Page 1

USER MANUAL

CELSIUS 10.0

Control software for MEMMERT appliances

Page 2

Manufacturer and customer service

MEMMERT GmbH + Co. KG

PO Box 17 20

91107 Schwabach, Germany

Äußere Rittersbacherstr. 38

91126 Schwabach

Germany

Phone: +49 (0) 09122 / 925-0

Fax: +49 (0) 09122 / 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Phone: +49 (0) 09122/925-128

and: +49 (0) 09122/925-126

Email: service@memmert.com

© 2010 Memmert GmbH + Co. KG

Edition 10/2010

Subject to modifications

Page 3

CELSIUS 10.0

About this manual

Intended use and target group

This user manual describes the installation and use of the MEMMERT control software CELSIUS 10.0. It is intended for use by trained personnel of the operating company, who have the

task of programming/operating MEMMERT ovens.

If you intend to work with the software, please read this manual carefully before starting.

Familiarise yourself with the programme and run several tests before actually controlling an

oven. Incorrect use could result in damage to the oven and/or to the chamber load.

If there is something you do not understand, or certain information is missing, ask your superior or get in touch with the manufacturer. Do not do anything without authorisation.

Explanation of terms

Below, we shall explain a number of terms that are used repeatedly in this manual.

Term Meaning

Tempering

profile/ramp

Protocol Recording of the actual physical values/combinations

Controller internal control of an oven

a time sequence of physical values/combinations

(temperature and – depending on oven type – humidity, vacuum, CO

perform

(temperature and – depending on oven type – humidity, vacuum, CO

during the execution of a tempering profile (measuring values)

and O2), that the oven should

2

and O2), that the oven should create

2

Description

on/from page

27

38

Other documents that you must read:

Please also read the user manual for the respective oven to be operated with the software

and familiarise yourself with it.

Storage and forwarding

This manual should always be kept in a place where those working with the software have

access to it. It is the responsibility of the operator to ensure that persons who work with or

will work with the software are informed as to the whereabouts of this user manual. We recommend that it is always stored in a protected location close to the computer on which the

software is installed. Make sure that the manual is not damaged by heat or damp.

An electronic version of this manual in PDF format can be run from the software via the

help function (see page 19 ).

3

Page 4

CELSIUS 10.0

Content

1. Introduction 6

1.1 Description ........................................................................................................................... 6

1.2 System Requirements .......................................................................................................... 6

1.3 Supported MEMMERT ovens and parameters .................................................................... 7

2. Installing CELSIUS and device drivers 8

3. Programme description 11

3.1 Starting CELSIUS ................................................................................................................11

3.2 Programme interface ......................................................................................................... 12

3.2.1 Language......................................................................................................................... 13

3.2.2 Menu bar .........................................................................................................................13

3.2.3 Toolbar 19

4. Connect ovens and external devices 21

4.1 Connect ovens with a USB interface to a computer with an

USB interface ..................................................................................................................... 21

4.2 Connect ovens with an RS-232 interface ..........................................................................22

4.3 Connect ovens with an Ethernet interface to a network (LAN) ....................................... 22

4.3.1 Setting the IP address of the oven with XTADMIN ......................................................... 23

4.3.2 Setting the IP address in CELSIUS ................................................................................... 24

4.4 Connecting an external card reader .................................................................................. 24

5. Logging on ovens 25

5.1 Logging on online and offline ...........................................................................................25

5.2 Logging on an oven ..........................................................................................................25

6. Working with CELSIUS 27

6.1 Tempering profiles ............................................................................................................. 27

6.1.1 Creating a new tempering profile ..................................................................................27

6.1.2 Graphical and tabular view ............................................................................................. 27

6.1.3 Device status line ............................................................................................................. 28

6.1.4 Working in the graphical view ........................................................................................ 29

6.1.5 Working in the tabular view ........................................................................................... 34

6.1.6 Executing a tempering profile ........................................................................................35

6.1.7 Saving and loading tempering profiles ..........................................................................36

6.1.8 Printing a tempering profile ............................................................................................ 37

6.2 Protocol .............................................................................................................................38

6.2.1 Types of Protocols ...........................................................................................................38

6.2.2 Recording the actual progression ................................................................................... 38

6.2.3 Saving and loading protocol data (*.pro) ...................................................................... 39

6.2.4 Loading protocol data from the internal MEMoryCard of the oven ..............................39

6.2.5 Loading protocol data (*.bin) from the ring protocol memory of the oven..................39

6.2.6 Export log data in tabular form (Report) ........................................................................ 41

6.3 Ending work with CELSIUS ............................................................................................... 43

4

Page 5

CELSIUS 10.0

7. Settings and Options 43

7.1 Working directories ........................................................................................................... 43

7.2 Auto-Update Ring Protocol ...............................................................................................43

7.3 Backup Folder .................................................................................................................... 43

7.4 Saving Settings ................................................................................................................. 44

7.5 Logging off ovens .............................................................................................................. 44

7.6 Working with

7.7 GLP Data ............................................................................................................................ 45

7.8 Programme language ........................................................................................................ 46

7.9 Connection details .............................................................................................................46

7.9.1 Pin assignment RS-232 and RS-485 ................................................................................46

7.9.2 Interface cable for RS-232 in accordance with DIN 12900 part 1 .................................. 46

7.10 Deinstalling CELSIUS ......................................................................................................... 47

MEMoryCard ..............................................................................................45

8. Index 48

5

Page 6

CELSIUS 10.0

1. Introduction

1.1 Description

CELSIUS is a computer programme for the programming, control and logging of MEMMERT

ovens with an RS-232, or alternatively RS-485, USB or Ethernet interface.

With CELSIUS, you can

► Create, change and save tempering profiles on your computer in graphical or tabular

form.

► Control one or more MEMMERT ovens via one or more serial interfaces and log the current

values. up to eight ovens can be controlled via RS-232 or USB, and if RS-485 or Ethernet

interfaces are used (not for ovens of the E class), you can control up to 16 ovens simultaneously;

► if your oven is equipped accordingly, you can use the functions of the MEMoryCard XL,

i. e. to store a tempering profile on a MEMoryCard XL, as well as load tempering profiles

and protocols from a MEMoryCard XL, display this on the monitor and save it to a different data medium (hard drive, USB stick);

► read out, manage and document the internal ring protocol memory (1024 kB) of the

MEMMERT ovens;

► print out tempering profiles and accompanying protocol data (depending on the oven

type, temperature, humidity, vacuum, CO

contacts, see page 7 ) including GLP data, graphically or numerically.

, O2, fan speed, air flap position and switch

2

1.2 System Requirements

Category Minimum system reqirements

Processor Pentium 1 GHz

Main memory 1 GB

Available free space on hard

drive

CD-ROM drive yes

Graphics VGA graphics and colour monitor

Interfaces

Operating system Windows XP, Vista, 7

1 GB

an unused RS-232 or USB interface, if several ovens are being

operated, one interface for each oven

6

Page 7

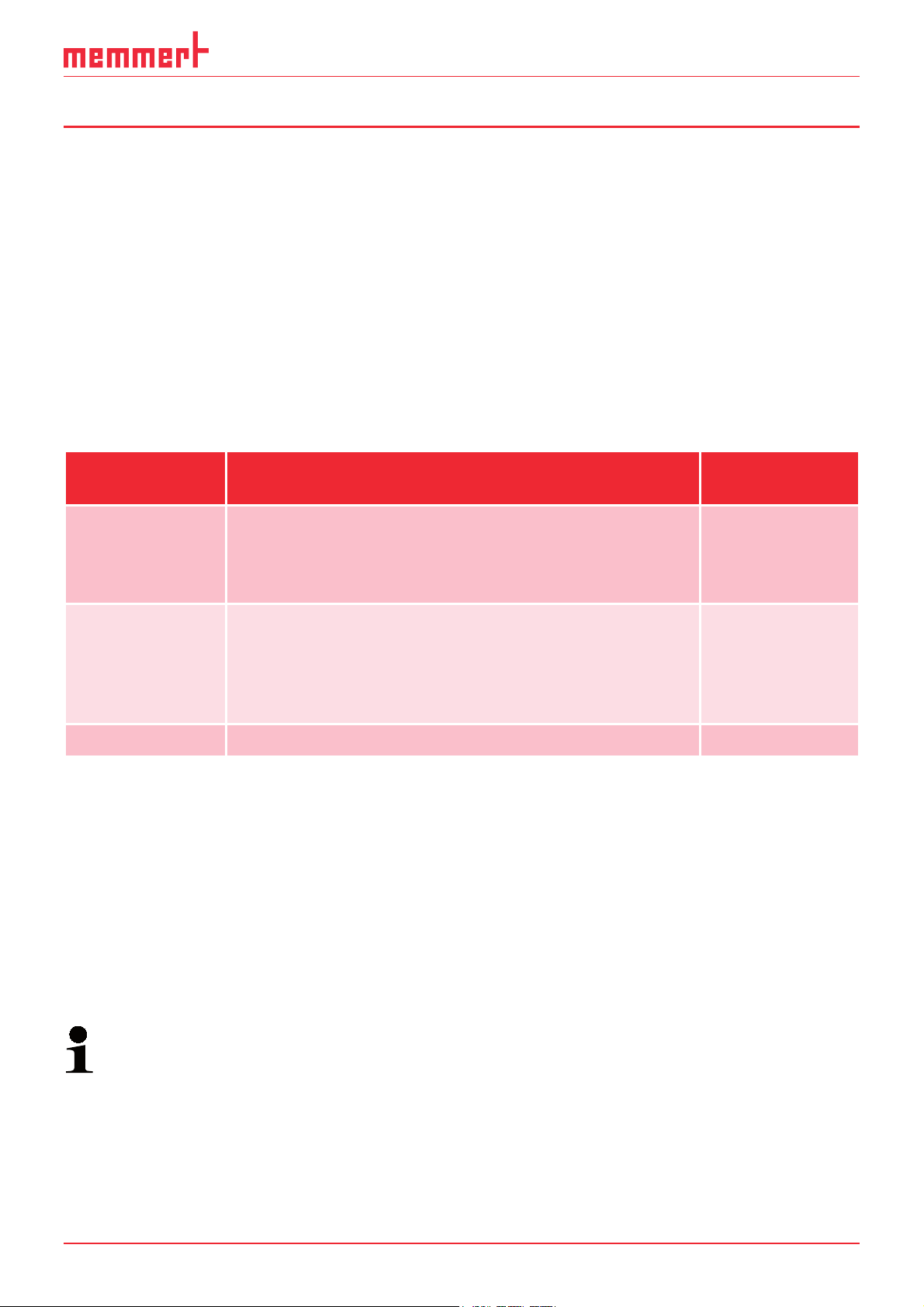

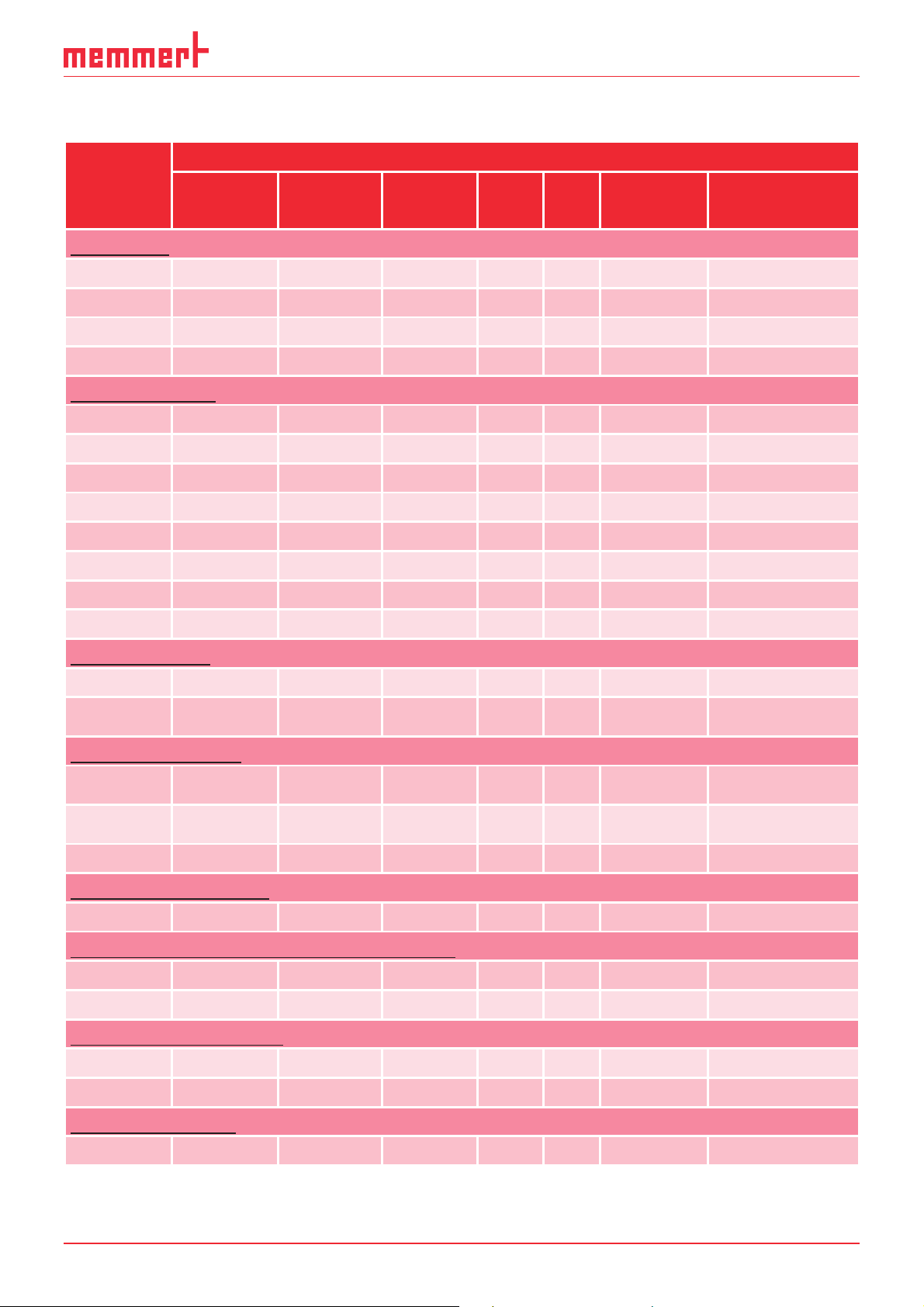

1.3 Supported MEMMERT ovens and parameters

Oven type Parameters

CELSIUS 10.0

Tempera-

Incubators

INE, BE

INP, BP

IFE

IFP

Universal ovens

UE

ULE

UNE

UNP

UP

UFE

UFP

ULP

ture

Humidity Vacuum CO

O2Fan speed Servo air flap

2

––––– –

––– –

––––

––––

–

––––– –

––––

–

––––– –

–––––

––––– –

––––

––––

––––

–

CO2 incubator

INCO

2

2

+

INCO

Oxigene

*

*

–

–

Cooled incubators

ICP (Min:

