Installation Manual

for MEMC Silvantis 60 cell Photovoltaic Modules

Product List: MEMC-M235AMA, MEMC-M240AMA, MEMC-M245AMA, MEMC-M250AMA, MEMC-M255AMA,

MEMC-M240LMA, MEMC-M250LMA, MEMC-M260LMA, MEMC-M240AMC, MEMC-M245AMC,

MEMC-M250AMC, MEMC-M255AMC, MEMC-M260AMC,

MEMC-M240LMC, MEMC-M250LMC, MEMC-M260LMC

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

Table of Contents

1.0 INTRODUCTION.................................................................................................................................................... 3

2 of 14

2.0 PHOTOVOLTAIC MODULES PRODUCT CODE

3.0 MODULE OVERVIEW

3.1 STORAGE, UNPACKING, AND HANDLING........................................................................................................... 3

3.2 SAFETY........................................................................................................................................................................ 4

3.3 MAINTENANCE.......................................................................................................................................................... 4

........................................................................................................................................... 3

..................................................................................... 3

4.0 MECHANICAL INSTALLATION......................................................................................................................... 5

4.1 PLANNING AND DESIGN.......................................................................................................................................... 5

4.2 MODULE INSTALLATION OPTIONS........................................................................................................................ 5

4.3 MODULE INSTALLATION USING CENTER MOUNTING BRACKETS................................................................... 7

4.4 MODULE INSTALLATION USING SHARED RAILS M240/250/260LMA AND M240/250/260LMC........ 7

4.5 MECHANICAL INSTALLATION WARNINGS............................................................................................................ 8

5.0 ELECTRICAL INSTALLATION.............................................................................................................................. 8

5.1 PLANNING AND DESIGN.......................................................................................................................................... 8

5.2 MODULE WIRING....................................................................................................................................................... 8

5.3 GROUNDING.............................................................................................................................................................. 9

5.4 ELECTRICAL INSTALLATION WARNINGS............................................................................................................. 10

6.0 DISCLAIMER OF LIABILITY.............................................................................................................................. 10

7.0 MECHANICAL AND ELECTRICAL PARAMETERS AND SPECIFICATIONS

8.0 APPENDIX

8.1 MODULE DETAILS.................................................................................................................................................... 13

8.2 MODULE ILLUSTRATIONS...................................................................................................................................... 14

8.3 PREMOUNTED CABLES AND CONNECTORS.................................................................................................... 15

.................................................................................................................................................................. 13

............................... 11

Customer Service

MEMC Singapore PTE. LTD.

11 Lorong 3 Toa Payoh

Block B Jackson Square 4th Floor

Singapore 319579

Fax: (65) 6681-9301

Email: Module_Warranty@memc.com

Website: www.memc.com

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

1.0 INTRODUCTION

The purpose of this guide is to provide general information regarding the proper installation and handling of MEMC photovoltaic

modules that serve residential, commercial, and industrial segments. System design, construction, and commissioning should be

performed by qualied personnel only.

To ensure system integrity, designers, installers and operators must meet all mechanical and electrical requirements for the system and

its components. It is the responsibility of the system designer and installer to ensure that all codes and requirements are followed as

well.

Please review all the sections that pertain to proper installation of modules listed in this Guide. The instructions detailed in this guide

must be followed throughout the module’s lifetime deployment. If you need additional information about the safe, proper use and

handling of MEMC photovoltaic module products, please contact MEMC.

2.0 PHOTOVOLTAIC MODULES PRODUCT CODE

This guide is to be used for MEMC Silvantis 60 cell photovoltaic (PV) module installation. Please refer to the following module numbers

before using the guide:

Modules with tempered glass: MEMC-M235AMA, MEMC-M240AMA, MEMC-M245AMA, MEMC-M250AMA, MEMC-M255AMA

Modules with anti-reective coating (AR coating or ARC): MEMC-M240AMC, MEMC-M245AMC, MEMC-M250AMC,

MEMC-M255AMC, MEMC-M260AMC

3 of 14

Modules with corner cap and tempered glass: MEMC-M240LMA, MEMC-M250LMA, MEMC-M260LMA

Modules with corner cap and anti-reective coating: MEMC-M240LMC, MEMC-M250LMC, MEMC-M260LMC

3.0 MODULE OVERVIEW

MEMC Silvantis Photovoltaic modules consist of a series of electrically interconnected crystalline silicon solar cells that are sealed within

a laminated sheet of tempered glass superstrate* and EVA/back-sheet substrate. These laminates are secured inside an aluminum

frame to provide rigidity and a means for attachment to mounting sub-structures. The frames should not be modied or removed.

* Tempered glass may have AR coating.

• Photovoltaic modules are designed and constructed for outdoor use. Do not submerge modules in water at any time.

• The front and back of each module is labeled with a product bar code. Do not cover, remove or deface these labels. This may

be required for product identication.

