WARNING

ENGLISH OPERATING INSTRUCTIONS

CONSIGNES D’UTILISATION

DX

DX

©2018 MELTRIC Corporation. All rights reserved.

A manufacturer of products using Marechal technology

GENERAL

MELTRIC’s DX Series plugs & receptacles are designed for industrial use according to IEC/EN 60309-

1. They are designed for applications where rugged

metal construction is required and when there is a

need for amperages up to 100A. Follow the instructions below to ensure the proper installation and use of

this product.

There are inherent

dangers associated with

electrical products. Failure to follow safety precautions can result in serious injury or death. These

instructions must be followed to ensure the safe and

proper installation, operation and maintenance of the

MELTRIC devices. Before installation, disconnect all

sources of power to the circuit to eliminate the risk

of electrical shock.

RATINGS & CERTIFICATIONS

To ensure the safe use of this product,

the installer must verify that the product

is properly rated for the application.

The amperage, voltage, temperature, and environmental ratings are indicated on the product label.

MELTRIC’s DX Series plugs and receptacles are

ATEX-rated in accordance with the European ATEX

Directive (94/9/EC).

The ATEX rating certies the product for use in surface

(non-underground) applications where a high level of

protection is required and where the presence of an

explosive atmosphere is likely to occur (Zone 1 and

Zone 21 environments). It’s suitable for installation in

areas that may contain ammable gases, vapors, mists,

or dusts, including subdivision C gases. The product possesses explosion protection and is provided

with ‘e’ increased safety in the conductor termination

area and ‘d’ explosion proof chambers for making

and breaking electrical current that can withstand the

pressure of internal ignition. It also can prevent arcs,

ame or other ignition events from being communicated to the surrounding atmosphere. The maximum

allowable surface temperature of the product is 85°C

(185°F) at 40°C (104°F) ambient.

INSTALLATION

DX Series devices must be used in conjunction

INSDX I

with other appropriately rated hazardous duty prod-

ucts and must be installed by qualied electricians

and in accordance with all applicable local and national electrical codes.

Before installing, verify that (1) the power is off, (2)

the product ratings are appropriate for the application,

and (3) the conductors meet the requirements of the

National Electric Code and are within the capacities of

the DX terminals noted in Table 1.

Table 1 - Wiring Terminal Capacity1 (in AWG)

Main Contacts

Device Min Max

DX1 - 20A 14 8

DX3 - 32A 14 8

DX6 - 63A 6 1

DX9 - 125A 2 2/0

1

Capacity is based on THHN wire sizes

General Installation Notes & Precautions

1. Wire strip lengths are indicated in Table 2. Strip

lengths for cable sheathing will depend on the

specic application. When used with handles, the

cable sheathing should extend into the handle to

ensure secure cord gripping.

Table 2 - Wire Strip Length – Dimension A

Phase & Neutral Earth

Conductor Conductor

Device Inches mm Inches mm

DX1 20A 0.79 20 0.79 20

DX3 32A 0.79 20 0.79 20

DX6 63A 1 1/16 27 1 3/16 30

DX9 125A 1 3/8 35 1 3/16 30

2. Wiring terminals are spring assisted to prevent

loosening due to wire strand settlement, vibration and thermal cycling. NOTICE: They should

not be overtightened. Appropriate tools and tightening torques are indicated in Table 3. Wiring

must be made according to applicable national

installation standards. Follow all conductor coding

and terminal marking standards. Back out terminal screws far enough (but not completely) to

allow a complete insertion of conductors. All

metal parts must be connected to Earth ground.

Table 3 - Terminal Screw Tightening Torques

Torque Required Flat

Device/Contact In. lb N-m Screwdriver

DX1 (20 A) 11 1.3 4 x 1 mm

DX3 (32 A) 11 1.3 4 x 1 mm

DX6 (63 A) 26 3 6 x 1.2 mm

DX9 (125 A) 53 6 6 x 1.2 mm

3. Only handles with supplied cord grips may be

used in order to maintain proper ATEX ratings.

