Page 1

Melitta SystemService

Melitta 190

Operating Instructions

Page 2

3

1

2

3

4

5

6

7 8

13

14

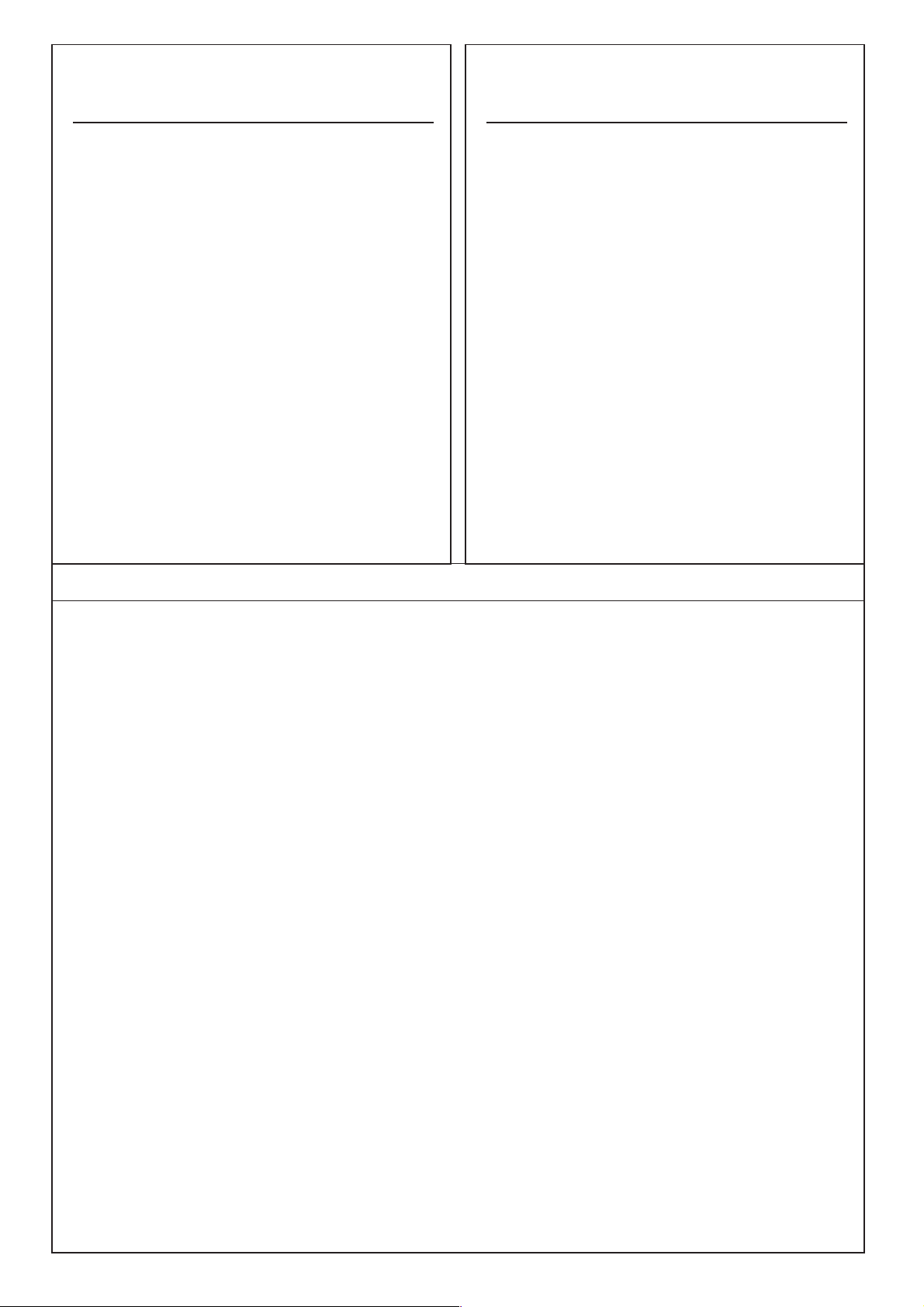

15

16

17

18

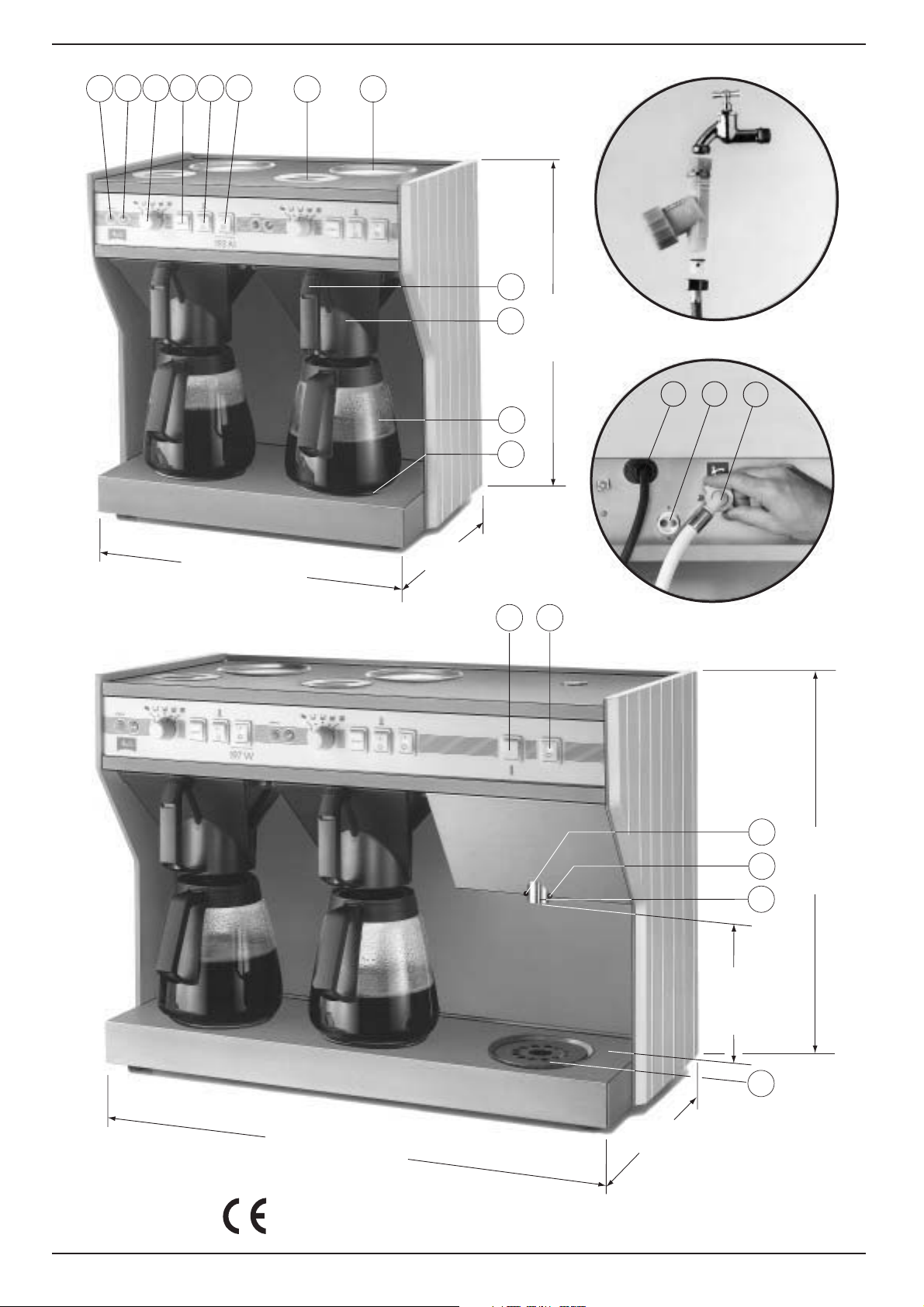

520

9

10

11

12

340

191 M/A = 270

192 M/A = 500

520

185

340

193 W = 500

197 W = 730

abc

IPX 3

Page 3

GB

Description of parts

1 Servicing indicator lamp

2 Operation indicator lamp

3 Quantity selector switch

4 Start button for filtering programme

5 On/Off switch for top warm holder

6 On/Off switch for filtering unit

7 Lid for water container

8 Top warm holder

9 Drip prevention lever

10 Slide-in filter

11 Glass jug

12 Lower warm holder

13 Switch hot water

14 On/off switch for hot water unit

15 Discharge water boiler

16 Temperature limiter

17 Hot water fittings

18 Drip tray

Connection and assembly

All Melitta appliances are supplied ready for connection. Prior

to installation all necessary connections which are to be

provided by customer must be easily accessible within a radius

of 1 mtr. This preliminary work must be carried out by licensed

experts and must be according to current rules and regulations.

Melitta service personnel is not authorised to do this and will

not take any responsibility for the installation.

a) Electric supply

The connection is dependent on the type of machine and its

technical specifications. Voltage must correspond with the data

indicated on the nameplate. The customer must provide separate fuse protection for the supply line. Connection should to

be via a sokket which must have a fault-current protection

switch. In case of permanent connection a switch with at least

3 mm power line separation should be provided to guarantee

an all mains power disconnection.