• Damage to the glass surface or the anti-reective coating can impact the power output and overall eciency of the system.

Scratches, handling marks, or any damage to the glass surface must be avoided.

• For best performance and to avoid potential issues, keep the front side of the module clean and free of obstructions including

covers, tape, adhesives, paint and debris.

3.1 STORAGE, UNPACKING, AND HANDLING

• Packaged modules must be stored in a dry and ventilated area.

• Packaged modules must not be exposed to rain, snow, hail or other environmental conditions that may compromise the

packaging material and the modules.

• Packaged modules must be on appropriate provided pallets and must not be stacked more than two pallet high for storage.

• Once the modules are opened, store modules in a dry and ventilated room.

• Modules should never be stored in a wet environment.

• Upon unpacking, do not carry a module by its wires or junction box. Only carry a module by its frame with two or more

people.

• Precaution should be taken to avoid damage to the glass surface with or without anti-reective coating due to improper

handling during storage or unpacking.

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

• Keep all electrical contacts clean and dry.

• All modules are manufactured with a sealed junction box and pre-attached cables and locking connectors. These

components should not be modied or tampered with in any way.

• Do not allow unauthorized persons near the installation site or storage area of modules.

• Do not place modules on top of one another.

• Do not place any load on the module or twist the module frame.

• Do not stand, step, walk, or jump on the module.

• Do not drop or place objects on the modules such as tools.

• Do not handle modules with bare hands and avoid scratches, handling marks, or any damage especially to the front glass of

the module, backsheet, or electrical components.

• Do not mark the modules with sharp instruments.

• Do not leave a module unsupported or unsecured.

• Do not modify module frames in any way.

3.2 SAFETY

The following safety guidelines and best practices should be followed:

• All installations must be performed in compliance with all applicable regional and local electrical codes or other national or

international electrical standards.

• Use insulated tools during installation, troubleshooting and maintenance of photovoltaic modules.

• Wear suitable protection to prevent direct contact with module’s electrical output and mechanical sharp edges.

• Cover the front of the modules with an opaque material to stop production of electricity when installing or working with a

module or wiring.

• Modules connected in a series should not be disconnected under illumination. Disconnecting modules under illumination may

cause electrical arcing which may result in burns, res or other problems.

• Follow industry best practices when commissioning, trouble shooting, disconnecting, or connecting a PV system.

• Trouble shooting should include planning, checking, disconnecting, cause seeking, replacement, and record keeping.

• Do not install or handle the modules or their components when they are wet or during periods of high wind.

• Do not attempt to disassemble, repair, or open any part of the module including junction box or sub-components.

• Do not articially concentrate sunlight on a module.

• Do not install or handle any broken modules. If a module is broken, or the back sheet is torn, contact with the surface or

frame can cause an electrical shock.

• Do not wear rings, jewelry, watches, or other metallic items while working with photovoltaic modules.eping.

4 of 14

3.3 MAINTENANCE

Check modules, glass, and frames for damage. Regularly inspect all MEMC Silvantis Solar Modules for safe electrical connections,

sound mechanical connections, and freedom from shading and corrosion. If dirt or debris buildup becomes excessive, periodically

clean the glass only with a soft cloth using mild, non-abrasive detergent and water. When using mild cleaning liquids, a neutral pH in

the range of 6.0 to 8.0 is recommended. Chemicals with pH less than 6.0 or greater than 8.0 should be avoided as it may damage

the glass surface and or the AR coating. Please consult with system designer to decide the cleaning and inspection frequency

according to local environmental conditions.

Do not power wash or use harsh cleaning materials or objects such as scouring powder, steel wool, scrapers, blades, or other sharp

instruments to clean the glass surface of the module. Use of such materials will invalidate the product warranty.

WARNING: Use caution when cleaning the back surface of the module to avoid penetrating the substrate materials.

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

4.0 MECHANICAL INSTALLATION

4.1 PLANNING AND DESIGN

• Before installation, check to ensure all sub-structure will accommodate expected system loads. This includes and is not

limited to roof, foundations, mechanical structure, and mechanical connections.

• For roof installations, utilize a re-resistant roof covering rated for the application.

• Mechanical structures should not contact the module backsheet under any expected load conditions

• Consider the following factors during system design, which will inuence performance:

a) MEMC solar modules produce the most power when they are pointed directly at the sun, and should be tilted for

optimum system performance.

b) Proximity to obstructions such as: walls, buildings, trees, groundcover, snow cover, or dust and debris that have the

potential to shade or damage the modules.

c) Elevated temperatures will decrease energy yield, so designs should ensure adequate airow across the back of the

module.

d) Allow a minimum spacing of 10 mm between modules for thermal expansion.

