Meltric INDUSTRIAL PLUGS & RECEPTACLES Catalog

PRODUCT CATALOG

INDUSTRIAL PLUGS & RECEPTACLES

• SWITCH-RATED PLUGS & RECEPTACLES

• HAZARDOUS LOCATION PLUGS & RECEPTACLES

• CUSTOM POWER DISTRIBUTION PANELS

• HIGH AMPERAGE CONNECTORS

• MULTIPIN CONNECTORS

meltric.com

INDUSTRIAL PLUGS & RECEPTACLES

• Introduction

MELTRIC Overview pg 3

Product Features & Benefits pg 5

Product Summary & Selection Guide pg 9

Part Number & Ordering Guide pg 15

• Switch-Rated Plugs & Receptacles

The Main Differences pg 17

Selection Guide pg 21

DSN

Type 4X/IP69/IP69K rated, metal or poly casings. From 20 – 150 A (1/2 – 75 hp) pg 25

DS

Type 3R rated, metal or poly casings. From 20 – 200 A (3/4 – 100 hp) pg 39

• Multipin Plugs & Receptacles

Multipin

4 – 37 pin connectors in poly and metal. From 2 – 50 A pg 57

• Standard Duty Plugs & Receptacles

DR

Type 3R rated, poly or metal casings. From 30 – 400 A pg 81

PN

IP66/IP67 rated or IP55 rated, poly or metal. 20 A pg 101

High Temp

For environments up to 465°F (240°C) pg 109

• Direct Current Plugs & Receptacles

DSDC

DC current rated, poly or metal casings. From 20 - 200 A (up to 750 VDC) pg 113

• High Ampacity Plugs & Receptacles

PF/PFQ

IP66/IP67 rated, metal construction. From 300 – 600 A pg 119

DR400

Type 3R rated, metal casings. 400 A pg 127

SP

Single pole, connectors up to 600 A pg 131

CS1000

Single pole, connectors up to 400 A pg 135

1

• Power Distribution

Custom Power Distribution Solutions

Built specifically to meet customer needs pg 141

Integral Circuit Protection Wall Boxes

Premounted receptacles wired to circuit protection 20 - 60 A pg 147

GFCI Combinations

Premounted receptacles wired to GFCI boxes 20 - 100 A pg 155

Safety Switch/Receptacle Combinations

Switch-rated receptacles mounted to single throw, fusible safety switch pg 157

• Specialty Products

WS – Welding Connectors

Single pole connectors (max 50 VAC) pg 161

Adapter Plates

For converting existing receptacles to MELTRIC pg 162

Cord Grips pg 165

Voltage/Phase Rotation Meter Assemblies pg 167

• Hazardous Location Plugs & Receptacles

Hazardous Duty Selection Guide pg 169

DXN

Hazardous rated, poly casings. From 20 – 60 A (1/4 – 20 hp) pg 173

DXA

Hazardous rated, metallic casings. 20 A pg 185

DSN/DS/DR/DSDC

Hazardous rated, metallic casings. 2 – 250 A (up to 100 hp) pg 189

DX

Hazardous rated, metallic casings. From 20 – 125 A pg 211

Multipin

Hazardous rated, 12 to 37 pins. 10 A pg 221

SPeX

Hazardous rated, up to 680 A, 1000VAC pg 227

• Reference

Accessories/Option pg 233

Technical Manual pg 243

Suffixes Quick Reference Guide pg 259

Old/New Accessories References pg 261

Parts Index pg 265

2

MELTRIC Corporation

The best in industrial wiring devices

At MELTRIC Corporation, our only business

is electrical plugs and receptacles. We are

focused on providing our customers with

the best overall value by offering the safest,

Product Technology & Safety

The technology behind MELTRIC’s products was developed

specifically to address the shortcomings and safety hazards

common with pin & sleeve type plugs and receptacles. In

1952, following the observation of an accident with a pin

and sleeve device, Gilles Marechal devised the concept of

combining the advantages of silver-nickel butt contacts and

the load making and breaking capabilities of a switch with

the convenience of a plug and receptacle. Shortly thereafter,

the first of these products was born. MELTRIC licensed this

technology in the early 1980’s and has been supplying its

products to North American customers ever since.

highest quality and most reliable plugs and

receptacles, and by backing them with

outstanding service and support.

Value

With their unique features and capabilities, MELTRIC products

provide users with a safer and more reliable product than

competitive pin and sleeve devices. MELTRIC’s butt-style

contacts provide longer operating lives, optional integral pilot

contacts reduce the need for additional connectors and our

switch-rated plugs and receptacles can eliminate the need

for auxiliary interlocks and disconnect switches, helping

users reduce equipment costs. These advantages, together

with competitive pricing, short lead times, and 5-year

warranty on electrical contacts, make MELTRIC’s products

the best overall value in the plug & receptacle/connector

market.

3

Service & Support

MELTRIC backs its superior products with outstanding service and support. A network of over 150 sales associates and over 2000

distributor locations throughout the US, Canada and Mexico make access to our product easy.

MELTRIC’s Customer Service group is trained to answer most questions on the spot and is located at our manufacturing

facility in order to help streamline the order fulfillment process. Our engineering team stands ready to provide both

application support and custom designed products incorporating MELTRIC and third party components into power distribution

products tailored to meet your needs. Friendly and personal assistance is only a toll free call away at (800) 433-7642.

Many of MELTRIC’s products are designed in a modular fashion, which permits cost effective stocking of components and

quick final assembly of the product. Together with efficient order handling by Customer Service, this helps MELTRIC to

provide the shortest lead times in the industry.

Quality

Quality is not just an inspection function at MELTRIC.

Quality starts with intelligent designs, robust materials,

clear procedures, process measurement and controls and

effective communications. It is completed by the care,

commitment and involvement of each of our employees.

MELTRIC is dedicated to the continuous improvement of

all its critical production and support processes and is ISO

9001:2015 certified. MELTRIC designs and manufactures

its products to exceed the requirements of applicable UL,

CSA and IEC standards.

Worldwide Availability

Marechal Technology products are

manufactured in North America,

Europe, South Africa and Australia.

MELTRIC supplies product directly from

its factory in Franklin, Wisconsin to

customers in the United States, Canada

and Mexico. For customers outside

of North America, product is provided

through other Marechal Electric Group

companies and sales agents.

SALES OFFICES & MANUFACTURING PLANTS

COMPANY SALES PRESENCE

SALES AGENTS & DISTRIBUTORS

4

MELTRIC PRODUCT FEATURES...

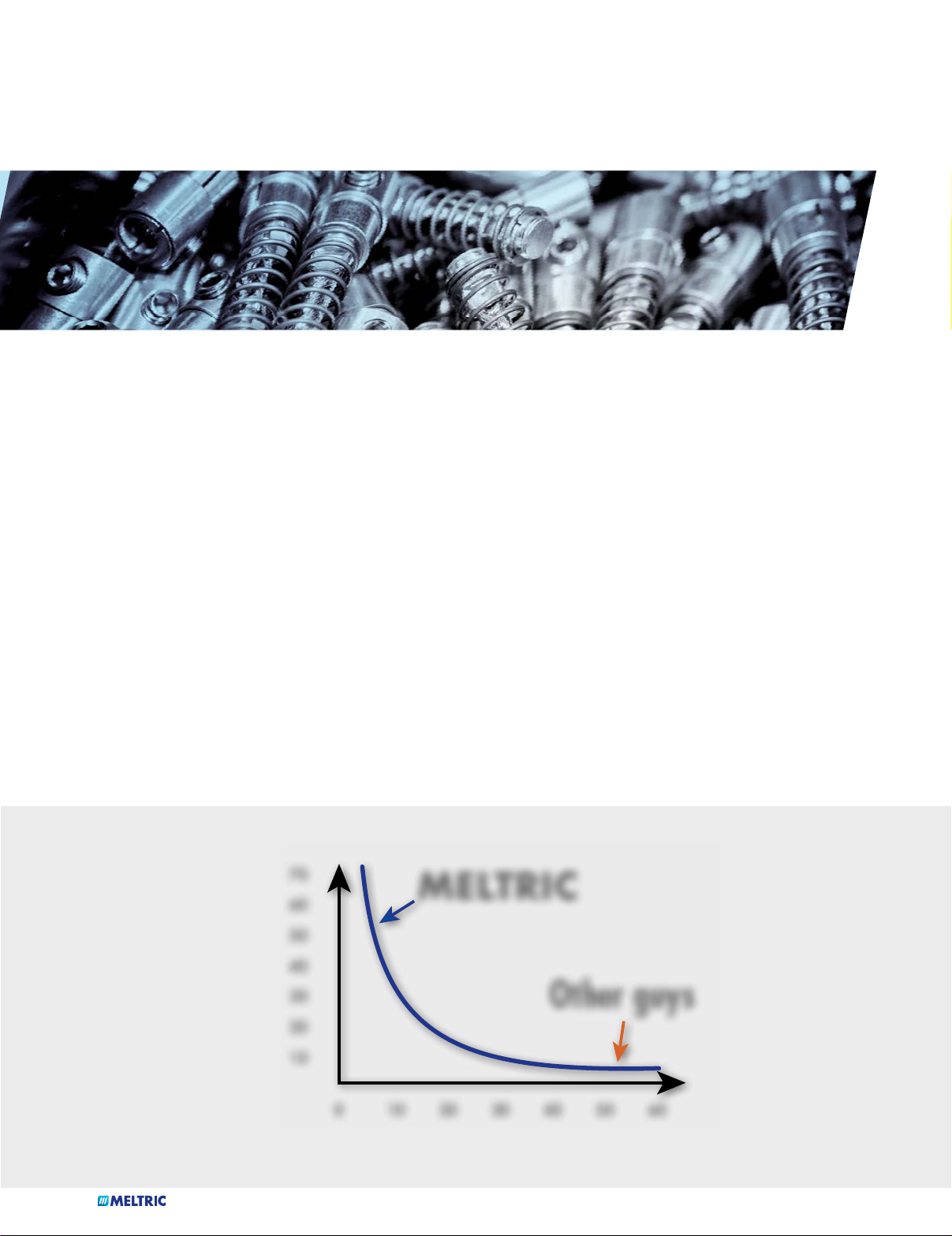

0 10 20 30 40 50 60

70

60

50

40

30

20

10

Other guysOther guys

MeltricMeltric

Spring-Loaded Butt Contacts

MELTRIC products feature spring-loaded, butt contacts

similar to those used in contactors and switchgear. These

contacts have numerous advantages, which help improve

electrical performance and user safety relative to pin and sleeve

contacts or the arcuate contacts used in twist-type devices.

Butt-style contacts ensure a very positive and consistent

connection. The spring-loading of these contacts, which is

accomplished with coil springs, provides a desirably high

contact force that remains constant over thousands of

operations. In addition, it automatically compensates for

any wear and/or deviations in contact length resulting from

manufacturing tolerances.

This is a critical point, as contact force is a key determinant

of the quality of a contact. As the accompanying chart

demonstrates, contact resistance increases as contact force

is reduced. Higher contact resistance generates more heat

70

60

50

and oxidation, both of which contribute to the deterioration

of the contact. This is a problem with pin and sleeve and

arcuate type contacts because their contact force varies with

manufacturing tolerances and is reduced due to wear that

occurs with normal use.

Most MELTRIC contacts close with a self-cleaning wiping

action. When the contacts initially mate, they are slightly

offset. In completing the connection, the plug contacts are

rotated across the receptacle contacts, helping to remove

deposits from the contact surfaces.

In conjunction with the ejection springs used on many

MELTRIC products, the spring-loaded contacts ensure a

quick breaking of the connection that is independent of the

motion of the user. By contrast, the disconnection speed of

pin and sleeve and twist-type devices is dependent upon the

motion of the user.

MELTRIC

40

30

(Force)

20

Contact Pressure

10

0 10 20 30 40 50 60

Other guys

Contact Resistance

5

...AND BENEFITS

Silver-Nickel Contact Material

MELTRIC uses solid silver-nickel (85%/15%) contacts. The

silver-nickel material has significant advantages over the

brass contacts commonly used on competitive devices.

Silver has very low initial contact resistance and is not negatively

affected by oxidation. This helps to give it excellent electrical

properties that are maintained even at high temperatures

and after tarnishing. Nickel is a much harder material and

contributes excellent mechanical properties. The combination

of silver and nickel results in a contact material that has both

superior electrical capabilities and excellent resistance to

wear. Silver-nickel only welds at extremely high pressure

and temperature, and thus, also withstands arcs very well.

