Page 1

OPERATING MANUAL

ICH 256

Cooled incubator with compressor cooling and humidity control

Optional CO

supply or interior lighting

2

Page 2

Willi-Memmert-Straße 90–96

When contacting customer service, always quote the product serial number on the nameplate

).

Willi-Memmert-Str. 90-96

We reserve the right to make changes

Page 3

About this Manual

About this Manual

This manual describes the assembly, function, transport and operation of ICH 256 cooled

work on the unit. Familiarise yourself with the safety regulations. Only perform work that is

tion is missing, ask your superior or contact the manufacturer. Do not do anything without

authorisation.

The ICH 256 cooled incubator is available with different configurations: If specific equipment

features or functions are available only with one of the configurations, this is indicated at the

appearance.

to the enclosed, separate manual.

), please refer to the separate service manual.

This instruction manual belongs to the cooled incubator and should always be stored where

whereabouts of this instruction manual. We recommend that it is always stored in a protected

a different location, this manual must also go with it.

Page 4

4

Contents

.........................................................................................................................

........................................................................................

................................................................................................................................

.............................................................................................................................

....................................................................................................................

.......................................................................................................................

....................................................................................................................

...........................................................................................................

.........................................................................................................................

..............................................................................................................

............................................................................................................................

..............................................................................................................................

..........................................................................................................................

4. Putting into Operation 23

4.1 Check the door and adjust if necessary

............................................................................

4.2 Connecting

..........................................................................................................

..................................................................................................

......................................................................................................

............................................................................................................

...............................................................................................................

45

46

............................................................................................................

47

....................................................................................................

48

......................................................................................................................

Page 5

........................................................................................

.............................................................................................................................

..............................................................................................

..............................................................................................................................

Page 6

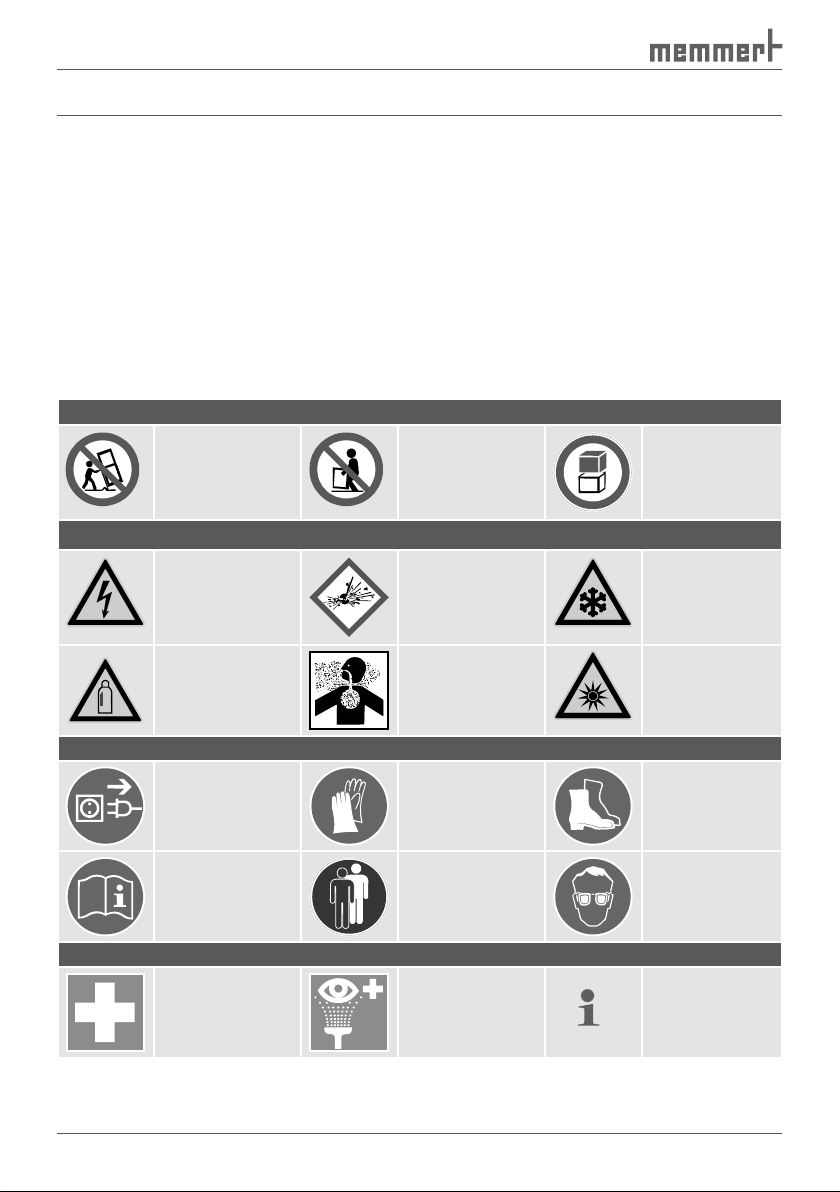

Terms and signs used

and regulations to avoid accidents and damage. These terms and signs are explained below.

Terms used

"Warning"

"Caution"

Prohibition sign (forbidding an action)

appliance

appliance

appliance

atmosphere

frostbite/cold

Warning of gas

Wear gloves

Wear safety

Two or more

Wear UV safety

first aid

additional

Warning signs (warning of a danger)

Regulation signs (stipulate an action)

Other icons

Page 7

and subject to many hours of testing in the factory. They contain the latest technology and

Warning!

After removing covers, live parts may be exposed. You may receive

an electric shock if you touch these parts. Disconnect the mains plug

Any work inside the unit may only be performed by qualified electri-

cians.

Warning!

When loading the chamber with an unsuitable load, poisonous or

explosive vapours or gases may be produced. This could cause the

chamber to explode, and people could be badly injured or poisoned.

The chamber may only be loaded with materials/test objects which

on page

).

Additional safety regulations for cooled incubators with interior UV

Warning!

when you open the door of the cooled incubator with interior UV

).

Page 8

Additional safety regulations for cooled incubators with CO

2

supply.

Warning!

can have a suffocating effect in high

concentrations. In normal operation, the cooled incubator gives

off small amounts of CO

2

to its surroundings. You should therefore

ensure that the room in which it is installed is properly ventilated.

Always close the stop valve or pressure reducer on the gas bottle if

there is no gas bottle connected or if the bottle connected is empty.

Warning!

can cause cold burns or frostbite.

Avoid contact with CO

gas to the eyes and skin.

Warning!

water from penetrating as well as backflow into the gas bottles. It is

essential that you read the safety notes and regulations of the gas

2

is not a dangerous substance in terms of the German Hazardous Substances Ordinance

Warning signs for dangerous UV radiation in the working

area are attached to the doors or cooled incubators

with interior UV lighting (

). They indicate that

UV

These stickers must not be removed and must always

from Memmert customer service.

The cooled incubator may only be operated and maintained by persons who are of legal age,

and who have received relevant instructions. Personnel who are to be trained, instructed or

who are undergoing general training may only work with the appliance under the continuous

The cooled incubator may only be transported (with a forklift truck or manual pallet jack)

Fig. 1

Warning sign on the door

Page 9

The owner of the cooled incubator

and for its proper

);

are qualified to do this, have received the respective instructions and are familiar with this

and repair work is properly carried out;

and its surroundings are kept clean and tidy;

safety goggles, safety shoes, protective gloves.

)

The manufacturer is not liable for any damage, danger or injuries that result from

The cooled incubator may only be used in a flawless condition. If you as the operator notice

and inform your superiors.

You can find information on eliminating malfunctions from page

47

.

Page 10

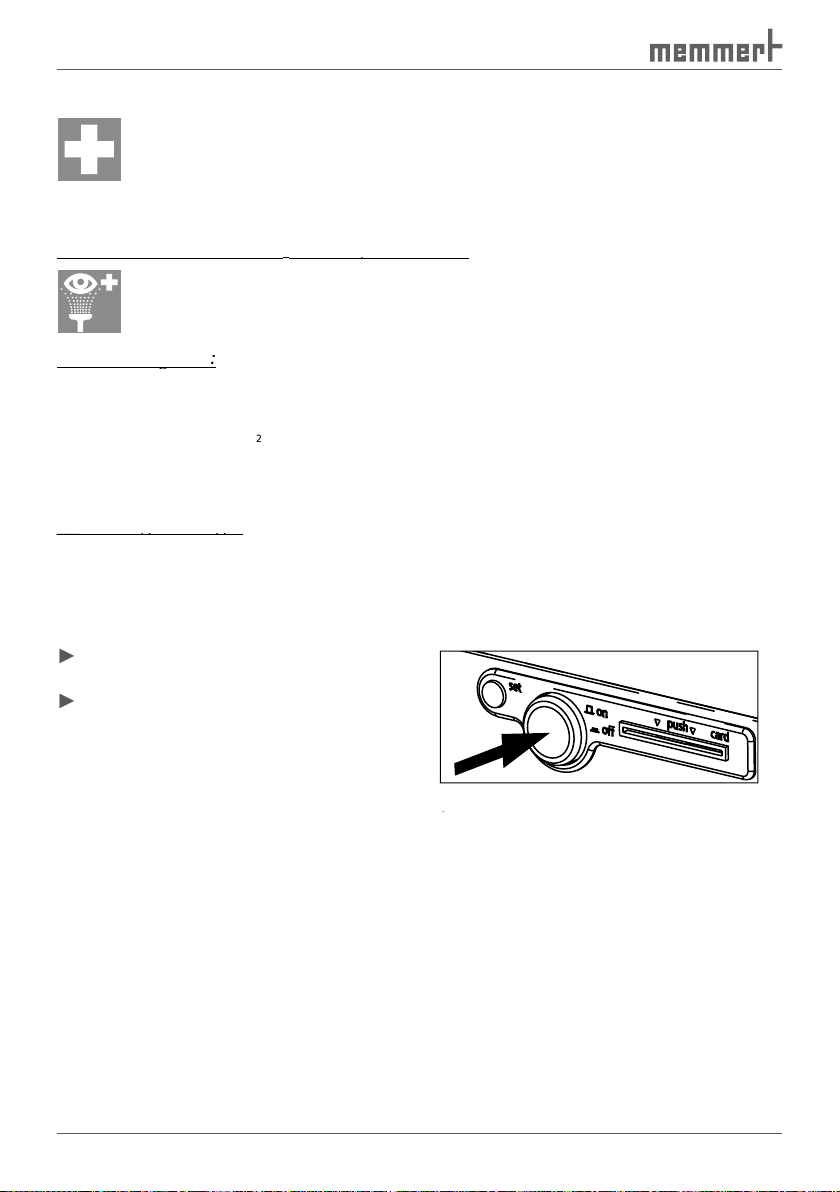

What to do in case of

4.

In case of contact with CO

to the eyes and skin:

to the eyes and skin:

After inhaling CO

After inhaling CO

2

2

can cause accelerated breathing and headaches.