-12º)

ICP (Min:

0º)

IPP

––––

––––– –

––––– –

Vacuum drying ovens

VO

–

Constant climate and humidity chambers

HCP

HPP

–––– –

–––– –

Climatic test chambers

CTC

TTC

––––

–––

*

* *

–– –

––

–

–– – –

–

–

Storage chambers

IPS

* Parameter is logged by CELSIUS, but cannot be set with CELSIUS.

––––– –

7

Page 8

CELSIUS 10.0

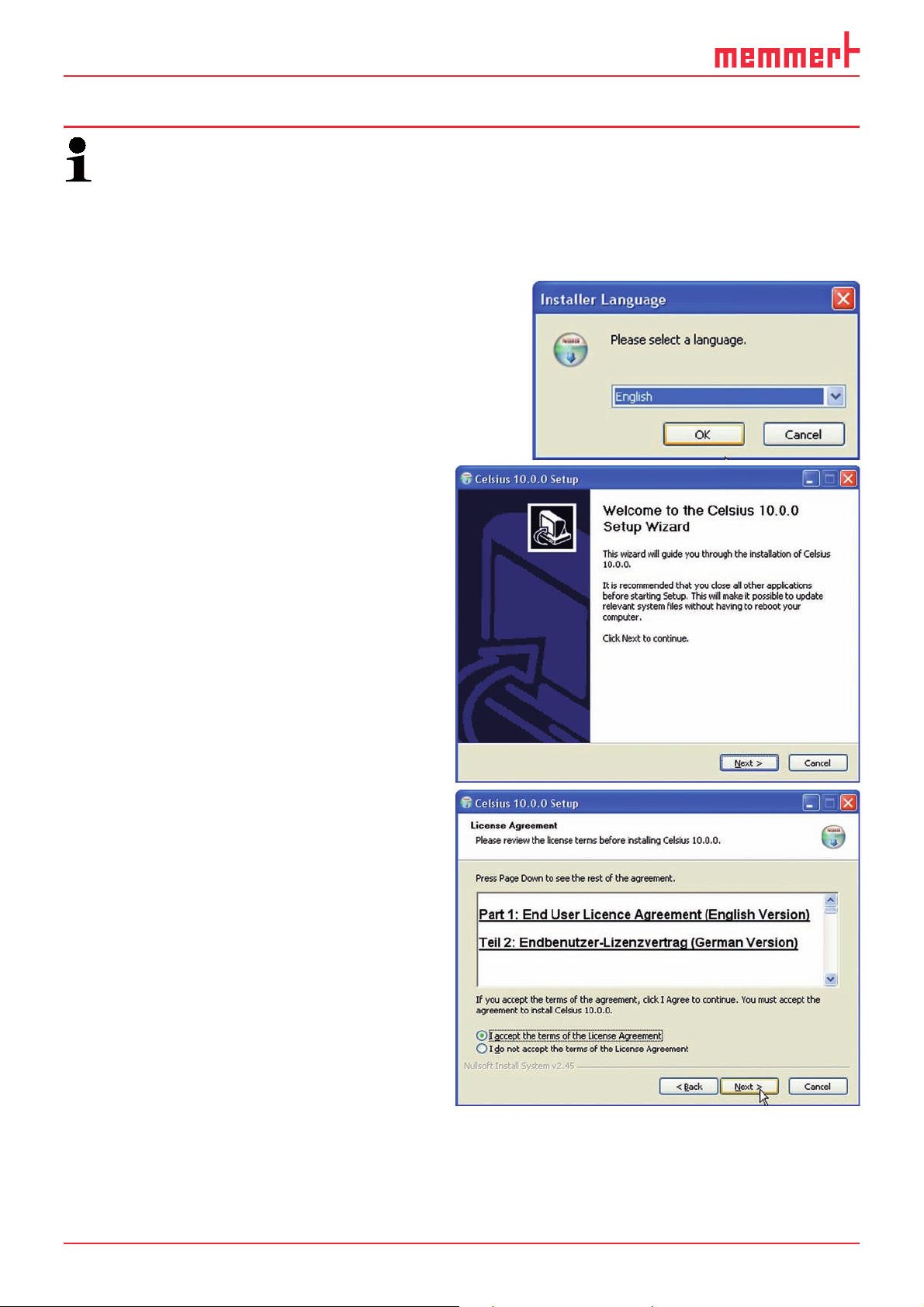

2. Installing CELSIUS and device drivers

Caution:

Always first install CELSIUS before you connect an oven to your computer.

You must have administrator rights to be able to install CELSIUS.

Insert the installation CD into the CD drive. The installation procedure should now start automatically.

If this is not the case, double-click on the file Setup.exe on the CD.

1. You are first requested to select the language

for the installation. Select the desired language

and confirm with OK.

2. The installation wizard takes you

throught the installation procedure.

Click on "Next" to continue.

3. You are shown the License conditions for

the use of the software in German and

English. You must accept the license

conditions before you can continue with

the installation. If you reject the license

agreement, the installation procedure is

terminated; but it can be restarted at any

time. Click on "I accept the terms of the

License Agreement" if you agree with the

terms of the license, and then click on

"Next".

8

Page 9

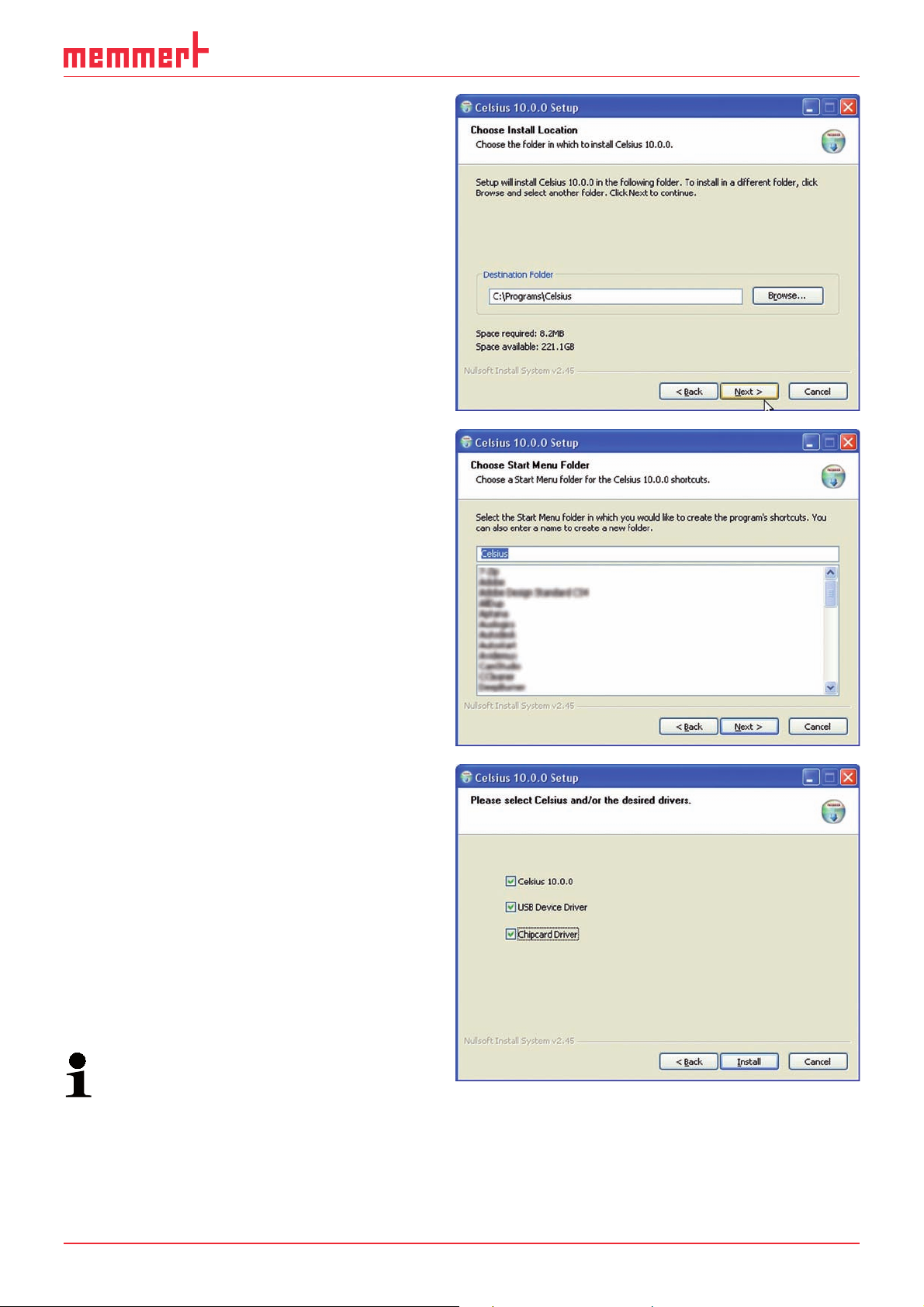

4. Then you must choose the target

directory where the programme files will

be installed. With "Browse", you can

change the preset path/folder.

Click on "Next" to continue.

5. Choose a Start Menu folder for the

programme shortcuts. The default

setting is "CELSIUS". You can choose a

different directory from the list or enter

the name of a folder that should be

newly created.

CELSIUS 10.0

6. In the next window, select the

programme components/drivers that

should be installed:

► Select "CELSIUS 10.0.0" if you only

want to install the programme itself.

► Also select " USB Device Driver" if you

want to connect ovens via the USB

interface.

► In addition, you should select

" Chipcard Driver" if you want to use

a MEMoryCard XL in an external card

reader device (see page 24 ).

You can also install USB and chip card

drivers later on. To do this, restart the

installation and, in the top window,

select the components to be installed

additionally.

