Page 1

AtmoCONTROL

FDA Edition Validatable in according to 21CFR

Part 11 U. S. Food and Drug Administration

Version 2.X.X

SOFTWARE MANUAL

100% ATMOSAFE. MADE IN GERMANY.

www.memmert.com | www.atmosafe.net

Page 2

Willi-Memmert-Straße 90–96

We reserve the right to make changes

Page 3

AtmoCONTROL FDA Version

About this manual

target group

This user manual describes the installation and use of the MEMMERT programming software

AtmoCONTROL. It is intended for use by trained personnel of the operator, who have the task

to the appliance. Incorrect use could result in damage to the appliance and/or to the chamber

with AtmoCONTROL and familiarise yourself with it.

This manual should always be kept in a place where those working with the software have

will work with the software are informed as to the whereabouts of this user manual. We rec-

The current version of AtmoCONTROL and this manual are available for download at

Page 4

4 D30396 | Date 09/2014

AtmoCONTROL FDA Version

...........................................................................................................................

.........................................................................................................

..................................................................................................

4. Working with AtmoCONTROL 10

4.1 Starting AtmoCONTROL

....................................................................................................

4.2 Programme interface

.........................................................................................................

4.2.1 Menu bar

.........................................................................................................................

4.2.2 Toolbar

.............................................................................................................................

4.2.3 Status bar

........................................................................................................................

4.3 Installing the device licence

...............................................................................................

4.3.1 Using a USB storage medium (only possible for PLUS appliances)

................................

4.3.2 Via Ethernet with AtmoCONTROL

..................................................................................

4.4 Adding and disconnecting devices

...................................................................................

4.4.1 Adding device connected via Ethernet

...........................................................................

4.4.2 Connecting device using USB storage

............................................................................

4.4.3 Connecting a device using database file

........................................................................

4.4.4 Log file

.............................................................................................................................

4.4.5 Displaying device and licence information

.....................................................................

4.4.6 Disconnecting devices

.....................................................................................................

...................................................................................................

..........................................................................................................

.............................................

...................................................................................................

..........................................................................................

.............................................................................

.....................................................

..................................................

........................................................................................................

............................................................................

.........................................................................

...................................................................................

..............................................................................................

Page 5

AtmoCONTROL FDA Version

...........................................................................................................................

..............................................................................................................................

......................................................................................................................

.........................................................

.............................................................................

..........................................................................................................

..........................................................

....................................................................................................

Page 6

AtmoCONTROL FDA Version

This end user licence agreement forms a legally binding agreement between you, whether a

This licence agreement bindingly regulates the use of software licences of MEMMERT GmbH

your legally binding agreement that you accept the conditions of this licence agreement and

The software is protected by copyright laws, international copyright agreements, as well as by

The software product is licenced, not sold. All property and user rights remain with MEMMERT

The software product is licenced as follows:

As customer you must use the software only for the MEMMERT equipment entered in the

You are not entitled to hire out, lease, loan or otherwise dispose of the software product. You

technological development. The user hereby notes this situation.

All warranty lapses if the user modifies programmes or programme parts or has such changes

from incorrect operation, use of unsuitable operating material, or unusual operating condi-

tions.

Page 7

AtmoCONTROL FDA Version

The user must employ the SOFTWARE PRODUCT only for his own purpose unless expressly

The user must notify MEMMERT GmbH & Co.KG without delay of any faults which occur,

together with a brief description of the fault.

the SOFTWARE PRODUCT is supplied, is free from material faults and manufacturing faults.

The software has been carefully developed and tested by MEMMERT GmbH & Co.KG. There

the use of this software product or any inability to use this software product.

This applies also in case MEMMERT GmbH & Co.KG has been advised of the possibility of such

This exclusion does not apply to damage which has been wilfully caused by MEMMERT GmbH

from such contravention.

The agreement is concluded exclusively on the basis of the General Utilization Conditions of

All legal relations between the parties, including delict law, are subject to the law of the Ger-

