Melink Intelli-Hood Installation Manual

INSTALLATION MANUAL

Melink Corporation (513) 965-7300 www.melinkcorp.com

®

Revision 130711

Table of Contents

Step Installation Page

Contractor

1 Install System Controller 4

2 Install Variable Frequency Drive 6

3 Install Touchpad 8

4 Install Temperature Sensor(s) 10

5 Install Canopy Sensor Mechanical 13

6 Install Hood Controllers 15

7 Install Optic Sensors Mechanical 17

8 Install Air Purge Units 21

9 Install Cables 22

10 Setting Addresses 28

11 Install Options (if applicable) Mechanical 29

Electrical

Electrical

Mechanical

Mechanical

Mechanical

Mechanical

Mechanical

Mechanical

Melink Corporation (513) 965-7300 www.melinkcorp.com

2

Tools & Materials Required

Tools Required

● Drill and Drill Bits (Cobalt is best for stainless steel) - bit sizes: 1/8” & 1/4”

● Hole Cutter or Punch for Stainless Steel with cutter sizes: 1-1/2” & 1-1/8”

● Adjustable Pliers and Adjustable Wrench

● Screwdrivers - Straight & Phillips, Large and Small

● Wire Cutter and Wire Stripper

● Measuring Tape and Level

● Step Ladder

Materials Required

● Suitable fasteners for mounting the System Controller and Variable Frequency Drive

(VFD)

▫ hollow cinder block (3/16” toggle bolts)

▫ concrete or filled cinder block (lead anchors 1/2” dia. with 1/4” x 1-14” lag screws)

▫ drywall (3/16” toggle bolts)

▫ plywood (#8 X 1-1/4” wood screws)

▫ metal back-plate (#8 X 1-1/4” sheet metal screws)

● Conduit and wire for wiring the System Controller and VFDs

Note: All high voltage wiring to be completed by trained service personnel. (Local code

may require a licensed electrician.)