9

Page 10

CELSIUS 10.0

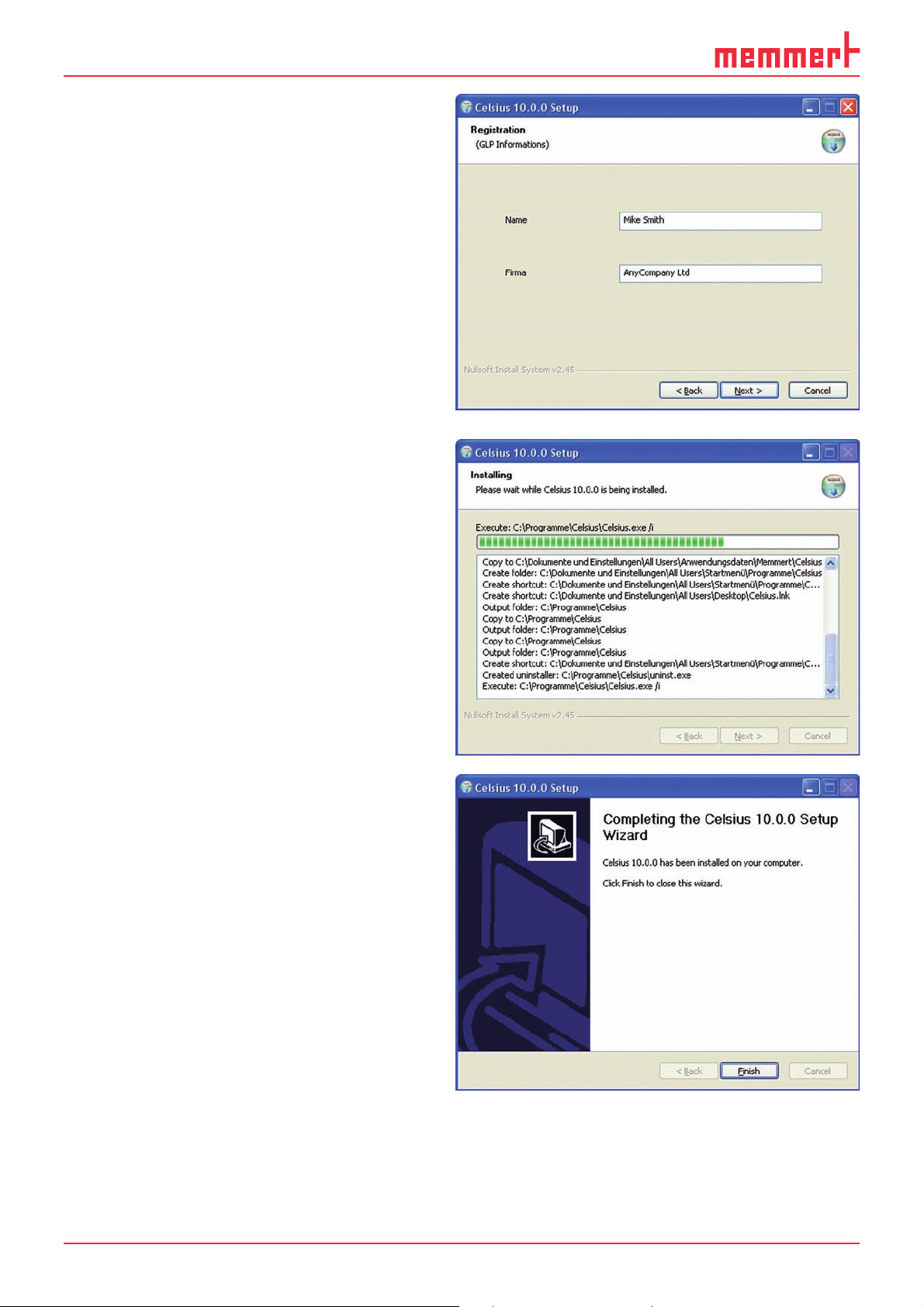

7. You now have the option of registering

with GLP data (GLP = good laboratory

practice) (name and company). You may

also skip this step and enter GLP data at

a later date (see page 45 ).

8. Click on "Install". Each of the installation

routines for the selected components are

now run one after another. In the same

way, carry out steps 2 to 4. Click on

"Next" each time to continue the

installation or finally to complete it.

9. Click on "Finish" to complete the

installation. CELSIUS 10.0.0 and the

selected drivers are now installed on your

PC/laptop and can be used.

10

Page 11

3. Programme description

3.1 Starting CELSIUS

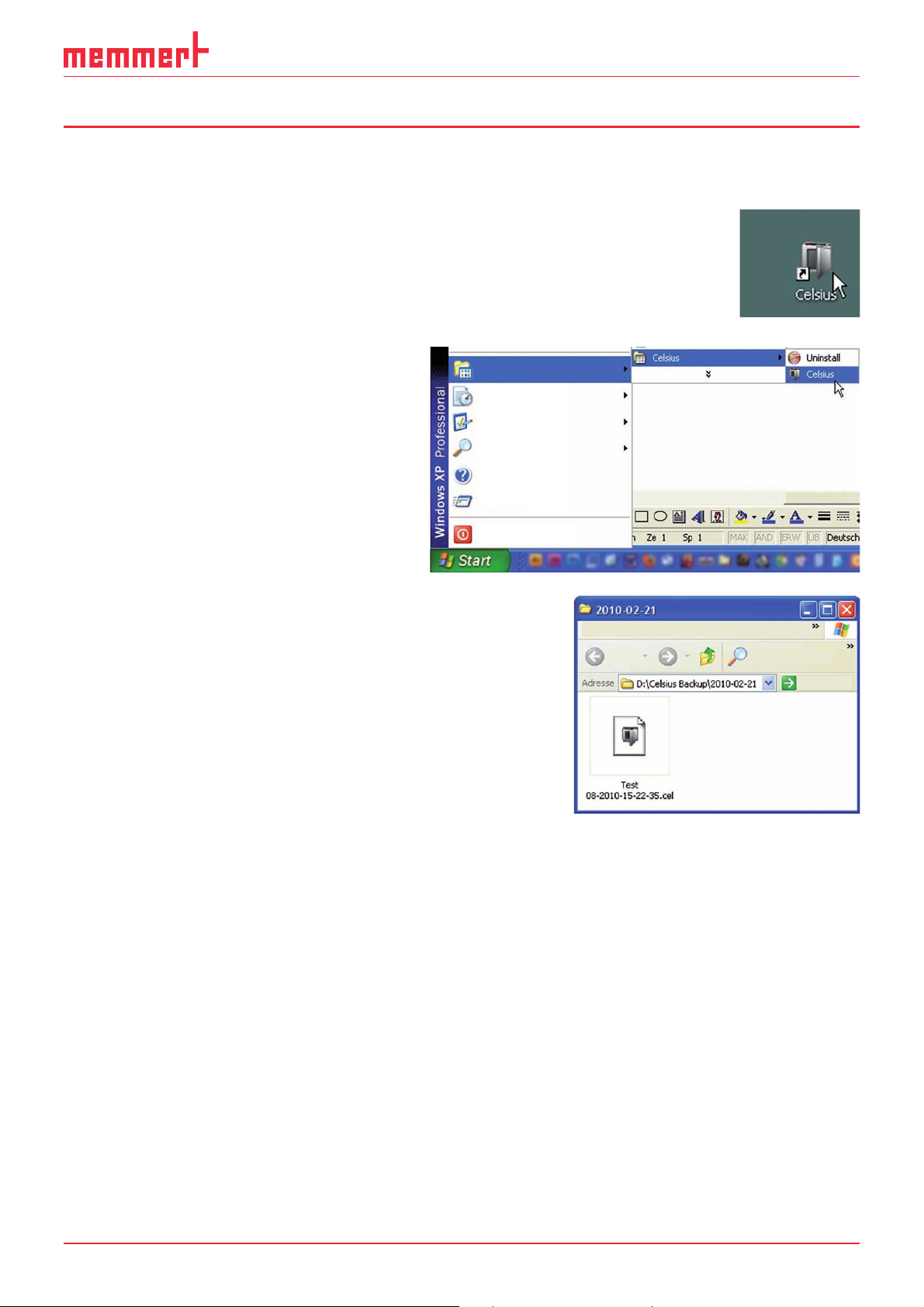

CELSIUS can be started in three ways:

► by double-clicking on the shortcut created on

the desktop:

CELSIUS 10.0

► by going to the Start menu:

Programs

Documents

Settings

Search

Help and Support

Run

Shut down

► by double-clicking on a profile file generated by

CELSIUS (*. cel) or log file (*. pro) (see also pages 36

and 39 ):

File Edit View Favorites Extras

Back

Search

11

Page 12

CELSIUS 10.0

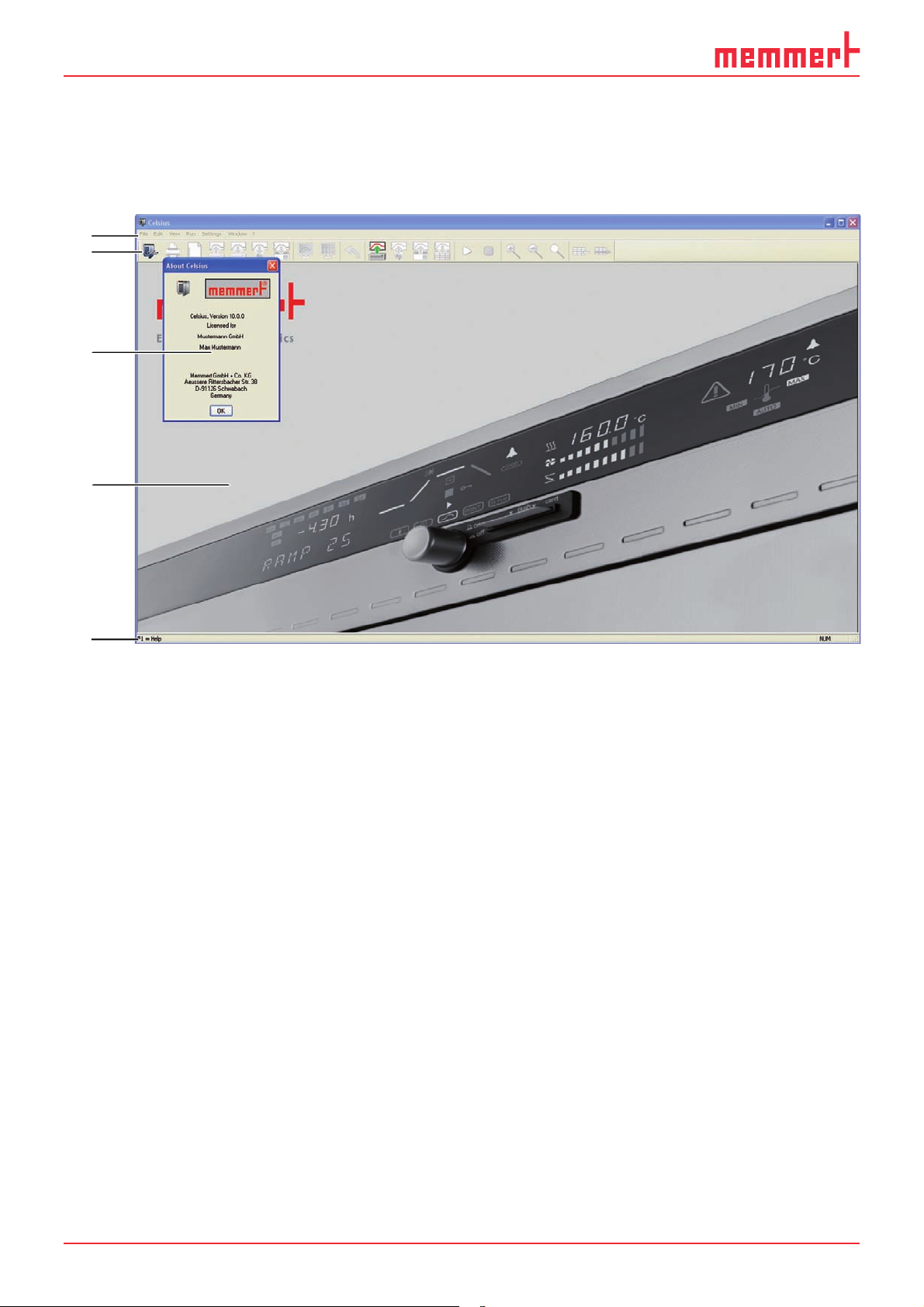

3.2 Programme interface

Once the programme has started, the start screen appears. Confirm the infobox (3) with

license information by clicking on "OK".

The main programme window of CELSIUS is divided into the following areas:

1

2

3

4

5

1 Menu bar: The various processing options are given here (description from page 13 ).

2 Toolbar: This contains buttons to quickly access the main functions

(for an explanation, see page 19 ).

3 Information box

4 Main window: When functions have been run, you can create and edit tempering profiles

here (in graphical or tabular form, see page 27 and display logs (see page 38 ).

5 Status line: A help text for the function currently chosen is displayed here, along with vari-

ous information on the current PC configuration.

12

Page 13

CELSIUS 10.0

3.2.1 Language

Programme interface and menus can be displayed in five languages (German, English, Spanish, French and Italian). If you want to use a different language than the one currently set, you

can change the language via the menu bar:

Preset language Can be changed via ...

German Einstellungen→Sprache

English Settings

Spanish Ajustes→Lenguaje

French Réglages→Langue

Italian Impostazioni→Lingua

Confirm the language selection with OK and restart CELSIUS for the change to take effect.

→Language

3.2.2 Menu bar

All programme functions can be run from the menu bar. The most important programme

functions can also be run quickly via the icons of the tool bar (see page 19 ). The individual

functions and how they are run are described below.

As long as no oven is logged in, only general programme parameters can be changed and

log files loaded. Functions currently not available are greyed out and cannot be clicked on.