Page 8

AtmoCONTROL FDA Version

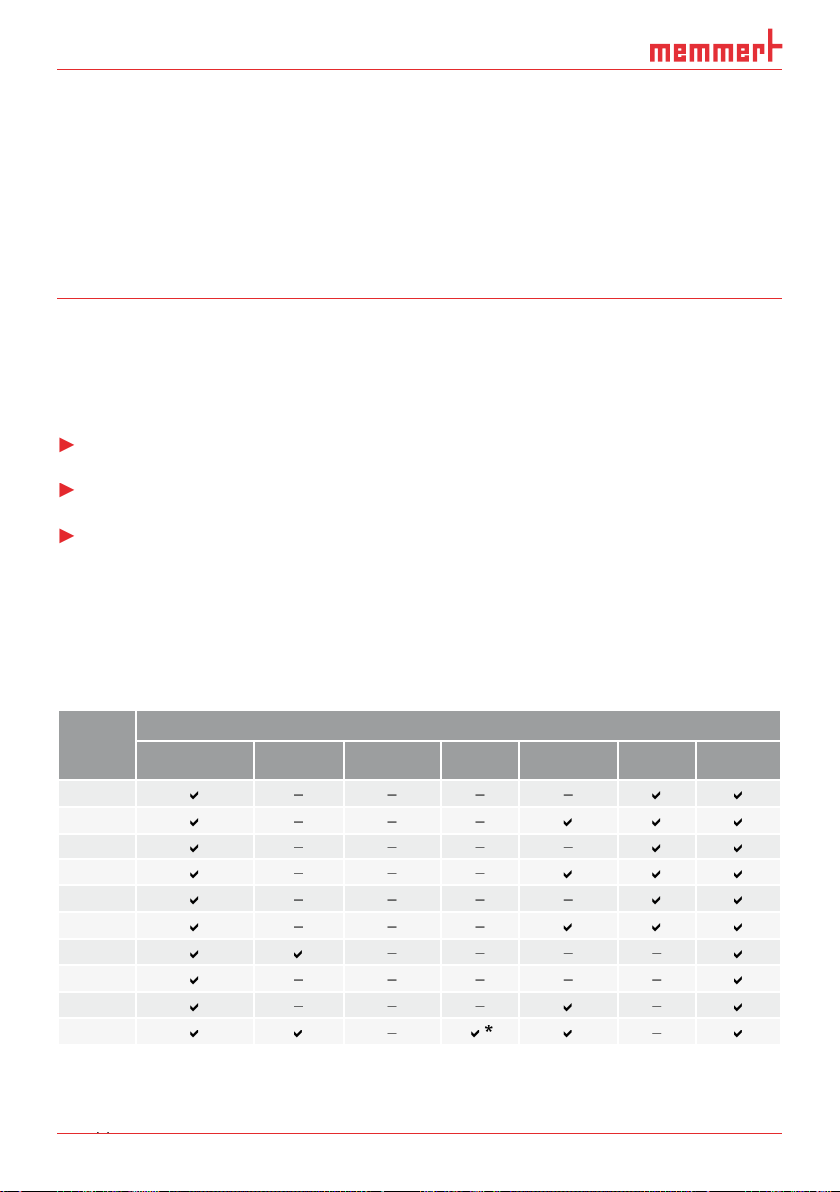

AtmoCONTROL is a software for programming and logging MEMMERT appliances of the

With AtmoCONTROL, you can

Appli-

the appliance itself, and FDA functions are not available.

the appliance itself, and FDA functions are not available.

ance

Temperature Humidity Pressure CO

Programmable main parameter

Fan speed Air fl ap Light*

2

Page 9

AtmoCONTROL FDA Version

Advanced functions of the AtmoCONTROL FDA version

Within a closed system, this specially developed software meets the requirements of the Food

tion processes in the food, chemical and pharmaceutical industry:

►

trail

The regulation 21 CFR (Code of Federal Regulation) part 11 came into force in 1997. It

tion and long-term archiving of the process variables.

The regulation applies to all production and quality assurance documents that had to be pro-

vided signed in paper form before. These documents may as of now be created, stored and

They are stored in:

Audit trails

The FDA compliant software AtmoCONTROL FDA edition fulfils the requirements for the use of

the US Food and Drug Administration (FDA):

Authenticity: The users and administrators of electronic records must be uniquely identifi-

Automatic audit-trailing with timestamp, signature and type of modification to the

Access option to data for the inspectors of regulatory authorities

►

►

►

►

►

►

►

►

►

Page 10

D30396 | Date 09/2014

AtmoCONTROL FDA Version

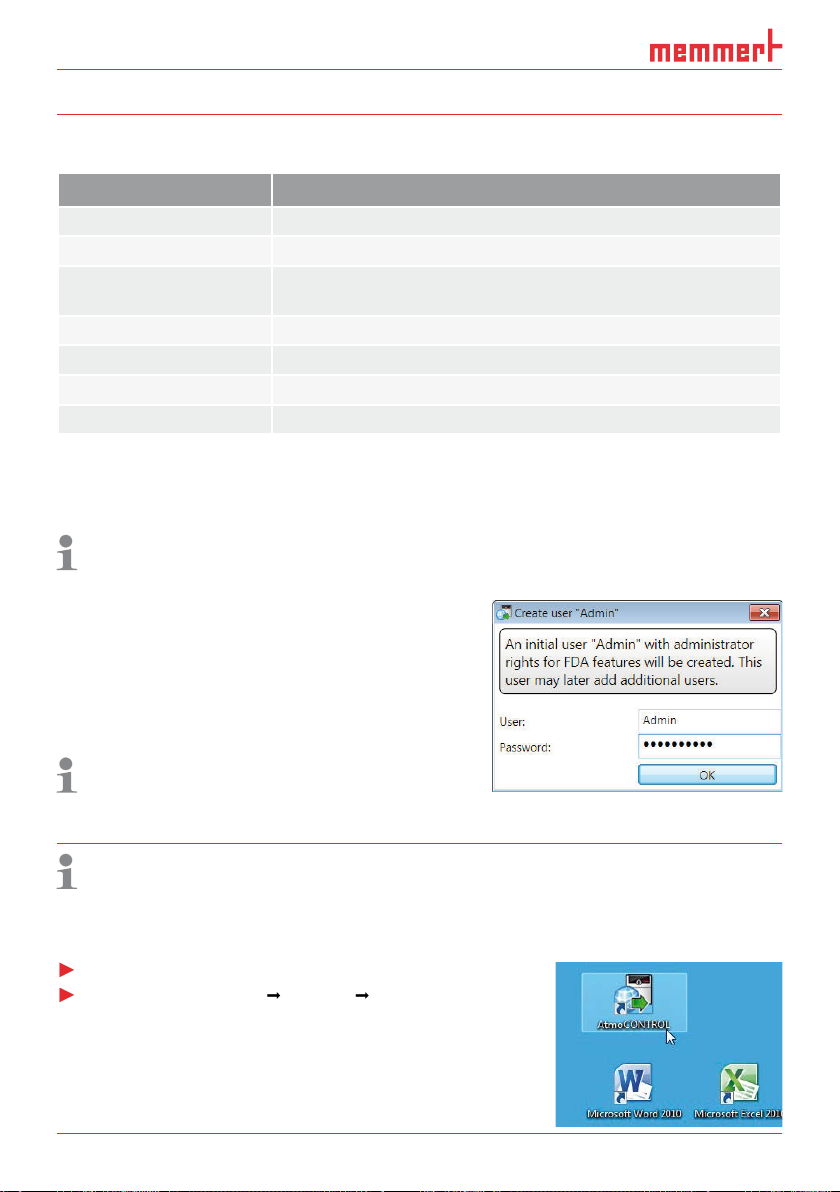

Category Minimum system requirements

Available free space on

4 GB

VGA graphics and colour monitor

Windows 7, Windows 8

You must have Windows administrator rights to be able to install the AtmoCONTROL FDA

the installation process step by step.

