OPERATING INSTRUCTIONS

WARNING

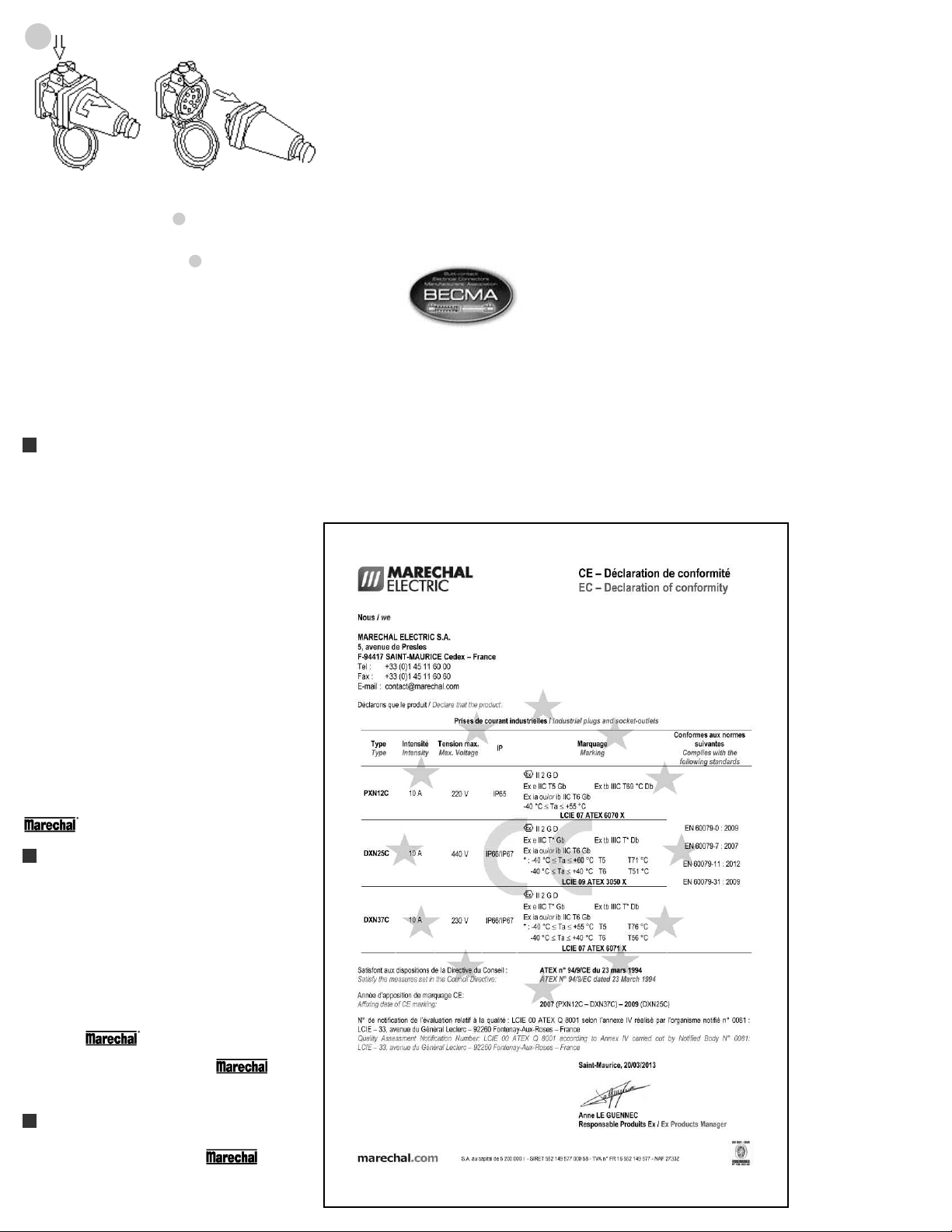

PXN12c

DXN25c

DXN37c

INSPXNDXNMULTI E

Meltric Corporation / 4640 Ironwood Drive Franklin, WI 53132

el. : 800 433 7642 / Fax : 414 817 6161 / e-mail : mail@meltric.com

T

manufacturer of products using M arechal technology

A

eltric.com

m

. Contacts can be soldered or crimped. If

1

rimping, crimp the contact with a KNIPEX

c

rimping tool part # 61-CA500 or a GREENLEE

c

rimping tool part # 45505. Use the 4 mm

c

footprint whatever the conductor cross-section.