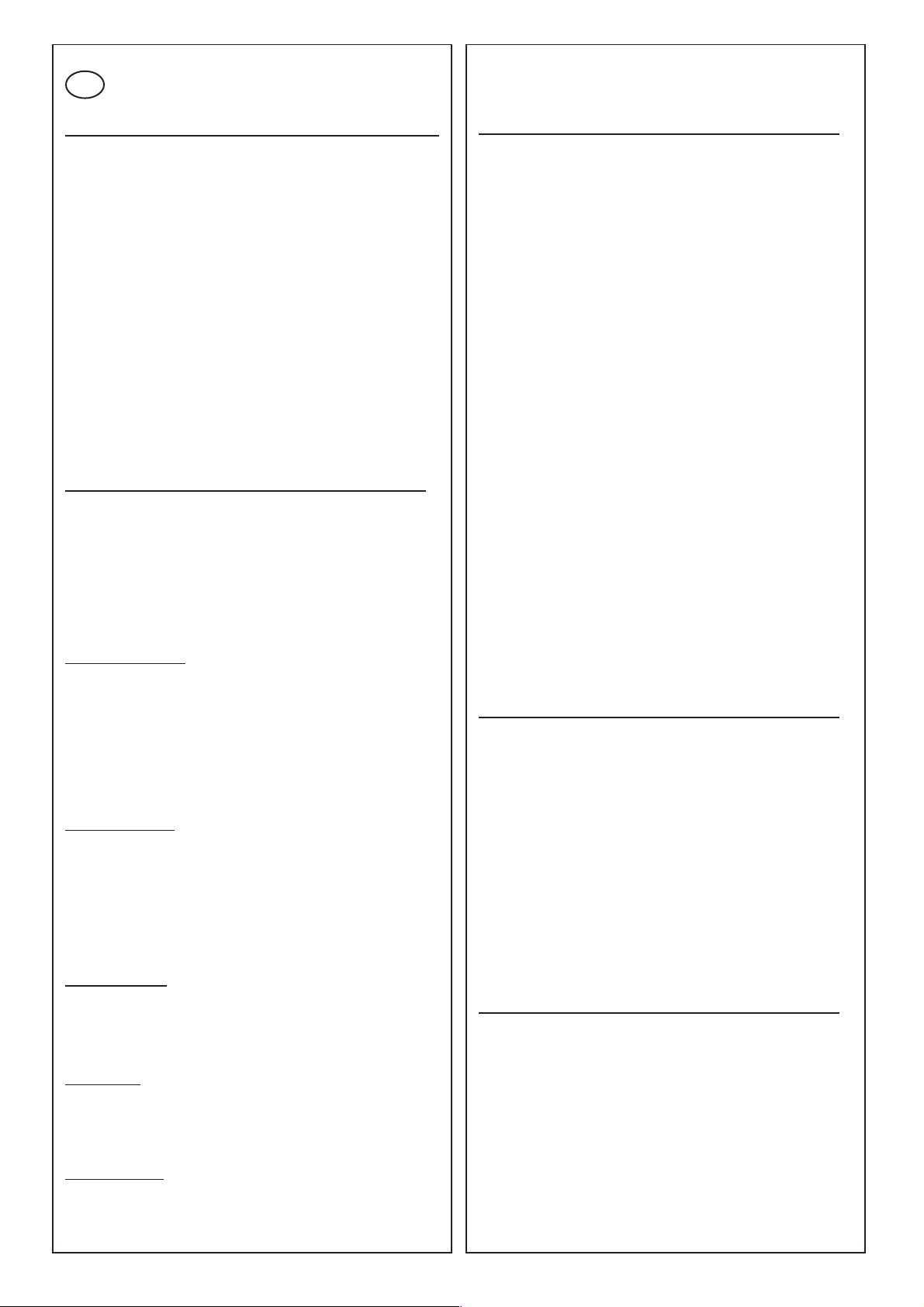

b) Water supply (does not apply for machines type M)

In accordance with regulations a tap with a non-return valve is

to be installed at an easily accessible place. A special connection hose is supplied with the machine and for safety reasons

this hose must not be shortened at assembly. Water pressure

must be at least 2 bar. If water pressure is more than 6 bar

then a pressure reducing valve must be installed between the

main tap and the machine.

c) Water outlet (does not apply for machines type M)

All machines are equipped with a connection piece at the water

outlet which can be loosely affixed to a drain pipe together with

the supplied hose.

Water filter

Upon request we install water treatment equipment in all our

coffee machines. These water filter systems reduce scale buildup considerably and improve the quality of the fresh water.

Wall mounting

For wall mounting special wall brackets can be supplied with

machines type A. Instructions for assembly are supplied with

the machine.

Initial operation

Always ensure that the machines are placed on an even

surface as otherwise exact dosage is not possible.

For the initial operation before making the first coffee we

strongly recommend to run the machine with water only.

The Melitta System and its principle of unpressurized filtering

can generally guarantee for a high rate of extraction i. e. making full use of flavour and aroma substances of the ground

coffee.

But the best possible quality of the beverage can only be

achieved if the quantity of water is in correct proportion to the

amount of coffee powder.

This proportion is not always constant though. Amongst other

things it depends on the brand of coffee used and also on the

required quantity of coffee.

If only 2 cups of coffee are to be filtered the 8 gr. coffee

powder per cup are necessary whilst if larger quantities of

coffee are to be prepared then sometimes 5 gr. coffee per cup

can be sufficient.