13

Page 14

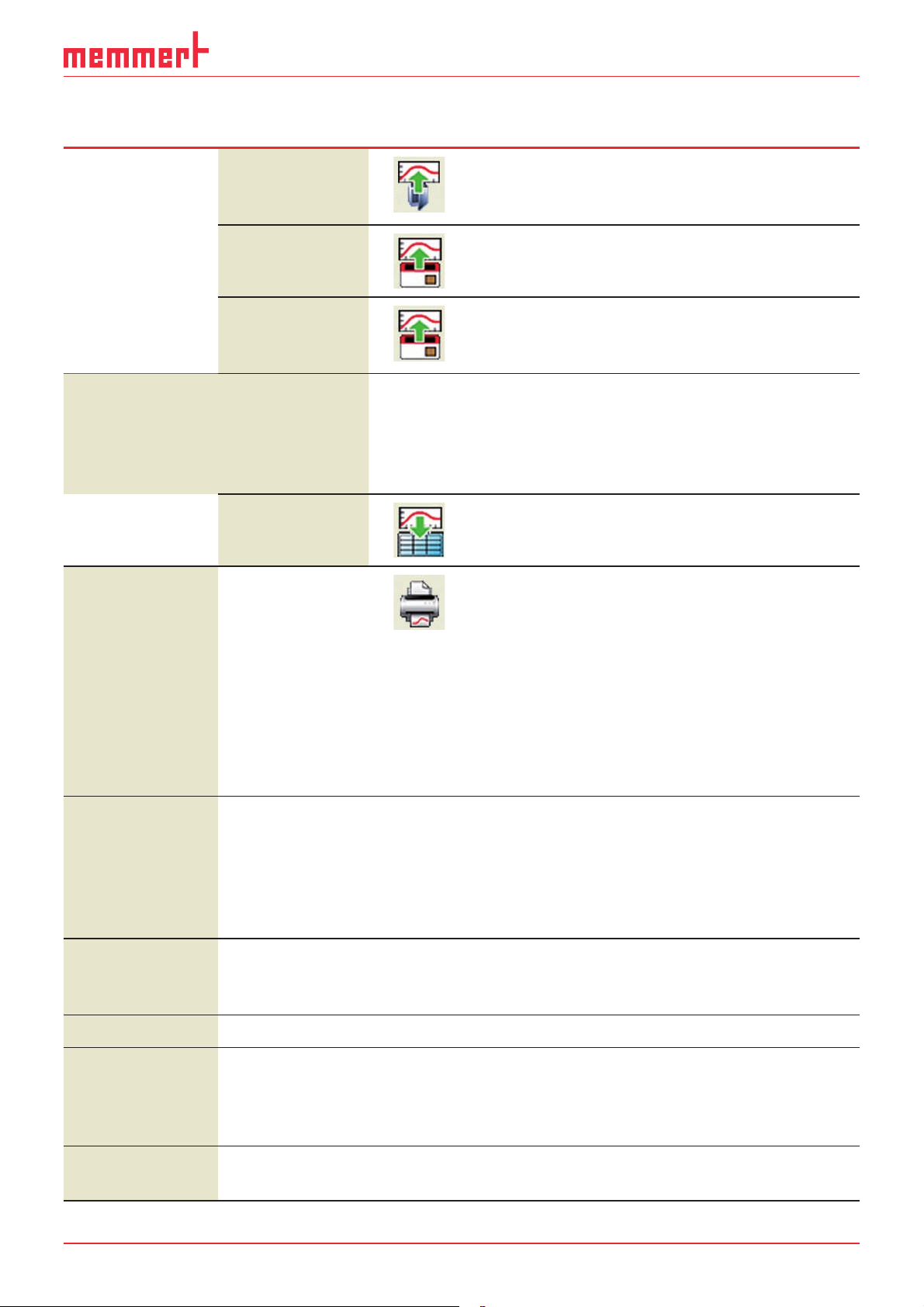

CELSIUS 10.0

"File" menu

Menu item Submenu

items

New Profi le –

Load Tempering

Profi le ►

From File

From Device

From Internal

MemoryCard

From External

MemoryCard

(USB/RS 232)

Quick

call via

Description See

page

Creates a new tempering profile.

A possible existing profile will be

deleted. Deleting a profile that

has not yet been saved must be

confirmed.

Loads a tempering profile from a

file

Loads a tempering profile from the

oven

loads a tempering profile from the

MEMoryCard in the oven

Loads a tempering profile from the

MEMoryCard in the external card

reader The card reader must be

logged in beforehand via the menu

item Settings→ Options (see page ).

27

36

36

36

36

Save T empering

Profi le ►

Load Protocol

Data ►

To File

To Device

To Internal

MemoryCard

To External

MemoryCard

(USB/RS 232)

From File

From File

( Ring Protocol

Memory *.bin)

Saves the current tempering profile

to a file

Saves the current tempering profile

to the internal memory of the oven

Saves a tempering profile on the

MEMoryCard in the oven if no

external card reader is connected

Saves a tempering profile on the

MEMoryCard in the external card

reader, if connected

Opens an existing log file (*.pro)

Opens an existing log file (*.bin)

which has been transferred from

the ring protocol memory of the

oven

36

36

36

36

39

39

14

Page 15

CELSIUS 10.0

Menu item Submenu

items

From Device

( Ring Protocol

Memory)

From Internal

MemoryCard

From External

MemoryCard

Save Protocol

Data ►

To File (*.pro)

Report

Quick

call via

Description See

page

Loads the log files from the internal

ring protocol memory of the oven

Loads log files from the

MEMoryCard in the oven

Loads log files from the

MEMoryCard in the external card

reader

If no log file was specified when

a tempering profile was started,

the log file can be generated with

this after the sequence has been

completed.

Print log data as a spreadsheet or

save as Excel® format (.xls)

39

39

39

39

41

Print Profi le

Multipage

Printout

Preset GLP Data

Show GLP Data

The tempering profile in the active

window is printed. Depending on

the display type currently selected

on the screen, the printout is as

a graphic (including possible log

values) or as a table (without log

values). The exact screen contents

are printed here. The printout is

prefixed with a GLP header if this

option has been enabled.

The printout is done as in Print

tempering profile, but the entire

tempering profile is printed out –

on several pages, if necessary. The

time axis is selected according to

the current screen display.

If a tempering profile is to be

printed with GLP data, it must be

specified here first.

Display of GLP data entered

37

37

45

45

Tr ansmit GLP

Data to Device

1 Test-11-03-10

2 Test-10-03-10

Sends the GLP data to the controller of the oven. The GLP data

appear in the GLP header on each

printed page.

Most recently saved tempering

profiles

45

15

Page 16

CELSIUS 10.0

Menu item Submenu

items

Exit

Menu "Edit"

Menu item Quick

call via

Quick

call via

Description See

Description See

page

Ends CELSIUS. If the function " Save

Settings on Exit" is activated (see

page ), the assignment of the

interfaces to the ovens and their

configurations are saved for the

next programme start. Other basic

settings are always saved when the

programme is terminated. If some

ovens are still active or if tempering

profiles have not yet been saved

a prompt appears for security

reasons.

page

Insert Line

Delete Line

Undo

Wr ap-Up Profi le

Adds a new line to the table. The current ramp is

divided.

Deletes the current line in the table 35

Undoes the last action

Allows a tempering profile to be edited after a programme sequence. The values logged for this oven so

far are deleted and the tempering profile can now be

edited.

35

16

Page 17

Menu "View"

CELSIUS 10.0

Menu item Quick

call via

Graphics

Table

Zoom In

Z oom Out

Zoom all

Description See

page

Displays the opened tempering profile in

graphical form

Displays the opened tempering profile in

tabular form

Zooms into the time range displayed in the

graphical view at fixed steps. The smallest

display range is one hour.

Zooms out of the time range displayed in the

graphical view. The largest time unit is 10 000

h.

Displays the standard time range in the graphical view so that all data are displayed

29

34

Menu "Run"

Menu item Quick

call via

Start

Stop

Pause

Continue

Description See

page

Starts the tempering profile displayed in the

current window

Ends the sequence of a started tempering profile prematurely. Continuation not possible.

Interrupts the sequence of a started tempering

profile

Continues an interrupted sequence

35

17

Page 18

CELSIUS 10.0

Menu " Settings"

Menu item Quick

access

via

Log-on Device

Log-off Device

Log-off all Devices

Save Settings

Save Settings on

Exit

Description See

page

Logs on a new oven 25

Logs off the oven in the current window. If the

oven is still active or if the tempering profile has

not yet been saved, you are prompted for confirmation.

Logs off all ovens

Saves the current assignment of interfaces to

ovens, and their configurations. All other basic

settings of this menu are saved automatically

when the programme ends

When this function is enabled, the allocation of

interfaces to ovens and their configurations is

automatically saved when the programme ends.

The next time the programme starts, CELSIUS

tries to log on the ovens exactly as before. If an

oven that was previously logged on online is no

longer available, it is not logged on again.

44

44

Options

Language

Show Color Leg-

ends

Auto-Update Ring

Protocol

Backup Folder

Open Celsius W orking Directory

Open Common

Celsius Directory

Toolbar

This assigns default settings to the GLP data and

enables the GLP header and log to be activated.

If an external card reader is used, the relevant

interface is specified here.

Setting the desired language

Switches the colour legend in the log window on

and off

Updates the transmitted ring memory of the oven

at regular intervals

Selecting a directory in which backup copies are

saved automatically

Opens the working directory in which tempering

profiles and logs are saved, in Windows Explorer

Opens the directory in which tempering profiles

and logs are saved for all users, in Windows

Explorer

Switching toolbar on and off

45 , 27

13

38

43

43

43

43

19

18

Page 19

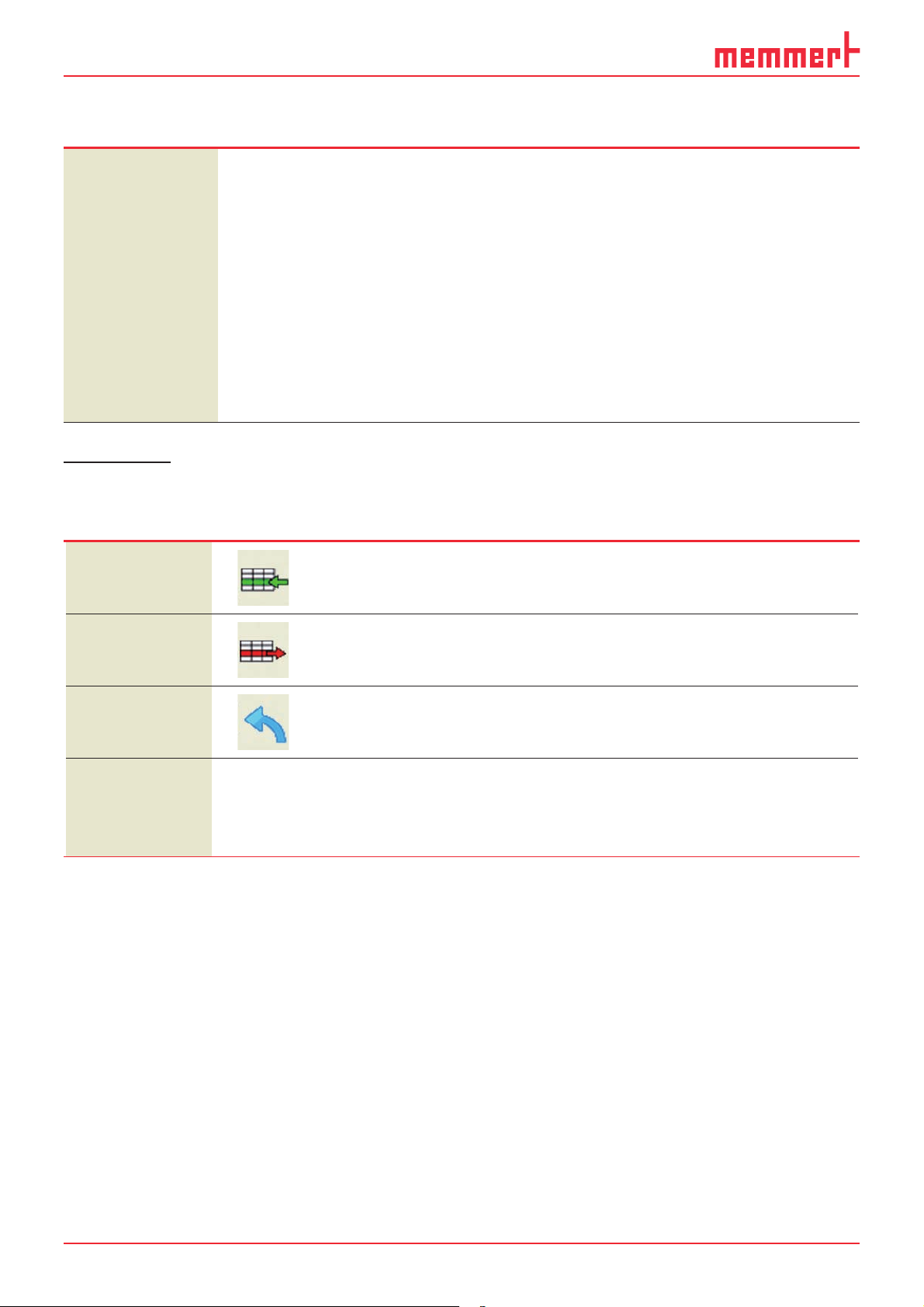

"Window" menu

Menu item Description

CELSIUS 10.0

Cascade

Tile

Arrange I cons

1, 2 ...

Arranges windows in overlapping form

Arranges windows next to each other

Re-arranges iconified windows

Moves to the corresponding device window

Menu "?"

