Meltric SPeX Instruction Manual

A

COMPANY OF MARECHAL ELECTRIC

L1 L2 L3 N

L1 L2 L3 N

P1 P2

WARNING

ENGLISH OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

SPeX

©2020 MELTRIC Corporation. All rights reserved.

A manufacturer of products using Marechal technology

INSSPEX E

The supply of the pilot circuit must be protected

against transient over-voltages of 4 kV by means of an

appropriate isolating device. Follow the requirements

set forth by the ATEx classication. DO NOT ATTEMPT

TO TURN THE RING TOWARDS ‘‘1’’ WHEN THE

PLUG IS NOT ENGAGED.

Electrical interlocking with a contactor is mandatory.

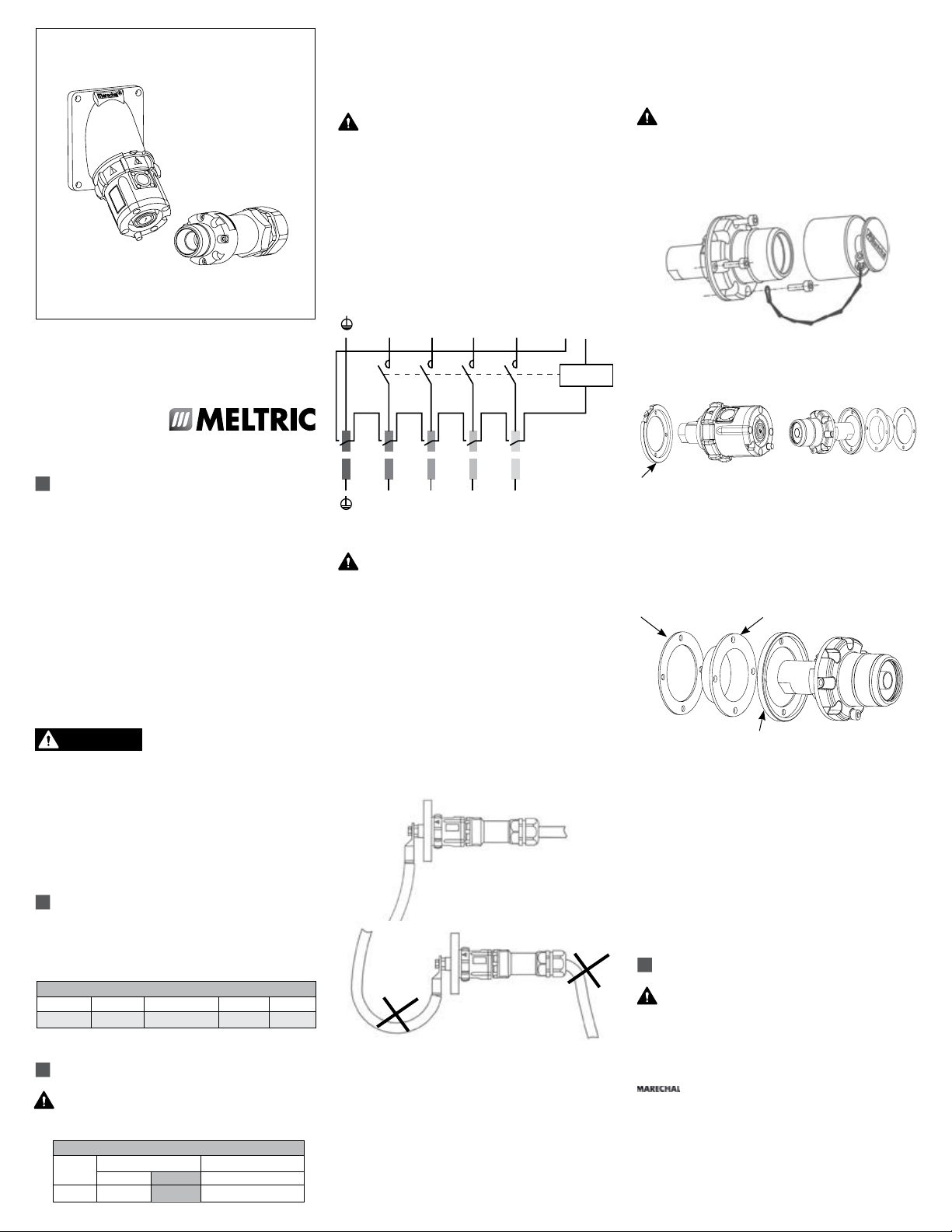

Assembly

Insert cable through the cable gland and the handle or

through the inclined sleeve.

Wiring of the pilot wires

Use exible conductors with a cross-sectional area

between 0.5 and 1 mm

NOTICE: These conductors must be connected to the

wires of the microswitch by means of the isolated crimping

lugs supplied. Use an appropriate crimping tool.

A typical pilot circuit wiring diagram is shown below.

L1 L2 L3 N

2

(16 to 20 AWG).

P1 P2

Assembly of the metal inclined sleeve.

Maintain air and creepage distances when assembling

the appliance inlet or the receptacle onto the metal

inclined sleeve, according to the operating voltage of

the main and auxiliary circuit and the degree of pollution.

The metal inclined sleeve must be grounded

to Earth.

Assembly of the plug/inlet cap

Place the lug located at the tip of the wire under one

of the mounting screws on the inlet side, or under the

screw provided under the receptacle side.

Color-coded rings

In order to achieve watertightness, do not forget the

color-coded ring at the rear of the inlet or receptacle.

GENERAL

The SPeX is a single-pole plug and receptacle for use

in explosive atmospheres and conforms to the relevant

international and European standards, particularly the

ATEx Directive 2014/34/UE. SPeX can be used in

zones 1 and 2 (gas) and 21 and 22 (dust).

In order to guarantee a connection and disconnection

in complete safety, the SPeX receptacle is tted with