Melink Corporation (513) 965-7300 www.melinkcorp.com

3

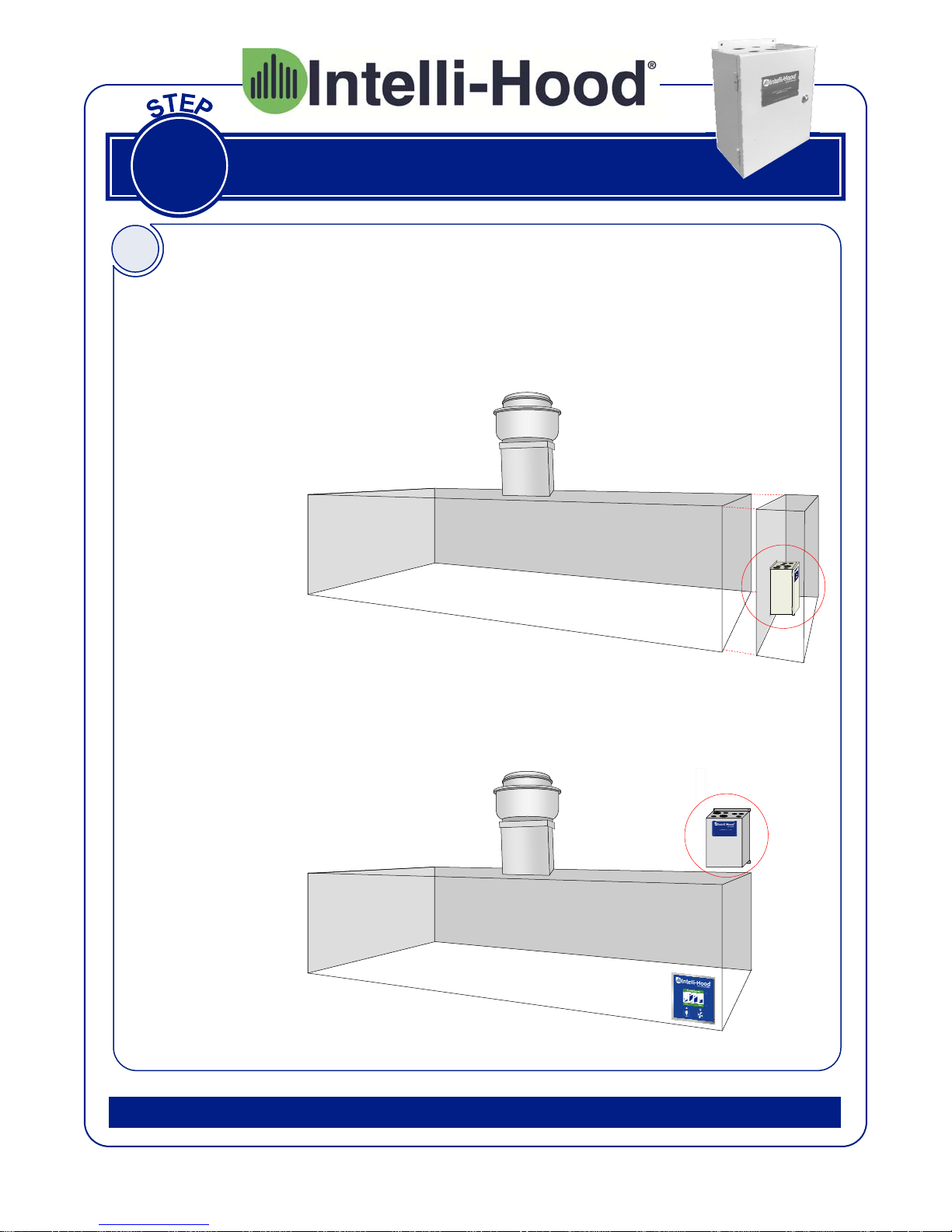

1

Install System Controller

A

Select System Controller Location

For new construction, the hood

manufacturer typically provides a

utility cabinet in which to mount

the System Controller. If the

hood has a utility cabinet with

extra space, mount the System

Controller (and VFDs) there.

For retrofits, the System

Controller is typically mounted

above the hood. Select a location

that is easily accessible and close

to where the Touchpad will be

mounted. Ideally, you should

secure it to a wall. DO NOT

PENETRATE THE HOOD

EXHAUST PLENUM.

