Page 1

OPERATING INSTRUCTIONS

Humidity Chambers

HCP 108

HCP 153

HCP 246

Page 2

HCP page 2

Page 3

1 General notes and safety notes ............................................................................................................5

1.1 Transport .................................................................................................................................5

2 Installation ..........................................................................................................................................6

2.1 Subframe (accessory) ...............................................................................................................6

2.2 Stackable version (accessory) .................................................................................................... 6

2.3 Initial start-up .......................................................................................................................... 7

2.4 Oven load ................................................................................................................................7

3 Technical data ..................................................................................................................................... 8

3.1 Working range of the HCP units ...............................................................................................9

3.2 Standard equipment of HCP units ..........................................................................................10

3.3 Material quality .....................................................................................................................11

3.4 Electrical equipment ..............................................................................................................11

3.5 Note on EMC (electromagnetic compatibility) .........................................................................11

3.6 External connection ............................................................................................................... 11

3.7 Water connection ..................................................................................................................11

4 Oven construction and operation ...................................................................................................... 12

4.1 Operating the door ................................................................................................................12

4.2 Controls and indications ........................................................................................................ 12

4.3 Switching on ......................................................................................................................... 13

4.4 Setting the temperature (quick setting) .................................................................................. 13

5 Selecting the operating mode ...........................................................................................................13

6 Setting the parameters ......................................................................................................................13

7 Normal operation ..............................................................................................................................14

8 Weekly programmer ..........................................................................................................................16

9 Programme operation .......................................................................................................................18

9.1 Closure commands for ramp segments .................................................................................. 20

10 Printer .............................................................................................................................................24

11 Basic oven settings (Setup) .............................................................................................................. 25

11.1 Real-time clock .................................................................................................................... 26

12 Temperature monitor and protection devices ................................................................................... 26

12.1 Mechanical temperature monitor: temperature limiter (TB) ................................................... 26

12.2 Electronic temperature monitor ...........................................................................................27

12.2.1 Overtemperature protection ..............................................................................................27

12.2.2 Undertemperature protection ........................................................................................... 27

12.2.3 Adjustable temperature monitor (TWW) Protection Class 3.1 to DIN 12 880 ...................... 27

12.2.4 Automatic temperature monitor (ASF) ..............................................................................28

13 Active humidity control (%rh) .......................................................................................................... 30

14 Audible alert signals ........................................................................................................................31

15 Sterilisation chip card ......................................................................................................................32

16 User-ID-Card (available as optional extra) .........................................................................................33

17 Calibration ......................................................................................................................................34

17.1 Temperature ........................................................................................................................34

17.2 Humidity .............................................................................................................................36

HCPpage 3

Page 4

18 Communication interface for the PC ................................................................................................38

18.1 Communication interface RS232C ........................................................................................38

18.2 Bus interface RS485 .............................................................................................................39

19 Report memory ............................................................................................................................... 40

19.1 Reading the report memory .................................................................................................40

19.2 Reading the report memory into the PC via RS232C .............................................................40

19.3 Printing the report memory from the oven ........................................................................... 40

20 Cleaning .........................................................................................................................................41

21 Maintenance ................................................................................................................................... 42

22 Check list for fault rectification ........................................................................................................43

23 Supply failure ..................................................................................................................................44

24 CE Conformity Declaration ..............................................................................................................45

25 Address and customer service ..........................................................................................................46

HCP page 4

Page 5

1 General notes and safety notes

You have purchased a technically fully proven product which has been produced in Germany with the use

of high-grade materials and the application of the latest manufacturing techniques; it has been factory

tested for many hours.

For this unit we guarantee availability of spares for 10 years

Observation of the Operating Instructions is necessary forfaultless

operation and for any possible claims under warranty.

If these Instructions are disregarded, all claims under warranty,

guarantee and indemnification are excluded.

This mark on the product means:

Note Operating Instructions

Warning – oven hot when operating

The right to technical modifications is reserved.

Dimensional details are not binding.

1.1 Transport

Always use gloves!

For transportation, please put the unit in upright position on a suitable transportation cart. If the units have

to be carried, at least 2 people are necessary for model 108, 153 and 4 people for model 246.

Do not place the oven on a readily inflammable support surface!

It is important that the oven is set up accurately horizontally!

HCPpage 5

Page 6

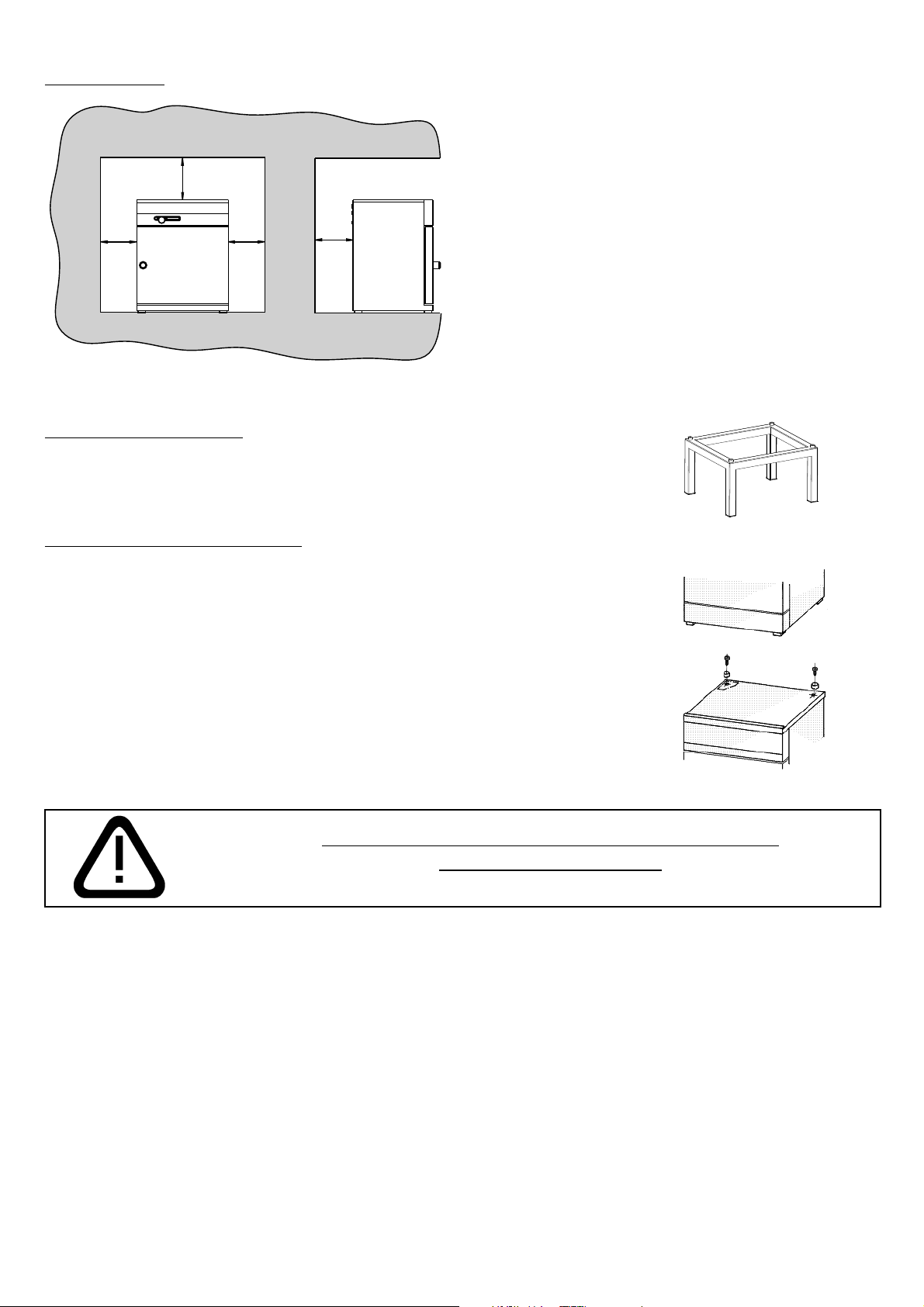

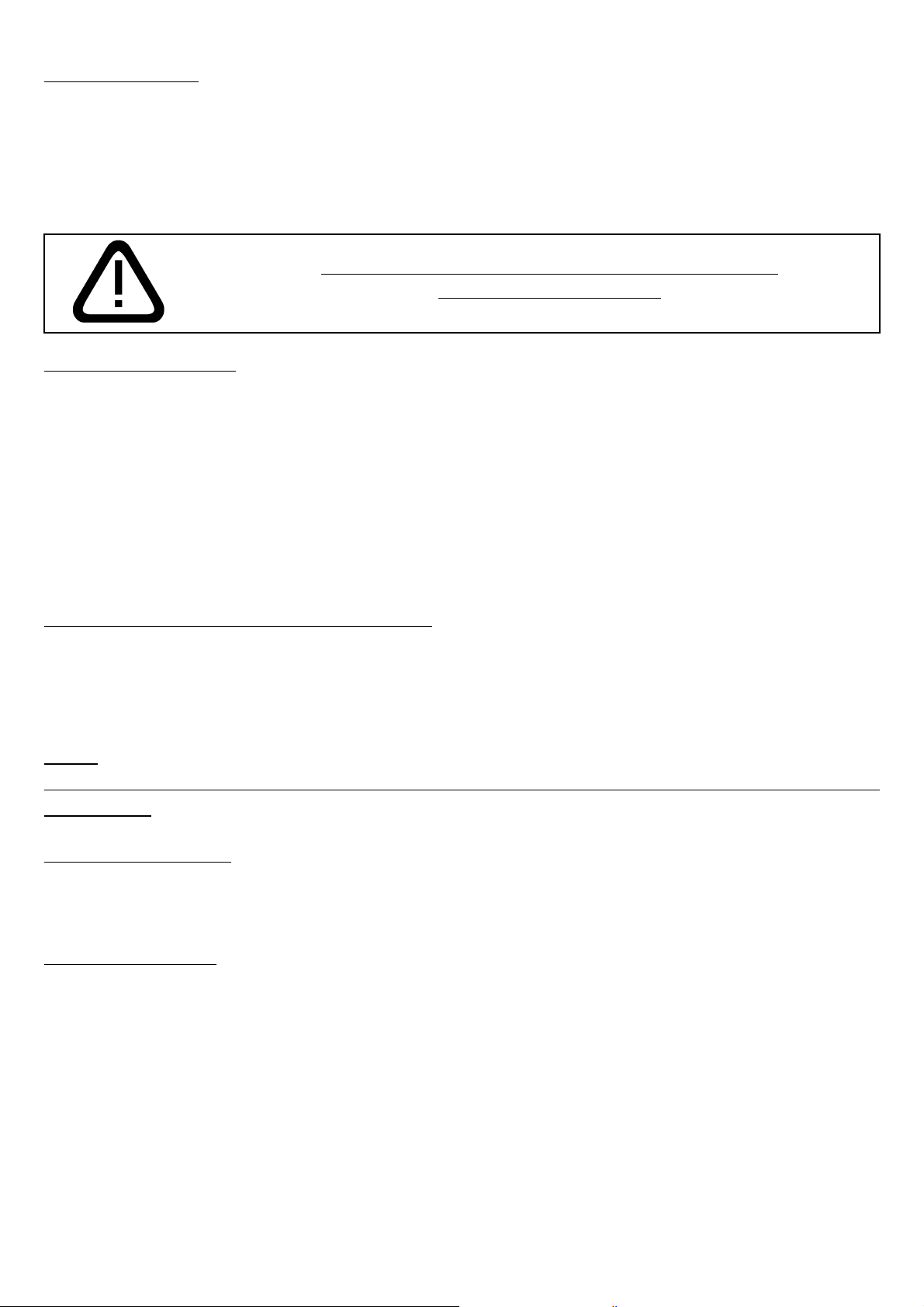

2 Installation

The oven can be placed on the floor or on a bench

(working surface).

cm

min. 20

It is important that the oven is set up accurately

horizontally; the door may have to be adjusted

min. 8

cm

min. 8

cm

min. 15

cm

(see section 21)

The spacing from the back of the oven to the wall

should be at least 15 cm. The spacing to the ceiling

must not be less than 20 cm and that at the side to

the wall not less than 8 cm. Generally it is essential

to have adequate air ventilation around the oven.

2.1 Subframe (accessory)

Models 108, 153 and 246 can be placed on a subframe.

2.2 Stackable version (accessory)

Two ovens of the same model size can be stacked on each other.

Foot locators have to be fitted on the bottom oven.

Mounting:

• Take off cover of bottom oven

• Place drill jig (supplied with foot locators) into the inverted cover

at the back

• Mark holes and drill 4.2 mm dia

• Screw the foot locators to the top of the cover using the screws

and nuts supplied

• Re-fit the cover

WARNING! Always pull out the supply plug before

opening the oven cover!

