WARNING

A

ENGLISH OPERATING INSTRUCTIONS

DXA SERIES

©2020 MELTRIC Corporation. All rights reserved.

A manufacturer of products using MARECHAL® TECHNOLOGY

COMPANY OF MARECHAL ELECTRIC

GENERAL

Plugs, receptacles, connectors, inlets and

couplers are herein referred to as “devices”. DXA

DECONTACTOR™ devices are intended for

industrial applications in potentially explosive

atmospheres. In addition to IECEx and cCSAus

hazardous location ratings, they are cCSAus rated

for current interrupting duty and are HP rated for

use as a motor disconnecting means. They are

not intended to be used as the primary motor or

branch circuit disconnect switch.

The receptacle safety shutter blocks access to the

contacts and creates a dead front that prevents user

exposure to live parts. The opening/closing of the

safety shutter is controlled by the insertion/

withdrawal of a plug with compatible ratings and

contact congurations.

These instructions must

be followed to ensure the

proper installation, operation

and maintenance of the devices. There are inherant

dangers associated with electrical products and

failure to follow appropriate safety precautions can

result in serious injury or death. Be sure to

disconnect all sources of shock before starting

installation or maintenance.

• All metal parts must be connected to Ground.

A Ground connection is supplied with all

• These devices must be used in accordance

with their assigned current, voltage, IP and

Class/Division or Zone hazardous location.

• Any additional components used (e.g. cable

entry, adaptor, thread plug, etc.) must be

certied with a protection mode(s) and IP

ratings that are compatible with and maintain

the ratings of the device they are used with.

They must be installed according to the

manufacturer’s instructions.

• Respect recommended tightening torques

(see Table T2).

metal accessories.

INSDXA B

•

devices must be used with

INSTALLATION

complementary devices only. Connection to

devices not bearing genuine parts

will void the warranty and ratings.

• Certication requires that any replacement of

component(s) must be performed under the

control of the manufacturer MARECHAL

ELECTRIC S.A.S.

