Page 1

Design & Engineering Services

Demand Control Ventilation for Commercial

Kitchen Hoods

ET 07.10 Report

Prepared by:

Design & Engineering Services

Customer Service Business Unit

Southern California Edison

June 30, 2009

Page 2

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

Acknowledgements

Southern California Edison’s Design & Engineering Services (D&ES) group is responsible for

this project. It was developed as part of Southern California Edison’s Emerging Technology

program under internal project number ET 07.10. D&ES project manager Angelo Rivera

conducted this technology evaluation with overall guidance and management from Paul

Delaney. For more information on this project, contact Angelo.Rivera@sce.com.

Disclaimer

This report was prepared by Southern California Edison (SCE) and funded by California

utility customers under the auspices of the California Public Utilities Commission.

Reproduction or distribution of the whole or any part of the contents of this document

without the express written permission of SCE is prohibited. This work was performed with

reasonable care and in accordance with professional standards. However, neither SCE nor

any entity performing the work pursuant to SCE’s authority make any warranty or

representation, expressed or implied, with regard to this report, the merchantability or

fitness for a particular purpose of the results of the work, or any analyses, or conclusions

contained in this report. The results reflected in the work are generally representative of

operating conditions; however, the results in any other situation may vary depending upon

particular operating conditions.

Southern California Edison

Design & Engineering Services June 2009

Page 3

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

ABBREVIATIONS AND ACRONYMS

MUA Make-Up Air

cfm Cubic Feet Per Minute

DCV Demand Control Ventilation

HVAC Heating Ventilation and Air Conditioning

IR Infrared

MDL Micro Data Loggers

CT Current Transducers

FLA Full Load Amps

hp Horse Power

SF Supply Fan

Southern California Edison Page i

Design & Engineering Services June 2009

Page 4

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

FIGURES

Figure 1 Commercial Kitchen Exhaust Hood Styles1..........................4

Figure 2 Commercial Kitchen MUA Configuration types2...................5

Figure 3 Melink Intelli-HOOD HARDWARE (Court esy of Melink®).........7

Figure 4 Melink Intelli-Hood Heat and Smoke Detection (Courtesy

of Melink

Figure 5 Monitoring Equipment Installation ...................................10

Figure 6 Typical Demand Usage for EF 160 at Desert Springs

Marriott ...................................................................18

Figure 7 Typical Demand Usage for EF 8 at The Westin Mission Hills .20

Figure 8 Typical Demand Usage for EF 1,2,3 at El Pollo Loco............22

Figure 9 Typical Demand Usage for EF 1 at Panda Express..............24

Figure 10 Typical Demand Usage fro EF 1 at Farmer Boys...............26

Figure 11 Desert Springs Marriott Hood 1 System A.......................28

Figure 12 Desert Springs Marriott Hood 2 System A.......................29

Figure 13 Desert Springs Marriott Hood 3 System A.......................29

Figure 14 Desert Springs Marriott Hood 1 System B.......................30

Figure 15 Desert Springs Marriott Hood 2 System B.......................30

Figure 16 Desert Springs Marriott Hood 3 System B.......................31

Figure 17 Typical Demand Usage for EF 159 at Desert Springs

Marriott ...................................................................31

®

).................................................................8

Figure 18 Typical Demand Usage for EF 161 at Desert Springs

Marriott ...................................................................32

Figure 19 Typical Demand Usage for EF 162 at Desert Springs

Marriott ...................................................................32

Figure 20 Typical Demand Usage for EF 163 at Desert Springs

Marriot.....................................................................33

Figure 21 Typical Demand Usage for EF 164 at Desert Springs

Marriott ...................................................................33

Figure 22 Westin Mission Hills Hood 1 ..........................................34

Figure 23 Westin Mission Hills Hood 2 ..........................................35

Figure 24 Westin Mission Hills Hood 3 ..........................................36