their rights later on (see page 33).

Working with AtmoCONTROL

Which of the following functions are available for you depends on the user rights the

AtmoCONTROL administrator has given you (see page 33).

AtmoCONTROL can be started in two ways:

AtmoCONTROL)

Page 11

AtmoCONTROL FDA Version

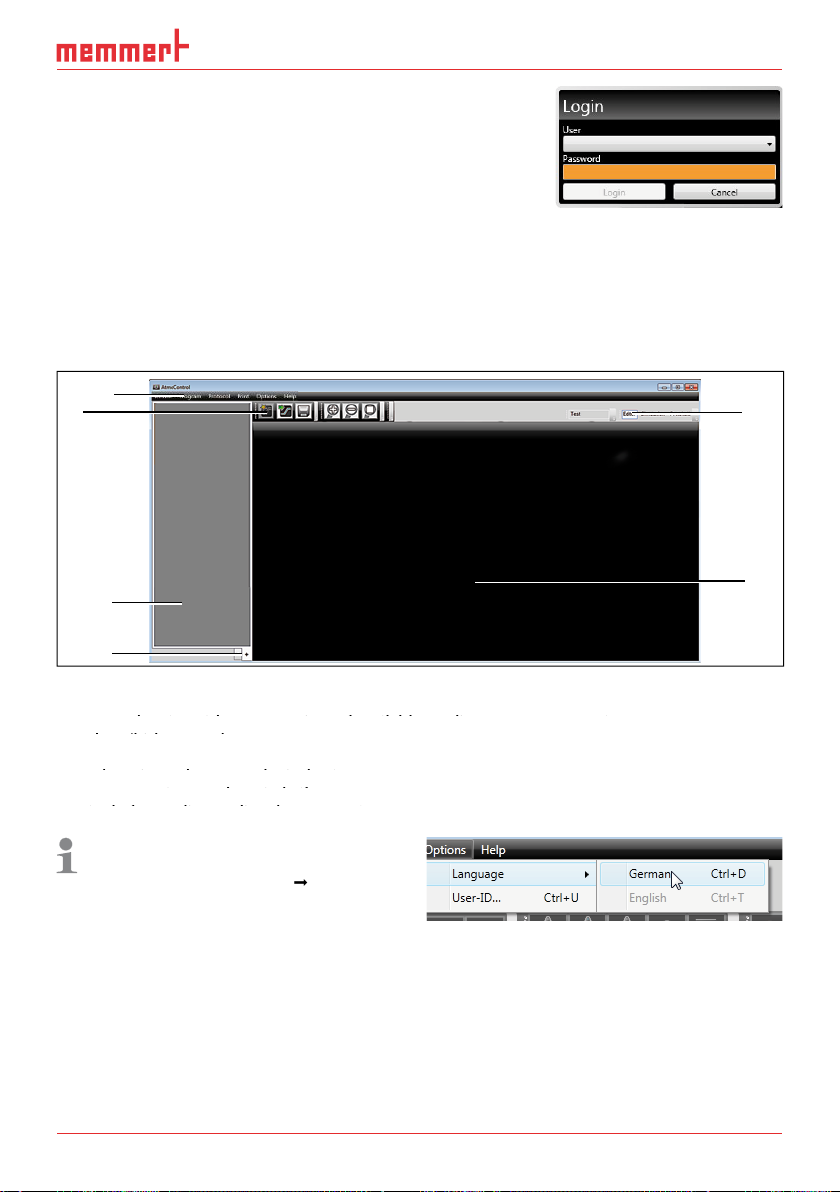

When starting AtmoCONTROL FDA, you have to login as

AtmoCONTROL user with your user name and password. Users

you start AtmoCONTROL FDA for the first time, you are asked

whether these data should be encrypted. This is required for compliance with the FDA require-

The

1

4

Menu bar (see section 4.2.1)

3

Status bar (provides an overview of available appliances, see page 13)

Show/hide status bar

Status bar (provides an overview of available appliances, see page 13)

Status bar (provides an overview of available appliances, see page 13)

5

Editor, simulation and protocol window (only for appliances listed on page 8,

otherwise only protocol window)

Editor, simulation and protocol window (only for appliances listed on page 8,

Editor, simulation and protocol window (only for appliances listed on page 8,

Programming mode switch (for editor/simulation/protocol, see pages 24 and 30)

otherwise only protocol window)

otherwise only protocol window)

You may change the

2

3

6

5

Page 12

D30396 | Date 09/2014

AtmoCONTROL FDA Version

Device Program Protocol Print Options Security Help

Connect to device via

Ethernet (see page 13)

2

protocol data on USB

storage medium (see

protocol data on USB

protocol data on USB

page 14)

3

database file (see page

4

Disconnect selected de-

vice (see page 15)

