WARNING

ENGLISH OPERATING INSTRUCTIONS

A

COMPANY OF MARECHAL ELECTRIC

OPERATING INSTRUCTIONS

DR/DR7C/DS7C

©2019 MELTRIC Corporation. All rights reserved.

DR/DR7c/DS7c

A manufacturer of products using MARECHAL

GENERAL

MELTRIC’s DR, DR7c and DS7c series industrial plugs

and receptacles are designed to ensure user safety

and provide reliable connections. Please follow the

instructions below to ensure the proper installation and

use of the product.

There are inherent dangers

products. Failure to follow safety precautions can

result in serious injury or death. These instructions must

be followed to ensure the safe and proper installation,

operation and maintenance of the MELTRIC devices.

Before installation, disconnect all sources of power to

the circuit to eliminate the risk of electrical shock.

RATINGS

All DR devices are rated to withstand short circuit

currents with appropriate fusing as indicated in Table 1.

Table 1 - Short Circuit Withstand Rating

Device Fuse Rating Type*

DR30 30A 100kA @ 600 VAC

DR50 50A 100kA @ 600 VAC RK1 50A

DR100 100A 100kA @ 600 VAC RK1 100A

DR150 150A 65kA @ 600 VAC RK1 175A

DR225 225A 10kA @ 600 VAC RK1 250A

DR250 250A 10kA @ 600 VAC RK1 250A

DR400 400A 18kA @ 600 VAC/VDC RK1 400A

* Rating applies with fusing up to this amperage. Ratings are based on tests

performed with Mersen non-time delay current limiting fuses.

The DR products are manufactured and rated in

compliance with applicable UL and CSA standards.

The products ratings are indicated on the device labels.

Some DR, DR7 and DS7 devices are provided with

optional auxiliary contacts that make after and break

before the phase contacts. The ratings for auxiliary

contacts are shown in Table 2.

Table 2 - Auxiliary Contact Ratings

Device 120VAC 240VAC 480VAC 600VAC

DR30, DR50 6A 3A 1.5A 1.2A

DR100

2 Aux

DR100

3 & 4 Aux

DR150, DR400 1.5A .75A .37A .3A

DR225, DR250 1.5A .75A .37A .3A

DS7c – – 5A (400V max)* –

DR7c – 5A* – –

* Rating is not UL or CSA listed

associated with electrical

6A 3A 1.5A 1.2A

3A 1.5A .75A .6A

INSDR/DR7/DS7 O

®

TECHNOLOGY

RK5 30A

RK1 30A

INSTALLATION

These products should be installed by qualified

electricians in accordance with all applicable

local and national electrical codes.

Before starting, verify that the power is off, that the

product ratings are appropriate for the application,

and that the conductors meet code requirements

and are within the capacities of the terminals noted

in Table 3.

Table 3 - Wiring Terminal Capacity1 (in AWG)

Device

DR30

DR50

DR100

DR150

DR250

4

DR400

DS7c/DR7c

1

Capacity is based on THHN wire sizes

2

Auxiliary contacts are optional and may not be on all products.

3

Auxiliary contacts are prewired at the factory.

4

Use with 75 degree C wire.

Main Contacts

Min Max Max

14 8 14

14 4 14

10 2 14

4 2/0 14

4 4/0 14

350 MCM

2

14 8 8

Aux.

Contacts

3

3

3

3

14

2

General Notes & Precautions

1. Self-tapping screws are provided for use with

some polymeric accessories. High torque may

be required to drive them in. Once they are

seated, care should be taken in order to avoid

over-tightening them against the plastic material.

2. Various handles and cord grip options may be used.

These instructions are based on handles provided

with integral multi-layer bushing cord grips.

3. Wire strip lengths are indicated in Table 4. Strip

lengths for cable sheathing will depend on the

specific application. When used with handles, the

cable sheathing should extend into the handle to

ensure secure cord gripping.

Table 4 - Wire Strip Lengths – Dimensions A

Receptacle Plug/Inlet

Device/Contact Inches mm Inches mm

DR30 Phase 7/16 10 3/4 19

DR50 Phase 3/4 18 7/8 22

DR100 Phase 15/16 24 15/16 24

DR150 Phase 1-3/16 30 1-3/16 30

DR225,DR250Phase 1-1/2 30 1-1/2 30

DR400 Phase 2-3/8 60 2-3/8 60

DS7c/DR7c Phase 1-1/16 27 1-1/16 27

Auxil. 7/16 10 3/4 19

Auxil. 7/16 10 3/4 19

Auxil. 5/8 16 5/8 16

4. Wiring terminals are spring assisted to prevent

loosening due to wire strand settlement, vibration

and thermal cycling. NOTICE: They should not

be over-tightened. Appropriate tools and

tightening torques are indicated in Table 5.

5. NOTICE: MELTRIC threaded handles come with

tapered style threads. The use of fitting seal tape is

recommended to maintain watertightness of

all NPT fittings and joints.