These features make silver-nickel a commonly used contact

material by switchgear manufacturers.

By contrast, the brass material used in most competitive plug

and receptacles has a much higher initial contact resistance

and is negatively affected by oxidation. In an oxidized state,

the contact resistance of brass is more than 20 times higher

than that of silver-nickel. In addition, brass is a soft material

that wears rapidly. In use, brass pin and sleeve and arcuate

contacts suffer from the combined effects of the limitations

of the material and the design. As oxidation and wear

induced reductions in contact force occur, contact resistance

increases. This increases operating temperature, which

causes further oxidation and wear, perpetuating a vicious

cycle of degradation. Brass is not arc resistant and is not

suitable for making and breaking under load.

MATERIAL CONTACT RESISTANCE

NEW OXIDIZED

SILVER

SILVER-NICKEL

COPPER

BRASS

μΩ 25 μΩ

6

23

μΩ 60 μΩ

29

μΩ 400 μΩ

370

μΩ 1400 μΩ

Dead Front Construction

Most MELTRIC products feature dead front construction,

which greatly enhances safety by eliminating any unintended

access to live parts. On most MELTRIC products, the dead front

is accomplished with a safety shutter that can be opened only

by an appropriate mating plug. The live receptacle contacts

can only be accessed by the plug, after its insertion into the

receptacle. The design of the product also ensures that the

plug contacts are dead before the user can remove the plug

from the receptacle.

By contrast, pin and sleeve and twist-type devices do not have

a safety shutter. Access to live receptacle contacts is possible,

and on some devices the plug contacts may be live and

accessible when the plug is being removed.

6

MELTRIC PRODUCT FEATURES...

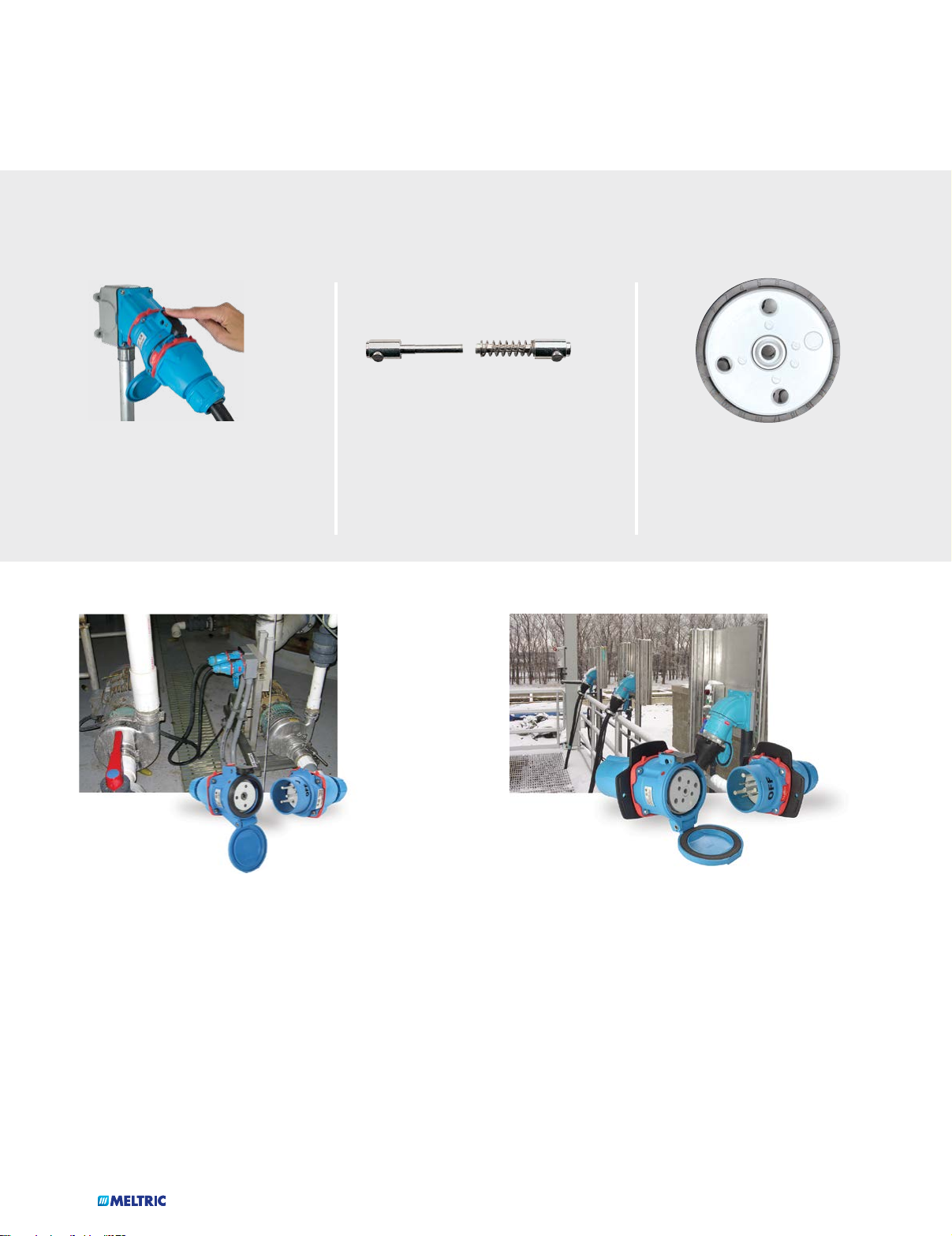

Push-Button Circuit Disconnection

To disconnect most MELTRIC products, the user simply needs

to press the pawl. This causes the circuit to be disconnected and

the plug to be ejected to its rest (off) position in the receptacle. If

desired, the user can then remove the plug from the receptacle

by rotating it slightly and then withdrawing it. This mode of

operation ensures that it is only possible to remove the plug

after its contacts have been de-energized.

Enclosed Arc Chambers

The contacts on most MELTRIC products make and break

within enclosed arc chambers. This ensures that the arcing

which normally occurs during the making and breaking of the

contacts is contained inside the device. This greatly enhances

safety and avoids potential injury to users and/or harm to the

outside environment.

Optional Auxiliary/Pilot Contacts

Many MELTRIC products are available with optional auxiliary/

pilot contacts. These integral pilot contacts allow users the

convenience and flexibility of controlling auxiliary equipment,

monitoring parameters (such as motor temperature), and/or

communicating alarms through the same plug and receptacle

used to supply power to the equipment. Because the pilot

contacts are integral, they also facilitate the rapid change-out

or reconfiguration of equipment by eliminating the need for

hard wiring or multiple plug connections.

Automatic Watertightness

On most pin and sleeve devices, an additional plastic ring

must be tightened in order to ensure the achievement of rated

watertightness. Users frequently fail to do this, resulting in

leakage. MELTRIC solves this problem with its DS and DSN

Switch-Rated plugs and receptacles, which achieve their rated

watertightness of up to Type 4X/IP69/IP69K simply by mating

the plug with the receptacle. After the removal of the plug,

rated watertightness is maintained for the receptacle by simply closing the lid.

Auxiliary/Pilot

Contacts

7

...AND BENEFITS

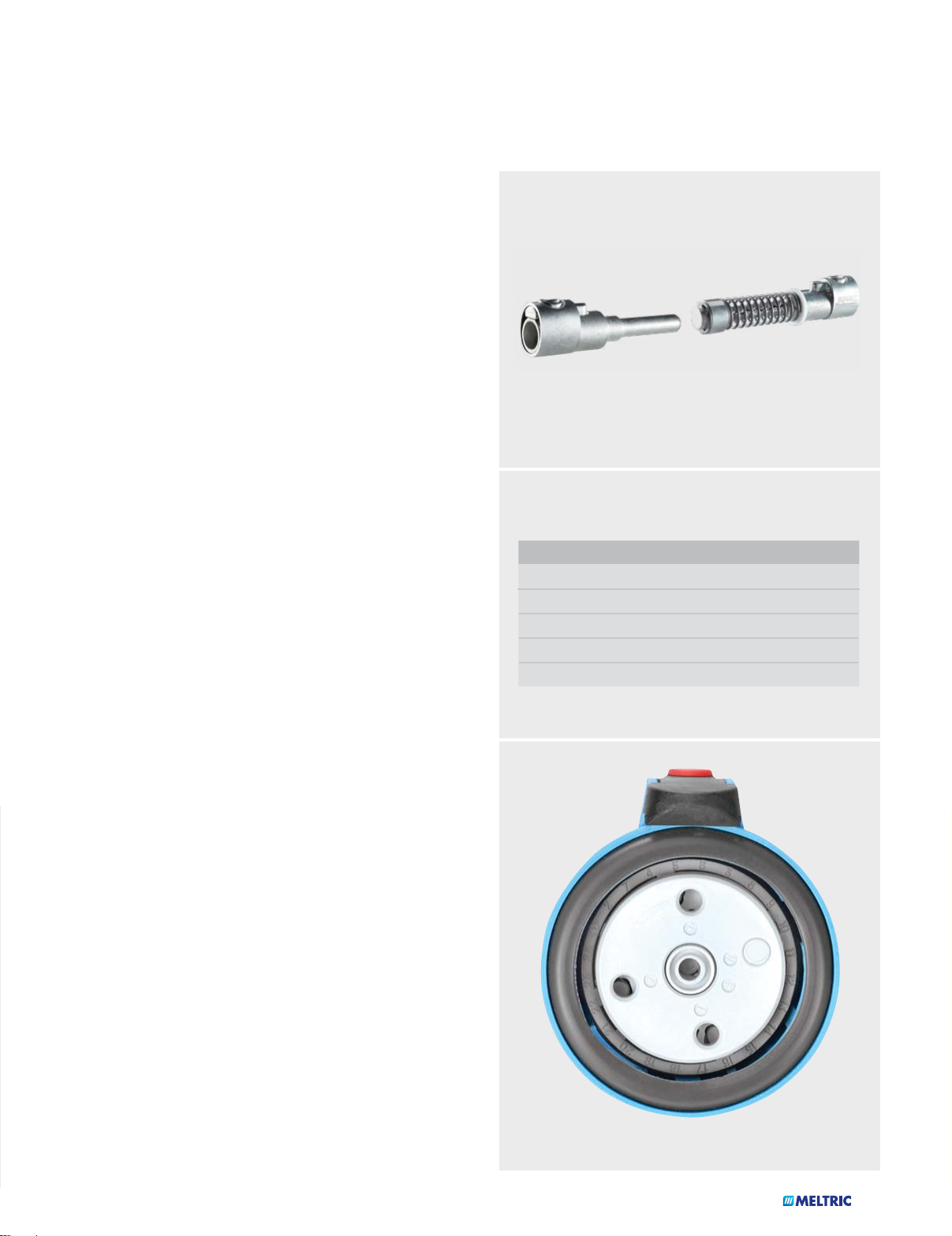

Spring-Assisted Terminals

The loosening of terminal screws is a common cause for failure

on standard plugs and receptacles. MELTRIC provides a more

permanent and secure connection with its unique and patented

spring-assisted terminal design.

As the terminal screw is tightened against the conductor, the

associated pressure expands the split terminal body, causing a

spring ring surrounding the terminal to deform into an elliptical

shape. The natural tendency for the spring ring to return to

its original size and shape ensures that a constant pressure

is maintained on the conductor. This allows the terminal to

effectively compensate for strand settlement and conductor

yield, due to cold flow of the material, and provides superior

resistance to vibration, shock and thermal cycling.