an electromechanical device (switch + ring) for electrical

interlocking with a contactor (breaker) and an integral

pilot control circuit.

Receptacle contacts are protected against standard

test nger (IP2x/IPxxB) according to IEC/EN 60529

standard.

There are inherent dangers

ducts. Failure to follow safety precautions can result in serious injury or death. These instructions

must be followed to ensure the safe and proper

installation, operation and maintenance of the

MELTRIC devices. Before installation, disconnect all

sources of power to the circuit to eliminate the risk

of electrical shock. This product must be installed

with an electrical interlock that prevents connection or

disconnection in a loaded condition.

RATINGS

SPeX devices are provided with optional auxiliary

contacts that make after and break before the phase

contacts. The ratings for auxiliary contacts are shown

in Table 1.

Table 1 - Auxiliary Contact Ratings

Device 120VAC 240VAC 480VAC 600VAC

SPeX – 6A (220 max)* – –

* Rating is not UL or CSA listed.

INSTALLATION

SPeX must be installed by a qualied person in

accordance with all applicable local and national

electric codes. Be sure power is off before starting.

Table 2 - Wiring Terminal Capacity

Main Contacts Aux. Contacts

Max Min

SPeX 750 MCM 2/0 12-14 AWG

associated with electrical pro-

L1 L2 L3 N

Wiring of the main conductor

Wire the main conductors within the amperage

and hazardous duty requirements of the ATEX

(T5) classication. The cross-section must be at least

that dened in the certicate or the CE Declaration of

Conformity, depending on the maximum current.

Strip the conductor by 1.8” (46 mm). Crimp the

threaded lug or the ferrule with the appropriate die

(NFC 20-130 or VDE 0220 or another). Hexagonal

crimping is recommended.

Tighten the threaded lug with a 24 mm wrench or

tighten the ferrule with a screw and a washer with a

19 mm wrench. Apply a torque ca. 95 ft-lbs (70 N.m).

While tightening the ferrule, prevent the contact from

rotating or transmitting torque to the device with a 24

mm wrench.