HCP page 6

Page 7

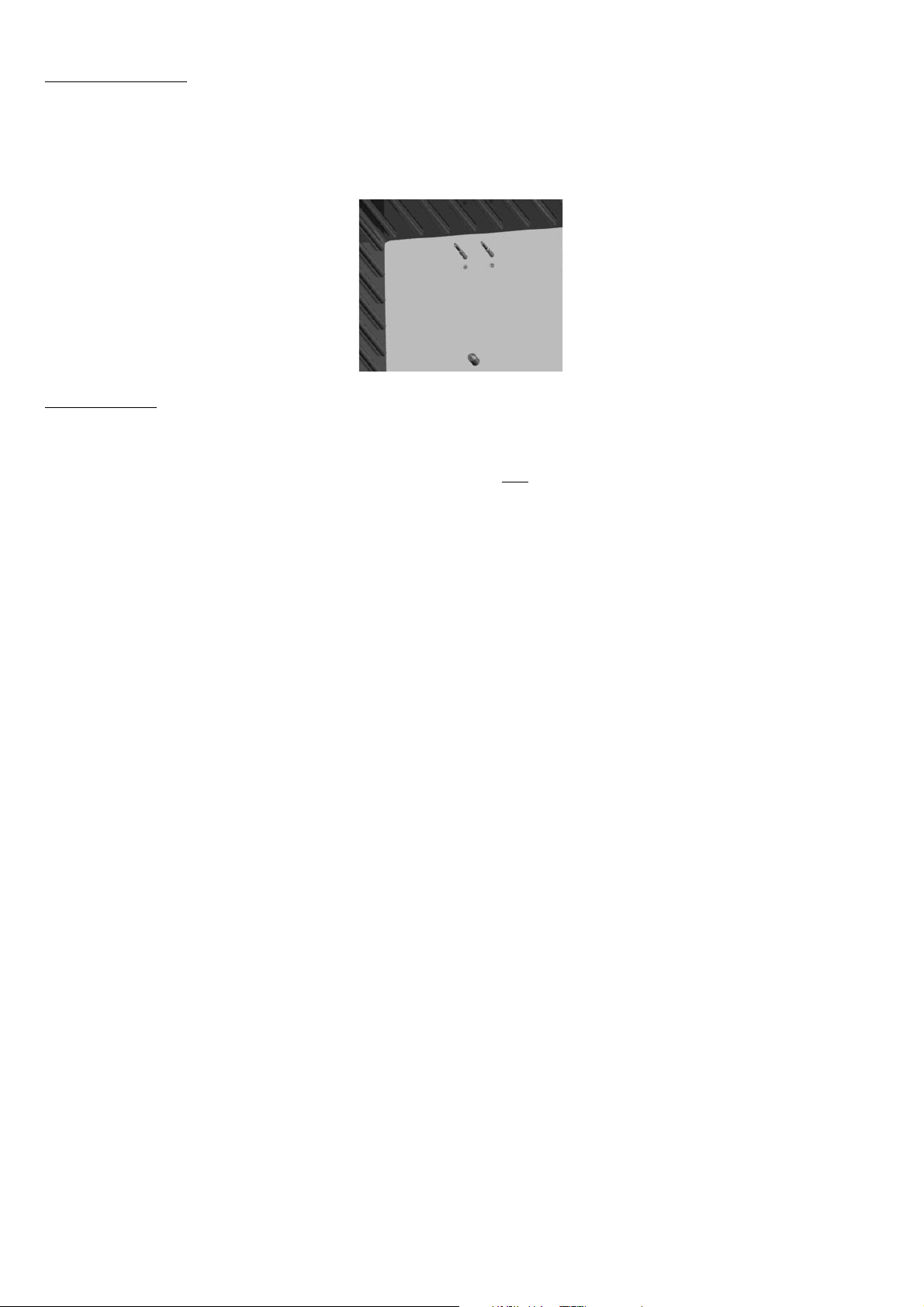

2.3 Initial start-up

When the oven is started up for the first time, it should be supervised continuously until steady conditions

have been reached. Severe vibrations during transport may cause movement of the temperature probes

in their holder inside the chamber. Note therefore that before the first start-up the temperature probes

should be checked for their correct position and, if necessary, carefully aligned in their mounting (see ill).

2.4 Oven load

Full consideration must be given to the physical and chemical properties of your load (e.g. combustion

temperature etc.) in order to prevent serious damage to load, oven and surroundings.

Please note that the MEMMERT ovens described here are not explosionproof (they do not conform to the

Industrial Association Specification VBG 24) and are therefore not suitable for drying, evaporating and

burning-in of paints, enamels or similar materials whose solvents may produce an inflammable mixture

with air. There must be no possibility of the formation of inflammable gas/air mixtures either within the

oven chamber or in the immediate surroundings of the equipment.

Large amounts of dust or corrosive fumes inside the oven chamber or in the surroundings of the equipment

may produce deposits within the oven and lead to short-circuits or damage the electronics. It is therefore

important that adequate precautions are taken against excessive dust or corrosive fumes.

In order to ensure proper air circulation inside the chamber, there must be sufficient spacing of the load

inside the oven. Do not place any load on the floor, against the side walls or underneath the ceiling of the

chamber (heating ribs).

HCPpage 7

Page 8

3 Technical data

supply cable serial and parallel interface

H

O

2

inner

glas door

mm (minimum height)

adjusting screw

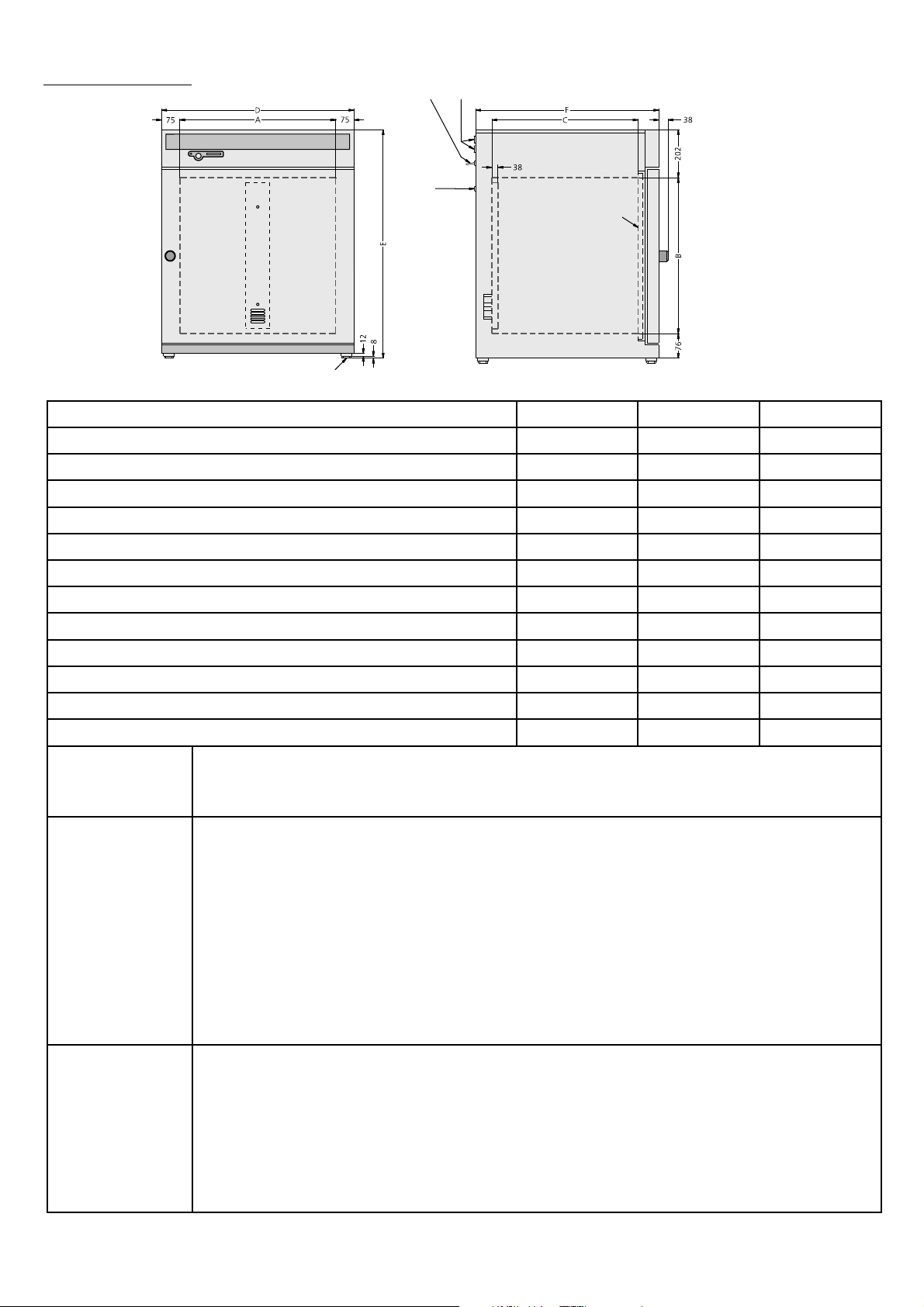

Model HCP 108 HCP 153 HCP 246

Chamber width A [mm] 560 480 640

Chamber height B [mm] 480 640 640

Chamber depth C [mm] 400 500 600

Housing width D [mm] 710 630 790

Housing height E (variable through adjustable feet) [mm] 778 920 938

Housing depth F (including door handle) [mm] 590 690 790

Chamber volume [litre] 108 153 246

Weight [kg] 70 90 110

Power [W] 1000 1500 2000

Max. number of shelves

577

Max. load per shelf [kg] 30 30 30

Max. load per oven [kg] 60 60 80

Ambient

conditions

• ambient temperature 5°C to 35°C

• rh 80% max. (no condensation)

• overvoltage category: II, contamination level: 2

Temperature • temperature is measued with Pt100 in 4-wire circuit

• adjustment range:: - normal operation with humidity: 20°C to 90°C

- normal operation without humidity: 20°C to 160°C

- sterilisation operation: 160°C (4 hours) via STERICard

• setting accuracy: 0,1°C

• control range: from 8°C above ambient up to 90°C / 160°C

• variation (time): ±0,1°C max

• uniformity (space): ±0.25°C max. at 50°C and 20-90%rh

±0,5°C at 90°C and 20-90%rh

±1,3°C at 160°C and with humidity control deactivated

Humidity The relative humidity in the chamber is measured by a capacitive humidity sensor and

indicated digitally in %.

• accuracy of humidity sensor: 1% rh

• adjustment range: 20 to 95%rh

• setting accuracy: 1rh%

• indication range: 10 to 98rh%

• variation (time): ±1%rh max

HCP page 8

Page 9

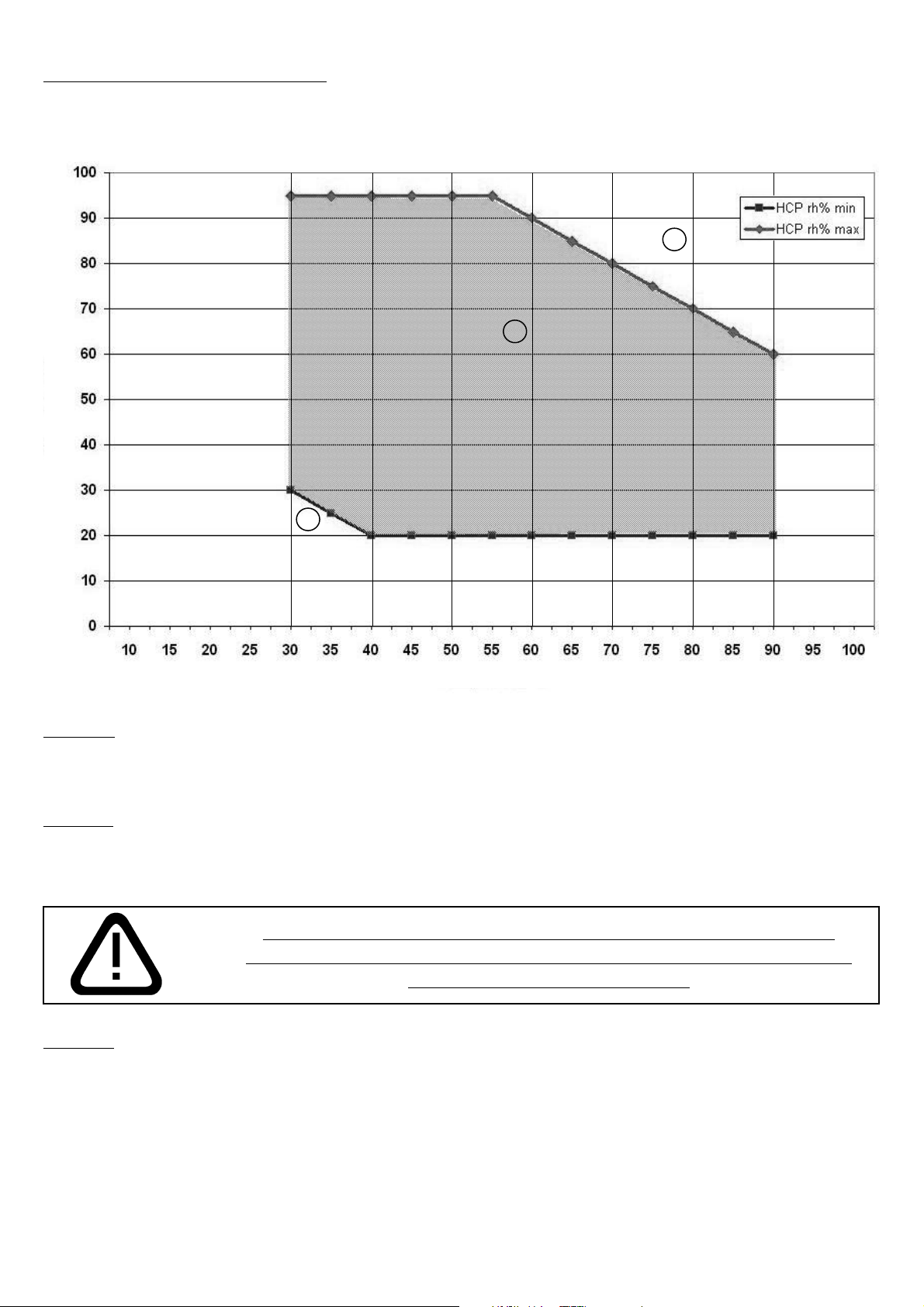

3.1 Working range of the HCP units

The temperature-humidity diagram of the humidity chamber HCP indicates the range of temperature and

humidity within which continuous condensation-free operation is possible.

B

A

Humidity %rh

C

Temperature °C

Range A:

Within this range, any combination of temperature and humidity is possible without any appreciable

condensation.

Range B:

Above the range indicated, e.g. 80% rH at 80°C, the steam introduced immediately condenses at the

coldest point of the unit due to the dew point.

With prolonged operation outside the working range there is a

possibility of water puddles forming inside the chamber and water

can escape from the door seal!

Range C:

At low temperatures and low relative humidity, the usable range depends largely on ambient temperature

and humidity. In order to be able to use the range of low temperatures and low relative humidity the unit

has to be set up in a cool and dry room.

HCPpage 9

Page 10

3.2 Standard equipment of HCP units

• Electronic fuzzy-supported PID process controller with plus-package control and permanent power

proportioning and a time-saving autodiagnostic system for rapid fault finding (see section 22)

• Recessing push/turn control for simple operation of oven

• Language selection (English, French, Spanish, Italian, German)

• Alphanumerical text display

• Large-area all-round heating with additional heat conduction jacket

• Capacitive humidity sensor

• Active humidity control (fresh air via sterile filter) avoids condensation and ensures rapid

achievement of set humidity as well as short recovery times

• Uniform atmosphere and temperature distribution through encapsulated and turbulence-free

ventilation system

• Control of oven and documentation of actual values on MEMoryCard XL

• Programme sequence control for up to 40 ramp segments

• 7 different ramp exit commands for advanced temperature applications

• STERIcard for fully automatic sterilisation control during hot air sterilisation of complete cabinet

including sensors and fan disc

• Integral weekly programmer with group function (e.g. all workdays)

• Two separate PT100 temperature sensors Class A in 4-wire circuit for control and monitoring

• Digital monitor controller for overtemperature, undertemperature, and as automatically setpoint

following monitor (ASF)

• Mechanical temperature limiter (TB Class 1)

• Monitor relay to switch off heating in case of fault

• Visual alarm indication

• Audible signal on over-/undertemperature, over-/under-humidity and open door

• Internal documentation memory 1024kB as ring memory for all temperature and humidity values,

errors and settings with real-time and date. Documentation approx. 3 months at 1 minute storage

interval

• Calibration possible without separate PC: 3-point calibration for temperature on the controller and

2-point calibration for humidity at 20% rH and 90% rH

• Parallel printer interface (PCL3-compatible) for printing documentation data

• Serial RS-232C interface for computer-supported temperature programmes and for reading the

internal report memory

• MEMMERT software “Celsius 2007“ for control and documentation of temperature and relative

humidity via a PC

• A pre-formatted blank MEMoryCard XL with 32 kB storage capacity, reprogrammable for up to 40

ramp segments and additionally 270 hours report memory at 1 minute intervals

HCP page 10

Page 11

3.3 Material quality

For the external housing MEMMERT employs stainless steel (Mat.Ref. 1.4016). The chamber is made from

stainless steel (Mat.Ref. 1.4301) which exhibits high stability, optimal hygienic properties and corrosion

resistance against many (not all) chemical compounds (care required e.g. with chlorine compounds).

