301 – ASTM 304) is used, which stands out through

its high stability, optimal hygienic properties and corrosion resistance to many (but not all!)

chemical compounds (caution for example with chlorine compounds).

The chamber load for the appliance must be carefully checked for chemical compatibility with

the materials mentioned. A material resistance table can be requested from the manufacturer.

2.4 Electrical equipment

► Operating voltage and current consumption: See nameplate

► Protection class I, i.e. operating insulation with PE conductor in accordance with EN 61010

► Protection type IP 20 acc. to EN 60 529

► Interference suppression acc. to EN 55011 class B

► Appliance fuse: Safety fuse 250 V/15 A, quick-blow

► The temperature controller is protected with a miniature fuse 100 mA (160 mA at 115 V)

2.5 Connections and interfaces

2.5.1 Electrical connection

This appliance is intended for operation on an electrical power system with a system impedance Z

must ensure that the appliance is operated only on an electrical power system that meets

these requirements. If necessary, you can ask your local energy supply company what the

system impedance is.

Observe the country-specific regulations when making connections (e.g. in Germany DIN VDE

0100 with earth leakage circuit breaker).

of a maximum of 0.292 ohm at the point of transfer (service line). The operator

max

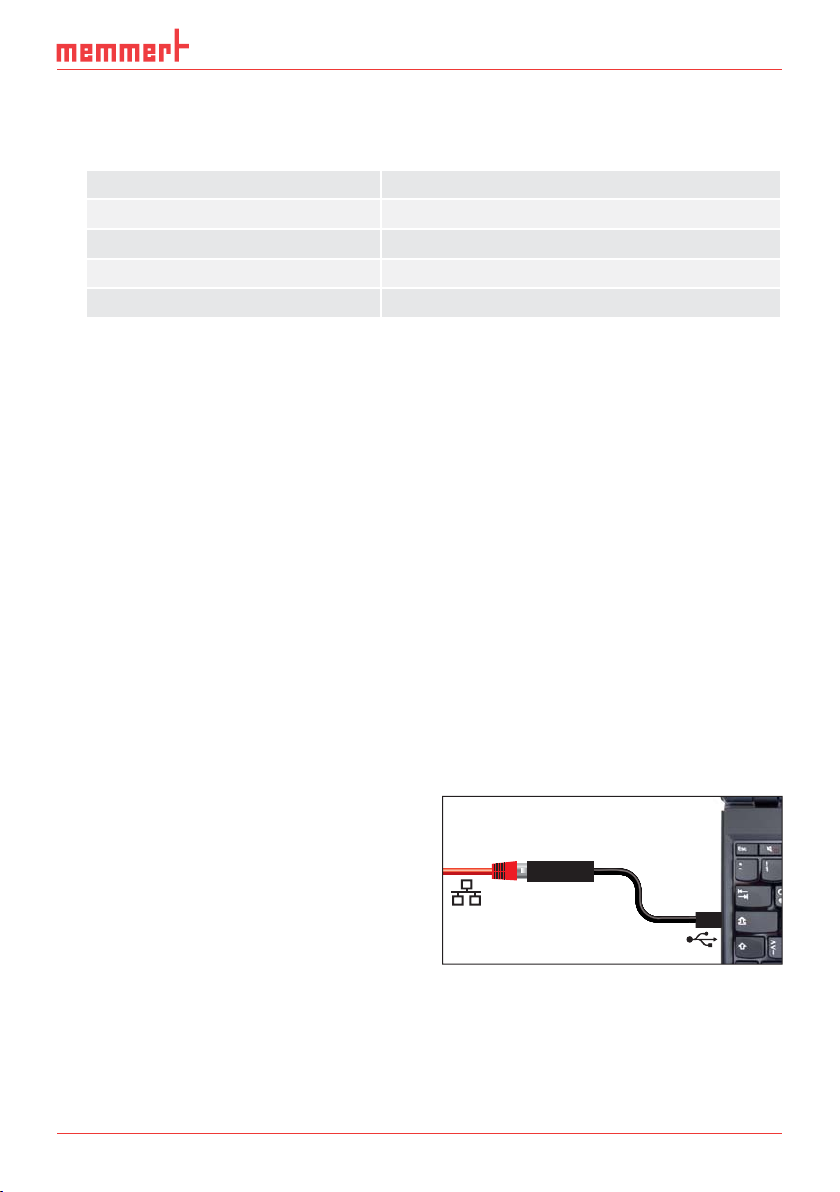

2.5.2 Communication interfaces

The communication interfaces are intended for appliances which meet the requirements of

IEC 60950-1.

USB interface

The appliance is fitted by default with a USB

interface in accordance with the USB specification. This way, you can

► transfer software stored on a USB storage

medium to the appliance (see page 58).

► export protocol logs from the appliance to

a USB storage medium (see page 60).

► transfer user ID data stored on a USB stor-

age medium to the appliance (see page

61).

The USB port is located on the right side of the ControlCOCKPIT (Fig. 3).

D33451 | Edition 11/2016 11

Fig. 3 USB interface

Page 12

Construction and description

Ethernet interface

Via Ethernet interface, the appliance can

be connected to a network, so that you

can transfer programmes created with the

AtmoCONTROL software to the appliance and

read out protocols. The Ethernet interface is

located on the rear of the appliance (Fig. 4).

For identification purposes, each appliance connected must have its own unique IP address.

Setting the IP address is described on page

48 .

You will find a description of how to transfer programmes via Ethernet in the enclosed AtmoCONTROL manual.

With an optional USB to Ethernet converter, the appliance can be directly connected to a computer / laptop (see Optional accessories on page 15).

Fig. 4 Ethernet interface

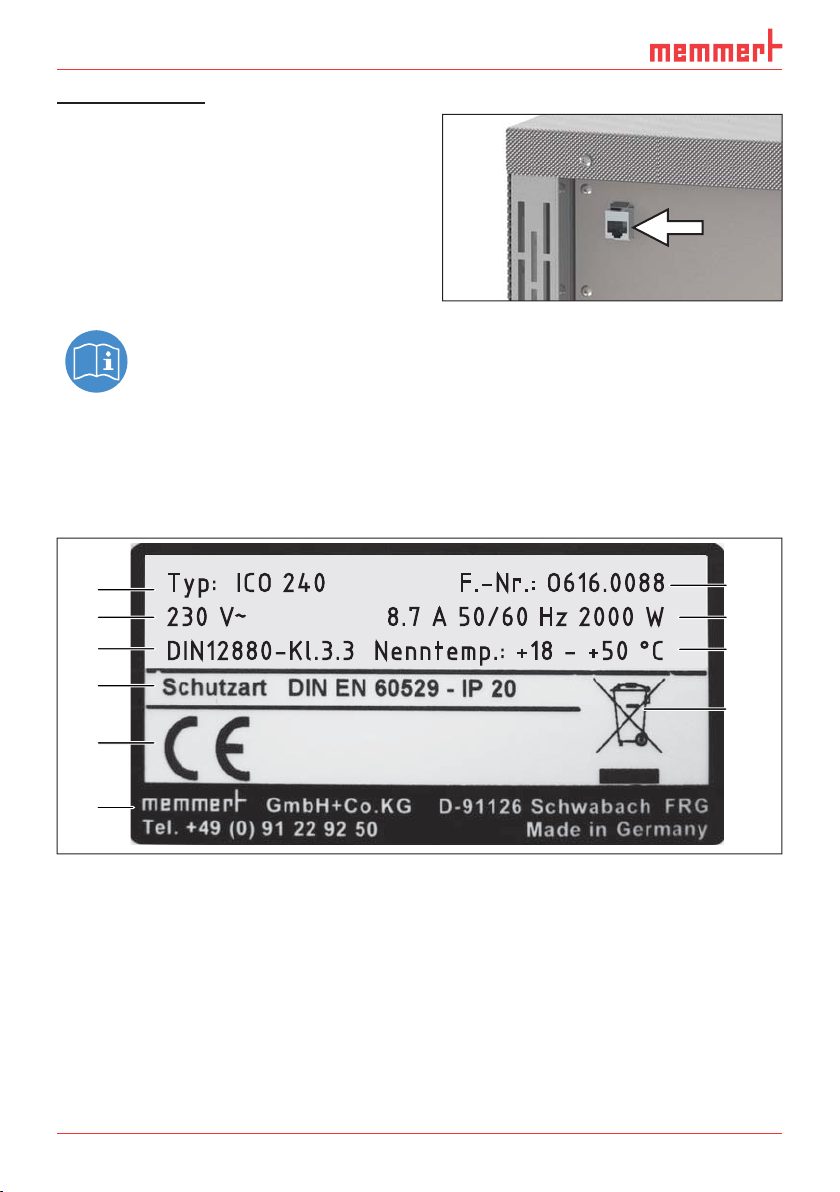

2.6 Designation (nameplate)

The nameplate (Fig. 5) provides information about the appliance model, manufacturer and

technical data. It is attached on the upper right behind the door (see page 10).