Assembly of the connector

Assemble the handles on the body of the products

with the supplied gaskets and screws and tighten the

cable gland with an appropriate tool. To achieve the

IP65/IP66 of an interlocked connector, use a cable that

incorporates the two pilot wires that are required for the

interlock, or use an ATEX cable gland bushing that allows

the passage of the main cable and the two pilot cables.

The silicone ring must be assembled on the receptacle

ring.

Color-coded ring

The color-coded rings allows visual identication of

the pole depending on the color code of each country.

Place the color coded gasket between the inlet or

receptacle and its rear accessory or panel.

Isolating ring

Flat gasket Isolating ring

Color-coded ring

When assembling the SPeX on a metallic support

(enclosure, panel, etc.), the isolating ring must be

positioned as above. Be sure to use the black at

gasket, which guarantees the watertightness, between

the isolating ring and the accessory.

Receptacles, plugs, connectors and inlets are protected

against dust and water ingress by means of caps,

which must be re-assembled after use.

To achieve IP65/IP66, the receptacle or connector cap

must be assembled with its slot facing the socket-outlet

protruding nger.

OPERATION

To ensure safe and reliable operation, MELTRIC

plugs and receptacles must be used in accordance

with their assigned ratings.

They can only be used in conjunction with mating

receptacles or plugs manufactured by MELTRIC or

another licensed producer of products bearing the

TM

technology trademark.

1 Insert the plug straight into the receptacle, until a

WARNING

Type

Type

Marquage

Marking

C

aractéristiques d’étanchéité

W

atertightness characteristic

s

Conforme aux normes suivantes

Complies with the following stan

dards

LCIE 07 ATEX 6073 X

‘click’ is heard. NOTICE: The plug and its exible

cable must not exert constraint on the receptacle.

2 Pull on the plug to make sure it is properly

latched in the receptacle. A small rotation of the

plug, in either direction, allows the locking nger of the

receptacle to prevent any further rotation.

MAINTENANCE

Any repair or service must be achieved with genuine

Before inspecting, repairing, or

maintaining MELTRIC products,

MANUFACTURER’S RESPONSIBILITY

disconnect electrical power to the receptacle to eliminate

the risk of electrical shock. Rules applying to products

for use in explosive atmospheres impose that any

replacement of component must be performed under

the control of the manufacturer: MELTRIC Corporation.

MELTRIC’s responsibility is strictly limited to the

repair or replacement of any product that does not

conform to the warranty specied in the purchase

contract. MELTRIC shall not be liable for any

penalties or consequential damages associated with

MELTRIC products require little on-going maintenance.

However, it is a good practice to periodically perform

the following general inspections:

• Check the mounting screws for tightness.

• Verify that the weight of the cable is supported

by the strain relief mechanism and not by the

terminal connections.

• Check the IP gaskets for wear and resiliency.

Replace as required.

• Verify the electrical continuity of the ground circuit.

• Check the contact surfaces for cleanliness

and pitting.

the loss of production, work, prot or any nancial loss

incurred by the customer.

MELTRIC Corporation shall not be held liable when

its products are used in conjunction with products not

bearing the

devices that are not marked with the

technology trademark shall void all warranties on

the product.

MELTRIC Corporation is an ISO 9001 certied company. Its

products are designed, manufactured and rated in accordance

with applicable UL, CSA and IEC standards. MELTRIC designs

and manufactures its products in accordance with Marechal key-

ing standards established to ensure intermatablility with similarly

rated products manufactured by Marechal Electric Group.

Use a clean cloth to rub off deposits of dust or similar

foreign materials on the contacts and the plug interiors.

Sprays should not be used, as they tend to collect dirt.

If any signicant pitting of the contacts or other serious

damage is observed, the device should be replaced.