RATINGS & CERTIFICATIONS

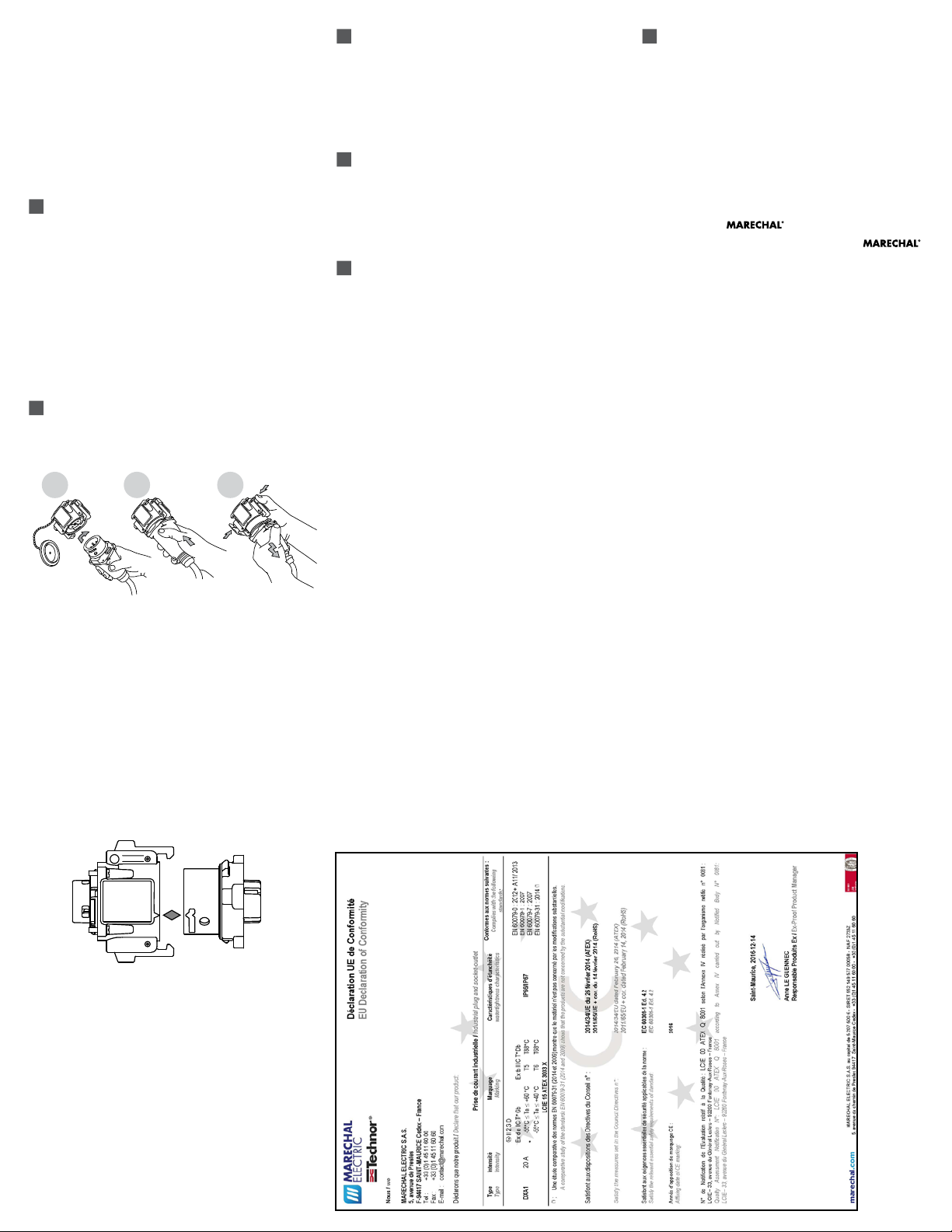

See Figure F3

•

Install the receptacle on a downward angle, with

the latching pawls at the top and at the bottom.

• Panel mounted devices must be assembled on a

“Ex e” increased safety enclosure according

to the drilling Figure F1.

Figure F1

A

4x

Ø

DXA devices have both cCSAus and IEC ratings

for use in hazardous environments.

Class I Zone 1 AEx de IIC T*Gb Zone 21 AEx tD T*Db

Class 1 Division 2 Group A, B, C, D

Class 2 Division 2 Group E, F, G

D

DXA1 inch mm

A 1.89 48

A

D 2.24 57

Ø

.196 (#9) 5

This NEC and CEC rating certies the product for

use in applications where ammable gases, such

as acetylene, hydrogen, ethylene or propane, or

dusts, such as magnesium, coal or grain, may be

WIRING

present under abnormal conditions.

• The contact terminals are spring-assisted to

Ex de IIC T*Gb Ex tb IIIC T* Db

This IEC rating certies the product for use in

surface (non-underground) applications where

a high level of protection is required and where

the presence of an explosive atmosphere of

any type of gas or dust is likely to occur. The

associated maximum surface temperature of

the product is 88°C (190°F), at an ambient

temperature of 60°C (140°F).

Short Circuit Make & Withstand Rating

DXA devices are rated to make and withstand short

circuit currents with appropriate fusing as indicated in

Table T1. Consult NEC for Short Circuit Limits.

T1 - Short Circuit Make & Withstanding Ratings

Device Rating Fuse Type*

DXA1 - 20A 25 kA @ 600 Vac RK1 30A

------------

------------

---------------

---------------

* DXA1, DXA3 Ratings are based on testing with Mersen Non-Time

delay. Current Limiting fuses.

DXA6, Ratings are based on testing with Little fuse Non-Time

delay. Current Limiting fuses.

--

--

--

--

prevent loosening due to strand settlement,

vibration or thermal cycling.

CONDUCTOR PREPARATION

• Remove an adequate length of cable outer

sheath according to the accessory used.

• Ensure that the cable sheathing extends

through the cord grip into the handle or box as

required to achieve the intended sealing and

cord gripping performance.

• Strip conductor insulation to the length

indicated in Table T2.

• (Do not back terminal screws completely out).

Fully insert the conductor and tighten the terminal

screws to the torque indicated in Table T2.

GROUNDING CONNECTIONS

DXA1 metal casings are equipped with 3

ground terminals as shown in Figure F2.