1

2

3

4

5

6

Fig. 5 Nameplate (example)

1 Type designation

2 Operating voltage

3 Applicable standard

4 Protection type

5 CE conformity

12 D33451 | Edition 11/2016

Typ: ICO 240 F.-Nr.: O616.0088

230 V

~

8.7

50/60 Hz 2000 W

DIN12880-Kl.3.3 Nenntemp.: +18 - +50 °C

6 Address of manufacturer

7 Disposal note

8 Temperature range

9 Connection / power ratings

10 Appliance number

10

9

8

7

Page 13

Construction and description

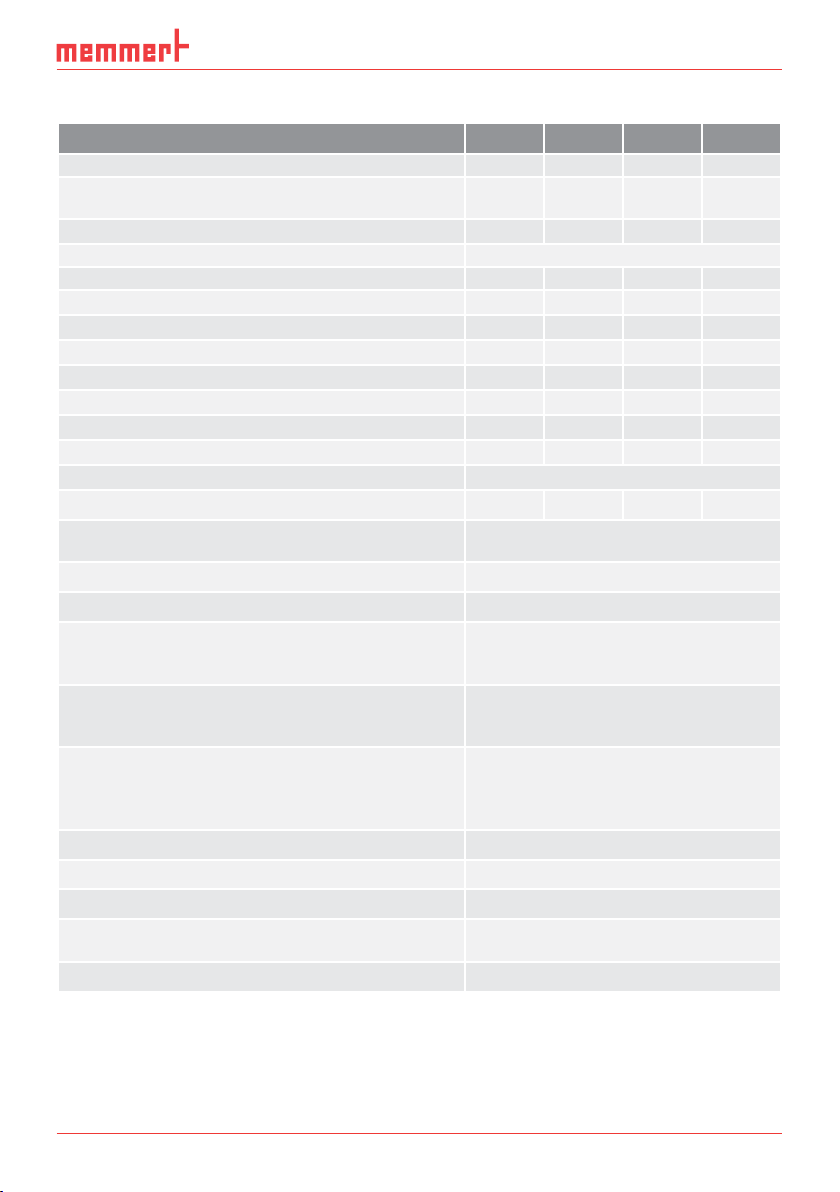

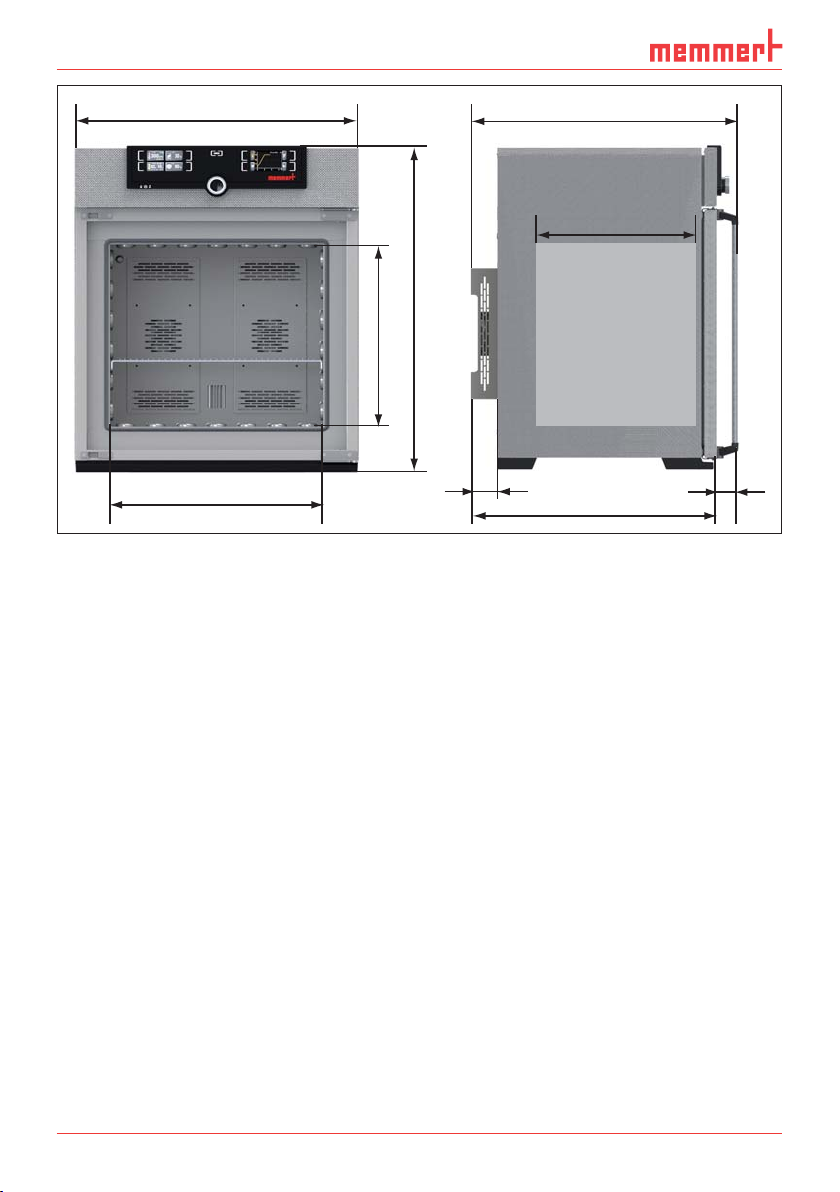

2.7 Technical data

Appliance size 50 105 150 240

Appliance width D* [mm] 559 719 719 759

Appliance height E* [mm]

(varies due to adjustable feet)

Appliance depth F* (without door handle) [mm] 521 591 591 691

Depth of door handle [mm] 56

Chamber width A* [mm] 400 560 560 600

Chamber height B* [mm] 425 480 700 810

Interior depth C* [mm] (less 35 mm for fan) 330 400 400 500

Chamber volume [litres] 56 107 156 241

Net weight [kg] 55 75 90 110

Weight including packaging [kg] 74 100 116 145

Power [W] 1000 1500 2000 2000

max. number of sliding shelves 5 6 10 12

max. load per sliding shelf [kg] 15

max. load per appliance [kg] 75 90 120 140

Operating temperature range

Setting temperature range [°C] +18 to +50

Adjustment precision [°C] 0.1

Temporal temperature deviation

(in accordance with DIN 12880:2007-05) at 37 °C

[K]

Spatial temperature deviation at +37 °C

(in accordance with DIN 12880:2007-05) at 37 °C

[K]

Adjustment range of active humidity control

[% rh]

(only for appliances with the corresponding configuration)

Setting accuracy humidity [%] 0.5

Adjustment range for CO

Setting accuracy for CO

Adjustment range for O

appliances with active humidity control)

Setting accuracy for O

[%]

2

[%]

2

[%] (optional and only for

2

[%]

2

* see Fig. 6 on page 14 .