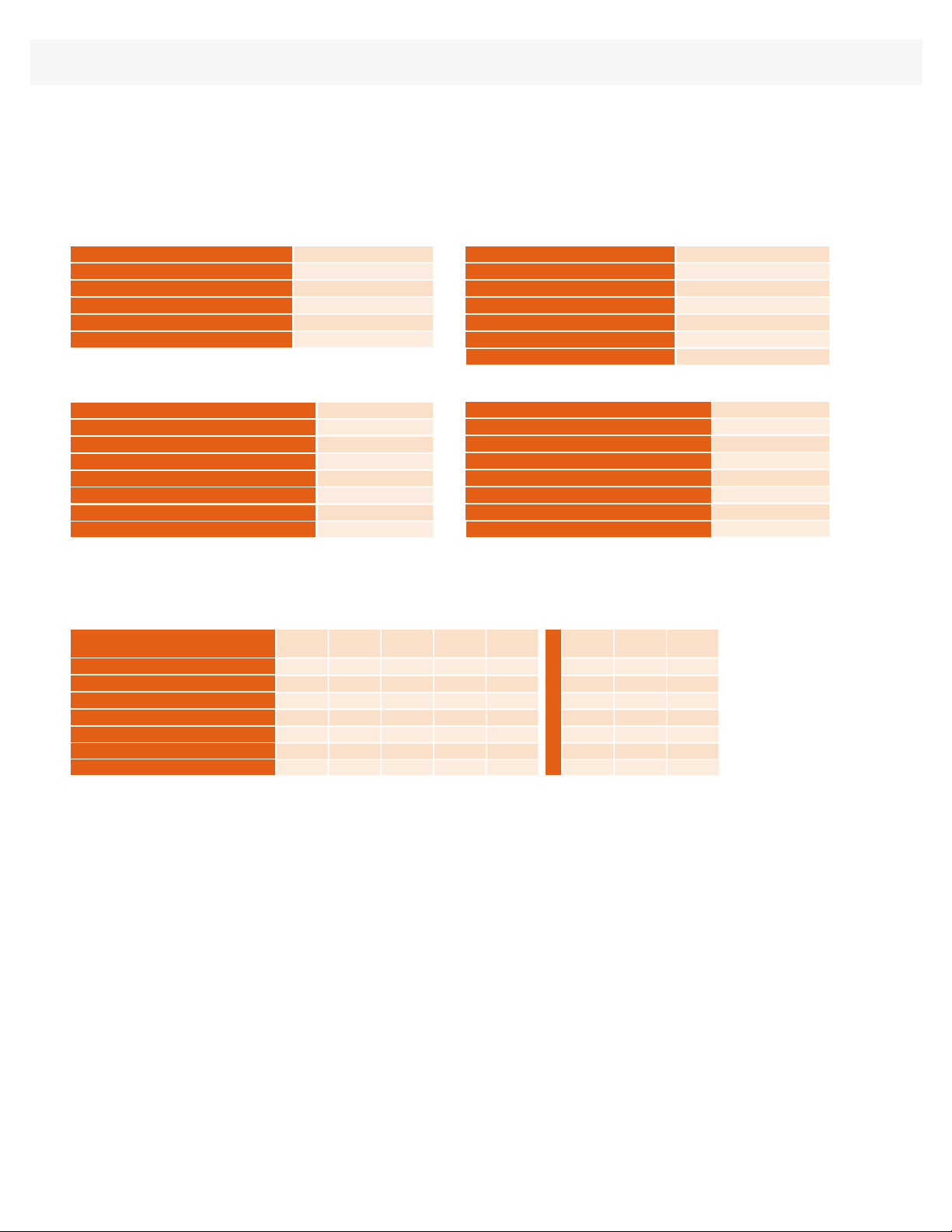

4.2 MODULE INSTALLATION OPTIONS FOR MOUNTING LOCATIONS

For mounting locations for clamps or bolt for specied load, please refer to Table on page 6.

5 of 14

• Each module should be mounted using four bolts through the mounting holes on the rear side of the module, or with four

clamps over the front side.

• Depending on the desired load capability of the array, modules may be mounted either perpendicular or parallel to the

structure rails. Clamps can be mounted anywhere inside of the safe mounting range for each case illustrated below (referring

to chart showing clamp and bolt mounting locations).

• If using bolts, eight mounting holes are provided on the rear side the module frame as shown in Appendix 8.1. Use a stainless

steel bolt stack no smaller than ¼"-20 or M6, with two at washers and a locking washer as shown in Appendix 8.2.

• To ensure an adequate clamping area, all clamps used should comply with the following general conditions:

1. Clamp height must correspond to 50 mm frame height

2. Clamp must have a minimum width of 38 mm

3. Clamp depth must be between 6 mm to 10 mm

• All fasteners used to x the modules with clamps should be stainless steel, and no smaller than ¼”-20 or M6.