Table 4 - Cord Grip Cable Tightening Range

Sufx# Range

Inches mm

-20M 0.31 - 0.51 8 - 13 mm

-25M 0.35 - 0.63 9 - 16 mm

-32M 0.47 - 0.83 12 - 21 mm

-40M 0.63 - 1.06 16 - 27 mm

-50M 0.91 - 1.38 23 - 35 mm

-63M 1.42 - 1.89 36 - 48 mm

Assembly for In-line Plugs/Connectors

Do not overtighten terminal or self-tapping

screws. Tighten screws to the proper torque

to ensure a secure connection. Insert cable

through handle (connector) or remove plug interior

molding from the front and insert cable through plug

body (plug/inlet). Strip the cable sheath as required

to provide a workable wire length while being aware

that the strain relief must clamp on the cable sheath.

Strip the individual wires to the lengths indicated

in Table 2 and twist the strands of each conductor

together. Back out the terminal screws on the receptacle (or inlet) only far enough to allow the conductors

to pass. Insert the conductors fully into their respective terminals and tighten the terminal screws with a hand

screwdriver to the torque indicated in Table 3. Verify that

the cable jacket will extend beyond the strain relief

and into the handle. Assemble the receptacle (or

connector) to the handle. Adjust the cable location

so that it will not be under tension inside the handle

and tighten the compression nut to secure the cable.

After assembly, the cable sheath must extend into the

handle. Assemble handle with supplied screws and

gasket (connector) or assemble interior molding into

plug casing (plug) and tighten cord grip (cable gland).

Cord grip cable tightening ranges are indicated in

Table 4. While clamping or anchoring, the conductors inside the handle must not be tight.

NOTICE: For a proper clamping the use of PVC

cables is not recommended.

Assembly for Mounted Receptacles (or Inlets)

In applications where DX receptacles are mounted

to wall boxes, panels or other equipment, optimal

operation is achieved when the device is installed with

the pawl latch at the top. (However, if the receptacle

is mounted to the MELTRIC surface box accessory,

the pawl latch will be on the bottom due to the vertical

orientation of the box/receptacle.)

NOTICE: if the DX device is mounted to a wall box,

make sure that hole plugs are securely tightened in

any unused connection holes.

All wires brought into a MELTRIC wall box or hazardous duty box/panel must be connected in accordance

with all approved local and national electrical codes

based on the rating of the hazardous location environment. The individual wire insulators should be

stripped off base on the dimensions given in Table 2.

Then, twist the strands of each conductor together.

Back out the terminal screws on the receptacle (or

inlet) far enough to allow the conductors to pass

and insert the conductors fully into their respective

terminals. Tighten the terminal screws with a hand

screwdriver to the torque indicated in Table 3. Assemble the receptacle (or inlet) on adapter or wall

box, using gaskets and screws provided. When not

in use, ensure that the protective cap or lid supplied is

properly secured to prevent environmental contamination. Assemble the mating plug (or inlet) to the cord

end as indicated in the assembly instructions for inline connections. In cases where custom mounting is

being performed to an appropriate hazardous duty box

or panel, the clearance and mounting holes should be

drilled as indicated in the next section, Hole Pattern

for Custom Mounting.