791 846 1066 1176

5 °C above room temperature up to

50 °C

±0.1

±0.3

40 to 97 and rh off

0 to 20

0.1

1 to 20

0.1

D33451 | Edition 11/2016 13

Page 14

Construction and description

D

F

C

E

B

A

Fig. 6 Dimensions

90

G

2.8 Applied directives and standards

► Directive 2004/108/EC amended (Directive of the council for harmonisation of the laws of

the member states on electromagnetic compatibility). Standards complied with:

DIN EN 61326:2004-05, EN 61326:1997, EN 61326/A1:1998, EN 61326/A2:2001

EN 61326/A2:2003

► Directive 2006/95/EC amended (Directive of the council for harmonisation of the laws of

member states relating to electrical equipment designed for use within certain voltage

limits). Standards complied with:

DIN EN 61 010-1 (VDE 0411 part 1)

DIN EN 61 010-2-010 (VDE 0411 part 2-010)

EN 61 010-1:2001, EN 61 010-2-010

56

2.9 Declaration of conformity

You can download the EC declaration of conformity of the appliance online:

English: http://www.memmert.com/en/service/downloads/ce-statement/

German: http://www.memmert.com/de/service/downloads/eg-konformitaetserklaerung/

14 D33451 | Edition 11/2016

Page 15

Construction and description

2.10 Ambient conditions

► The appliance may only be used in enclosed areas and under the following ambient condi-

tions:

Ambient temperature

Humidity rh max. 70 %, non-condensing

Overvoltage category II

Pollution degree 2

Altitude of installation max. 2,000 m above sea level

10 °C to 35 °C

► The appliance may not be used in areas where there is a risk of explosion. The ambient air

must not contain any explosive dusts, gases, vapours or gas-air mixtures. The appliance is

not explosion-proof.

► Heavy dust production or aggressive vapours in the vicinity of the appliance could lead to

sedimentation in the interior and, as a consequence, could result in short circuits or dam-

age to electrical parts. For this reason, sufficient measures to prevent large clouds of dust

or aggressive vapours from developing should be taken.

2.11 Scope of delivery

► Power cable

► 1 or 2 stainless steel perforated sheets (load capacity: 15 kg each)

► 1 stainless steel water tray (only for appliances with passive humidity control)

► 1 water tank (only for appliances with active humidity control)

► Gas connection hose (depending on the model: one to three)

► USB storage medium with software and AtmoCONTROL manual

► the operating instructions at hand

► Calibration certificates

► Separately packaged fastening material for wall mounting (see page 19)

2.12 Optional accessories

► USB to Ethernet converter (Fig. 7). Makes it

possible to connect the Ethernet connection

interface (see page 12) to the USB port of

a computer / laptop.

Fig. 7 USB to Ethernet converter

D33451 | Edition 11/2016 15

Page 16

Delivery, transport and setting up

3. Delivery, transport and setting up

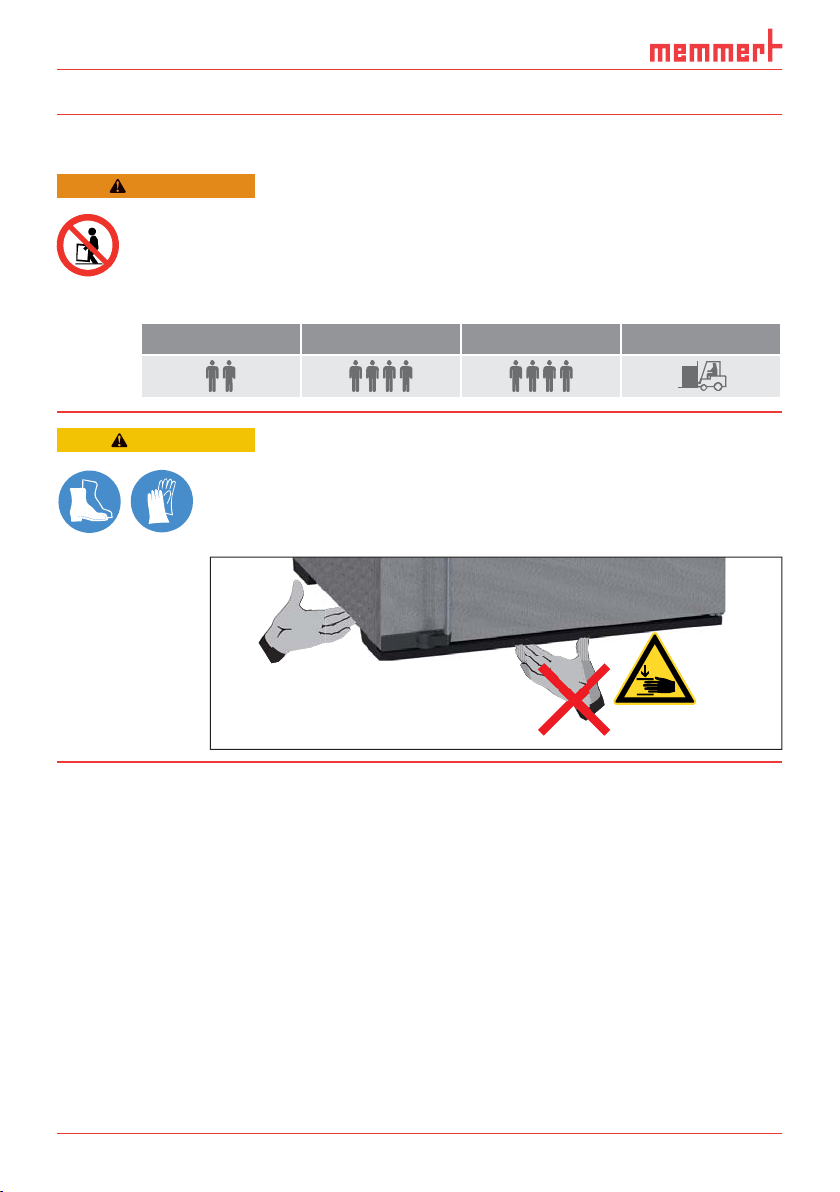

3.1 For your safety

WARNING

Because of the heavy weight of the appliance, you could injure yourself if you try to lift it. To carry appliances of size 50, at least two

persons are needed; for appliances of the sizes 105 and 150, four

people are needed. Appliances larger than that may not be carried

but must be transported with a manual pallet jack or forklift truck.

CAUTION

50

You might get your hands or feet squashed when transporting and installing the appliance. Wear protective gloves and

safety boots. When grasping the bottom of the appliance,

grasp it only on the sides:

105

150 240

9

16 D33451 | Edition 11/2016

Page 17

Delivery, transport and setting up

3.2 Delivery

The appliance is packed in cardboard and is delivered on a wooden palette.

3.3 Transport

The appliance can be transported in the following ways:

► With a forklift truck; move the forks of the truck entirely under the pallet.

► On a manual pallet jack

3.4 Unpacking

NOTICE

► To avoid damage, do not unpack the appliance until you reach the installation site.

Remove the cardboard packaging by pulling it upwards or carefully cutting along an edge.

3.4.1 Checking for completeness and transport damage

► Check the delivery note to ensure that the delivery is complete.

► Check the appliance for damage.

If you notice deviations from the delivery note, damage or irregularities, do not put the appliance into operation but inform the haulage company and the manufacturer.

3.4.2 Removing the transport protection

Remove the transport protection. It is located between the door hinge, door and frame and

has to be removed after opening the door.

3.4.3 Disposing of packaging material

Dispose of the packaging material (cardboard, wood, foil) in accordance with the applicable

disposal regulations for the respective material in your country.

3.5 Storage after delivery

If the appliance is first to be stored after delivery: Read the storage conditions from page

64.