Figure F2

Auxiliary Contact Ratings

Some DXA devices are provided with optional

auxiliary contacts that make after and break before

the phase contacts. The ratings for auxiliary

contacts are shown in Table T2.

marechal

T2

1-2-3-N

A-B A-B A-B A-B

Device mm1 AWG mm2 AWG mm inch mm inch mm inch mm inch Nm inch-lbs Nm inch-lbs

DXA1 1.5-6 16-10 -- -- 12 0.50 -- -- 12 0.50 -- -- 0.8 7.1 -- --

-------- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

--------

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

1

Wire capacity is based on certification testing. Wire size should be determined in accordance with the electrical code.

2

A device intended for flexible connections must be equipped with a flexible cord listed for extra-hard usage and terminated with listed fittings in accordance with all applicable local and national electrical codes

1 2

Auxiliary

1 2

1-2-3-N Auxiliary 1-2-3-N Auxiliary 1-2-3-N Auxiliary

3 (Philips)

3x0.75 mm

1/8"

----------

----------

• One ground terminal is factory-wired to the

ground contact. This wire must not be removed

as it also grounds the second and third ground

terminals.

• Second ground terminal is used for the

ground conductor.

• Third ground terminal is used to ground the

accessory (box, handle, angle).

COLOR CODED GASKETS

Insert the color-coded gaskets between the device

and its rear accessory (box, handle, angle).

The two protrusions on the gasket must be

positioned on the latch sides of the receptacle/

connector and on the catch side for the inlet/plug.

This gasket is needed to maintain the IP rating.

If used in conjunction with nger draw plates, the

gasket must be between the receptacle (or inlet).

OPERATION

See Figure F3

F3

1 2 3

1

2 3

CONNECTION LOCKING (OPTION)

With the plug fully mated to the receptacle, insert the

metal locking pin through the hole in the pawl on the

receptacle and place a padlock or other locking

device through one of the holes on locking pin.

This will prevent unintended disconnection.

PLUG LOCKOUT (OPTION)

• To prevent the plug from being inserted

into a receptacle, place a padlock or other

lockout device through the hole provided

in the plug casing.

MAINTENANCE

• IEC/EN 60079-17 & UL 60079-17standard:

Explosive atmospheres – Part 17: “Electrical

installations inspection and maintenance”,

foresees very strict requirements regarding

the maintenance of electric installations which

must be imperatively respected.

• Ensure that the xing screws, caps and cable

glands are tight.

• Verify that the weight of the cable is supported

by the strain relief mechanism and not by the

terminal connections.

MANUFACTURER’S RESPONSIBILITY

MELTRIC’s responsibility is strictly limited to the

repair or replacement of any product that does not

conform to the warranty specied in the purchase

contract. MELTRIC shall not be liable for any

penalties or consequential damages associated with

the loss of production, work, prot or any nancial

loss incurred by the customer.

MELTRIC Corporation shall not be held liable when

its products are used in conjunction with products

not bearing the

The devices that are not marked with the

technology trademark.

technology trademark shall void all warranties on

the product and listing is invalidated.

MELTRIC Corporation is an ISO 9001 certied

company. Its products are designed, manufactured

and rated in accordance with applicable UL, CSA

and IEC standards. MELTRIC designs and

manufactures its products in accordance with

Marechal keying standards established to ensure

intermatablility with similarly rated products

manufactured by Marechal Electric Group.

• Only devices with compatible contact

congurations and electrical ratings will

mate with each other.

• The receptacle is shielded by a protective

lid held in the closed position by two latches.

Depress the latches to release the lid.

• To connect, align the arrow heads on the

housings (see Figure F4), insert the device

and turn it clockwise until it hits a stop. The

device is in the rest position and the circuit

remains open.

Figure F4

marechal

• Check the cleanliness of contacts.

• To inspect the contacts, depress the springloaded

ejection ring on two opposite points. The safety

shutter can then be rotated clockwise to inspect

contact tips.

• Any deposit can be rubbed off with a clean

cloth or compressed air.

• In case of damage, contact your supplier to

have them replaced by the manufacturer.

• Do not forget to re-lock the safety shutter

after inspection.

• Inspect periodically IP gaskets for wear and

resilience. Replace as required.

• Check regularly the continuity of the ground

circuit by electric tests.

• Push the device straight into the complementary

device until it becomes securely latched.

• To disconnect, depress the latching pawls

simultaneously. The device returns to its rest

position and the circuit is open.

• To remove the device, turn it counter-clockwise

and pull. Replace receptacle lid.

INSDXA B

Loading...

Loading...