Table 5 - Terminal Screw Tightening Torques

Device/Contact

DR30 Phase 15 1.7 4 mm or 3/16” precision tip

Auxil. 13 1.5 4 mm or 3/16” precision tip

DR50 Phase 15 1.7 5 mm or 3/16” precision tip

Auxil. 7 .8 3 mm or 1/8” precision tip

DR100 Phase 48 5.4 4 mm hex head

DR150 Phase 90 10.2 4 mm hex head

DR250 Phase 110-133 12.5-15.0 5 mm hex head

DR400 Phase 70-90 7.9-10.1 4 mm hex head

DS7c/DR7c Phase 16 1.8 3.5 mm or 1/8” precision tip

Torque

in-lbs N-m

Required Screwdriver or

Allen Wrench

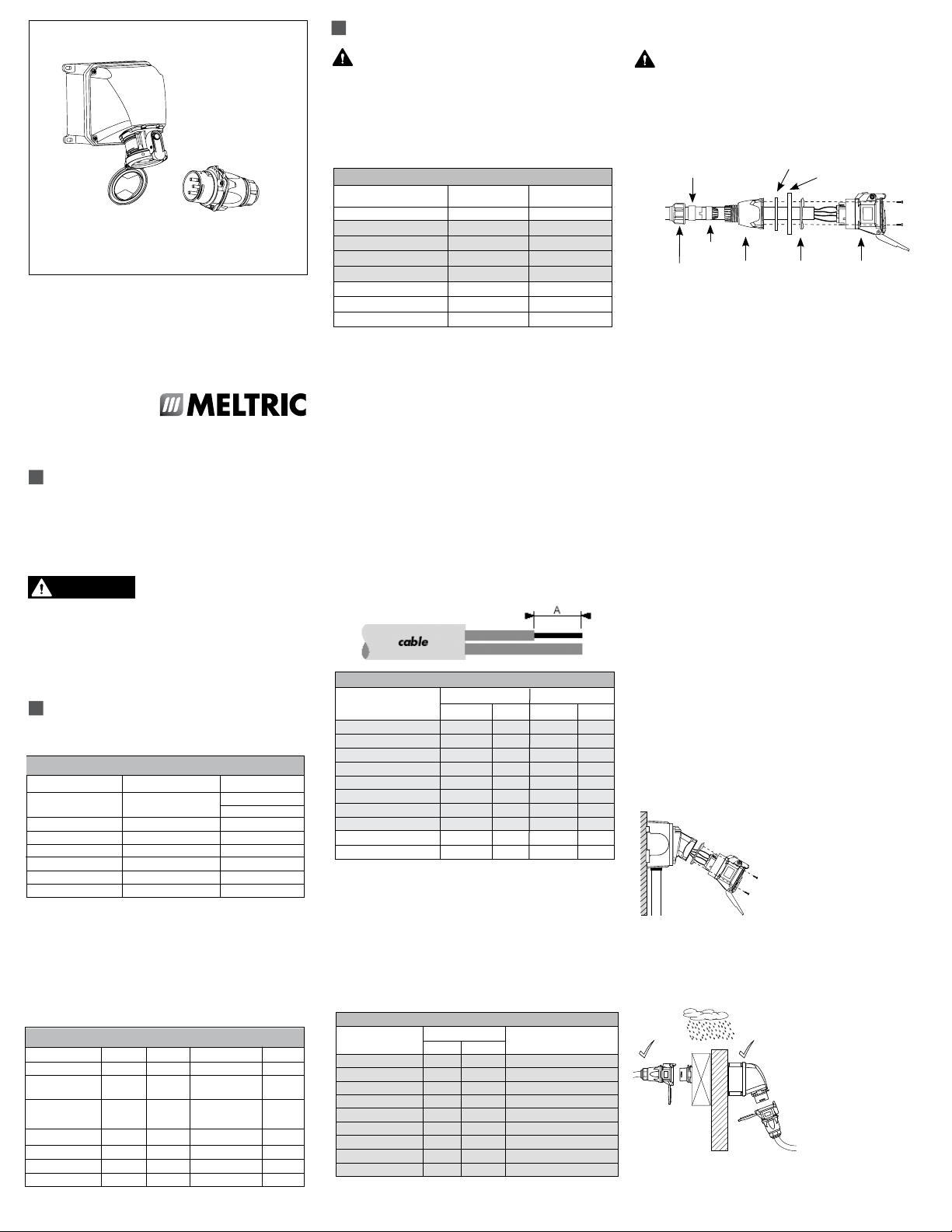

Assembly for In-Line Connections

Do not overtighten terminal or self-tapping screws.

Tighten screws to the proper torque to ensure a

secure connection.

When these products are used as in-line connectors, finger

drawplates (or a drawbar mechanism) should be installed on

both the receptacle and plug in order for the user to more

easily provide the leverage required to connect the device.

Bushing

Compression

Nut

Strain

Relief

Handle

Finger Drawplate Gasket

Finger Drawplate

Color-Coded

Gasket

Receptacle

(or Inlet)

For poly handles with strain relief, adjust the bushing diameter

to fit the cable by removing inner sections of the bushing

as required. Insert the bushing into the strain relief, then

insert the assembly into the handle and loosely install the

compression nut. Insert the cable through the handle, the thin

black drawplate gasket and finger drawplate (if applicable)

and the color coded gasket. Strip the cable sheath to provide

a workable wire length, being mindful that the sheath must

extend into the handle to achieve a secure cord grip. Then

strip the individual wires to the lengths indicated in Table 4

and twist the strands of each conductor together.

Back out the terminal screws on the receptacle (or inlet) far

enough (but not completely) to allow the conductors to pass,

insert the conductors fully into their respective terminals and

tighten the terminal screws with the appropriate tool to the

torque indicated in Table 5.

Verify that the cable sheath extends beyond the strain relief

and into the handle. Assemble the receptacle (or inlet), the

color coded gasket, the finger drawplate, and the thin black

drawplate gasket to the handle with the four self-tapping

screws provided. Adjust the cable location so that it will

not be under tension inside the handle and tighten the

compression nut to secure the cable.

Assembly for Mounted Receptacles (or Inlets)

In applications where the receptacles (or inlets) are

mounted to wall boxes, panels or other equipment, optimal

operation is achieved when the device is installed with the

latch at the top.

Insert the cable or wires through the wall box and cut to

allow adequate length, strip the cable sheath as desired,

strip the individual wires to the lengths indicated in Table

4. Back out the terminal screws on the receptacle (or inlet)

far enough (but not completely) to allow the conductors

to pass, insert the conductors fully into their respective

terminals and hand tighten the

terminal screws to the torque

indicated in Table 5.

Assemble the receptacle (or

inlet) and the color-coded

gasket to the box with the

appropriate hardware.

Assemble the mating plug (or

receptacle) to the cord end

as indicated in the assembly instructions above for in-line

connections, except there will be no finger drawplate or

associated black gasket.

Reverse Service Installations

For reverse service

applications having inlets

rigidly moutned to a wall

Type 3R

rated devices

180°

180°

Type 4X

rated

devices

panel or box + angle,

the mating connector

(receptacle + handle)

may require a 180°

Open Lid.

Most DR Receptacles

have 180° open lids

as standard. They are

an available option on;

DR100 metal, DR150

metal, DR250, DR7c

metal and DS7c metal.

For reverse service

WARNING

applications where use

of a receptacle with a

180° Open Lid is not

Type 4X

possible, install inlet

Type 3R

rated devices

Periodic inspection and replacement of the gaskets may be

required to maintain water tightness in the pictured Type

4X installations.

