DS & DSN

DECONTACTORS

OPERATING INSTRUCTIONS

Meltric Corporation

4640 Ironwood Drive

Franklin, WI 53132

(800)433-7642

www.meltric.com

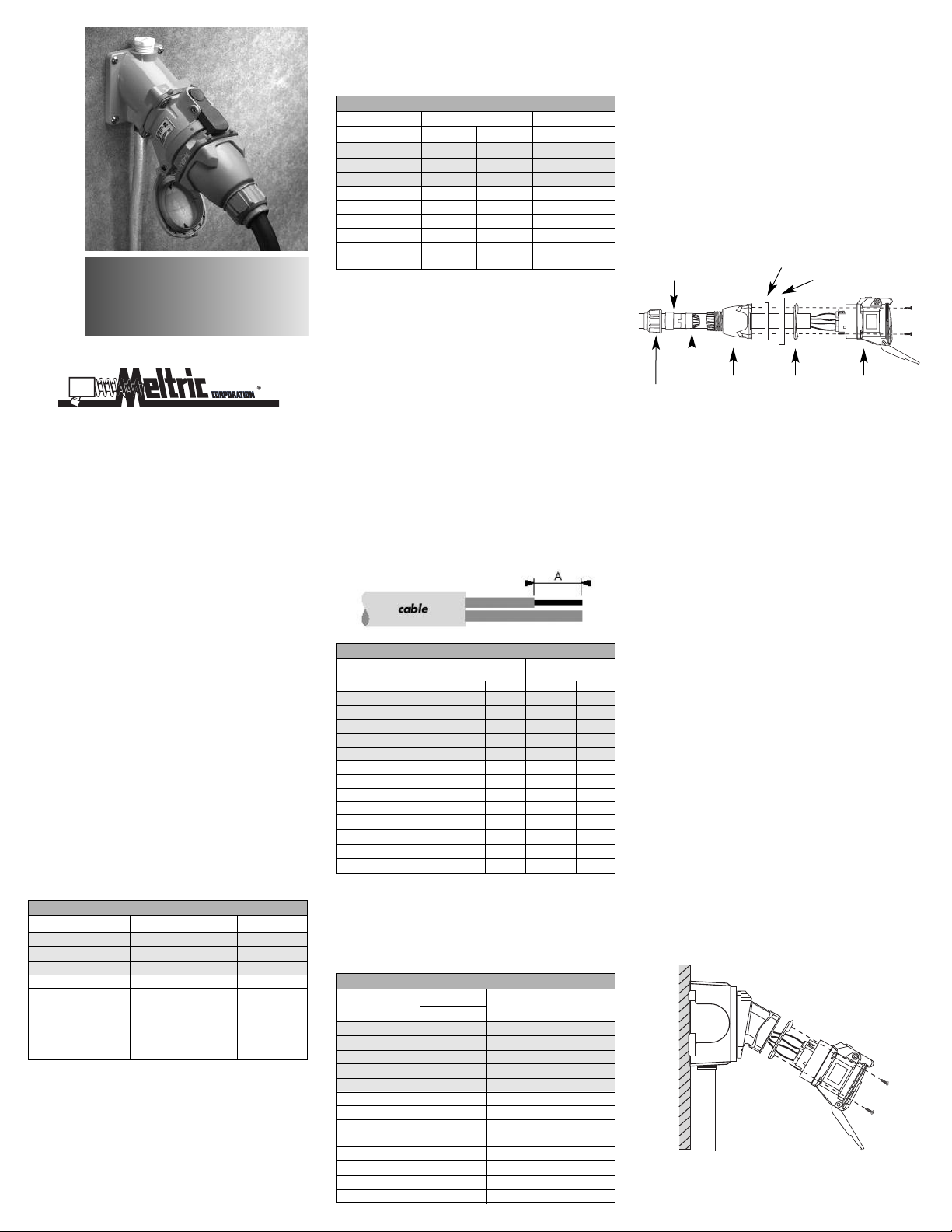

GENERAL

DS and DSN Decontactor™ Series products are

designed to provide the safety and functionality of a

switch with the convenience of a plug & receptacle.

They can safely be used to make and break electrical

connections, even in overload situations and are an

approved ‘line of sight’ disconnect switch. Please follow the instructions below to ensure the proper installation and use of the product.