5

Disconnect all devices

vice (see page 15)

vice (see page 15)

Load a saved programme

8

Save programme

9

Save programme under a

Save programme

Save programme

new name

device via Ethernet (see

page 25)

Export programme to

page 25)

Import protocol from

page 25)

page 25)

page 30)

Export protocol data (see

page 30)

page 30)

page 31)

Print (see page 31)

guage (German/English)

page 31)

Automatic sending of

page 31)

page 31)

emails (see page 32)

Automatic sending of

Automatic sending of

Edit backup folder (see

emails (see page 32)

emails (see page 32)

page 33)

Sign a programme or

protocol electronically

Sign a programme or

Sign a programme or

34)

20

Edit user rights (FDA func-

tion, see page 33)

21

34)

22

tion, see page 34)

23

Display audit trail (FDA

tion, see page 34)

tion, see page 34)

function, see page 35)

Display audit trail (FDA

Display audit trail (FDA

24

Lock AtmoCONTROL

function, see page 35)

function, see page 35)

35)

25

Programme information

26

format

27

device (see page 13)

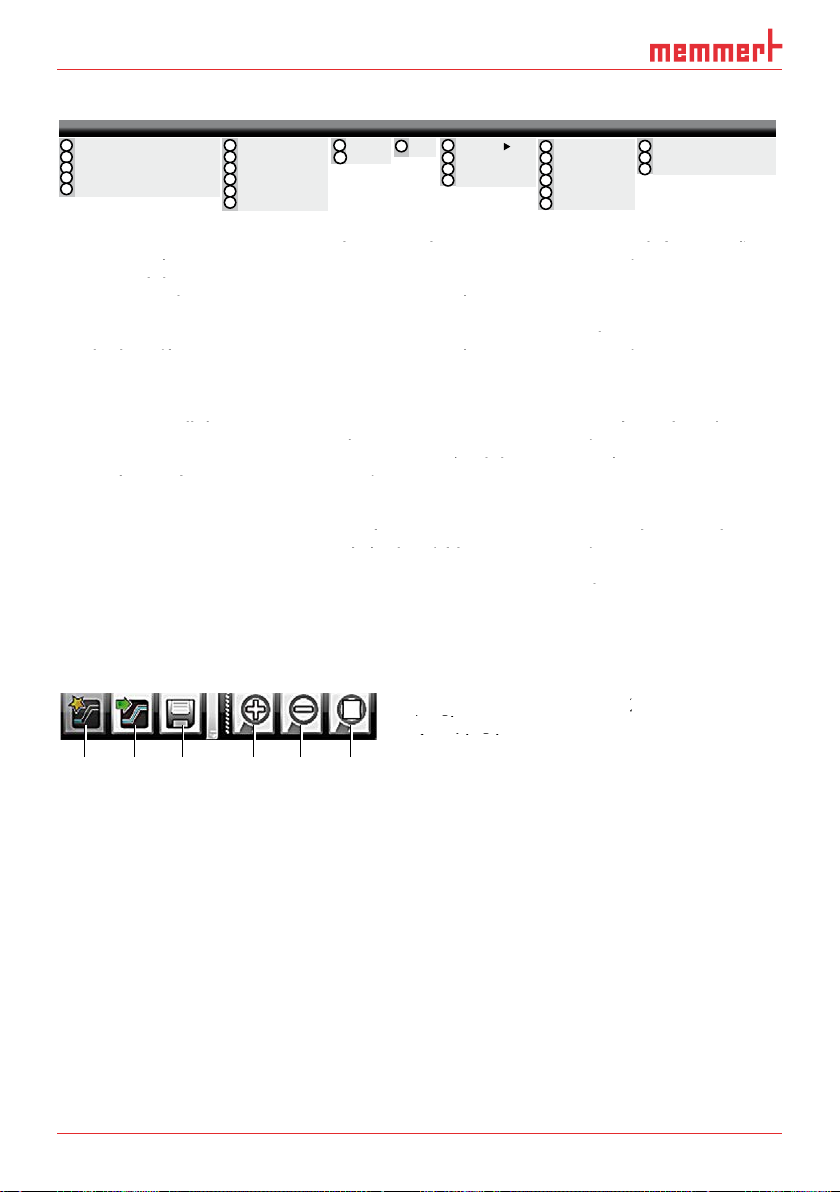

4.2.2

Toolbar

The toolbar provides rapid access to the most important menu functions:

programme

2

Load programme

programme

programme

from the data

Load programme

Load programme

medium

3

Save new

programme

4

Enlarge view

zoom in)

5

Reduce view

Show full

programme

Connect online via Ethernet

1

Connect offline from USB device

2

Connect offline from database

3

Disconnect device

4

Disconnect all devices

5

New

6

Load

7

Save

8

Save As...

9

Upload to Device

10

Export to USB drive

11

12

13

Import...

Export...

15

Print

14

Language

USER-ID

16

Email options

17

Edit Backup Folder

18

Sign document

19

Edit users

20

Change password

21

Change user

22

Audit trail

23

Lock AtmoCONTROL

24

25

26

27

About...

User Manual

Upload license file to device

1 2 3 4 5 6

Page 13

AtmoCONTROL FDA Version

4.2.3

The status bar gives an overview of the appliances logged on to AtmoCONTROL. Appliances

1 2

Fig. 1

An appliance of type UF 260

(1), named "Laboratory" (2) by the user, is registered via Ether-

net (3) in AtmoCONTROL; current temperature 180.0 °C (4)

Installing the

With AtmoCONTROL FDA, only Memmert appliances with the corresponding electronic licence

There are two methods of installing a licence:

4.3.1

Switch off the respective appliance.