The oven load has to be checked carefully for its chemical compatibility with the above materials.

A compatibility table for materials can be requested from MEMMERT.

WARNING! Always pull out the supply plug before

opening the oven cover!

3.4 Electrical equipment

• Operating voltage see label, 50/60 Hz

• Current rating see label

• Protection Class 1, i.e. operating isolation with ground connection to EN 61010

• Protection IP20 to DIN EN 60529

• Interference suppression to EN55011 Class B

• Oven protected by a fuse 250V/15A fast blow

• Temperature controller protected by a 100 mA fuse (200 mA on 115 V)

• When connecting a MEMMERT oven to the electrical supply you have to observe any local

regulations which apply (e.g. in Germany DIN VDE 0100 with FI protection circuit)

3.5 Note on EMC (electromagnetic compatibility)

This product is intended to operate on a supply network with a system impedance Z

(building connection) of 0.292 Ohm max. The user has to ensure that the product is only operated on an

electrical supply network which meets these requirements. If necessary, details of the system impedance

can be obtained from the local electricity supply authority.

at the transfer point

max

Note:

Any work involving opening up the oven must only be carried out by a suitably qualified

electrician!

3.6 External connection

Equipment connected to the external connections must have interfaces which meet the requirements for

safe low voltage (e.g. PC, printer).

3.7 Water connection

The water container supplied has to be filled with distilled water and connected to the H2O connection

using the hose supplied.

For steam generation, use only:

• Steam-distilled water (aqua dest)

or

• Demineralised water (aqua dem) in accordance with VDE 0510/DIN EN 50272; regulations must be

strictly adhered to (production conductivity ≤ 10 μS/cm). Battery water in accordance with VDE 0510 is

available in larger chemist‘s shops, super markets, hardware stores and in the wholesale trade. The standard

VDE 0510/DIN EN 50272 has to be explicitly specified on the label. Otherwise, possible calcification in the

steam generators, steam piping and peristaltic pumps could affect the operability of the device.

Use only water with a pH value of > 5 and < 7.

HCPpage 11

Page 12

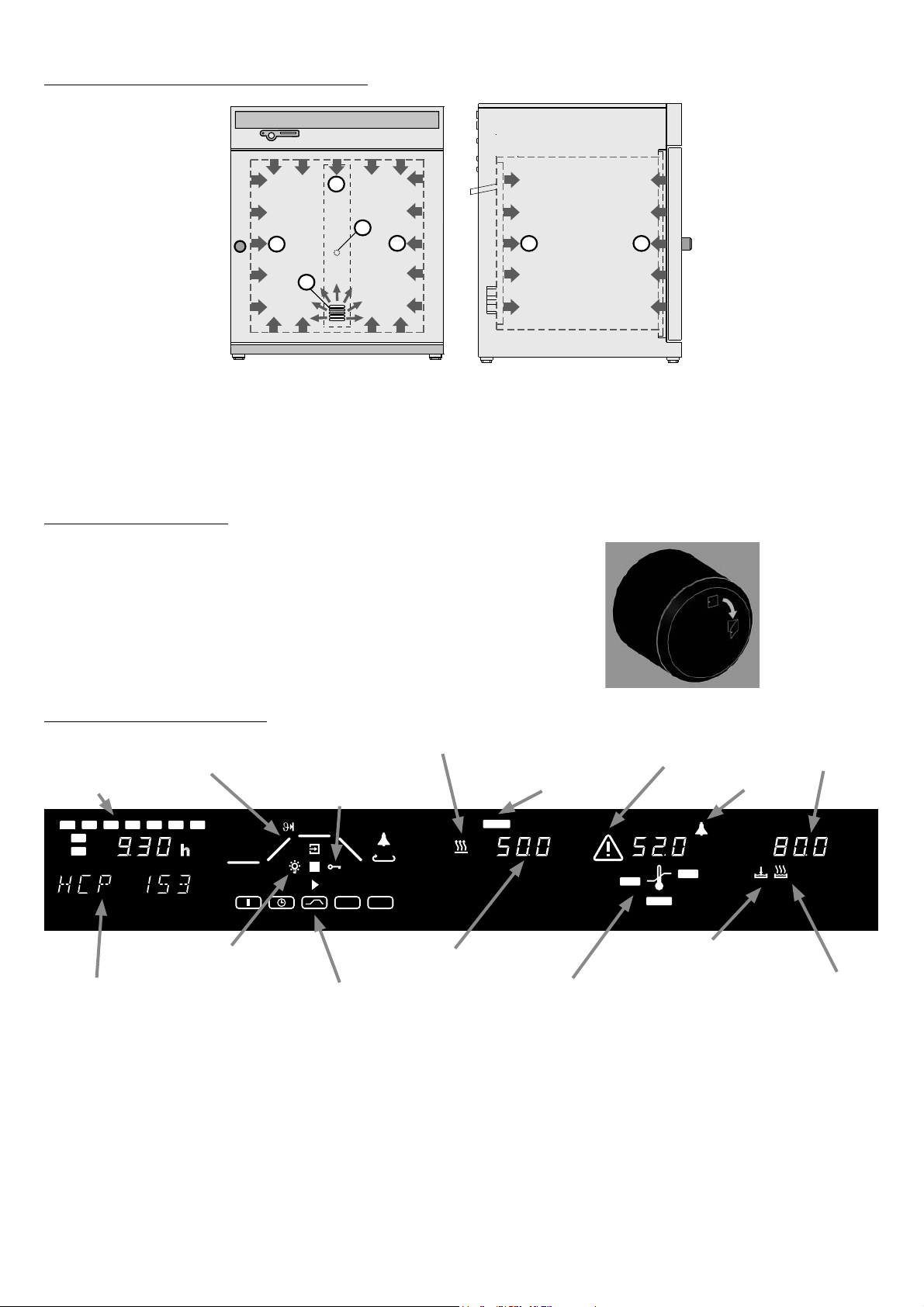

4 Oven construction and operation

1

2

1

3

1

The special feature of the HCP is the particularly uniform conditions inside the chamber. The air is heated by

large-area allround heating (1). Humidity is provided by a dry steam generator which produces controlled

evaporation of the water. The sterile dry steam is introduced into the chamber above the fan and mixed into

the air flow (2). A continuous uniform atmosphere is ensured by the turbulence-free chamber ventilation

(3).

4.1 Operating the door

11

The door is opened by clockwise rotation of the handle.

Close the door by turning the door handle anticlockwise.

4.2 Controls and indications

time

display

Tu

Mo

on

off

text

display

Programme

operation

manipulation prevention

(User-ID-Card)

We

t2

t1

Sa Su

Fr

Th

t3

t4

PRINT

Interior lighting

(option)

operating mode

indication

heating

4

3

loop

2

1

SETUP

temperature

display

temperature indication

sterilisation

operation

STERI

DEFRO

monitor

°C

alarm

indication

°C

MIN

MAX

AUTO

warning water

container empty

sounder

IN 1

humidity

indication

OUT

IN 2

rh

%

mb

steam

generation

HCP page 12

Page 13

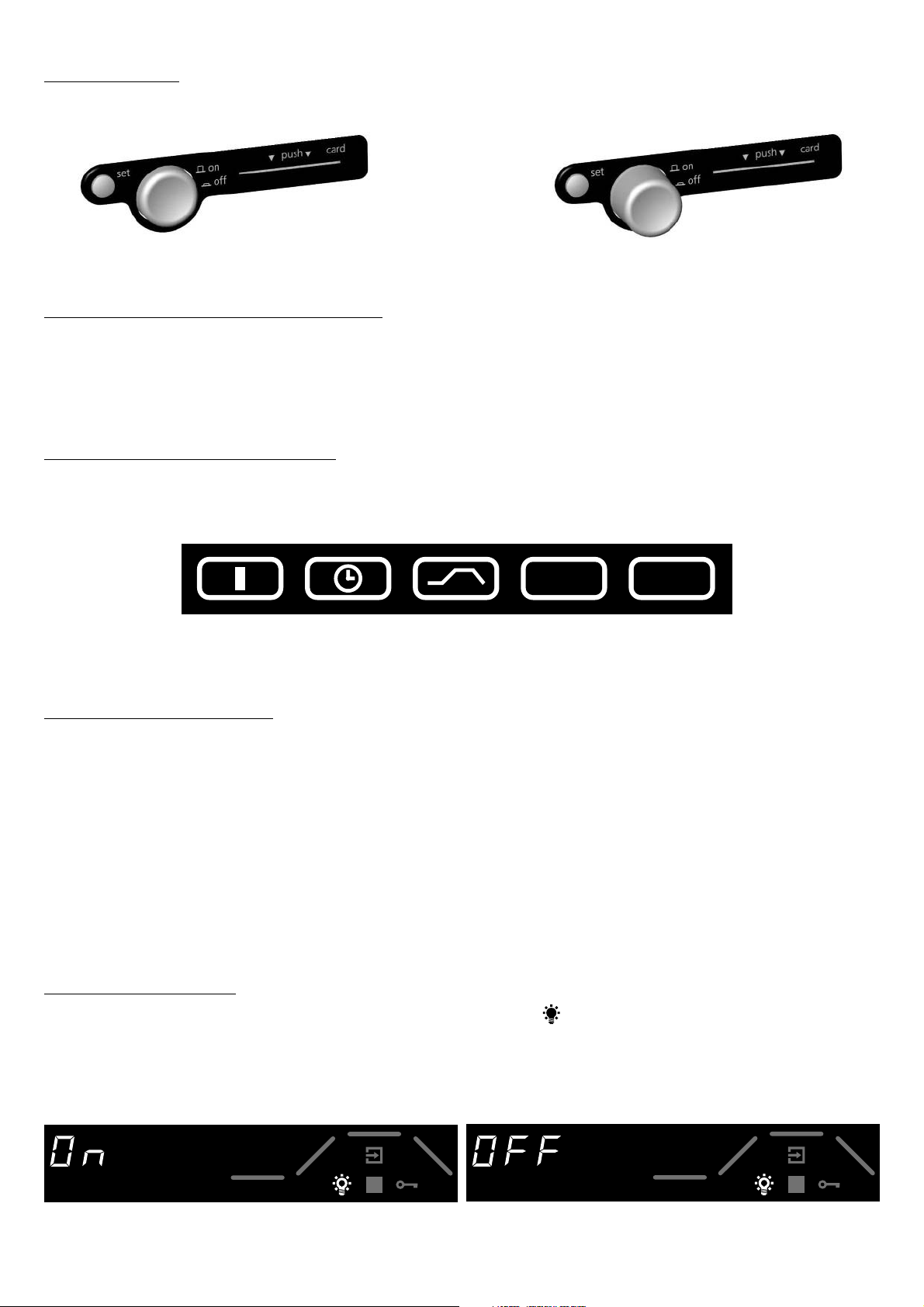

4.3 Switching on

The oven is switched on by pressing the push/turn control.

Oven switched off. The push/turn control is

pushed in and protected against damage.

Oven switched on and can be operated using

the push/turn control and the SET key.

4.4 Setting the temperature (quick setting)

Hold down the SET key and set the temperature setpoint with the push/turn control.

After the SET key has been released the display briefly flashes the temperature setpoint. The display then

changes to the actual current temperature and the controller starts to control to the selected temperature

setpoint.

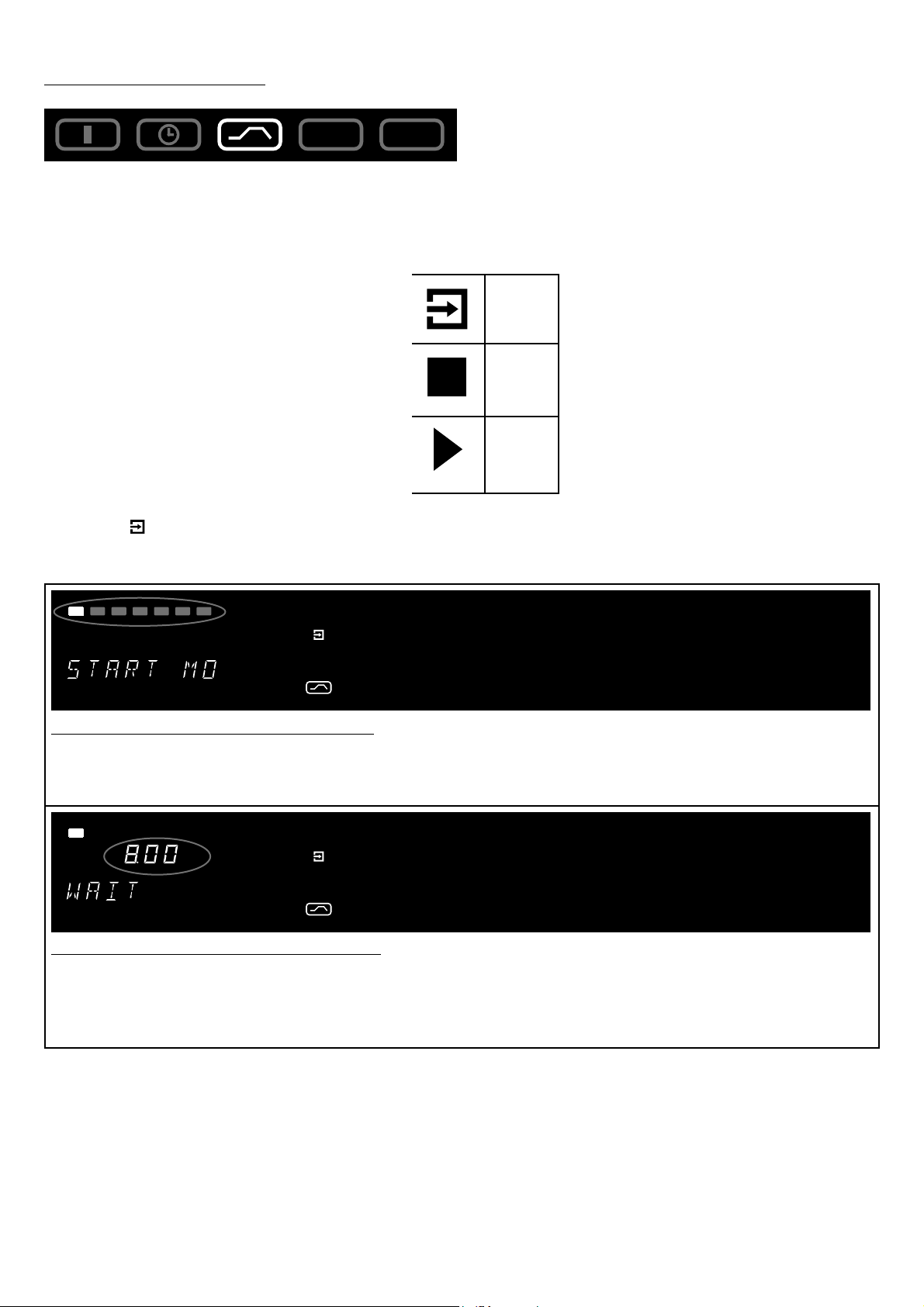

5 Selecting the operating mode

After holding down the SET key (approx. 3 sec), the current operating mode flashes on the display. A

different operating mode can be selected with the push/turn control while the SET key is being held down.