RATINGS

Meltric’s Decontactor™ Series Switch Rated plugs &

receptacles are UL & CSA listed in accordance with

UL Subject 2682, UL 1682 and CSA 22.2 182.1. All

are listed as ‘Branch Circuit Disconnect Switches’

and most are also horsepower rated and listed as

‘Motor Circuit Disconnect Switches’. The amperage,

voltage, horsepower, switch and environmental ratings are indicated on the product labels.

All Decontactors are rated to make and withstand

short circuit currents of 65kA or more. These ratings

are indicated in Table 1 along with the fusing upon

which they are based.

Table 1 - Short Circit Make & Withstand Ratings

Device Rating Fuse Type*

DSN20 - 20A 100 kA @ 480 VAC RK1 35A

DSN30 - 30A 100 kA @ 600 VAC RK1 125A

DSN60 - 60A 100 kA @ 600 VAC RK1 110A

DS100 - 20A 100 kA @ 600 VAC RK1 80A

DS30 - 30A 100 kA @ 600 VAC RK1 125A

DS60 - 60A 100 kA @ 600 VAC RK1 250A

DS100C - 100A 100 kA @ 600 VAC RK1 250A

DS100 - 100A 65 kA @ 600 VAC RK5 100A

DS200 - 200A 65 kA @ 600 VAC RK5 200A

* Rating applies with fusing up to this amperage. Ratings

are based on tests performed with Ferraz Shawmut non-time

delay current limiting fuses.

INSTALLATION

Decontactors should be installed by qualified electricians in accordance with all applicable local and

national electrical codes. Before starting, verify that

INSDS/DSN 072408 E

he power is off, that the product ratings are appropri-

t

ate for the application, and that the conductors meet

ode requirements and are within the capacities of

c

he terminals noted in Table 2.

t

able 2 - Wiring Terminal Capacity

T

Device Minimum Maximum Maximum

SN20 - 20A 20 12 n/a

D

SN30 - 30A 14 88

D

SN60 - 60A 12 4 12

D

DS20 - 20A 14 88

DS30 - 30A 12 4 12

DS60 - 60A 62 14

S100C - 100A 62 14

D

S100 - 100A 4 2/0 14

D

S200 - 200A 4 3/0

D

1

apacity is based on THHN wire sizes

C

2

Auxiliary contacts are optional and may not be on all products.

3

Auxiliary contacts are prewired at the factory.

4

/0 AWG if part number includes the ‘A06’ suffix.

4

Main Contacts Aux. Contacts

1

in AWG)

(

4

2

3

3

3

3

4

1

General Notes & Precautions

1. Self-tapping screws are provided for use with

ome polymeric accessories. High torque may

s

e required to drive them in. Once they are

b

seated, care should be taken in order to avoid

ver-tightening them against the plastic material.

o

2. Various handles and cord grip options may be

sed. These instructions are based on handles

u

provided with integral multi-layer bushing cord grips.

3. Wire strip lengths are indicated in Table 3. Strip

lengths for cable sheathing will depend on the

specific application. When used with handles, the

cable sheathing should extend into the handle to

ensure secure cord gripping.

Table 3 - Wire Strip Length – Dimensions A

Receptacle Plug/Inlet

Device Inches mm Inches mm

DSN20 Phase 1/2 13 5/8 16

DSN30 Phase 7/16 10 3/4 19

Auxil. 1/2 12 3/4 19

DSN60 Phase 9/16 14 7/8 22

Auxil. 1/2 13 5/8 16

DS20 Phase 7/16 10 3/4 19

Auxil. 1/2 12 3/4 19

DS30 Phase 9/16 14 7/8 22

Auxil. 1/2 13 5/8 16

DS60 Phase 15/16 24 15/16 24

DS100C Phase 15/16 24 15/16 24

DS100 Phase 1 3/16 30 1 3/16 30

DS200 Phase 1 3/16 30 1 3/16 30

4. Wiring terminals are spring assisted to prevent

loosening due to stand settlement, vibration and

thermal cycling. They should not be over-tightened.

Appropriate tools and tightening torques are indicated in Table 4.