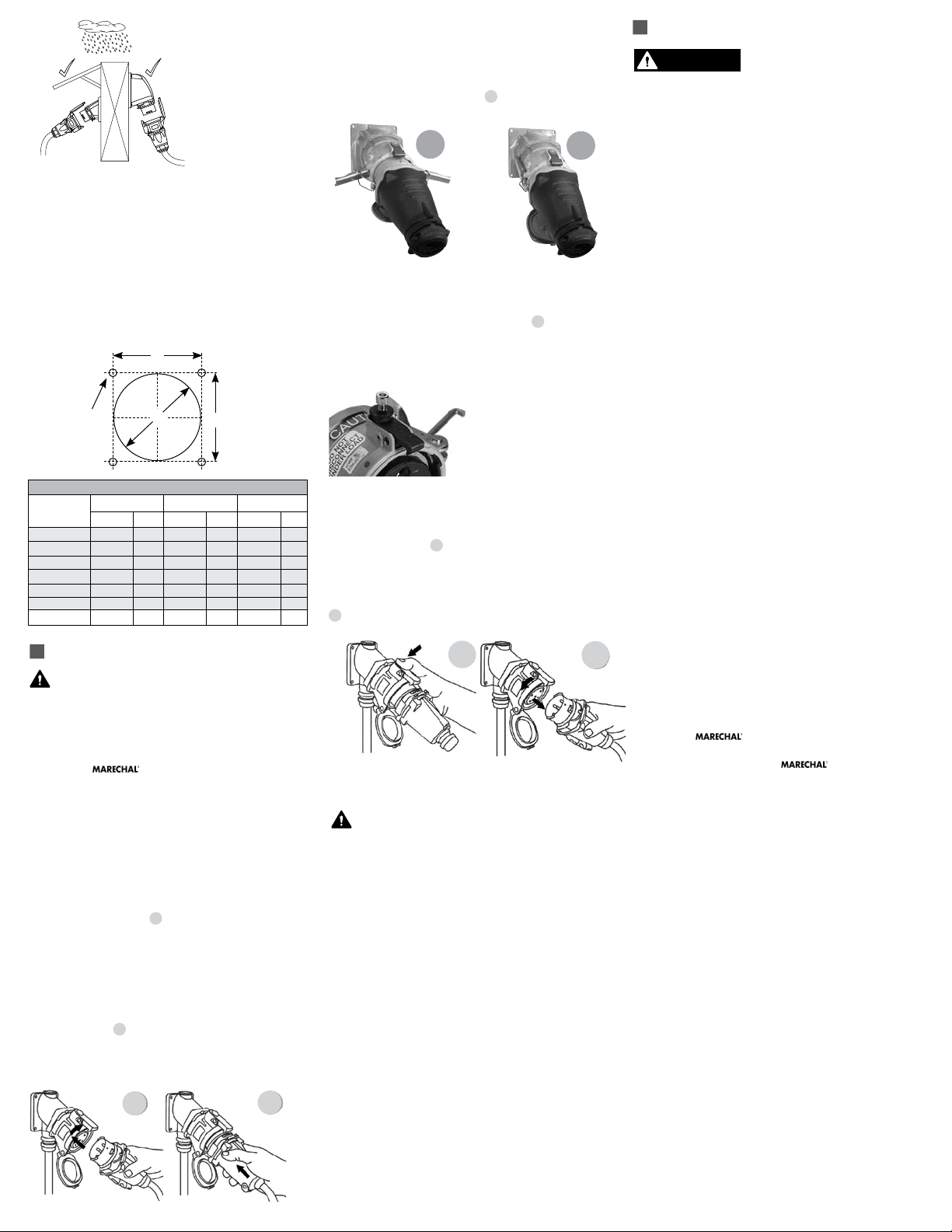

Hole Pattern for Custom Mounting

In applications where custom mounting to a panel or

box is desired, the clearance and mounting holes should

be drilled as indicated in the following diagram and

Table 6.

C

Table 6 - Custom Mounting Dimensions

‘A’ ‘B’ ‘C’

Model Inches mm Inches mm Inches mm

DR30 2.25 57 1.89 48 .19 5

DR50 2.50 64 2.17 55 .19 5

DR100 3.25 83 2.59 66 .22 5.5

DR150 4.00 102 3.20 81 .22 5.5

DR250 4.50 114 3.86 98 .28 7

DR400 4.50 114 3.86 98 .28 7

DS7c/DR7c 3.25 83 2.59 66 .22 5.5

OPERATION

To ensure safe and reliable operation MELTRIC

plugs and receptacles must be used in

accordance with their assigned ratings.

MELTRIC plugs can only be used in conjunction

with mating receptacles or plugs manufactured by

MELTRIC or another licensed producer of products

bearing the technology trademark.

MELTRIC plugs & receptacles are designed with

different keying arrangements, so that only plugs and

receptacles with compatible contact configurations and

electrical ratings will mate with each other.

Connection

To connect a plug and receptacle, first depress the

pawl to open the lid on the receptacle, then orient the

plug as shown in figure 1 so that the red dot on the

outside of the casing lines up with the red dot just to

the left of the latch on the receptacle casing. Using

a straight motion, push the plug partially into the

receptacle until it hits a stop, then rotate the plug in the

clockwise direction until it hits another stop after about

30° of rotation. At this point, the circuit is still open.

Push the plug straight into the receptacle as shown in

figure 2 until it becomes securely latched in place.

On in-line connectors with drawplates, squeeze the

drawplates on both sides of the device together until

the plug latches in place.

rated

with latch on bottom.

devices

When facing downwards

Type-3R inlets do

not protect mating

connectors against

streaming water. Use

Type-4X devices or a

rain hood for additional

water protection.

B

A

1

B

2

On the DR150, DR250 & DR400 devices, an integral

mechanism provides easy connection of the plug to the

receptacle. With the DR150, DR250 & DR400 plug

partially inserted and rotated 30° so that it is positioned

for connection, place the wire clamps around the

boltheads as shown in figure 3

3

To pull the plug into the receptacle, simply push the

handles back along the side of the receptacle and then

push the plug into the receptacle until the plug

is latched in place, as shown in figure 4. The

electrical connection is now made. The mechanism

must be released to allow disconnection of the device.

KEY FEATURE

Standard Locking Pawl 5/16" hole (standard).

DR400 receptacles are

provided with a screw-type

locking pawl that prevents

accidental disconnections

under load.

Disconnection

To break the connection, simply depress the pawl

as shown in figure 5. This will break the circuit and

eject the plug straight out to the rest, or off, position.

The plug contacts are de-energized at this point. To

remove the plug, rotate it counter-clockwise (about 30°)

until it releases from the receptacle as shown in figure

6. Close and latch the lid on the receptacle.

5

Achieving Environmental Ratings and Watertightness

For devices rated Type 4, 4X or 3R, use only

with mating devices having identical markings to

maintain enclosure rating of the mated pair.

Rated ingress protection applies to the device when

the plug and receptacle are mated and latched

together. It also applies to the receptacle when the lid

is latched closed.

Lockout Provisions

Some MELTRIC plugs are provided with lockout

provisions. To lockout the plug, insert a locking device

through the hole provided in the casing. This will

prevent the plug from being inserted into a receptacle.

Some receptacles may be purchased with optional

lockout provisions and used with 5/16-inch shank

locks. To lockout the receptacle, close and latch the

lid and then attach the locking device through the hole

provided in the pawl. This will prevent the lid from

being opened for the insertion of a plug.

4

6

MAINTENANCE

Before inspecting, repairing, or

disconnect electrical power to the receptacle to

eliminate the risk of electrical shock.

MELTRIC products require little on-going maintenance.

However, it is a good practice to periodically perform

the following general inspections:

• Check the mounting screws for tightness.

• Verify that the weight of the cable is supported

by the strain relief mechanism and not by the

terminal connections.

• Check the IP gaskets for wear and resiliency.

Replace as required.

• Verify the electrical continuity of the ground circuit.

• Check the contact surfaces for cleanliness and

pitting.

Deposits of dust or similar foreign materials can be

rubbed off the contacts with a clean cloth. Sprays

should not be used, as they tend to collect dirt. If

any significant pitting of the contacts or other serious

damage is observed, the device should be replaced.

Receptacle contacts may be inspected by a qualified

electrician. This should only be done with the power

off. It is accomplished by depressing the numbered

ring around the circumference of the interior on two

opposite points. This will allow the shutter to be

manually turned clockwise as required to permit access

to the contacts. Once the inspection is complete, the

shutter must be rotated counter-clockwise until it is

locked in the closed position.

MANUFACTURER’S RESPONSIBILITY

MELTRIC’s responsibility is strictly limited to the repair

or replacement of any product that does not conform

to the warranty specified in the purchase contract.

MELTRIC shall not be liable for any penalties or

consequential damages associated with the loss of

production, work, profit or any financial loss incurred by

the customer.

MELTRIC Corporation shall not be held liable when

its products are used in conjunction with products not

bearing the

of MELTRIC products in conjunction with mating devices

that are not marked with the

trademark shall void all warranties on the product.

MELTRIC Corporation is an ISO 9001 certied company. Its products are designed, manufactured and

rated in accordance with applicable UL, CSA and IEC

standards. MELTRIC designs and manufactures its

products in accordance with Marechal keying standards

established to ensure intermatablility with similarly rated

products manufactured by Marechal Electric Group.

maintaining MELTRIC products,

technology trademark. The use

technology

NOTICE: Attaching the receptacle locking device with

the receptacle lid open will not prevent the insertion of

a plug. Lockout of the receptacle is only accomplished

when the lid is locked closed.

INSDR/DR7/DS7 O

FRANÇAIS CONSIGNES D’UTILISATION

A

COMPANY OF MARECHAL ELECTRIC

DR/DR7C/DS7C

©2019 MELTRIC Corporation. All rights reserved.