This means that the quality of the coffee is maintened although

less coffee powder is needed to prepare larger quantities of

coffee.

A few trial filtering sessions might be to be find out the best

dosage results.

Preparing the filter

쎲 Fold the embossed surfaces. Now insert filter bag into the

filter (10) and fill with coffee powder or tea. Recommend

quantity:

Coffee =

approx.

5 - 7 gr. per cup or approx.

35 - 50 gr. per ltr.

Tea =

approx. 1,5 gr. per cup or approx. 5 - 12 gr. per ltr.

Use Melitta filter paper type Pa 202 S. Order no. 14576.

Filtering with machines type M

(Manually operated machines without firmly attached water

supply)

쎲 Remove the lid (7) of the water container and fill in fresh,

cold water with a jug.

쎲 The measuring range depicted on the jug indicates how

much fresh water is required for a certain amonut of coffee.

쎲 Please make sure that the lid is always inserted on the

glass jug as otherwise temperature losses may occur.

쎲 Switch machine on with On/Off (6). The lower warm holder

(12) is automatically switched on as well.

쎲 The indicator lamp (2) remains illuminated as long as water

flows into the filter.

쎲 The instantaneous water heater switches off automatically

after the filtering process has finished.

쎲 The coffee outlet of the filter can be closed and thus drip-

ping prevented by pressing the drip prevention lever.

Filtering with machines type A

(Automatic machines with firmly attached water supply)

Make sure that prior to putting the machine into operation the

tap for water at the water supply pipe is open.

Please also make sure that the lid of glass jug is always

inserted as otherwise temperature losses may occur.

쎲 Switch on the machine by pressing On/Off switch (6). The

lower warm holder (12) is automatically switched on as well.

쎲 Pre-select the quantity to be filtered by adjusting the

quantity selector.

쎲 Start the filtering process by pressing button (4). The

indicator lamp remains illuminated as long as water flows

into the filter.

쎲 After the pre-selected quantity has run through the

instantaneous water heater is switches off automatically.

19

Page 4

Maintenance

Depending on water quality and frequency of use the

instaneous water heater must be descaled more or less often

(hard water and frequent use = frequent descaling).

By installing a water filter these service intervals can be increased considerably.

Advise for descaling

쎲 Fill the 2 ltr. jug half full of water and stir-in quick descaling

powder with a pplastic spoon (50 - 100 gr. per ltr.) until

the powder is completely dissolved.

쎲 Insert filter (10).

쎲 Set quantity selector (3) to the smallest quantity.

쎲 Remove the round lid from the top covering plate and fill

the solution into the water container. Hold back powder

particles which have not dissolved. Boil thoroughly until 1/3

of the solution has evaporated.

쎲 Now switch off the machine and allow solution to react for

about 10 minutes.

쎲 Switch on the machine again and boil until the residual

solution has evaporated.

쎲 Afterwards adjust to 1/1 programme and fill water container

3 times with water (without descaling detergent) and boil

thoroughly.

193 W / 197 W:

쎲 Check if the water discharge hose of the machine has

been properly connected to the drain pipe on customer’s

site.

쎲 Operate switch (13) and fill 1,5 ltr. of water out of the

boiler via fittings (17) into the 2 ltr. jug. Stir in quick

descaling powder (300 - 400 gr.) with a plastic spoon until

the powder is completely dissolved.

쎲 Switch off hot water unit (14).

쎲 Remove the cap for emptying the boiler (no. 15). Open

fully the draining tap behind the cap by turning it a quarter

to the left using the socket spanner provided. The boiler

will now be emptied completely into the customer’s drain.

Close the draining tap again by turning it as far as possible

to the right.

쎲 Remove the cap of the top covering plate above the water

boiler and fill in the prepared solution with the funnel.

쎲 Switch on the hot water unit (14). After letting the machine

heat up fpr approx. 5 minutes operate switch (13) and let

approx. 0,5 ltr. of water out of the boiler via fittings (17).

Allow the solution to react for approx. 10 minutes.

쎲 Empty the boiler as described.

쎲 Fill into the water boiler 2 ltr. fresh water with the funnel.

Switch on the hot water unit again. After the boiler has

been filled with water, operate switch (13) and let approx.

0,5 ltr. of water flow out via fittings (17). Switch off the

machine again and empty the boiler as described. Repeat

rinsing process 3 times, using fresh water each time.

쎲 Fill into the water boiler 2 ltr. fresh water with the funnel.

Now switch on the hot water unit. As soon as the indicator

lamp within switch (13) ceases to burn the unit is ready

for operation.

쎲 Insert the cap of the discharge opening and put the lid

back on the boiler again.

We recommend to use Swirl-Quick-descaling-powder in 1 kg tin

as descaling detergent. Order no. 1012538.

20

193 W / 197 W

쎲 Switch on the hot water unit by pressing On/Off switch (14).