Melink Corporation (513) 965-7300 www.melinkcorp.com

4

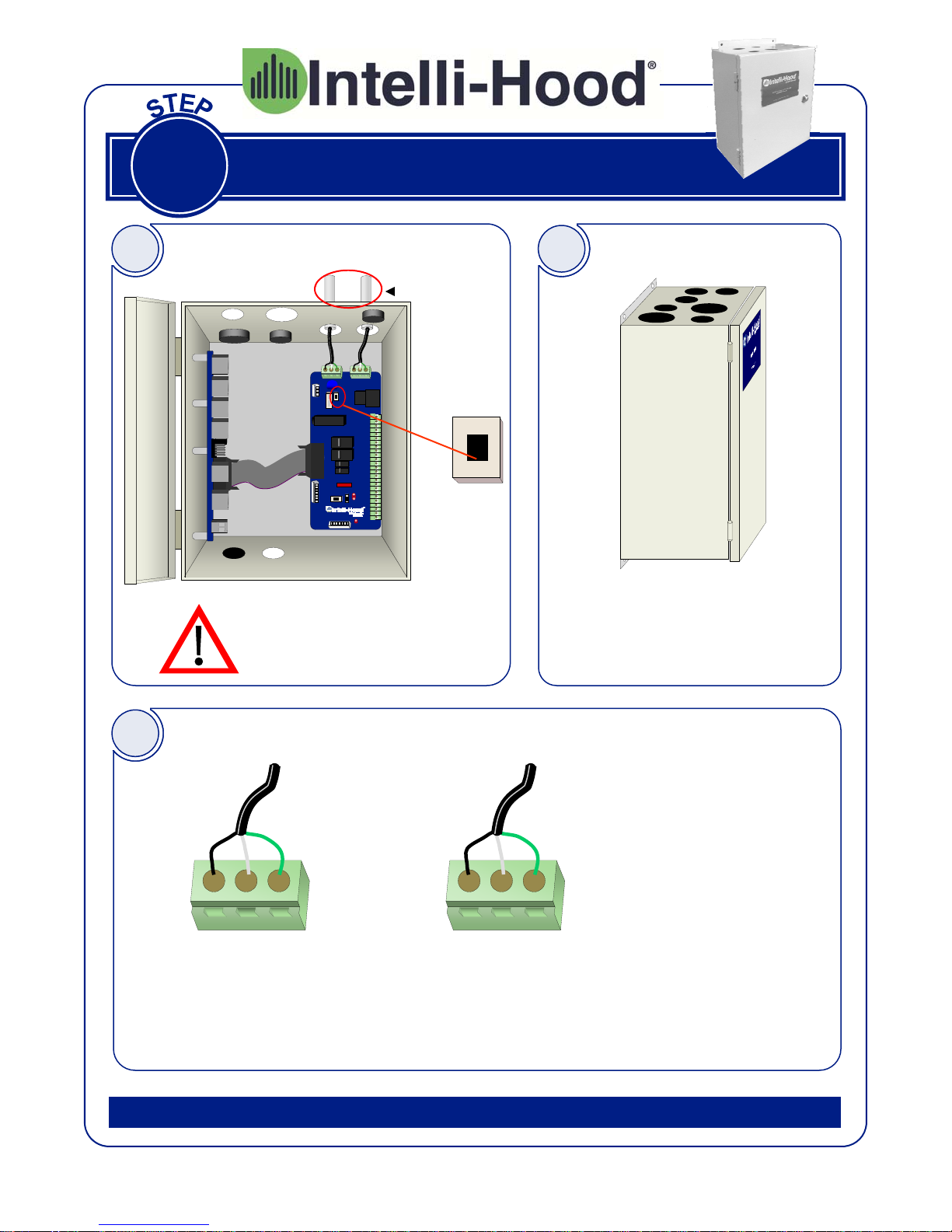

1

Install System Controller

B

Turn Off Power Switch Wire System Controller

115V or 230V

ON

OFF

Turn OFF the System Controller power switch before

wiring. Also turn off the

breaker feeding this circuit.

C

For both New Construction & Retrofits, wire the System Controller

using the hood light circuit. The

circuit must be 115V to 230V, at

50-60Hz. Maximum input current

is 17A.

D

115/230V

INPUT

L N G

Wire gauge per NEC; allowable size range is 16AWG to 12AWG.

New Construction & Retrofits:

Main Input Power

from Hood Light Circuit

115-230 VAC @ 50/60Hz; 17A Max

Melink Corporation (513) 965-7300 www.melinkcorp.com

Wire Connections Inside System Controller

115/230V (15A)

LIGHTS (OUTPUT)

L N G

New Construction:

Outgoing Power to Hood Lights

Output Voltage Matches Input

15 Amps max

It is not required to use

these output terminals if

there are other provisions

in place to control the

hood lights. Note that

output voltage will be the

same as the input voltage.

Tungston Output Rating:

8A @ 120V

5.4A @ 240V

Retrofits:

5

2

Install Variable Frequency Drive

A

For new construction, the Intelli-Hood includes a Variable Frequency Drive or VFD for each

kitchen exhaust and make-up air fan. This type of starter is for use with 3-phase motors only. It

not only turns the fans on and off, but also varies the speed of the motors by varying the output

frequency and voltage. Therefore, you do not need a conventional magnetic motor starter with

our system. Caution: If you have a tempered make-up air unit, then the control circuit for the

heating system must be fed by a separate power source and NOT from the VFD! The output of

the VFD must be wired to the motor ONLY and NOT to a transformer or any part of a control cir-

cuit!

If there is a make-up air unit, then the VFD for this unit must be interlocked with the fire suppression micro-switch so that this fan turns off in the event of a fire. This is accomplished by connecting a low-voltage cable between designated terminals on the VFD (01 and 04 for Allen-Bradley)

and the Normally Closed (NC) terminals on the micro-switch. Caution: With variable frequency

drives, there must be a separate conduit run for the output of each VFD (inputs may be run together if desired). If this is not done, there is a strong probability of problems due to line interference and inaccurate motor control.