A manufacturer of products using MARECHAL

RENSEIGNEMENTS GÉNÉRAUX

Les fiches et prises industrielles DR, DR7c et DS7c

de MELTRIC sont conçues pour assurer la sécurité

des utilisateurs et la fiabilité des connexions. Veuillez

suivre les instructions ci-dessous pour garantir

l’installation et l’utilisation adéquates du produit.

Les produits électriques

présentent des dangers

inhérents. Le non-respect des règles de sécurité peut

entraîner des blessures graves ou la mort. Les

présentes instructions doivent être suivies pour assurer

une installation, une utilisation et un entretien adéquats

et sécuritaires des appareils MELTRIC. Avant

l’installation, débranchez toute source d’alimentation du

circuit afin d’éliminer les risques d’électrocution.

CLASSIFICATION

Tous les appareils DR sont conçus pour résister à des

courants de court circuit Avec fusion approprié, indiqué

dans le tableau 1.

Table 1 - Short Circuit Résistent Note

Appareil Fusible Type*

DR30 30A 100kA @ 600 VAC

DR50 50A 100kA @ 600 VAC RK1 50A

DR100 100A 100kA @ 600 VAC RK1 100A

DR150 150A 65kA @ 600 VAC RK1 175A

DR225 225A 10kA @ 600 VAC RK1 250A

DR250 250A 10kA @ 600 VAC RK1 250A

DR400 400A 18kA @ 600 VAC/VDC RK1 400A

* Valable Rating Avec jusqu’à ce ampérage fusion. Les évaluations

sont basées sur des tests Ferraz Shawmut effectués avec des

fusibles de courant de retard non-temps de limitation.

Les produits de DR sont fabriqués en conformité et

classé UL et CSA aux normes en vigueur. Les produits

évaluations sont indiqués sur les étiquettes de l’appareil.

Certains appareils DR, DR7 et DS7 sont fournis avec

des contacts auxiliaires optionnels qui rendent pause

avant et après les contacts de phase. Les notes de

contacts auxiliaires sont présentés dans le tableau 2.

Tableau 2 – Calibre des contacts auxiliaires

Appareil 120V c.a. 240V c.a. 480V c.a. 600V c.a.

DR30,DR50 6A 3A 1.5A 1.2A

DR100 3A 1.5A .75A .6A

DR150, DR400 1.5A .75A .375A .3A

DR225, DR250 1.5A .75A .37A .3A

DS7c – – 5A (400V max)* –

DR7c – 5A* – –

* Calibre non homologué UL ou CSA.

INSDR/DR7/DS7 O

®

TECHNOLOGY

RK5 30A

RK1 30A

INSTALLATION

Ces produits doivent être installés par un

électricien qualifié, dans le respect de tous les

codes de l’électricité locaux et nationaux.

Avant de commencer l’installation, assurez-vous que

l’alimentation électrique est coupée, que le calibre des

produits correspond à l’utilisation prévue et que les

conducteurs satisfont aux normes des codes et qu’ils

ne dépassent pas la capacité des bornes indiquée au

tableau 3.

Tableau 3 – Capacité des bornes de raccordement

Appareil

DR30

DR50

DR100

DR150

DR250

4

DR400

DS7c/DR7c

1

Capacité indiquée pour des fils de type THHN.

2

Les contacts auxiliaires sont offerts en option sur certains produits seulement.

3

Les contacts auxiliaires sont précâblés en usine.

4

Utiliser avec le fil neutre de 75 degrés.

Contacts princ. Contacts aux.

Min Max Max

14 8 14

14 4 14

10 2 14

4 2/0 14

4 4/0 14

350 MCM

2

14 8 8

1

2

3

3

3

3

14

Remarques et précautions générales

1. Des vis autotaraudeuses sont fournies pour la pose

de certains accessoires en polymère. Un couple

élevé peut être nécessaire pour les enfoncer, mais

prenez soin de ne pas trop les serrer sur le plastique.

2. Différents types de poignées et différentes brides de

cordon peuvent être utilisés. Ces instructions sont

basées sur l’utilisation de poignées dont les embouts

s’adaptent à plusieurs grosseurs de câble.

3. Les longueurs de fil dénudé sont indiquées au

tableau 4. La longueur de câble à dénuder dépend de

l’utilisation prévue. Pour fixer un câble à une poignée,

assurez-vous que la gaine du câble dépasse à

l’intérieur de la poignée pour que le cordon offre une

bonne prise.

Tableau 4 – Longueurs de fil à dénuder – Dimensions A

Dispositif/Contact po mm po mm

DR30 Phase 7/16 11 3/4 19

Aux. 1/2 13 3/4 19

DR50 Phase 9/16 14 7/8 22

Aux. 1/2 13 5/8 16

DR100 Phase 15/16 24 15/16 24

DR150 Phase 1 3/16 30 1 3/16 30

DR225,DR250Phase 1-1/2 30 1-1/2 30

DR400 Phase 2 3/8 60 2 3/8 60

DS7c/DR7c Phase 1 1/16 27 1 1/16 27

DS7c/DR7c Aux. 5/8 16 5/8 16

Prise Fiche

4. Les bornes de raccordement sont dotées de ressorts

pour empêcher la formation d’un jeu causée par le

déplacement des brins des câbles, les vibrations et

les cycles thermiques. MISE EN GARDE: Elles ne

doivent pas être trop serrées. Le tableau 5 indique les

outils à utiliser et les couples de serrage appropriés.

5. MISE EN GARDE: Les poignées filetées de

MELTRIC sont munies d’un filetage conique.

L’utilisation du ruban d’étanchéité pour maintenir

l’étanchéité à l’eau de tous les joints et raccords

NPT est recommandée.

Tableau 5– Couple de serrage des bornes de raccordement

Dispositif/Contact

DR30 Phase 15 1.7 4 mm ou pointe de 3/16” po

Aux. 13 1.5 4 mm ou pointe de 3/16” po

DR50 Phase 15 1.7 5 mm ou pointe de 3/16” po

Aux. 7 .8 3 mm ou pointe de 1/8” po

DR100 Phase 48 5.4 tête hex. de 5 mm

DR150 Phase 90 10.2 tête hex. de 5 mm

DR250 Phase 110-133 12.5-15.0 tête hex. de 5 mm

DR400 Phase 70-90 7.9-10.1 tête hex. de 4 mm

DS7c/DR7c Phase 16 1.8 3.5 mm ou pointe de 1/8” po

Torque

po-lb N.m

Tournevis

ou clé Allen

Assemblage pour montage en série

Ne serrez pas trop les vis des bornes et les vis

autotaraudeuses. Serrez les vis au couple approprié

pour assurer une bonne connexion. Pour l’utilisation de

ces produits comme connecteur en série, il est préférable

d’installer des plaques de levage (ou une barre) sur la

prise et sur la fiche afin de faciliter les branchements et

débranchements de l’appareil.

Embout

Écrou à

compression

Joint d’étanchéité de la plaque de levage

Serre-

câble

Poignée

Joint

d’étanchéité à

code de couleur

Plaque de levage

Prise (ou raccord

d’entrée)

Réglez le diamètre de l’embout à celui du câble en retirant

des rondelles intérieures au besoin. Insérez l’embout

dans le serre-câble, puis insérez l’assemblage dans la

poignée, pour ensuite installer l’écrou de compression sans

le serrer. Faites passer le câble dans la poignée, dans

la plaque de levage et son mince joint d’étanchéité noir

(si l’appareil en est équipé) et dans le joint d’étanchéité

à code de couleur. Retirez suffisamment de gaine pour

disposer d’une longueur facilitant le travail, en tenant

compte que la gaine doit entrer dans la poignée pour

assurer une prise solide. Dénudez ensuite chaque fil en

respectant les longueurs indiquées dans le tableau 4, puis

entortillez les brins de chaque conducteur.