The indicator lamp is illuminated and the boiler for preparing

hot water starts to heatup.

After approx. 14 minutes the boiler has reached working

temperature. The indicator lamp (13) ceases to burn and the

hot water unit is ready for operation.

Hot water extraction:

Hot water can be despensed via fittings (17) is switch (13) is

pressed. Water can be dispensed as long as this switch is

operated.

Hot water outlet:

If requested we can supply a screw-on extension for the outlet (17)

so that tapping height can be reduced from 185 to 130 mm.

Order no. 11628.

Switching off the machine

쎲 The machine should be switched off overnight and during

longer stillstands.

쎲 By operating switch (6) the coffee machine unit and the

lower warm holder can both be switched off at once.

쎲 The top warm holders (8) are switched off with switch (5).

쎲

The hot water unit of W-type machines is switched off by

pressing switch (14).

쎲 The facilities provided on site i. e. electric connections and

water supply should be switched off if the machine is not

to be operated for a longer period of time.

Servicing indicator lamp

A defect within the heating system of the water heater (i. e.

excessive build-up limescale) is indicated by the servicing

indicator lamp. If this lamp is illuminated the heater is

automatically switched off for safety reasons.

Depending on the degree of limescala build-up the heater

automatically strats to work again after a break.

The total filtering time increases repectively.

Descaling the machine is now urgently necessary and must be

carried out as soon as possible as otherwise the built-in

machine safety fuse strats to react. If this is the case a

servicing engineer must be requested in oreder to restore the

working condition of the machine.

Cleaning and maintenance

Attention:

The machine should not be put into water for cleaning purposes

nor should water be poured or sprayed over the machine.

Always pull the main plug out of the socket before starting to

clean the machine.

Larger coffee machines used in the field of commercial catering

are generally rather expensive and therefore shuld be

maintained properly. Regularly mainained machines not only

look better but the coffee made with these machines over a

longer period of time is also of better quality.

Melitta can offer a cleaning programme especially designed for

these purposes.

Outer cleaning:

쎲 Wipe plastic and stainless steel surfaces regularly with a

damp cloth. We recommend Swirl-EST-care products in

spray can for special treatment steel surfaces.

Order no. 201025.

Page 5

21

Instructions concerning safety

쎲 Keep instructions for use near the machine, so that it is

always possible for the operator to operate the machine

correctly.

쎲 Do not pull the filter out of the machine if the filtering

process has not yet finished. After the filtering process is

over, please be aware of idle running of the unit: danger

of scalding.

쎲 Only use the glass jug for hot drinks. Do not clean with

hard devices. Do not use for cooking beverages. Not

suitable for use in micro-wave oven.

쎲 Do not heat up the jug if empty or wash in dish washer

at a temperature of over 92°C.

쎲 Do not hold the full jug above persons.

쎲 Do not touch the warm holders. Risk of burning!

쎲 Switch off the warm holders as soon as the glass jugs are

empty.

쎲 Melitta SystemService is not liable for damages which

occur due to lack of maintenance, improper handling of the

machine, or installation of parts which are not genuine

Melitta parts.

쎲 Melitta SystemService reserves the right to carry out

alterations at any time without prior notice if these

alterations are necessary for technical improvement.

쎲 Prior to opening the machine pull the plug out of the

socket.

쎲 Switch off the water supply on site if the machine is not

to be operated for a longer period of time.

쎲 The machine must not be operated outdoors.

Conditions of guarantee

We guarantee for the perfect working of this machine / installation over a period of 12 months beginning at date of invoice.

If assembly is performed by us or a company authorized by

us then warranty beginning is date of assembly. Throughout

this period all defects due to faulty material, poor design, and

faulty construction work will be repaired free of charge by us,

provided that the machine was operated and maintained

properly. Parts which have to be exchanged remain property of

MSS and are to be made available to us.

We are not responsible for damages caused by lack of

maintenance and care even if they occur during the period of

guarantee. Damages caused by unauthorized or improper repair

work or installation of not genuine Melitta spare parts are also

not covered by this guarantee. All parts made of porcelaine or

glass or wearing parts are also excluded from our guarantee

Wearing parts are: sealings/gaskets, valves, faucets, heating

resistors, coat of lacquer, switches and thermostates/thermoregulators. Claims for damages under conditions of guarantee

can only be accepted if a written report has been handed in

by our customer service and an inspection of the machine has

taken place in our work.