For retrofits, the only difference between new construction and retrofits is that on retrofits you

will already have conventional magnetic motor starters installed. In most cases, it is

recommended that you install the VFD on the output side of the existing starters. This will enable

the cooks/chefs to use the existing hood fan (and light) switch and not have to change their habits. This will also allow you to keep the existing circuit intact between the magnetic starter for the

make-up air unit and the fire suppression system micro-switch.

Verify Variable Frequency Drive Wiring

All wiring must comply with the National Electric Code (NEC

and local code requirements.

Melink Corporation (513) 965-7300 www.melinkcorp.com

6

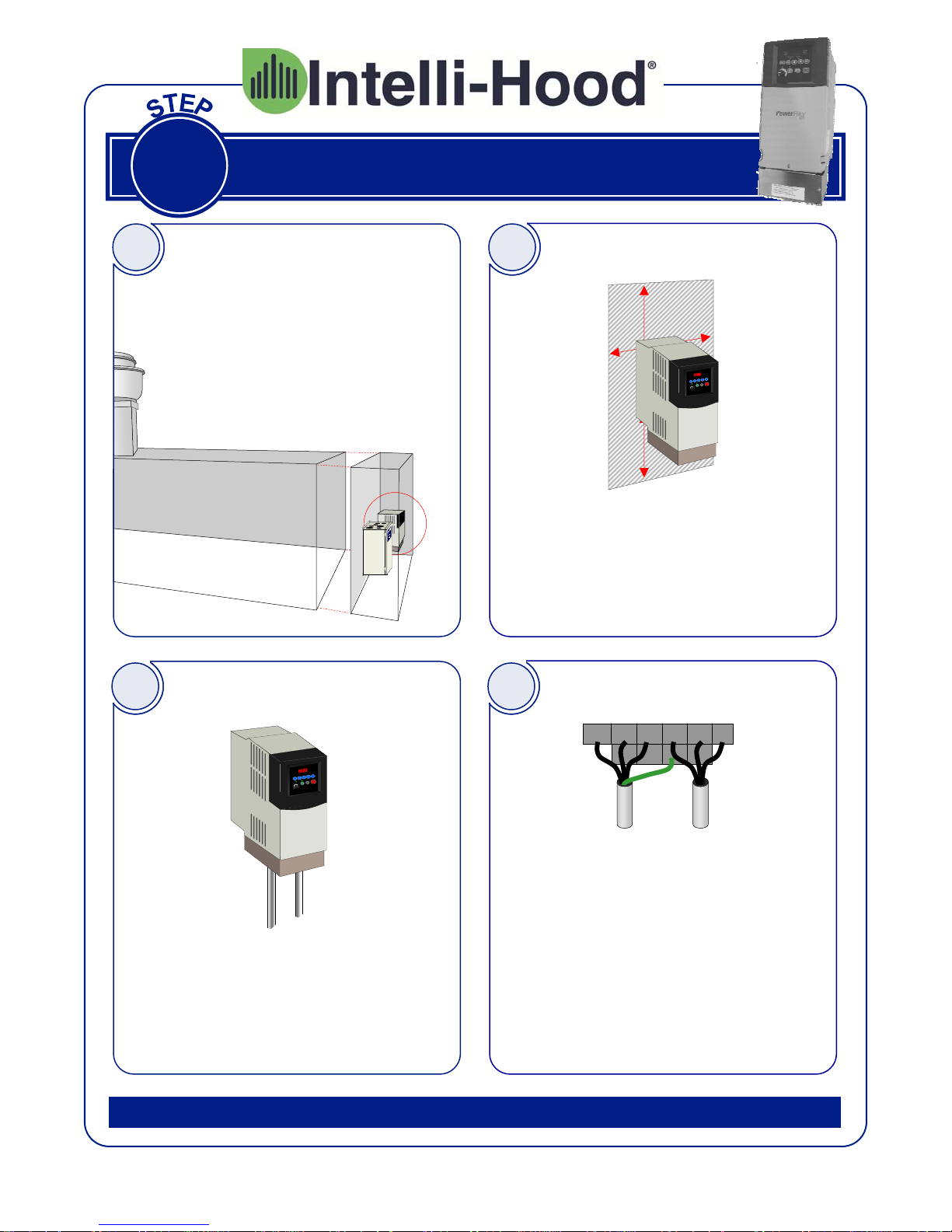

2

Install Variable Frequency Drive

B

For retrofits, each VFD is typically

mounted on the output side of the existing motor starter, which is often located

in an electrical room, above the hoods,

or inside a utility cabinet. For new con-

struction, the hood manufacturer typi-

cally provides a utility cabinet in which to

mount the VFDs.

D

Select VFD Location Check VFD Location

Mount VFD Wire VFD

C

5”

1”

1”

5”

The location must be relatively free of dirt,

grease, and water. The ambient temperature must be between +14 degrees F and

+122 degrees F. There should be 5” of

clearance on the top and bottom and 1” on

the sides for adequate ventilation/cooling.

E

L1 L2 L3 U V

3-phase

input from

breaker or

magnetic

motor starter

3-Phase

Input

Mount each VFD with appropriate fasteners.

Then install separate conduit for the input

and output power wiring to prevent electrical

interference between the conductors.

Melink Corporation (513) 965-7300 www.melinkcorp.com

3-Phase

Output

Remove the VFD top cover and connect

the line voltage wiring to the VFD input

power terminal block as shown above.

Then connect the output power from the

terminal block to the respective fan motor

on the roof. The ground wire must be a

minimum of 14 AWG and as short as possible. The output wiring for each VFD

MUST be in a separate conduit run.