After the SET key has been released the controller operates in the new operating mode.

SETUP

settings

Normal

operation

Weekly

programmer

Programme

operation

PRINT

Printer Basic

6 Setting the parameters

After an operating mode has been selected, all relevant controller settings are shown simultaneously on

the display.

A parameter (menu item) can be selected by rotating the push/turn control; all other parameters are then

dimmed.v

The selected parameter flashes brightly and can now be altered with the push/turn control while holding

down the SET key.

After the SET key has been released the newly set value is stored.

If the push/turn control or the SET key have not been operated for a period of 30 seconds, the controller

automatically returns to the main menu.

Interior lighting (option)

Turn the push/turn control anticlockwise until the light symbol

While holding down the SET key, use the push/turn control to set the light on or off.

When operating in the “weekly programmer” mode the internal illumination is switched off automatically

when the equipment is switched off by the weekly programmer.

t2

t1

is flashing.

t2

t1

HCPpage 13

Page 14

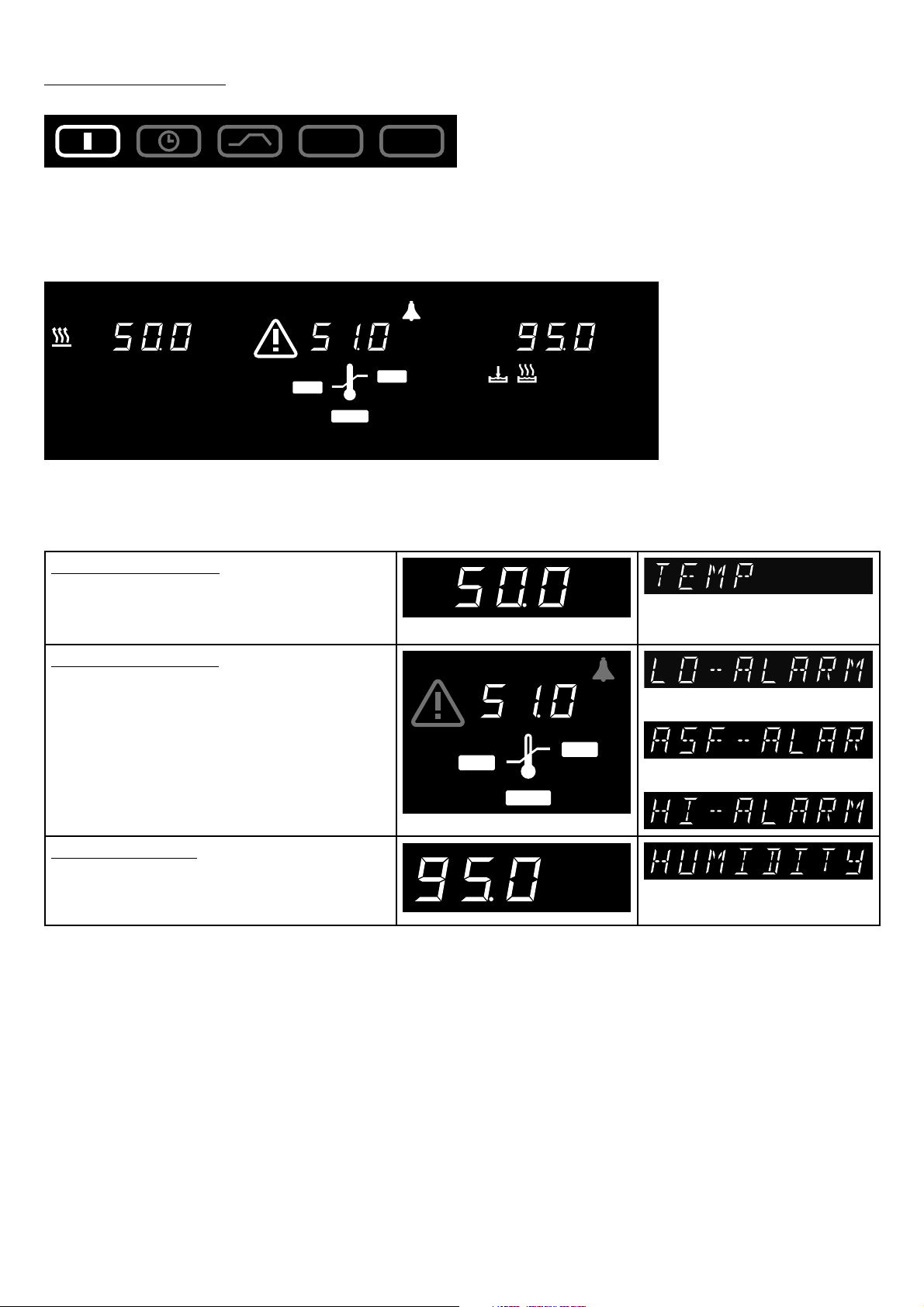

7 Normal operation

PRINT

In this operating mode the oven operates continuously. The settings for operating the oven can be selected.

The settings act directly on the operation of the oven.

°C

MIN

AUTO

By rotating the push/turn control the following parameters can be selected and can be altered as described

in the section 6:

Temperature setpoint

Adjustment range:

- with humidity 20 to 90 °C

- without humidity: 20 to 160 °C

SETUP

°C

MAX

IN 1

IN 2

OUT

%

mb

°C

rh

Temperature monitor

Settigng: MIN, MAX, AUTO

(see section 12)

Humidity setpoint:

Adjustment range: 20 to 95 %rh

MIN

AUTO

MAX

%

°C

rh

HCP page 14

Page 15

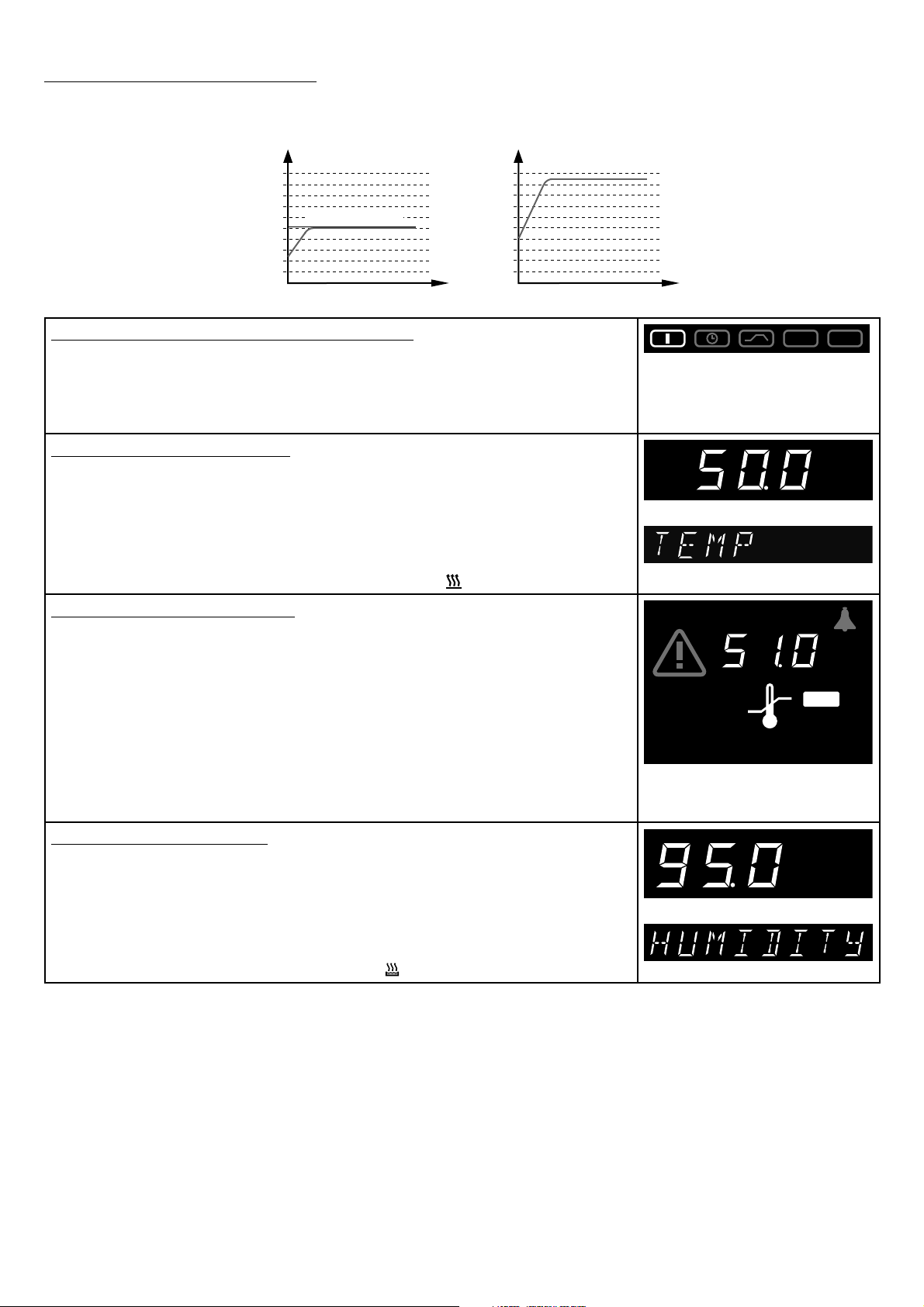

Setting example Normal operation

The unit has to heat up to 50°C at a humidity of 95%rh. The monitor function has to be activated at

51°C.

temperature

°C

100

80

60

40

20

temperature monitor

relative humidity

(rh) %

100

80

60

40

20

time

1. Select operating mode “Normal operation“

After holding down the SET key (approx. 3 sec), the current operating

mode is flashing. Select operating mode I with the push/turn control while

holding down the SET key.

After the SET key has been released the controller is in operating mode I.

2. Select temperature setpoint

Hold down the SET key and use the push/turn control to select the required

temperature setpoint of 50.0 °C. After the SET key has been released the

oven briefly flashes the temperature setpoint. The display then changes to

the actual temperature and the controller starts to control to the selected

temperature setpoint 50,0 °C.

Heating is indicated by the orange heater symbol

.

3. Select monitor temperature:

Turn the push/turn control clockwise until the overtemperature protection

and the symbol

MAX

or

MIN

flashes. Keep the SET key depressed and

use the push/turn control to set the overtemperature protection to 51.0 °C

and the undertemperature protection to 49.0 °C.

or:

Turn the push/turn control clockwise until the monitor temperature and

AUTO

the symbol

flashes. Keep the SET key depressed and set the push/

turn control to on .

The tolerance band is selected in the SETUP menu (see section 11).

time

MIN

AUTO

PRINT

SETUP

°C

°C

MAX

4. Select humidity setpoint:

Turn the push/turn control clockwise until the humidity display flashes.

Keep the SET key depressed and use the push/turn control to set the

required humidity setpoint of 96 %. After the SET key has been released

the humidity setpoint continues to flash briefly. The display then changes

to the actual humidity and the controller starts to control to the set value.

Humidification is indicated by the symbol

.

%

rh

HCPpage 15

Page 16

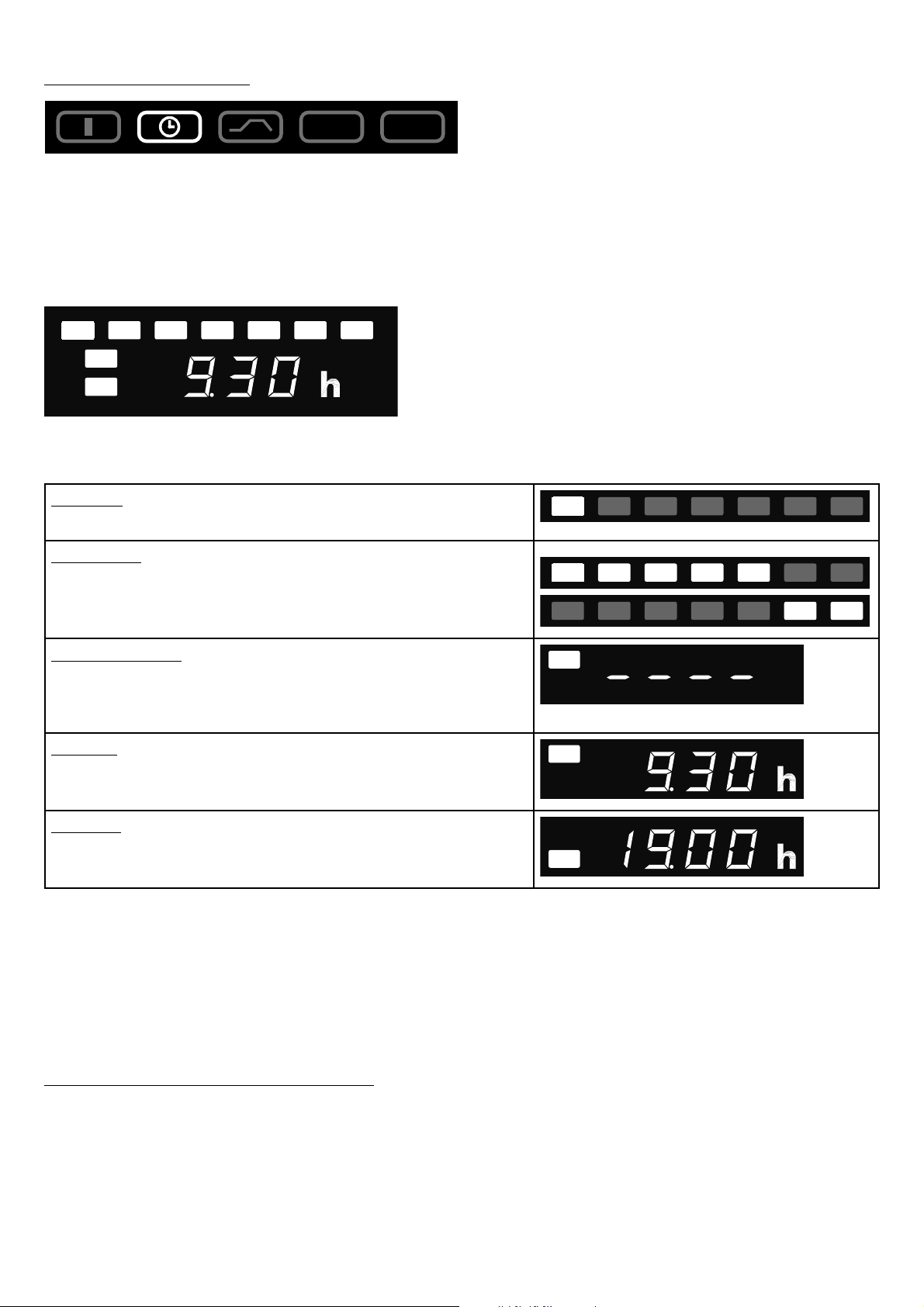

8 Weekly programmer

PRINT

SETUP

In this operating mode the weekly programmer is activated and the oven switches on and off automatically

at the programmed times.