D33451 | Edition 11/2016 17

Page 18

Delivery, transport and setting up

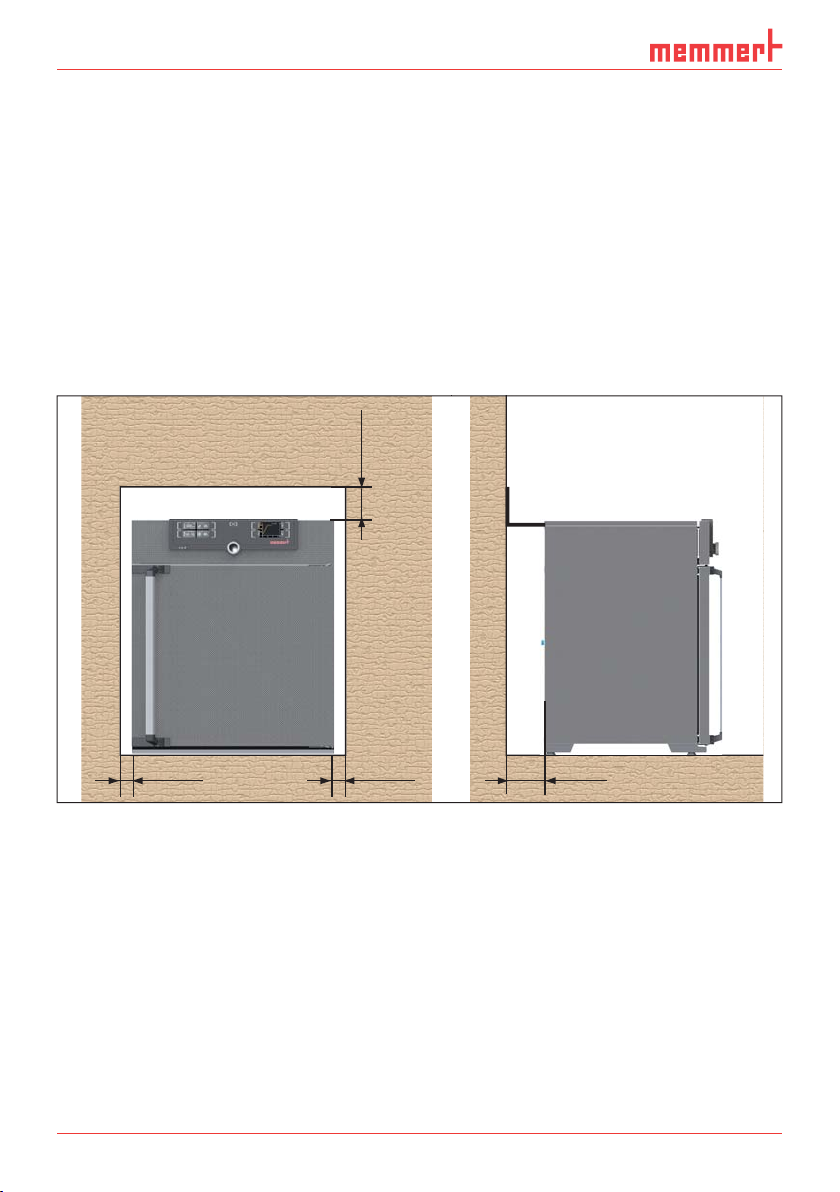

3.6 Setting up

3.6.1 Preconditions

The installation site must be flat and horizontal and must be able to reliably bear the weight

of the appliance (see Technical data on page 13). Do not place the appliance on a flammable surface.

The appliance emits small amounts of CO

fore, the installation site must be ventilated.

Depending on the model (see nameplate), a 230 V or 115 V power connection must be available at the installation site.

The distance between the wall and the rear of the appliance must be at least 15 cm. The clearance from the ceiling must not be less than 20 cm and the side clearance from walls or nearby

appliances must not be less than 5 cm (Fig. 8). Sufficient air circulation in the vicinity of the

appliance must be guaranteed at all times.

and N2 to its surroundings during operation. There-

2

FP

FP FP

Fig. 8 Minimum clearance from walls and ceiling

18 D33451 | Edition 11/2016

FP

Page 19

Delivery, transport and setting up

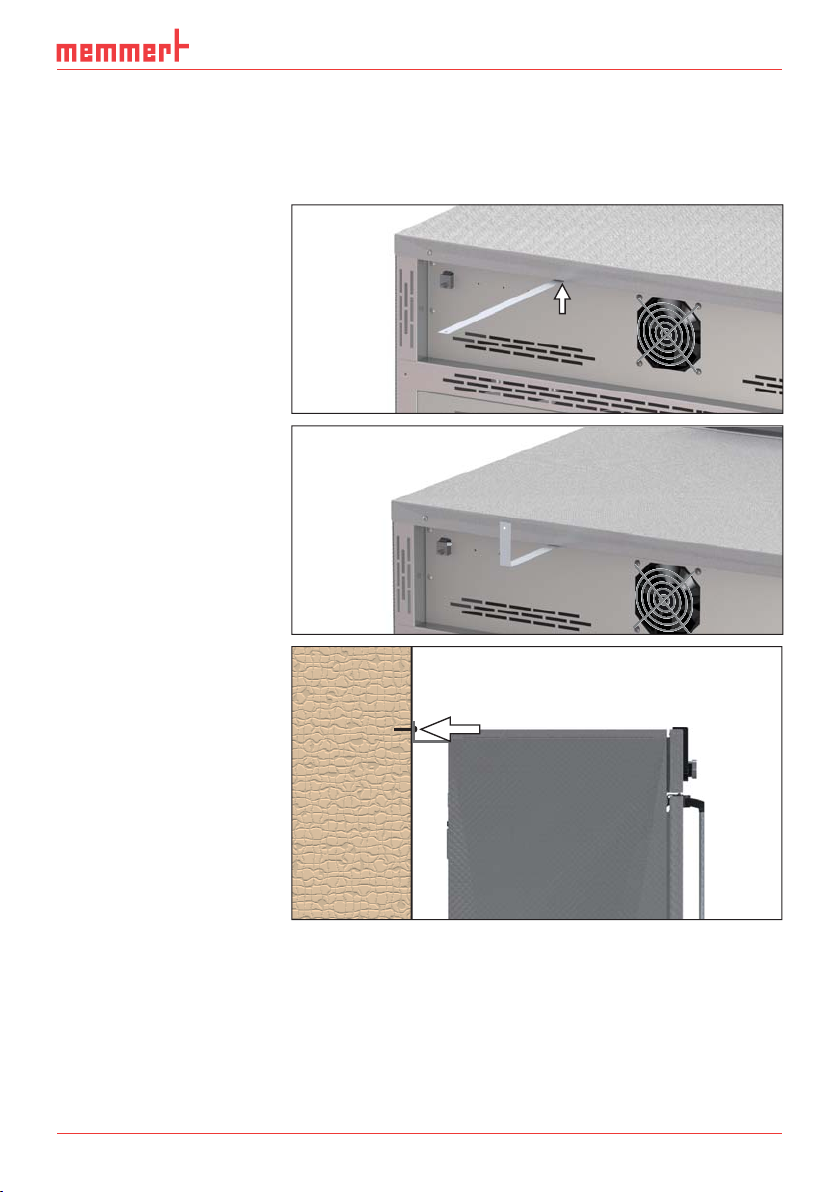

3.6.2 Tilt protection

Due to its centre of gravity, the appliance can fall over to the front and injure you or other

people. Always attach the appliance to a wall with the tilt protection included in the delivery.

In case there is not enough space, do not put the appliance into operation and do not open

the door. Contact the Memmert service (see page 2).

1. Screw the tilt protection

onto the back of the ap-

pliance as illustrated.

2. Bend the tilt protec-

tion upwards by 90 ° in

the desired distance to

the wall (consider the

minimum distance to the

wall, see Fig. 8).

3. Drill a hole, insert a plug

and screw the tilt protec-

tion to a suitable wall.

D33451 | Edition 11/2016 19

Page 20

Putting into operation

4. Putting into operation

NOTICE

The first time the appliance is operated, it must not be left unattended until it has reached the

steady state.

4.1 Connect the appliance to the power supply

Observe the country-specific regulations when making

connections (e.g. in Germany: DIN VDE 0100 with earth

leakage circuit breaker). Observe the connection and

power ratings (see nameplate and "Technical Data" on

page 13). Make sure to establish a safe PE conductor

connection.

Plug the provided power cable into the rear of the appliance and connect it to the power supply ( Fig. 9 ). Place the

power cable so that

► it is easily accessible at all times and can be pulled off quickly, for example in case of inter-

ference or an emergency;

► it does not represent a trip hazard;

► it cannot come into contact with any hot parts.

4.2 Establishing water supply

4.2.1 Water specifi cations

For humidification with a water tray or steam generator, only use: demineralised water (aqua

dem) in accordance with VDE 0510/DIN EN 50272 if you are working according to these

regulations (production conductivity ≥ 5 ≤ 10 μS/cm). You can buy battery water in accordance with the VDE 0510 standard in all larger drug stores, supermarkets and hardware stores

as well as from wholesale traders. The VDE 0510/DIN EN 50272 standard has to be explicitly

specified on the label.

Otherwise, possible calcification in the steam generators, steam piping and steam generator

pumps could affect the correct functioning of the appliance.

Only use chlorine-free water with a pH value of > 5 and < 7.