Lockout-Tagout Capability

SPLIT TERMINAL

(allows constant force)

ELLIPTICAL

DEFORMING RING

(prevents loosening)

CONDUCTOR

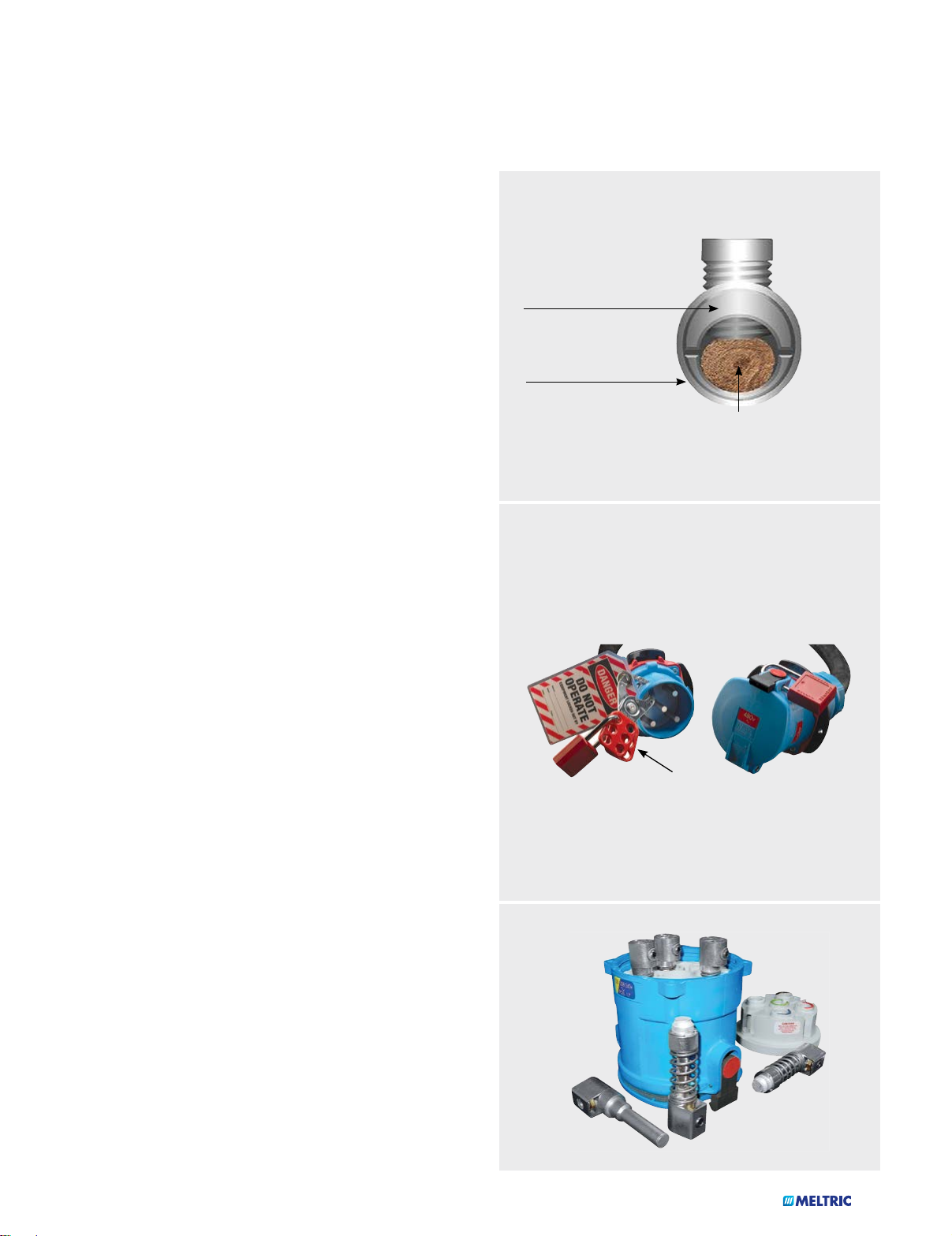

Most MELTRIC plugs and receptacles facilitate compliance

with OSHA lockout-tagout requirements. Only a lock or lockout

hasp and tag are needed to ensure that the plug is properly

locked out and tagged out. Additional mechanisms are not

required because the lockout provision is integral to the device

– it is always available when you need it. On most models the

lockout provision is a simple 5/16” hole in the plug shroud that

facilitates the insertion of a typical padlock or lockout hasp

which prevents the plug from being inserted into a receptacle.

An optional provision for locking out MELTRIC receptacles is

also available. In most cases this is accomplished via a specially

machined hole in the receptacle casing which allows insertion

of a padlock to secure the receptacle lid in a closed position.

This same optional provision can be used to prevent removal

of the plug if desired.

By comparison, in order to lockout most competitivepin and

sleeve type plugs, an additional third-party ‘lockout shield or

‘plug cap’ is required. These devices can be expensive and are

often times lost, broken, or not available when you need them.

Modular Construction

Due to the robust construction of MELTRIC devices, the

need to replace worn parts is rare. However, should they be

required, parts are readily available and reasonably priced.

The modular construction of most MELTRIC devices enables

easy replacement of parts in the field.

LOCKOUT HASP

8

MELTRIC PRODUCT SUMMARY...

Model

Amp

Rating

Maximum

Voltage Rating

Environmental

Ratings

Available Casing Materials

Maximum Number of

Contacts

VAC VDC Type IP Poly Metal SS Main Aux.

DSN20 20 600 - 4X 69/69K Poly - - 3P+N+G 2**

DSN30 30 600 - 4X 69/69K Poly - - 3P+N+G 2

DSN60 60 600 - 4X 69/69K Poly - - 3P+N+G 4

DSN150 150 600 - 4X 69/69K Poly Metal - 3P+N+G 6

DS20 20 600 -

DS30 30 600 -

DS60 60 600 -

DS100C 100 600 -

DS100 100 600 -

DS200 200 600 -

PN7c 15 480 130 -

3R

3R

3R

3R

3R

3R

+

+

+

+

+

+

- Poly - - 3P+N+G 2

- Poly - - 3P+N+G 4

- Poly Metal - 3P+N+G 4

- Poly Metal - 3P+N+G 4

- Poly Metal - 3P+N+G 6

- - Metal - 3P+N+G 6

*

66/67

Poly Metal SS 6P+G -

PN12c 2 600 130 -

Multipin Switch-Rated

PN12c 7.5 600 130 -

DSN24c 2 480 130 - 66/67 Poly - - 24 -

DSN24c 7.5 480 130 - 66/67 Poly - - 24 -

DS24c 2 250 130 - 54/55 - - SS 24 -

DS24c 7.5 250 130 - 54/55 - - SS 24 -

DSN37c 2 480 130 - 66/67 Poly - - 37 -

DSN37c 7.5 480 130 - 66/67 Poly - - 37 -

DS37c 2 480 130 - 54/55 - - SS 37 -

DS37c 7.5 480 130 - 54/55 - - SS 37 -

DN9c 20 480 130 - 54/55 - Metal - 9 -

DN20c 20 480 130 - 54/55 - Metal - 20 -

DS7c 30 600 130 - 54/55 Poly Metal - 7 3

DR7c 50 600 130 - 54/55 Poly Metal - 7 3

66/67

66/67

*

Poly Metal SS 11P+G -

*

Poly Metal SS 11P+G -

The indicated ratings do not apply to devices with SS casings.

*

+

Type 4X optional

** DSN20 auxiliary contacts just provide a continuity loop thru the receptacle to indicate that a plug is connected.

9

...AND SELECTION GUIDE

Current

Model

DSN20 Switch-Rated 3 hp 7.5 hp 7.5 hp 14 AWG 12 AWG Screw

DSN30 Switch-Rated 5 hp 10 hp 15 hp 14 AWG 8 AWG Screw

DSN60 Switch-Rated 7.5 hp 20 hp 20 hp 12 AWG 4 AWG Screw

DSN150 Switch-Rated 30 hp 75 hp 75 hp 4 AWG 2/0 AWG Screw

DS20 Switch-Rated 5 hp 7.5 hp 10 hp 14 AWG 8 AWG Screw

DS30 Switch-Rated 5 hp 15 hp 15 hp 12 AWG 4 AWG Screw

DS60 Switch-Rated 10 hp 25 hp 25 hp 10 AWG 2 AWG Screw

DS100C Switch-Rated 20 hp 50 hp 50 hp 10 AWG 2 AWG Screw

DS100 Switch-Rated 10 hp 30 hp - 4 AWG 2/0 AWG Screw

DS200 Switch-Rated 40 hp 100 hp 100 hp 4 AWG 4/0 AWG Screw

PN7c Current Interrupting - - - 18 AWG 10 AWG Screw

Interruption

Rating*

(see catalog section for other voltages)

240V - 3Ø 480V - 3Ø 600V - 3Ø Min Max

Horsepower Ratings

Main Contacts Wire

Size Capacity

Terminal Type

PN12c Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

PN12c Non-Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DSN24c Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DSN24c Non-Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DS24c Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DS24c Non-Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DSN37c Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DSN37c Non-Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DS37c Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DS37c Non-Current Interrupting - - - 18 AWG 14 AWG Solder/Crimp

DN9c Current Interrupting 3 hp 5 hp - 16 AWG 10 AWG Screw

DN20c Current Interrupting 1 hp 3 hp - 16 AWG 10 AWG Screw

DS7c Current Interrupting - - - 14 AWG 8 AWG Screw

DR7c Non-Current Interrupting - - - 14 AWG 8 AWG Screw

‘Switch-Rated’ and ‘Current Interrupting’ ratings apply to alternating current only.

*

10

MELTRIC PRODUCT SUMMARY...

Model

DR30 30 600 -

DR50 50 600 -

DR100 100 600 -

DR150 150 600 -

Standard

DR250 250 600 -

DR400 400

PN20 20

PNHT 30 480 130 - 44 - Metal - 3P+N+G -

DSDC1 20 - 250

DSDC1 15 - 600

DSDC1 10 - 750

DSDC3 30 - 250

DSDC3 30 - 600

DSDC3 20 - 750

Direct Current

DSDC6 60 - 250

DSDC6 50 - 600

DSDC6 30 - 750

DSDC9 100 - 250

DSDC9 60 - 600 4X - Poly - - 2P+G -

DSDC2 200 - 250 3R - - Metal - 2P+G -

DSDC2 100 - 600 3R - - Metal - 2P+G -

Amp

Rating

Maximum

Voltage Rating

Environmental

Ratings

Available Casing Materials

Maximum Number

of Contacts

VAC VDC Type IP Poly Metal SS Main Aux.

480

480

**

*

3R

3R

3R

3R

3R

- -

- -

3R

3R

3R

3R

3R

3R

3R

3R

3R

3R

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

- Poly - - 3P+N+G 2

- Poly - - 3P+N+G 4

- Poly Metal - 3P+N+G 4

- Poly Metal - 3P+N+G 6

- - Metal - 3P+N+G 6

54/55

55

±

±

- Metal - 3P+G 2

Poly Metal SS 3P+N+G -

- Poly - - 2P+G -

- Poly - - 2P+G -

- Poly - - 2P+G -

- Poly - - 2P+G -

- Poly - - 2P+G -

- Poly - - 2P+G -

- Poly Metal - 2P+G -

- Poly Metal - 2P+G -

- Poly Metal - 2P+G -

- Poly Metal - 2P+G -

PFQ300 300 600 250 - 66/67 - Metal - 3P+N+G 8

PF300 300 600 250 - 66/67 - Metal - 3P+N+G 4

PF400 400 600 250 - 66/67 - Metal - 3P+N+G 4

PF600 600 600 250 - 66/67 - Metal - 3P+N+G 4

SP 600 1000 1500 - 66/67 Poly - - 1P 2++

CS1000 400 1000 1500 - 66/67 Poly - - 1P -

High Ampacity

600 VAC available at 15 A and less

*

600 VAC available at 350 A and less

**

+

Type 4X optional

± IP66/IP67 optional

++ SP auxiliary contacts just provide a continuity loop thru the receptacle to indicate that a plug is connected.