BR+

BR-

G

W

3-phase

output to

fan motor

7

3

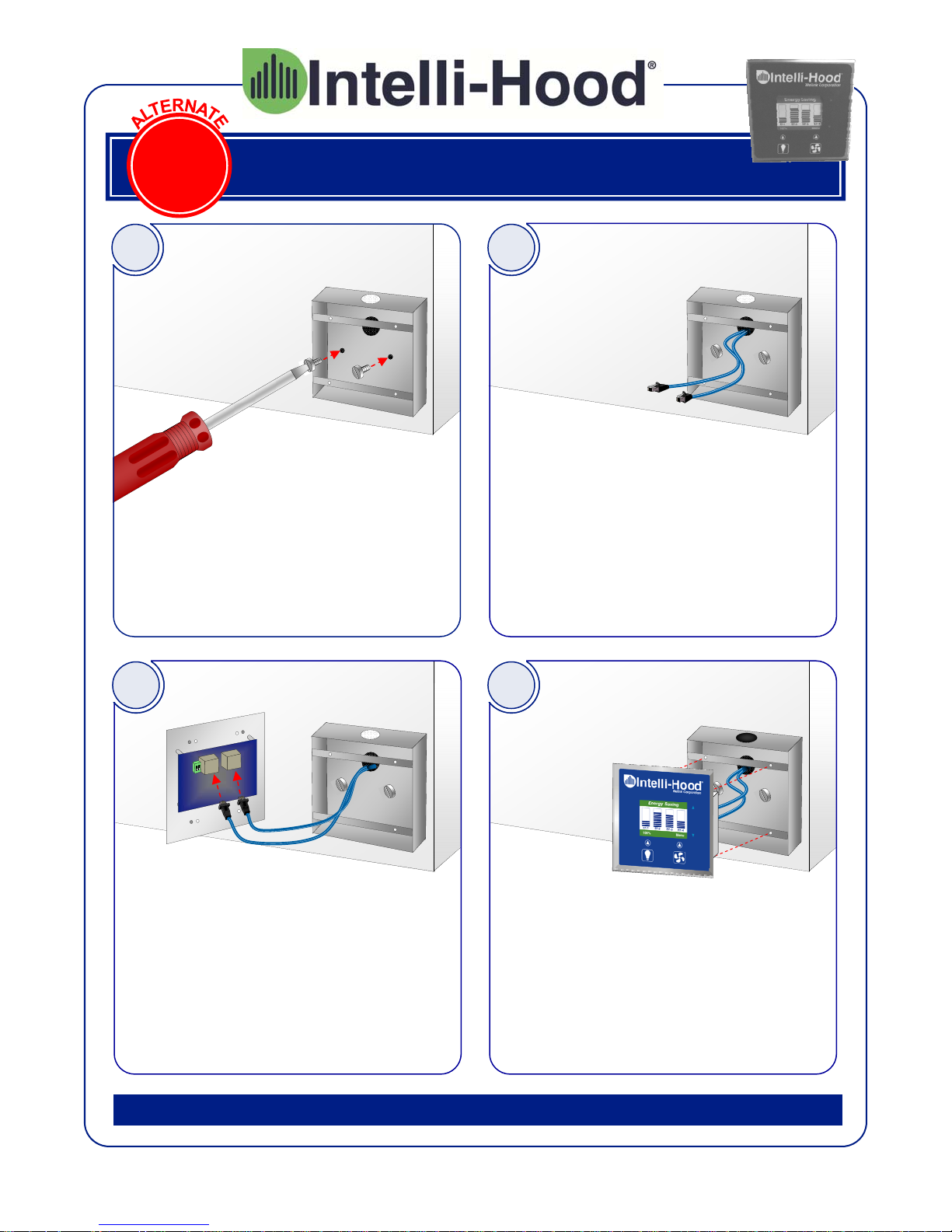

Install Touchpad

A

C

Remove Existing Switches

Before removing the switch

cover plate, turn off the circuit

breaker.

For retrofits, if you want to replace the

existing fan and light switch with our

Touchpad, remove these switches from the

junction box. Then remove the existing

wires to make room for the Touchpad Cable.

Plug In Cable Mount Touchpad

B

Run the Touchpad Cable inside the existing conduit and leave approximately 5

inches of slack inside the junction box.

You will connect the other end of the Cable

to the System Controller in Step 9.

D

Run Touchpad Cable

O

Plug the connector into the receptacle on

the back of the Touchpad.

Melink Corporation (513) 965-7300 www.melinkcorp.com

Mount the Touchpad to the junction box

and secure the cover plate by snapping it

on.

8

3

Install Touchpad

A

C

Install Surface Mount Box

Install the Surface Mount box by attaching

screws through the holes provided inside

the box. If possible to bring cable in

through the wall behind the box, first drill a

1” hole in the wall. If not, install 3/4” conduit stubbed up above the ceiling for the

cable run.

Plug In Cables Mount Touchpad

B

Run the Touchpad Cable inside the 3/4”

conduit or through the back of the box and

leave approximately 5 inches of slack inside the junction box. You will connect the

other end of the Cable to the System Controller in Step 9. If another device will be

installed downstream of the Touchpad, run

two cables.

D

Run Touchpad Cable

O

Plug the connector(s) into the receptacle

on the back of the Touchpad.

Melink Corporation (513) 965-7300 www.melinkcorp.com

9

Mount the Touchpad to the junction box

and secure the cover plate by snapping it

on.