While the weekly programmer is in the OFF phase the unit is in stand-by mode. Heating and the supply of

humidity are switched off, the controller display is dimmed and shows the clock time.

The sequence of the weekly programmer is repeated every week.

A maximum of 9 time blocks, each consisting of ON time and OFF time, can be programmed.

Mo

on

off

Tu

We

Th

Fr

Sa Su

By rotating the push/turn control the following parameters can be selected and can be altered as described

in the section 6:

Weekday

Mo

Tu

We

Th

Fr

Sa Su

Adjustement range: Monday to Sunday

Day groups

Adjustement range: weekend Sa-Su

weekend Sa-Su

Mo

Mo

Tu

Tu

We

We

Th

Th

Fr

Fr

Sa Su

Sa Su

No ON time: ---On these days the oven is not switched on

(without an ON time being entered, an OFF time cannot be

on

off

programmed for the respective time block either)

ON time

Adjustment range: 00.00 to 23.59 hrs.

OFF time

Adjustment range: one minute above ON time to 24.00 hrs

on

off

on

off

Further clockwise rotation selects the parameters (temperature and humidity setpoint etc.) as under

operating mode I.

If no settings (temperature and humidity setpoint etc.) are made for the ON phase, the controller takes the

values from operating mode I.

For safety reasons, always check that an ON time has been programmed only during the required time

blocks and days.

Direct setting of the temperature setpoint

When the controller is in stand-by mode or if the weekly programmer is in the ON phase, the temperature

setpoint can be selected directly by briefly pressing the SET key. Further clockwise rotation reaches

temperature monitor and humidity adjustment. Anticlockwise rotation reaches again adjustment of the

individual time blocks.

HCP page 16

Page 17

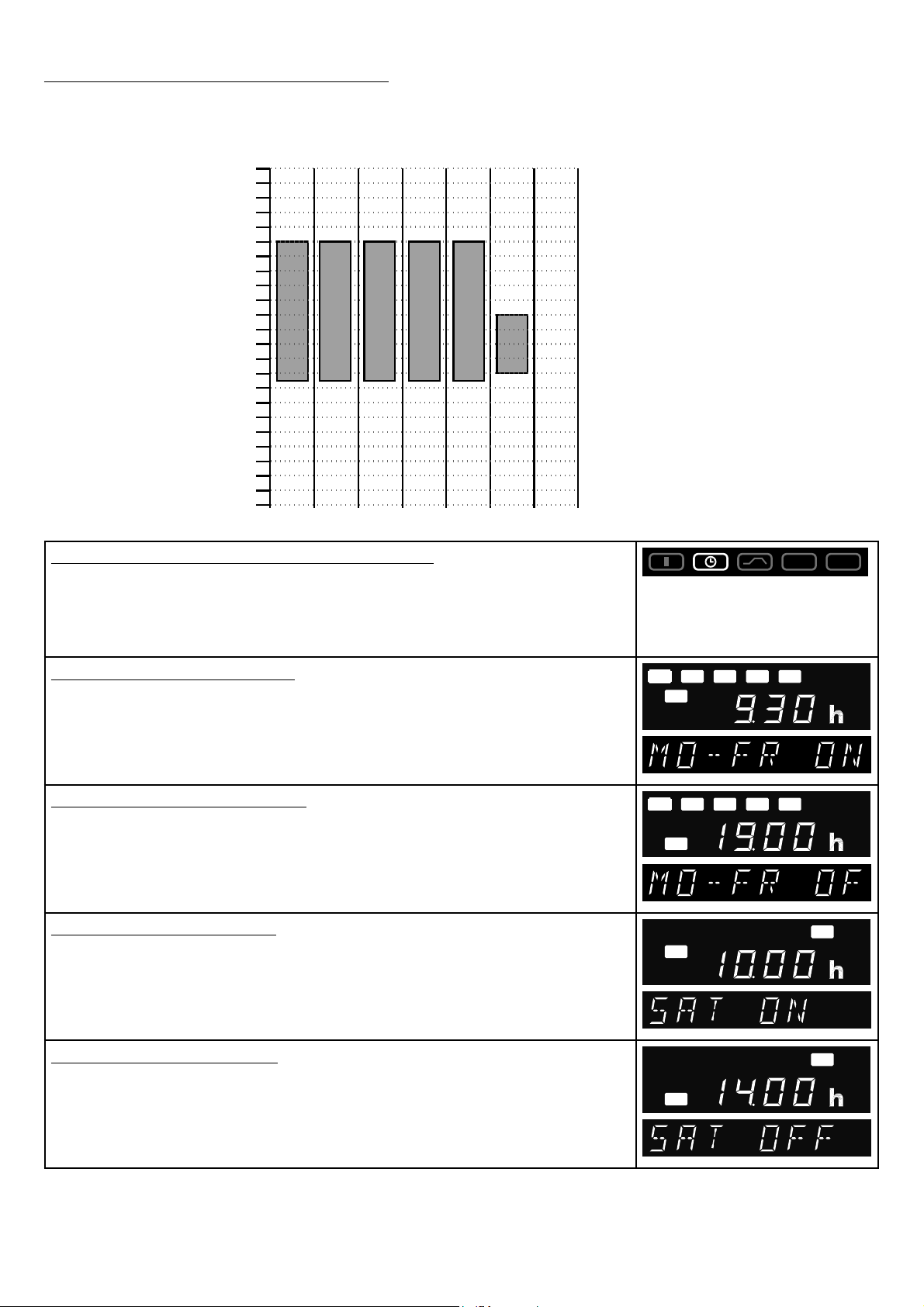

Programming example Weekly programmer

The unit has to switch on at 9.30 hrs from Mo to Fr (workday group) and switch off at 19.00 hrs. In

addition it has to operate on Saturday from 10.00 to 14.00 hrs.

24:00h

12:00h

9:30h - 19:00h

9:30h - 19:00h

Mo

Tu

9:30h - 19:00h

9:30h - 19:00h

Th

We

9:30h - 19:00h

9:30h -

14:00h

Fr

Sa

Su

1. Select operating mode “Weekly programmer“

After holding down the SET key (approx. 3 sec) the current operating

mode is flashing. Select operating mode “Weekly programmer“ with the

push/turn control while holding down the SET key. After the SET key has

been released the controller is in operating mode “Weekly programmer“.

2. Switch on at 9.30 hrs Mo-Fr

Turn the push/turn control anticlockwise to select Mo-Fr on (workday

group).

Hold down the SET key and use the push/turn control to set the switch on

time to 9.30.

Mo

on

off

Tu

We

Th

PRINT

Fr

SETUP

Sa Su

3. Switch off at 19.00 hrs Mo-Fr

Using the push/turn control to select Mo-Fr off (workday group).

Hold down the SET key and use the push/turn control to set the switch off

time to 19.00.

4. Switch on at 10.00 hrs Sa

Using the push/turn control to select Sat on.

Hold down the SET key and use the push/turn control to set the switch on

time to 10.00.

5. Switch off at 14.00 hrs Sa

Using the push/turn control to select Sat off.

Hold down the SET key and use the push/turn control to set the switch off

time to 14.00.

Mo

Mo

Mo

on

off

on

off

on

off

Tu

Tu

Tu

We

We

We

Th

Th

Th

Fr

Fr

Fr

Sa Su

Sa Su

Sa Su

HCPpage 17

Page 18

9 Programme operation

PRINT

SETUP

In this operating mode it is possible to set up to 40 freely programmable ramps for temperature and

humidity. Rotating the press/turn control while holding down the SET key selects the following parameters

in sequence after released the SET key:

- a new programme can be programmed or

an existing programme can be edited

- stops the programme

- starts the programme

After EDIT

has been activated, the following parameters can be selected and can be altered as described

EDIT

STOP

START

in the Section 6.

STERI

Tu

Mo

We

on

off

Sa Su

Fr

Th

h

t2

t1

t3

PRINT

t4

SETUP

loop

4

3

2

1

DEFRO

°C

MIN

°C

MAX

AUTO

IN 1

IN 2

OUT

%rh

mb

Delayed programme start: switch-on day

Range: Monday to Sunday, workdays Mo-Fr, weekend Sa-Sun, all days Mo-Su or no day. If no day of the

week is selected, the oven starts up immediately after the programme is started. ( instant start )

STERI

Tu

Mo

We

on

off

Sa Su

Fr

Th

h

t2

t1

t3

PRINT

t4

SETUP

loop

4

3

2

1

DEFRO

°C

MIN

°C

MAX

AUTO

IN 1

IN 2

OUT

%rh

mb

Delayed programme start: switch-on time

Range: 00.00 to 23.59

If no switch-on day has been selected it is not possible to select a switch-on time, and the programme

starts immediately. ( instant start )

HCP page 18

Page 19

Tu

Mo

We

on

off

Sa Su

Fr

Th

h

t2

t1

Duration of first ramp segment

Range: 1 minute to 999 hours.

STERI

t3

PRINT

t4

SETUP

loop

4

3

2

1

DEFRO

°C

MIN

°C

MAX

AUTO

IN 1

IN 2

OUT

%rh

mb

STERI

Tu

Mo

We

on

off

Sa Su

Fr

Th

h

t2

t1

t3

PRINT

t4

SETUP

loop

4

3

2

1

DEFRO

°C

Setpoint temperature / temperature at the end of the ramp segment

Range with humidity: 20 to 90 °C

without humidtiy: 20 to 160 °C

STERI

Tu

Mo

We

on

off

Sa Su

Fr

Th

h

t2

t1

t3

PRINT

t4

SETUP

loop

4

3

2

1

DEFRO

°C

Humidity setpoint / humidity at end of the ramp segment

Range: 20 to 95 %rh.

STERI

Tu

Mo

We

on

off

Sa Su

Fr

Th

h

t2

t1

t3

PRINT

t4

SETUP

loop

4

3

2

1

DEFRO

°C

MIN

MIN

MIN

AUTO

AUTO

AUTO

MAX

MAX

MAX

°C

°C

°C

IN 1

IN 1

IN 1

IN 2

IN 2

IN 2

OUT

%rh

mb

OUT

%rh

mb

OUT

%rh

mb

Closure command of ramp segment

Range: NEXT, SPWT (T), SPWT (H), SPWT (TH), LOOP, HOLD, END (see section 9.1).

STERI

Tu

Mo

We

on

off

Sa Su

Fr

Th

h

t2

t1

t3

PRINT

t4

SETUP

loop

4

3

2

1

DEFRO

°C

MIN

°C

MAX

AUTO

IN 1

IN 2

OUT

%rh

mb

Exit the programme write mode EDIT

Turn the push/turn control clockwise unti EXIT appears on the display, briefly press the SET key to enter.

HCPpage 19

Page 20

9.1 Closure commands for ramp segments

NEXT Follow-on with next programme segment.

SPWT (T)

SET-POINT WAIT (temperature)

SPWT (H)

SET-POINT WAIT (humidity)

SPWT (TH)

SET-POINT WAIT (temperature

and humidity)

LOOP

Wait until the setpoint temperature is reached.

The unit only starts the next programme segment when the programmed

setpoint temperature has been reached, even if the programmed heating

time has already elapsed.

Wait until set humidity is reached.

The unit starts with the next programme segment only when the

programmed humidity setpoint has been reached, even if the

programmed heating time has already elapsed.

Wait until set temperature and set humidity are reached.

The unit starts with the next programme segment only when the

programmed temperature setpoint and the programmed humidity

setpoint have been reached, even if the programmed heating time has

already elapsed.

Ramp repeat function

The set programme is repeated after passing through all programmed

segments.

1-99 = repeats

cont = continuous repeat function

HOLD

End of programme without switching off the heating and the humidifying

system.

END

End of programme, heating and humidifying system are switched off.

The programme segments are linked together by the segment closure command. These commands

therefore control the programme sequence.

closure

command

ramp

segment 4

next

command

segment 5

segment 5

closure

ramp

end

°C

delayed

programme start

closure

command

ramp

segment 1

spwt (t)

segment 1

closure

command

segment 2

segment 2

ramp

next

closure

command

ramp

segment 3

spwt (tH)

segment 4

segment 3

Ramp

HCP page 20

t=time

Page 21

Programming example programme operation

On Monday at 08.00 hrs the unit has to heat up as quickly as possible to 50°C and reach a relative humidity

of 95%rh. Once the temperature and humidity have been reached, the unit has to hold the setpoints for

45 minutes and then cool down to 37°C at a humidity of 50%rh.

°C

wait until set

temperature and set

humidity have been

50°C

reached

37°C

sucient if SPWT (TH)

closure command

Mo 8.00 h

is set as segment

0.01 h

0.45 h

1.00 h

t

1. Select operating mode “programme“

After holding down the SET key (approx. 3 sec) the current operating

mode is flashing. Hold down the SET key and select operating mode

“programme“ using the push/turn control.

After the SET key has been released the controller is in operating mode

“programme operation“.

2. Edit programme

Hold down the SET key and turn the push/turn control to select ”EDIT”.

After the SET key has been released, the controller is in the programme

writing mode.

PRINT

SETUP

3. Weekday for delayed programme start

Hold down the SET key and turn the push/turn control to set the start

day Mo.