Anyone affected should breathe fresh air, using a breathing device independent of

In

case of gas leakage:

case of gas leakage:

atmosphere is harmless.

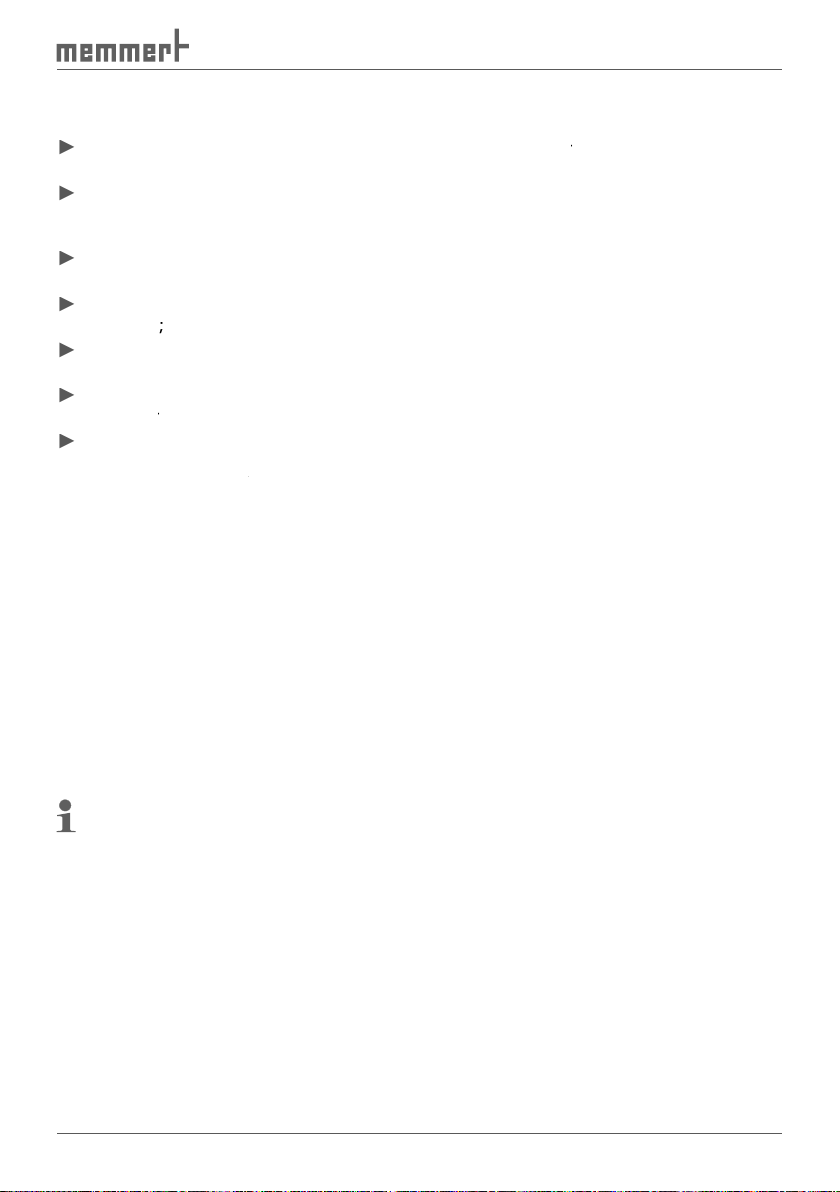

Switching off the cooled incubator in an

appliance (

).

Fig. 2

Switch off the cooled incubator

by pressing the main switch

Fig. 2

Fig. 2

Page 11

Design and Function

1

Fig. 3

Design of ICH cooled incubators

Controller/control panel (see page

28

)

2

Push/turn control (see page

Controller/control panel (see page

Controller/control panel (see page

28

)

3

Standard feed-through

Push/turn control (see page

Push/turn control (see page

Humidity sensor

Standard feed-through

Standard feed-through

5

Cooling compressor (see page

Humidity sensor

Humidity sensor

65 )6

Locking swivel castors

Cooling compressor (see page

Cooling compressor (see page

Nameplate (see page

Locking swivel castors

Locking swivel castors

)

8

Glass door

Nameplate (see page

Nameplate (see page

9

Sliding grid

Chamber fan

Sliding grid

Sliding grid

Connection for the

illumination box (only

for models with interior lighting, see page

illumination box (only

illumination box (only

66

)

Illumination box (only for models with

interior lighting, see page

Illumination box (only for models with

Illumination box (only for models with

66

)

Chipcard reader

interior lighting, see page

interior lighting, see page

Air is heated inside the cooled incubator by means of large-area all-round heating. Humidifica-

tion

is achieved by

fan and mixed with the air current. Humidity is reduced by condensing on two Peltier cooling

automatically defrosted in cycles.

2

13

12

11

10

9

3

4

8

7

5

6

Page 12

2

supply,

through a sterile filter. The turbulence-free interior ventilation ensures a uniform gas distri-

2

content is reduced by introducing

fresh air.

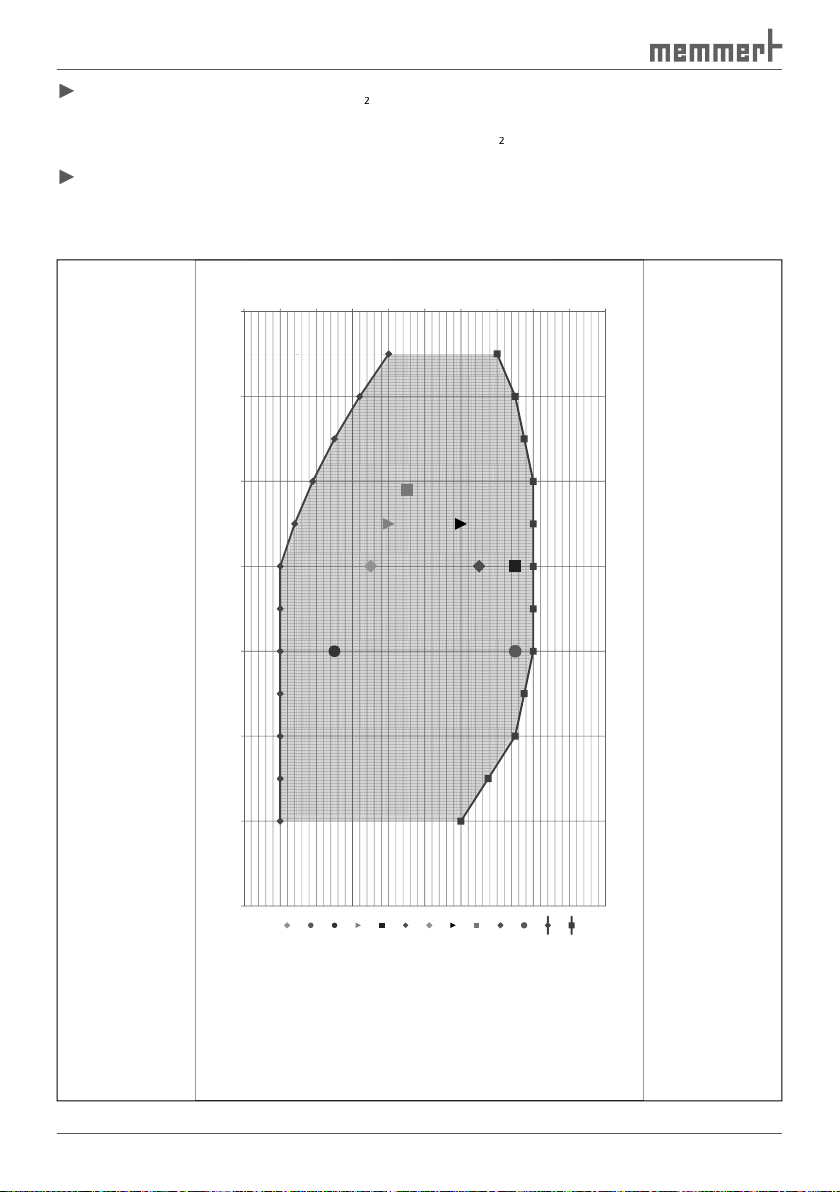

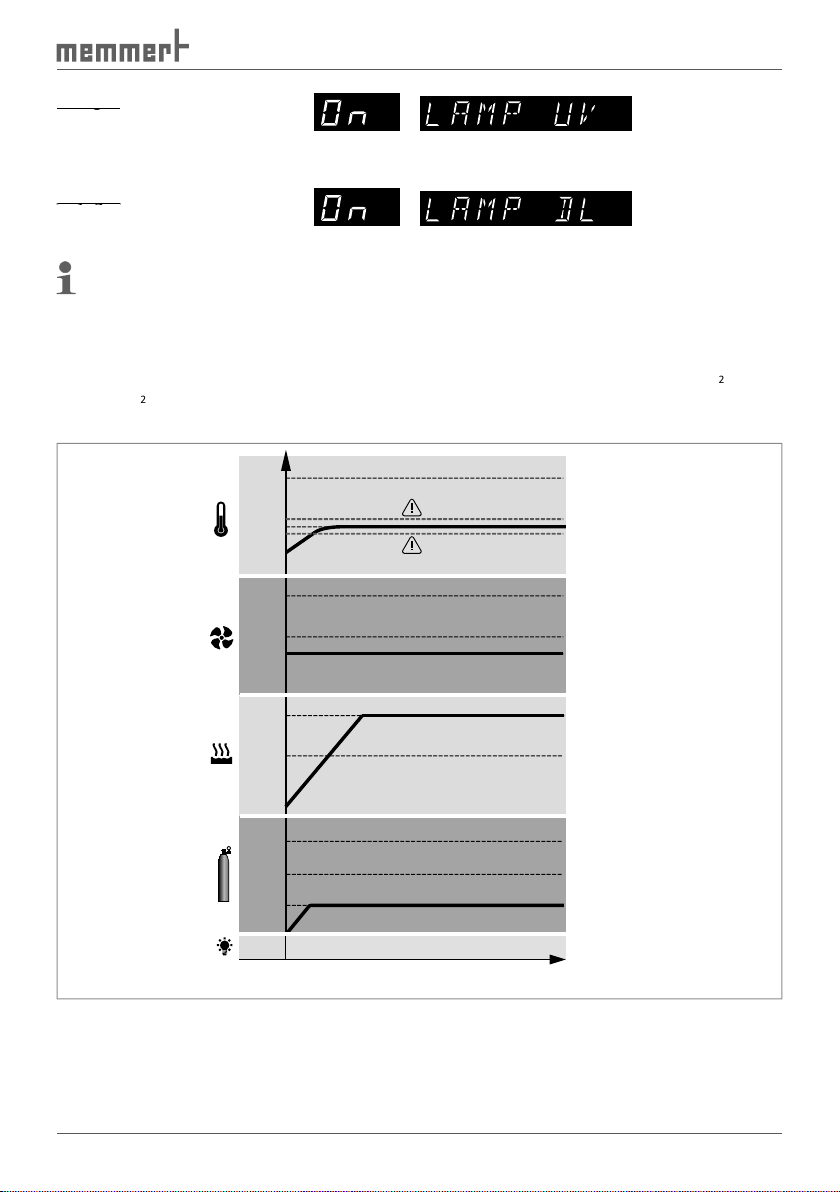

at the top of the interior (see

on page

) that contains fluorescent tubes (daylight

rh without light max.

rh without light max.

rh without light min.