Menu item Description

User Manual

Info about Celsius

Opens this manual in PDF format

Information on the programme version and registration

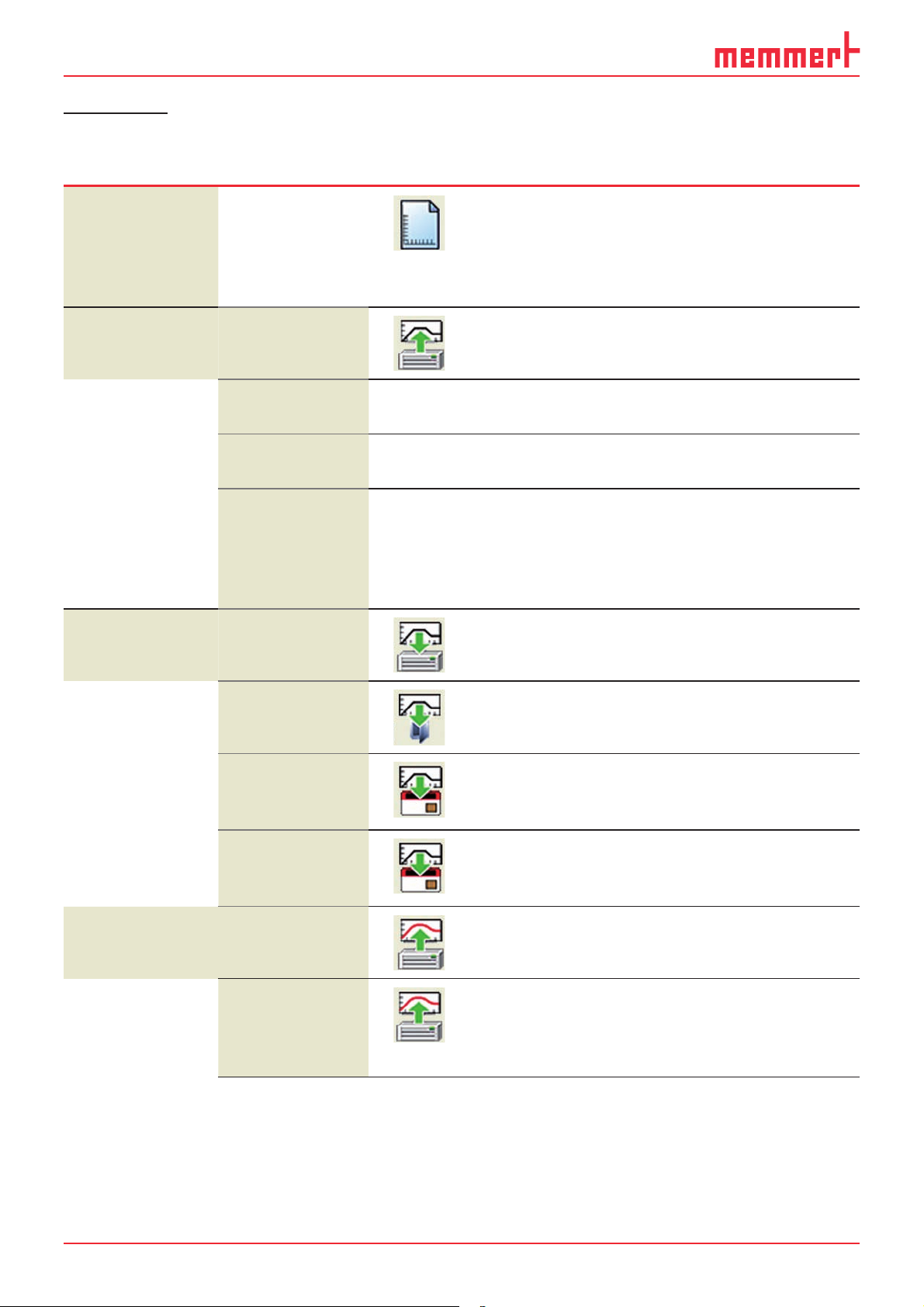

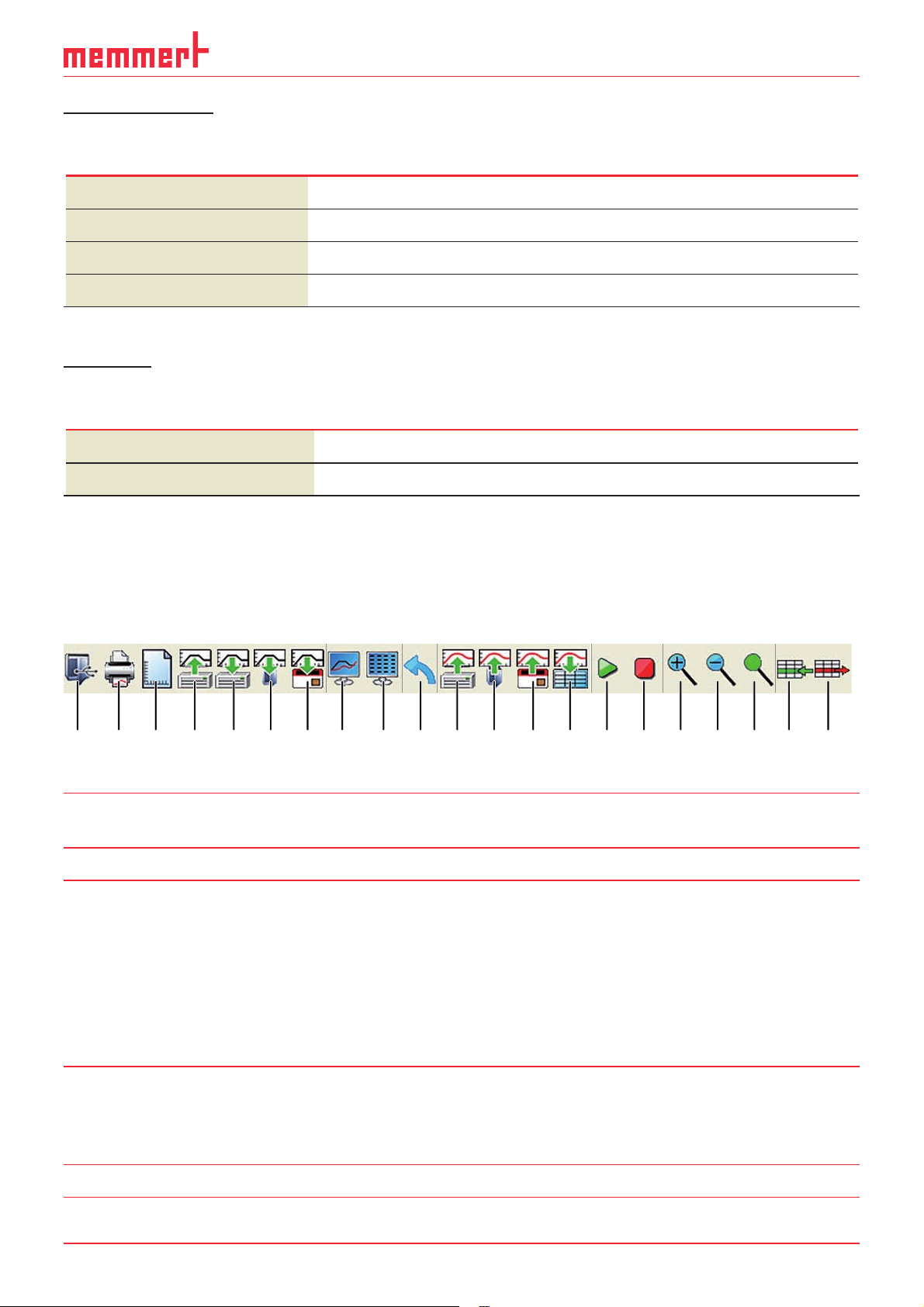

3.2.3 Toolbar

Via the toolbar, you have quick access to the most important and most frequently used programme functions. Functions currently not available are greyed out and cannot be clicked on.

The toolbar can be switched on and off via the " Settings" menu.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Item Function Description See

page

1 Log-on Device Logs on a new oven 25

2 Print Profile The tempering profile in the active window is

printed. Depending on the display type currently selected on the screen, the printout is as

a graphic (including possible measured values)

or as a table (without measured values). The

exact screen contents are printed here. The

printout is prefixed with a GLP header if this

option has been enabled.

3 New Profile Creates a new tempering profile. A possible

existing tempering profile will be deleted.

Deleting a tempering profile that has not yet

been saved must be confirmed.

4 Load Tempering Profile Loads a tempering profile from a file 35

37

27

19

Page 20

CELSIUS 10.0

Item Function Description See

page

5 Save tempering profile

to file

6 Save tempering profile

to oven

7 Save tempering profile

to MEMoryCard

8 Graphical View Displays the opened tempering profile in

9 Tabular View Displays the opened tempering profile in

10 Undo Undoes last action

11 Load the log data from

file

12 Load the log data from

oven

13 Load the log from the

MEMoryCard

Saves the current tempering profile to a file 35

Saves the current tempering profile to the

internal memory of the oven

Saves a tempering profile on the MEMoryCard

in the oven or in an external card reader, if

connected

graphical form

tabular form

Opens an existing log file (*.pro) 39

Loads the log files from the internal ring protocol memory of the oven

Loads log files from the MEMoryCard in the

external card reader

35

35

29

34

39

39

14 Report Print log data as a spreadsheet or save as

Excel® format (.xls)

15 start profile Starts the tempering profile displayed in the

current window

16 Stop Ends the sequence of a started tempering pro-

file prematurely. Continuation not possible.

17 Zoom In Zooms into the time range displayed in the

graphical view at fixed steps. The smallest

display range is one hour.

18 Zoom out Zooms out of the time range displayed in the

graphical view. The largest time unit is 10 000

h.

19 Zoom all Displays the standard time range so that all

data are displayed

20 insert cell Adds a new line to the table. The current ramp

is divided (only available in tabular view).

21 Delete Line Deletes the current line in the table (only avail-

able in tabular view).

41

35

35

35

20

Page 21

CELSIUS 10.0

4. Connect ovens and external devices

Always install the software and necessary drivers (e.g. USB) first before connecting an oven

to the computer.

When connecting an oven, read the information and notes concerning this in the

oven's user manual.

To control an oven from the PC and – if it is equipped accordingly – to be able to access the

integrated card reader, the oven must be connected to the PC and switched on. It must be in

the "I" operating mode. In addition, the address with which you want to access the oven from

the CELSIUS software must be set (see also page 25 and the user manual for the oven).

Connecting wires to the ovens with the RS-232 or USB interface (alternatively via RS-485 or

Ethernet, for the P class only) is described in the user manual.

The correct installation and configuration of the PC interfaces is in general dependent on the

type and manufacturer, which is why we refer you to the appropriate system documentation.

4.1 Connect ovens with a USB interface to a computer with an

USB interface

For every oven with a USB interface that is to be connected to the computer, one USB interface must be available on the computer.

Connect the USB connections of the oven and computer with a standard USB cable (maximum 5 m) and log on the oven in CELSIUS as described on page 25 .

P

P

21

Page 22

CELSIUS 10.0

4.2 Connect ovens with an RS-232 interface

To connect an oven with an RS-232 interface, a

twisted RS-232 connection cable in accordance

with DIN 12900 part 1 is required (see also page

48 ). If the computer has no nine-pin RS-232

interface, then a USB–RS-232 adapter is additionally required (available in specialist shops, see

figure on the right).

Connect the RS-232 connection of the oven to the

RS-232 or USB connection of the computer and log

on the oven in CELSIUS as described on page 25 .

4.3 Connect ovens with an Ethernet interface to a network ( LAN)

For identification purposes, each oven that is to be connected to a network ( LAN) should have

its own unique IP or DNS address (e.g. firmxyz.dyndns.org). Schematic example:

Each oven is delivered by default with the IP address 192.168.100.100. The programme

"XTADMIN", which can be found on the CELSIUS CD-ROM, can be used to change the IP address of the oven.

22

Page 23

CELSIUS 10.0

4.3.1 Setting the IP address of the oven with XTADMIN

1. Connect the oven whose IP address you want to change with a standard network cable to

a free network socket and switch it on.

2. Install and run the programme XTADMIN on the installation CD. The main programme

window of XTADMIN appears.

3. Click on "SET IP" (1), a new "XTIP" window opens

4. In the window column to the left, click on the plus sign next to the name of the oven ("XTNANO") whose IP address you want to change and highlight the lowest entry ("XT-NANO

xxx", the name may deviate from this) (2). In the XTIP window, the preset IP address and

the name of the oven must now appear (3).

5. Enter the IP address which you want to assign to the oven (4). Make a note of the IP address.

6. Click on "Set IP" (5) in the XTIP window. The oven is now assigned the IP address entered.

7. Close XTADMIN.

XT-NANO

192.168.100.100

XT-NANO xxx

1

2

5

192.168.100.100

3

XT-NANO-xxx

4

Now the IP address of the oven needs to be set in CELSIUS (see next page).

23

Page 24

CELSIUS 10.0

4.3.2 Setting the IP address in CELSIUS

8. Start CELSIUS and in the " Settings" menu, select

the item " Options". Click on " LAN".

9. Enter the IP address or DNS of the oven set in

XTADMIN and confirm this with "OK":

10. Close the window "Global Options" by clicking on

"OK".

You can now log on the oven in CELSIUS, as described

from page 25 .

4.4 Connecting an external card reader

If you want to connect an external card reader (can be

acquired separately as an accessory) to your computer

so that you can store data on a MEMoryCard , the card

reader must first be logged on.

1. Connect the card reader to a USB or COM interface

of the computer.

2. In the " Settings" menu, click on the menu item

" Options".

3. Select the interface to which you have connected

the card reader (USB or COM) and close the options and settings windows with "OK". The card

reader can now be used.

If you click on "Format MEMoryCard", the card is

re-formatted. All data stored on it is then deleted.

24

Page 25

CELSIUS 10.0

5. Logging on ovens

5.1 Logging on online and offline

When logging an oven on, read the information and notes concerning this in the

oven's user manual.

In order to create and edit a tempering profile, an oven must always be logged on. There are

basically two ways of doing this:

► Logging on online:

An oven can be logged on that is switched on and connected to an interface of the PC.