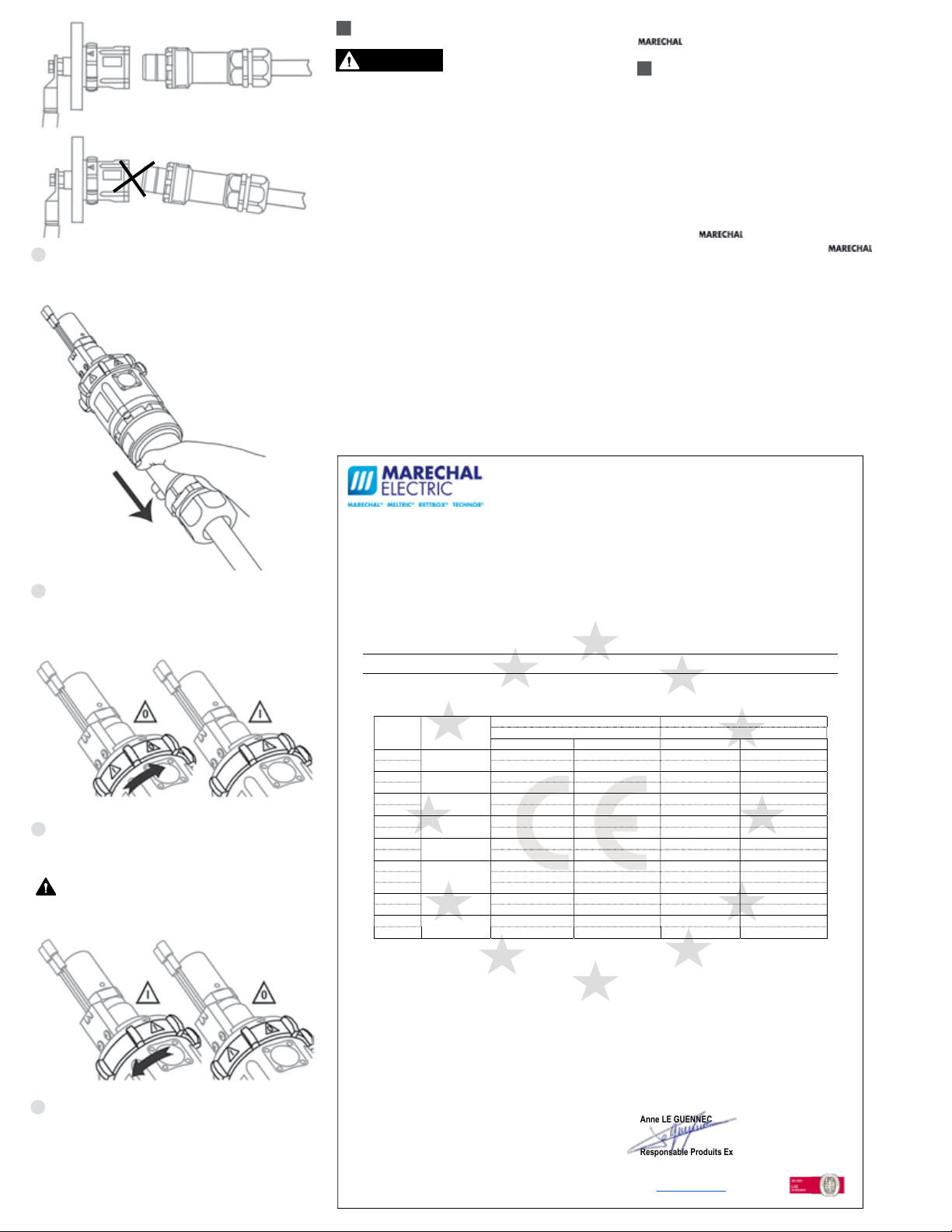

Déclaration UE de Conformité

EU Declaration of Conformity

Nous / We

MARECHAL ELECTRIC S.A.S.