UF 260plus Laboratory

180.0°C

3 4

i

Page 14

D30396 | Date 09/2014

AtmoCONTROL FDA Version

4.3.2

Via Ethernet with AtmoCONTROL

transfer the licence to.

A description of how to set the IP address is

4.

tered) in AtmoCONTROL as described in the following section.

Adding and disconnecting devices

With the AtmoCONTROL FDA edition, only Memmert appliances can be registered which

Adding device connected via Ethernet

vices have at delivery (192.168.100.100). The IP address

A description of how to set the IP address is

When connecting, all data are automatically updated.

Connecting device using USB storage

A description of how to read protocol data on a device is provided in the user

Page 15

AtmoCONTROL FDA Version

4.4.3

Connecting a device using

A window opens, in which you can open the

type.

Log fi le

file Log.txt is also transferred and saved in a sub-

folder of the directory

The log file is structured as shown in the

A

– End of the event

Alarm / event code

Alarm / event description

A detailed list of all event codes is given

from page 34.

4.4.5

When a device has been added, you can

time. To do this, click on the

A window is opened displaying detailed

4.4.6

Disconnecting devices

the status bar, select it and then click on

A B C D

Page 16

D30396 | Date 09/2014

AtmoCONTROL FDA Version

temperature, pressure and humidity), which the appliance then implements from a definable

To be able to create a programme in AtmoCONTROL, the appliance which is to perform the

Two editor threads are always shown for appliances with humidity or pressure control,

want to see the parameter values for a specific point in time, you must change to the simula-

tion mode (see page 24).

Fig. 2

Elements to create a programme

Appliance selected

Elements to create a programme

Elements to create a programme

Available parameters (functions)

Appliance selected

Appliance selected

3

Editor thread

Available parameters (functions)

Available parameters (functions)

Additional editor thread for appliances with humidity or pressure control

2

1

3

4

Page 17

AtmoCONTROL FDA Version

To create a programme, drag the individual parameter icons onto the editor thread one after

the zoom icons in the toolbar list (see section 4.2.2 on page 12) or with the mouse wheel,

you can zoom in or out of the display or have the entire programme displayed.

Ramp 05

Fig. 3

Drag the parameter icon (in this case a tem-

perature change) onto the editor thread while

holding the mouse button down

Fig. 4

Drag other parameters – light and a humidity

change in this case – onto the editor thread.

A red insertion mark helps you to find the

correct position.

The temperature icons (change/hold temperature) may only be placed on the upper editor

thread, humidity and pressure icons only on the lower one.

The meaning of the individual icons and the adjustment options are described from page

Removing a parameter icon from the editor thread

Removing a parameter icon from the editor thread

To remove a parameter

function) from an edi-

tor thread – if you have

with the mouse button

Fig. 5

with the mouse button depressed, to the recycle bin symbol.

10h:00m

11h:30m

Ramp 05

10h:00 m

11h:30 m

LIGHT

21.0 °C 180.0°C

180.0°C

21.0 °C 180.0°C

Increase

40.7%rh 70.6%rh

180.0°C

2h:30 m

0%

Page 18

D30396 | Date 09/2014

AtmoCONTROL FDA Version

To adjust values, click successively on the corresponding fields – in

the example on the right, the setpoint temperature. The value is

The adjustment range depends on the appliance for which the

The main parameters have additional adjustment options, which

fold down icon (Fig. 6, No. 1).

tolerance

Fig. 6

Further adjustment options fold down after clicking on the arrow icon on the right

edge of the window (1)

Fig. 6

Fig. 6

Further adjustment options fold down after clicking on the arrow icon on the right

Further adjustment options fold down after clicking on the arrow icon on the right

Available

Which parameters are available to adjust the programme depends on the appliance for

which a programme is to be created. Only those parameters are available that the appli-

- - h:- - m

- - - .- °C21.0 °C

Ramp 01

21.0 °C

2

Tolerance band

1

0,1 K/min

11h:30m

37.0°C

Tolerance band

0,1 K/min

3

Page 19

AtmoCONTROL FDA Version

Broad

parameter representation

parameter representation

Depiction in

?

temper-

Function

Adjustment options

Adjustment options

)

Temperature to be maintained

Tolerance value above/below

Alarm if limits are exceeded

?

temper-

Function

Adjustment options

Adjustment options

Target (setpoint) temperature

Tolerance value above/below

3

?

15

Function

Adjustment options

Adjustment options

)

tained

Tolerance value above/below

Alarm if limits are exceeded

When run, this is displayed in the

When

3

value is reached, even if the set time has already expired. If this is "off", the programme sequence is

icon bar

Meaning

Depiction on

editor thread

Tolerance band

Tolerance band

Function and

adjustment options

0,1 K/min

70.0%rh

Tolerance band

+

0.0%rh

-

5.0%rh

on off

Alarm

Safe

Hold

12h:00 m

Page 20

D30396 | Date 09/2014

AtmoCONTROL FDA Version

Depiction in

?

15

Function

value.

Adjustment options

Adjustment options

Target (setpoint) humidity

Tolerance value above/below

3

?

15

STAND BY

Function

Adjustment options

Adjustment options

)

Tolerance value above/below

Alarm if limits are exceeded

?