Figure 25 Typical Demand Usage for EF 7 at Westin Mission Hills .....36

Figure 26 Typical Demand Usage for EF 9 at Westin Mission Hills .....37

Figure 27 Typical Demand Usage for EF 10 / MUA at Westin Mission

Hills.........................................................................37

Figure 28 Typical Demand Usage for SF 2 at Westin Mission Hills .....38

Southern California Edison Page ii

Design & Engineering Services June 2009

Page 5

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

Figure 29 Typical Demand Usage for SF 3 at Westin Mission Hills .....38

Figure 30 El Pollo Loco Hood 1 ....................................................39

Figure 31 El Pollo Loco Hood 2 ....................................................40

Figure 32 Typical Demand Usage for MUA at El Pollo Loco...............40

Figure 33 Panda Express Hood 1 .................................................41

Figure 34 Panda Express Hood 2 .................................................42

Figure 35 Typical Demand Usage for EF 2 / MUA at Panda Express...42

Figure 36 Farmer Boys Hood 1....................................................43

Figure 37 Farmer Boys Hood 2....................................................44

Figure 38 Farmer Boys Hood 3....................................................45

Figure 39 Typical Demand Usage for EF 1 at Farmer boys...............45

Figure 40 Typical Demand Usage for EF 2 at Farmer Boys...............46

TABLES

Table 1 Overall Field Evaluation Results..........................................2

Table 2 Overall Field Evaluation Results For All Sites ......................15

Table 3 Desert Springs Marriott Exhaust Fan Results ......................16

Table 4 Desert Springs Marriott MUA Results.................................17

Table 5 Westin Mission Hills Results.............................................19

Table 6 El Pollo Loco Results.......................................................21

Table 7 Panda Express Results....................................................23

Table 8 Farmer Boys Results.......................................................25

EQUATIONS

Equation 1 Percentage Average kW Reduction...............................14

Equation 2 Average Daily Operational Hours .................................14

Southern California Edison Page iii

Design & Engineering Services June 2009

Page 6

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

CONTENTS

EXECUTIVE SUMMARY _______________________________________________ 1

INTRODUCTION ____________________________________________________ 3

Objective .............................................................................. 3

CONFIGURATIONS _________________________________________________ 4

Baseline................................................................................5

Demand Control Ventilation System..........................................6

Hardware.........................................................................6

Controls...........................................................................7

APPROACH_______________________________________________________ 9

Monitoring Equipment.............................................................9

TEST SITE DESCRIPTIONS_____________________________________________ 11

Desert Springs Marriott.........................................................11

Westin Mission Hills..............................................................12

El Pollo Loco........................................................................12

Panda Express.....................................................................12

Farmer Boys........................................................................13

RESULTS AND DISCUSSION___________________________________________ 14

Desert Springs Marriott.........................................................15

Westin Mission Hills..............................................................18

El Pollo Loco........................................................................20

Panda Express.....................................................................23

Farmer Boys........................................................................25

CONCLUSIONS ___________________________________________________ 27

Recommendations................................................................27

APPENDIX A – DESERT SPRINGS MARRIOTT ______________________________ 28

Kitchen Hood Description..................................................28

PPENDIX B – WESTIN MISSION HILLS__________________________________ 34

A

Kitchen Hood Description..................................................34

A

PPENDIX C – EL POLLO LOCO ______________________________________ 39

Southern California Edison Page iv

Design & Engineering Services June 2009

Page 7

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

Kitchen Hood Description..................................................39

A

PPENDIX D – PANDA EXPRESS ______________________________________ 41

Kitchen Hood Description..................................................41

APPENDIX E – FARMER BOYS ________________________________________ 43

Kitchen Hood Description..................................................43

REFERENCES _____________________________________________________ 47

Southern California Edison Page v

Design & Engineering Services June 2009

Page 8

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

EXECUTIVE SUMMARY

Commercial kitchen hoods (hoods) are a significant componen t of energy consumption in

restaurant and fast-food kitchens. They function to reduce fire hazards and exhaust cooking

effluent to comply with air quality standards within a commercial kitchen. Exhaust hoods in

these kitchens are normally tied to a make-up air (MUA) unit that balances building

pressure during the kitchens operation. Generally, the hoods’ exhaust requirements are

sized to peak cooking usage of each appliance under the hood. Typical hoods have a simple