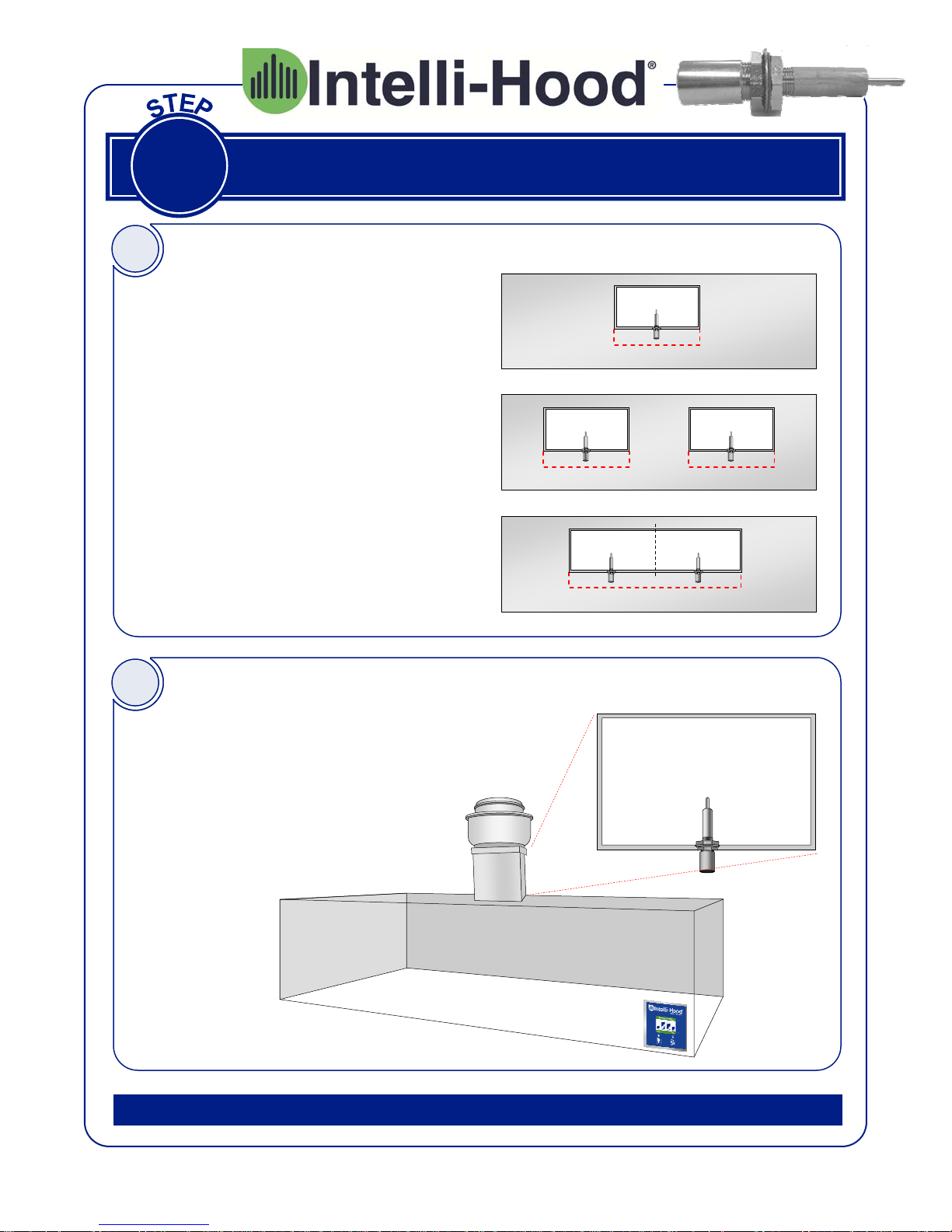

4

Install Exhaust Temperature Sensor

4

5

A

B

Determine Number of Sensors

Install one (1) Temperature Sensor

per exhaust duct, if the length of the

duct is less than 24”. In most cases

this will mean one Temperature

Sensor per hood.

In some cases, this will mean two

Temperature Sensors per hood.

If the length of the duct is more than

24”, then install two Temperature

Sensors in order to obtain a better

average reading.

Select Location for Mounting Sensor

L < 24” (600mm)

Hood 1 (Top View)

L ≤ 24” (600mm)

Hood 2 (Top View)

L ≥ 24” (600mm)

Hood 3 (Top View)

L ≤ 24” (600mm)

Select a location for mounting each

Temperature Sensor. The tip of the

sensor should be inside the center

of the duct to sense the average

temperature. For most installations,

proceed with steps C-F on page

10. An alternate mounting procedure is described in steps C-J on

pages 11 and 12.

Melink Corporation (513) 965-7300 www.melinkcorp.com

10

Duct Top View

Loading...

Loading...