15

STAND BY

Function

Adjustment options

Adjustment options

Target (setpoint) pressure

Tolerance value above/below

3

When run, this is displayed in the

When

3

value is reached, even if the set time has already expired. If this is "off", the programme sequence is

icon bar

Meaning

Depiction on

editor thread

Function and

adjustment options

2h:30 m

40.7%rh 70.6%rh

hold p

decrease

1100mb

2h:30 m

500mb

2h:30 m

500mb

Tolerance bandIncrease

+

5.0%rh

-

5.0%rh

on off

SPWT

Tolerance band

+

20mb

-

10mb

on off

Alarm

Safe

Tolerance band

+

20mb

-

10mb

on off

SPWT

Page 21

AtmoCONTROL FDA Version

Narrow

parameter representation

parameter representation

With the narrow

tive position – and remains active until it is changed by the insertion of a new parameter icon

Depiction

?

15

STAND BY

?

15

STAND BY

15

STAND BY

15

STAND BY

Air flap

15

STAND BY

15

STAND BY

15

STAND BY

Adjustment options: none

Appliance emits an acoustic signal at the

was inserted, for example if a specific setpoint

value is reached or the programme is finished.

in icon bar

Meaning Depiction on

editor thread

CO

2

50%

15

0

O2

CO2

12.0%

FAN

100%

FLAP

100%

LIGHT

Adjustment options/

comments

100%

UV LIGHT

on off

HORN

Page 22

D30396 | Date 09/2014

AtmoCONTROL FDA Version

Depiction

15

STAND BY

Adjustment options: open/close

15

STAND BY

15

STAND BY

Activates the defrosting function of the appli-

15

STAND BY

The programme is repeated each week at the

STAND BY

CALENDAR

Year

30

05

2012

STAND BY

Synchronis-

finished on both editor threads.

finished.

in icon bar

15

Meaning Depiction on

editor thread

DOOR

openclose

SWITCH

A

openclose

DEFROST

CLOCK TIMER

Mo

Tu

We

Th

Fr

Sa

Su

11h:30 m

CALENDAR

Day

18

05

Month

Year

2012

- - - -h: m

22h:30 m

Adjustment options/

comments

SYNC

and or

Page 23

AtmoCONTROL FDA Version

Depiction

STAND BY

The programme jumps back from the insertion

the range that is to be repeated.

... ...

in icon bar

Meaning Depiction on

editor thread

Adjustment options/

comments

STAND BY

JUMP

TARGET

STANDBY

LOOP

JUMP

4 X

TARGET

JUMP

TARGET

LOOP

LOOP

2 X

4 X

Page 24

D30396 | Date 09/2014

AtmoCONTROL FDA Version

While creating the programme, you can display the prospective progression of all parameters

Fig. 7

Programme preview diagram (simulation)

you want to alter the programme.

Saving, loading, transferring and running the programme

The name with which you save the programme is later

Via Program

the saved programmes (*.atpro).

Page 25

AtmoCONTROL FDA Version

Transferring programme via Ethernet

To be able to transfer a programme via Ethernet, the appliance and computer must be

Transferring a programme via USB storage medium

With appliances that have humidity control, make sure that the

water supply tank of the

vals, especially for programmes that run for long periods. The same applies for appliances

with gas supply.

Page 26

D30396 | Date 09/2014

AtmoCONTROL FDA Version

5 841

Fig. 8

maintain this temperature (infinitely

) (4) until it is changed: also Monday to Friday (5) at 6

pm (6) to 50 °C (7) – again continued (infinitely

maintain this temperature (infinitely

maintain this temperature (infinitely

) (4) until it is changed: also Monday to Friday (5) at 6

) (4) until it is changed: also Monday to Friday (5) at 6

) (8) until it is changed again in the morning

at 8 am (2).

120 °C

50 °C

20 °C

2 3

6 7

347

8

Mo. Tu. We. Th. Fr. Sa. Su.