Instructions for eliminating possible faults/defects

Fault/Defect Cause Elimination

Servicing indicator lamp (1) 쎲 Excessive build-up of limescale in instantenous

Descale machine at the end of the

starts to burn, water heater filtering process

filtering process is interrupted 쎲 Temperature control defective Request service engineer

쎲 Water supply line to heater is clogged Clense the tubes and sieves

쎲 Defective switch Request service engineer

Retarded filtering process 쎲 See above mentioned

쎲 Very fine ground coffee, very soft water = Choose coarser ground brand of

filter pores clog up coffee

Water dosing not according to 쎲 Machine is not on an even surface = Even out uneven patches of the surselected programme the water level in the fresh water container face beneath the machine, change

is not as indicated position of the machine

쎲 Water pressure is not correct

Check water pressure and adjust by

means of valve/pressure pump

쎲 Solenoid valve dirty Request service engineer

Coffee does not taste good 쎲 High rate of chlorine in water

Inform Melitta service personnel to install

water filter

쎲

Contains residual descaling or dish washing agent

Rinse machine or jug with water

쎲

Coffee has been stored for more than one hour

Consume fresh coffee as soon as

possible

쎲 Poor quality of the supplied coffee powder Speak with coffee supplier

Coffee too cold 쎲 No lid on the jug Insert lid on jug

Coffee too hot 쎲

Small quantity of coffee has been kept in the

Consume freshly filtered coffee as

machine too long soon as possible

HW-unit 193 W / 197 W 쎲 Temperature limiter has responded Remove cap (16), press in the limiter

does not heat up situated beneath the cap, request for

service engineer

HW valve does not close, drips 쎲 Limescale in closing area of valve Operate switch several times

Request service engineer

Please contact MSS service personnel if other faults/defects than the above mentioned occur.

Page 6

min. °C

Zulässige Umgebungstemperatur -

max °C

Geräuschpegel

D

DK

E

F

FIN

GB

N

NL

S

31

Typenübersicht und Technische Daten Types and Technical Data

Typeoversigt, tekniske specifikationer Typeoversikt, tekniske specifikasjoner

Modelos y Datos Técnicos Type overzicht, technische gegevens

Types et donées techniques Översikt, tekniska data

Mallit ja tekniset tiedot

< 70 dB (A) < 70 dB (A) < 70 dB (A) < 70 dB (A) Noise level

Maße und Daten

Mål og data

Medidas y Datos

Dimensions et caracteristiques

Mitat ja tiedot

191 M

191 A

192 A1

192 A2

193 W 197 W

Measures and Data

Mål og data

Maten en gegevens

Mått och Data

Leistungsaufnahme Gesamt in kW

Effekt i KW Totaleffekt

Potencial total en KW 230/400 V

Puissance totale en KW

Kokonaistehonotto kW

2,06

3,06

4,11

3,66 6,25

Power Input (kW) Total

Totaleffekt i KW

Stroomverbruik in KW totaal 230/400V

Effekt i KW Totalt

Absicherung in Amp

Sikringe (A)

Fusibles en Amperios

Fusible en A

Varoke (A)

16

230-240

–

– 120 120

130

200

260

100 260

16/7,5

32/10

32/7,5

16/10 32/7,5

270 x

340 x 520

500 x

340 x 520

500 x

340 x 520

730 x

340 x 520

8,5

10,5

17 17 24

–

R3/4“A

R3/4“A R3/4“A R3/4“A

–

NW 1“

Ø 33 mm

NW 1“

Ø 33 mm

NW 1“

Ø 33 mm

NW 1“

Ø 33 mm

230-240

400-415

2N앑

230-240

400-415

3N앑

16 16 16

Fuse

Sikring-Amp.

Amperage

Säkring Amp.

Elektroanschluss in Volt

El-tilslutning i Volt

Voltaje en Voltios

Raccordement électrique en volts

Sähköliitäntä

Electric Connection (single phase)

El-tilkopling i Volts

Elektro aansluiting in Volts

El-anslutning i. Volt

Stundenleistung Ta/h Wasser

Timekapacitet kopper pr. time vand

Rendimiento en Tazas/hora agua (125 ml)

Rendement horaire tasses/heure d’eau

Tuntiteho (kkp/h) vettä

Stundenleistung Ta/h Kaffee

Timekapacitet kopper pr. time Kaffe

Rendimiento en Tazas/hora Café (125 ml)

Rendement horaire tasses/heure Café

Tuntiteho (kkp/h) Kahvia

Hourly Performance Cups/hour-Water

Timekapasitet kopper pr. time-vann

UUr capaciteit kopjes/uur water (125 ml)

Kopp-kapacitet pr time vatten

Sofortleistung Ta in Min.

Hurtigbrygge-kapacitet kopper pr. minut

Rendimiento en Tazas por minuto

Rendement immédiat en tasses/min.

Teho (kkp/min)

Hourly Performance Cups/hour-Coffee

Timekapasitet kopper pr. time Kaffe

UUr capaciteit kopjes/uur Koffie (125 ml)

Kopp-kapacitet pr time Kaffe

Maße in mm: Länge x Breite x Höhe

Mal i mm: Bredde x Dybde x Højde

Dimensiones en mm:ancho-fondo-alto

Mes. en mm: Largeur x Profond. x Hauteur

Mitat (mm): Leveys x Syvyys x Korkeus

Capacity Cups/min.