“on” or “off” control strategy. When the hood is on, its exhaust and make up air fans are on

at full speed or not at all. In reality food is not being cooked at all times t herefore not

needing the peak exhaust requirements. Due to the common control strategies employed in

most commercial kitchens a significant amount of energy is wast ed on venting unnecessary

cubic feet per minute of air when appliances are not fully used. It is evident that there is an

opportunity for energy efficient savings. The Melink Int elli-Hood demand control ventilation

system (DCV) is an energy management system for commercial kitchen hoods. It optimizes

energy efficiency by reducing the exhaust and make up air fan speed. This is accomplished

by leveraging an infrared and temperature sensors to determine the minimum amount of

exhaust air required to capture and contain effluent from the cookline.

The primary objective of this project is to verify field performance and demonstrate how the

Melink Intelli-Hood demand control ventilation (DCV) system can reduce energy costs. The

projects secondary objective is to evaluate the market sectors impacts on field performance

and energy reduction on a DCV system. The different market sectors can have different

hours of operation, appliances, and kitchen exhaust hood configurations. For this field

evaluation two hotels and three quick-service restaurants were chosen. Also in this field

evaluation only the exhaust and make up air fan motor energy savings were accounted for.

Air conditioning savings, due to heat load reduction in the kitchen area, were not accounted

for.

The Melink Intelli-Hood DCV system was shown to significantly reduce the energy

consumption and electrical demand associated with operating a commercial kitchen exhaust

hood.

daily energy consumption, annual energy consumption, annual savings, percentage energy

usage reduction, and estimated annual operational cost for all hood data at each site. The

savings results from the Melink Intelli-Hood DCV system installation can realize a 37-62%

energy savings over current commercial kitchen hoods. The DCV system was most effective

in the hotel market sector due to the amount of hoods, amount of HP servicing the hotel,

and the hours of operations. Hotel kitchens are sized for peak food production - defined as

the maximum food prepared at any given time in a hotel’s kitchen. The hotel’s kitchen

sizing also means there are multiple hoods and higher amounts of HP needed to meet the

maximum food demands. Since maximum food demands rarely happen, the hotel market

sector has a high potential for savings. Most of the time there is limited kitchen use

occurring in a given day, allowing a DCV system to save energy by running at minimal

exhaust settings.