Intermediate test zone II 30

°

C/65%rh

Long term test zone I 21

°

C/45%

Long term test zone II 25

°

C/60%rh

Long term test zone IVA 30

°

C/65%rh

rh without light max.

rh without light min.

Intermediate test zone II 30

°

C/65%rh

Long term test zone I 21

°

C/45%

Long term test zone II 25

°

C/60%rh

Long term test zone IVA 30

°

C/65%rh

Long term test zone IVB 30

°

C/75%rh

Alternate accelerated test 40

°

C/75%rh

Alternate intermediate test 30

°

C/35%rh

0 10203040506070

rh without light max.

rh without light min.

Intermediate test zone II 30

°

C/65%rh

Long term test zone I 21

°

C/45%

Long term test zone II 25

°

C/60%rh

Long term test zone IVA 30

°

C/65%rh

Long term test zone IVB 30

°

C/75%rh

Alternate accelerated test 40

°

C/75%rh

Alternate intermediate test 30

°

C/35%rh

Fig. 4

relative humidity [%]

relative humidity [%]

50

60

70

10

20

30

40

50

10

20

30

0

temperature[C°]

40

60

50

60

80

70

80

70

80

100

100

100

100

90

90

90

90

Working range relative humidity without condensation ICH256

Working range relative humidity without condensation ICH256

Working range relative humidity without condensation ICH256

Working range relative humidity without condensation ICH256

Testing conditions according to ICH Q1A

Testing conditions according to ICH Q1A

Testing conditions according to ICH Q1A

Testing conditions according to ICH Q1A

Long term test zone II 30°C/35%rh

Alternate long term test 25°C/40%rh

Alternate accelerated test 40°C/25%rh

Alternate long term test 25°C/40%rh

Alternate accelerated test 40°C/25%rh

Long term test zone II 30°C/35%rh

Long term test zone II 30°C/35%rh

Accelerated test 40°C/75%rh

Accelerated test 40°C/75%rh

Accelerated test 40°C/75%rh

valid at T

amb

~20°C

Page 13

All-round large-area heating with additional thermal conduction layer

Alphanumeric text display

Two separate Pt100 temperature sensors DIN class A in a 4-wire circuit for control and

following (ASF)

Visual alarm indication

Acoustic warning signal

at the appliance, without the

Additional fittings

The ICH 256 cooled incubator can be equipped with the following fittings:

2

supply

The chamber load for the appliance must be carefully checked for chemical compatibility with

the materials mentioned.

A material resistance table can be requested from the manufacturer.

Page 14

)

Appliance fuse: Fusible link 250 V/15 A quick-blow

The temperature controller is protected with a miniature fuse 100 mA (200 mA at 115 V)

The CO

controller is equipped with a 6.3 A miniature fuse.

1

Fig. 5

Connections on rear of appliance

Mains lead

Connections on rear of appliance

Connections on rear of appliance

2

CO

connection (only for models with CO

supply)

3

2

2

connection (only for models with CO

connection (only for models with CO

ethernet connection, see page

2

2

supply)

supply)

57

)

4

Printer connection (see page

51 )5

23

)

6

Fresh air connection (only for models with CO

2

supply)

with residual current circuit breaker).

This appliance is intended for operation on an electrical power system with a system imped-

ance Z

of a maximum of 0.292 ohm at the point of transfer (service line). The operator

the system impedance is.

3

4

CO

2

2

5

6

Page 15

2

supply)

The appliance can be connected with the supplied

tor with gas bottle monitor (DIN 8546) to a CO

2

compressed gas bottle or directly to a central

gas supply.

The

Water connection

The supplied tube can be used to connect the cooled incubator with the supplied water tank.

tests or similar. Any other use is improper, and may result in hazards and damage.

The incubators may not be used for drying, vaporising and branding paints or similar materi-

als the solvents of which could form an explosive mixture when combined with air. If there

2

gas bottles with a pressure regulator may be connected to the gas connection of the

appliance. The use of other gases or materials than CO

2

is not permitted.

Page 16

EC Declaration of Conformity

Manufacturer’s name and address:

This product complies with the provisions of the

Machinery Directive 2006/42/EC

Directive of the Council for harmonisation of

The tested product’s level of compliance with the essential protection requirements of the Directive is substantiated

by its compliance with the following standards:

EMC Directive 2004/108/EC

ouncil for harmonisation of the laws of

level of compliance with the essential protection requirements of the Directive is substantiated

by its compliance with the following standards:

Low Voltage Directive 2006/95/EC

ouncil for harmonisation of the laws of

equipment designed for use within certain voltage limits.

compliance with the essential protection requirements of the Directive is substantiated

by its compliance with the following standards:

1 (VDE 0411 part 1):2002

-

(legally binding signature of the manufacturer)

compliance

documents have to be observed.

MEMMERT GmbH + Co. KG

Äußere Rittersbacher Straße 38

, Germany

alternativ

the laws of Member States on the level of protection

EMC Directive 2004/108/EC

tates on electromagnetic

11: 2000

tates relating to electrical

010:2003

irectives, however, does not provide any warranted properties. The

D24249

Product:

Type:

Size:

Rated voltage:

EN ICO 12100-1, -2: 2004

EN ISO 13850: 2007

Directive of the C

The tested product’s

DIN EN 61326-1: 2006-10

DIN EN 61000-3-11: 2001-04

Applied harmonised standards:

Directive of the C

The tested product’s level of

DIN EN 61 010DIN EN 61 010-2-010 (VDE 0411 part 2

Schwabach, Germany, 09/02/2011

This declaration states the

safety instructions in the supplied

91126 Schwabach

Cooled incubator

ICH

256

AC 230 V,

directives:

and revisions

for accident prevention.

EN ISO 13857: 2008

EN 60204-1: 2007

and revisions

compatibility.

Member S

EN 61000-3-

and revisions

-08 EN 61 010-1:2001

010):2004-06 EN 61 010-2-

with the above D

EN 61326-1: 2006

Member S

ely AC 115 V 50/60 Hz

Page 17

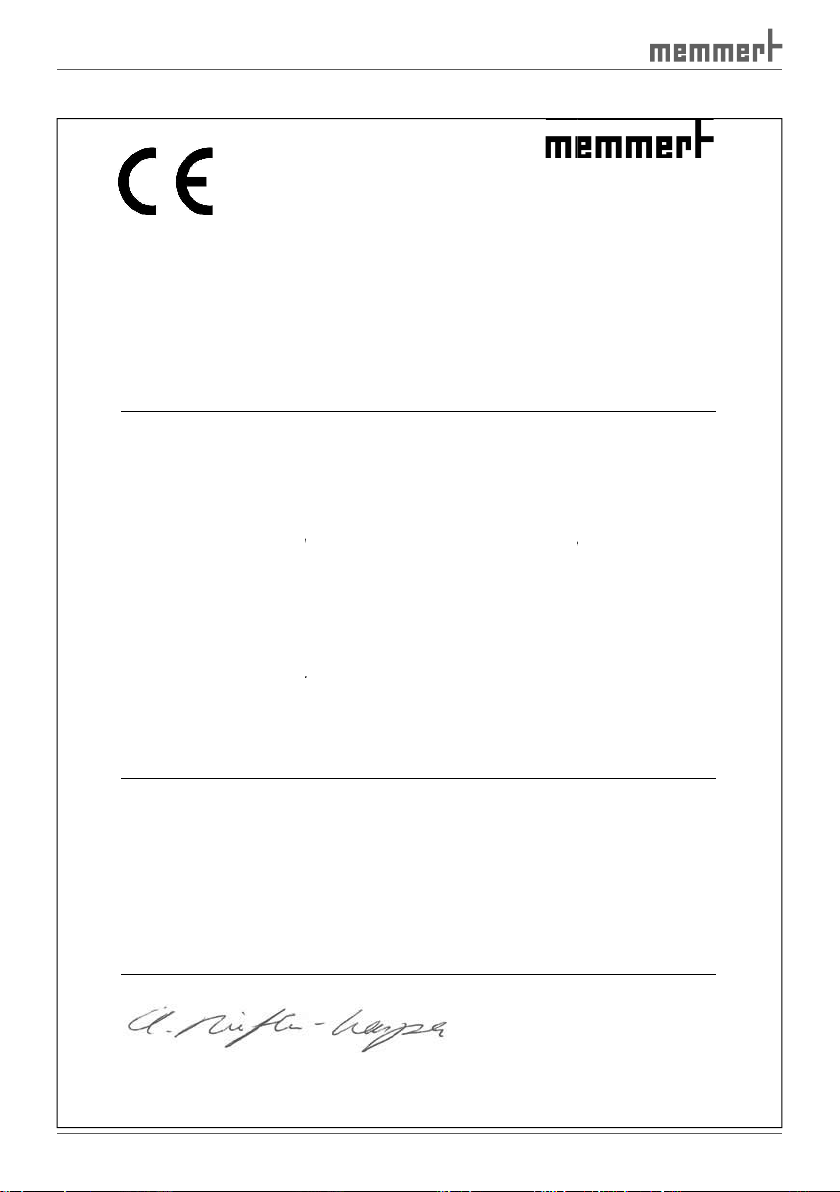

Designation

The nameplate (

) provides information about the appliance model, manufacturer and

technical data. It is attached to the front of the appliance, on the right beneath the door (see

1

Fig. 6

Nameplate

Operating voltage

3

Applied standard

Operating voltage

Operating voltage

Protection type

5

CE conformity

Protection type

Protection type

6

Address of manufacturer

Disposal note

8

9

Connection/performance values

Factory number

Connection/performance values

Connection/performance values

Technical data

Appliance width D* [mm]

Appliance height E* [mm]