1

Page 27

AtmoCONTROL FDA Version

3 4

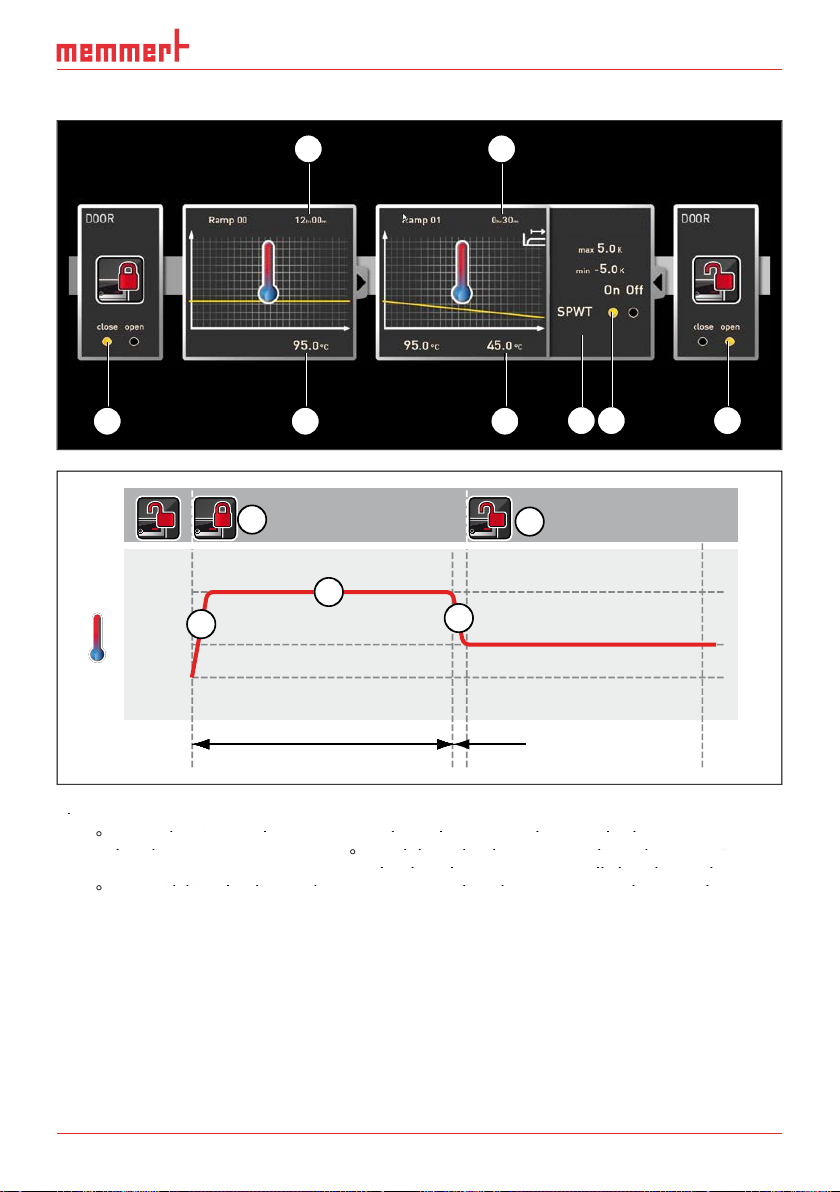

Fig. 9

95.0

lowered (5) for 30 minutes (4) to 45.0

SPWT

on" (8) ensures that the door is opened only when the temperature really has dropped to

45.0

K/min (7).

1 2 5

Tolerance band

1,7 K/min

8 6

7

95 °C

45 °C

20 °C

1

6

3

2

5

12:00 h ≥ 0:30 h

Page 28

D30396 | Date 09/2014

AtmoCONTROL FDA Version

4

Fig. 10

At the beginning, the fan is switched on to 100 % (1) and the air flap is closed (0 %) (2). Then,

Fig. 10

Fig. 10

the appliance heats up to 180.0

At the beginning, the fan is switched on to 100 % (1) and the air flap is closed (0 %) (2). Then,

At the beginning, the fan is switched on to 100 % (1) and the air flap is closed (0 %) (2). Then,

ting „Safe“ (5) ensures that the sterilisation time does not start (6) before the set tolerance band

the appliance heats up to 180.0

the appliance heats up to 180.0

6

Tolerance band

1 2 3

5

1

0 % 100 % 0 %

2

100 % 0 %

6

180 °C

4

3

20 °C

3:00 h

7

Page 29

AtmoCONTROL FDA Version

9

41

Unload

Fig. 11

First, the appliance heats up to 250.0 °C (2) for one hour (1). Then, the fan begins to run at 80

Fig. 11

Fig. 11

fan is switched off (6). This sequence is repeated from the jump target (7) ten times (8).

250 °C

20 °C

27 3 5

6

0% 80% 0% 80% 0% 80% 0% 80% 0% 80% 0% 80% 0% 80% 0% 80% 0% 80% 0% 80% 0% 80% 0%

235

1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h 1 h

1 4

8

6 8

Page 30

D30396 | Date 09/2014

AtmoCONTROL FDA Version

To be able to import a protocol via network, the appliance and computer must be con-

Fig. 12

Protocol display (example)

Importing protocol from USB data medium

At the appliance, protocols can be exported to an USB storage medium and imported in

AtmoCONTROL:

the user manual for the appliance.

TROL.

files on an USB storage medium (see page 14).

Page 31

AtmoCONTROL FDA Version

With Protocol

types *.csv or *.xlsx (Excel), which can be processed in

With the "Print" function, you can print out programmes

You can set the language of the user

With the appliances listed in the table on page 8, it

AtmoCONTROL cannot generate a USER-ID file,

figuration in AtmoCONTROL is also not possible.

There can be only one USER-ID on a USER-ID USB stick.

The settings in this file then apply for all appliances configured.

A USER-ID identifier on a USER-ID USB stick for one (or several) serial numbers can be pur-

Fig. 13

Exporting protocols

Fig. 14

User-ID

Page 32

D30396 | Date 09/2014

AtmoCONTROL FDA Version

with the USER-ID file into the

A window appears with the functions of the logged on appliance

that can be blocked (depending on the appliance type).

4.

Sending

AtmoCONTROL can automatically send an email to a freely definable recipient if an alarm

was triggered, e.g. if the temperature is exceeded. To make the corresponding settings, select

Fig. 15

Settings for the automatic sending of emails in case of alarm

events

Page 33

AtmoCONTROL FDA Version

You can set up a backup folder in which

AtmoCONTROL saves backup copies of

You can either use the default folder or

FDA functions (menu item “Security”)

Adding and deleting users and manage user rights

The FDA version of AtmoCONTROL comprises an own user management, which is independ-

The user management in AtmoCONTROL is accessed via the menu item “Security”

User rights

Fig. 16

Scroll to additional

user rights

password

Add new userChange user

Delete selected

user

Close User

Management

Page 34

D30396 | Date 09/2014

AtmoCONTROL FDA Version

The user management can only be accessed by users the administrator has assigned the

Changing the user password and user

Via the menu item “Security”

Via the menu item “Security”

Signing a document

With the function “Security”

A signature once given cannot be changed or removed

The user rights assigned by the administrator define the

type of signature a user is allowed to provide. The

A user can also sign with several roles, however only with

the corresponding rights. A role can in turn also be signed

Page 35

AtmoCONTROL FDA Version

Traceability by means of a protected audit trail fi le

All actions performed in AtmoCONTROL FDA are

The time span to be displayed can be defined

The audit trail function can be accessed via the

All important functions and activities are saved in

the audit trail. These include:

Adding and removing users

Actions in AtmoCONTROL which may only be performed with the corresponding rights

Actions which are executed via the operating system, as for example deleting files, if the

Event name Description

„Fehler“

„Error“

An error occurred during an action. Examples of this are: Corrupt data; at-

tempt to overwrite a file which has more signatures than the current one.