erform a double crimping with a 90° rotation, in

P

ompliance with IEN 60352-2.

c

. Prior to soldering or crimping a heat shrink

2

sleeve (supplied- part # 9CP0250) must be

lipped over each conductor or alternatively an

s

insulating sleeve (supplied - part # 9SES201007301)

an be used but the insulating sleeve must be

c

nstalled using sleeve tool 61-CA500 (sold

i

separately).

. If soldering use tin solder and a 50 W soldering

3

iron. Insert the conductor in the terminal and

eat the terminal for about 30 s. During heating,

h

insert the solder wire in the hole at the foot of the

erminal and let the solder penetrate by capillary

t

ction. Let the terminal cool without any tension

a

on the conductor.

2

eltric plugs & receptacles can only be used in

M

onjunction with mating receptacles or plugs

c

anufactured by Meltric or another licensed producer

m

f products bearing the

o

trademark. WARNING: PXN12c/DXN25c/DXN37c

lugs and receptacles must be operated in

p

ompliance with its explosion-proof classifications.

c

hen not in use, the receptacle is shielded by a

W

protective lid preventing the entry of dust and

oisture.

m

his is held in the closed position by one or two

T

atch(es). To release the spring-loaded lid, depress

l

the latch(es).

DXN25c/DXN37c

TM

echnology

t

1

2

GENERAL

PXN12c/DXN25c/DXN37c plugs and receptacles

comply with international and European safety rules

and particularly with ATEX 94/9/CE Directive.

PXN12c/DXN25c/DXN37c products can be used in

zones 1, 2 (Gas), and 21, 22 (Dust).

There are inherent dangers

products. Failure to follow safety precautions can

result in serious injury or death. These instructions

must be followed to ensure the safe and proper

installation, operation and maintenance of the Meltric

devices. Before installation, disconnect all sources of

power to the circuit to eliminate the risk of electrical

shock. It is imperative that Meltric explosion-proof

multicontact plugs and receptacles are connected or

disconnected without a load in a de-energized state.

INSTALLATION

PXN12c/DXN25c/DXN37c plugs and

receptacles must be used in conjunction with

other appropriately rated hazardous duty

products and must be installed by qualified

electricians in accordance with all applicable

local and national electrical codes.

Assembly

Optimum operating conditions are achieved by

installing PXN12c/DXN25c/DXN37c plugs and

receptacles with the latch at the top.

Wiring

Before starting, verify that the power is off, that

the product ratings are appropriate for the

application, and the conductors meet code

requirements and are within the capacities of

the terminals noted in Table 1.

Table 1 — Wiring Terminal Capacity* (in AWG)

Device Min Max

DXN25c 16 14

DXN37c 16 14

PXN12c 16 14

The maximum cross-section of the conductors is

4934 CM (2.5 mm

must be stripped by .315 in (8 mm).

associated with electrical

Contacts

2

) (solid or flexible). Conductors

4. Slip the heat shrink or insulating sleeve over the

whole visible part of the contact, down to the molding.

5. Slide the heat-shrink sleeve up to the shoulder of

the contact. With a heat gun, apply heat evenly

370° around the sleeve until it shrinks around the

terminal and wire.

NOTICE: For a proper clamping, the use of PVC

cables is not recommended.

WARNING: This product must be electrically

grounded to Earth. A grounding terminal is provided

on all metal accessories.