Only for an online log-on can the oven be controlled from the PC or the programme be

saved on a MEMoryCard (XL) located in the PC.

► Logging on offline:

As an alternative to logging on online, a virtual oven can also be logged on, which does

not have to be currently connected to the PC. This so-called offline operation is useful, for

example, when

• the tempering profile is created initially on a notebook computer that is to be con-

nected to the oven to control it at a later time;

• a new tempering profile is to be created while the oven is controlled from the same PC

with a different tempering profile;

• the tempering profile is created on the PC and is to be stored afterwards on a

MEMoryCard (XL) using an external card reader.

5.2 Logging on an oven

1. In the " Settings" menu, select the menu item

" Log-on Device" or click in the toolbar on the

icon.

The dialog box " Log-on Device" appears:

2. Each oven by default is given a device address.

What device address is preset can be found out in

the setup menu for the oven (see accompanying

user manual). The device address can also be

changed there. Every oven that is or is going to be

connected must have its own distinctive device

address. No ovens may have an identical device

address.

You can adjust the preset or altered device address

of the oven (e.g. "4") in the dialog box " Log-on

Device" in the drop-down menu "Device No.".

25

Page 26

CELSIUS 10.0

3. Select the interface (offline, COM1 or USB) (if you

select " LAN", "USB" or " COM", make sure that the

oven is in operating mode "I"):

► "offline", if the oven is (not yet) connected

(see above)

LAN1

► COM: The oven logged on is connected to the

serial RS-232 interface (optionally RS-485. Up

to 16 ovens can be connected and controlled

via USB ports. In the selection of the interface for logging on the oven, " COM 1...16" is

displayed.

► USB: The oven logged on is connected to the USB port. Up to 16 ovens can be con-

nected and controlled via USB ports. When connecting via a USB port, "USB 1...16" is

displayed automatically.

► LAN: The oven logged on is connected to a LAN (Ethernet) interface. Up to 16 ovens

can be connected and controlled via LAN interfaces (for configuration, see page 22 ). In

the selection of the interface for logging on the oven, " LAN 1...16" is displayed.

If an interface was specified and CELSIUS cannot find an oven at this interface, this setting

is switched automatically to offline. CELSIUS automatically determines the configuration of

ovens connected online.

For ovens logged on offline, the desired device

configuration must be specified in another dialog. The

configuration dialog appears automatically if an oven

was logged on offline.

Select from the list the oven type that you want to

simulate or to which you want to transfer a tempering profile, and confirm this with "OK". With optional

extras (e.g. additional switching contacts), these must

be activated manually for them to be used later on.

Depending on what oven type you set, different,

oven-specific setting options (e.g. flap or fan) will be

available later when you are creating a tempering

profile (see pages 29 and 34 ).

If an oven has been logged on for the first time, a graphics window

is automatically generated so that a new tempering profile can be

created. The window can be opened or minimised with a double

click.

If there is more than 30 minutes difference between the oven and computer times, a

warning is displayed when the oven is logged on. In this case, you should set the oven to

the time displayed by the computer (see user manual for the oven).

26

Page 27

CELSIUS 10.0

6. Working with CELSIUS

6.1 Tempering profiles

6.1.1 Creating a new tempering profile

A new, empty tempering profile can be created in three ways:

► in the graphics window that is automatically started when a new oven has been logged

on (see above)

► via "File"→"New Profile"

► by clicking on in the toolbar

6.1.2 Graphical and tabular view

Tempering profiles can be created and edited in graphical (see page 29 ) and tabular form (see

page 34 ).

You can switch between the two views at at any time:

► with the icons ( graphical view) and ( tabular view) in the toolbar

► via "View"→"Graphics" or "View"→"Table"

Example of graphical and tabular presentation of the same tempering profile:

Time

hh:mm

Period

hh:mm

Vacuum

mBar

Type

What setting options are available depends on what oven type is used for a tempering profile.

The setting options for individual oven types are listed from page 7 .

With "Edit"→"Undo" or

, the last performed entry / change can be revoked.

27

Page 28

CELSIUS 10.0

6.1.3 Device status line

The device status line is visible at the top of the graphical and tabular views while a tempering

profile is being created or run. It shows the following information:

Controller active

COM3 IST: 24.1 °C 40.1 °C 0:02h

12345

1 Controller status, e.g.:

► Edit Profile The tempering profile can currently be edited.

► starts at ...: Time at which the controller starts

► Controller active: The controller is currently controlled by the PC. At the

temperature curve, nothing can be changed.

► Controller passive: The programme sequence was interrupted by a pause in the Run

menu.

► STOP: The programme, and thus the controller, was stopped.

To edit the tempering profile, the menu item "Wrap-Up

Profile" in the "Edit" menu must be selected.

► ERROR <Text>: The controller has reported an error state.

The corresponding error text is displayed.

2 COM interface of oven or "offline"

3 Actual temperature value

4 Physical properties of the oven at the mouse position while a tempering profile is being

run (e. g. temperature, humidity, vacuum) or the temperature at the mouse cursor position

while the temperature profile is being entered

5 Current runtime or the time coordinates at the mouse cursor position while the tempera-

ture profile is being entered

The device status line can be switched on and off in the Settings menu.

28

Page 29

CELSIUS 10.0

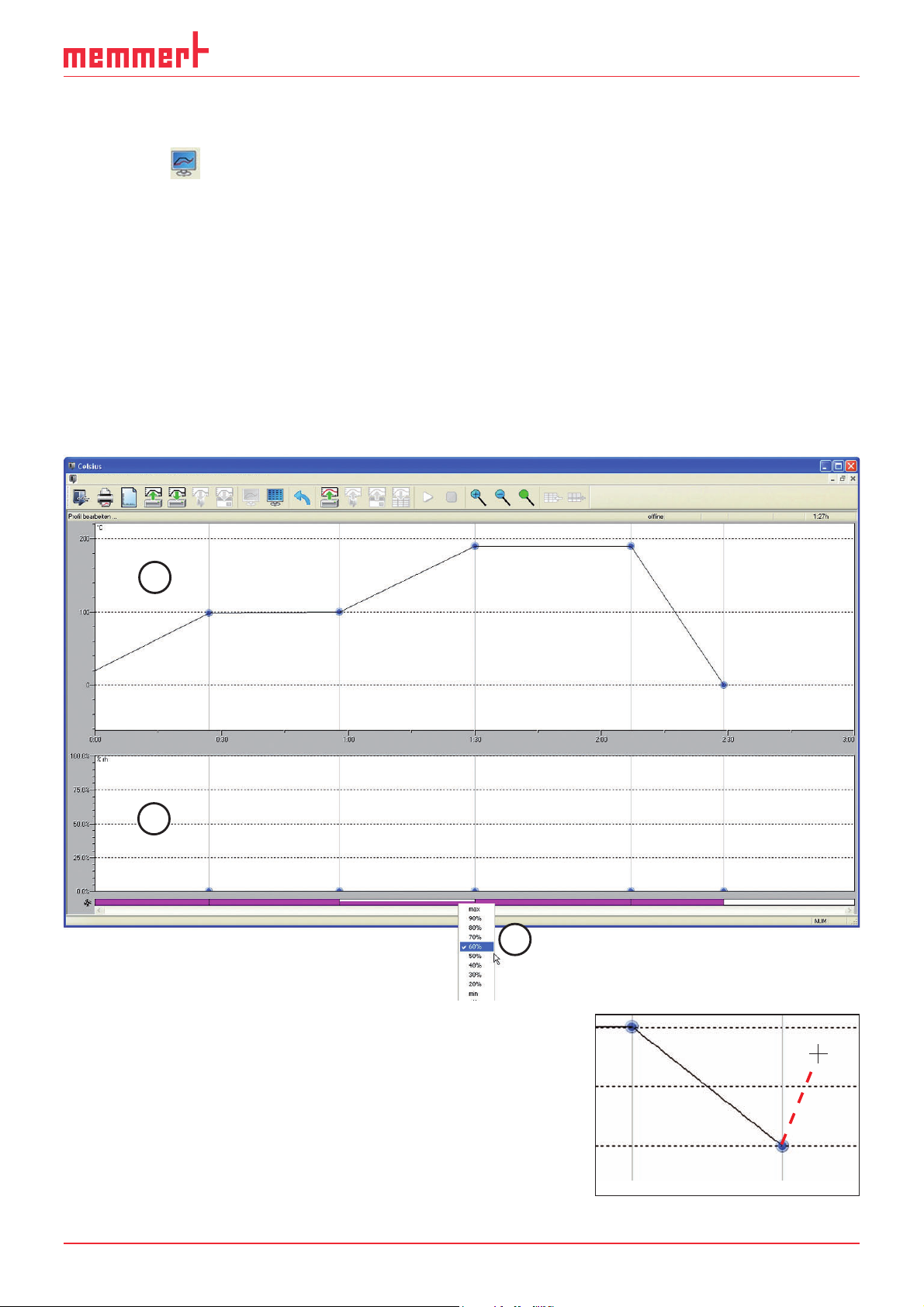

6.1.4 Working in the graphical view

The graphical view of a tempering profile can be displayed

► with the icon in the toolbar

► via "View"→"Graphics" in the menu bar

The graphics window is divided into horizontal segments, depending on the oven type. In the

top segment (1), a tempering profile can be created, and the temperature is logged when a

tempering profile is executed. In the lower segment (2), other oven-specific parameters (e.g.

humidity, vacuum) can be programmed and logged. What these are specifically can be seen in

the table on page 7 .

Depending on the oven type, additional oven-specific functions are available at the bottom of the graphics window, such as for adjusting the flaps, controlling the fan speed or for

programming the switching contacts (3). They can be enabled and disabled via mouse click or

adjusted via drop-down menus. These functions are shown in the tabular view as additional

table columns (see page 34 ).

File Edit View Run Settings Window ?

1

2

3

In the graphics window, the mouse cursor is displayed as a

cross. With this you can, in the coordinates system portrayed,

define and connect various points of the combination of time

and temperature or time and air pressure (in the example

VO).

To create a new segment, click on where you want the end

point to be. It is automatically connected to the end point

of the previous segment in the form of a line. The current

data of the mouse position are shown at the top right in the

status line (see page 28 ).

29

Page 30

CELSIUS 10.0

If you move the mouse cursor over predefined coordinates

(links between two segments), it turns into a cross with four

arrows. If you hold the mouse button down, you can then

move the respective point on the x and/or y axis.

If a coordinate is created in a prohibited area or you want to

move it to such an area, the mouse cursor turns into a

no-entry sign. The coordinate jumps automatically back to its

previous position when you let go.

Changes to the graphical view are automatically updated

when you switch to the tabular view, and vice versa.

Ramp close statements

Each segment (ramp) of a tempering profile must

end with a close statement and be linked to the next

segment. These positions are represented by the blue

dots.

To run the selection dialog, move the

mouse cursor to one of the blue ramp end points and

loop count

press the right mouse button. The following ramp

close statements are available:

delete

► normal: Resets the end point definition back to the standard value. At the

end of the ramp segment the oven continues straightaway with

the next ramp segment. If this is the final ramp segment, the

tempering profile is stopped and the connected oven is reset to

its default configuration.

30

Page 31

CELSIUS 10.0

► spwt() (= Setpoint wait). The oven waits for the end of the ramp seg-

ment until the required setpoint has approximately been reached.

Only then is the next segment processed. This command cannot

be applied for the final ramp segment of a tempering profile.

Which setpoint is involved depends on the oven, and can be

seen from the expression in brackets: spwt(t) = Temperature,

spwt(h) = Humidity, spwt(p) = Pressure etc.

Temperature for incubators (Ixx, INCO 2, IPP, ICP) and HCP humidity chambers:

If this function is enabled, the next ramp only begins when the

setpoint temperature has been reached with a tolerance of

± 0.5° C.

Temperature for universal ovens, sterilisers and vacuum ovens:

If this function is enabled, the next ramp only begins when the

setpoint temperature has been reached with a tolerance of

± 2.0° C.

Vacuum for VO vacuum ovens:

If this function is enabled, the next ramp only begins when the

setpoint vacuum has been reached with a tolerance of ± 3 mbar.

For VO vacuum ovens, the SPWT function can be enabled separately for temperature and vacuum.

Humidity for HCP humidity chambers:

If this function is enabled, the next ramp only begins when

the setpoint humidity has been reached with a tolerance of

± 2 % rh. For HCP humidity chambers, the SPWT function can be

enabled separately for temperature and humidity.

► loop:

The tempering profile is repeated endlessly from the beginning,

until the user ends the tempering profile. This command can only

be applied for the final ramp segment of a tempering profile.

► LOOP(n) The tempering profile is repeated from the beginning n-times

(n: 1 ... 99):

31

Page 32

CELSIUS 10.0

► HOLD At the end of the tempering profile, the parameters of the last

ramp segment are retained until the user ends the tempering

profile. This command can only be applied for the final ramp segment of a tempering profile.

► Delete Deletes the respective ramp segment. If a subsequent ramp seg-

ment exists, the end point of this is connected by a ramp to the

end point of the previous segment.

If no ramp close statement is specified, the command "normal" (see above) is automatically

applied.