The action was not performed.

„Info“

„Audit OK“

„Audit fail“

All actions requiring a password or authorisation check.

„Warnung“

„Warning“

The message itself is not critical but may be evidence of an operating er-

To prevent unauthorised use of AtmoCONTROL, for example in case of absence from the

workplace, choose “Security”

Page 36

D30396 | Date 09/2014

AtmoCONTROL FDA Version

Error codes for Generaon 2012 appliances Status: October 09, 2012

Error code

Parameter

Description

101: OS Error

Operang system error

102: File System Error

File system error

103: USB Error

USB error

104: GUI Error

Graphical user interface error

105: IP Stack Error

Ethernet error

106: I2C Bus Error

12C bus error

107: RTC Error

Realme clock error

108: RAM Disk Error

RAM disk error

109: WatchDog Reset

Watchdog error

Power Supply OK

110: Power Supply OK

111: Controller Restart

Restart aer reset

201: Config Error

Configuraon error

202: Calib User Error

Error in calibraon file (user)

203: Calib System Error

Error in calibraon file (calibraon system)

204: PID Config Error

Error in PID parameters

205: User Config Error

Error in user sengs

206: Baery Error

Baery low

207: SD Card Space

Warning at 95% disk space usage

208: SD Card Full

Error, SD card is full

209: SD Card Missing

SD card is missing

210: Failed To Copy Protocol

Error copying the protocol

211: Restauraon Failed

Error restoring LastState

212: Max Count Of Profiles

Maximum number of profiles on SD card reached

301: Fan Error

Fan speed error

302: Heang Error

Heang error

303: Temp Limitor

Temperature limiter has triggered

304: Door open

Door is opened

305: Hzg Err

200000

Triac optocoupler heang 1 power module 1

defecve

020000

Triac optocoupler heang 2 power module 1

defecve

Note:

002000

Triac optocoupler heang 1 power module 2

defecve

000200

Triac optocoupler heang 2 power module 2

defecve

000020

Triac optocoupler heang 1 power module 3

defecve

000002

Triac optocoupler heang 2 power module 3

defecve

100000

Triac heating 1 power module 1 defecve

010000

Triac heang 2 power module 1 defecve

001000

Triac heang 1 power module 2 defecve

000100

Triac heang 2 power module 2 defecve

In case of a hardware error of the oven, the controller displays the following error codes in a status /

error window, as well as logs them in the “Log.txt” file in the “Config” directory on the SD card.

The posion of the error number further specifies the posion of the error.

The posion of the red digit

indicates the defecve stage

of the appliance.

Page 37

AtmoCONTROL FDA Version

000010

Triac heang 1 power module 3 defecve

000001

Triac heang 2 power module 3 defecve

306: Comm Err

1000

Power module 1 is not responding

0100

Power module 2 is not responding

0010

Power module 3 is not responding

0001

Humidity power module is not responding

401: Humidity Sensor

Humidity sensor defecve

402: Humidity Min Al

Humidity below minimum value

403: Humidity Max Al

Humidity maximum value exceeded

405: Temp Sensor Defunct

Temperature sensor defecve

404: Water tank empty

Water tank empty

406: Sensor Alarm

Monitoring sensor defecve

407: Temp Min Alarm

Temperature below minimum value

408: Temp Max Alarm

Temperature maximum value exceeded

409: Temp Auto Alarm

Temperature tolerance band violated

410: Lights Off

Automac lights switch-off

501: Sensor CO2 Error

CO2 sensor defecve

502: CO2 Empty

CO2 supply interrupted / gas cylinder empty

503: CO2 Auto Switch

Noficaon of gas cylinder change

504: CO2 Min Alarm

CO2 below alarm limit

505: CO2 Max Alarm

CO2 alarm limit exceeded

506: Sensor O2 Error

O2 sensor defecve

507: N2 Empty

N2 supply interrupted / gas cylinder empty

508: O2 Min Alarm

O2 below alarm limit

509: O2 Max Alarm

O2 alarm limit exceeded

601: Vacuum Sensor Error

Pressure sensor defecve

801: Program Start

602: No Shelf

No shelf inserted

603: Vacuum Min Alarm

Pressure below alarm limit

604: Vacuum Max Alarm

Pressure alarm limit exceeded

700: Power Min Border

Voltage below minimum limit

701: Device Fail me

me of power failure

702: Device Start Time

me of restart

Programme start

802: Program Cancelled

Programme cancellaon

803: Program End

Programme end

804: Invalid Program

Programme cannot be loaded

Page 38

D30396 | Date 09/2014

AtmoCONTROL FDA Version

Air flap position 21

,

,

,

,

, , ,

,

Target group 3

Tolerance band 18

Toolbar 12

,

W

Water supply tank 25

Zooming 12

Page 39

Page 40

AtmoCONTROL

D30396 | Date 09/2014

englisch

Memmert GmbH + Co. KG

Willi-Memmert-Straße 90-96 | D-91186 Büchenbach

Tel. +49 9122 925-0 | Fax +49 9122 14585

E-Mail: sales@memmert.com

facebook.com/memmert.family

Die Experten-Plattform: www.atmosafe.net

Loading...

Loading...