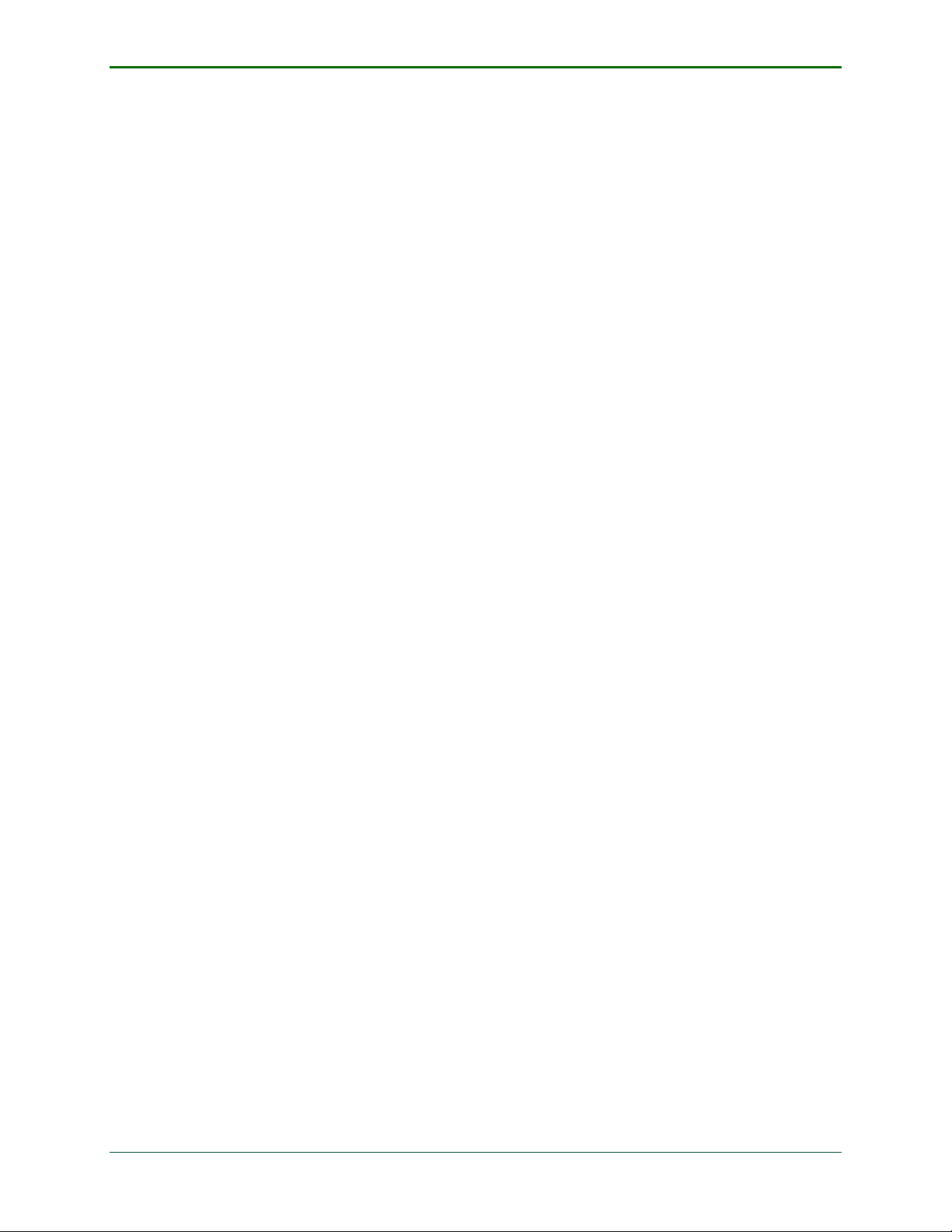

Table 1 lists the average kW draw, percentage reduction, daily operational values,

Southern California Edison Page 1

Design & Engineering Services June 2009

Page 9

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

In the quick-service restaurant market sector there was a large percentage energy drop at

each site, but a significantly lower energy savings. The lower energy savings were attributed

to the lower hp motors, operational time, appliance usage, and amount of hoods. In

addition to energy savings, with the installation of a DCV system, there was the added

benefit of noise reduction from the kitchens’ exhaust hood system.

This evaluation also showed that the performance of the DCV system was highly impacted

by the different appliance types and their controls. The appliance types ranged from lightduty to extra heavy-duty. The opportunity for energy savings decreased as the appliances

duty rating got closer to extra heavy-duty rated appliances. The higher the rating the higher

the heat load and more effluent the appliance created during cooking. The opportunity for

savings also decreased when the appliances controls created a constant heat load when

either in use or not in use. Appliances that only produce heat when cooking gave a large

opportunity for savings.