Appliance depth F*

Weight [kg]

on page

2

3

4

10

9

8

7

5

6

Technical data without interior

lighting

with interior

lighting

Page 18

Technical data without interior

Temperature

Temperature recording is done by means of Pt100 in a 4-wire

Adjustment range normal operation: -10 °C to 60 °C, for mod-

2

supply or interior lighting 0 °C to 60 °C

Adjustment precision: 0.1 °C

Adjustment range: 10 to 80 % rh

Adjustment precision: 1 % rh

The CO

content is determined

through an NDIR measuring pro-

ally in percent

Adjustment range: 0 to 20 %

Adjustment precision: 0.1 %

lighting

with interior

lighting

Page 19

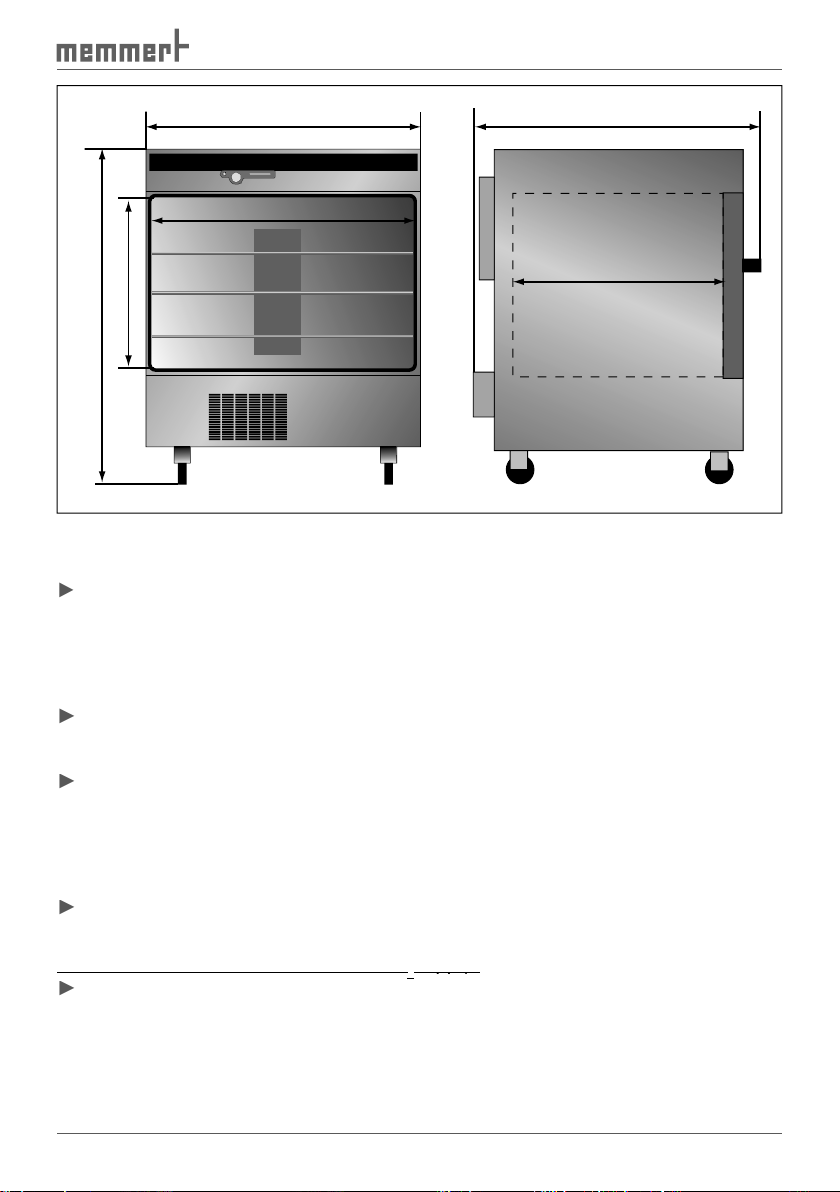

D

Fig. 7

Dimensions of ICH cooled incubators

Ambient conditions

The cooled incubator may only be used in enclosed rooms and under the following ambient

Ambient temperature: 5 ºC to 28 ºC

Altitude of installation: max. 2000 m above sea level

The cooled incubator may not be used in areas where there is a risk of explosions. The

ambient air must not contain any explosive dusts, gases, vapours or gas-air mixtures. The

age to electrical parts. For this reason, sufficient measures are to be taken to prevent large

Accessories

Water supply tank and connection tube

Additional for cooled incubators with CO

2

supply:

supply:

A

F

B

E

C

►

Page 20

Transport and

Warning!

You may injure your hands or feet when transporting and

gloves and work shoes.

Warning!

for this (e.g. forklift truck licence). The cooled incubator may not be

transported with a crane.

Warning!

The cooled incubator could fall over and seriously injure you. Never

tilt the cooled incubator and transport it only in an upright position.

Warning!

Warning!

The cooled incubator may only be set up on the floor, and never on

tables or similar. A table could collapse or the appliance could fall

off and seriously injure or kill

Transport

The cooled incubator can be transported in three ways:

with

a forklift truck; move the forks of the truck entirely under the test chamber

Page 21

The cooled incubator is delivered in cardboard packaging on a pallet.

from the delivery note, damage or irregularities, do not put the cooled incubator into

protective foil) in accordance with the legally

applicable disposal regulations for cardboard packaging in your country.

Page 22

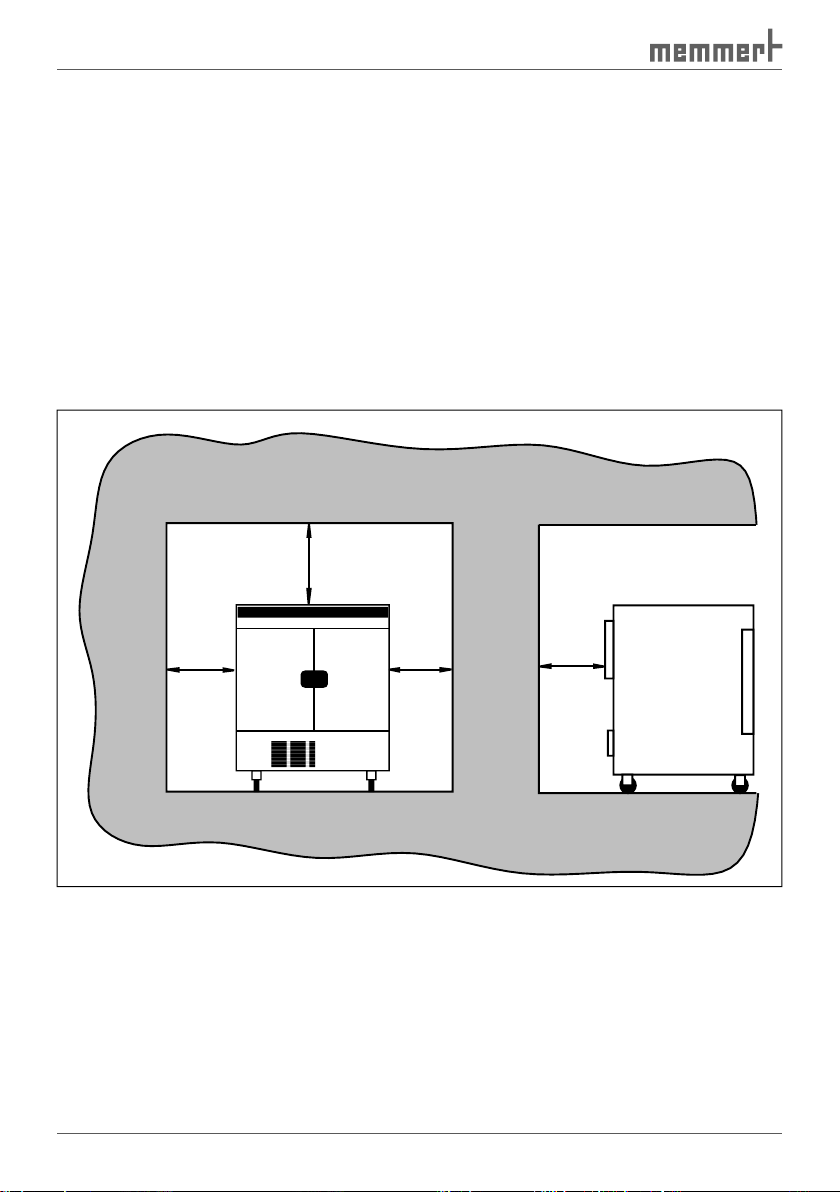

The cooled incubator may only be placed on the ground, not on a table. When doing this,

The installation site must be level

and must be able to reliably carry the weight of the cooled incubator (see page

). Do not

The front swivel castors can be locked with a catch. To ensure stability, always turn the front

A

) must

The distance between the wall and the rear of the cooled incubator must be at least 15 cm.

The clearance from the ceiling must not be less than 20 cm and the side clearance from the

wall must not be less than 8 cm (

). The ventilation slits of the

on the rear of

the appliance may not be adjusted.

Fig. 8

Minimum clearance from walls and ceiling

≥ 20 cm

.

≥ 8 cm

≥ 8 cm

≥ 15 cm

Page 23

4.1

.

4.2

4.2.1

The cooled incubator is intended for operation on an electrical power system with a

max

at the point of transfer (service line) of a maximum of 0.292 ohms. The op-

that meets these requirements.

on page

).

) whose interfaces comply with the requirements for safety extra-low voltage (e.g.

4.2.3

Water connection

2

).

aqua dest)

accordance with VDE 0510/DIN EN

adhered to (production conductivity ≤

with VDE 0510 is available in larger

trade. The standard VDE 0510/DIN EN

the label.

Fig. 9

Water connection

H2O

Page 24

4.2.4

Gas connection

supply)

Warning!

can have a suffocating effect in high

concentrations. In normal operation, the cooled incubator gives

off small amounts of CO

to its surroundings. You should therefore

ensure that the room in which it is installed is properly ventilated.

Warning!

can cause cold burns or frostbite. Avoid

contact with CO

gas to the eyes and skin.

Warning!

gas bottles away from open flames. Store gas bottles at lower than

as well as backflow into the gas bottles. It is essential that you read

the safety notes and regulations of the gas suppliers.

Attach the supplied pressure tube to the gas

2

and page

).

CO

Fig. 10

CO2 connection

2

Page 25

Warning!

when opening the door of the cooled incubator with interior UV

).

The cooled incubator may only be operated and by persons who are of legal age and have re-

To open the doors, pull out the knobs (

).

To close, press in the door knobs.

Switching on appliance

The cooled incubator is switched on and off by pressing the

).

).

Fig. 12

Switch on cooled incubator

Fig. 13

Switch off cooled incubator

close

Fig. 11

Opening and clos-

ing the doors

open

Page 26

As the

fluorescent

tubes prior to every test.

equipped with UV lighting: Wear

)

fluorescent tubes are working. If not: Replace the respective tube set (refer to

)

4.

and reading off the measured illuminance. Replace the fluorescent tubes if the light

).

Loading the cooled incubator

Warning!

When loading the appliance with an unsuitable load, poisonous or

explosive vapours or gases may be produced. This could cause the

cooled incubator to explode, and people could be seriously injured

or poisoned. The chamber may only be loaded with materials which

which cannot ignite. If there is any doubt as to the composition of

the chamber load for chemical compatibility with the materials of the cooled

), since considerable damage could otherwise occur to the

The cooled incubator is

explosion-proof (it does not comply with the German workplace

when combined with air. Potentially explosive gas-air mixtures must not form, neither in the

ance could lead to sedimentation in the chamber interior and as a consequence, could result

taken to prevent large clouds of dust or aggressive vapours from developing.