4. Select clock time for delayed programme start

Using the push/turn control, select the time display.

Hold down the SET key and set the time 8.00 using the push/turn control.

5. Select duration of first ramp segment

Turn the push/turn control further clockwise until the time of the first

ramp segment is flashing.

Hold down the SET key and set the time 00.01 using the push/turn

control.

Mo

h

h

HCPpage 21

Page 22

6. Select temperature of first ramp segment

Turn the push/turn control clockwise until the temperature display is

flashing.

Hold down the SET key and set the required temperature setpoint of

50.0 °C using the push/turn control.

°C

7. Select relative humidity of first ramp segment

Turn the push/turn control clockwise until the humidity display is

flashing.

Hold down the SET key and set the required humidity setpoint of 95.0

%rh using the push/turn control.

8. Set closure command of first ramp segment

Turn the push/turn control clockwise until a segment closure command

(e.g. end ) appears.

Hold down the SET key and set SPWT [TH] with the push/turn control.

9. Select duration of second ramp segment

Using the push/turn control select the time indication.

Hold down the SET key and set the time 00.45 using the push/turn

control.

10. Select temperature of second ramp segment

Turn the push/turn control clockwise until the temperature display is

flashing.

Hold down the SET key and set the required temperature setpoint of

50.0 °C using the push/turn control.

%rh

h

°C

11. Select relative humidity of second ramp segment

Turn the push/turn control clockwise until the humidity display is

flashing.

Hold down the SET key and set the required humidity setpoint of 95.0

%rh using the push/turn control.

12. Set closure command of second ramp segment

Turn the push/turn control clockwise until a segment closure command

(e.g. end ) appears.

Hold down the SET key and set nexT with the push/turn control.

13. Select duration of third ramp segment

Using the push/turn control select the time indication.

Hold down the SET key and set the time 00.01 using the push/turn

control.

%rh

h

HCP page 22

Page 23

14. Select temperature of third ramp segment

Turn the push/turn control clockwise until the temperature display is

flashing.

Hold down the SET key and set the required temperature setpoint of

37.0 °C using the push/turn control.

°C

15. Select relative humidity of third ramp segment

Turn the push/turn control clockwise until the humidity display is

flashing.

Hold down the SET key and set the required humidity setpoint of 50.0

%rh using the push/turn control.

16. Set closure command for third ramp segment

Turn the push/turn control clockwise until a segment closure command

(e.g end ) appears.

Press the SET key briefly to enter.

17. Exit programme writing mode EDIT

Turn the push/turn control clockwise until EXIT appears on the display.

Press the SET key briefly to enter.

18. Set temperature monitor

Turn the push/turn control clockwise and set the temperature monitor.

(see section 12)

MIN

%rh

°C

MAX

AUTO

19. Start programme

Turn the push/turn control anticlockwise until the stop symbol

flashing.

Hold down the SET key and select Start

with the push/turn control.

is

HCPpage 23

Page 24

10 Printer

PRINT

SETUP

All HCP ovens are fitted as standard with a parallel printer interface, as used on personal computers.

This parallel printer interface on the back of the oven is suitable for connecting conventional PCL3compatible printers which are provided with a parallel printer interface (e.g. HP Deskjet 5550 or HP Deskjet

9xx).

It is important to use a screened interface cable. The screen must be connected to the plug case.

The controller is provided with an internal report memory (see section 19). The report data can in this

operating mode be printed out through the printer connected to the oven.

When using a colour printer, the various graphics can be printed in colour.

On the printout the GLP data head is also printed automatically and contains the following information:

• Printing date

• Time period of report

• Running page number

• Serial number and oven designation

By turning the push/turn control the following parameters can be selected in turn and altered as described

in the section 6.

Reading the date of the first print page

Reading the date of the last print page

Start graphics print

Exit print menu and back to main menuExit print menu and back to main

menu

HCP page 24

Page 25

11 Basic oven settings (Setup)

PRINT SETUP

In this operating mode it is possible to make the basic settings of the oven. Clock time, date, day, year, and

settings of sounder, of address assignment, monitoring units, heater power and calibration are set here.

The following parameters can be selected by turning the push/turn control, and altered as described in the

section 6:

Clock time in 24-hour format

The winter/summer time changeover does not take place automatically

but must be set manually by the user.

Date

The controller incorporates a calendar which automatically allows for the

different lengths of the months and also for leap years.

Weekday

Year

Adjustment range: from 2000 to 2100

Audible signal at programme end

ENDSOUND

Setting: OFF or ON

Audible signal on alarm, e.g. overtemperature, open door

ALARM SOund

Setting: OFF or ON

Communication address

Range: 0 to 15

(see section 18)

Tu

Tolerance margin ASF

Range: 2 to 20

(see section 12.2.4)

Language

Settings: GERMAN, English, franCAIS, ESPANOL and italIANO

HCPpage 25

Page 26

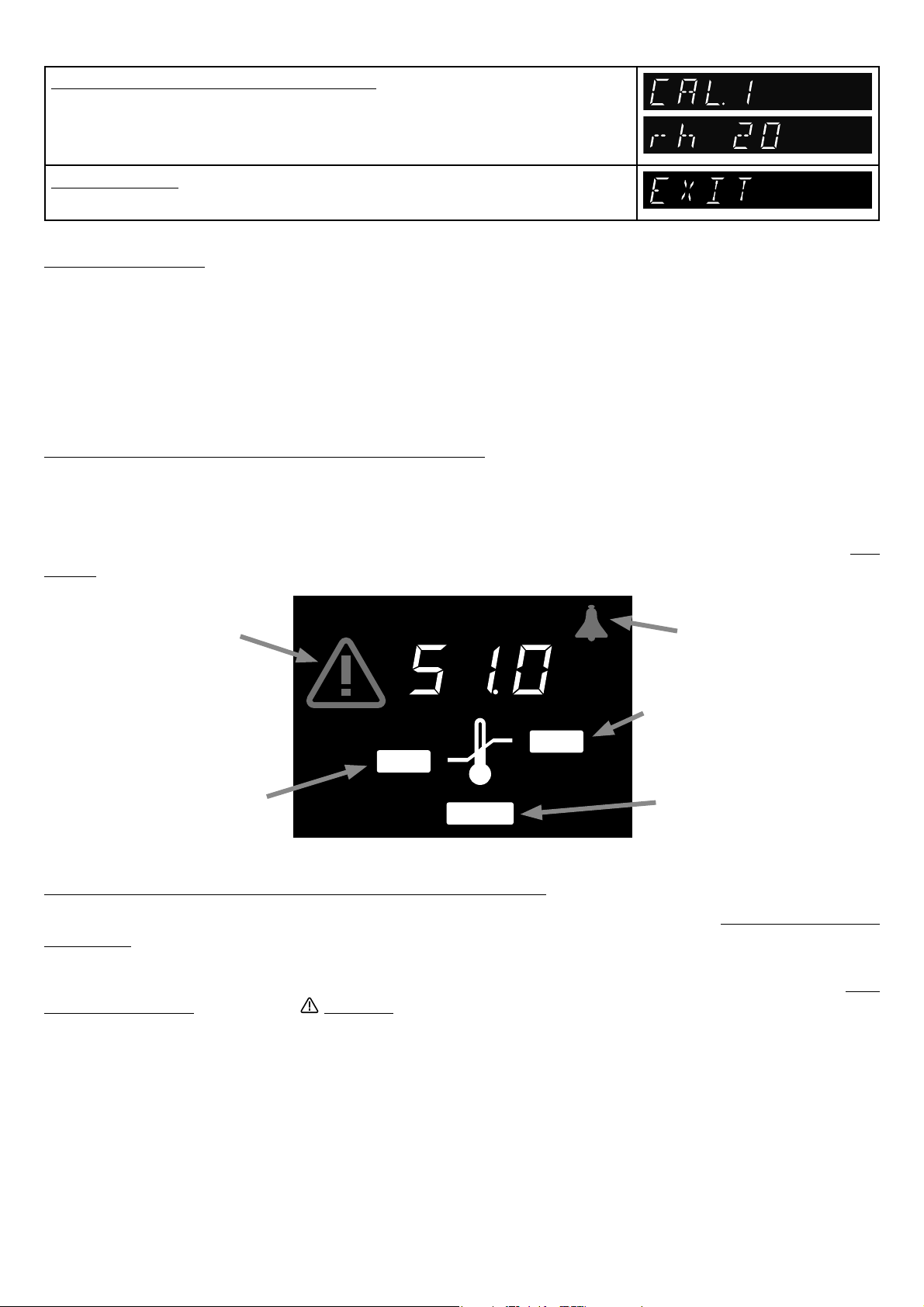

Calibration correction for user-calibration

(see section 17)

Exit setup mode

= store all settings and exit SETUP mode

11.1 Real-time clock

The real-time clock is set in SETUP and includes date and clock time.

The real-time clock serves for documentation according to GLP.

Date and clock time are marked in the report print.

On the graphics print the time axis is marked in real-time.

The clock runs with a buffer battery independently of the mains power supply.

The built-in lithium battery Type CR 2032 has a life of approx. 10 years.

12 Temperature monitor and protection devices

The monitor temperature is measured with a separate PT100 temperature sensor inside the chamber. The

monitor unit provides protection for the oven load as well as protection for oven and its surroundings.

The oven is provided with duplicate overtemperature protection (mechanical / electronic) according to DIN

12880.

visual alarm symbol

alight: TB alarm

flashing:

ASF-alarm

12.1 Mechanical temperature monitor: temperature limiter (TB)

All ovens of the HCP series are equipped with a mechanical temperature limiter (TB) Protection Class1 to

DIN 12880.

If the electronic monitor system should fail during operation and the fixed factory-set maximum temperature

is exceeded by approx. 20°C the temperature limiter switches off the heating permanently as a final

protective measure. The symbol

TWW alarm

undertemperature

protection

°C

MAX

MIN

AUTO

lights up as warning.

audible

alarm signal

overtemperature

protection

automatic

temperature monitor

(ASF)

Fault rectification after the TB cut-out has been activated:

1. Switch off the oven and allow it to cool down

2. Rectify the fault (e.g. replace temperature probe) and where appropriate contact customer service

3. The oven is again ready for operation only after it has cooled down and after the fault has been

rectified

HCP page 26

Page 27

12.2 Electronic temperature monitor

12.2.1 Overtemperature protection

Adjustment range: up to 10°C max

above nominal temperature (for nominal

temperature see label)

°C

MAX

MIN

Using the push/turn control

select the symbol

MAX

.

Hold down the SET key and

set the protection temperature

using the push/turn control.

AUTO

12.2.2 Undertemperature protection

Adjustment range: from 10°C below

minimum temperature of oven to 10°C

above nominal temperature of oven (for

nominal temperature see label).

The low alarm cannot be programmed

above the value set as high alarm.

°C

MAX

MIN

AUTO

Using the push/turn control

select the symbol

MIN

.

Hold down the SET key and

set the protection temperature

using the push/turn control.

Where no undertemperature protection

is required, this has to be set to the

lowest temperature.

Note:

The temperature monitor can be set independently of the operating mode.

The monitor temperature must always be set sufficiently far above the maximum working temperature.

The manually adjusted monitor temperature

MIN

and

of the electronic overtemperature protection

MAX

is monitored by an adjustable temperature monitor (TWW) Protection Class 3.1 to DIN 12880.

12.2.3 Adjustable temperature monitor (TWW) Protection Class 3.1 to DIN 12 880

MAX

If the manually set monitor temperatur

temperature and starts to control at the monitor temperature. As a warning the symbol

°C

TB approx. 20°C above Tmax

emergency operation

TWW set manually

setpoint temperature

controller fault

is exceeded, the TWW takes over the control of the

is flashing.

If the sounder is switched on in SETUP, the TWW

alarm is additionally signalled by an interrupted

tone. By pressing the SET key the sounder can be

t

switched off temporarily until the next occurrence

of an alarm event.

HCPpage 27

Page 28

C

12.2.4 Automatic temperature monitor (ASF)

A monitoring device which automatically follows the selected temperature setpoint.

Automatic temperature monitor

OFF

°C

(ASF OFF)

MAX

MIN

AUTO

Automatic temperature monitor

ON

°C

(ASF ON)

MAX

MIN

AUTO

Using the push/turn control select

the symbol

AUTO

.

Hold down the SET key and select

off using the push/turn control.

Using the push/turn control select

the symbol

AUTO

.

Hold down the SET key and select

on using the push/turn control.

Notes on the ASF:

The tolerance margin for the ASF is selected in SETUP (see the menu item Tolerance margin ASF in the

section 10).

Tolerance margin reached = ASF activated

The ASF is automatically activated when the actual temperature has reached 50% of the selected tolerance

margin of the setpoint (in the example 37°C, -1,5°C).

AUTO

The activation of the automatic temperature monitor is indicated by the bright symbol

°C

.

ASF set to

+/-3°C in

SETUP

15

ASF aktiv

ASF activated

40°C

34°C

ASF activated

ASF alarm

HCP page 28

Page 29

C

a

C

Going outside tolerance margin = ASF alarm

Going outside the selected tolerance margin of the setpoint (in the example 37°C, +/-3°C), for example

through opening the oven door during operation, triggers the alarm.

AUTO

Triggering the ASF alarm is indicated by flashing symbol

and .

If the sounder is switched on in SETUP, the ASF alarm is additionally signalled by an interrupted tone. By

pressing the SET key the sounder can be switched off temporarily until the next occurrence of an alarm

event.

°C

ASF set to

40°C

+/-3°C in

SETUP

34°C

15

ASF activated

ASF alarm

ASF activated

ASF-alarm

Again within tolerance margin = ASF alarm switched off

The automatic temperature monitor alarm is switched off automatically as soon as the selected tolerance

margin of the setpoint (in the example 37°C, +/-3°C) is reached again.

°C

ASF set to

+/-3°C in

40°C

34°C

40°C

34°C

SETUP

33°C

27°C

15

ASF activated

ASF alarm

ASF activated

ASF-alarm

ASF activated

ASF

HCPpage 29

Page 30

C

Setpoint changed = ASF de-activated automatically

If the temperature setpoint is altered, the automatic temperature monitor is automatically de-activated

temporarily (see in the example the setpoint is changed from 37°C to 30°C) until the tolerance margin of

the new temperature setpoint is reached (see in the example below: the ASF is re-activated at 30°C, +/3°C).