Fig. 9 Connect the power

cable to the rear of the appliance

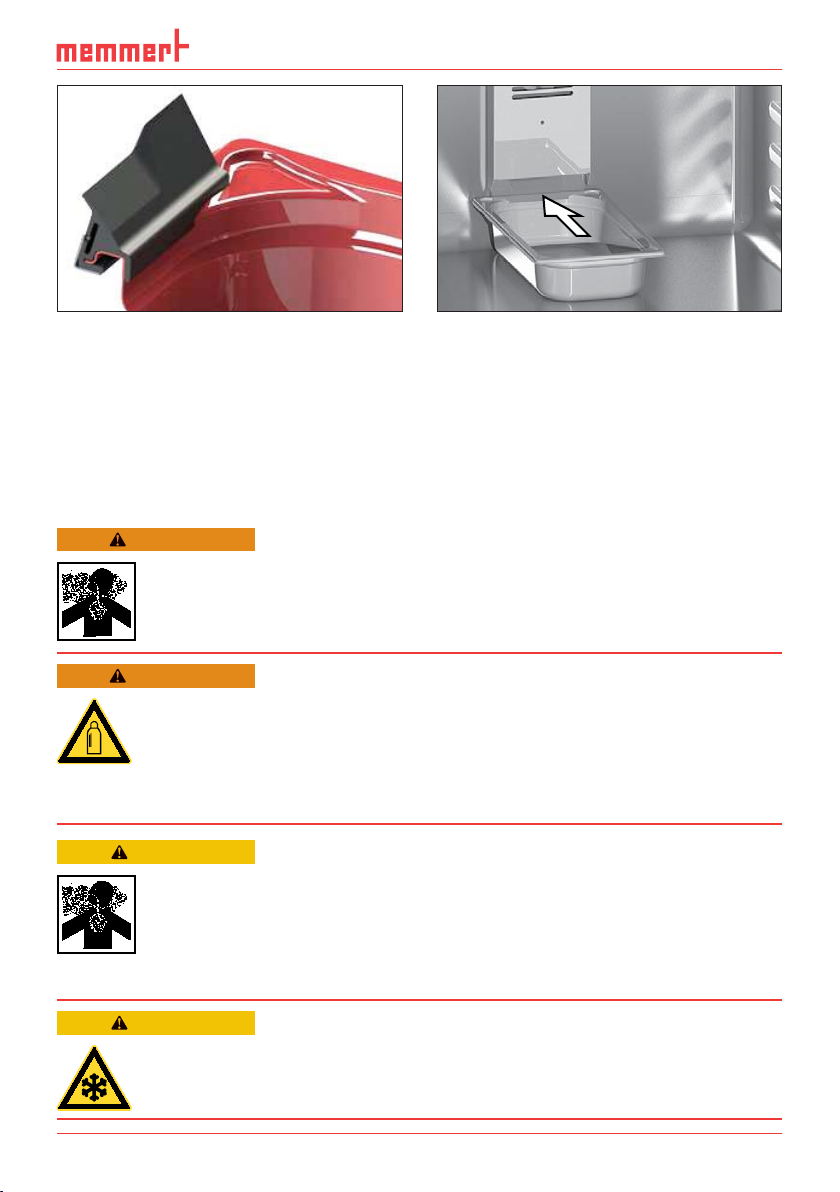

4.2.2 For appliances with passive humidity control: inserting the water tray

Mount the provided sealing lip to the narrow side of the water tray (Fig. 10) and fill 1.5 cm to

2 cm of water into the tray (for specifications see section 4.2.1).

Place the water tray with the attached sealing lip in the centre of the appliance floor and

carefully push it towards the rear panel until the sealing lip is completely under the ventilation

opening, touching the rear panel along its entire length (Fig. 11). The sealing lip magnetically

adheres to the rear panel and returns the water condensing on the humidity limiter to the

water tray.

NOTICE

Important: make sure not to spill any water and make sure that no water flows past the water

tray and onto the floor, as this would cause the humidity to exceed the maximum values.

20 D33451 | Edition 11/2016

Page 21

Putting into operation

Fig. 10 Attach the sealing lip

Fig. 11 Push the water tray to the rear

panel

4.2.3 For appliances with active humidity control: Fill up and connect the water

tank

Fill the supplied water tank with water and use the enclosed tube to connect it to the “H2O”

connection on the rear of the chamber (Fig. 12).

4.3 CO2 and N2 connection

WARNING

Danger of explosion and poisoning when introducing gases/substances other than CO2 and N2. Only carbon dioxide (CO2) and nitrogen (N2) may be introduced into the appliance through the gas

connections on the rear of the appliance.

WARNING

Gas bottles may burst or explode at high temperatures. Keep the gas

bottles away from open fl ames. Do not store gas bottles at or above

50 °C and ensure that the location is always well-ventilated. Prevent

water from penetrating as well as backfl ow into the gas bottles. It is

essential that you read the safety notes and instructions of the gas

supplier.

CAUTION

Danger of suffocation. CO2 and N2 can have a suffocating effect

in high concentrations. In normal mode, the appliance emits small

amounts of CO2 and N2 to its surroundings. You should therefore

ensure that the room in which it is installed is properly ventilated.

Always close the stop valve or pressure reducer on the gas bottles if

the appliance is not in operation.

CAUTION

High concentrations of CO2 can cause cold burns or frostbite. Avoid

contact with CO

D33451 | Edition 11/2016 21

gas to the eyes and skin.

2

Page 22

Putting into operation

ONN

On the rear of the appliance, connect

the delivered gas connection tubes to the

CO

and N2 gas bottles (pressure reducer)

2

and to the connections “CO2 In” and “N2

In” (N

only for appliances with active

2

humidity control) (Fig. 12). Set pressure

reducer to between 0.8 and 1.2 bar.

4.4 Switching on

Switch on the appliance by pressing the

On/Off switch

on the front of the appliance ( Fig. 13 ).

Three animated white dots

cate that start-up is in progress . If the

dots have another colour, an error has

occurred (see page 45).

After the first start-up, the appliance

display is set to English by default.

You can change the language as

described from page 47 . However,

to get a basic overview of operating

the appliance, you should read the

following chapter first.

indi-

123

4

Fig. 12 Media connections on the rear of the

appliance

1 Connection 1 CO

2 Connection 2 CO2 (optional)

2

3 Connection N2 (only for models with O2

module)

4 Water connection (only for appliances with

active humidity control)

ON

Fig. 13 Switch on appliance

22 D33451 | Edition 11/2016

Page 23

5. Operation and control

5.1 For your safety

WARNING

Leaving the door open during operation can cause the appliance to

overheat or pose a fi re hazard. Do not leave the door open during

operation.

WARNING

Gas bottles may burst or explode at high temperatures. Keep the gas

bottles away from open fl ames. Do not store gas bottles at or above

50 °C and ensure that the location is always well-ventilated. Prevent

water from penetrating as well as backfl ow into the gas bottles. It is

essential that you read the safety notes and instructions of the gas

supplier.

CAUTION

Danger of suffocation. CO2 and N2 in high concentrations can have

a suffocating effect. In normal mode, the appliance emits small

amounts of CO2 and N2 to its surroundings. You should therefore

ensure that the room is properly ventilated. Always close the stop

valve or pressure reducer on the gas bottles if the appliance is not in

operation.

Operation and control

CAUTION

High concentrations of CO2 can cause cold burns or frostbite. Avoid

contact with CO2 gas to the eyes and skin.

5.2 Operating personnel

The appliance may only be operated by persons who are of legal age and have been instructed accordingly. Personnel who are to be trained, instructed or who are undergoing general

training may only work with the appliance under the continuous supervision of an experienced person.

D33451 | Edition 11/2016 23

Page 24

Operation and control

5.3 Opening the door

► To open the door, pull the door handle to the side (to the left or to the right, depending

on the door variation, see Fig. Fig. 14 , A).

► To close the appliance, push the door closed and push the door handle to the side (B).

A

Fig. 14 Opening and closing the door

B

24 D33451 | Edition 11/2016

Page 25

Operation and control

5.4 Loading the appliance

WARNING

When loading the appliance with an unsuitable load, poisonous or

explosive vapours or gases may be produced. This could cause the

appliance to explode, and people could be severely injured or poisoned. The appliance may only be loaded with materials which do

not form any toxic or explosive vapours when heated up and cannot

ignite (see also Intended use on page 8). If there is any doubt as

to the composition of materials, they must not be loaded into the

appliance.

NOTICE

► Check the chamber load for chemical compatibility with the materials of the appliance (see

page 11).

Insert the sliding steel grids or sliding shelves. The maximum number or grids / shelves and the

load capacity are specified in the technical data overview from page 13 .

Load the chamber leaving

enough space between the

items so that proper air

circulation in the interior is

guaranteed. Do not place any

of the chamber load on the

bottom, touching the side

walls or right below the

ceiling of the chamber (Fig.

15, see also the "correct

loading" sticker on the

appliance).

In case of improper loading

(not enough space between

the items), the set temperature may be exceeded or it

may take longer until it is

reached.

Fig. 15 Correct placement of the chamber load

5.5 Operating the appliance

5.5.1 ControlCOCKPIT

In manual operation, the desired parameters are entered at the ControlCOCKPIT on the front

of the appliance (Fig. 16 and Fig. 17 ). You can also make basic settings here (menu mode). Additionally, warning messages are displayed, e.g. if the temperature is exceeded. In programme

mode, the parameters defined, the programme description, the programme segment currently active and programme duration remaining are displayed (for a more detailed description, see page 30).