Zooming

You can zoom in and out of the display in the various graphics windows. There are different

ways of doing this:

► via the tool and menu bar:

extends the time range (menu bar: View→ Zoom in)

squashes the time range (menu bar: View→ Zoom out)

displays the time range so that all data are displayed

(menu bar: View→Zoom all)

► Move the mouse cursor over the time axis. The

mouse cursor turns into a magnifying glass. You can now

• expand the time axis at the position of the magnify-

ing glass by clicking the left mouse button

• compress the time axis at the position of the magnify-

ing glass by clicking the right mouse button

► Move the mouse cursor over the vertical axis in the

temperature, humidity, pressure, CO

mouse cursor turns into a magnifying glass. You can now

or O2 windows. The

2

• expand the respective axis at the position of the mag-

nifying glass by clicking the left mouse button

• compress the respective axis at the position of the

magnifying glass by clicking the right mouse button

32

Page 33

CELSIUS 10.0

► If the mouse cursor is shown as a magnifying glass: Holding the left mouse button down,

select the area into which you want to zoom. Let go of the mouse button. The selected

area is now shown in a full window:

33

Page 34

CELSIUS 10.0

6.1.5 Working in the tabular view

The tabular view of a tempering profile can be displayed

► with the icon in the toolbar

► via "View"→"Table" in the menu bar

In the table window, the tempering profile is shown as a table. The individual adjustment

options are displayed in columns. What columns are displayed depends on the oven and how

it is configured. Time, duration and temperature can be entered or modified via the keyboard.

Inadmissible entries are simply ignored, with no messages. Settings that are only available in

certain predefined values (in the example below, type, flap and fan), can be specified via dropdown menus.

In contrast to the graphical view, protocol values are not shown in the table window.

Edit Profile

Time

hh:mm

2134567

Period

hh:mm

FlapType

Fan

89

Tabular View (example)

1 Ramp segment No. ...

2 Beginning of ramp segment after programme start

3 Duration of the ramp segment

4 Temperature in the ramp segment

5 Ramp close statement (see page 30 )

6 Flap position

7 Fan speed

8 Position of switching contact a

9 Position of switching contact b

In addition to the ramp segments entered, the table always shows an empty line (in the example: line 8). A further ramp segment can be added here.

34

Page 35

CELSIUS 10.0

Inserting and deleting lines

If the table window is active, the commands for deleting and inserting lines are additionally

available in the view menu and toolbar:

► Insert a line at the position marked

► Delete selected line

If the last ramp segment is deleted, the ramp close statement is automatically transferred

to the line above.

6.1.6 Executing a tempering profile

Before a tempering profile is started, disable the screen saver and the energy-saving mode

of your computer, as these could interfere with the programme sequence.

For a tempering profile to be started,

► it must have previously been saved (see page 36 )

► the relevant oven must be connected and logged on to the computer and be in operating

mode "I". If this is not the case, an error message will be displayed. In this case, you should

check that the oven is switched on, connected and logged in to CELSIUS.

Every tempering profile can only be run on the oven type for which it was created. The same

applies for saving to a MEMory Card (XL).

A tempering profile can be started

► via the button in the toolbar

► via "Run"→"Start" in the menu bar

35

Page 36

CELSIUS 10.0

When a tempering profile is started, the start dialog appears automatically with the following

setting options:

12 345 67 8910

1 Log and print GLP data (automatically enabed if GLP data were preset, see page 9 )

2 Select the storage location of the log file if " Create Log File" was clicked

3 Click on this if a log file is to be generated

4 GLP description of the procedure

5 GLP value company

6 Starting time; the default is "today" and the current time; both values can be changed. The

tempering profile then starts at the set time.

7 GLP value tested by

8 If "Protocol only" is clicked, no setpoint values are sent to the oven and only the actual val-

ues are logged. The setpoint values must be set on the oven. The "Protocol only" operating

mode is possible both in the main switch position "I" and in the "clock" position of the oven.

9 Starting time

10 GLP value sample ID

6.1.7 Saving and loading tempering profiles

A tempering protocol can be saved

► To File ( or "File"→" Save Tempering Profile"→"To File"). In the window that opens, you

can specify the file name and the storage location. In the preset directory there is a folder

each for tempering profiles and for protocols.

With "File"→"Load Tempering Profile"→"From File" or

profile files (*.cel) and edit them.

you can open saved tempering

► In the oven ( or "File"→" Save Tempering Profile"→"To Device"). The tempering pro-

file is saved in the ring protocol memory of the oven. It can be opened and edited with

"File"→"Load Tempering Profile"→"From Device".

36

Page 37

CELSIUS 10.0

► To Internal MemoryCard ( or "File"→"Save Tempering

Profile"→"To Internal MemoryCard "). With this command,

the tempering profile on the MEMoryCard can be stored

in the controller of the oven. In this case, the

MEMoryCard must be compatible with the oven model.

You may enter a name for the tempering profile saved on

the card (max. 8 characters, no spaces) or use the name

suggested.

If you enable "Write Protection", you ensure that the tempering profile on the MEMoryCard

cannot be altered by the controller of the oven. This write protection has no effect on

CELSIUS writing data to the MEMoryCard. The default setting for write protection is ON.

Only one tempering profile can be written on a MEMoryCard XL. The MEMoryCard XL can

be overwritten at any time, however.

► To External MemoryCard ("File"→" Save Tempering Profile"→"To External MemoryCard ( USB/

RS 232)". This allows you to save a tempering profile of up to 40 ramps on a card in a connected and logged on card reader (see page 45 ).

With "File"→"Load Tempering Profile"→"From Internal MemoryCard "/"... external" you can open

tempering profiles stored internally or externally on the MEMoryCard.

6.1.8 Printing a tempering profile

In order to print a tempering profile,

click on

or select "File→ Print

Profile".

The Windows print dialog appears.

The default setting is the standard

printer set for Windows. You may

select a different printer that is connected.

The print command prints out the

content of the active window. The

time range displayed on the screen is

printed, with or without GLP header

data.

If the graphics window is active on

the screen, the current tempering

profile and the protocol are printed

in the graphic mode. If the tempering profile is displayed on screen in tabular form, it will be

printed out in tabular form.

Print

Printer

Location

Comment

Print Range

All

Pages

Selection

Cancel

Printing is only possible if the tempering profile is not currently being run in the oven.

Multipage Printout

For the print option "File→ Multipage Printout", the printout is done as in " Print Profile", but the

entire tempering profile is printed out – on several pages, if necessary. The time axis is selected

according to the current screen display.

37

Page 38

CELSIUS 10.0

6.2 Protocol

A protocol is the recording of the actual physical values that prevail in the oven while a

tempering profile is running (e.g. temperature, humidity, air pressure and CO

allows a comparison to be made between the desired (set) and the actual values.

6.2.1 Types of Protocols

Protocol values can be generated and recorded in three ways:

► in the internal ring protocol memory of the oven. Each oven automatically records all

actual values of up to several months. If the memory is full, the oldest entries are overwritten. These protocol data can be read out with CELSIUS, transferred to the PC, saved in

*.bin file format or be further processed (see page 39 ).

► When a tempering profile is run via CELSIUS, the protocol data (actual values) are dis-

played as continuous curves in the graphic window and can be saved (file format *. pro)

(see next section).

► Protocol values can be stored on the MEMoryCard in the oven.

6.2.2 Recording the actual progression

When a tempering profile is run, the actual values of the oven are displayed in the graphical

view as colour curves (1) which follow the tempering profile (2). Each colour represents a different value (e.g. temperature, humidity), explained in a colour legend at the top right of the

window:

content). This

2

Tem p. Set

Temperature

2

1

The display of the colour legend can be switched on and off in the in the menu via

"Settings"→"Show Color Legends".

38

Page 39

CELSIUS 10.0

6.2.3 Saving and loading protocol data (*. pro)

If the option " Create Log File" is enabled when a tempering profile is run (see page 35 ), the

protocol values are saved to the protocol file (*. pro) selected. You may also write the actual

value curve with the corresponding tempering profile later on to a protocol file if the protocol

option is not enabled in the start dialog of the temperature programme.

The protocol can only be saved

later for as long as it is displayed

in the graphics window.

To create a file for the protocol displayed, select "File"→" Save Protocol

Data"→"To File (*. pro)". In the window appearing, you can select the

protocol file (button "File") and GLP

data that are to be recorded. This

option is automatically enabed if GLP

data have been set (see page 9 ).

Protocol data saved in this way can

be re-opened with "File"→" Load Pro-

tocol Data"→"From File" or

6.2.4 Loading protocol data from the internal MEMoryCard of the oven

If the oven is equipped with a MEMoryCard, protocol data are stored on it. They can be read

in with CELSIUS via "File"→" Load Protocol Data"→"From Internal MemoryCard" or

.

6.2.5 Loading protocol data (*.bin) from the ring protocol memory of the oven

The oven saves all values measured over a long period automatically in its internal ring

protocol memory. These measured values can be read in with CELSIUS ("File"→" Load Protocol

Data"→"From Device ( Ring Protocol Memory)" or

When they are first read out, the entire ring protocol memory is read out and saved as a file in

the format *.bin. This file is write-protected. The preset directory for ring protocol files varies

according to the operating system. This can be displayed via "Settings"→"Open Common Cel-

sius Directory". The ring protocol data are located in the subdirectory of this, "FlashProtocols".

Reading out the protocol memory for the first time may take some time (up to 15 minutes), depending on the device runtime.

).

39

Page 40

CELSIUS 10.0

After data have been read in, a

selection dialog appears. Here you

can select the period of time for

which you would like to display a

protocol. The protocol is read from

the bin file that was previously

transferred by the oven, and which is

displayed in the entry field "Ring

Protocol File".

If the protocol data for the selected period of time need more

main memory than is made available by the computer, a warning

appears. In this case, you should

make the period of time shorter.

With "Browse", you can open protocol files of other ovens that have already been transferred

in the format *. . No oven needs to be logged on for this. You can also run this function via

"File"→" Load Protocol Data"→"From File ( Ring Protocol Memory *. bin)"

Adding comments to the ring protocol

You can add comments later on to the ring protocol file. The comment is displayed as text in

the protocol window for the corresponding point in time:

Start Test #4

Position the mouse cursor in the graphic window at the point at which you would like to add

a comment (max. 30 characters). Press the right mouse button. In the window that opens,

you can enter the comment and save it with OK.

An added comment can also be changed later. To do this, right click on the comment. It is

recommended that you select the highest zoom level so that you can select exactly the same

point in time.

40

Page 41

CELSIUS 10.0

6.2.6 Export log data in tabular form (Report)

With the report function, it is possible to print log data in tabular form or save them as Excel®

format (.xls) for processing in a spreadsheet programme and graphically enhance them, for

example. This way, ring protocol data can be processed, as well as log data resulting from running a temperature-control profile (see Chapter “ Types of Protocols ” on page 38 ). The report

function is available if a log or ring protocol is displayed in the window, and this window is

active.

You can run the report function

► via the tool panel

► via “File” → “Save protocol data” → “Report”

41

Page 42

CELSIUS 10.0

A dialog window appears in which you can specify what is to be included in the report:

1

2

3

4

5

6

7

Report options and presentation as spreadsheet

1 Period presented in protocol window (can be changed by zooming [see page 32] and/or the

horizontal scroll bar)

2 Period to be included in the report

3 Interval of individual datasets, recordings are taken at one-minute intervals. To reduce the

amount of datasets, a larger interval (e.g. 5 minutes) may be chosen.

4 GLP data (see page 44) are also included if selected.

5 If selected, a short statistic (minimum, maximum and average value of displayed data) is

generated at the end of the report for the setting “Print Report”.

6 Selection whether the report is to be printed or saved as a file in the .xls format.

7 Selection of the columns to be included in the report. The left window shows the available

device dependent columns, the right window shows the columns that will appear in the

report. With > or <, columns can be added or removed, with >> or <<, all columns are

included or removed.

42

Page 43

6.3 Ending work with CELSIUS

You can end work with CELSIUS

► via "File"→"Exit"

► by closing the programme window

► with the key combination Alt + F4

CELSIUS 10.0

If an oven is stilll logged on or an opened tempering profile has not

been saved, a warning will appear:

If you confirm the prompt with Yes, open tempering profiles will be closed and not saved.

If you want to cancel this, click No. Save open tempering profiles (see page 36 ) and log off

ovens that are currently logged on (see page 45 ).

If the option " Save Settings on Exit" (see page 44 ) is enabled, the assignment of the inter-

faces to the ovens and their configurations are saved automatically if the programme is

ended via "File"→"Exit".

Yes No

7. Settings and Options

7.1 Working directories

Tempering profile and protocol files are saved in a predetermined directory if no other path is

specified when they are saved (see pages 36 and 39 ). With " Settings"→"Open Celsius Working

Directory" you can open this directory in Explorer.

For shared CELSIUS files, there is also a preset directory avaiable to all users. This can be run

in Explorer with " Settings"→"Open Common Celsius Directory". Ring protocol files (*.bin) are

stored in the subdirectory "FlashProtocols".

7.2 Auto-Update Ring Protocol

Via the menu item "Settings"→"Auto-Update Ring Protocol", CELSIUS can reload all online ring

protocols at specified intervals, so that any data that has arrived in the meantime is immediately displayed. This function should only be enabled if there is little activity in CELSIUS or in

the operating system in general, since it could overload system resources. If the data are not

constantly required, for example to observe an experiment, this function should be disabled.