Page 27

The chamber must not be loaded too tightly, so that proper

air circulation in the working

walls or right below the ceiling (heating ribs) of the working chamber. To guarantee optimum

air circulation, push in the sliding grids so that the gaps between the door, sliding grid and

Fig. 14

Correct and incorrect chamber loading

Connecting gas supply

supply)

).

Page 28

The desired parameters are entered on the operating panel of the controller on the front of

the appliance (

). Basic settings, as well as those for time and pressure, can also be made

1

Fig. 15

Operating panel

2

Operating mode display (see page

29

)

3

Display appliance is heating up

Operating mode display (see page

Operating mode display (see page

4

5

Display: appliance is cooling down

6

Alarm display (see chapter

Display: appliance is cooling down

Display: appliance is cooling down

)

chapter

)

8

Humidity display

chapter

chapter

9

Setting the CO

Humidity display

Humidity display

setpoint (only for models

with CO

Setting the CO

Setting the CO

2

supply)

2

2

setpoint (only for models

setpoint (only for models

Display: appliance is humidifying

Display: water tank empty

Display: appliance is humidifying

Display: appliance is humidifying

Display: fan speed

Display: water tank empty

Display: water tank empty

Card reader

Display: fan speed

Display: fan speed

Push/turn control

Set key

rior lighting) Display: interior lighting

All operating functions are selected by turning the push-turn control to the

Tu

Mo

on

off

Sa Su

Fr

Th

We

h

2 3 4 5 6 7 8 9

t3

t2

t1

set

t4

loop

SETUP

PRINT

on

off

STERI DEFRO

4

3

2

1

push

°C

MIN

AUTO

card

IN 1

OUT

IN 2

IN 1

OUT

°C

MAX

IN 2

%

mb

IN 1

OUT

IN 2

OUT

2

2

rh

CO

mb

10111213141516

set

set

Page 29

temperature), then all other parameters go dark and the selected one flashes.

With the SET key held down, set the desired value (e. g.

37.0

) with the

value, flashing. Then, the current temperature is displayed and the cooled

The control returns automatically to the main menu if neither the push-turn control

Quick adjustment of temperature:

Quick adjustment of temperature:

The appliance flashes briefly, displaying the temperature setpoint. Then, the current tempera-

ture appears on the display and the controller begins to adjust the temperature to the set

value.

):

Week time switch: The cooled incubator runs at the set values only at certain times. Opera-

tion in this mode is described from page

.

or lighting

values are programmed (so-called ramps), which the cooled incubator automatically works

through one after another. Operation in this mode is described from page

).

) and printouts (PRINT, see page

)

)

Week

time switch

) ) )

Fig. 16

Operating modes

set

set

set

PRINT

SETUP

Page 30

Setting the operating mode

Normal mode

values for operating the appliance can be selected. The settings have an immediate effect on

the functions of the appliance.

).

that it comes out of the appliance (see

on page

).

with the push-turn control as described

above.

As described above, set the individual parameters with the push-turn control and the SET

Adjustment range:

to

for models

without CO

supply and without interior

-10°C

to

Adjustment range: 10 % to 100 % in steps

Temperature monitoring

Temperature monitoring

Adjustment range:

)

Adjustment range:

to

%rh

%

rh

setpoint

setpoint

Adjustment range:

to

%

CO

set

set

set

SETUP

PRINT

°C

°C

MIN

MAX

AUTO

2

Page 31

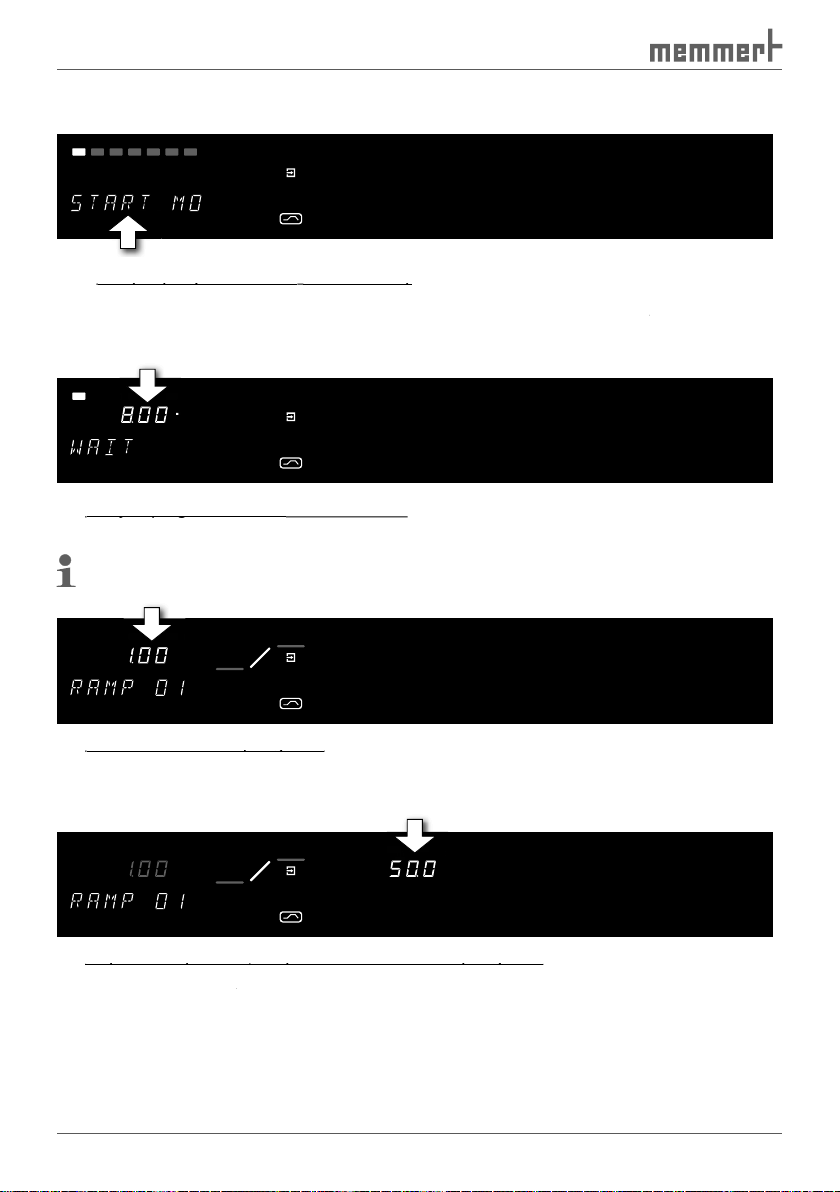

UV light

UV light

Adjustment range:

Adjustment range:

The appliance should heat up to 37 °C with a humidity of 80 % rh and a fan speed of 40 %.

The monitoring function should trigger at 38.5 °C and at 36.0 °C: For a model with CO

2

sup-

2

content should be 5.0 %. For a model with interior lighting, daylight should be

Fig. 17

Example for normal mode

50 °C

37 °C

80 %

50 %

40 %

80 %

rh

50 %

rh

15 %

10 %

5 %

DL

t

Page 32

with the push-turn

vated.

37.0

°C with the push-turn control.

temperature appears on the display and the control-

symbol.

icon.

Turn the push-turn control to the right, up to the moni-

toring temperature and until the MIN or MAX symbol

flashes. Hold down the SET key and, with the push-turn

°C and the

°C. Turn the push-turn

the AUTO symbol flash. Hold down the SET key and, with

the push-turn control, select

The tolerance band is set in the SETUP menu (see

).

4.

Turn the push-turn control to the right until the humid-

% rh with the push-turn

The humidification process is indicated by the

PRINT

SETUP

°C

°C

MIN

MAX

AUTO

%rh

Page 33

2

setpoint

2

supply)

Turn the push-turn control to the right until the CO2 dis-

the CO2 setpoint. The current CO2 actual value appears

CO

Adjust lighting

Turn the push-turn control to the right until

with the push-turn control. Release

the SET key. The daylight lighting is activated.

The cooled incubator is now running in permanent operation with the set values.

Week time switch

and cooling functions, along with the CO

2

and humidity supply are switched off here and the

The sequence of the week time switch repeats itself each week.

Weekday

Weekday

Adjustment range: Monday to Sunday

Mo

Adjustment range: Working days Mo-Fr

Weekend Sat-Sun

----

Appliance not switched on on this day

Adjustment range:

to

23:59

h

Adjustment range: one minute after the switch-

h

Tu

We

Th

2

SETUP

PRINT

Sa

Su

Fr

Mo

Mo

on

off

on

off

on

off

Tu

Tu

We

We

Th

Th

Sa

Sa

Su

Su

Fr

Fr

Page 34

the desired time blocks and days.

ture setpoint can be directly accessed by briefly pressing the SET key. By turning the control

to the right, you get to the temperature monitoring, humidity and CO

2

settings. By turning to

the left, you can return to the settings for the individual time blocks.

The appliance should switch on from Mo-Fr (workdays group) at 9.30 (am) and switch off at

).

Fr

Fig. 18

Operation with week time switch (example)

week time switch operating mode

with the push-

turn control, while the SET key is held down.

time switch operating mode.

Sa

PRINT

Tu

We

Mo

Th

Su

SETUP

Page 35

Turning the push-turn control to the left, select "

time with the push-turn switch to

(am).

Mo

turn control.

time with the push-turn switch to

With the push-turn control, select "

time with the push-turn switch to

With the push-turn control, select "

time with the push-turn switch to

).

Programme mode

2

or

automatically one after another.

Setting the programme operating mode

Setting the programme operating mode

with the push-turn

function with the push-turn.

function with the push-turn.

on

off

Tu

We

Th

Fr

Sa Su

Mo

Mo

Mo

on

off

Tu

Tu

on

off

Tu

on

off

We

We

We

Th

Th

Th

Fr

Fr

Fr

PRINT

Sa Su

Sa

h

Sa

h

Su

Su

SETUP

PRINT

SETUP

Page 36

You can now select and modify the following parameters in turn (see also the adjustment

):

STERI

4.