• To provide adequate xing or clamping force, torque the minimum recommended fasteners to 13.6 - 16.3 N.m [10 - 12 ft lb].

• All other structural dimensions, such as clamp and rail thickness, should be sized appropriately for the intended site load.

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

6 of 14

4.2A MOUNTING CONFIGURATIONS USING BOLT MOUNT OR CLAMP MOUNT OPTIONS

MOUNTING CONFIGURATIONS LOAD PARAMETERS

PERPENDICULAR MOUNTING

CASES 1 & 2

Structural rails running perpendicular to

the length of the module should be xed

via bolts or clamps at the mounting holes

between each long side frame, OR at the

holes on each short end frame.

NOTE: All modules are rated for a

Maximum

Rear Load:

2400 Pa or 50 psi

Maximum

CASE 1

Front Load:

5400 Pa or 113 psi

maximum rear load of 2400 Pa and a

maximum front load of 5400 Pa when

xed to the side frames mounting holes

for CASE 1 or a front load of 2400 Pa

when xed to the end frames mounting

holes for CASE 2.

Maximum

Rear Load:

2400 Pa or 50 psi

Maximum

CASE 2

Front Load:

5400 Pa or 113 psi

BOLT MOUNT

LOCATIONS

REAR VIEW

REAR VIEW

Pending CertifiCation

CLAMP MOUNT

LOCATIONS

A

Clamp mount

allowable range

FRONT VIEW

B

Clamp mount

allowable range

FRONT VIEW

PARALLEL MOUNTING CASE 3

Structural rails running parallel to the length

of the module should be xed via bolts or

clamps ONLY at the mounting holes on

each long side frame.

NOTE: All modules are rated for a

maximum rear load of 2400 Pa and a

maximum front load of 5400 Pa when

xed to the mounting holes on the long

side frames only.

Structural rails running parallel to the

length of the module should NEVER be

xed to the end frames.

Module Color Code: Mounting Hole Location Module Rail Clamp Mount Range

Maximum

Rear Load:

2400 Pa or 50 psi

Maximum

Front Load:

5400 Pa or 113 psi

CASE 3

allowable range

REAR VIEW

Clamp mount allowable range:

A

Clamp mount

FRONT VIEW

A – 382 mm

B – 248 mm

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

4.3 MODULE INSTALLATION USING CENTER MOUNTING BRACKETS

• Modules may also be mounted using center clamps as shown in Appendix 8.2, for use with trackers.

• Module clamps for center mounting must be based on MEMC approved extrusion and hardware.

• For module loads higher than 2400 Pa, module clamps and hardware must be pre-approved by MEMC.

4.4 MODULE INSTALLATION USING SHARED RAILS M240/250/260LMA AND M240/250/260LMC SPECIFIC

7 of 14

INSTALLATION STEP

Step 1: Place the bottom of the module on the

approved rail at an angle, allowing the module

to toe into the rail hook as shown in gure to the

right, and lower onto the ledge of the next rail.

Step 2: Ensure that the rails are tight against

the modules by adjusting the upper rail.

Step 3: Use the module clips provided to clamp

the module to the rail at each of the two upper

corners on the module frame as shown in gure

to the right.

Step 4: Tighten the included fasteners for the

clips to 11.5 Newton.meters (or 8.5 foot pounds

of torque).

ILLUSTRATION

STEP 1

Toeing module into rail hook

STEP 3

Module clip attachment

Toe in Modules using Corner Cap Feature

System Overview

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

4.5 MECHANICAL INSTALLATION WARNINGS

• Installation and maintenance should be performed by qualied personnel only.

• Use insulated tools during installation, troubleshooting and maintenance of photovoltaic modules.

• Installers should adhere to all applicable local, regional, and national codes and regulations when designing and constructing

the photovoltaic system.

• Do not stand or walk on any surface of the modules.

• Precaution should be taken to avoid damage to the glass surface with or without anti-reective coating due to improper

handling during installation.

• Mechanical structures should not contact the module backsheet under any expected load conditions.

• Additional mounting holes may not be drilled in the frame, glass or backsheet.

• Ensure that frame weep holes (see Appendix 8.1) are not obstructed by the mechanical installation.

5.0 ELECTRICAL INSTALLATION

5.1 PLANNING AND DESIGN

• All modules are manufactured with a sealed junction box and pre-attached cables and locking connectors. These

components should not be modied or tampered with in any way.

8 of 14

NOTE: Installers should ensure that the polarized locking connectors are from the same supplier when connected on the

same string. We do not recommend mixing polarized interlocking connectors from dierent manufacturers—including

connections at the inverter, combiner boxes, and modules.

• Ensure connectors are clean and dry before establishing connection.

• Ensure that all wire, fusing and disconnects are appropriately sized for the system design according to national, regional, and

local codes.