Dévissez juste assez les bornes de raccordement

de la prise (ou du raccord d’entrée) pour permettre

le passage des conducteurs, insérez complètement

chaque conducteur dans la borne respective et resserrez

les bornes de raccordement avec l’outil approprié en

respectant les couples indiqués au tableau 5.

Assurez-vous que la gaine du câble dépasse le serre-câble et

pénètre dans la poignée. Installez la prise, le joint d’étanchéité

à code de couleur ainsi que la plaque de levage et son mince

joint d’étanchéité noir sur la poignée à l’aide des quatre vis

autotaraudeuses fournies. Réglez la position du câble de

manière à ce qu’il ne soit pas tendu dans la poignée, puis

serrez l’écrou de compression pour fixer le câble en place.

Assemblage des prises montées

Lorsque les prises sont installées dans des boîtiers muraux,

sur des panneaux ou sur un autre équipement, il faut,

pour assurer un fonctionnement optimal, que le verrou du

dispositif se trouve sur le dessus.

Insérez le câble ou les fils dans le boîtier mural et coupezles à une longueur appropriée. Dénudez le câble de

sa gaine et dénudez ensuite chaque fil sur la longueur

indiquée au tableau 4 avant d’entortiller les brins de

chaque conducteur. Dévissez les bornes de raccordement

de la prise juste assez pour permettre le passage des

conducteurs. Insérez complètement chaque conducteur

dans la borne appropriée

et resserrez les bornes de

raccordement à la main,

aux couples indiqués au

tableau 5.

Fixez la prise et le joint

d’étanchéité à code de

couleur au boîtier au

moyen des attaches

appropriées. Fixez la fiche à l’extrémité du cordon, comme

l’indiquent les directives d’assemblage en série ci-dessus,

en omettant la plaque de levage et son joint d’étanchéité.

Installations de type: Service Inversé

Pour les applications de

service inverse ayant des

Appareils

de type 3R

180°

180°

entrées montées rigidement

sur un panneau mural ou un

Appareils de

type 4X

angle + boîte, le connecteur

correspondant (réceptacle

+ poignée) nécessitera un

couvercle ouvert de 180°.

La plupart des récipients DR

ont des couvercles à 180° en standard. Ils sont une option

disponible sur; DR100 métal, DR150 métal, DR250, DR7c

métal et DS7c métal.

Pour les installations de

de type 4X

type Service Inversé, et que

l’utilisation de receptacle

avec couvercle à ouverture

Appareils

Appareils

de type 3R

avec la facade vers le bas, elles ne protègent pas les

receptacles avec lesquels est sont branchée contre

l’infiltration d’eau. Pour ces applications, l’utilisation

de produit Nema 4X est requis ou l’ajout d’un capot de

protection pour l’eau.

Dimensions des trous pour montage sur mesure

Dans le cas d’un montage sur mesure dans un

panneau ou un boîtier, les dégagements et les trous

de fixation doivent respecter les dimensions indiquées

dans le graphique et le tableau 6.

C

Tableau 6 – Dimensions pour montage sur mesure

Modèle po mm po mm po mm

DR30 2.25 57 1.89 48 .19 5

DR50 2.50 64 2.17 55 .19 5

DR100 3.25 83 2.59 66 .22 5.5

DR150 4.00 102 3.20 81 .22 5.5

DR250 4.50 114 3.86 98 .28 7

DR400 4.50 114 3.86 98 .28 7

DS7c/DR7c 3.25 83 2.59 66 .22 5.5

UTILISATION

Pour assurer une utilisation sécuritaire et fiable,

les fiches et prises MELTRIC doivent être utilisées

conformément à leur classification respective.

Les prises MELTRIC peuvent uniquement être utilisées

avec des fiches ou des prises fabriquées par MELTRIC

ou un autre fabricant de produits portant la marque

Les fiches et prises MELTRIC sont offertes avec

différentes configurations de contacts, de manière à ce

que seules les prises et fiches dont les contacts et les

calibres sont compatibles puissent être connectées.

Connexion

Pour brancher une fiche et une prise, abaissez d’abord cliquet

de verrouillage pour ouvrir le couvercle du socle de la prise,

puis placez la fiche dans la position illustrée à la figure 1 de

façon à ce que le point rouge à l’extérieur de l’enveloppe soit

aligné sur le point rouge situé à gauche du verrou se trouvant

sur le socle de la prise. En utilisant un mouvement droit vers

l’avant enfoncez partiellement la fiche dans la prise jusqu’à

ce qu’elle bloque, puis tournez-la dans le sens des aiguilles

d’une montre jusqu’à ce qu’elle bloque de nouveau après

une rotation de 30°. À cette étape, le circuit est toujours

ouvert. Enfoncez la fiche dans la prise jusqu’à ce qu’elle

soit engagée, comme l’illustre la figure 2. Dans le cas des

connecteurs en ligne avec plaques de rapprochement,

pressez les plaques de rapprochement situées de chaque

côté du dispositif jusqu’à ce que la fiche soit engagée.

‘A’ ‘B’ ‘C’

.

1

à 180o n’est pas possible,

installer la prise mâle avec

le bouton d’éjection vers

le bas.

Lorsque les prises mâle

de type 3R sont installées

B

A

B

2

Les appareils DR150, DR250 et DR400 sont pourvus

d’un mécanisme intégré qui permet de brancher

facilement la fiche dans la prise. Avec la fiche des

appareils DR150, DR250 et DR400 partiellement

insérée et tournée à 30° de façon à ce qu’elle soit

placée pour le branchement, placez les serre-fils autour

des agrafes comme montré à la figure 3

3

4

Pour placer la fiche dans la prise, poussez simplement

les poignées vers l’arrière le long de la prise puis

poussez la fiche dans la prise jusqu’à ce que la fiche

soit verrouillée en place, comme montré à la figure 4.

La connection électrique estmaintenant faite. Le mécanisme

doit être déclenché pour permettre le débranchement du

dispositif.

Déconnexion

Pour couper le circuit, appuyez simplement sur le

bouton-poussoir, comme l’illustre la figure 5. Le circuit

sera ainsi ouvert et la fiche sera éjectée en position de

repos. À cette étape, les contacts de la fiche sont hors

tension. Pour retirer la fiche, tournez-la dans le sens

antihoraire d’environ 30°, jusqu’à ce qu’elle se dégage

de la prise comme montré à la figure 6. Fermez le

couvercle de la prise et verrouillez-le.

5

6

Classification environnementale et étanchéité

Les dispositifs affichant un indice de protection

de type 4, 4X ou 3R doivent uniquement être utilisés

avec des dispositifs homologues affichant des cotes

identiques pour conserver le même indice une fois la

paire raccordée.

L’indice de protection est obtenu lorsque la fiche et la prise

sont complètement raccordées. Il s’applique également à

la prise lorsque le couvercle est fermé et verrouillé.

Cadenassage

Certaines fiches MELTRIC sont équipées d’un dispositif de

cadenassage. Pour verrouiller la fiche, insérez un dispositif

de cadenassage dans l’orifice prévu dans le boîtier.

Cette action empêche la fiche d’être insérée dans la prise.