Adjustment range: Monday to Sunday, workdays Mo-Fr, weekends Sa-Sun, every day Mon-Sun

) after the start

Sa

Adjustment range:

to

(shown: Switch-on time

)

Th

Sa

Adjustment range:

to

999

hours. In the example shown: Duration of first ramp seg-

DEFRO

Adjustment range:

Tu

Mo

on

off

Sa Su

Fr

Th

We

t1

h

t3

t2

PRINT

4

t4

3

loop

2

1

SETUP

DEFRO

°C

MAX

MIN

AUTO

IN 1

OUT

IN 2

°C

%rh

mb

STERI

DEFRO

STERI

DEFRO

°C

MAX

MIN

AUTO

DEFRO

MAX

MIN

AUTO

°C

MAX

MIN

AUTO

Tu

Mo

on

off

Tu

Mo

on

off

Tu

Mo

on

off

Sa Su

Fr

Th

We

t1

h

Sa Su

Fr

Th

We

t1

h

Sa Su

Fr

Th

We

t1

h

t3

t2

PRINT

t3

t2

PRINT

t3

t2

PRINT

4

t4

3

loop

2

1

SETUP

4

t4

3

loop

2

1

SETUP

STERI

4

t4

3

loop

2

1

SETUP

IN 1

OUT

IN 2

°C

IN 1

°C

%rh

mb

OUT

IN 2

mb

°C

Page 37

STERI

Adjustment range: 10 % to 100 % in 10-% steps In the example shown: fan speed 60 % (six

Adjustment range:

to

80 % rh

and

OFF

2

content of first ramp segment

content of first ramp segment

2

supply)

Adjustment range:

to

20 %

2

content 5.0 %.

Adjustment range:

Tu

Mo

on

off

Tu

Mo

on

off

Tu

Mo

on

off

Sa Su

Fr

Th

We

t1

h

Sa Su

Fr

Th

We

t1

h

Sa Su

Fr

Th

We

t1

h

t3

t2

t2

t2

t4

loop

SETUP

PRINT

t3

t4

loop

SETUP

PRINT

t3

t4

loop

SETUP

PRINT

4

3

2

1

STERI

4

3

2

1

STERI

4

3

2

1

DEFRO

DEFRO

DEFRO

°C

MIN

°C

MIN

°C

MIN

AUTO

AUTO

AUTO

°C

MAX

%rh

°C

mb

MAX

%rh

°C

mb

MAX

CO

2

STERI

Tu

Mo

on

off

Sa Su

Fr

Th

We

t1

h

t3

PRINT

t4

loop

SETUP

t2

DEFRO

4

3

2

1

°C

MIN

AUTO

%rh

°C

mb

MAX

CO

2

Page 38

STERI

Adjustment range:

These commands thus control the programme sequence:

ter

"

" on page

).

Turn the push-turn control to the right until

appears the display and then press the SET

After releasing the SET key ...

as described above, or an existing

Tu

Mo

on

off

Tu

Mo

on

off

Tu

Mo

on

off

Sa Su

Fr

Th

We

t1

h

Sa Su

Fr

Th

We

t1

h

Sa Su

Fr

Th

We

t1

h

t3

t2

t2

t2

t4

loop

SETUP

PRINT

t3

t4

loop

SETUP

PRINT

t3

t4

loop

SETUP

PRINT

4

3

2

1

STERI

4

3

2

1

STERI

4

3

2

1

DEFRO

DEFRO

DEFRO

AUTO

AUTO

AUTO

%rh

°C

mb

MAX

%rh

°C

mb

MAX

%rh

°C

mb

MAX

°C

MIN

°C

MIN

°C

MIN

CO

CO

CO

2

2

2

Page 39

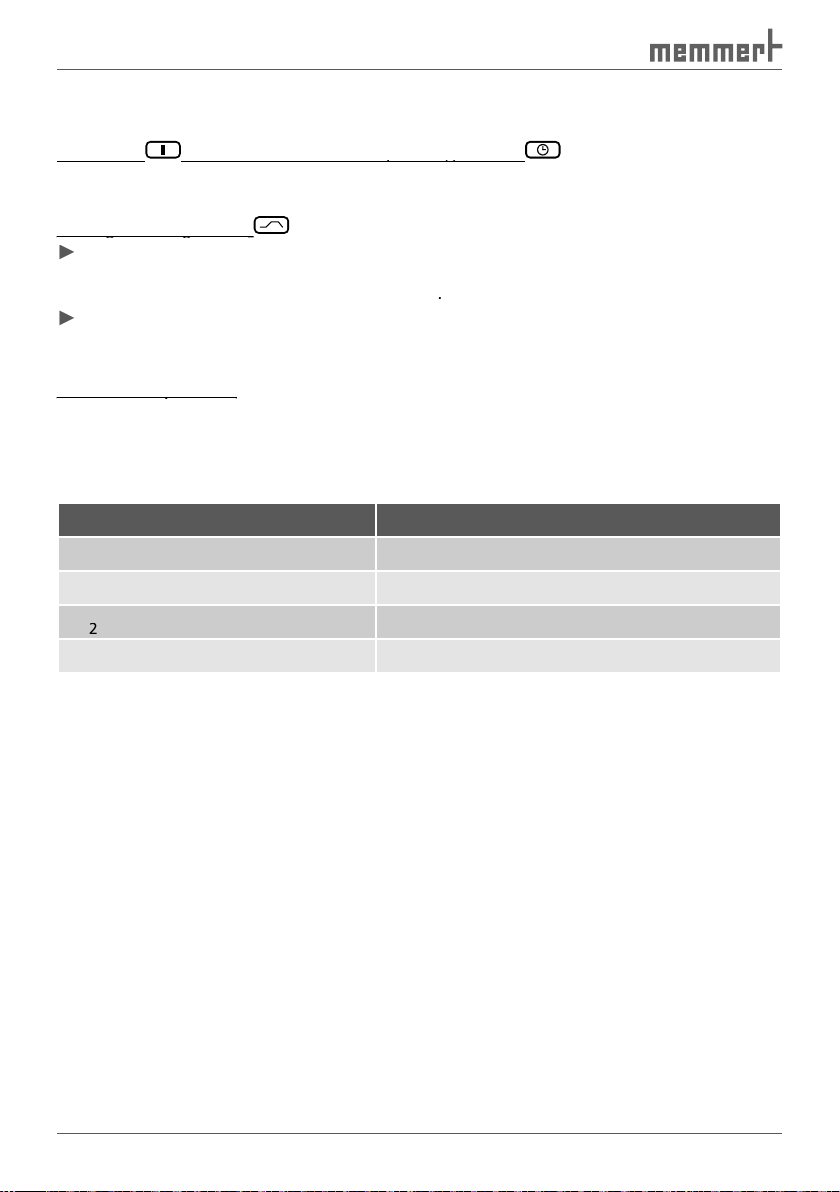

Close statements for

These commands thus control the programme sequence:

Wait until the setpoint temperature has been reached.

The appliance starts the next programme segment only when the

Wait until setpoint humidity has been reached.

Appliance starts the next programme segment only when the

time has already elapsed.

)

Wait until setpoint temperature and setpoint humidity have been

when the programmed setpoint temperature and programmed

already elapsed.

The programme entered is repeated after it has run through all

°C

t=time

Close

Fig. 19

Schematic example of the use of ramp segment close statements

Delayed

programme start

Close

command

ramp

segment

No. 1

spwt (t)

Segment1

command

segment

Segment2

Close

ramp

No. 2

next

Close

command

ramp

segment

No. 3

spwt (tH)

Segment3

Segment4

command

ramp

segment

No. 4

next

command

Segment5

Close

ramp

segment

No. 5

end

Page 40

40

a fan speed of 30 %, and reach a relative humidity of 70 % rh. For models with CO

supply,

the CO

2

content should be set to 5 % and for models with interior lighting, daylight should be

the setpoint values at a fan speed of 50 % for 45 minutes. For models with lighting, the test

Afterwards, the appliance should cool down to 20 °C and reach 50 % rh humidity within 1

supply, the CO

content should be adapted to

the natural content of the ambient air and for models with interior lighting, daylight should

50 °C

Fig. 20

Settings example programme mode

Ramp 1 Ramp 2 Ramp 3

no

combination

possible

DL

UV

37 °C

20 °C

80 %

50 %

30 %

70 % rh

50 % rh

15 %

10 %

5 %

overtemperature limit

0.01 h

0.45 h

1.00 h

t

Mo 8.00 h

Page 41

This ramp programme can only be set for cooled incubators equipped with CO

2

supply or

2

or lighting.

The respective descriptions in this example are therefore not relevant for these appli-

ances.

ter, using the "Celsius" software.

while the SET key is held down.

After releasing the SET key, the control is in the pro-

After releasing the SET key, the controller is in the pro-

Weekday for delayed programme start:

by turning the push-turn control

while the SET key is held down.

Mo

with the

Turn the push-turn control further to the right until the

time display flashes.

with the

Turn the push-turn control to the right until the tem-

37.0

with the push-turn control.

°C

PRINT

h

h

SETUP

Page 42

42

Turn the push-turn control to the right until the fan

mb

IN 1

IN 2

OUT

IN 1

IN 2

OUT

°C

°C

MIN

AUTO

MAX

rh

DEFROSTERI

%

Turn the push-turn control to the right until the humidity

70.0 % rh

with the push-turn control.

%

rh

content of the first ramp segment (only

for appliances with CO

supply, otherwise please con-

tinue with point 10):

Turn the push-turn control to the right until the CO

setpoint

to

with the push-turn control.

with lighting, otherwise please continue with item11):

Turn the push-turn control to the left until the

with the push-

turn control.

Turn the push/turn control to the right until a segment

appears.

with the push/turn control.

Turn the push-turn control further to the right until the

time display flashes.

with the

Turn the push-turn control to the right until the tem-

37.0

with the push-turn control.

CO

2

h

°C

Page 43

43

Turn the push-turn control to the right until the fan

Turn the push-turn control to the right until the humid-

70.0 % rh

with the push-turn control.

%

content of the second ramp segment

supply, otherwise please

Turn the push-turn control to the right until the CO

setpoint

to

with the push-turn control.

Turn the push-turn control to the left until the

with the push-

turn control.

Turn the push-turn control to the left until the

with the push-turn

Turn the push-turn control to the right until a segment

with the push/turn control.

Turn the push-turn control to the right until the tem-

with the push-

turn control.

rh

CO

2

h

°C

Page 44

44

Turn the push-turn control to the right until the humidity

with the push-turn control.

%

rh

2

content of the second ramp segment

2

supply, otherwise please

Turn the push-turn control to the right until the CO

2

2

setpoint

to

with the push-turn control.

for models with lighting, otherwise please continue with

Turn the push-turn control to the left until the

with the push-turn

Turn push-turn control to the right until a close state-

and press the SET

Turn push-turn control to the right until

appears in

the display, and press the SET key briefly to confirm.

Turn the push-turn control to the right and adjust the

temperature monitoring (for more detailed information

).

Activating the programme:

Turn the push-turn control to the right until the stop

flashes.

flashes.

with

with

the push-turn control. Release the SET key, and the pro-

Operation with

The cooled incubator can optionally be used, controlled and programmed with a PC/laptop.

and

).

The control of the appliance with the Memmert computer software “Celsius“ is

CO

2

°C

MIN

MAX

Page 45

45

Warning messages during operation: See page

47

.