Table 4 - Terminal Screw Tightening Torques

Torque Required Screwdriver

Device/Contact in-lbs N-m or Allen Wrench

DSN20 Phase 7 0.8 3 mm or 1/8” precision tip

DSN30 Phase 13 1.5 4 mm or 3/16” precision tip

Auxil. 13 1.5 4 mm or 3/16” precision tip

DSN60 Phase 16 1.8 5 mm or 3/16” precision tip

Auxil. 7 .8 3 mm or 1/8” precision tip

DS20 Phase 13 1.5 4 mm or 3/16” precision tip

Auxil. 13 1.5 4 mm or 3/16” precision tip

DS30 Phase 16 1.8 5 mm or 3/16” precision tip

Auxil. 7 0.8 3 mm or 1/8” precision tip

DS60 Phase 35 4.0 4 mm hex head

DS100C Phase 35 4.0 4 mm hex head

DS100 Phase 80 9.0 4 mm hex head

DS200 Phase 130 15.0 5 mm hex head

. The DS9 and DS2 are rated as general purpose

5

switches, but are not horsepower rated. If these

evices are installed in motor power supply

d

pplications, warning labels may be required to

a

advise users not to disconnect the device under

oad. Labels are provided in the package, but

l

hould only be used when required.

s

ssembly for In-Line Connections

A

hen Decontactors are used as in-line connectors,

W

inger drawplates (or a drawbar mechanism for the

f

DS9 & DS2) should be installed on both the recepta-

le and plug in order for the user to more easily

c

provide the leverage required to connect the device.

inger Drawplate Gasket

Bushing

Strain

Relief

Compression

Nut

djust the bushing diameter to fit the cable by remov-

A

H

andle

F

olor-Coded

C

asket

G

inger Drawplate

F

eceptacle

R

or Inlet)

(

ing inner sections of it as required. Insert the bushing

into the strain relief, then insert the assembly into the

handle and loosely install the compression nut.

Insert the cable through the handle, the thin black

drawplate gasket and finger drawplate (if applicable)

and the color coded gasket. Strip the cable sheath to

provide a workable wire length, being mindful that the

sheath must extend into the handle to achieve a

secure cord grip. Then strip the individual wires to

the lengths indicated in Table 3 and twist the strands

of each conductor together.

Back out the terminal screws on the receptacle (or

inlet) far enough (but not completely) to allow the

conductors to pass, insert the conductors fully into

their respective terminals and tighten the terminal

screws with the appropriate tool to the torque indicated

in Table 4.

Verify that the cable sheath extends beyond the strain

relief and into the handle. Assemble the receptacle

(or inlet), the color coded gasket, the finger drawplate, and the thin black drawplate gasket to the handle with the four self-tapping screws provided. Adjust

the cable location so that it will not be under tension

inside the handle and tighten the compression nut to

secure the cable.

Assembly for Mounted Receptacles (or Inlets)

In applications where DS or DSN receptacles (or

inlets) are mounted to wall boxes, panels or other

equipment, optimal operation is achieved when the

device is installed with the latch at the top.

nsert the cable or wires through the wall box and cut

I

to allow adequate length, strip the cable sheath as

esired, strip the individual wires to the lengths indi-

d

ated in Table 3, and twist the strands of each con-

c

ductor together. Back out the terminal screws on the

eceptacle (or inlet) far enough (but not completely)

r

o allow the conductors to pass, insert the conductors

t

ully into their respective terminals and hand tighten

f

he terminal screws to the torque indicated in Table 4.

t

ssemble the receptacle (or inlet) and the color-

A

oded gasket to the box with the appropriate hardware.

c

Assemble the mating plug (or receptacle) to the cord

nd as indicated in the assembly instructions above

e

for in-line connections, except there will be no finger

rawplate or associated black gasket.

d

Hole Pattern for Custom Mounting

In applications where custom mounting to a panel or

ox is being performed, the clearance and mounting

b

oles should be drilled as indicated in the following

h

diagram and Table 5.