Contact Assembly/Disassembly

Once wired, contacts must be inserted through the

rear of the interior moulding 1. Push each contact

fully home. Check its proper engagement by a light

pull 2. Contacts can be removed with the supplied

tool: insert the tool through the front 3 and push fully

home 4. Tool part # 9-LD12-37.

Contact

Tool

Contact Configurations

This is in reference to different keying positions on the

PXN12c. If or when 2 contacts are not in use, 9

different contact/keying configurations can be achieved

by plugging the contact holes not in use with the hole

plugs supplied.

OPERATION

To ensure safe and reliable operation, Meltric

plugs and receptacles must be used in

accordance with their assigned ratings.

3

4

To connect, align the plug bayonets with the hollow

part of the receptacle. Insert the plug and turn until

the stop. The plug is in the rest position, circuit is

open, figure 1. Push the plug fully home until

latched, figure 2. To disconnect, depress the latch.

The plug returns to its rest position, figure 3. Turn

the plug in the opposite direction to remove it. Shut

the receptacle lid, figure 4.

PXN12c

5

6

o connect, align the plug bayonets with the hollow

T

arts of the receptacle (if any, use the two red marks

p

as a visual indication), figure 5. Push the plug in and

urn counter-clockwise; the circuit is closed figure 6.

t

o disconnect, press the latch, push the plug and turn

T

it clockwise to withdraw it figure 6. Close the lid.

ockout Provisions

L

ARNING: It is imperative to lock out PXN12c/

W

DXN25c/DXN37c plugs and receptacles after

connection or disconnection.

A mechanical locking device on receptacle latches, by

means of either a padlock(s) or by a specific screw

revents any accidental disconnection under load.

p

AINTENANCE

M

WARNING: Before inspecting, repairing, or main-

taining Meltric products, disconnect electrical power

to the receptacle to eliminate the risk of electrical shock.

Rules applying to products for use in explosive

atmospheres require that any replacement of

components must be performed under the control of

the manufacturer: Meltric Corporation.

irectives, and particularly of the European ATEX

d

irective. They bear the CE marking whenever

D

pplicable. They also bear the markings of their

a

xplosion-proof classification.

e

eltric Corporation is an ISO 9001 certified company.

M

Its products are designed, manufactured and rated in

ccordance with applicable UL, CSA and IEC

a

standards. Meltric is also a member of BECMA, the

nternational Butt-contact Electrical Connectors

i

anufacturers’ Association. Like all members, Meltric

M

M

T

additionally designs and manufactures its products in

ccordance with BECMA standards established to

a

nsure intermatablility with similarly rated products

e

manufactured by other members.

From time to time, the fastening screws should be

checked for tightness. Care should be taken that the

weight of the cable is taken by the glanding

arrangement and not the terminals themselves.

Contact surfaces may be checked for cleanliness.

Any deposit of dust can be rubbed off with a clean

cloth. Sprays should not be used, as they tend to

collect dirt. Depending on prevailing conditions, the

pitting of plug and socket contacts should be regularly

monitored. In the event of serious damage, contact

your supplier to have the contacts replaced.

IP gaskets between plug and receptacled bodies

should be inspected periodically.

Any repair or service must be achieved with genuine

parts only.

MANUFACTURER’S RESPONSIBILITY

Meltric’s responsibility is strictly limited to the repair or

replacement of any product that does not conform to

the warranty specified in the purchase contract.

Meltric shall not be liable for any penalties or

consequential damages associated with the loss of

production, work, profit, or any other kind of financial

loss incurred by the customer.

Meltric Corporation shall not be held liable when its

products are used in conjunction with products not

bearing the

use of Meltric products in conjunction with mating

devices that are not marked with the

TM

technology trademark. The

TM

technology trademark shall void all warranties on the

product.

DECLARATION OF CONFORMITY

PXN12c/DXN25c/DXN37c use the

TM

technology. They have been designed, manufactured

and controlled in a strict respect of the relevant

international and European standards, laws and

INSPXNDXNMULTI E

Loading...

Loading...