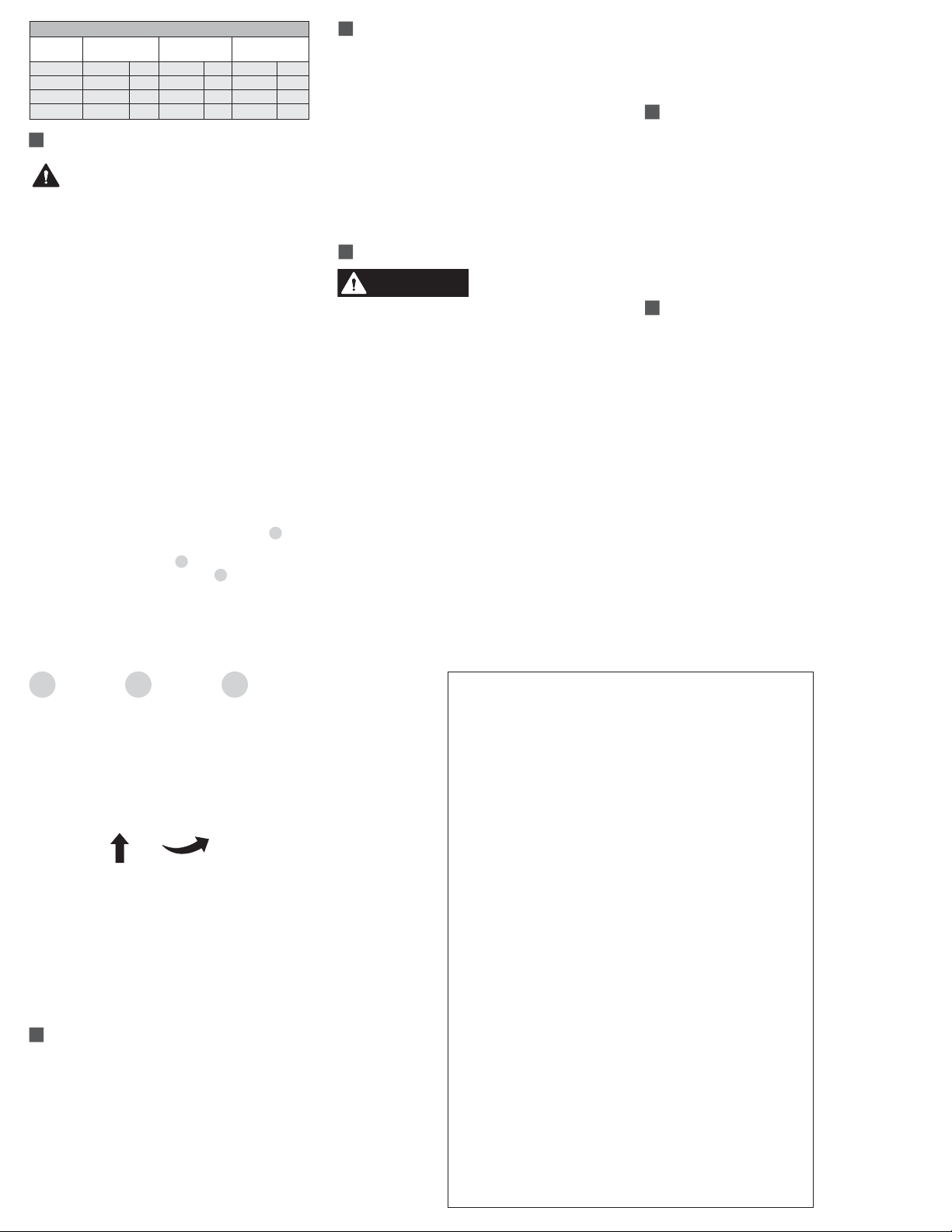

Hole Pattern for Custom Mounting

NOTICE: In order to maintain IP65 protection in cus-

tom installations, watertight seals must be used under

the heads of the four mounting bolts and they must

be retained by a lock washer and nut on the inside of

the box or panel. The hole depth must be sufcient to

achieve adequate gasket compression. Refer to the

following instructions and drawing for the assembly of

the plug/receptacles or inlets on ‘e’ increased safety

boxes, panels or enclosures:

B

A

C

B

WARNING

Table 5 - Custom Mounting Dimensions

A B C

Device Inches mm Inches mm Inches mm

DX1 4.3 109 3.62 92 1/4 M6

DX3 4.3 109 3.62 92 1/4 M6

DX6 5.9 150 4.80 122 5/16 M8

DX9 5.9 150 4.80 122 5/16 M8

OPERATION

To ensure a safe and reliable operation,

MELTRIC’s DX Series plugs & receptacles

must be used in accordance with their assigned electrical and Ex ratings, as well as their IP

ratings according to IEC/EN 60309-1.

They can only be used in conjunction with mating

receptacles or plugs manufactured by MELTRIC or

another licensed producer of products bearing the

technology trademark.

MELTRIC plugs & receptacles are designed with

different keying arrangements so that only plugs and receptacles with compatible contact congurations and

electrical ratings will mate with each other. When not

in use, the receptacle is shielded by a protective lid to

prevent the entry of dust and moisture. This is held in

the closed position by a latch.