• Electrical characteristics are within plus or minus 5% of rated values for Isc, Voc, Impp and Vmpp. Modules may operate

under conditions which may be signicantly dierent than STC. MEMC suggests multiplying specied ratings by a minimum

of 1.25* or more when specifying the system and balance of system components. 1.25* Refer to local codes before planning

and design of the system. For detailed electrical characteristics, please refer to Section 7.0, page 10 through 11 of this

Installation Manual.

• Determine the maximum number of modules connected in series using the following formula: N

= Vmaxs / Voc

s

m

Where:

equals the maximum modules in series

N

s

equals the maximum system voltage

Vmax

s

is limited to a maximum of 1000 V for IEC and 600 V for UL

Vmax

s

equals the module open circuit voltage at coldest conditions for the site (refer to local codes)

Voc

m

WARNING: Installers should adhere to all applicable local, regional, and national codes and regulations when designing and

constructing the photovoltaic system.

NOTE: In colder climates, it may be necessary to further reduce the maximum number of modules in series by using Voc

m

at the minimum expected operating temperature.

5.2 MODULE WIRING

• The module includes wires and polarized locking connectors from the junction box on the back of the module. The wires

have sucient length to connect to adjacent modules in either a portrait or landscape conguration. Field replacement of

connectors or cables must be avoided and it will invalidate the product warranty. Polarized locking connectors of the same

type and make are needed for all series string wiring. The maximum operating temperature of wires and connectors should

not exceed 85ºC.

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

WARNING: It is not recommended to mix connectors from dierent suppliers within the same string. This includes

connections at the inverter, combiner boxes, and modules.

• Always wire modules so that proper polarity is maintained. Avoid placing excessive tension on the cables.

• There is no limit to the maximum number of series strings that can be combined in parallel. However, when doing so, each

string must include overcurrent protection with a maximum rating of 15A. MEMC recommends the use of DC rated fuses or

overcurrent protection devices with the appropriate maximum voltage rating.

• Do not connect modules directly to a parallel bus.

• The cross-sectional area of cable and the connector type must be selected to align with the overall system design and should

include the maximum short circuit current of the system, maximum operating temperatures, and cable run lengths.

2

• For eld connections, use at a minimum #12 AWG/4 mm

5.3 GROUNDING

• The module frame includes several labeled grounding holes. These holes may not be used for any other purpose.

• MEMC recommends a Burndy BGBL-4 AL lay-in lug for grounding.

• Only Negative grounding circuits (negative polarity to ground) shall be used within the array design.

• Attach the grounding lug to the frame as follows:

wires insulated for a minimum of 85°C. Use copper wire only.

9 of 14

Step 1: Use stainless steel hardware.

Step 2: Place the grounding lug over the grounding hole on the exterior of the module frame.

Step 3: Place a star washer directly between the bottom of the grounding lug and the exterior surface of the frame.

Step 4: Place an M4 or #8-32 bolt through the lug, star washer and frame grounding hole.

Step 5: Secure the lug to the frame using a at washer, split washer and M4 or #8-32 nut.

Step 6: Torque the bolt stack to approximately 1.5 N.m (or 1.1 foot pounds) to ensure the star washer scratches the

anodized frame.

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

5.4 ELECTRICAL INSTALLATION WARNINGS

• Installation and maintenance should be performed by qualied personnel only.

• Use insulated tools during installation, troubleshooting and maintenance of photovoltaic modules.

• Installers should adhere to all applicable local, regional, and national codes and regulations when designing and constructing

the photovoltaic system.

• Photovoltaic modules produce DC electrical energy from light. When illuminated, each module can have a DC potential of

greater than 45V and should be handled with care.

• Disconnecting modules under illumination may cause electrical arcing which may result in burns, res, or other problems.

Modules connected in series should not be disconnected under illumination.

• Always use a wire management system that keeps wires and cables out of direct contact with edge surfaces which could cut

or damage the insulation. Do not allow wires to rest on the ground or roof surface.

• The module junction box should not be opened or modied in any way in the eld.

• Additional grounding holes may be added only with the express written consent of MEMC. New grounding holes must be

drilled using an approved drill jig, avoiding damage to the module glass, backsheet, or other module components.

• Do not use mirrors, lenses, or other techniques to magnify or concentrate additional light on the module.

10 of 14

6.0 DISCLAIMER OF LIABILITY

The information in this manual is based on MEMC’s knowledge and experience and is believed to be accurate. However, all

information in this manual (without exception) including recommendations and specications does not constitute a warranty,

expressed or implied. MEMC reserves the right to change the manual, the module, or specications without prior notice.

The product warranty shall be VOID if handling and installation of the product does not conform to MEMC’s written installation

instructions, or if the product has been reworked, repaired or otherwise modied in a manner not previously authorized by MEMC in

writing, or if the product is installed in an environment for which it was not designed. MEMC shall not be liable for special, indirect,

consequential, contingent or incidental damages related to or arising from the installation or use of the product by purchaser under

any circumstances.