°C

ASF set to

+/-3°C in

40°C

40°C

SETUP

33°C

27°C

15

ASF activated

ASF alarm

34°C

ASF activated

34°C

ASF activated ASF activated

ASF-alarm

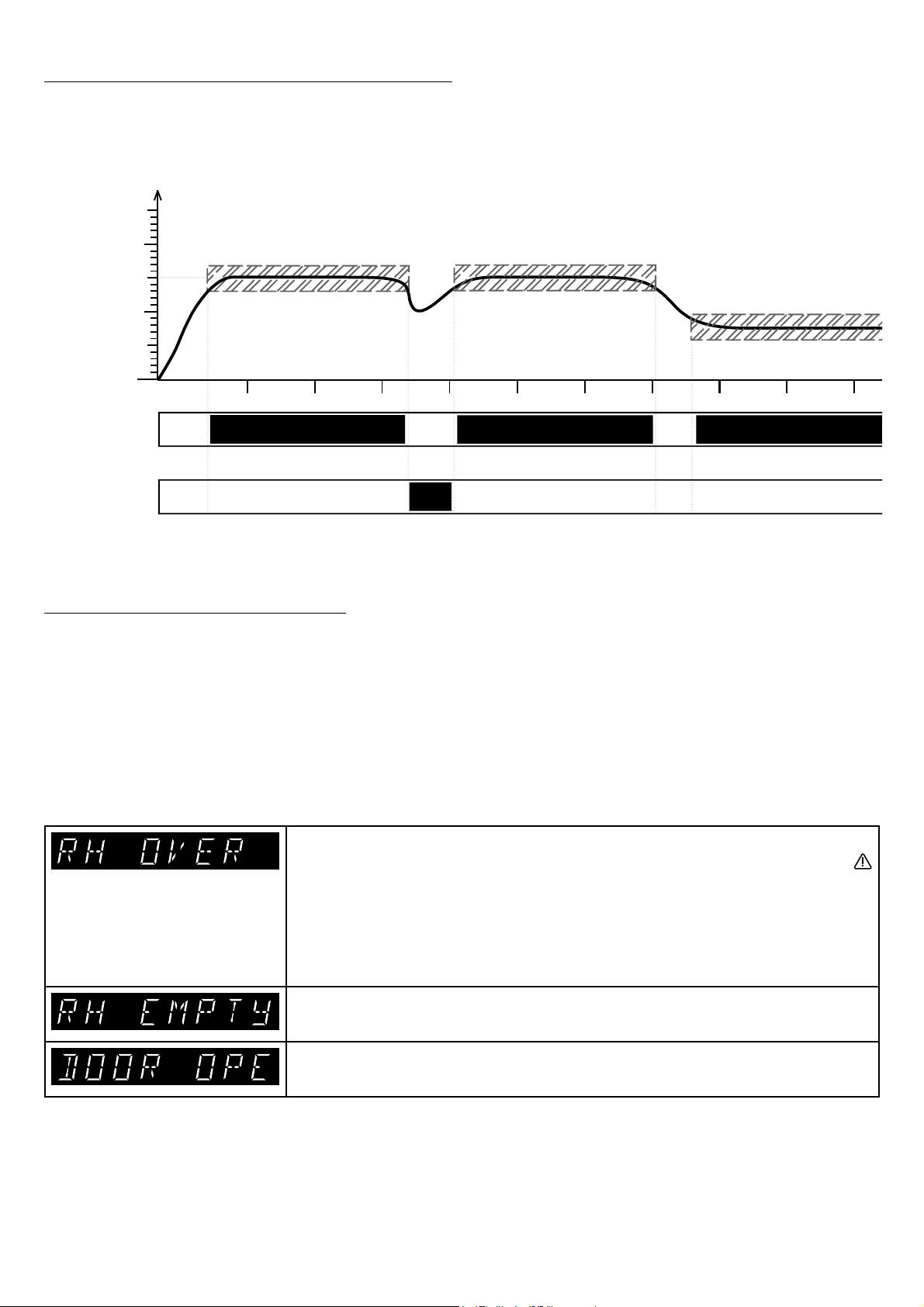

13 Active humidity control (%rh)

Active humidity control ensures that the set humidity is reached rapidly without the use ofwater dishes.

During the heating-up phase the humidity control is initially de-activated. Humidification and

dehumidification control starts to operate approx. 5 minutes after the set temperature has been reached.

The setpoint can be adjusted between 20% rh and 95% rh. The humidity setpoint can be set or altered

during the stabilisation phase. Humidification operates by passing water vapour through a dosing pump

into the working chamber. In order to prevent bacteria formation the steam is first heated to approx.

140°C. De-humidification consists of the supply of dry air through sterile filter.

If no humidity is required in the chamber, humidity control can be de-activated by the setting OFF.

is indicated if the humidity exceeds the selected setpoint for longer than

30 minutes. The humidity indication then flashes as well as the symbol

. In this case open the door for 30 sec and wait whether the controller

controls in a stable manner on the setpoint. If the fault is repeated, contact

customer service.

(Note: this monitor function becomes activated only after the humidity

setpoint has been reached for the first time)

is indicated when the water container is empty.

Humidification is interrupted automatically when the outer door is opened.

The text display shows DOOR open.

HCP page 30

Page 31

14 Audible alert signals

The interval sound indicates a fault in the temperature control system or the humidifying system. It is

triggered in the following cases:

Fault in the temperature control system:

Tb activ - temperature limiter activated if the temperature limiter operates

(see section 12.1)

hi-alarm - overtemperature alarm activated if the overtemperature

protection operates (see section 12.2.3)

lo-alarm- undertemperature alarm activated if the undertemperature

protection operates (see section 12.2.3)

asf-alarm - temperature outside tolerance if the automatic monitoring

function operates (see section 12.2.4)

Fault in the humidifying system:

when the water container is empty.

when the humidity exceeds the selected setpoint for longer than 30

minutes.

DOOR OPEN when the door of the unit is opened for longer than 3 minutes.

The audible alarm can be switched off temporarily by pressing the SET key.

HCPpage 31

Page 32

15 Sterilisation chip card

Sterilisation

Process Control

Card

Sterilisation Parameter:

160 °C / 4:00 h

Unit-ID:

________________________

As protection against contamination the HCP is equipped as standard with a STERICard. The STERICard

starts an automatic and pre-set sterilisation procedure.

To activate, insert the STERICard into the slit in the control field, select the Start symbol

with the push/

turn control and the depressed SET key.

The auto-sterilisation sequence begins as soon as the sterilisation procedure is activated:

Ramp 1: heating to 160°C

Ramp 2: hold for 4 hours (after the sterilisation temperature has been reached)

Ramp 3: cooling to 70°C

Ramp 4 wait 10 minutes

The automatic sterilisation programme can not be altered by the user.

After successful sterilisation the control displays STERILISATION OK. For documentation purposes the

sterilisation process can be reported on the STERICard and can be read using „Celsius 2007“.

Important note:

On incubators the sterilisation programme does not serve for

sterilising the load but solely for sterilising the chamber. The incubator

is not a steriliser within the scope of the medical product regulations.

HCP page 32

Page 33

16 User-ID-Card (available as optional extra)

access

authority

card

Name:

ID:

_____________________

_____________________

The User-ID-Card stores the serial number of the oven and a unique user number in encrypted format. The

User-ID-Card therefore functions only in the oven with the corresponding serial number.

Each log-on via the User-ID-Card is documented in the internal flash memory.

If the USER-IDcard is inserted, the SETUP menu includes the additional item ID-LOCK. When the setting is

hanged to ON, all changes to the oven are blocked after the chip card has been removed.

The blockage through the User-ID-Card is indicated by the illuminated

symbol on the control panel.

HCPpage 33

Page 34

17 Calibration

17.1 Temperature

User-calibration of oven at the controller, with three calibration temperatures selected by the user.

CAL.1 Temperature calibration at low temperature

CAL.2 Temperature calibration at medium temperature

CAL.3 Temperature calibration at high temperature

Either a positive or a negative calibration correction can be applied to each selected calibration point.

General calibration instructions:

1. Select the required calibration temperature in SETUP and set the corresponding calibration

correction to 0.0 °C.

2. Measure the deviation from the selected calibration temperature under steady conditions, using a

reference instrument.

3. Set the calibration correction in SETUP. If the measured reference temperature is too low, the

calibration correction setting has to have a negative sign.

4. Carry out a check measurement using the reference meter.

5. The procedure can be carried out for up to 3 calibration temperatures.

Example: Correction of a temperature deviation in the load at 60,0°C:

1. Set calibration temperature CAL.2 to 60.0 °C in SETUP and set the corresponding calibration

correction to 0.0 °C.

2. Using a calibrated reference instrument, an actual temperature of 59.6°C is measured in

normal operation for a setpoint temperature of 60.0 °C.

3. In SETUP set the calibration correction for CAL.2 to -0.4 °C.

4. After the oven has settled down the reference instrument should read 60.0°C.

5. With CAL.1 a further calibration temperature can be programmed below CAL.2 , and with CAL.3 an

6. additional calibration temperature above CAL.2.

CAL. 3

+0,3 °C

CAL. 1

+0,2 °C

factory

calibration

CAL. 2

-0,4 °C

0°C

HCP page 34

20°C

40°C

60°C

80°C

Page 35

calibration point1

calibration temperature

calibration correction

adjustment range

-4.9 °C to +4.9 °C

calibration point 2

calibration point 3

calibration temperature

calibration temperature

°C

°C

°C

calibration correction

adjustment range

-4.9 °C to +4.9 °C

°C

calibration correction

adjustment range

-4.9 °C to +4.9 °C

°C

°C

Note:

If all calibration corrections are set to 0.0 °C the factory temperature calibration is

restored.

HCPpage 35

Page 36

17.2 Humidity

User-calibration of the unit at the controller, using two humidity points:

RH 20 Humidity calibration at 20% relative humidity

RH 90 Humidity calibration at 90% relative humidity

Either a positive or a negative calibration correction can be applied to each selected calibration point.

General calibration instructions:

1. Select the required calibration humidity in SETUP and set the corresponding calibration

correction to 0.0 °C.

2. Measure the deviation from the selected calibration humidity under steady conditions, using a

reference instrument.

3. Set the calibration correction in SETUP. If the measured reference humidity is too low, the

calibration correction setting has to have a negative sign.

4. Carry out a check measurement using the reference instrument.

5. The procedure can be carried out for up to 2 calibration humidities.

Example: Humidity deviation at the load at 90% has to be corrected:

1. Set calibration humidity in SETUP on RH 90 and set the corresponding calibration correction

to 0.0 %

2. Using a calibrated reference instrument, an actual humidity of 88% is measured in normal

operation for a humidity setting of 90 %.

3. In SETUP set calibration correction for RH 90 to -2.0 %

4. The reference instrument should read 90.0% after the unit has settled down.

5. An additional calibration can be programmed with RH 20 at 20% relative humidity.

rh 90

-2 %

rh 20

+3 %

HCP page 36

factory

calibration

Page 37

calibration humidity

20%rh

calibration correction

adjustment range

-5.0 % to +5.0 %

Tu

Mo

We

on

off

Sa Su

Fr

Th

calibration humidity

90%rh

t3

t2

t1

t4

PRINT

SETUP

4

3

loop

2

1

STERI DEFRO

°C

°C

MIN

MAX

AUTO

IN 1

OUT

IN 2

rh

%

mb

IN 1

calibration correction

adjustment range

OUT

IN 2

2

CO

mb

-5.0 % to +5.0 %

Tu

Mo

We

on

off

Sa Su

Fr

Th

t1

t3

t2

t4

PRINT

SETUP

4

3

loop

2

1

STERI DEFRO

°C

°C

MIN

MAX

AUTO

IN 1

OUT

IN 2

rh

%

mb

IN 1

OUT

IN 2

2

CO

mb

Note:

If all calibration corrections are set to 0.0 % the factory humidity calibration is

restored.

HCPpage 37

Page 38

18 Communication interface for the PC

18.1 Communication interface RS232C

The oven is provided as standard with a serial communication interface RS232C according to DIN 12 900-

1. Using this interface it is possible to control the oven from the PC and to produce reports. This is done

using the “Celsius 2007“ software.

For this purpose the oven has to be assigned a unique device address in sub-menu SETUP, option ADDRESS;

This is the address through which the PC communicates with the oven. The default setting is ADDRESS 0.

Using this address each oven can be addressed by the PC and programmed.

If several ovens are connected by the RS232C interface to one PC, each oven requires a corresponding

interface on the PC as well as a separate cable.

The maximum cable length is 15 m.

For connection of the oven to the PC there is a 9-pin connector on the back of the oven. The oven can be

connected to the PC using a screened interface cable. The screen has to be connected to the plug case. If

the serial interface is not being used, the cover supplied has to be fitted!

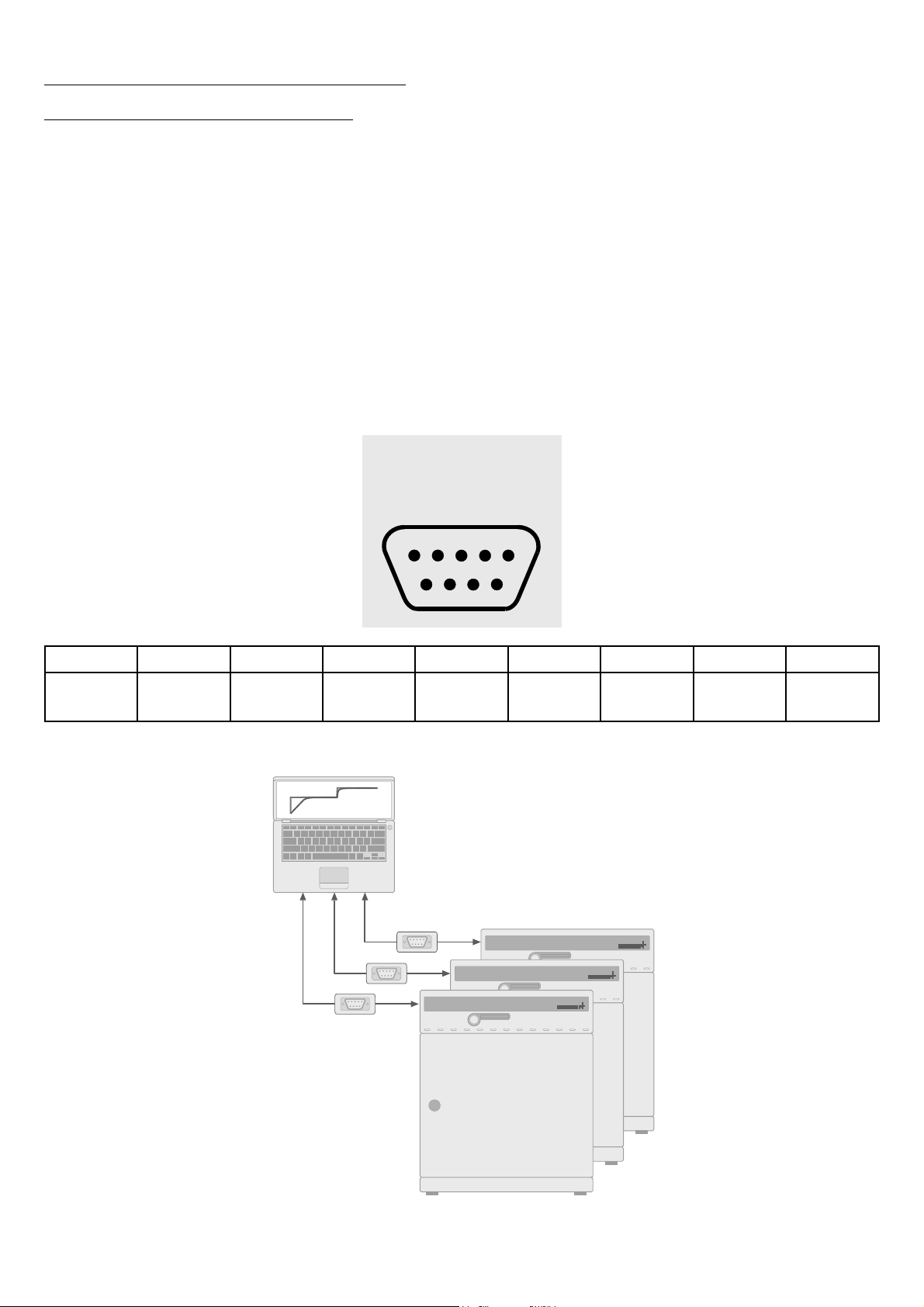

RS 232-C

9-pin serial

123456789

not

used

RXD TXD not

used

GND not

used

not

used

not

used

not

used

HCP page 38

Page 39

18.2 Bus interface RS485

When so ordered, the oven can be equipped at the factory with an RS485 interface instead of the RS232C

interface. This permits networking of several ovens (up to 16) with a single PC using a common 2-wire circuit.