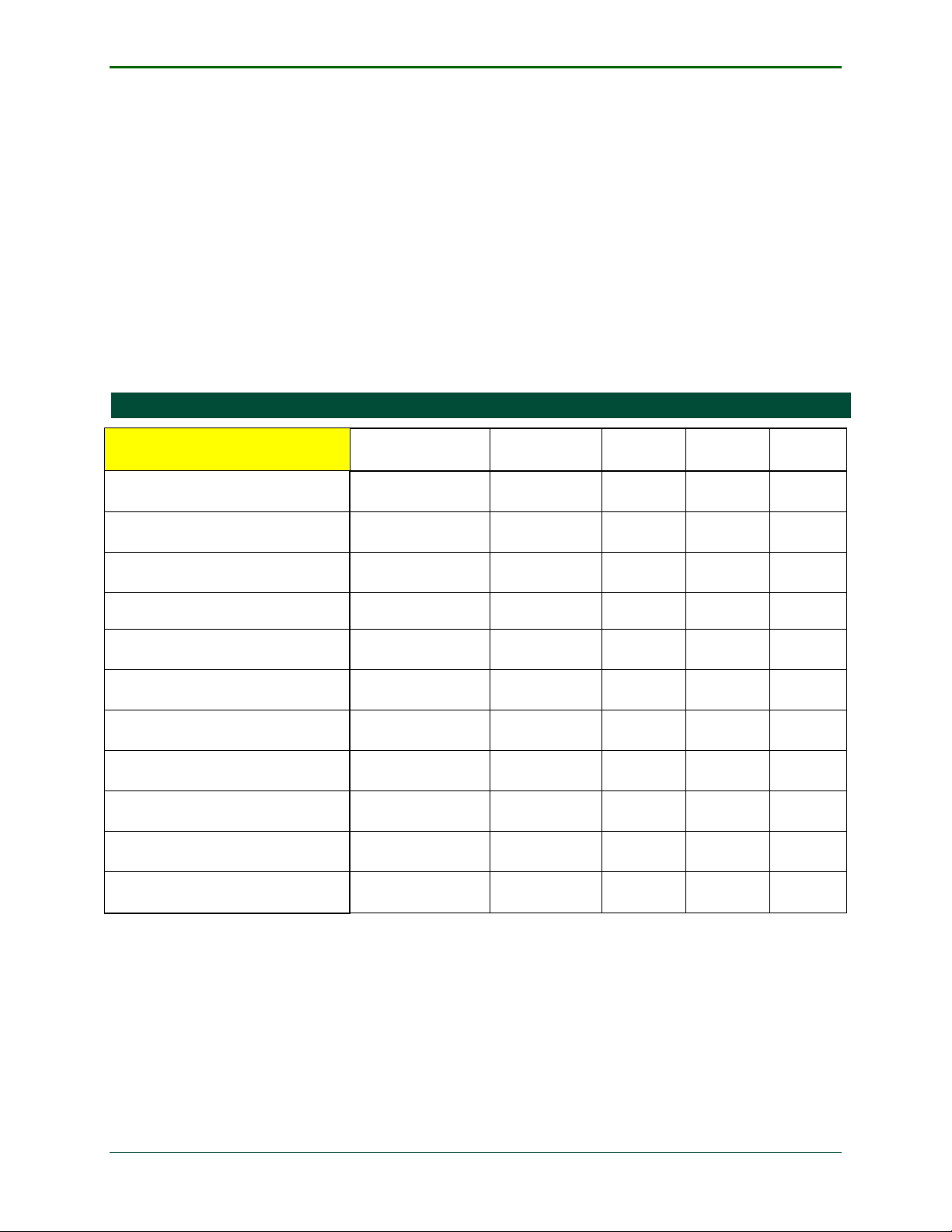

TABLE 1 OVERALL FIELD EVALUATION RESULTS

Overall Results For All Sites

Average demand without DCV

system (kW)

Average demand with DCV

system (kW)

Average kW reduction (%)

Daily Operational Hours

Daily energy usage without

DCV system (kWh/day)

Daily energy usage with DCV

system (kWh/day)

Annual energy usage without

DCV system (kWh/yr)