Certaines prises sont proposées avec un dispositif

optionnel permettant l’utilisation d’un cadenas doté

d’une anse de 5/16" po. Pour cadenasser la prise,

fermez le couvercle et verrouillez-le, puis insérez le

cadenas dans l’orifice prévu à cette fin. Cela empêchera

le couvercle d’être ouvert pour l’insertion d’une fiche.

MISE EN GARDE

la prise lorsque le couvercle de la prise est ouvert

n’empêchera pas l’insertion d’une fiche. Le couvercle

doit être fermé et verrouillé pour permettre le

cadenassage de la prise.

ENTRETIEN

réparation ou à l’entretien de produits MELTRIC,

coupez l’alimentation électrique de la prise pour

éliminer tout risque de décharge électrique.

Les produits MELTRIC nécessitent peu d’entretien.

Cependant, il est recommandé d’effectuer périodiquement les inspections suivantes:

• Assurez-vous que les vis de montage sont bien

serrées.

• Assurez-vous que le poids du câble est supporté

par le serre-câble, et non par les bornes.

• Vérifiez l’état et l’usure des joints IP. Remplacezles au besoin.

• Vérifiez la continuité électrique du circuit de mise

à la terre.

• Examinez les surfaces de contact pour vous assurer

de leur propreté et de l’absence de piqûres.

Utilisez un linge propre pour enlever les dépôts de

poussière ou de corps étrangers. N’utilisez pas de

produits en vaporisateur, car ils ont tendance à ramasser

la saleté. En cas de piqûres importantes sur les contacts

ou d’autres dommages graves, remplacez l’appareil.

Les contacts de la prise doivent être inspectés par un

électricien qualifié, et seulement lorsque l’alimentation

électrique est coupée. Pour ce faire, abaissez l’anneau

numéroté situé autour de la circonférence intérieure

en deux points opposés. Vous pourrez alors tourner

manuellement le mécanisme d’obturation dans le sens

horaire afin d’accéder aux contacts. Une fois l’inspection

terminée, tournez le mécanisme d’obturation dans le sens

antihoraire jusqu’à ce qu’il revienne en position fermée.

RESPONSABILITÉ DU FABRICANT

La responsabilité de MELTRIC se limite strictement à

la réparation ou au remplacement de tout produit non

conforme à la garantie précisée dans le contrat d’achat.

MELTRIC ne peut être tenue responsable des pénalités

ou des dommages indirects découlant d’une perte de

production, de travail, de bénéfices, ou de toute perte

financière subie par le client.

MELTRIC Corporation ne peut être tenue responsable

lorsque ses produits sont utilisés avec d’autres produits

qui ne portent pas la marque de commerce . Le

branchement de produits MELTRIC dans des produits qui

ne portent pas la marque de commerce

effet d’annuler toutes les garanties du produit.

La société MELTRIC possède la certification ISO 9001, Ses

produits sont conçus, fabriqués et classés selon les normes

UL, CSA et IEC applicables. MELTRIC conçoit et fabrique

ses produits selon les standards de Marechal et assure la

compatibilité de ses produits avec ceux de maréchal ayant les

spécifications similaires.

: L’utilisation d’un cadenas avec

Avant de procéder Avant de

procéder à l’inspection, à la

a pour

INSDR/DR7/DS7 O

WARNING

DANGER

CAUTION

NOTICE

ESPAÑOL INSTRUCCIONES DE OPERACIÓN

con proteccion

A

COMPANY OF MARECHAL ELECTRIC

DR/DR7C/DS7C

©2019 MELTRIC Corporation. All rights reserved.

A manufacturer of products using MARECHAL

GENERAL

Los tomacorrientes y clavijas MELTRIC de la serie

DR, DR7c y DS7c están diseñados para mantener la

seguridad del usuario y proveer conexiones seguras.

Favor de seguir las instrucciones a continuación para

asegurar una instalación apropiada y uso del producto.

ADVERTENCIA

Existen peligros inherentes

asociados con los productos

eléctricos. El no seguir las precauciones de seguridad

puede resultar en lesiones graves o la muerte. Seguir

estas instrucciones para mantener una segura y

apropiada instalación, operación y mantenimiento de

los productos MELTRIC. Antes de instalar, desconecte

todas las fuentes de energía al circuito para eliminar

riesgos de una descarga eléctrica.

RANGOS

Todos los dispositivos DR están manufacturados para

soportar las corrientes de cortocircuito en conjunto con los

fusibles correspondientes, de acuerdo con la Tabla 1.

Table 1 - Rango de Soporte al Corto Circuito

Dispositivo Fusible Tipo*

DR30 30A 100kA @ 600 VAC

DR50 50A 100kA @ 600 VAC RK1 50A

DR100 100A 100kA @ 600 VAC RK1 100A

DR150 150A 65kA @ 600 VAC RK1 175A

DR225 225A 10kA @ 600 VAC RK1 250A

DR250 250A 10kA @ 600 VAC RK1 250A

DR400 400A 18kA @ 600 VAC/VDC RK1 400A

* Los Rangos aplican con fusibles hasta este rango en amperes. Los

rangos están basados en el desempeño en pruebas con fusibles

sin retardo de tiempo Ferraz Shawmut.

Los productos DR son manufacturados y calificados de

conformidad con las normas UL y CSA aplicables. Las

clasificaciones de productos están indicadas en las

etiquetas de los dispositivos. Algunos de los dispositivos

DR, DR7y DS7 se suministran con contactos auxiliares

opcionales, los cuales se conectan después y

desconectan antes que los contactos de fase. Los rangos

de los contactos auxiliares se muestran en la Tabla 2.

Tabla 2 - Rangos de los Contactos Auxiliares

Dispositivo 120VAC 240VAC 480VAC 600VAC

DR30,DR50 6A 3A 1.5A 1.2A

DR100 3A 1.5A .75A .6A

DR150, DR400 1.5A .75A .375A .3A

DR225, DR250 1.5A .75A .37A .3A

DS7c – – 5A (400V max)* –

DR7c – 5A* – –

* Los rangos no están listados por UL o CSA

INSDR/DR7/DS7 O

®

TECHNOLOGY

RK5 30A

RK1 30A

INSTALACIÓN

Estos productos deben ser instalados por electricistas

calificados, de acuerdo con todas las normas de

instalaciones eléctricas vigentes aplicables locales y

nacionales.

Antes de iniciar, verifique que el circuito no este energ-izado,

que el rango del producto es el apropiado para la aplicación, y

que los conductores cumplan con la normatividad vigente y se

encuentren dentro de la capa-cidad de las terminales que se

mencionan en la Tabla 3.

Tabla 3 – Capacidad de Alambrado1 (AWG)

Dispositivo

DR30

DR50

DR100

DR150

DR250

4

DR400

DS7c/DR7c

1

La Capacidad se basa en las dimensiones del cable THHN.

2

Los contactos auxiliares son opcionales y pueden no incluirse en todos los

productos.

3

Los contactos auxiliares se cablean previamente en fabrica.

4

Para uso con conductores de 75 C o más.

Contactos

Principales

Min Max Max

14 8 14

14 4 14

10 2 14

4 2/0 14

4 4/0 14

350 MCM

2

14 8 8

Contactos

Auxiliares

14

2

3

3

3

3

Notas & Precauciones Generales

1. Se proporcionan tornillos autorroscantes para ser

utilizados con algunos componentes poliméricos, puede

requerirse de un gran torque para colocarlos, una vez

hecho esto, evite apretarlos demasiado en

el material plástico.