CO

mode

2

controller is initially deactivated. The CO

2

inlet is interrupted

2

2

gas is introduced into the chamber via a sterile filter. The

Displays in CO

Displays in CO

2

mode:

2

display,

CO

After the setpoint temperature has been reached,

the CO

2

concentration is displayed in % depending

concentration exceeds the

icon flash.

icon flash.

and wait to see if the controller steadily adjusts to

the setpoint. If the error occurs again, contact the

This monitoring function only starts

working once the CO

The pressure in the gas bottles is a constant

approx. 57 bar at 20 °C ambient tempera-

ture. The pressure in the bottle cannot be

2

Page 46

46

Active humidity control

Active humidity control

The active humidity control guarantees that setpoint humidity is quickly reached, without the

after the setpoint temperature is reached, the humidification and dehumidification control

that it clicks into the appliance (

).

supply: Close the

valve on the gas bottle.

Fig. 21

Switch off cooled incubator

Page 47

47

Warning Messages and Malfunctions

Warning Messages and

Warning messages

The warning messages also set off an intermittent acoustic signal:

This can be temporarily switched off by pressing the SET key.

Error in the temperature control system (see also chapter "

Error in the temperature control system (see also chapter "

"

on page

on page

53

):

):

Tb active -

if the

temperature limiter is

triggered

automatic monitoring

function is triggered

ASF temperature monitor.

Error in the dehumidification system:

Error in the dehumidification system:

water supply tank with distilled

water if it is empty.

the setpoint. If the error occurs

again, contact the customer

Error in the CO

system (only for models with CO

system (only for models with CO

2

supply)

supply)

Page 48

48

Warning Messages and Malfunctions

2

supply is defec-

tive

2

setpoint to

the gas bottle is empty, replace

2

setpoint to the

2

concentra-

tion exceeds the defined

the customer service.

System/

Warning!

After removing covers, live parts may be exposed. You may

).

Error Possible cause Remedy

The display

although the

Appliance fuse or

Appliance error

Appliance

with

).

display

module

Page 49

49

Warning Messages and Malfunctions

Error Possible cause Remedy

icon flashes

Temperature protection

triggered

).

... and

Water supply tank empty

water, then reset humidity setpoint back to

... and

the customer service.

... and

2

setpoint is exceeded

the controller steadily adjusts to the setpoint.

... and

Autozero pump

controller defect

Appliance/system error

for only 10 sec.

after switching

when saving setpoint

values)

The error can be rectified by the controller

adapter faulty

Ambient temperature

too high

ambient temperature + 8 °C

Temperature in

appliance higher

than defined setpoint

temperature

Wait until the appliance has cooled down.

symbol is

symbol is

Temperature protection

Page 50

Warning Messages and Malfunctions

In normal

and week time switch operating modes

and week time switch operating modes

After the

The time and duration of the power failure are documented in the

In Programming mode

In Programming mode

After a power failure of less than 60 minutes, the current programme is continued from

the point at which it was interrupted. The time and duration of the power failure are

)

values (see table below).

For remote operation

For remote operation

The programme can only be continued from the computer. The time and duration of the

Parameters Default value

Temperature

Page 51

Advanced Functions

Advanced Functions

The cooled incubator is equipped with a parallel printer port as used in computers. Standard

).

The controller has an internal

). The log data can be printed out in

this mode via the connected printer.

Running the

Running the

printing function:

printing function:

turn control, as described on page 27. By turning

the push-turn control and holding down the SET

as described in chapter

on page

:

PRINT

SETUP

Page 52

Advanced Functions

appliance can be made.

and changed, as described in chapter Basic operation on page 27:

The controller features a calendar that automatically

Weekday

Weekday

Tu

Year

Adjustment range from

to

2100

Acoustic signal at programme end

Acoustic signal at programme end

ON

Acoustic Signal for

Acoustic Signal for

alarm, e.g. over/undertemperature

alarm, e.g. over/undertemperature

ON

Adjustment range:

to

15

“ on page

)

Automatic defrosting system

Automatic defrosting system

).

12h

PRINT SETUP

Page 53

Advanced Functions

Tolerance band ASF

Adjustment range:

to

5°C

)

and

italIANO

for customer-side

2

(see chapter "

" on page

)

The

for logging purposes in accordance with GLP. Date and clock time are specified on the log

Temperature monitoring

The

temperature sensor in the

for the appliance and surroundings.

The appliance is equipped with a double overtemperature protection (mechanical/electronic)

1

Fig. 22

Visual

alarm icon lit up: TB

alarm flashing: TWW

alarm, ASF

alarm

2

alarm icon lit up: TB

alarm icon lit up: TB

alarm flashing: TWW

alarm flashing: TWW

3

Automatic temperature monitor (ASF, see page

56

)

4

Overtemperature protection (TWW, TWB, see page

54 )5

6

Acoustic

alarm icon

1

°C

6

5

2

3

MIN

AUTO

MAX

4

Page 54

Advanced Functions

Mechanical temperature monitoring:

Temperature limiter (TB)

The cooled incubator is equipped with a mechanical temperature limiter (TB) of protection

temperature is exceeded by approx. 20 °C, the temperature limiter, as the final protective

icon lights up.

icon lights up.

Error rectification after the TB has been triggered:

Error rectification after the TB has been triggered:

). Press until you hear a „click“

Temperature monitoring can be adjusted indepen-

The manually set monitoring temperature

MIN

and

and

MAX

the overtemperature control is monitored by an

adjustable over/undertemperature controller (TWW) protection class 3.3 acc. to DIN 12880.

MAX

is exceeded, the TWW takes over

temperature control and begins to regulate the monitoring temperature (

).

The alarm icon flashes as a warning

°C

Fig. 24

Schematic diagram of how the TWW

temperature monitoring works

The monitoring temperature must always be set sufficiently high above the

alarm is switched on in the SETUP, the TWW

alarm is additionally signalled by

an intermittent tone. If the SET key is pressed, the acoustic alarm can be temporarily switched

Fig. 23

TB Reset

Emergency operation

Setting MAX

Set

temperature

Controller error

t

Page 55

Advanced Functions

Setting:

Setting:

Adjustment range: up to max. 10 °C above nominal temperature

MAX

with the push-turn control (e.g. to

38.5

°C)

MIN

Adjustment range: 10 °C below the minimum temperature of

the appliance up to 10 °C above nominal temperature of the

appliance (for details of the nominal temperature, see nameplate).

The lower alarm limit value cannot be set higher than the top

the lowest temperature.

MIN

°C

MAX

AUTO

°C

MAX

AUTO

Page 56

Advanced Functions

Automatic

temperature monitor (

ASF)

ASF is a monitoring device that automatically follows the set temperature setpoint within an

adjustable tolerance band (

).

The ASF is activated – if switched on – automatically if the actual temperature value reaches

first time (section A). The activation of the ASF is shown by the brightly lit

AUTO

icon.

When the temperature violates the set tolerance band around the setpoint (in the example in

: 37 °C ± 3 °C) – e. g. if the door is opened during operation (section B of illustration) –

the

alarm is set off. This is shown by the

AUTO

and

icons flashing.

alarm is switched on in the SETUP, the ASF

alarm is additionally signalled by an

The ASF

alarm is automatically triggered as soon as 50 % of the set tolerance band of the

tolerance range of the new temperature setpoint (section E).

°C

Fig. 25

Schematic diagram of how the ASF temperature monitoring works

Switching on the automatic temperature monitor:

Switching on the automatic temperature monitor:

with the push-turn control.

Switching off the automatic temperature monitor:

Switching off the automatic temperature monitor:

with the push-turn control.

The tolerance band for the ASF can be set in the SETUP

°C (see page

).

37 °C

40 °C

34 °C

A B C D E

40 °C

33 °C

27 °C

ASF active

34 °C

AUTO AUTO AUTO

ASF alarm

ASF active ASF active

MIN

MIN

t

°C

MAX

AUTO

°C

MAX

AUTO

Page 57

Advanced Functions

The cooled incubator is equipped by default with a

on page

). With this interface, it is possible to control and log the

appliance remotely from the computer. This is done with the help of the

To do this, the cooled incubator must be given a unique

). Using this, the respective cooled incubator can be selected and programmed from

the computer. The default setting is

The cooled incubator can optionally be equipped with an

ethernet interface to connect it to

a network. For identification purposes, each cooled incubator connected must have its own

The programme "

XTADMIN", which can be found on the “Celsius“ CD-ROM, can be used to

192.168.1.216

Fig. 26

One or more cooled incubators are connected to a network via

ethernet interface

(schematic diagram)

Fig. 26

Fig. 26

LAN 1: 192.168.1.233

LAN 2: 192.168.1.215

LAN 3: 192.168.1.241

Page 58

Advanced Functions

Log memory

The controller continually logs all relevant measured values, settings and error messages at

The internal

automatically with new data.

The logging function cannot be switched off and is always active. The measured data are

timestamp.

The internal

about three months in permanent operation.

Reading in the log memory to the computer via

Reading in the log memory to the computer via

The log data can be read out either via the

and from there be displayed graphically, printed out and stored.

The

Printing out log memory

Printing out log memory

" on page

)

Automatic defrosting system

The integrated automatic defrosting system for the

the cooled incubator at low temperatures and in permanent operation. The time values for

the automatic defrosting system can be set in the submenu

SETUP

under

under

(see page

).

working chamber. Afterwards, the smooth surface of the interior can easily be cleaned.

Page 59

Advanced Functions

at regular intervals. If you would like to further reduce this detraction in performance, you can

for defrosting, 12 hours, is not sufficient. If this is the case, you should set a more frequent

Automatic defrosting is disabled with the parameter

tures, this causes the cooling unit to ice over over time. Regular defrosting needs to be carried

The device number of the appliance and a

). The

To use it, insert the card into the chip

) on the

appliance control panel.

additional menu item

appears

against all adjustments once the chip

on the control

).

Calibration

Temperature calibration

The cooled incubator can be calibrated customer-specifically using three calibration

temperatures of your choice:

Temperature calibration at low temperature (e.g. 5 °C)

Temperature calibration at medium temperature (e.g. 25 °C)

Temperature calibration at high temperature (e.g. 50 °C)

access

authority

card

Name:

ID:

_____________________

_____________________

Fig. 27

User ID Card

Page 60

Advanced Functions

), a positive or negative compensation correction value

CAL. 3

Default

30°C

20°C

0°

10°C

40°C

Fig. 28

Temperature calibration (example)

Setting:

Setting:

)

and the

accompanying compensation correction value to

°C.

temperature.

temperature is too low, the compensation correction value must be set with a negative

Temperature deviation at 35 °C is to be corrected.

°C

and set the corresponding

°C:

°C

With a calibrated reference instrument and at a defined setpoint temperature of

in

is measured.

calibration

+0,3 °C

CAL. 1

+0,2 °C

CAL. 2

-0,4 °C

h

°C

°C

Page 61

Advanced Functions

- 0.4

°C:

h

°C

After the calibration procedure, the reference instrument should display

With

°C, the factory calibration settings are

The cooled incubator can be calibrated for the individual customer by means of two balance

tive compensation correction value can be set between –5 % and +5 %.