Annual energy usage with

DCV system (kWh/yr)

Annual energy savings with

DCV system (kWh/yr)

Percentage energy usage

reduction (kWh/yr)

Estimated annual operational

savings (@$0.15 a kWh)

Desert Springs

Marriott

Westin

Mission Hills

El Pollo

Loco

Panda

Express

Farmer

Boys

27.9 12.1 4.7 5.2 2.9

10.7 5.2 2.9 2.0 1.4

61.6% 57.0% 38.3% 61.5% 51.7%

24 24 15.36 13.1 15.83

670 291 72 67 44

257 125 45 26 23

244,500 106,034 26,313 24,620 16,159

93,681 45,595 16,442 9,559 8,276

150,819 60,439 9,871 15,061 7,884

61.7% 57.0% 37.5% 61.2% 48.8%

$22,623 $9,066 $1,481 $2,259 $1,183

Southern California Edison Page 2

Design & Engineering Services June 2009

Page 10

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

INTRODUCTION

Commercial kitchen hoods are a significant component of energy consumption in

commercial kitchens. They function to reduce fire hazards and exhaust cooking effluent to

comply with air quality standards within a commercial kitchen. Exhaust hoods in

commercial kitchens are normally tied to a make-up air (MUA) unit that balances building

pressure during the kitchens operation. Generally, commercial kitchen hoods exhaust

requirements are sized to peak cooking usage of each appliance under the hood. Typical

commercial kitchen hoods have a simple “on” or “off” control strategy. When the hood is on,

its exhaust and MUA fans are on at full speed or not at all. In reality food is not being

cooked at all times therefore not needing the peak exhaust requirements. Due to the

common controls strategies employed in most commercial kitchens a significant amount of

energy was wasted on venting unnecessary cubic feet per minute of air (cfm) when

appliances were not fully used. It was evident that there was an opportunity for change. A

demand control ventilation system (DCV) is an energy management system for commercial

kitchen hoods. It optimizes energy efficiency by reducing the exhaust and MUA fan speed.

This is accomplished by leveraging sensors to determine the minimum amount of exhaust

air required to capture and contain effluent from the cookline.

Derived from the SCE service territory database there are 37,212 restaurants, 5,553 hotels,

3,313 grocery stores, 9,105 schools/colleges, and 1,076 hospitals. Within the SCE service

territory there is a total of 56,156 customers with the potential to use DCV systems. Within

California it is estimated there are 124,040 restaurants, 18,510 hotels, 11,043 grocery

stores, 30,553 schools and 3,243 hospitals. Within all of California it is estimated there is a

total of 187,187 customers with the potential to use DCV systems. This was estimated by

assuming SCE has 30%, PGE has 35%, SDGE has 20% and municipal utilities have 15% of

Californians total customer utility service. For some market segments the applicability of the

DCV technology might be as low as 50% and as high as 80%.

OBJECTIVE

The Primary objective of this project is to verify field performance and demonstrate

how the Melink Intelli-Hood demand control ventilation (DCV) system can reduce

energy costs. The project’s secondary objective is to evaluate the market sectors’

impact on field performance and energy reduction using a DCV system. The different

market sectors can have different hours of operation, appliances, and kitchen

exhaust hood configurations.