Kapasitet kopp i min

Stootvoorraad kopjes/uur

per bryggning kkp/min.

Gewicht in kg

Vægt i kg

Peso en kg

Poids en kg

Paino (kg)

Measures in mm: Width x Depth x Height

Mål i mm: Bredde x Dybde x Høyde

Maat in mm: Breedte x Diepte x Hoogte

Måt i mm: Bredd x Djup x Höjd

Wasserzulauf bauseits

Fremføring af vandledning

Tubería de entrada de agua

Arrivée d’eau filet extérieure

Vesiliitäntä

Water Inlet

Vanntilkopling

Waterleiding bouwkundig

Vattenanslutning

Drain hose

Vannavlop

Wateroverloop

Avlopp Vedenpoisto

Wasserablauf bauseits

Afløb

Salida de agua (desagüe)

Tuyan d’evacuation

Vedenpoisto

min. °C

Permissible ambient temperature -

max °C

Weight (kg)

Vekt kg

Gewicht in kg

Vikt kg

Die technischen Daten können je nach Länderausführung abweichend sein.

Technical Data may vary from country to country.

+5 - +30

Page 7

D

DK

E

F

FIN

GB

N

NL

S

32

Zubehör Accessories

Tilbehør Tilbehør

Accesorios Toebehoren

Accessoires Tillbehör

Varusteet

Zubehör

Tilbehør

Accesorios

Accessoires

Varusteet

Filterpapier

Filterpose

Papel filtro Pa 202

Papierk-Filtre

Suodatinpaperi

191 M

191 A

193 W

1

192 A

1

197 W

1

Accessories

Tilbehør

Toebehoren

Tilbehör

Filterpaper

Filterpapir

Filterpapier Pa 202

Filterpåser

Einschubfilter

Filterindsats

Porta filtro SF 202/1

Porte filtré à glissière

Suodatin

122

Slide-in Filter

Filtertrakt

Inschuiffilter SF 202/1

Bryggtratt

Wasserzulaufschlauch

Tilløbsslange

Tubo flexible entrada de agua

Tuyau d’alimentation

Vesiletku

–

1

1

11

Water Supply Hose

Tilkoplingsslange

Watertoevoerslang

Slang för vattentillförsel

Wasserablaufschlauch

Afløb slange

Tubo flexible salida de agua

Tuyau d’evacuation

Poistoletku

–

1

1

11

Drain Hose

Avløpslange

Wateroverloppslang

Avloppsslang

Gebrauchsanleitung

Brugsanvisning

Manual de instrucciones

Mode d’emploi

Käyttöohje

111

Operating Instructions

Bruksanvisning

Gebruiksaanwijzing

Bruksanvisning

Tassenmaß 50 g

Kaffemål 50 g

Medidor 50 gr

Dosé graduée 50 g

Kahvimitta 50 g

Glaskanne

Glaskande

Jarra de cristal

Verseuse en verre

Lasikannu

Trichter

Påfyldningstragt

Embudo

Entonnou

1

1

–

–

1

1

2

–

1

2

–

Measuring Cup 50 g

Kaffemål 50 g

Maatschep 50 g

Kaffemått 50 g

Glas Jug

Glasskanne

Glaskan

Glaskanna

Funnel

Trechter

Tratt

Page 8

33

EG-Konformitätserklärung

EC-declaration of conformity

Certificat de conformité CE

Die Firma

The company

La société

Melitta SystemService GmbH & Co. KG

D-32373 Minden, Postfach 13 26

erklärt, daß das Produkt

certifies that the product

certifie que le produit

Filterkaffeemaschine

Filtercoffeemachine

Machine à café filtre

mit der Typbezeichnung

with the type designation

avec la désignation

Melitta 190 A/M/W

DE 5

auf das sich diese Erklärung bezieht, mit den nachfolgenden EG-Richtlinien übereinstimmt:

this declaration refers to corresponds with the following EC-directives:

objet de cette declaration, est conforme aux directives européennes ci-dessous:

89/392/CEE in der Fassung

89/336/CEE modified by 93/68/CEE

73/23/CEE

modifié par la

Angewandte Normen

Applied standards

Normes appliquées

94

Minden, den 01. Dezember 1994

Minden, 01st december 1994

Minden, le 01. décembre 1994

ppa.:

by procoration

par procuration

i. Vollm.:

by delegation

par délégation

Leitung Technik

Director of Engineering

Directeur Technique

Leitung Qualitätswesen

Director of Quality Assurance

Directeur Assurance-Qualité

EN 60 335

EN 50 104; EN 55 014

Page 9

A CDN

DK

FIN

N RUS

TH

AUS

CH E

GB

NL

S TW

B

D

F J

RC

SG

USA

MELITTA Ges. mbH & Co. KG

Postfach 62

5021 Salzburg 2

Tel.: 0043-662 / 43 95 11-42

Fax: 0043-662 / 43 95 11 39

CAFINA AG

Römerstraße 2

5502 Hunzenschwil

Tel.: 0041-62 / 889 42 42

Fax: 0041-62 / 889 42 89

Instructions-Nr.: 11602 379892

MELITTA SystemService

GmbH & Co. KG

Zechenstraße 60

32429 Minden-Dützen

Tel.: 0049-571 / 50 49-0

Fax: 0049-571 / 50 49-233

aromateknik a/s

Industrivej 44

4000 Roskilde

Tel.: 0045-46 / 75 33 66

Fax: 0045-46 / 75 38 10

Tecnimel Hosteleria, S.L.