11

...AND SELECTION GUIDE

Current

Model

DR30 Non-Current Interrupting - - - 14 AWG 8 AWG Screw

DR50 Non-Current Interrupting - - - 12 AWG 4 AWG Screw

DR100 Non-Current Interrupting - - - 10 AWG 2 AWG Screw

DR150 Non-Current Interrupting - - - 4 AWG 2/0 AWG Screw

DR250 Non-Current Interrupting - - - 4 AWG 4/0 AWG Screw

DR400 Non-Current Interrupting - - - 2 AWG 500 MCM Screw

PN20 Current Interrupting - - - 14 AWG 8 AWG Screw

PNHT Non-Current Interrupting - - - 14 AWG 8 AWG Screw

DSDC1 Non-Current Interrupting - - - 14 AWG 8 AWG Screw

DSDC1 Non-Current Interrupting - - - 14 AWG 8 AWG Screw

DSDC1 Non-Current Interrupting - - - 14 AWG 8 AWG Screw

DSDC3 Non-Current Interrupting - - - 12 AWG 4 AWG Screw

DSDC3 Non-Current Interrupting - - - 12 AWG 4 AWG Screw

DSDC3 Non-Current Interrupting - - - 12 AWG 4 AWG Screw

DSDC6 Non-Current Interrupting - - - 10 AWG 2 AWG Screw

DSDC6 Non-Current Interrupting - - - 10 AWG 2 AWG Screw

DSDC6 Non-Current Interrupting - - - 10 AWG 2 AWG Screw

DSDC9 Non-Current Interrupting - - - 4 AWG 2/0 AWG Screw

DSDC9 Non-Current Interrupting - - - 4 AWG 2/0 AWG Screw

DSDC2 Non-Current Interrupting - - - 4 AWG 4/0 AWG Screw

DSDC2 Non-Current Interrupting - - - 4 AWG 4/0 AWG Screw

Interruption

Rating*

(see catalog section for other voltages)

240V - 3Ø 480V - 3Ø 600V - 3Ø Min Max

Horsepower Ratings

Main Contacts Wire

Size Capacity

Terminal Type

PFQ Non-Current Interrupting - - - 2 AWG 600 MCM Lug

PF300 Non-Current Interrupting - - - 2 AWG 600 MCM Lug

PF400 Non-Current Interrupting - - - 2 AWG 600 MCM Lug

PF600 Non-Current Interrupting - - - 2 AWG 600 MCM Lug

SP Non-Current Interrupting - 500 hp 500 hp 2/0 AWG 777 MCM Lug

CS1000 Non-Current Interrupting - - - 1/0 AWG 444 MCM Lug

12

MELTRIC PRODUCT SUMMARY...

Model

DXN20 20 600 - - 66/67 Poly - - 3P+N+G -

DXN30 30 600 - - 66/67 Poly - - 3P+N+G 2

DXN60 60 600 - - 66/67 Poly - - 3P+N+G 2

DXA1 20 600 - - 66/67 - Metal - 3P+N+G -

DS20 20 600 - 4X - Poly - - 3P+N+G 2

DS30 30 600 - 4X - Poly - - 3P+N+G 4

DS60 60 600 - 4X - - Metal - 3P+N+G 4

Hazardous Location

DS100C 100 600 - 4X - Poly Metal - 3P+N+G 4

DSN150 150 600 - 4X - - Metal - 3P+N+G 6

DS200 200 600 - 4X - - Metal - 3P+G 6

DR30 30 600 - 4X - Poly - - 3P+N+G 2

DR50 50 600 - 4X - Poly - - 3P+N+G 4

DR250 250 600 - 4X - - Metal - 3P+G 6

Amp

Rating

Voltage Rating

VAC VDC Type IP Poly Metal SS Main Aux.

Maximum

Environmental

Ratings

Available Casing Materials

Maximum Number

of Contacts

DSDC1 20 - 250 4X - Poly - - 2P+G -

DSDC3 30 - 250 4X - Poly - - 2P+G -

DSDC6 60 - 250 4X - Poly Metal - 2P+G -

DSDC9 100 - 250 4X - - Metal - 2P+G -

DSDC2 200 - 250 4X - - Metal - 2P+G -

DX1 20 750 - - 65 - Metal - 3P+N+G -

DX3 32 750 - - 65 - Metal - 3P+N+G -

DX6 63 750 - - 65/66 - Metal - 3P+N+G -

DX9 125 750 - - 65/66 - Metal - 3P+N+G -

PXN12c 10 220 - - 65/66 - Metal - 11P+G -

DXN25c 10 440 - - 66/67 - Metal - 24P+G -

DXN37c 10 220 - - 66/67 - Metal - 36P+G -

SPeX 680 1000 - - 65/66 Poly - - 1P 2*

SPeX auxiliary contacts just provide a continuity loop thru the receptacle to indicate that a plug is connected.

*

13

...AND SELECTION GUIDE

Current

Model

DXN20 Current Interrupting 2 hp 5 hp 5 hp 16 AWG 10 AWG Screw

DXN30 Current Interrupting 5 hp 10 hp 15 hp 14 AWG 6 AWG Screw

DXN60 Current Interrupting 7.5 hp 20 hp 20 hp 10 AWG 4 AWG Screw

DXA1 Current Interrupting 2 hp 5 hp 5 hp 16 AWG 10 AWG Screw

DS20 Non-Current Interrupting 5 hp 7.5 hp 10 hp 14 AWG 8 AWG Screw

DS30 Non-Current Interrupting 5 hp 15 hp 15 hp 14 AWG 4 AWG Screw

DS60 Non-Current Interrupting 10 hp 25 hp 25 hp 10 AWG 2 AWG Screw

DS100C Non-Current Interrupting 20 hp 50 hp 50 hp 10 AWG 2 AWG Screw

DSN150 Non-Current Interrupting 30 hp 75 hp 75 hp 4 AWG 2/0 AWG Screw

DS200 Non-Current Interrupting 40 hp 100 hp 100 hp 4 AWG 4/0 AWG Screw

DR30 Non-Current Interrupting - - - 14 AWG 8 AWG Screw

DR50 Non-Current Interrupting - - - 14 AWG 4 AWG Screw

DR250 Non-Current Interrupting - - - 4 AWG 4/0 AWG Screw

Interruption

Rating

(see catalog section for other voltages)

240V - 3Ø 480V - 3Ø 600V - 3Ø Min Max

Horsepower Ratings

Main Contacts Wire

Size Capacity

Terminal Type

DSDC1 Non-Current Interrupting - - - 14 AWG 8 AWG Screw

DSDC3 Non-Current Interrupting - - - 14 AWG 4 AWG Screw

DSDC6 Non-Current Interrupting - - - 10 AWG 2 AWG Screw

DSDC9 Non-Current Interrupting - - - 4 AWG 2/0 AWG Screw

DSDC2 Non-Current Interrupting - - - 4 AWG 4/0 AWG Screw

DX1 Current Interrupting - - - 14 AWG 8 AWG Screw

DX3 Current Interrupting - - - 14 AWG 8 AWG Screw

DX6 Current Interrupting - - - 6 AWG 1/0 AWG Screw

DX9 Current Interrupting - - - 2 AWG 2/0 AWG Screw

PXN12c Non-Current Interrupting - - - 16 AWG 14 AWG Solder/Crimp

DXN25c Non-Current Interrupting - - - 16 AWG 14 AWG Solder/Crimp

DXN37c Non-Current Interrupting - - - 16 AWG 14 AWG Solder/Crimp

SPeX Non-Current Interrupting - - - 2/0 AWG 750 MCM Lug

14

MELTRIC PART NUMBERING...

First seven (7) digits for a basic inlet

One (1) to six (6) suffixes for special features

or receptacle part number

1 2

AMP (A) Voltage Polarization

Rating Position Voltage Hz

MELTRIC

Product Line Type

and Casing Material

PN/PN7c

01 = Blue Poly

09 = Blue Metal

PN12c

03 = Blue Poly

07 = Blue Metal

PXN12c

06 = Black Metal

DN

19 = Blue Metal

DXN

22 = Black Poly

DXA1

28 = Black Metal

DX

26 = Black Metal

DS

33 = Blue Poly

35 = Black Poly

36 = Black Metal (HazLoc)

37 = Blue Metal

DXN25/37c

36 = Black Metal

DR

31 = Blue Poly

35 = Black Poly

36 = Black Metal (HazLoc)

39 = Blue Metal

SPeX

42 = Black Poly

CS1000/SP

45 = Black Poly

PFQ

47 = Gray Metal

PF

49 = Gray Metal

DSN

63 = Blue Poly

65 = Black Poly

66 = Black Metal (HazLoc)

69 = Blue Metal

3

DSN

1 = 20

3 = 30

6 = 60

9 = 150

DS

1 = 20

3 = 30

6 = 60/100C

9 = 100

2 = 200*

DR

1 = 30

3 = 50

6 = 100

9 = 150

2 = 250*

4 = 400*

PN20

N = 20 (IP66/

IP67)

S = 20 (IP54/

IP55)

PNHT

2 = 20

DXN

1 = 20

3 = 30

6 = 60

DXA1

1 = 20

*

4 5 6 7

DX

2 = 20*

3 = 30*

6 = 60*

9 = 100*

PF

3 = 300*

4 = 400*

6 = 600*

PFQ

3 = 300*

DN

1 = 20*(DN9)

6 = 20*(DN20)

Available in metal only.

Form and Mounting Phasing

Female

4 = Receptacle

Male

8 = Inlet

DX, DXN37c,

PXN12c, SPeX

Only

Female

0 = Receptacle

on box

3 = Connector

4 = Receptacle

Male

1 = Plug

6 = Inlet on Box

X X X Y Y Y

01 = 50

220 - 250

380 - 440

02 = 20/24 60

03 = 50

04 = 60

110 - 130

190 - 230

255 - 277

440 - 480

06 = 25/28 50

07 = 60

110 - 125

220 - 250

08 = 20/24 50

09 = 480/500 50

10 = 110/130 DC

11 = 400

12 = 200

115 - 127

200 - 220

115 - 127

200 - 220

13 = 40/48 50

AC

2 = 2P+G AC

3 = 3P+G AC

5 = 1P+N+G AC

6 = 2P+N+G AC

7 = 3P+N+G AC

+

= 2P AC

A

+

= 3P AC

B

+

= 3P+N AC

C

+

= 1P+N AC

D

+

= 2P+N AC

G

DC

++

= 2P+G DC

8

9 = 2P+G DC

+

= 2P DC

Z

= 2P+2P+G DC

P

+

For 50V or less only.

++

Includes jumpers.

14 = 347/600 60

16 = 60

17* = 60

120 - 127

208 - 220

110 - 125

220 - 250

18* = 347/600 60

19 = 50

380 - 400

660 - 690

20 = 220/250 DC

22 = 577/1000 50

23* = 60

24* = 60

For DS100C and DR devices.

*

120 - 127

208 - 220

255 - 277

440 - 480

Notes: • On metal devices, inlets are not painted, receptacles are painted.

• This is the Keying Standard for MELTRIC products. Suffixes are available to accommodate non-interchangeable devices of the same size at the same voltage.

Please ask for more details.