Southern California Edison Page 3

Design & Engineering Services June 2009

Page 11

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

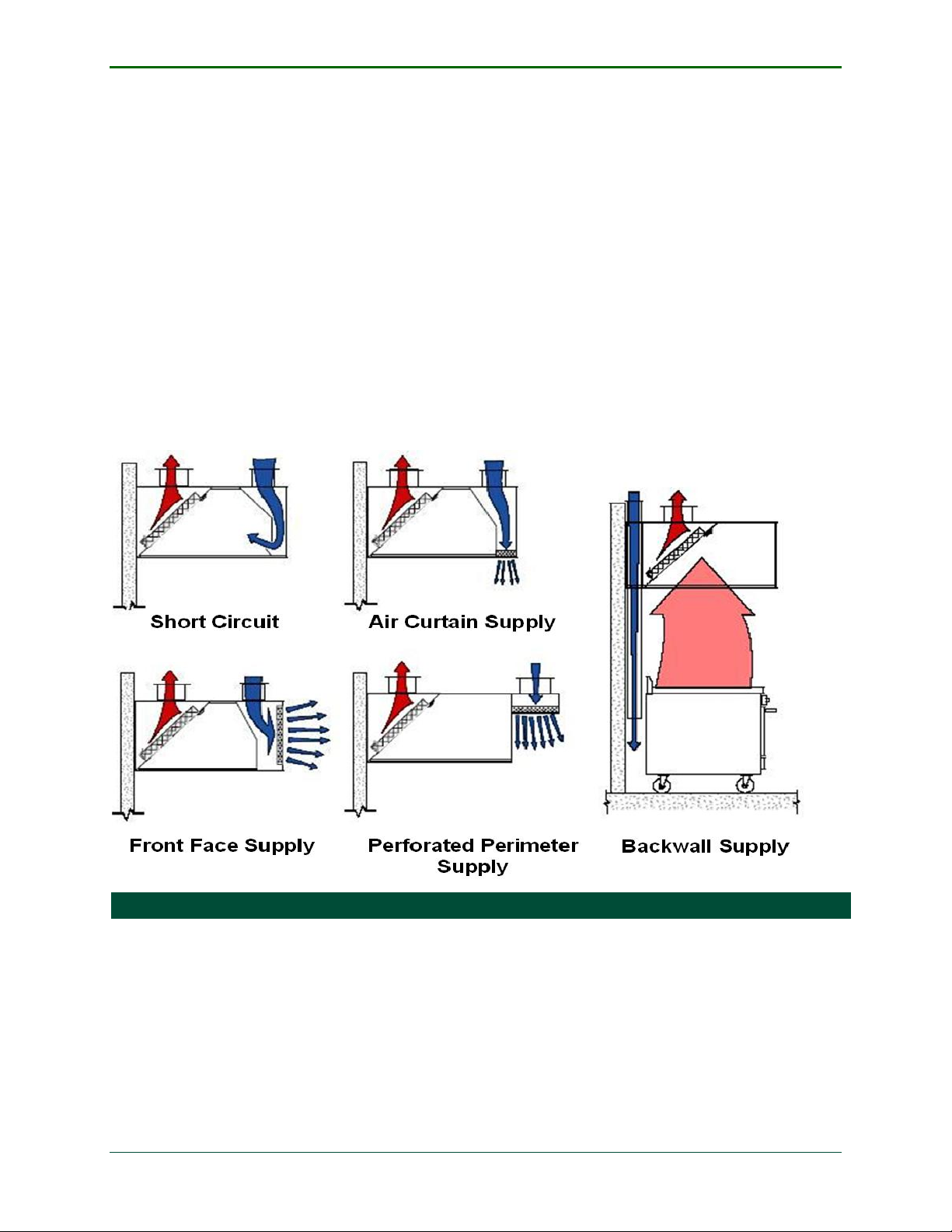

CONFIGURATIONS

Commercial kitchen exhaust hoods can come in many different configurations. These

varying configurations can impact the hoods ability to capture and contain effluent,

including odors, gases, heat, and oil. The better the system is designed, the lower the cfm

needed to capture effluent and the lower the energy consumption of the kitchen exhaust

hood. The hood style, construction features, and proximity of hood installation, give

different capture areas, dictating the necessary exhaust cfm. The hood styles, in order from

highest exhaust requirement to least, generally include; single-island canopy hood, wallmounted canopy hood, double-island canopy hood, and back-shelf hood, as depicted in

Figure 1.