Avda. Esparteros, 15

Pol. S. J. de Valderas Sanahuja

28918 Leganés (Madrid)

Tel.: 0034-91 / 644 81 30

Fax: 0034-91 / 644 81 31

MELITTA SystemService

France SA

16 Rue P.H. Spaak

Saint Thibault des Vignes

77462 LAGNY sur Marne Cedex

Tel.: 0033-1 / 6430 32 95

Fax: 0033-1 / 6430 33 40

aromateknik a/s

Industrivej 44

DK-4000 Roskilde (Dänemark)

Tel.: 0045-46 / 75 33 66

Fax: 0045-46 / 75 38 10

aromateknik A/S

Radiovägen 2

Box 662

13526 Tyresö

Tel.: 0046-8 / 7 98 77 88

Fax: 0046-8 / 7 98 90 18

Michaelo Espresso, Inc.

3801 Stone Way N.

Seattle, WA 98103

Tel.: 001-206 / 548-9000

Fax: 001-206 / 695-4951

Internet: www.melitta.de/mss

E-Mail: info@mss.melitta.de

Gebrauchsanleitung

MELITTA 190 - 0902

Sach.-Nr. 11602

Hackman Metos Oy AB

Ahjonkaarre

04220 Kerava

Tel.: 00358-204 / 39 13

Fax: 00358-204 / 39 44 33

MELITTA SystemService Benelux BV

Industriestraat 6

3371 XD HARDINXVELD GIESSENDAM

Tel.: 0031-18 467 / 16 60

Fax: 0031-18 461 / 04 14

Axtens Pte. Ltd.

100 E, Pasir Panjang Road

# 06-03 Century Warehouse

Singapore 118521

Tel.: 0065 / 274 90 02

Fax: 0065 / 274 79 11

M.S.S. (UK) Limited

21 Grove Park

White Waltham

Maidenhead Berkshire

SL6 3LW

Tel.: 0044-1628 / 82 98 88

Fax: 0044-1628 / 82 51 11

Edward Keller

21/F Southmark

11 Yip Hing St.

Wong Chuk Hang

Hongkong / China

Tel.: 00852 / 28 95-96 20

Fax: 00852 / 28 95-00 39

LE MOKO Trading Ltd. Part.

1 Ban Chang Glas Haus Building,

#803/2 Sukhumvit 25, Klongtoey

Wattana, Bangkok 10110

Tel.: 0066-2 / 260-63 75

Fax: 0066-2 / 661-61 83

MELITTA Japan Ltd.

9F abc Kaikan

2-6-3, Shiba-koen, Minato-ku

Tokyo 105-0011 Japan

Tel.: 0081-3 / 5470-2770

Fax: 0081-3 / 5470-2774

MELITTA Russland

Sofiskaya 14 of. 805

192236 St. Petersburg

Tel.: 007-812 / 3 26 65 56

Fax: 007-812 / 3 26 65 57

JAS Corporation

No. 155

Sung Teh Road

Taipei / Taiwan

Tel.: 00886-2 / 27 27-06 30

Fax: 00886-2 / 27 27-06 40

National Coffee Distributors

PO Box 201

Fairy Meadow NSW 2519

Tel.: 0061-2 / 95 71- 44 44

Fax: 0061-2 / 42 84 - 60 99

MELITTA SystemService Benelux

Bijkantoor MELITTA SystemService

Brandstraat, 8

9160 Lokeren

Tel.: 0032-9 / 331 52 30

Fax: 0032-9 / 331 52 35

MELITTA Canada Inc.

1 Greensboro Drive

Suite 202

Rexdale, Ontario M9W 1C8

Tel.: 001-416 / 243 89 79

Fax: 001-416 / 243 18 08

A

CDN

DK

FIN

N

RUS

TH

AUS

CH

E

GB

NL

S

TW

B

D

F

J

RC

SG

USA

Kundendienstadressen

Addresses of service

Serviceadresser

Huoltopisteiden osoitteita

Serviceadresser

Service

Adresses of service

Addresses of service

Kundendienstadressen

Servico Tecnicos

Addresses of service

Serviceadressen

Serviceadresser

Addresses of service

Serviceadressen

Kundendienstadressen

Services Techniques

Addresses of service

Addresses of service

Addresses of service

Addresses of service

34

Loading...

Loading...