MEMC assumes no responsibility for any product application or use which is beyond MEMC’s direct control. MEMC does not accept

responsibility and expressly disclaims liability for loss, damage, or expense arising out of or in any way connected to such installation,

operation or maintenance of the product.

International Product Certications:

IEC 61215, IEC61730, CE, UL 1730, and Safety Class II certications ensure that MEMC solar products operate safely and comply with

global electrical, performance, reliability, and re safety codes.

• IEC61215 certied by TÜV SÜD to ensure long-term operation in a variety of climates

Certication

Environmental AB8 (-50°C to +40°C)

Fire Resistance Rating Class C

• IEC61730 certied by TÜV SÜD to ensure electrical safety

• Stringent outgoing quality acceptance criteria benchmarked to industry standards

• UL1703 listed by CSA for Canada and US

MEMC Modules are certied by:

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

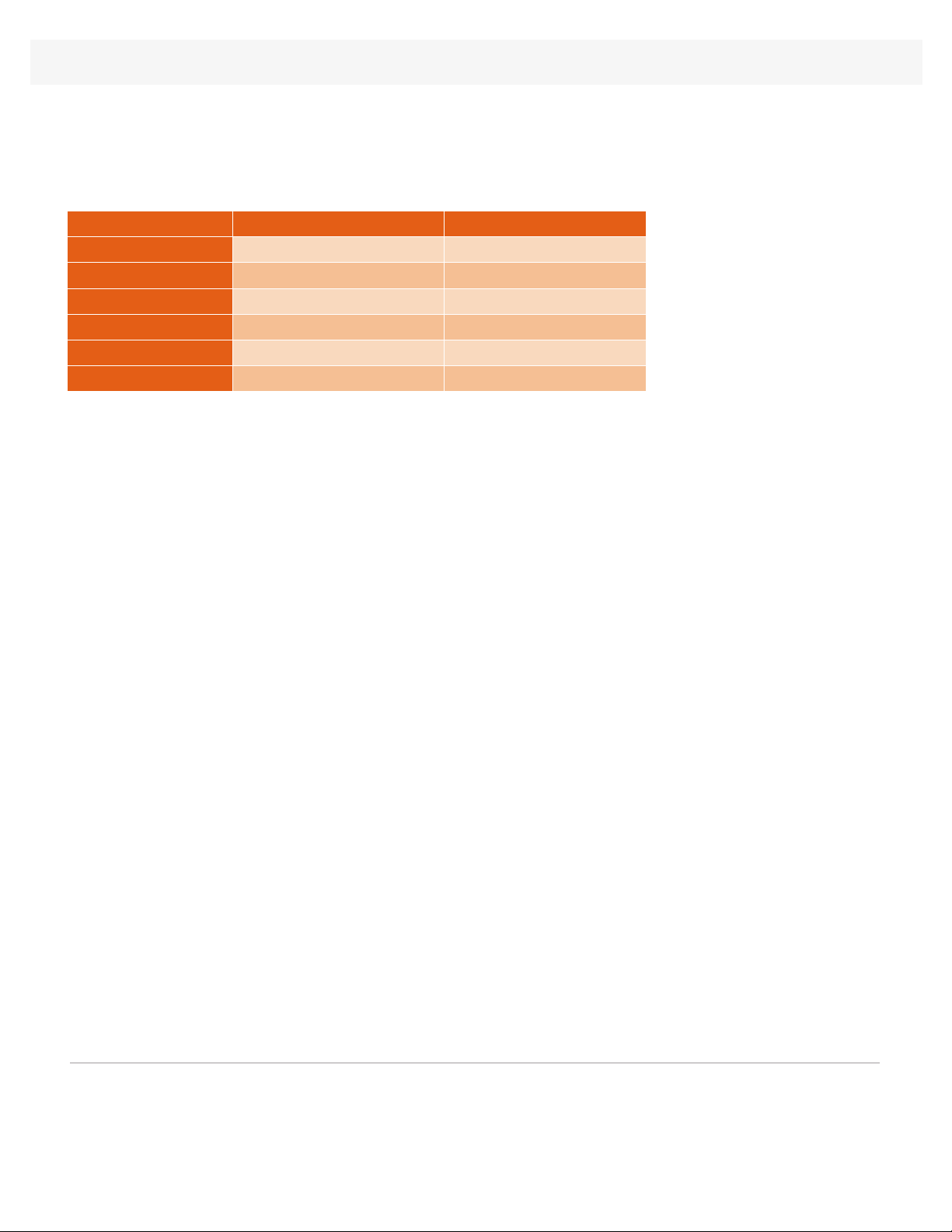

7.0 MECHANICAL AND ELECTRICAL PARAMETERS AND SPECIFICATIONS

11 of 14

Modules with tempered glass:

MEMCM235/240/245/250/255AMA

PHYSICAL PARAMETERS

Module Dimensions (mm)

Module Weight (kg)

Cell-Type

Number of Cells

Frame Material

Glass (mm)

TEMPERATURE COEFFICIENTS AND PARAMETERS

Nominal Operating Cell Temperature (NOCT) (°C)

Temperature Coecient of P

Temperature Coecient of V

Temperature Coecient of I

(%/°C)*

max

(%/°C)*

oc

(%/°C)*

sc

Operating Temperature (°C )

Maximum System Voltage (V)

Limiting Reverse Current (A)

Maximum Series Fuse Rating (A)

Temperature coecients may vary by ±10%

*Refer 240W solar module and MEMC Silvantis 250W module data sheets for specic

temperature coecients

ELECTRICAL CHARACTERISTICS

Model #

Rated Maximum Power Pmax (W)

Open-Circuit Voltage V

Short Circuit Current I

Module Eciency (%)

Maximum Power Point Voltage V

Maximum Power Point Current I

Power Range (W)

All electrical data at STC: 1000W/m2, AM1.5, 25ºC

Electrical characteristics may vary by ±5%

* Listed specications are preliminary and subject to change without prior notice.

(V)

oc

(A)

sc

(V)

mpp

(A)

mpp

1,658 x 990 x 50

19

Mono-crystalline

60

Anodized Aluminum

3.2 Tempered Glass

*

MEMCM235AMA

235

37.3

8.60

14.3

29.3

8.03

-0/+5

*

46±2

-0.47 to -0.49

-0.35

+0.036 to +0.055

-40 to +85

600 (UL)

& 1000 (IEC )

8.40

15

MEMCM240AMA

240

37.4

8.70

14.6

29.5

8.15

-0/+5

MEMCM245AMA

245

37.5

8.80

14.9

29.7

8.25

-0/+5

Modules with corner cap and tempered glass:

MEMCM240/250/260LMA

PHYSICAL PARAMETERS

Module Dimensions (mm)

Module Weight (kg)

Cell-Type

Number of Cells

Frame Material

Corner Caps

Glass (mm)

1,674 x 1,006 x 50

19.3

Mono-crystalline

60

Black Anodized Aluminum

Black Anodized Aluminum

3.2 Tempered Glass

TEMPERATURE COEFFICIENTS AND PARAMETERS

Nominal Operating Cell Temperature (NOCT) (°C)

Temperature Coecient of P

Temperature Coecient of V

Temperature Coecient of I

Operating Temperature (°C )

Maximum System Voltage (V)

Limiting Reverse Current (A)

Maximum Series Fuse Rating (A)

Temperature coecients may vary by ±10%

*Refer 240W solar module and MEMC Silvantis 250W module data sheets for specic

temperature coecients

MEMCM250AMA

250

37.6

8.90

15.2

29.9

8.36

-0/+5

MEMCM255AMA

255

37.8

9.00

15.5

30.0

8.50

-0/+5

MEMCM240LMA

240

37.4

8.70

14.6

29.5

8.15

Modules with corner caps

±6

(%/°C)*

max

(%/°C)*

oc

(%/°C)*

sc

MEMCM250LMA

250

37.6

8.90

15.2

29.9

8.36

-4/+5

MEMCM260LMA

260

38.0

9.10

15.8

30.1

8.64

±5

*

46 ±2

-0.47 to -0.49

-0.35

+0.036 to +0.055

-40 to +85

600 (UL)

& 1000 (IEC )

8.40

15

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

7.0 MECHANICAL AND ELECTRICAL PARAMETERS AND SPECIFICATIONS

12 of 14

Modules with anti-reective coating:

MEMCM240/245/250/255/260AMC

PHYSICAL PARAMETERS

Module Dimensions (mm)

Module Weight (kg)

Cell-Type

Number of Cells

Frame Material

Glass (mm)

1,658 x 990 x 50

19

Mono-crystalline

60

Anodized Aluminum

3.2 Tempered ARC glass

Modules with corner cap and anti-reflective coating:

MEMCM240/250/260LMC

PHYSICAL PARAMETERS

Module Dimensions (mm)

Module Weight (kg)

Cell-Type

Number of Cells

Frame Material

Corner Caps

Glass (mm)

46±2

-0.49

-0.35

+0.055

-40 to +85

600 (UL)

8.40

15

MEMCM245AMC

245

37.7

8.90

14.9

29.2

8.47

-0/+5

*

& 1000 (IEC )

MEMCM250AMC

250

37.8

9.00

15.2

29.4

8.57

-0/+5

TEMPERATURE COEFFICIENTS AND PARAMETERS

Nominal Operating Cell Temperature (NOCT) (°C)

Temperature Coecient of P

Temperature Coecient of V

Temperature Coecient of I

Operating Temperature (°C )