2. Pueden utilizarse varias empuñaduras y conectores tipo

glándula para el conductor, estas instrucciones están

basadas en empuñaduras que utilizan conectores tipo

glándula para el cable con un empaque multicapa.

3. El largo del conductor requerido sin aislamiento para

introducir en las terminales se indica en la Tabla 4, este

largo dependerá de la aplicación específica, cuando

se utiliza con manijas el largo del cable sin aislamiento

deberá de llegar al fondo de la terminal para asegurar un

sujeción segura del conductor.

Tabla 4 - Largo del Cable sin Aislamiento – Dimensiones

Dispositivo/Polo Pulgadas mm Pulgadas mm

DR30 Fase 7/16 11 3/4 19

DR50 Fase 9/16 14 7/8 22

DR100 Fase 15/16 24 15/16 24

DR150 Fase 1 3/16 30 1 3/16 30

DR225/250 Fase 1-1/2 30 1-1/2 30

DR400 Fase 2 3/8 60 2 3/8 60

DS7c/DR7c Fase 1 1/16 27 1 1/16 27

DS7c/DR7c Auxil. 5/8 16 5/8 16

Auxil. 1/2 13 3/4 19

Auxil. 1/2 13 5/8 16

Tomacorriente Clavija

4. Las terminales están asistidas por un resorte (arillo de

seguridad) para evitar que se aflojen debido a vibración,

asentamiento o ciclo térmico. AVISO: No se deberá

dar un apriete excesivo a las mismas, herramientas

apropiadas y torques específicos deberán ser utilizados

como se indica en la Tabla 5.

5. AVISO: Se recomienda el uso de cintas selladoras

para la cuerdas, para impedir el ingreso de agua en las

uniones y juntas del tubo conduit (NPT).

Tabla 5 - Torques para los Tornillo de las Terminales

Dispositivo/Polo

DR30 Fase 15 1.7 4 mm o 3/16” tip de precisión

Aux. 13 1.5 4 mm o 3/16” tip de precisión

DR50 Fase 15 1.7 5 mm o 3/16” tip de precisión

Aux. 7 .8 3 mm o 1/8” tip de precisión

DR100 Fase 48 5.4 4 mm de cabeza hexagonal

DR150 Fase 90 10.1 4 mm de cabeza hexagonal

DR250 Fase 110-133 12.5-15.0 5 mm de cabeza hexagonal

DR400 Fase 70-90 7.9-10.1 4 mm de cabeza hexagonal

DS7c/DR7c Fase 16 1.8 3.5 mm o 1/8” tip de precisión

Pulg.-Lb

Torque

Desarmador Requerido

N-m

o Llave Allen

Ensamble de las tomacorrientes tipo extensión

No sobre apriete las terminales o los tornillos autorroscantes.

Apriete los tornillos al torque apropiado para mantener una

conexión segura. Cuando un DR / DR7c / DS7c son utilizados

como extensión se recomienda instalar “placas para

facilitar el cierre con los dedos”, tanto en las tomacorrientes

como en las clavijas para que el usuario pueda tener la palanca

necesaria para realizar la conexión del dispositivo. En los

dispositivos de rangos mayores (DR150, DR250 y DR400) las

“placas para facilitar el cierre con los dedos” no son necesarias

porque un mecanismo de cierre fácil se incluye como estándar

.

Ajuste el diámetro del Empaque Multicapa removiendo cada

una de las mismas según se requiera, inserte el Empaque

Multicapa en el Relevador de Esfuerzo, luego inserte el

ensamble en la empuñadura, enseguida libremente inserte

la Tuerca de Compresión. Inserte el cable en la Manija, el

empaque negro delgado, la Placa de Cierre con los Dedos (si

es necesario) y el Empaque Codificado por Color. Remueva

el aislamiento del cable para proveer un área de trabajo

adecuada, tomando en cuenta que se deberá de introducir en

la manija lo suficiente como para proveer un agarre seguro del

cable, entonces remueva el aislamiento de cada uno de los

conductores la distancia que se indica en la Tabla 4 y tuerza

los hilos de cada conductor para que se unan.

Empaque

Multicapa

Relevador

de Esfuerzos

Tuerca de

Compresión

Manija

Empaque para Placa

de Cierre con los

Empaque Codificado

Placa de Cierre con

por Color

Dedos

los Dedos

Tomacorriente

Afloje los tornillos de las terminales en la tomacorriente (o

clavija) lo suficiente (pero no completamente) para permitir que

pase el conductor, inserte completamente el conductor en las

terminales apropiadas y apriete los tornillos con la herramienta

apropiada al torque indicado en la Tabla 5.

Verifique que el aislamiento del cable se extienda más allá del

Relevador de Esfuerzos y dentro de la Manija. Ensamble el

tomacorriente (o clavija), el Empaque Codificado por Color, la

Placa de Cierre con los Dedos y el Empaque Negro Delgado

a la Manija con los 4 tornillos autorros cantes suministrados.

Ajuste el cable para que no esté bajo tensión dentro de la

Manija y apriete la Tuerca de Compresión para asegurar el

cable.

Ensamble para la Instalación de Tomacorrientes

(o Clavijas) en Cajas de Conexiones

Inserte el cable o alambre a través de la Caja de Conexiones

y corte permitiendo un largo adecuado, elimine el aislamiento

tanto como sea deseado, elimine el forro de los conductores

al largo indicado en la Tabla 4, tuerza las puntas de cada

conductor para unirlas. Afloje el tornillo de las Terminales

en la Tomacorriente (o

Clavija) lo suficiente (pero

no completamente) para

permitir que el conductor

pase, inserte el conductor

completamente en su

respectiva Terminal y apriete

manualmente el tornillo

al torque indicado en la

Tabla 5.

Cuando el tomacorriente esta instalada en un cable

Para aplicaciones de servicio

inverso que tienen entradas

Dispositivos

con proteccion

Tipo 3R

180°

180°

rígidamente montadas en

un panel de pared o caja

Dispositivos

+ ángulo, el conector de

Tipo 4X

acoplamiento (receptáculo +

mango) requerirá una tapa

abierta de 180°.

La mayoría de los

Receptáculos DR tienen

tapas de 180° como

estándar. Son una opción

disponible en; DR100 metal,

DR150 metal, DR250, DR7c

metal y DS7c metal.

Para aplicaciones de

WARNING

DANGER

CAUTION

NOTICE

con proteccion

servicio inverso donde el

uso de un tomacorriente con

tapa de apertura en 180 no

Dispositivos

Dispositivos

con proteccion

Tipo 3R

contra el ingreso de agua. La certificación Tipo 3R se

pierde. Use dispositivos con protección Tipo 4X o una

cubierta para la lluvia para protección adicional.

Ensamble el Tomacorriente (o Clavija) y el Empaque

Codificado por Color a la caja con la tornillería

adecuada. Ensamble la Clavija (o Tomacorriente) al

final del cable como se indican en las instrucciones

de ensamble ya descritas para extensiones, excepto

que no habrá Placas de Cierre con los Dedos o el

Empaque Negro Delgado asociados.

Dimensiones de Barrenos para Montajes Especiales

En aplicaciones en donde se requieran montajes

especiales a un panel o caja, los barrenos y las

distancias entre ellos deberán de hacerse de acuerdo

con el diagrama siguiente y la Tabla 6.