B

C

able 5 - Custom Mounting Dimensions

T

Model Inches mm Inches mm Inches mm

DSN20

-Recept 2.00 51 1.65 42 .19 5

DSN30 2.25 57 1.89 48 .19 5

DSN60 2.50 64 2.17 55 .19 5

DS20 2.25 57 1.89 48 .19 5

DS30 2.50 64 2.17 55 .19 5

DS60&DS100C 3.25 83 2.59 66 .22 5.5

DS100 4.00 102 3.20 81 .22 5.5

DS200 4.50 114 3.86 98 .28 7

A

‘A’ ‘B’ C

B

t becomes securely latched in place. The electrical

i

connection is now made. On in-line connectors,

queeze the drawplates on both sides of the device

s

ogether until the plug latches in place.

t

isconnection

D

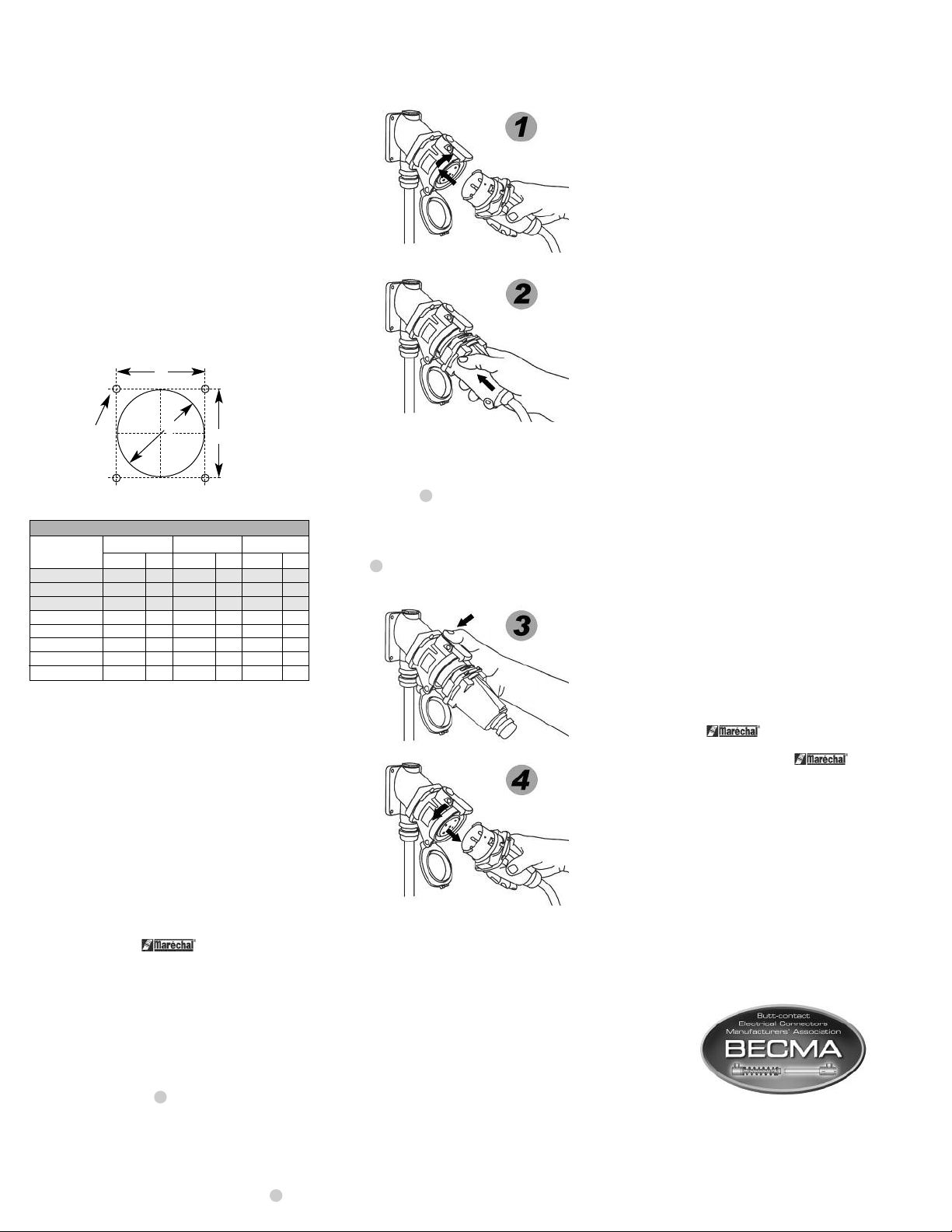

To break the connection, simply depress the pawl as

shown in figure 3 . This will break the circuit and

eject the plug straight out to the rest, or off, position.