15

...AND ORDERING GUIDE

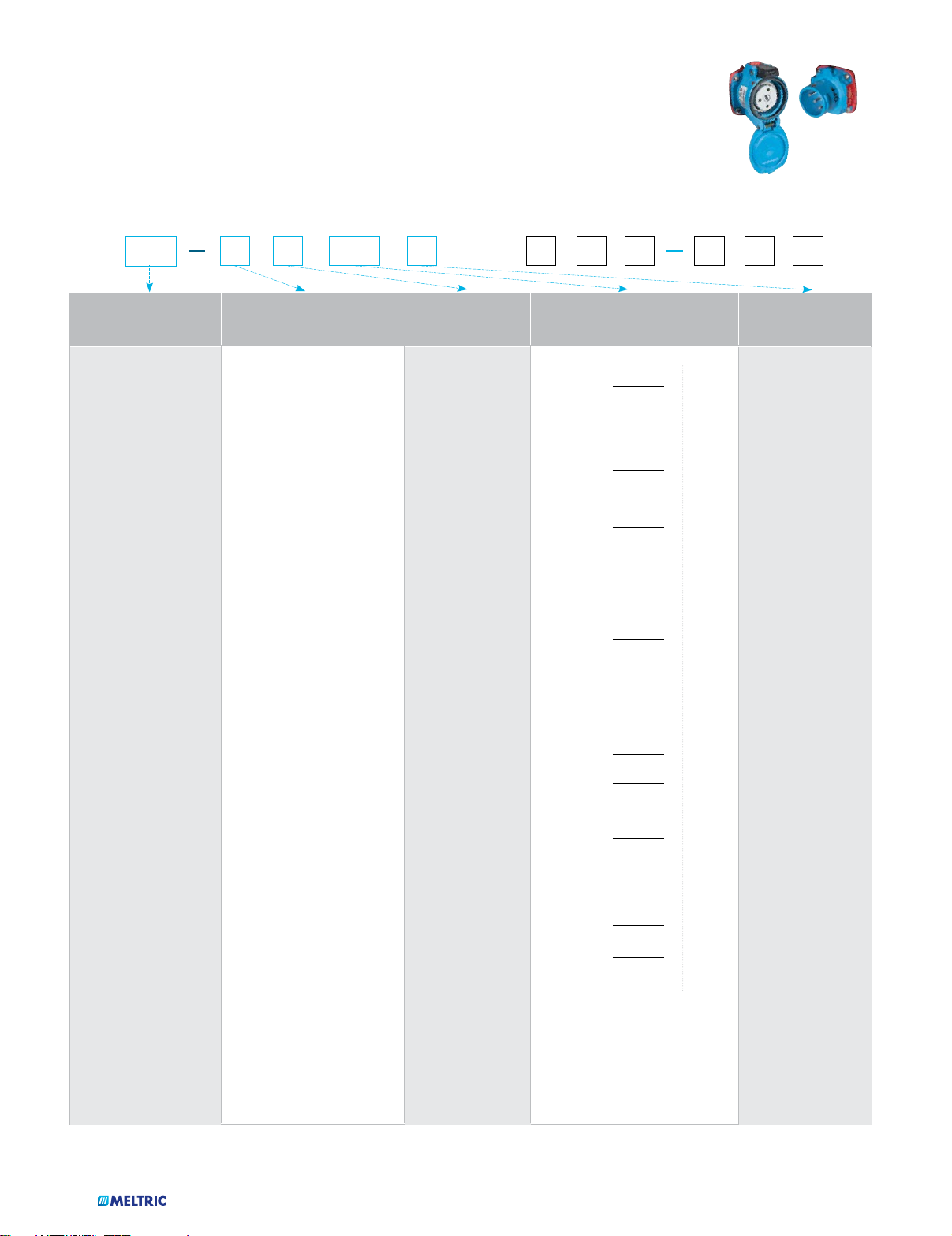

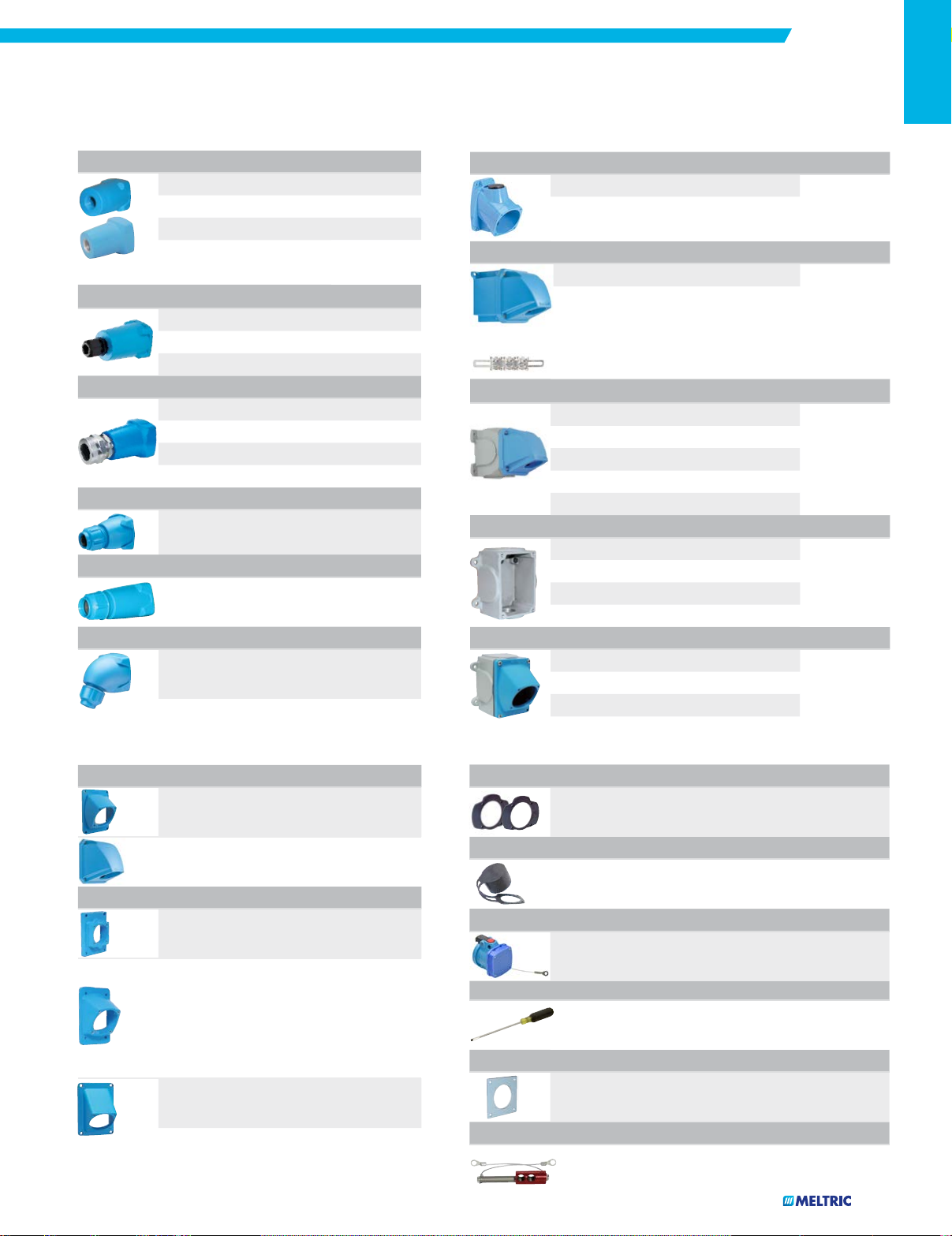

A MODULAR SYSTEM

MELTRIC products are ordered and assembled in a modular fashion. Customers should select the desired male inlet and

female receptacle part numbers. Then matching accessories such as handles, angles, and junction boxes should be identified

and added to the order to create plugs, connectors, or other configurations. This modular system allows MELTRIC to build

and ship product to customer specifications in a very short time - 90% of orders ship by the next business day.

FEMALE

RECEPTACLE

EXAMPLE

Female Receptacle

on Angle

Angle with

Junction Box

Angle Adapter

Handle

Female Receptacle

on Angle with

Junction Box

=

Female Receptacle

=

=

on Angle

Connector

MALE

INLET

Poly Conduit

Entry Box

=

Angle Adapter

=

Handle

=

EXAMPLE

= +

Female Receptacle Angle Adapter Male Plug Male Inlet Handle

= +

Male Inlet on Poly

Conduit Entry Box

Male Inlet

on Angle

Plug

TYPICAL ORDER

63-34047 Female Receptacle

512M3 Angle Adapter for Female

63-38047 Male Inlet

512P0D21 Handle for Male

16

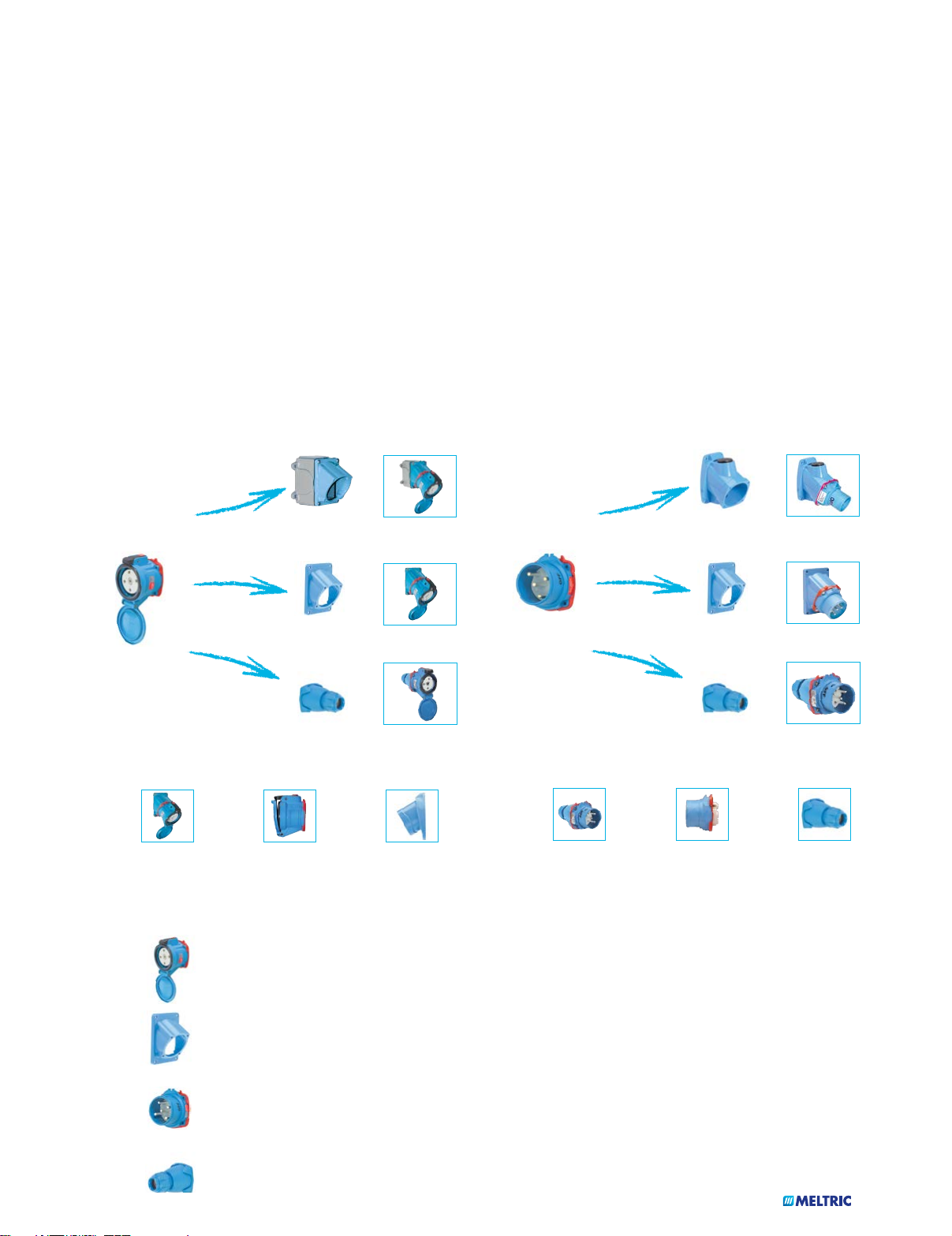

SWITCH-RATED

Plugs & Receptacles

THE MAIN DIFFERENCES

DECONTACTOR

Technology

Pressing the pawl/button on the receptacle will safely switch off

power to the load. The plug can then be withdrawn in complete safety.

(Cutaway model shown for illustration purposes)

®

Like most MELTRIC products, Switch-Rated plugs and

receptacles feature (see pgs 7-8)

u Spring-loaded butt contacts

u Silver-nickel contact materials

u Dead front design

u Enclosed arc chambers

u Spring-assisted terminals

u Auxiliary contacts

MELTRIC Switch-Rated plugs and receptacles have

additional features, including:

u UL & CSA switch-ratings

u Horsepower ratings

u Short circuit ratings up to 100 kA

in fuse protected circuits

Switch and Hp Ratings

MELTRIC Switch-Rated products are a combination plug, receptacle and non-fusible disconnect switch in the same device. Their

integral switch technology ensures the safe breaking of resistive and inductive loads (up to 100 hp or 200 A) before an operator

can physically remove the plug from the receptacle.

They are UL and CSA approved for both “branch circuit” and “motor circuit” disconnect switching, making them ideal for connecting

motors, welding machines and virtually any other electrical equipment.

Short Circuit Ratings

MELTRIC Switch-Rated plugs and receptacles help ensure worker safety even in fault conditions. They are rated to close into and

withstand short circuit currents of up to 100 kA. The protection far surpasses that offered by other plugs and receptacles, and

even surpasses the short circuit protection offered by most manual motor controllers and mechanical interlocks.

=

To match the functionality of a Switch-Rated device, it would take a

pin and sleeve plug plus a non-fused safety switch.

17

+

UL & CSA Standards

Test requirements and ratings comparison table

To achieve their UL 2682 switch ratings, MELTRIC Switch-Rated plugs and receptacles have passed tests that far exceed those

of ordinary plugs and receptacles. These tests include horsepower/locked rotor overload tests from the UL 508 Standard for

Industrial Control Equipment and electrical endurance and short-circuit make-and-withstand testing from the UL 98 standard

for Enclosed and Dead Front Switches.