Fig. 29

Humidity calibration (example)

Setting:

Setting:

)

and set the accompany-

With a reference instrument, measure the deviation in the stationary state in the selected

4.

The procedure can be performed with humidity balance points of 20 % rh and 80 % rh.

rh 20

+3,0 %

Default calibration

°C

°C

rh 80

-2,0 %

0%

20%

40%

60%

80% 100%

Page 62

Advanced Functions

and set the accompanying compensation

IN 1

%

With a calibrated reference instrument, an actual humidity of 78 % rh is measured at

.

to

–2.0 %

:

%

IN 2

OUT

4.

After the calibration procedure, the reference instrument should display 80.0 %.

With

a further comparison can be programmed at 20 % relative humidity.

% rh, the factory calibration settings

are restored.

CO

2

calibration

points:

calibration at 5 % CO

content

2

calibration at 10 % CO

2

content

2

calibration at 15 % CO

2

content

Fig. 30

CO

2

calibration (example)

OUT

Tu

Mo

on

off

Tu

Mo

on

off

Sa Su

Fr

Th

We

Sa Su

Fr

Th

We

t3

t2

t1

t2

t1

t4

loop

SETUP

PRINT

t3

t4

loop

SETUP

PRINT

STERI DEFRO

4

3

2

1

4

3

2

1

STERI DEFRO

°C

°C

°C

MAX

MIN

AUTO

°C

MAX

MIN

AUTO

rh

%

mb

OUT

IN 2

rh

%

mb

IN 2

2

CO

mb

IN 1

OUT

IN 2

2

CO

mb

co2 10

Default calibration

+1,5 %

co2 15

-0,7 %

co2 5

-0,4 %

0%

10%

20%

Page 63

Advanced Functions

Setting

Setting

2

balance point in the SETUP (

)

and set the accompanying

With a reference instrument, measure the deviation in the stationary state in the selected

2

balance point.

4.

The procedure can be performed for the CO

2

balance points 5 %, 10 % and 15 %.

2

deviation at 10 % should be corrected:

2

balance point in the SETUP to

and set the accompanying compensation

IN 1

With a calibrated reference instrument and at a defined setpoint CO

2

content of

an

actual CO

2

content of 11.5 % is measured.

to

1.5 %:

The reference instrument should display 10 % after the calibration procedure.

With

and

CO2 15

%

2

calibration

IN 1

OUT

Tu

Mo

on

off

Tu

Mo

on

off

Sa Su

Fr

Th

We

Sa Su

Fr

Th

We

t3

t2

t1

t2

t1

t4

loop

SETUP

PRINT

t3

t4

loop

SETUP

PRINT

STERI DEFRO

4

3

2

1

4

3

2

1

STERI DEFRO

°C

°C

°C

MAX

MIN

AUTO

°C

MAX

MIN

AUTO

IN 2

rh

%

mb

IN 1

OUT

IN 2

rh

%

mb

OUT

IN 2

2

CO

mb

IN 1

OUT

IN 2

2

CO

mb

Page 64

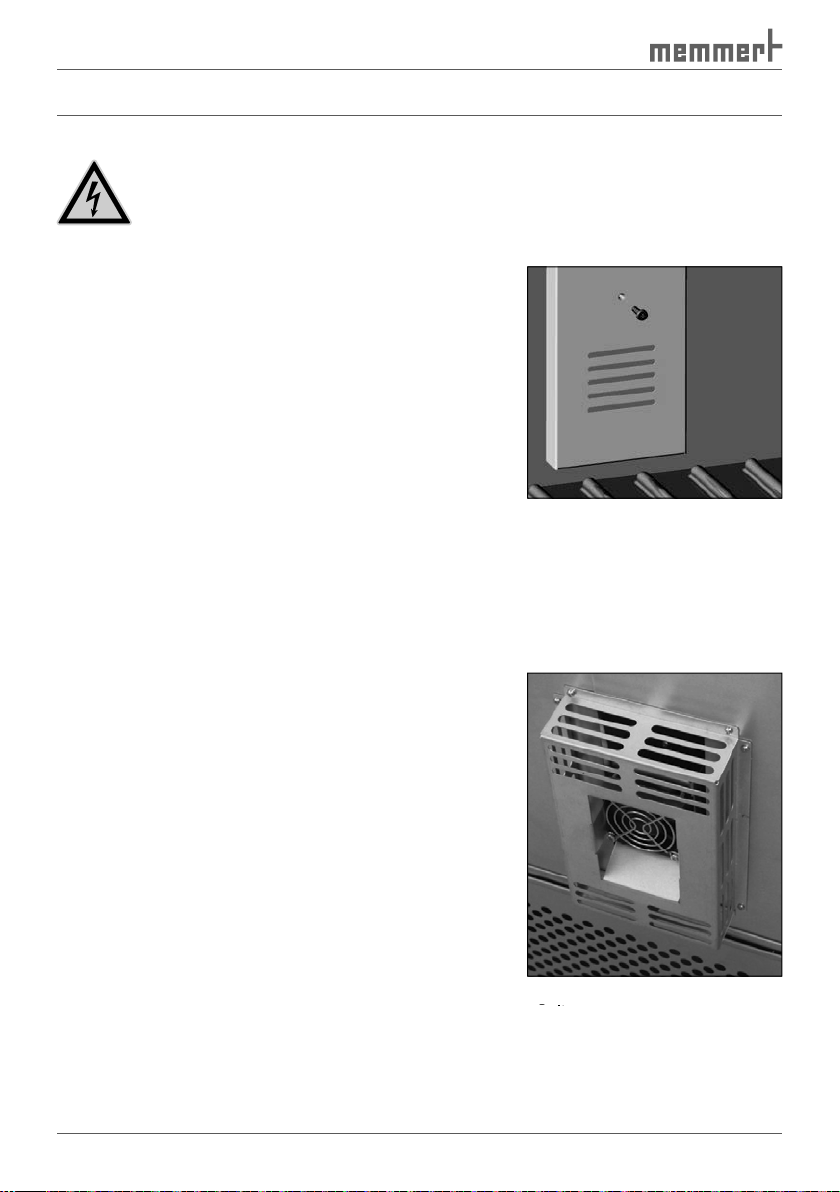

Warning!

out the mains plug.

appearance and functionality of the stainless steel

To clean the interior, the fan cover can be removed by

). The metal surfaces of

the chamber can be cleaned with normal stainless steel

the working chamber or with the stainless steel housing.

working chamber due to impurities, immediately clean

and polish the affected area.

To make cleaning easier, the protective cover can be

).

Fig. 31

To take off the fan

cover, remove two screws

Fig. 32

Cover of the Peltier

cooling modules

Fig. 32

Fig. 32

Page 65

function and long lifetime of the

from the condenser (

, no. 1)

amount).

After the screws (2) have been

front (3) can be removed and the

After the screws have been loos-

to clean the refrigeration module

from both sides if necessary.

Every three months

Every three months

).

Annually

Annually

that the hinge screws are not loose.

).

). Replace them if they are

supply, see service

Additional maintenance every two years, for models with CO

Additional maintenance every two years, for models with CO

2

supply

supply

4

Fig. 33

Cooling compressor

1

3

2

Page 66

fluorescent tubes only with

fluorescent tubes of the same type; e.g. UV

fications, please refer to chapter "

Technical data

" on page

.

).

).

Fig. 34

Open the bayonet

catch and pull off the plug

Fig. 34

Fig. 34

Open the bayonet

Open the bayonet

Fig. 35

Pull out the illumination box

Turn the illumination box around and place it carefully on a smooth surface so that the

fluorescent tubes are on top (

).

4.

).

Fig. 36

Turn around the illumination

box

Fig. 36

Fig. 36

Fig. 37

Remove Allen screws and retaining plate

and take out the glass cover.

Fig. 37

Fig. 37

Remove Allen screws and retaining plate

Remove Allen screws and retaining plate

Page 67

the tubes carefully (

).

2

Fig. 38

Remove the plastic fixing and slide to the middle.

Pull the tubes carefully out of the holder.

Remove the plastic fixing and slide to the middle.

Remove the plastic fixing and slide to the middle.

Attach the glass cover and fix it with the restraining plate. To do so, screw in the two Allen

1

1

2

Page 68

Adjusting door

A well-closing door is indispensable for cooled

appliances optimally guarantee the tight closing

the door closes exactly despite this, an adjust-

).

The top section (1) of the door hinge can be

the two screws (2) at the top and bottom of the

Adjusting door:

Adjust the door by turning the eccentric (3)

with a screwdriver.

Apply the locking paint to the headless

The locking plate (

) can also be adjusted

Tighten the screws again.

Warning!

After removing covers,

voltage-carrying parts may

an electric shock if you touch

these parts. Disconnect the

any covers. Any work

electricians.

2

Fig. 39

Adjusting door

Adjusting door

Adjusting door

Mounting bolts

3

Eccentric tappet

Eccentric socket

Eccentric tappet

Eccentric tappet

5

Headless screw

Fig. 40

Adjusting locking plate

6

Screw

Locking plate

1

3

4

5

6

7

Page 69

Storage

The cooled incubator may only be stored under the following conditions:

frost-free

This product is subject to the Directive 2002/96/EC on Waste Electrical Electronic

th

Any appliances that are infected, infectious or contaminated with

The appliance may not be left at public or communal recycling or col-

Page 70

Index

A

Accessories 19

Accidents 10

Acoustic signal 52

Additional fittings 13

Adjusting door 68

Air circulation 27

Alarm 52

, , ,

Alterations 9

Ambient conditions 19

Appliance error 48

Aqua dest 23

ASF 56

Automatic temperature

, , ,

value 53

,

,

,

,

toring 54

,

,

,

,

,

, , ,

,

,

,

47

,

, 48, , , , ,

Page 71

, , ,

,

,

T

Technical data 17

Temperature calibration 59

,

Temperature comparison 59

Temperature deviation 60

Temperature limiter 54

Temperature monitor 56

Temperature monitoring 53

Temperature protection 49

Temperature sensor 53

Tolerance band ASF 53

Transport 20

TWW temperature monitor-

tion 55

,

,

, , , , ,

,

Warning messages 57

Water connection 14

,

,

Water specifications 23

Water tank 23

Weekday 52

Week time switch 29

,

Weight 17

What to do in case of ac-

X

XTADMIN 57

Year 52

Page 72

Memmert GmbH + Co KG | PO Box 1720 | D-91107 Schwabach, Germany | Phone +49 (0) 9122-925-0 | Fax +49 (0) 9122-145-85 | E-Mail: service@memmert.com | www.memmert.com

28.06.2013

ICH englisch

D23989

Loading...

Loading...