The system is operated using the “Celsius 2007” software. A unique device address has to be assigned to

the oven in sub-menu SETUP, option ADDRESS. This is the address through which the PC communicates with

the oven.

The default setting is ADDRess 0. Using this address each oven can be addressed by the PC and programmed.

For this purpose the PC must be equipped with an RS485 interface or must be fitted with an RS232/RS485

converter. The cabling has to suit the individual location using a screened cable. The maximum total length

of the cable is 150 m.

A maximum of 16 devices can be addressed on the RS485 bus.

A termination resistance of 220 Ohm has to be connected to the last device.

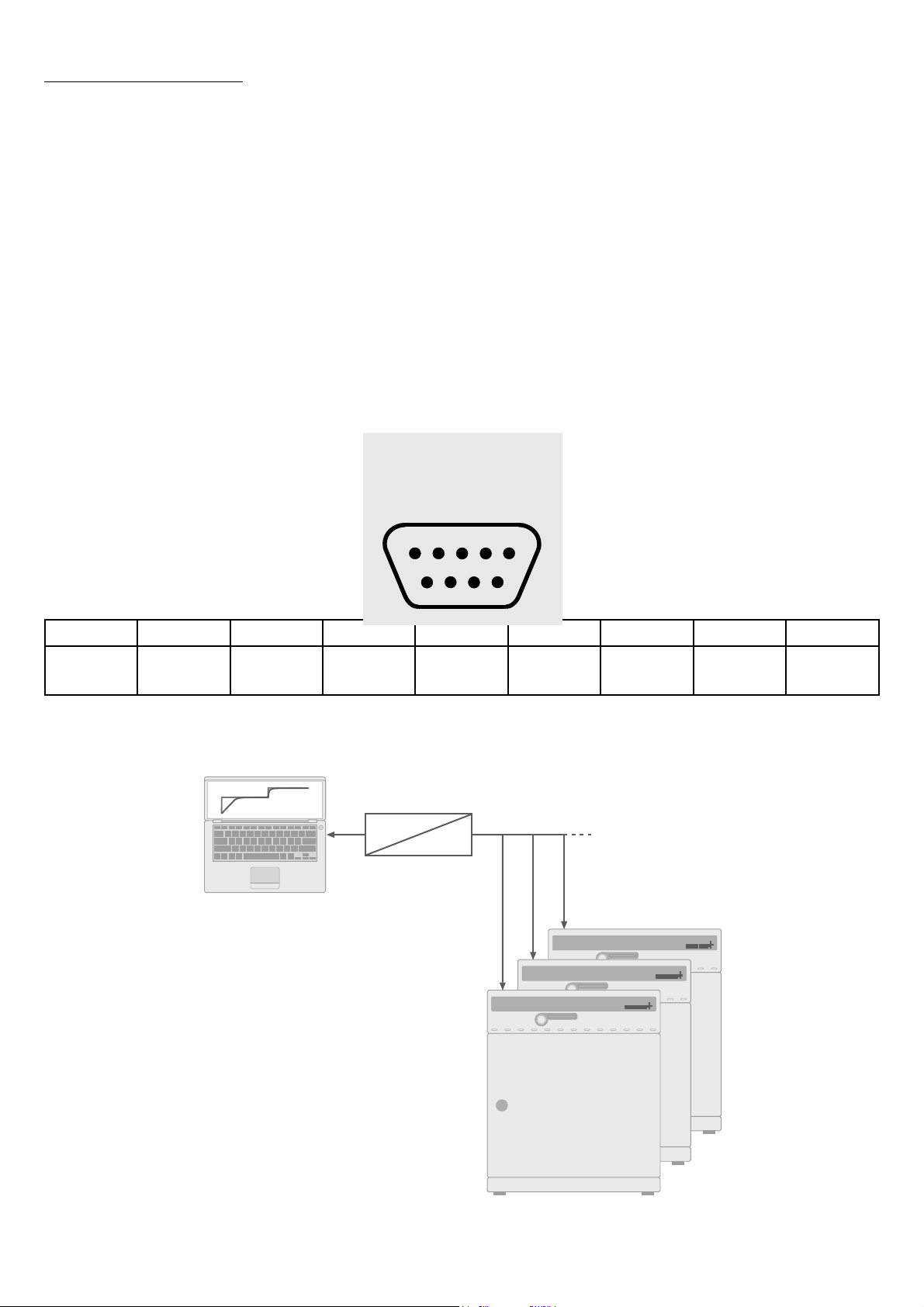

RS 485

9-pin serial

123456789

not

used

not

used

A not

Umsetzer

used

Converter

RS232

not

used

RS485

not

used

not

used

B not

used

HCPpage 39

Page 40

19 Report memory

The controller continuously records all relevant measurements, settings and error messages at 1-minute

intervals.

The internal report memory is arranged as a ring memory, i.e. the new data always overwrite the oldest

report data.

The report function can not be switched off but remains active at all times. The data are stored in the controller,

protected against any manipulation. The controller memory can be read to produce documentation.

Every data set is stored with a unique date stamp.

The size of the internal report memory is 1024kB. This corresponds to a memory capacity of approximately

3 months continuous operation.

If the power supply is interrupted, the instants of power failure and restoration of power are stored in the

controller.

19.1 Reading the report memory

Past report data can be printed either via the RS232C interface or by a PLC3-compatible printer connected

to the oven.

19.2 Reading the report memory into the PC via RS232C

Using the “Celsius 2007“ program the record memory of the controller can be read via the RS232C interface

into a PC where it can be shown graphically, printed, and stored in memory.

Note:

The report memory of the controller is not altered or cleared by the reading

procedure.

19.3 Printing the report memory from the oven

(see section 10)

If the printer is not ready, e.g. cartridge empty or no paper, no report data are lost. Prints can be repeated

several times since the report memory is not cleared after printing.

The GLP data header is automatically included in the print-out: it contains the following information:

• Printing date

• Time period of report

• Running page number

• Serial number and oven designation

HCP page 40

Page 41

20 Cleaning

By regular cleaning of the (easy to clean) interior, residues are avoided which may impair the outfit and

function of the incubator.

The unit can be cleaned with commercial stainless steel cleaning agent. Please note that objects liable

to rust must not be placed into the interior. Rust sediments lead to contamination of the interior or the

external casing.

If rust stains caused by contamination occur on the interior surface, the affected areas must be cleaned

and polished immediately.

ATTENTION !

Do not use cleaning fluids which contain scouring agents or solvents for cleaning the

operating module, the plastic trims or other plastic parts.

For cleaning of the working chamber the fan cover plate can be taken off the rear wall by removing the

screws.

HCPpage 41

Page 42

21 Maintenance

Important for a long life of your MEMMERT product and in case of warranty claims.

Note:

Any work involving opening up the oven must only be carried out by a suitably qualified

electrician!

MEMMERT products require little maintenance. It is however recommended to lubricate all moving parts

of the doors (hinges and closure) once a year (or 4 times a year with continuous operation) using a thin

Silicone grease, and to check that the hinge screws are tight.

A well-closing door is essential on an oven. On MEMMERT ovens, tight closure of the door is ensured by

a seal on the oven and another one on the door. In continuous operation the flexible sealing material may

take a permanent set. Readjustment may then be necessary in order to ensure proper closing of the door.

The top part (1) of the door hinge can, after releasing the

2 screws (2) at the top or bottom of the door, be moved

slightly in the direction of the arrow.

The door can be adjusted after releasing the socket screw (3)

and rotating the excentric (4) by means of a screwdriver.

NOTE ! Screw (3) is locked with locking varnish. It can be

released by a sharp tug using a hexagon socket key. Apply

more locking varnish to screw (3) and tighten it.

The closing panel (6) can also be adjusted in the direction

of the arrow after releasing the screw (5). It is important

that the panel is then screwed down firmly.

1

4

6

2

3

5

HCP page 42

Page 43

22 Check list for fault rectification

Mains switch switched on:

• no indication on the display of

the temperature module

• no fan operation instrument fuse; T50mA on power supply for internal fan

Symbol

Symbol

Symbol

• and rh empty water container empty

• and rh over humidity setpoint has been exceeded

E-0 in temperature module error on self-test

E-1 in temperature module power unit triac faulty

E-2 in temperature module power unit faulty

E-3 in temperature module Pt100 temperature sensor faulty

E-6 in humidity module

error sensor rh

nor alight

is alight

is flashing

equipment fuse has blown; 15A

instrument fuse has blown; T100mA 250V~ on board 55162.x

controller faulty (board 55616.x)

power supply interrupted

55145.x has blown

ambient temperature too high

temperature inside the unit higher than the selected setpoint

temperature

temperature protection (TB) has been activated

temperature protection (TWW, ASF) has been activated

humidity sensor faulty

E-L1 in timer module error communication to power unit L1

As far as HCP appliances are concerned, error messages are shown in the alphanumeric display.

In case there is a fault on the oven, please get in touch with an authorised service organisation or contact

the MEMMERT customer service department. (see section 25)

In case of queries always specify model and serial number (on the rating label)

23 Supply failure

HCPpage 43

Page 44

Supply failure in operating mode “Normal operation“

After a supply failure the operation is continued with the set parameters. The instant and duration of the

supply failure are documented in the record memory.

Supply failure in operating mode “Weekly programmer“

After a supply failure the operation is continued with the set parameters. The instant and duration of the

supply failure are documented in the record memory.

Supply failure in programme operation

After a supply failure lasting less than 15 minutes the current programme is continued at the point where

it was interrupted. The instant and duration of the supply failure are documented in the report memory.

On a supply failure lasting longer than 15 minutes the oven immediately starts in manual operation for

safety reasons and all settings are set to safe default values (see table).

Supply failure in remote operation

On a supply failure in remote operation the oven immediately starts in manual operation for safety reasons

and all settings are set to safe default values (see table). Programme continuation has to take place from

the PC. The instant and duration of the supply failure are documented in the report memory.

Parameter Default-Werte

Temperature 20 °C

rh

off

HCP page 44

Page 45

24 CE Conformity Declaration

EC Declaration of Conformity

Manufacturer´s name and address: MEMMERT GmbH + Co. KG

Product: Humidity Chambers

Type: HCP

Sizes: 108 l / 153 l / 246 l

Nominal voltage: AC 230 V 50/60 Hz

The designated product is in conformity with the European EMC-Directive

Äußere Rittersbacher Straße 38

D-91126 Schwabach

2004/108/EEC

including amendments

Council Directive of 03 May 1989 on the approximation of the laws of the Member States relating to

electromagnetic compatibility.

Full compliance with the standards listed below proves the conformity of the designated product with the essential

protection requirements of the above-mentioned EC Directive:

DIN EN 61326:2004-05 EN 61326:1997

The designated product is in conformity with the European Low Voltage Directive

EN 61326/A1:1998

EN 61326/A2:2001

EN 61326/A2:2003

2006/95/EEC

including amendments

Council Directive on the approximation of the laws of the Member States relating to Electrical

equipment for use within certain voltage limits.

Full compliance with the standards listed below proves the conformity of the designated product with the essential

protection requirements of the above-mentioned EC Directive:

DIN EN 61 010-1 (VDE 0411 part 1):2002-08 EN 61 010-1:2001

DIN EN 61 010-2-010 (VDE 0411 part 2-010):2004-06 EN 61 010-2-010:2003

Schwabach, 03.07.08

______________________________

(Legally binding signature of the issuer)

This declaration certifies compliance with the above mentioned directives but does not include a property assurance. The

safety note given in the product documentation which are part of the supply, must be observed.

HCPpage 45

Page 46

Standard ovens (HCP) are safety-approved and bear the test marks:

This product is subject to the Directive 2002/96/EC by the European Parliament

and the EU Council of Ministers which concerns Waste Electrical and

Electronic Equipment (WEEE). This product has been put on the market after

13 August 2005 in countries which have already incorporated this Directive

into National Law. It should not be disposed off as part of domestic refuse.

For disposal please contact your dealer or the manufacturer. Products which

are infected, infectious or contaminated with health-endangering substances

are excluded from return. Please note also all further regulations

in this context.

25 Address and customer service

MEMMERT GmbH+Co.KG

PO Box 17 20

91107 Schwabach

Germany

Phone: 00 49 9122 / 925-0

Fax:: 00 49 9122 /14585

E-mail: sales@memmert.com

Internet: www.memmert.com

Customer service:

Phone: 00 49 9122 / 925-143

or 00 49 9122 / 925-126

E-mail: service@memmert.com

In case of queries always specify model and serial number (on the rating label)

© by MEMMERT GmbH+Co.KG

HCP page 46

Page 47

HCPpage 47

Page 48

Memmert GmbH + Co. KG | Postfach 1720 | D-91107 Schwabach | Tel. +49 (0) 9122 / 925 - 0 | Fax +49 (0) 9122 / 145 85 | E-Mail: sales@memmert.com | www.memmert.com

28.10.2010

HCP englisch

D10345

Loading...

Loading...