5, avenue de Presles

F-94417 SAINT-MAURICE Cedex – France

Tel : +33 (0)1 45 11 60 00

Fax : +33 (0)1 45 11 60 60

E-mail : contact@marechal.com

Déclarons sous notre seule responsabilité que le produit / Declare under our sole responsibility that the product:

Connecteur unipolaire de puissance / Single-pole power Connector

TM

parts only.

TM

technology trademark. The

TM

3 To close the pilot circuit, turn the ring of the receptacle

up to the stop towards “1”.

Check the continuity of the pilot.

Do not attempt to turn the ring toward “1” when

there is no plug engaged. Defeating the mechanical

lock could create a potentially hazardous or explosive

condition if energized under load.

4 To open the pilot circuit and unlock the plug, turn

the ring back to “0” up to the stop. Press on the

button to release the plug. The caps must then be

re-assembled on both sides.

SPeX

Intensité /

Current

A

235

290 T5 / T56°C /

335

415 T5 / T56°C /

376

456 T5 / T56°C /

415

493 T5 / T56°C /

450

530 T5 / T56°C /

497

570 T5 / T56°C /

584 T5 T4 T59°C T79°C

540

620 T5 / T56°C /

600

680 T5 / T56°C /

(*)

: Une étude comparative des normes: EN 60079-0 (versions 2018, 2012 + A11:2013 et 2009), EN 60079-7 (2007 et 2015) et EN 60079-31 (2014 et 2009) montre que le matériel

n’est pas concerné par les modifications substantielles.

A comparative study of the standards: EN 60079-0 (version 2018, 2012 + A11: 2013 and 2009), EN 60079-7 (2007 and 2015) and EN 60079-31 (2014 and 2009) shows that

the products are not concerned by the substantial modifications.

Satisfont aux dispositions des Directives du Conseil n° : 2014/34/UE du 26 février 2014 (ATEX)

2011/65/UE + amendement n°2015/863 du 31/03/2015 (RoHS)

Satisfy the measures set in the Council Directives n°: 2014/34/EU dated February 26, 2014 (ATEX)

2011/65/EU + amendment no 2015/863 dated 2015/03/31 (RoHS)

N° de notification de l’évaluation relatif à la qualité : LCIE 00 ATEX Q 8001 selon l’Annexe IV réalis é par l’organisme notifié n° 0081 :

LCIE – 33, avenue du Général Leclerc – 92260 Fontenay-Aux-Roses – France

Quality Assessment Notification Number: LCIE 00 ATEX Q 8001 according to Annex IV carried out by Notified Body N° 0081:

LCIE – 33, avenue du Général Leclerc – 92260 Fontenay-Aux-Roses – France

Saint-Maurice, 2019-10-25

Anne LE GUENNEC

Responsable Produits Ex / Manager of Ex-Proof Product

MARECHAL ELECTRIC S.A.S. au capital de 5 341 400 € - SIRET 552 149 577 00058 - NAF 2733Z – N° TVA FR16552149577

5, avenue du chemin de Presles 94410 Saint-Maurice FRANCE - +33 (0)1 45 11 60 00 - contact@marechal.com

II 2 G D

Ex e IIC T Gb, Ex tb IIIC T Db

Section / Secti on

mm²

70

95

120

150

185

240

300

400

Classe de température pour / Temperature class for: Température de surface / Surface temperature for:

-20°C ≤ Ta ≤ + 40°C -20°C ≤ Ta ≤ + 60°C -20°C ≤ Ta ≤ + 40°C -20 °C ≤ Ta ≤ + 60°C

GAZ / GAS POUSSIERES / DUST

T6 T5 T56°C T76°C

T6 T5 T56°C T76°C

T6 T5 T56°C T76°C

T6 T5 T56°C T76°C

T6 T5 T56°C T76°C

T6 T5 T56°C T76°C

T6 T5 T56°C T76°C

T6 T5 T56°C T76°C

IP65/IP66

EN IEC 60079-0 : 2018(*)

EN 60079-7 : 2015 (*)

EN 60079-31 : 2014 (*)

INSSPEX E

Loading...

Loading...