7.3 Backup Folder

If you want verification of all changes

to the temperature profiles and

protocol files, it is possible to create

backup copies with time and date

stamp when any change is made

and store these in a separate,

write-protected backup folder. The

backup function can be enabled via

" Settings"→ "Backup Folder".

If the checkmark "Use backup folder" is set, an existing directory can be entered, or an existing

backup directory can be selected via the button.

Backup folder can be located locally on the same computer as CELSIUS or on a network drive

with write permission.

43

Page 44

CELSIUS 10.0

Only existing folders or network drives may be selected. No new folders may be created.

Backup copies in the backup folder can be read, but not deleted or overwritten. If backup

files are to be deleted, the "Read only" property of the directory must be changed.

A copy of the following file types is saved automatically in the backup folder:

► *.cel: CELSIUS tempering profiles

► *. pro: CELSIUS protocol files

► *. bin: Protocol files of the internal controller ring protocol memory

For each day when data is saved, a separate folder with

the appropriate date is created. All the backup copies for

one day are located in this folder. The current time is

added to the file name each time. In this way, it is

possible to save several backup copies under the same

file name on the same day.

File Edit View Favorites Extras

Back

Search

Example:

The tempering profile file "Test 08-2010.cel" is

backed up on 21 February 2010 at 15:22:35 in

the folder

D:\CELSIUS Backup\2010-02-21 as

"Test 08-2010-15-22-35.cel":

File Edit View Favorites Extras

Back

Search

7.4 Saving Settings

„ Settings→ Save Settings" saves the current

assignment of interfaces to ovens and their configurations. All other basic settings of this menu

are saved automatically when the programme

ends.

If you enable " Save Settings on Exit" and close CELSIUS via "File"→ "Exit", the assignment of the

interfaces to the ovens and their configurations are saved automatically when the programme

ends. The next time the programme starts, CELSIUS tries to log on the ovens exactly as before.

If an oven that was previously logged on online is no longer available, it is not logged on

again.

7.5 Logging off ovens

With " Settings→Log-off Device" you can log off the oven that is shown in the current window.

If the oven is still active or if the tempering profile has not yet been saved, you are prompted

for confirmation. "Log-off all Devices" - logs off all devices.

44

Page 45

CELSIUS 10.0

7.6 Working with MEMoryCard

MEMMERT ovens with P fittings are equipped

with an integrated card reader for MEMoryCard

XL (32 kB). On each MEMoryCard, a tempering

profile with up to 40 ramps can be stored. This

tempering profile is then processed by the oven

on its own, i.e. without a PC connection. During

the profile sequence, the MEMoryCard saves the

actual data that are accumulated in electronic

form. For vacuum ovens or humidity chambers,

the vacuum or humidity actual values are saved

on the MEMoryCard . These protocol data can be

read out later on from the PC with the help of CELSIUS. The MEMoryCard is therefore a

transportable and interchangeable storage medium for tempering profiles and protocols.

More information on the MEMoryCard can be found in the user manual for the oven.

7.7 GLP Data

CELSIUS supports archiving and the printout of GLP

data (GLP = " good laboratory practice"). Global data

that is always to be used (e.g. company name and

Tested by), can be specified via " Settings→ Options":

This data can be modified and/or oven-specific details

can be added to it:

► when running a tempering profile in the start

dialog (see page 35 )

► if you create a protocol file (see page 39 )

► at any time via "File→Preset GLP

Data"

Only digits and capital letters are

permitted in the field "Sample ID".

With "File→Show GLP Data" you can

have the currently stored GLP data

displayed.

45

Page 46

CELSIUS 10.0

7.8 Programme language

The programme and the menus can be displayed in five different languages. How you can

change the languages is described on page 13 .

7.9 Connection details

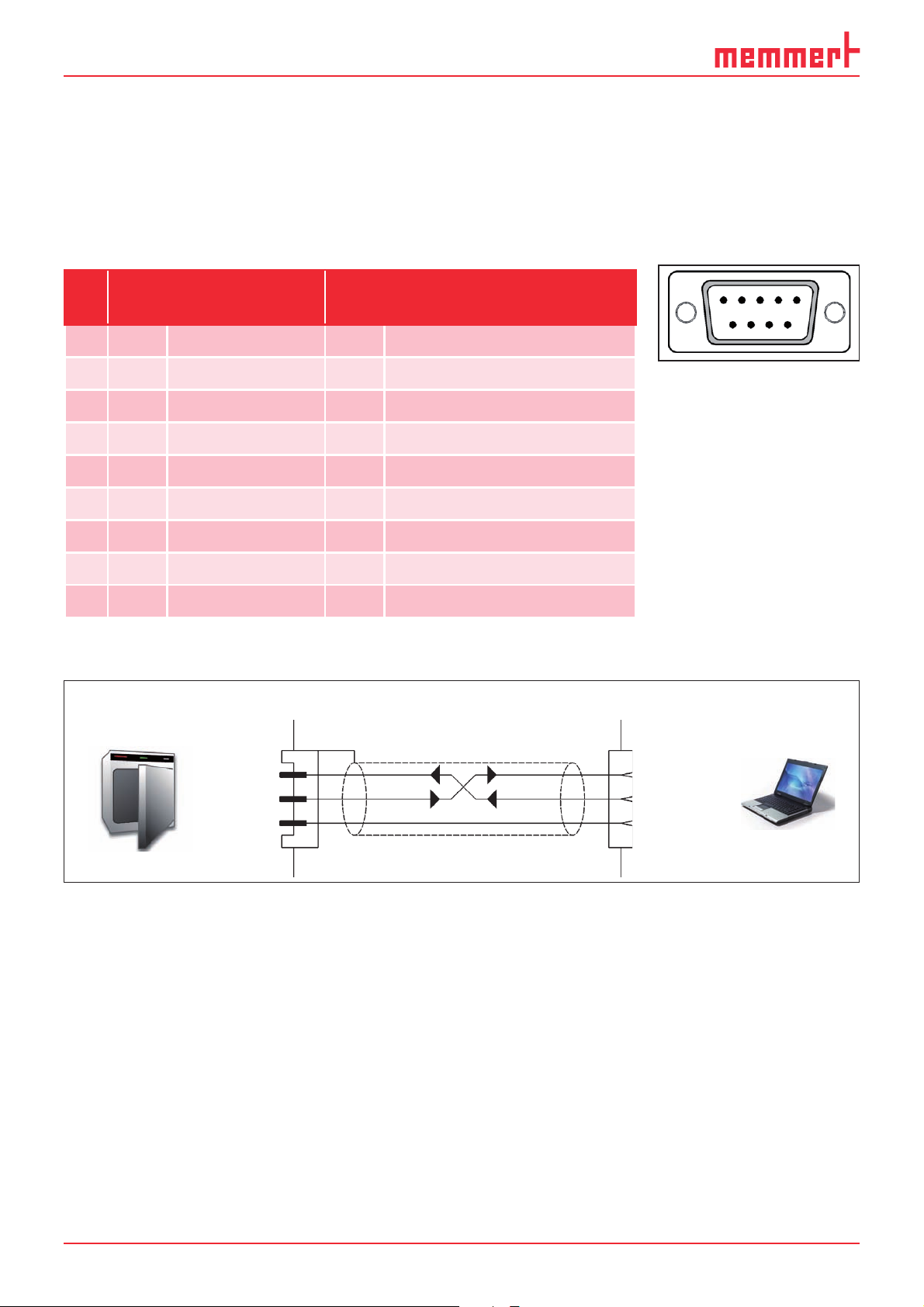

7.9.1 Pin assignment RS-232 and RS-485

Pin assignment RS-

232

1 – not occupied –

2 RxD

Received data –

Pin assignment

RS-485

5

9

3 TxD Send data B Send and receive data

4 – not occupied –

5 GND Signal ground –

6 – not occupied –

7 – not occupied –

8 – not occupied A Send and receive data

9 – not occupied –

7.9.2 Interface cable for RS-232 in accordance with DIN 12900 part 1

1

3

1

2

3

4

6

7

8

2

RxD 2

TxD 3

GND 5

2 RxD

3 TxD

5 GND

8 Pin contacts (male)

9 Screening

10 Spring contacts (female)

► Use screened interface cables

► Connect screening at one end to the plug casing

A standard-compliant connecting cable can be purchased from the company MEMMERT

under the name V6. The protocol description of the interface (according to NAMUR) can be

requested from MEMMERT customer service.

46

Page 47

7.10 Deinstalling CELSIUS

You must have administrator rights to be able to deinstall CELSIUS.

CELSIUS 10.0

If you want to remove CELSIUS from

your computer, you can run the

deinstallation routine via

Start→Programs→CELSIUS→

Uninstall:

Programs

Documents

Settings

Search

Help and Support

Run

Shut down

47

Page 48

CELSIUS 10.0

8. Index

*.bin file 14, 40, 44

*.cel file 44

*.pro file 11, 14, 15, 20, 38,

39, 44

A

Additional functions 29

Address 21, 22, 23, 24

All deviceslog off 18

Arrange icons 19

B

Backup directory 18, 43, 44

Bin file 40

C

Card reader 10, 24

Cel 11

Chipcard driver 10

Close statement 30

COM 24, 26, 28

Comments 40

Configuration dialog 26

Connect 8, 10, 21, 22, 24

Continuation 17

Controller status 28

Coordinates 30

Create tempering profile 27

Customer service 2

D

Deinstalling CELSIUS 47

Delete 14, 19, 35

Delete line 16, 20, 35

Determining GLP data 15

Device status line 28

E

“Edit” menu 16

End 16

Ethernet interface 6, 22

Excel® format 41

“Execute” menu 17

Executing a tempering pro-

file 35

Export to spreadsheet 20

External card reader 24

F

Fan speed 34

“File” menu 14

Flap position 34

G

GLP Data 6, 9, 15, 18, 36,

39, 45

Good laboratory practice 9,

45

Graphical View 20, 27, 29

Graphics window 27, 29,

37, 39

H

HOLD 32

I

Information about CELSIUS

19

Information box 12

Insert cell 20

Inserting and deleting lines

35

Inserting comments 40

Insert line 16

Installation assistant 8

Installation procedure 8

Install device driver 8

Interface cable 46

IP address 22, 23, 24

L

LAN 22, 24, 26

Language 13

Last profile 15

License terms 8

Load protocol data 14, 39,

40

Load protocol data from

file 20

Load protocol from

MEMoryCard 20

Load protocol from oven 20

Load tempering profile 14,

19

Logging off ovens 44

Logging on offline 25

Logging on online 25

Logging on online and of-

fline 25

Logging on ovens 25

Loop 31

M

Main memory 6, 40

Main programme window

12

Manufacturer 2

MEMoryCard 6, 10, 14, 15,

20, 24, 25, 37, 39, 45

Menu bar 12

Menu “?”(Help) 19

Mouse cursor 29, 30, 32

Multiple page graphics print-

ing 15, 37

N

Network 22

New Profile 14, 19

O

Open CELSIUS work direc-

tory 18

Options 14, 18, 24, 43, 44,

45

P

Pause 17

PDF format 3

Pin assignment 46

Print dialog 37

Printing 15, 37

Printing a tempering profile

37

Print profile 15, 19, 37

Profile file 11

Profilepostprocessing 16

Programme description 11

Programme interface 12

Programme language 46

Programme shortcuts 9

Protocol 18, 20, 38, 39, 40

Protocol file 11, 14, 15, 20,

36, 39, 40, 45

Protocol files 40, 43, 44

48

Page 49

CELSIUS 10.0

R

Ramp close statement 30

Ramp segment 29, 34

report function 41

Ring protocol memory 14,

15, 36, 39, 40

RS-232 interface 22, 26

S

Save protocol data 15, 39

Save settings 18, 44

Save settings when ending

18

Save tempering profile 14,

36, 37

Save tempering profile to

file 20

Save tempering profile to

MEMoryCard 20

Save tempering profile to

oven 20

Saving and loading protocol

data 39

Saving and loading temper-

ing profiles 36

Send GLP data to device 15

Setpoint wait 31

Settings 13, 14, 16, 18, 19,

24, 25, 28, 34, 43, 44,

45

“Settings” menu 18

Setting the IP address 23

Shared CELSIUS directory 18

Show GLP data 15

spreadsheet 41

Spwt 31

Standard printer 37

Start 17

Start dialog 36, 39, 45

Starting CELSIUS 11

Start menu 11

Start menu folder 9

Start profile 20

Start screen 12

Start time 36

Status line 12

Stop 17, 20

Storage location 36

Supported MEMMERT ovens

7

Switch off device 18

Switch on device 18, 19, 25

T

Table columns 29

Table window 28, 34, 35

Tabular view 20, 27, 34

Target directory 9

Toolbar 12, 19

U

Undo 16, 20

USB device driver 10

USB interface 6, 21, 26

USB–RS-232 adapter 22

V

“View” menu 17, 19

W

Working directories 43

Working with MEMoryCard

45

X

XTADMIN 22, 23, 24

Z

Zoom in 17

Zoom In 20, 32

Zooming 32

Zoom out 20, 32

Zoom Out 17

49

Page 50

Page 51

Page 52

Memmert GmbH + Co KG | PO Box 1720 | D-91107 Schwabach, Germany | Tel. +49 (0) 9122-925-0 | Fax +49 (0) 9122-145-85 | Email: service@memmert.com | www.memmert.com

26.10.2010

CELSIUS 10.0 englisch

D23498

Loading...

Loading...