C

Tabla 6 - Dimensiones de Barrenos para Montajes Especiales

Modelo Pulgadas mm Pulgadas mm Pulgadas mm

DR30 2.25 57 1.89 48 .19 5

DR50 2.50 64 2.17 55 .19 5

DR100 3.25 83 2.59 66 .22 5.5

DR150 4.00 102 3.20 81 .22 5.5

DR250 4.50 114 3.86 98 .28 7

DR400 4.50 114 3.86 98 .28 7

DS7c/DR7c 3.25 83 2.59 66 .22 5.5

OPERACIÓN

Para asegurar una operación segura y confiable

de los Tomacorrientes y Clavijas MELTRIC estas

se deberán de utilizar de acuerdo con sus

Rangos de Operación.

Los Tomacorrientes MELTRIC solo pueden utilizarse

en conjunto con Clavijas MELTRIC o de otro fabricante

autorizado de los productos que ostenten la marca

registrada

MELTRIC diseña sus Tomacorrientes y Clavijas con

posiciones de bloqueo diferentes de tal manera que solo

los Tomacorrientes y Clavijas que tienen las mismas

configuraciones de contactos y voltajes pueden acoplarse

entre sí, de acuerdo con la legislación local vigente.

Conexión

Para conectar un tomacorriente y clavija, primeramente

presione el gatillo para abrir la tapa del tomacorriente

y luego oriente la clavija como se indica en la figura 1,

de tal manera que el punto rojo en la parte exterior de

la clavija este alineado con el punto rojo a la izquierda

del gatillo en el tomacorriente. Empuje la clavija

parcialmente en el tomacorriente hasta que llegue

al tope. Gire la clavija en dirección de las manecillas

del reloj hasta que llegue al tope, después de girar

aproximadamente 30°.

‘A’ ‘B’ ‘C’

1

es posible, instale la clavija

Tipo 4X

con el enganche orientado

hacia abajo.

Cuando las clavijas están

orientadas hacia abajo no

protegen a los tomacorrientes

B

A

.

B

2

En este punto el circuito sigue abierto, empuje la

clavija hacia el tomacorriente como se muestra en

la figura 2, hasta que esté asegurada en su lugar, la

conexión eléctrica se ha realizado. En tomacorrientes

y clavijas utilizadas como extensiones, apriete

las placas para cierre con los dedos en los lados del

dispositivo hasta que se asegure en su lugar.

En los dispositivos DR150, DR250, y DR400 un

mecanismo integral provee una conexión fácil de la

clavija al tomacorriente. Con las clavijas DR150,

DR250 y DR400 parcialmente insertadas y giradas 30°

de tal forma que estén en posición para conectarse,

ponga los arillos de alambre en las cabezas de los

tornillos como se muestra en la figura 3.

3

4

Para insertar la clavija al tomacorriente simplemente

empuje los manerales de cada lado del dispositivo

hasta que la clavija esté asegurada en su lugar como

se muestra en la figura 4. Después de la conexión el

mecanismo deberá de ser liberado para permitir la

desconexión del dispositivo.

Desconexión

Para desconectar, simplemente presione el gatillo

como se muestra en la figura 5. Esto abrirá el circuito

y expulsara la clavija directamente a la posición de

descanso o fuera, en este punto los contactos de la

clavija esta desenergizados. Para retirar, gire la clavija

en sentido contrario de las manecillas del reloj (cerca

de 30°) hasta llegar a un tope. Retire la clavija del

tomacorriente como se muestra en la figura 6. Cierre y

asegure la tapa del tomacorriente.

5

Protección Contra el Ingreso de Agua y Rangos

Ambientales.

Para los dispositivos tipo 4, 4X, o 3R, use únicamente

para acoplarlos los tomacorrientes y clavijas con los

rangos idénticos para mantener la protección requerida

en el par.

El rango de protección solo es alcanzado cuando el

tomacorriente y clavija están cerrados y asegurados por

el gatillos. También aplica para el tomacorriente cuando

la tapa está asegurada con el gatillo.

Accesorios de Bloqueo

Todas las Clavijas se provén con provisiones

para bloqueo. Para bloquear la Clavija, inserte

en el barreno provisto en el cuerpo de la Clavija el

dispositivo de bloqueo, esto impedirá que se pueda

insertar en el Tomacorriente.

6

Los tomacorrientes pueden ser adquiridos con

provisiones opcionales de bloqueo y etiquetado, y

utilizados con candados con un diámetro de 5/16

pulgadas. Para bloquear el tomacorriente, cierre la

tapa y asegúrela e inserte el dispositivo o candado

en el barreno que se encuentre en el gatillo. Esto

impedirá que la tapa sea abierta e insertar la clavija.

AVISO: Instalar el dispositivo de candado con la

tapa abierta no impedirá la inserción de la clavija. El

bloqueo del tomacorriente solo se puede lograr cuando

la tapa está cerrada y asegurada por el gatillo y con el

dispositivo de bloqueo instalado.

MANTENIMIENTO

ADVERTENCIA

MELTRIC desconecte la alimentación al tomacorriente

para eliminar el riesgo de una descarga eléctrica.

Los productos MELTRIC requieren de muy poco

manteni-miento, de cualquier manera es muy

recomendable que realicen las siguientes prácticas de

inspección general:

• Revise el apriete de los tornillos de montaje.

• Verifique que el peso del cable este soportado en el

relevador de esfuerzos y no en las terminales

de conexión.

• Revise el desgaste y ajuste del empaque IP,

intercámbielo según se requiera.

• Verifique la continuidad eléctrica del circuito de tierra.

• Revise la limpieza y desgaste de la superficie de los

contactos.

Depósitos de polvo o materiales ajenos similares pueden

ser limpiados con un trapo limpio. Aerosoles no deben

ser utilizados por que atraen suciedad. Su un desgaste

es severo en los contactos o cualquier otro daño serio en

el dispositivo son encontrados, el dispositivo deberá de

ser reemplazado.

Los contactos del tomacorriente pueden ser

inspeccionados por un electricista calificado, esto deberá

de ser realizado con el equipo desenergizado, y puede

ser realizado presionando el arillo numerado colocado

en la circunferencia interior del dispositivo en dos puntos

opuestos. Esto permitirá que la cortinilla de bloqueo se

mueva manualmente en el sentido de las manecillas del

reloj para permitir el acceso a los contactos. Una vez que

la inspección a terminado la cortinilla de bloqueo deberá

de ser girada en el sentido opuesto de las manecillas del

reloj hasta regresarla a su posición de bloqueo.

RESPONSABILIDAD DEL FABRICANTE

La responsabilidad de MELTRIC está limitada

estrictamente a la reparación y o reemplazo de

cualquier producto que no cumpla con la garantía

especificada en el contrato de compra. MELTRIC

no puede ser responsabilizado por fallas, daño a

consecuencia de la perdida de producción o cualquier

perdida financiera en la que incurra el cliente.

MELTRIC Corporation no puede ser responsabilizado

cuando sus productos son utilizados en conjunto

con otra marca que no tenga la marca registrada

. El uso de dispositivos acoplables que no

tengan la marca registrada

garantía en el producto.

MELTRIC Corporation es una compañía certicada ISO

9001. Sus productos están diseñados, manufacturados y certicados de acuerdo con las normas aplicables de UL, CSA e

IEC. MELTRIC diseña y manufactura sus productos conforme

las normas de conguración establecidas por Marechal para

asegurar su compatibilidad con productos con rangos simi-

lares manufacturados por Marechal Electric Group

Antes de inspeccionar, reparar

o mantener los productos

invalidara toda

.

INSDR/DR7/DS7 O

Loading...

Loading...