D33451 | Edition 11/2016 25

Page 26

Operation and control

ONN

ONN

ONN

ONN

5 678912 3 4

Fr 20.10.2010 20:31

min

000°C

LIGHTONLIGHT

ON

min

auto

ALARM

ALARM

15.0°C

CO2

1.0 %

Set

15.

0

%

of °C

max

max

40.0°C

000°C

auto off

+

+

/

-

-

TEMP

22.4°C

TIMER

TIMER

44h:44m

End

13:30 23.11.

End14 :45

ON

ON

O2

10.0 %

10.

0

%

Set

Set 37

.0°C

HUMIDITY

30m04h

30%rh

Set 30 %rh

13:44

12.Sept.2012

off

Manual Mode

Holz trocknen

aufheizen

09:12h

GRAPH

%rh°C

0.0K

012

99K

19 2015 16 17 1810 11 12 13 14

Fig. 16 ControlCOCKPIT of ICO appliances with O2 and active humidity control in operating

mode

5678912

TEMP

°C22.4

°CSet 37.0

TIMER

TIMER

30m04h

44h:44m

Ende

13:30 23.11.

End14 :45

ON

ON

min

000°C

LIGHTONLIGHT

ON

min

auto

ALARM

ALARM

15.0°C

CO2

1.0 %

Set

Fr 20.10.2010 20:31

13:44

12.Sept.2012

off

Manual Mode

Holz trocknen

aufheizen

09:12h

15.

0

%

GRAPH

of °C

max

max

%rh°C

40.0°C

000°C

auto off

+

+

/

0.0K

012

-

99K

-

19 2015 16 17 1810 11 12

Fig. 17 ControlCOCKPIT of ICO appliances without O2 and active humidity control in operating mode

1 Activation key for temperature setpoint

adjustment

2 Setpoint and actual temperature display

3 Display O

4 Activation key for setting the O

5 Switch to menu mode (see page 46)

6 Activation key for setting the CO

7 Display CO

8 Appliance state and programme display

setpoint and actual value

2

setpoint and actual value

2

setpoint

2

2

setpoint

9 Activation key for the appliance state

10 Activation key digital backwards counter

with target time setting, adjustable from 1

minute to 99 days

11 On/Off switch

12 Display digital backwards counter with

target time setting, adjustable from 1 minute to 99 days

13 Display humidity setpoint and actual

value

14 Humidity control activation key

15 Turn control for setpoint adjustment

16 Confirmation key (accepts setting made

with the turn control)

17 Activation key for setting the temperature,

humidity, CO

18 Temperature, humidity, CO

monitoring

and O2 monitoring

2

and O2

2

19 Graphical representation of setpoint and

actual values

20 Activation key for graphic representation

26 D33451 | Edition 11/2016

Page 27

5.5.2 Basic operation

TIMERmh

T

T

In general, all settings are made according to the following pattern:

1. Activate the desired parameter (e.g. temperature). To do so, press the corresponding activation key on the left or right or

the respective display. The activated display is lined in colour, the other displays

are dimmed. The set value is highlighted

in colour.

Operation and control

TEMP

TEMP

22.4°C

37.0°CSet

.5°C100

2. By turning the turn control to the left

or right, adjust the set value (e.g. to

37.0 ºC).

TEMP

22.4°C

3. Save the set value by pressing the confirmation key.

The display returns to normal and the

appliance begins adjusting to the defined

set value.

Additional parameters can be set accordingly.

If no new values are entered or confirmed for approx. 30 seconds, the appliance automatically restores the former values.

If you want to cancel the setting procedure, press the

activation key on the left or right of the display that you

want to exit. The appliance restores the former values.

Only the settings that you have confirmed by pressing the

confirmation key before cancelling the setting procedure

are accepted.

5.5.3 Operating modes

The appliance can be operated in different modes:

► Manual mode: The appliance runs in permanent operation at the values set on the Con-

trolCOCKPIT. Operation in this mode is described in chapter 5.5.4 .

► Operation with digital backwards counter with target time setting, adjustable from 1

minute to 99 days (timer): The appliance runs at the values set until the timer has elapsed.

Operation in this mode is described in chapter 5.5.5 .

► Programme mode: The appliance automatically runs programme sequences which have

been defined using AtmoCONTROL software at a computer / laptop and then transferred

to the appliance from a USB stick or via Ethernet. Operation in this mode is described in

chapter 5.5.6 .

► via remote control (AtmoREMOTE)

TEMP

23.2°C

Set 37

37.0°CSet

.0°C

T

D33451 | Edition 11/2016 27

Page 28

Operation and control

The status display shows you which operating mode or operating state the appliance is

currently in. The current operating state is highlighted in colour and indicated by the text

display:

Appliance is in programme mode

■ Programme is stopped

Appliance is in manual mode

The example on the right shows the appliance in manual

mode, identified by the coloured hand symbol.

12.Sept.2012

Manual Mode

13:44

► When the appliance is in timer mode, Timer active

is displayed:

12.Sept.2012

Timer active

13:44

► If the appliance is in remote control mode,

the

symbol appears in the temperature display:

5.5.4 Manual mode

In this operating mode, the appliance runs in permanent

operation at the values set on the ControlCOCKPIT.

Adjustment options

As described in chapter 5.5.2 , you can set the following parameters after pressing the corresponding activation key (in any sequence):

Temperature

Adjustment range: +18 °C to +50 °C

Heating operation is indicated by the

You can select °C or °F as the temperature unit displayed (see

page 49).

Humidity (only for appliances with active humidity control)

Adjustment range: 40 to 97 % rh and OFF

Humidification is indicated by the

Dehumidification is indicated by the

When the appliance heats up, the humidity is dynamically adjusted

to approach the setpoint depending on the dew point of the

interior temperature.

symbol.

symbol.

symbol.

TEMP

23.2°C

Set 38

TEMP

22.4

37.0

Set

HUMIDITY

34%

70

Set

.0°C

°C

%rh

°C

rh

28 D33451 | Edition 11/2016

Page 29

CO

2

Adjustment range: 0 to 20 % in steps of 0.1 %

The number 1 or 2 displayed in the gas bottle symbol indicates

which gas bottle is currently active.

Operation and control

CO2

1.0 %

15.0

Set

1 2

%

O2 (only for corresponding model)

Adjustment range: 1 % to 20 % in steps of 0.1 %

O2

1.0 %

10.

Set

0

%

5.5.5 Operation with digital backwards counter with target time setting,

adjustable from 1 minute to 99 days ( timer)

In timer operation, you can adjust the time the appliance runs at the set values. The appliance

has to be in manual operating mode for this.

1. Press the activation key to the left of

the timer display. The timer display is

activated.

2. Turn the turn control until the desired

duration is displayed – in this example 4

hours 30 minutes. The approximate end

time is shown beneath, in a smaller font.

Up to a duration of 23 hours 59 minutes, the time is displayed in hh:mm (hours:minutes)

format. For 24 hours and more, the format dd:hh (days:hours) is used. The maximum

duration adjustable is 99 days 00 hours.

TIMER

-

--h- m

9:00 23.11.

Ende

TIMER

04 mh 3

13:30 23.11.

End

0

3. Press the confirmation key to confirm.

The display now shows the remaining time

in a large font and the approximate end time

in a smaller font beneath. The status display

shows Timer active.

D33451 | Edition 11/2016 29

TIMER

End

30m04h

13:30 23.11.

12.Sept.2012

Timer active

13:44

Page 30

Operation and control

0

4. Now, as described under 5.5.2 , set the individual values which you want the appliance

to operate at. The set values can be changed at any time while the timer elapses. The

changes are effective immediately.

In Setup, you can choose if the timer should run setpoint-dependent or not. This determines whether the timer should not start until a tolerance band around the set temperature is reached or if it should start right after activation (see page 50). If the timer runs

setpoint-dependent, this is indicated by the symbol in the timer display.

When the timer expires, the display shows 00h:00m.

All functions (heating etc.) are switched off. In addition, an

TIMER

acoustic alarm sounds, which can be turned off by pressing the

confirmation key.

Note that condensation may occur in the interior after you

End

00m00h

13:30 23.11.

switch off the heating.

To deactivate the timer, open the timer display by pressing the

activation key again and then turning the turn control to reduce

TIMER

the timer setting until --:-- is displayed. Confirm with the confirmation key.

5.5.6 Programme mode

End

--m--h

9:00 23.11.

In this operating mode, programmes saved in the appliance can be started with different

combinations of individual parameters (temperature, humidity, etc.) at staggered intervals,

which the appliance then automatically processes in sequence. These programmes are not created directly at the appliance but externally at a computer / laptop and using AtmoCONTROL

software. Transfer to the appliance is possible using the provided USB storage medium or via

Ethernet.

A description of how to create and save programmes can be found in the separate

AtmoCONTROL software manual.

NOTICE

One or several default sterilisation programmes are saved in the appliance (see page 58).