To illustrate how the electrical and mechanical endurance of MELTRIC Switch-Rated plugs and receptacles far exceeds standard

plugs, the following chart compares the test requirements for achieving a Switch-Rated plug & receptacle listing with those

required for a standard pin and sleeve plug & receptacle listing.

UL Subject 2682

(used for both UL & CSA listings)

(Tests passed by MELTRIC devices)

Test

UL 1682 & CSA 22.2 No. 182.1

Plugs, Receptacles & Cable Connectors of the Pin & Sleeve Type Switch-Rated Plugs & Receptacles

Non-Current Interrupting Break

(minimum requirements)

Current Interrupting

(minimum requirements)

Motor Circuit/Branch Circuit Disconnect Switching

Temperature Rise < 30°C < 30°C < 30°C

Voltage Withstand 3,000VAC for 1 Minute 3,000VAC for 1 Minute 3,000VAC for 1 Minute

Overload

General Use Devices

Mechanical Endurance

(Plus Req’d Electrical Opns)

3 Operations

@ 150% Rated Current

(p.f. = .75 - .80)

15-20 A = 5000 Operations

21-63 A = 2000 Operations

64-250 A = 250 Operations

50 Operations

@ 150% Rated Current

(p.f. = .75 - .80)

15-20 A = 0 Operations

21-63 A = 1000 Operations

64-250 A = 500 Operations

50 Operations

@ 150% Rated Current

(p.f. = .75 - .80)

4000 Cycles

15-20 A = 5000 Operations

1

1

6000 Operations

@ Rated Current & Voltage

(p.f. = .75 - .80)

Electrical Endurance

(with load)

21-63 A = 1000 Operations

–

64-250 A = 250 Operations

@ Rated Current & Voltage

(p.f. = .75 - .80)

Overload - Locked Rotor

(Horsepower Rated Devices)

Short Circuit

Withstand

Short Circuit

Closing

1

Testing alternates between mechanical & electrical operations. This reduces the severity of the electrical test by allowing additional cooling time during electrical testing.

+

All MELTRIC Switch-Rated devices are UL listed with short circuit ratings of at least 65kA achieved at 600VAC and ≤ .15 power factor.

–

–

(600V and ≤ .50 power factor)

– –

50 Operations

@ 600% of Full Load Motor

Current (p.f. = .40 - .50)

≥ 10 kA

+

(600V and ≤ .50 power factor)

(600V and ≤ .50 power factor)

50 Operations

@ 600% of Full Load Motor

Current (p.f. = .40 - .50)

≥ 10 kA

≥ 10 kA

+

+

18

BENEFITS OF USING

MELTRIC SWITCH-RATED DEVICES

Ensure Worker Safety

Switch-Rated plugs and receptacles ensure safety by eliminating hazards associated with pin and sleeve and twist-type devices.

uThe integral switching function ensures that the plug contacts are de-energized before an operator can remove the plug from

the receptacle. The dead-front design prevents unintended access to live parts.

uSpring-loaded, silver-nickel butt-style contacts maintain proper contact force, withst and arcing, resist wear, and maintain

low contact resistance. This ensures the integrity of the connection over thousands of operations and eliminates performance

and safety problems common to plugs with brass contacts.

uSpring-loaded plug and receptacle disengagement with push button operation ensures fast and easy load breaking, which

minimizes arcing during disconnection. Enclosed arc chambers eliminate arc flash hazards.

uHorsepower, switch, and short-circuit ratings provide additional protection during locked-rotor or other significant overload situations.

Simplify Code Compliance

Switch-Rated devices provide a simple and

cost-effective means of helping facilities

to achieve compliance with the National

Electrical Code and NFPA 70E.

NEC Compliance

Articles 430.101 to 430.113 of the National Electrical Code regulate

the means of motor disconnection (Canadian Electrical Code

section 28-600–28-604). They require motors to have readily

accessible, ‘line of sight’ disconnects that are an approved

switch or a properly rated plug and receptacle.

u430.102 A disconnecting means must be located in sight of

the motor and driven equipment.

u430.107 The disconnecting means must be readily accessible.

u430.109 The disconnecting means may be an approved

switch or horsepower rated plug and receptacle.

MELTRIC Switch-Rated plugs and receptacles are both

horsepower and switch-rated. They can function as a ‘line of sight’

disconnect in addition to providing a convenient plug and

play power connectionfor the motor. Installing a switch-rated

device eliminates the need for an auxiliary disconnect switch.

NFPA 70E (CSA Z462)

This OSHA consensus standard covers electrical safety-related

work practices and procedures for employees who work on or

near exposed energized electrical conductors or other live

circuit parts. Relevant requirements include:

Power must be proven to be off before work can be

performed. This requires:

u The safe interruption of the load and opening of

the disconnect

uVisual verification/voltage testing to ensure de-energization

The potential electrical hazard must be identified

and documented.

u An arc flash risk assessment must be performed

uFlash protection boundaries must be determined

Appropriate steps must be taken to protect persons working

near live parts or within the flash protection boundary.

uPPE must be worn based on incident energy exposure

levels (cal/cm2)

uOnly properly qualified persons are allowed to perform work

19

...THROUGHOUT YOUR FACILITY

Wiring and connection systems utilizing conventional switches and/or pin & sleeve devices would typically require all of the previously

listed protective measures to comply with NFPA 70E or CSA Z462. By using MELTRIC Switch-Rated plugs and receptacles to

connect equipment, users can very simply comply with these requirements.

Switch ratings ensure the safe interruption of the load. Visual verification that the power is off is provided when the plug is

removed from the receptacle. A dead front design prevents an operator from being exposed to live parts, eliminating the need to

perform hazard analysis, establish flash protection boundaries and use electrical personal protective equipment.

A Comparison of the Motor Change-Out Process

MOTOR HARD-WIRED TO A

BLADED DISCONNECT SWITCH

The disconnect switch may be

difficult to install in “line of

sight” of the motor.

MOTOR CHANGE-OUT PROCESS

1. Switch disconnect to OFF position

2. Apply lockout/ tagout

3. Perform Shock/Arc Flash Risk Assessment

4. Obtain permit for energized electrical work

5. Suit up with appropriate PPE

6. Remove the disconnect switch cover

7. Voltage test to verify deenergization

8. Disconnect motor from hard-wiring

9. Remove old/install new motor

10. Connect new motor to hard-wiring

11. Jog the motor to ensure proper rotation

18”

Qualified

Worker

w/PPE

MOTOR CONNECTED WITH A

MELTRIC MOTOR PLUG

u Cord connection allows easy

OR

MOTOR CHANGE-OUT PROCESS

1. Depress the pawl on the receptacle to break

the circuit

2. Mechanic removes plug from receptacle

3. Apply lockout/tagout as required

4. Mechanic removes old/installs new motor

5. Mechanic inserts plug into receptacle

“line of sight” location

u Dead front eliminates access

to live parts and need for

cumbersome PPE

u Ability to safely make &

break under load eliminates

the need for interlocks

OR

u ≥10k A short circuit make-

and-withstand rating ensures

safety during reenergization

MELTRIC Makes it

Safe & Easy

MOTOR CONNECTED WITH A

COMPETING PLUG & RECEPTACLE

u Expensive mechanical

interlocks are required

since these plugs &

receptacles cannot safely

make & break under load

u The interlock must be

mounted on a fixed

surface this may make

“line of sight” location

more difficult

MOTOR CHANGE-OUT PROCESS

1. Open interlock switch

2. Determine PPE requirements and obtain permit for

electrical work

3. Remove interlock cover

4. Verify deenergization with a voltmeter test

5. Remove plug

6. Apply lockout/tagout as required

7. Remove old/install new motor

8. Insert plug into receptacle

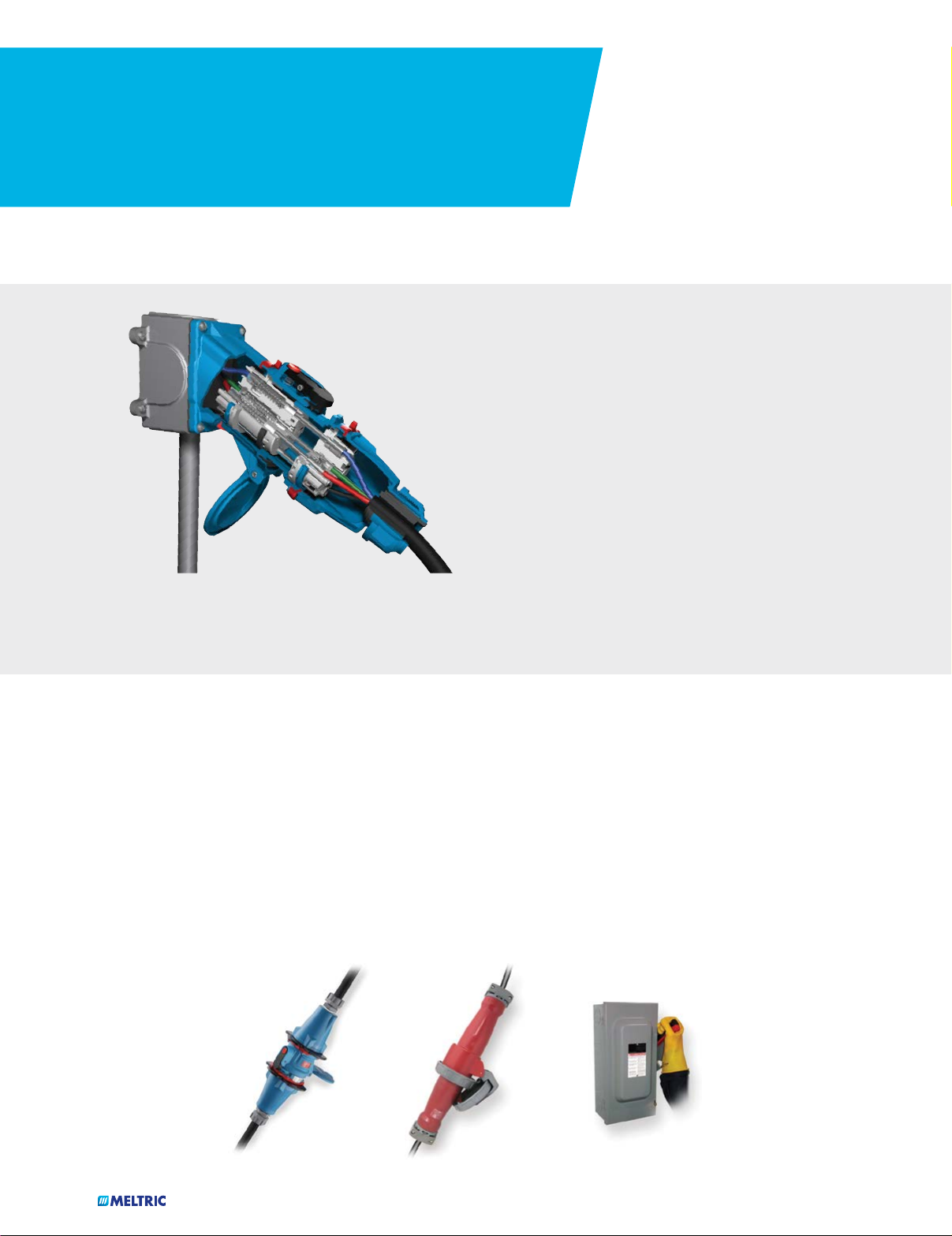

Reduce Equipment and Installation Costs

The ability of MELTRIC Switch-Rated devices to safely make and break under full load eliminates the need for the expensive interlocks

that are required with pin and sleeve devices. Their ability to function as the NEC required ‘line of sight’ disconnect switch eliminates the

need for auxiliary disconnect switches. Optional pilot contacts can eliminate the need of auxiliary connectors in control circuits.

Reduce Equipment Change-out Downtime and Cost

Using MELTRIC Switch-Rated plugs and receptacles to connect motors and other equipment instead of hard-wiring can help

reduce equipment change-out time by as much as 50%. With new motors pre-wired with MELTRIC plugs or inlets, the only electrical

connection required during the change-out will be to plug in the new motor. Thus, a mechanic will be able to perform the changeout without the immediate aid of an electrician. This avoids the inconvenience of scheduling an electrician for a service call. So,

extra downtime required to do the wiring is eliminated. The pre-wiring of replacement motors with MELTRIC plugs or inlets can

be done off-site and during the convenience of non-downtime periods. This makes MELTRIC plugs and receptacles an ideal choice

for ‘plug and play’ and modular process applications.