Connection

To connect a plug and receptacle, rst depress the

pawl to release the lid on the receptacle, then orient

the plug so that the colored mark on the outside ridge

of the plug casing lines up with the Ø or unlock symbol on the receptacle casing. Push the plug in partially into the receptacle until it hits a stop Fig. 1. At

this point, the circuit is still open. To close the circuit,

turn the plug clockwise Fig. 2 until it hits another

stop after about 30° of rotation. Fig 3.

NOTICE: When making a connection, ensure that

the plug latch is secured behind the catch on the

pawl. A properly connected plug cannot be pulled out

of the receptacle.

LOCKOUT PROVISIONS

All DX receptacles are provided with padlocking

lockout provisions. To operate, insert the 3 hole shaft

through the hole under the receptacle pawl. Place

user supplied lock or lockout hasp through one of the

holes. This system may be used to lock mated devices together to prevent unintended disconnection or

to prevent mating of devices by locking the receptacle

lid closed.

NOTICE: Attaching the receptacle locking device with

the lid open will not prevent the insertion of a plug.

Lockout is only accomplished when the lid is locked

closed.

MAINTENANCE

Before inspecting, repairing,

or maintaining MELTRIC

products, disconnect electrical power to the receptacle to eliminate the risk of electrical shock. Any

replacement of DX components must be performed

under the control of the manufacturer: MELTRIC

Corporation.

MELTRIC products require little on-going maintenance. However, it is a good practice to periodically

perform the following general inspections:

• Check the mounting screws for tightness.

• Verify that the weight of the cable is supported

by the strain relief mechanism and not by the

terminal connections.

• Check the IP gaskets for wear and resiliency.

Replace as required.

• Verify the electrical continuity of the ground circuit.

• Check the inlet contact surfaces for cleanliness

and pitting.

Deposits of dust or similar foreign materials can be

rubbed off the contacts with a clean cloth. Sprays

should not be used, as they tend to collect dirt. If

any signicant pitting of the contacts or other serious

damage is observed, the device should be replaced.

DECLARATION OF CONFORMITY

DX Series plugs/receptacles use the

technology. They have been designed, manufactured

and controlled in a strict respect of the relevant international and European standards, laws and directives,

and particularly of the European ATEX Directive.

They bear the CE marking whenever applicable.

They also bear the markings of their explosion-proof (Ex)

classication.

Note: The CE marking does not apply to spare parts

and components supplied separately.

MANUFACTURER’S RESPONSIBILITY

MELTRIC’s responsibility is strictly limited to the

repair or replacement of any product that does not

conform to the warranty specied in the purchase

contract. MELTRIC shall not be liable for any penalties or consequential damages associated with the loss

of production, work, prot or any nancial loss incurred by

the customer.

MELTRIC Corporation shall not be held liable when

its products are used in conjunction with products not

bearing the

use of MELTRIC products in conjunction with mating

devices that are not marked with the

technology trademark. The

technology trademark shall void all warranties on the

product.

MELTRIC Corporation is an ISO 9001 certied company. Its

products are designed, manufactured and rated in accordance

with applicable UL, CSA and IEC standards. MELTRIC designs

and manufactures its products in accordance with Marechal keying standards established to ensure intermateablility with similarly

rated products manufactured by Marechal Electric Group.

1

2 3

Disconnection

To break the connection, depress the pawl and rotate

the plug counterclockwise about 30° until it hits a

stop. At this point, the electrical circuit is open. To

fully remove the plug, depress the pawl and pull the

device straight out. The self-closing lids on the receptacles may need to be manually latched to ensure

optimal environmental ratings.

Achieving Rated Watertightness

MELTRIC’s DX Series plugs & receptacles have an

IP65 rating for protection against ingress of water,

dust and other matter. IP65 provides total protection

against dust and water jets. These ratings apply when

the plug and receptacle are mated. They also apply

to the receptacle alone, provided that its lid is latched

in the closed position. Optional plug caps are available for providing IP65 protection on unmated plugs.

INSDX I

Loading...

Loading...