They only serve to sterilise the appliance itself. Do not use them to sterilise medical devices.

The hold time in the sterilisation programme set in the appliance at 180 °C is 1 h. The total

time including heating up and cooling down to 50 °C is 6 h 30 min.

Starting a programme

1. Press the activation key to the right of

the status display. The current operating

mode is highlighted automatically, in this

example

Manual mode ( ).

2. Turn the turn control until the start

symbol is highlighted. The current

programme is displayed, in this example

Steri 180.

30 D33451 | Edition 11/2016

Fr 20.10.2010 20:31

Manual mode

manueller Betrieb

Activate

GRAPH

8

80

17:4413.Sept.2012

Steri 180

ready

10:4412.Sept.2012

Page 31

Operation and control

0

Only the programme currently selected in menu mode and shown in the display can be

used. If you want to process another programme, you need to activate it in menu mode

first (description from page 58).

3. To start the programme, press the confirmation key. The programme is executed.

The display shows:

► the programme description (in this exam-

ple Steri 180)

Steri 180

Heat up

► the programme segment description, in

this example

Heat up

► the current run (in case of loops)

You cannot change any parameters (e.g. the temperature) at the appliance while a

programme is running. However, the displays

ALARM and GRAPH can still be used.

Cancel programme

You can cancel an active programme at any

time.

1. Press the activation key to the right of

the status display. The status display is

automatically highlighted.

2. Turn the turn control until the stop symbol

is highlighted.

■

%

%

°

Fr 20.10.2010 20:31

manueller Betrieb

Steri 180

Heat up

GRAPH

80

8

10:4412.Sept.2012

Progr. Stopp

Steri 180

10:4412.Sept.2012

10:4812.Sept.2012

3. Press the confirmation key to confirm.

The programme is cancelled.

End

Steri 180

A cancelled programme cannot be resumed at the point it was cancelled. It must be

restarted from the beginning.

End of programme

End is shown on the display to indicate that

the programme has finished.

D33451 | Edition 11/2016 31

End

Steri 180

10:4912.Sept.2012

10:4912.Sept.2012

Page 32

Operation and control

You can now

► restart the programme as described

► select another programme for processing in menu mode (see page 58) and run it as

described.

► return to manual mode. To do so, reactivate it by pressing the

activation key next to the status display, then turn the turn

control until the hand symbol

press the confirmation key.

is highlighted in colour and

12.Sept.2012

Manual Mode

13:44

5.6 Monitoring function

5.6.1 Temperature monitoring

The appliance is equipped with a multiple overtemperature protection in accordance with

DIN 12 880. This serves to avoid damage to the chamber load and/or appliance in case of a

malfunction:

► electronic temperature monitoring (TWW)

► automatic temperature monitor ( ASF)

► mechanical temperature limiter (TB)

The monitoring temperature of the electronic temperature

monitor is measured via a separate Pt100 temperature sensor in

the interior. Temperature monitoring settings are made via the

ALARM display. The settings made apply to all operating modes.

If temperature monitoring has been triggered, this is indicated

by the temperature display: the actual temperature is highlighted

in red and a warning symbol

temperature monitoring triggered (TWW in this example) is

shown beneath the temperature.

If the acoustic alarm has been activated in menu mode (

see page 59, indicated by the speaker symbol

display), the alarm is additionally signalled by an intermittent

acoustic signal, which can be turned off by pressing the confirmation key. Information on what to do in this case is provided

in chapter Malfunctions, warning and error messages from page

41.

Before reading how to adjust temperature monitoring (from page 34), please read the

description of the individual monitoring functions here.

is displayed ( Fig. 18 ). The type of

Sound

in the alarm

Electronic temperature monitoring ( TWW)

The manually set monitoring temperature min and max of the overtemperature control is

monitored by an adjustable over/undertemperature controller (TWW) of protection class 3.3

according to DIN 12 880. If the manually set monitoring temperature

TWW takes overtemperature control and begins to regulate the monitoring temperature (Fig.

19).

ALARM

min

36.5 °C

auto

TEMP

max

38.5 °C

+

2.0K

-

42.4°C

TWW Set 38.5 °C

Fig. 18

Temperature monitoring

triggered

max is exceeded, the

32 D33451 | Edition 11/2016

Page 33

Operation and control

°C

Emergency operation

Setting MAX

Set

temperature

Controller error

t

Fig. 19 Schematic diagram of how TWW temperature monitoring works

Automatic temperature monitor ( ASF)

ASF is a monitoring device that automatically follows the set temperature setpoint within an

adjustable tolerance band (Fig. 20).

The ASF – if switched on – is automatically activated as soon as the actual temperature value

reaches 50 % of the set tolerance band of the setpoint (in the example: 50 °C ± 1 K) for the

first time (section A).

When the temperature violates the set tolerance band around the setpoint (in the example in

Fig. 20:

50 °C ± 2 K) – e.g. if the door is opened during operation (section B of illustration) – the alarm

is set off. The ASF alarm is automatically triggered as soon as 50 % of the set tolerance band

of the setpoint (in the example: 50 °C ± 1 K) are reached again (section C).

If the temperature setpoint is altered, the ASF is automatically disabled temporarily (in this

example: The setpoint is changed from 50 °C to 25 °C, section D), until it reaches the tolerance

range of the new temperature setpoint (section E).

°C

52°C

ABCDE

52°C

50°C

25°C

48°C

48°C

27°C

23°C

t

ASF active

Fig. 20 Schematic diagram of how the ASF temperature monitoring works

D33451 | Edition 11/2016 33

AUTO AUTO AUTO

ASF alarm

ASF active ASF active

Page 34

Operation and control

Mechanical temperature monitoring: Temperature limiter (TB)

The appliance is equipped with a mechanical temperature

limiter (TB) of protection class 1 in accordance with DIN 12 880. If

the electronic monitoring unit fails during operation and the

default maximum temperature is exceeded by at least 20 °C, the

temperature limiter, as the final protective measure, switches off

the heating permanently.

Adjusting temperature monitoring

1. Press the activation key to the left of the

ALARM display. The temperature moni-

toring setting is automatically activated

(

).

TEMP

72.4°C

TB Set 38.5 °C

ALARM

ALARM

min

max

max

40

15.0 °C .0 °C

auto

000°C

auto off

+

+

0.0K

99K

-

-

min

000°C

2. Save the selection by pressing the confirmation key. The

min setting (under-

temperature protection) is automatically

activated.

1. By turning the turn control, adjust the

desired lower alarm limit value, in the

example on the right 35.5 °C.

The lower alarm limit value cannot be set

higher than the top one. If no undertemperature protection limit is required, set

the lowest temperature.

2. Press the confirmation key to confirm.

The

max display (overtemperature pro-

tection) is activated.

3. By turning the turn control, adjust the

desired upper alarm limit value, in the

example on the right 38.5 °C.

The monitoring temperature must be set

sufficiently high above the maximum set

temperature. We recommend 0.5 to 1 K.

4. Accept the upper alarm limit value by

pressing the confirmation key. The setting

of the automatic temperature monitor

(ASF) is automatically activated (

auto).

min

15.0 °C .0°C

auto

min

°C

auto

min

°C

auto

min

°C

35 5.

auto

min

35.5°C

auto

ALARM

40

ALARM

ALARM

ALARM

ALARM

max

+

-

max

40.0°C35 5.

+

-

max

+

-

max

38 5.

+

-

max

38.5 °C

+

-

0.0K

0.0K

0.0

0.0K

0.0K

°C355. 400.

K

°C

34 D33451 | Edition 11/2016

Page 35

Operation and control

°

m

FEUCHTE

30.0%rh

Set 30.0%rh

°CSet 37.0

5. With the turn control, select ON (

) or

OFF ().

6. Press the confirmation key to confirm.

The ASF tolerance band setting is activated.

7. With the turn control, adjust the desired

tolerance band. We recommend 0.5 to

1 K.

8. Press the confirmation key to confirm.

Temperature monitoring is now active.

5.6.2 Humidity monitoring

(only for appliances in the corresponding configuration)

If humidity monitoring was triggered, this

is indicated by the humidity display: the

actual humidity is highlighted in red and a

warning symbol

is shown ( Fig. 21 ). If the

acoustic alarm has been activated in menu

mode (

by the speaker symbol

Sound, see page 59, as indicated

), the alarm is

additionally signalled by an intermittent

acoustic signal. Information on what to do

in this case is provided in chapter Malfunctions, warning and error messages from

page 46.

MP

°C22.4

°CSet 37.0

0C°C

FEUCHTE

HUMIDITY

30.0%rh

m

75.4

m

:30

Fig. 21

Humidity monitoring triggered

Set 30.0%rh

Set 70

ALARM

min

35.5°C

auto

max

38.5 °C

+

-

0.0K

ALARM

min

°C

auto

max

38.5°C35 5.