20

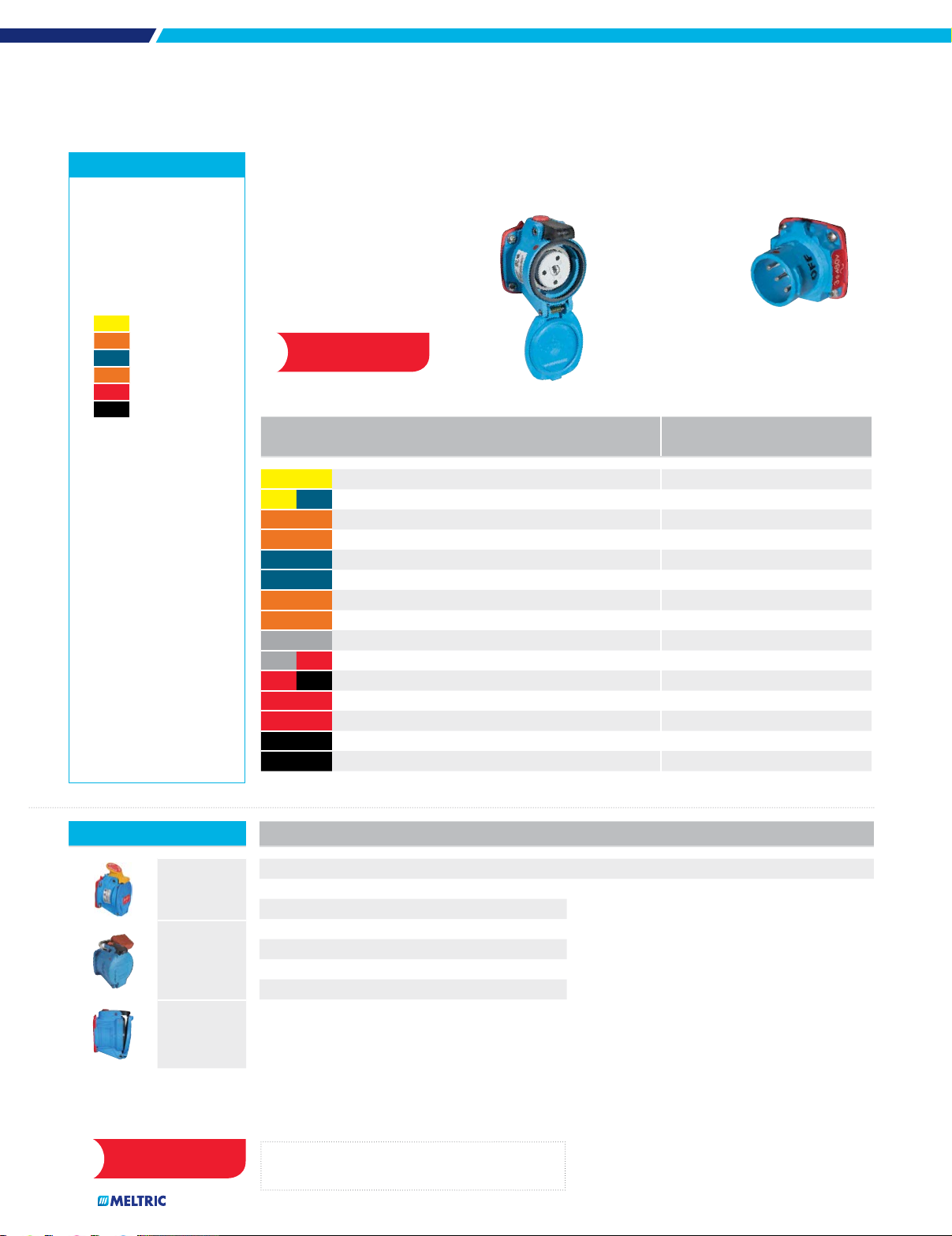

SELECTING THE RIGHT MELTRIC SWITCH-RATED

PLUG & RECEPTACLE

All SWITCH-RATED devices (DSN and DS) feature DECONTACTOR® Technology:

uUL and CSA switch-ratings

u Short circuit closing and withstand

protection (10kA to 100kA)

DSN Series

(pages 25-38)

Choose DSN Series for its…

u Compact, lightweight design

u Automatic Type 4X/IP69/IP69k watertightness

u High HP Ratings (up to 75 hp)

Common Applications

uWet or washdown environments

uPlug & play electrical connections

uSilver-nickel contact material

uSpring-loaded, butt-style contacts

DS Series

(pages 39-56)

Choose DS Series for its...

uAmperage range (up to 200 A)

uPoly or metal casing materials (60 A and above)

u Larger conductor capacities

u High HP Ratings (up to 100 hp)

Common Applications

u Heavy industry

u High amperage equipment

uDead front safety shutter

uOptional auxiliary contacts

21

DSN Models and Ratings

Model

Casing

Material

Maximum

Voltage (VAC)

Amperage

Rating

Maximum Number

of Contacts

Main Auxiliary 480 VAC 600 VAC

Environmental Rating

Maximum

Horsepower Rating

DSN20 Poly 600 VAC 20 A 3P+N+G 2 pilots Type 4X/IP69/IP69K 7.5 hp 7.5 hp

DSN30 Poly 600 VAC 30 A 3P+N+G 2 Type 4X/IP69/IP69K 10 hp 15 hp

DSN60 Poly 600 VAC 60 A 3P+N+G 4 Type 4X/IP69/IP69K 20 hp 20 hp

DSN150

Poly or Metal 600 VAC 150 A 3P+N+G 6 Type 4X/IP69/IP69K 75 hp 75 hp

DS Models and Ratings

Maximum Number

Model

Casing

Material

Maximum

Voltage (VAC)

Amperage

Rating

of Contacts

Main Auxiliary 480 VAC 600 VAC

Environmental Rating

DS20 Poly 600 VAC 20 A 3P+N+G 2 Type 3R 7.5 hp 10 hp

DS30 Poly 600 VAC 30 A 3P+N+G 4 Type 3R 15 hp 15 hp

Maximum

Horsepower Rating

DS60 Poly 600 VAC 60 A 3P+N+G 4 Type 3R 25 hp 25 hp

DS100C Poly or Metal 600 VAC 100 A 3P+N+G 4 Type 3R 50 hp 50 hp

DS100 Poly or Metal 600 VAC 100 A 3P+N+G 6 Type 3R 30 hp –

DS200

Metal 600 VAC 200 A 3P+N+G 6 Type 3R 100 hp

100 hp

22

SWITCH-RATED

Plugs & Receptacles

23

MELTRIC’s Switch-Rated product line featuring DECONTACTOR®

technology, includes devices rated from 20 amps to 200 amps.

An integral switch mechanism enables workers to safely

connect and disconnect motors, welding machines and other

industrial equipment.

DS P. 39

DSN P. 25

COMPACT SIZE WITH IP69K WATERTIGHTNESS

• 20 A to 150 A (75 hp)

• Automatic Type 4X/IP69/IP69K watertightness

DSN

LARGER WIRING CAPACITY AND METAL CASINGS

• 20 A to 200 A, Type 3R (4X optional)

• Poly or metal casings (60 A and above)

• Larger conductor capacities

24

Switch-Rated Plug and Receptacle

DSN

with Type 4X/IP69/IP69K protection

Main Advantages

u Switch & Hp rated

u 100 kA short circuit rated*

u Type 4X/IP69/IP69K or IP66/IP67

u Compact, lightweight design

u Up to 6 auxiliary contacts

See note under General Ratings on the next page.

*

25

Highlighted Advantage

Simplify Compliance to

NFPA 70E & CSA Z462

!

see pgs 19-20 for

more information.

u Features and Ratings p. 26

u DSN20 p. 27

u DSN30 p. 29

u DSN60 p. 31

u DSN150 p. 33

u Spare Parts p. 35

u Dimensions p. 37

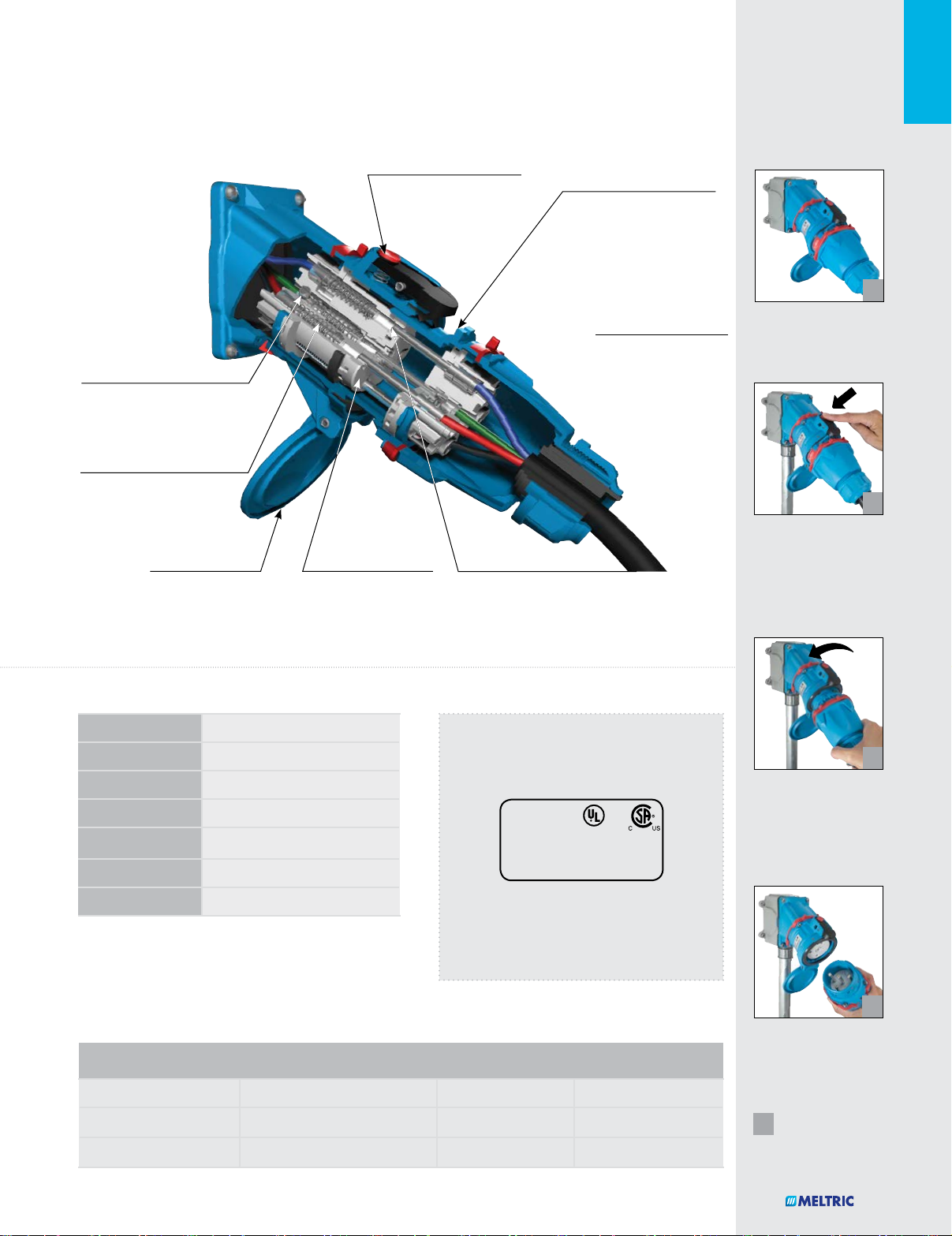

PRODUCT FEATURES

DECONTACTOR

Technology

®

OFF Button

Press to de-energize. Provides

push button circuit disconnection.

DSN

Operating

Instructions

Casing

Fiberglass reinforced thermoplastic

polyester material offers great

resistance to impact, corrosion and

harsh environmental conditions.

1

Spring Assisted Screw Terminals

Patented design assures “Tighten

and Forget” confidence.

Spring-Loaded Butt-Style Contacts

Ensures optimal contact force and

superior electrical performance over

thousands of operations.

Lid

Provides additional protection

in harsh environments.

General Ratings

Amperage

Voltage

Frequency

Horsepower

Short-Circuit

(Make & Withstand)

Environmental

20 to 150 A

600 VAC

50-400 Hz

.75 to 75 hp

100kA*

Type 4X/IP69/IP69K

Dead Front Safety Shutter

Assures safety by preventing

user access to live parts.