The plug contacts are de-energized at this point. To

remove the plug, rotate it counter-clockwise (about

30°) until it releases from the receptacle as shown in

figure 4 . Close and latch the lid on the receptacle.

OTE: Attaching the receptacle locking device with

N

the receptacle lid open will not prevent the insertion

f a plug. Lockout of the receptacle is only accom-

o

lished when the lid is locked closed.

p

MAINTENANCE

eltric products require little on-going maintenance.

M

owever, it is a good practice to periodically perform

H

he following general inspections:

t

Check the mounting screws for tightness.

•

• Verify that the weight of the cable is supported

y the strain relief mechanism and not by the

b

erminal connections.

t

Check the IP gaskets for wear and resiliency.

•

Replace as required.

Verify the electrical continuity of the ground circuit.

•

• Check the contact surfaces for cleanliness and

itting.

p

Deposits of dust or similar foreign materials can be

ubbed off the contacts with a clean cloth. Sprays

r

should not be used, as they tend to collect dirt. If

ny significant pitting of the contacts or other serious

a

amage is observed, the device should be replaced.

d

eceptacle contacts may be inspected by a qualified

R

lectrician. This should only be done with the power

e

ff. It is accomplished by depressing the numbered

o

ring around the circumference of the interior on two

pposite points. This will allow the shutter to be

o

manually turned clockwise as required to permit

access to the contacts. Once the inspection is complete, the shutter must be rotated counter-clockwise

until it is locked in the closed position.

MANUFACTURER’S RESPONSIBILITY

Meltric’s responsibility is strictly limited to the repair

or replacement of any product that does not conform

to the warranty specified in the purchase contract.

Meltric shall not be liable for any penalties or consequential damages associated with the loss of production, work, profit or any financial loss incurred by the

customer.

In order to maintain the NEMA 4X or IP 66 & 67 protection provided by DSN models in custom installations, watertight seals should be used under the

heads of the four mounting bolts and they must be

retained by a lock washer and nut on the inside of

the box or panel. Alternatively, four blind holes may

be drilled and threaded to accommodate the mounting screws, provided that the hole depth is sufficient

to achieve adequate gasket compression.

OPERATION

To ensure safe and reliable operation Meltric plugs

and receptacles must be used in accordance with

their assigned ratings. They can only be used in

conjunction with mating receptacles or plugs manufactured by Meltric or another licensed producer of

products bearing the

TM

Quality Label.

Meltric plugs & receptacles are designed with different keying arrangements, so that only plugs and

receptacles with compatible contact configurations

and electrical ratings will mate with each other.

Connection

To connect a plug and receptacle, first depress the

pawl to open the lid on the receptacle, then orient the

plug as shown in figure 1 so that the red dot on the

outside of the casing lines up with the red dot just to

the left of the latch on the receptacle casing. Push

the plug partially into the receptacle until it hits a

stop, then rotate the plug in the clockwise direction

until it hits another stop after about 30° of rotation.

At this point, the circuit is still open. Push the plug

straight into the receptacle as shown in figure 2 until

Achieving Rated Watertightness

Rated ingress protection applies to the device when

the plug and receptacle are mated and latched

together. It also applies to the receptacle when the

lid is latched closed.

Lockout Provisions

All DS and DSN plugs are provided with lockout provisions. To lockout the plug, insert a locking device

through the hole provided in the casing. This will

prevent the plug from being inserted into a receptacle.

DS and DSN receptacles may be purchased with

optional lockout provisions. To lockout the receptacle,

close and latch the lid and then attach the locking

device through the hole provided in the pawl. This

will prevent the lid from being opened for the insertion of a plug.

Meltric Corporation shall not be held liable when its

products are used in conjunction with products not

bearing the

Meltric products in conjunction with mating devices

that are not marked with the

TM

Quality Label. The use of

M

T

Quality

Label shall void all warranties on the product.

Meltric Corporation is an ISO 9001 certified company.

Its products are designed, manufactured and rated in

accordance with applicable UL, CSA and IEC standards. Meltric is also a member of BECMA, the international Butt-contact Electrical Connectors

Manufacturers’ Association. Like all members,

Meltric additionally designs and manufactures its

products in accordance with BECMA standards

established to ensure intermatablility with similarly

rated products manufactured by other members.

www.becma.ch

INSDS/DSN 072408 E

Loading...

Loading...