+

K

0.3

-

ALARM

min

35 5.

auto

°C

max

38.5°C

+

-

2.0

K

ALARM

min

36.5 °C

auto

HUMIDITY

75.4

%rh

.0%rh

Set 70

max

38.5 °C

%rh

.0%rh

+

-

2.0K

LIGOLIG

O

min

a

000

D33451 | Edition 11/2016 35

Page 36

Operation and control

Adjusting humidity monitoring (only for appliances in the corresponding

configuration)

1. Press the activation key to the left of the

ALARM display. The temperature moni-

toring setting is automatically activated.

2. Turn the turn control until the humidity

monitoring entry

3. Accept the selection by pressing the con-

firmation key. The lower humidity alarm

limit is automatically highlighted.

4. By turning the turn control, adjust the

desired lower alarm limit, in the example

on the right 50 % rh.

5. Accept the selection by pressing the con-

firmation key. The upper humidity alarm

limit is automatically highlighted.

6. By turning the turn control, adjust the

desired upper alarm limit, in the example

on the right 70 % rh.

is highlighted.

min

min

min

min

min

20.0%rh

ALARM

20.0%rh

ALARM

50.0%rh

ALARM

50.0%rh

ALARM

50.0%rh

min

15.0 °C .0 °C

min

auto

000°C

ALARM

ALARM

ALARM

40

max

60.0%rh

max

60.0 %rh

max

60.0%rh

max

60.0 %rh

max

70.0 %rh

max

max

000°C

auto off

+

+

0.0K

-

-

99K

7. Accept the selection by pressing the

confirmation key and leave the

Alarm

display by pressing the activation key on

the side. Humidity monitoring is now

active.

ALARM

max

70.0%rh

min

50.0%rh

36 D33451 | Edition 11/2016

Page 37

5.6.3 CO2 monitoring

H

au

09

Fr 20

ALARM

of °C

ON

LIGHT

ON

LIGHT

LICHT

%

100

ALARM

Ma

12.Se

If CO2 monitoring was triggered, this is

indicated by the CO

value is highlighted in red and a warning

symbol

is shown ( Fig. 22 ). If the acoustic

display: the actual

2

alarm has been activated in menu mode

Sound, see page 59, as indicated by the

(

speaker symbol

), the alarm is additionally signalled by an intermittent acoustic

signal. Information on what to do in this

case is provided in chapter Malfunctions,

warning and error messages from page

41.

Adjusting CO2 monitoring

12.0

E

.0%rh

t 30.0%rh

Fig. 22

CO

monitoring triggered

2

CO2

Operation and control

%

Set 15

.0%

LIGHTONLIGHT

ON

min

000°C

min

35.5°C

auto

LICHT

CO2

100

ALARM

ALARM

%

%12.0

Set 15

.0%

of °C

max

max

38.5°C

000°C

auto off

+

+

/

0.0K

-

99K

-

1. Press the activation key to the left of the

ALARM display. The temperature moni-

toring setting is automatically activated.

2. Turn the turn control until the CO2 adjust-

ment entry is selected (upper gas bottle

symbol

3. Accept the selection by pressing the

confirmation key. The lower alarm limit is

automatically selected.

4. By turning the turn control, adjust the

desired lower alarm limit, in the example

on the right 7 %.

5. Accept the selection by pressing the

confirmation key. The upper alarm limit is

automatically highlighted.

).

min

10 4.

10.0

min

10 4.

7.0

min

7.0%

min

000°C

ALARM

min

10.0 %

ALARM

%

ALARM

%

ALARM

ALARM

ALARM

min

max

max

40

15.0 °C .0 °C

000°C

auto

auto off

+

max

10.0 %

max

10.0%

max

10.0%

max

10.0%

+

0.0K

99K

-

-

D33451 | Edition 11/2016 37

Page 38

Operation and control

FEUCHTE

.0°C

6. By turning the turn control, adjust the

desired upper alarm limit, in the example

on the right 15 %.

7. Accept the selection by pressing the

confirmation key and leave the

Alarm

display by pressing the activation key on

the side. CO

monitoring is now active.

2

5.6.4 O2 monitoring

(only for appliances in the corresponding configuration)

If O

monitoring was triggered, this is

2

indicated by the O

is highlighted in red and a warning symbol

display: the actual value

2

is shown ( Fig. 23 ). If the acoustic alarm

has been activated in menu mode (

see page 59, as indicated by the speaker

symbol

), the alarm is additionally

signalled by an intermittent acoustic signal.

Information on what to do in this case is

provided in chapter Malfunctions, warning

and error messages from page 41.

Sound,

O2

O2

12.0

10.0 %

Set 15

10.0

Set

C

FEUCHTE

Fig. 23

O

monitoring triggered

2

Adjusting O2 monitoring

O2 monitoring is set the same way as CO2

monitoring (see page 37). After the alarm

display is activated, turn the turn control until the O

gas bottle symbol

values as described above.

adjustment entry is selected (upper

2

) and set the min and max

ALARM

max

15.0%

min

7.0%

ALARM

min

7.0%

O2

O2

12.0

10.0 %

%

.0%

%

Set

ALARM

min

10.0 %

Set 15

10.

max

15.0 %

%

.0%

0

%

max

10.0 %

5.7 Graph

The GRAPH display provides an overview of the chronological sequence of the setpoint values

and actual values for temperature, humidity, CO

Press the activation key to the

right of the

GRAPH display. The

display is enlarged and the temperature profile shown.

38 D33451 | Edition 11/2016

°C

100

40

80

39

60

40

38

20

0 4 8 12162024

14.00 16.00 18.00

and O2 content as a curve.

2

12.09.2012

Fr 20.10.2010 20:34

Page 39

Operation and control

0

:

► To display the setpoint and ac-

tual values for humidity, CO

and O

: Press the activation

2

key next to the parameter

selection.

Select the humidity symbol or

one of the gas bottle symbols

with the turn control. Accept the

selection by pressing the confirmation key.

°C

100

2

40

80

39

60

40

38

20

0 4 8 12162024

14.00 16.00 18.00

12.09.2012

Fr 20.10.2010 2

40

39

12.09.2012

38

12.09.2012

► To change the time frame to

be displayed: Press the activation key next to the arrow symbols. The time frame

to be displayed can now be

changed by turning the turn

control.

°C

100

40

80

39

60

40

38

20

0 4 8 12162024

14.00 16.00 18.00

Fr 20.10.2010 20

► To zoom the graph in or out:

2

Press the activation key next

to the magnifying glass symbol. Select whether you want

to zoom in or out (+/–) with

the turn control and confirm

your selection by pressing the

confirmation key.

To close the graphical representation, press the activation key you used to activate it again.

.2010 20:34

D33451 | Edition 11/2016 39

Page 40

Operation and control

0

ONN

5.8 Sterilising the appliance

One or several sterilisation programmes are saved in the appliance. They are used to sterilise

the appliance. Do not use them to sterilise medical devices.

The hold time in the appliance’s sterilisation programme at 180 °C is 1 h. The total time

including heating up and cooling down to 50 °C is 6 h 30 min. At the end of the sterilisation

programme, the appliance maintains a constant temperature of 37 °C and the status display

shows

Steri End.

Appliance sterilisation procedure

1. Empty the water trays or, for appliances with active humidity control, open the door briefly

to vent the appliance and let the humidity escape.

2. Insert the slide-in units and the water tray with the rubber seal and close the door.

3. In the menu mode, prepare the sterilisation programme for execution (see page 58).

4. Switch to the operating mode and start the sterilisation programme as described on page

30. You cannot set or change any values as long as the programme is running.

5. Once sterilisation is finished and the ap-

pliance has cooled down to 37 °C, end

the sterilisation programme. To do so,

press the activation key to the right of

the status display. The status display is

automatically highlighted.

%

%

°

Fr 20.10.2010 20:31

manueller Betrieb

Steri 180

Steri End

GRAPH

8

80

10:4412.Sept.2012

6. Turn the turn control until the hand

symbol is highlighted.

Manual mode

Activate

7. Press the confirmation key to confirm.

You can now load the appliance and con-

tinue to operate it as usual. You have to enter

all set values again (temperature, CO

humidity), see chapter 5.5.4.

, O2,

2

12.Sept.2012

Manual Mode

5.9 Ending operation

1. Switch off active appliance functions

(turn back the set values).

2. Close the valves on the gas bottles.

3. Remove the chamber load.

4. Check and, if required, fill up the water

tank (see page 21) or remove the

water tray(s) of appliances with passive

humidity control.

5. Switch off the appliance with the main

switch (Fig. 24).

40 D33451 | Edition 11/2016

Fig. 24 Switching off the appliance

17:4413.Sept.2012

13:44

ON

Page 41

Malfunctions, warning and error messages

6. Malfunctions, warning and error messages

WARNING

After removing covers, live parts may be exposed. You may receive