Lockout-Tagout Provisions

Allows plug to be easily locked

out and tagged. Optional

Padlock Pawl allows lockout/

tagout of the receptacle.

Silver-Nickel Contact Material

Solid silver-nickel contact surfaces

provide superior conductivity, durability

and corrosion resistance.

Highlighted Feature

Typical Device Labels

Meltric DSN30

30 A, TYPE 4X

10 HP, 480VAC

63-34043

SWITCH-RATED RECEPTACLE/CONNECTOR

MOTOR CIRCUIT DISCONNECT SWITCH

BRANCH CIRCUIT DISCONNECT SWITCH

LISTED 49B6

When the plug and receptacle

are latched together, the

circuit is connected.

2

Pressing the pawl breaks

the connection and opens

the circuit. The plug is

ejected to its rest position;

The contacts are now dead.

3

Rotating the ‘dead’ plug 30°

counterclockwise closes the

safety shutter and frees the

plug to be withdrawn from

the receptacle.

Temperature

DSN20, DSN30, DSN60: Testing was performed with RK1 current limiting fuses

*

sized at 400% or more of the highest full load motor ampacity associated with

the devices horsepower ratings.

DSN150: 100kA testing was performed with 225 A RK1 non-time delay Mersen

*

fuses. 10kA testing was performed with 400 A RK1 non-time delay Mersen fuses.

min -40°F/max 140°F

MELTRIC DSN Series Switch-Rated devices are

UL & CSA rated for “motor circuit” and “branch

circuit” disconnect switching – up to 75 hp and

up to 150 A.

Listings

Category UL CSA IEC

Plugs and Receptacles UL 1682 C22.2 No. 182.1 60309-1

Branch Circuit Disconnect

Switching (AC only)

Motor Circuit Disconnect

Switching (AC only)

CE ratings available upon request.

UL Subject 2682

(Performance tests from UL 98)

UL Subject 2682

(Performance tests from UL 98)

UL Subject 2682 60947-3, AC22, AC23

UL Subject 2682 60947-3, AC22, AC23

4

The plug and the receptacle are

separated. The safety shutter

prevents access to live parts.

To reconnect, insert

5

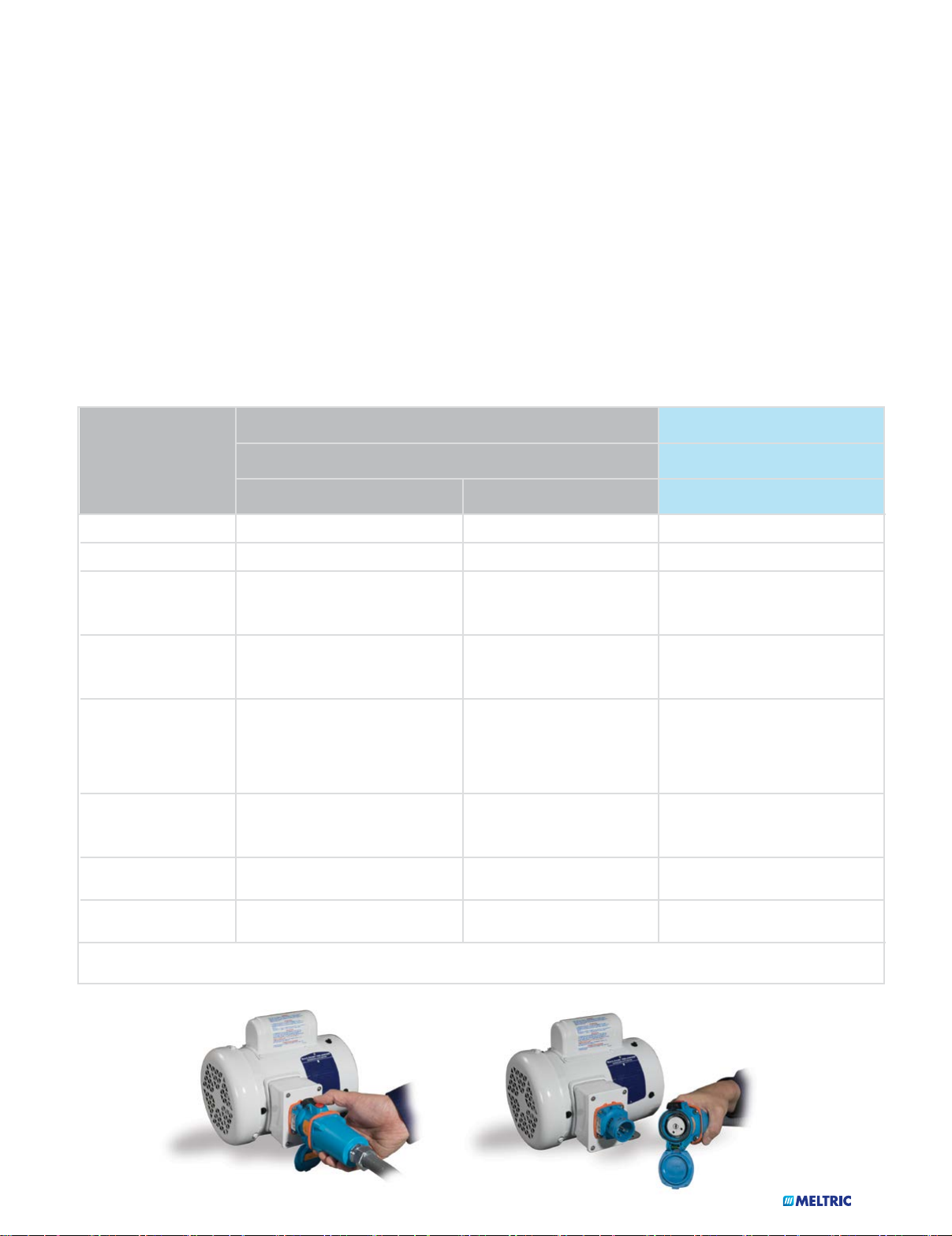

plug into receptacle,

rotate 30° clockwise, and

apply insertion force.

26

26

DSN20 Switch-Rated Plugs & Receptacles – 20 A

UL/CSA Ratings

• Max Amperage & Voltage

20 A, 600 VAC

• Switch-Rating (AC Only)

Branch Circuit & Motor Circuit

Disconnect Switching

• Horsepower Ratings

1Ø .75 hp

120V

240V

1Ø 2 hp

208V

3Ø 3 hp

240V

3Ø 3 hp

480V

3Ø 7.5 hp

600V

3Ø 7.5 hp

• Short Circuit Rating

100kA Close & Withstand

Testing was performed with 35 A RK1

non-time delay Mersen fuses.

10kA Close & Withstand

Testing was performed with 50 A RK1

non-time delay Mersen fuses.

• Environmental Ratings

Type 4X/IP69/IP69K*

* Also meets IP66/IP67 requirements

• Temperature Range

Min -40°F/Max 140°F

See pg 256 for temps below -15°F.

• Wiring Capacity

Min 14 AWG Max 12 AWG

Aux Contacts - 18 AWG prewired

• Certifications

UL 2682, UL 1682, CSA 182.1

Don’t forget to add installation

accessories to your order

!

Voltage Polarity

120V

120 208V

125V

125 250V

208V

208V

250V

250V

277V

277 480V

347 600V

480V

480V

600V

600V

1P+N+G 63-14165 63-18165

3P+N+G 63-14167 63-18167

1P+N+G 63-14075 63-18075

2P+N+G 63-14076 63-18076

1P+N+G 63-14045 63-18045

3P+N+G 63-14047 63-18047

3P+N+G 63-14147 63-18147

Receptacle

(female)

Inlet

(male)

North American UL/CSA Congurations

Part # Part #

Poly Poly

2P+G 63-14162 63-18162

3P+G 63-14163 63-18163

2P+G 63-14072 63-18072

3P+G 63-14073 63-18073

2P+G 63-14042 63-18042

3P+G 63-14043 63-18043

2P+G 63-14142 63-18142

3P+G 63-14143 63-18143

Main Options

See pages 233-242 for detailed

information on these options

!

27

Mushroom

Pawl

Padlock Pawl

Closed Lid

Configuration

Recommended for cord

applications to keep lid

tucked in to avoid damage.

Receptacle Options Suffix # Inlet Options Suffix #

With 2 Auxiliary/Pilot Contacts

Straight Insertion

Self-Ejecting Connector Release

Mushroom Pawl

Padlock Pawl

Padlockable Mushroom Pawl

Metal Pawl

Closed Lid Configuration

Notes: + Unlike other DSN & DS products, the DSN20 pilots are only on

the receptacle side and create a continuity loop that is completed when a

plug is connected to the receptacle.

Order Example: 480V DSN20 with padlock pawl

DSN20 Receptacle 3P+G = 63-14043-843

Recept # - 972+

Recept # - 352

Recept # - 354

Recept # - 375

Recept # - 843

Recept # - 375-843

Recept # - 824

Recept # - NC

Self-Ejecting Plug Release

With No Lockout Hole

Inlet # - 338

Inlet # - A155

INSTALLATION ACCESSORIES – SIZE 1

DSN20

DSNDSN

HANDLE w/NPT

1/2” 511P0N05 791P0N05L

Poly

HANDLESANGLES

3/4” 511P0N07 791P0N07L

1” 511P0N10 791P0N10L

Metal

For available cord grips, see page 165.

POLY HANDLE w/CORD GRIP

METAL HANDLE w/CORD GRIP

POLY HANDLE

POLY EXTENDED HANDLE

POLY ANGLED HANDLE

Part # Poly Part # Metal

Cable Range Part #

.350 - .520” 711P0BP6

.520 - .680” 711P0CP5

.680 - .980” 711P0DP4

.438 - .500" 791P0BS3L

.500 - .562" 791P0BS4L

.562 - .625" 791P0BS5L

.625 - .750" 791P0CS4L

.35 - .70” 511P0D18

.20 - .83” 511P0D21

.35 - .70” 511P6D18

POLY CONDUIT ENTRY w/NPT

BOXESMISCELLANEOUS ACCESSORIES

30° 1/2” 511B3N05

30° 3/4” 511B3N07

3

* 6.7 in

Part #

POLY WALL BOX w/ANGLE

70° 511C7000

3

* 82.0 in

Ground Bar 51AA089

POLY ANGLE WITH METAL BOX w/NPT

70° 1/2” 711C7N05

70° 3/4” 711C7N07

70° 1” 711C7N10

70° 1 1/4” 711C7N12

3

* 74.6 in

70° 1 1/2” 711C7N15

METAL BOX w/NPT

0° 1/2” 7T1F0N05

0° 3/4” 7T1F0N07

0° 1” 7T1F0N10

0° 1 1/4” 7T1F0N12

POLY ANGLE WITH METAL BOX w/NPT

* 29.8 in

30°

30° 3/4” 711C3N07

30° 1” 711C3N10

3

30° 1 1/4” 711C3N12

1/2”

711C3N05

NPT on top or bottom (if rotated). For other NPT configurations, contact customer service.

* Interior volume with

receptacle installed.

70° poly boxes are

not drilled. Contact

customer service

if factory drilled is

required.

* Interior volume with

receptacle installed.

* Interior volume with

receptacle installed.

* Interior volume with

receptacle installed.

POLY ANGLE

METAL ANGLE

MB Box 30° 511M3

70° 511M7

0° 591M0

FS/FD Box 30° 791M3FS

45° 591M4

* Base measures

approximately 4.2” x

2.7”. Due to the

variation in sizes of

FS boxes, please

verify that your FS

box matches our

dimensions, if not call

Customer Service for

other solutions.

FINGER DRAWPLATES

61-1A346

Set of Two (2)

Recommended for cord to cord assembly applications,

for easier connector closure.

PROTECTIVE INLET/PLUG CAP

61-1A426 For Inlets/Plugs Only.

PADLOCKABLE INLET/PLUG CAP

61-1A826 For Inlets/Plugs Only.

SCREWDRIVER FOR TERMINAL SCREWS

SD18 Klein 608-3 1/8” cabinet with 3” round shank.

EASY RETROFIT ADAPTER PLATES

see pg 162 Mount to existing boxes.

RECEPTACLE LOCKING PIN

LP-843 Requires Padlockable Pawl option (-843) on receptacle.

28

Loading...

Loading...