Maximum System Voltage (V)

Limiting Reverse Current (A)

Maximum Series Fuse Rating (A)

MEMCM255AMC

255

37.9

9.10

15.5

29.6

8.67

-0/+5

MEMCM260AMC

260

40.0

9.20

15.8

29.8

8.77

-0/+5

Modules with corner caps

MEMCM240LMC

240

37.6

8.80

14.6

29.0

8.37

-6/+6

max

(%/°C)

oc

(%/°C)

sc

TEMPERATURE COEFFICIENTS AND PARAMETERS

Nominal Operating Cell Temperature (NOCT) (°C)

Temperature Coecient of P

Temperature Coecient of V

Temperature Coecient of I

Operating Temperature (°C )

Maximum System Voltage (V)

Limiting Reverse Current (A)

Maximum Series Fuse Rating (A)

Temperature coecients may vary by ±10% Temperature coecients may vary by ±10%

ELECTRICAL CHARACTERISTICS

Model #

Rated Maximum Power Pmax (W)

Open-Circuit Voltage Voc (V)

Short Circuit Current I

Module Eciency (%)

Maximum Power Point Voltage V

Maximum Power Point Current I

Power Range (W)

All electrical data at STC: 1000W/m2, AM1.5, 25ºC

Electrical characteristics may vary by ±5%

* Listed specications are preliminary and subject to change without prior notice.

(%/°C)

max

(%/°C)

oc

(%/°C)

sc

*

MEMCM240AMC

240

37.6

(A)

sc

8.80

14.6

(V)

mpp

mpp

(A)

29.0

8.37

-0/+5

(%/°C)

MEMCM250LMC

250

37.8

9.00

15.3

29.4

8.57

-4/+5

1,674 x 1,006 x 50

19.3

Mono-crystalline

60

Black Anodized Aluminum

Black Anodized Aluminum

3.2 Tempered ARC glass

*

46 ±2

-0.49

-0.35

+0.055

-40 to +85

600 (UL) & 1000 (IEC)

8.40

15

MEMCM260LMC

260

40.0

9.20

15.8

29.8

8.77

-5/+5

IV CURVES AT MULTIPLE IRRADIANCES* [25°C]

9

8

7

6

5

4

Current (A)

3

2

1

0

0

1000 W/m2

800 W/m

600 W/m

105

15 20 25 30 35 40

Voltage (V)

2

2

400 W/m

200 W/m

2

2

IV CURVES AT MULTIPLE TEMPERATURES* [1000 W/m

10

8

6

Current (A)

4

2

0

50 10 15 20 25 30 35 40

25°C

45°C

60°C

Voltage (V)

© Copyright 2012 MEMC Electronic Material

2

]

Installation Manual: MEMC Silvantis 60 cell PV Modules

8.0 APPENDIX

8.1 MODULE DETAILS

13 of 14

Dimension MM INCH Dimension MM INCH

Module Dimensions

A 990 39.0

B 1,658 65.3

C 50 2.0

D 40 1.6

Mounting Hole Spacing

E 940 37.0

F 1,608 63.3

G 994 39.1

H 594 23.4

Dimension MM INCH

Cable Length for AMA and AMC

L 1,000 39.4

Cable Length for ACA and ACC

L 1,300 51.2

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

8.0 APPENDIX

8.1A MODULE DETAILS M240/250/260LMA AND M240/250/260LMC SPECIFIC DIMENSIONS: INCH MM

14 of 14

Front View

8.2 MODULE ILLUSTRATIONS

Center Mount Option

Side View

Bolt Stack Details

© Copyright 2012 MEMC Electronic Material

Installation Manual: MEMC Silvantis 60 cell PV Modules

8.0 APPENDIX

8.3 PREMOUNTED CABLES AND CONNECTORS

Mounting Conguration Pre-mounted cables Pre-mounted connectors

Type TUV – PV1-F & UL – PV wire locking polarized connectors

Cross section 4.0 mm² 4 mm dia.

Max. current 16 A 25 A

Max. system voltage 1000 VDC/ UL 600 V 1000 VDC/ UL 600 V

Temperature rating -40°C to +90°C -40°C to +85°C

Qualication TUV 2PFG & UL PV wire EN 50521 & UL for PV sys

15 of 14

© Copyright 2012 MEMC Electronic Material Controlled Document - MEMC Electronic Materials, Inc. Void if Printed or Electronically

Duplicated. Information contained herein may not be revealed or disclosed to unauthorized persons or sent outside MEMC without prior

authorization. Match printed version to documentation database.

MEMC Electronic Materials, Inc. 501 Pearl Drive (City of O’Fallon) St. Peters, MO 63376 USA | 1-636-474-5000 | www.memc.com |

60-Cell Install Manual Q2_2012

© Copyright 2012 MEMC Electronic Material

Loading...

Loading...