FIGURE 1 COMMERCIAL KITCHEN EXHAUST HOOD STYLES1

The appliances and the food being cooked under the hood can factor in the exhaust cfm

requirements. Cooking appliances are categorized as light, medium, heavy, or extra heavyduty, due to their strength of thermal plumes it can create. Thermal plume strength is also

affected by the type of food being cooked on the appliance. The stronger the thermal plume

the more exhaust cfm that is required.

Configuration of how MUA is introduced into the kitchen is also an important configuration.

MUA balances the pressure of the kitchen when exhaust fans are in operation. As air is

exhausted out of the hood, the air is replaced by an equal volume of air. Typically, a

dedicated MUA unit is employed in a commercial kitchen. A dedicated MUA unit only makes

up a percentage of the air exhausted. By not matching cfm exhausted air, the kitchen keeps

Southern California Edison Page 4

Design & Engineering Services June 2009

Page 12

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

a negative pressure. The remaining air volume, not replaced by the MUA unit, is taken from

transfer air such as the dining area or a kitchens’ air handlers system. A small negative

pressure is desired to keep the kitchens odors from transferring into other areas the kitchen

is connected to. If no MUA is introduced, kitchen pressure may become too negative and

affect the capture and containment of effluent. When designing a dedicated MUA system for

a commercial kitchen, how the air is introduced into the kitchen can factor into how much

exhaust air to replace, and can affect the kitchen hoods ability to capture and contain

affluent. A poorly designed MUA system with a high exhaust replacement cfm can make a

kitchen hood perform poorly. Poorly designed MUA systems can hinder effluent or push

effluent outside of the hoods containment area and into the kitchen space. MUA can be

untreated (air taken from outside), or treated air (evaporative cooled or heated air). When

MUA is introduced into the kitchen it has the abil ity to save Heating, Ventilation and Air

Conditioning (HVAC) energy. This is accomplished by reducing the amount of conditioned air

being exhausted. The most common configuration to introduce MUA into the kitchen is

through integrated hood plenums. The different integrated hood plenums types in order of

worst design to best are: short circuit, air curtain supply, front face supply, perforated

perimeter supply, back wall supply, or any combination of integrated hood plenum types as

depicted in Figure 2.

FIGURE 2 COMMERCIAL KITCHEN MUA CONFIGURATION TYPES2

BASELINE

For this field evaluation the baseline for each site was a commercial kitchen hood

with the simple “on” or “off” control strategy. When the hood is “on” both exhaust

and make-up air units are at full speed until turned off. The customers chosen for

this field evaluation were either customer’s who needed the DCV system retrofit to

participate, or customers with an existing DCV system installed. At sites where the

DCV system was a retrofit, electrical usage was logged. At sites where the DCV

system was already installed, the keypad was used to override the DCV system

Southern California Edison Page 5

Design & Engineering Services June 2009

Page 13

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

before monitoring electrical usage. By overriding the DCV system, the simple “on” or

“off” controls of the kitchen exhaust hood was restored to measure baseline data for

the hood.

DEMAND CONTROL VENTILATION SYSTEM

The Melink Intelli-Hood DCV system was selected for this field evaluation because, at

the time, it was the only commercially available DCV system. Although other

manufacturers are in the process of developing their DCV systems, none were

available at the time of this study. The Melink Int elli-Hood DCV system is an energy

management system for commercial kitchen exhaust hoods. It can be installed in

new construction or as a retrofit. The Intelli-Hood controls optimize energy efficiency

by reducing the exhaust and MUA fan speed by leveraging sensors to determine the

amount of exhaust air required to capture and contain effluent from the cookline.

Since cooking does not occur at a constant, the kitchen exhaust and MUA fans vary

their speed using a variable speed controller to meet the necessary minimum

exhaust air requirements. This allows the exhaust system to run at the lowest

possible speed to perform the required job. In addition, the noise level in the kitchen

is reduced significantly as the system decreases the exhaust and MUA fan speed

during low exhaust demand.

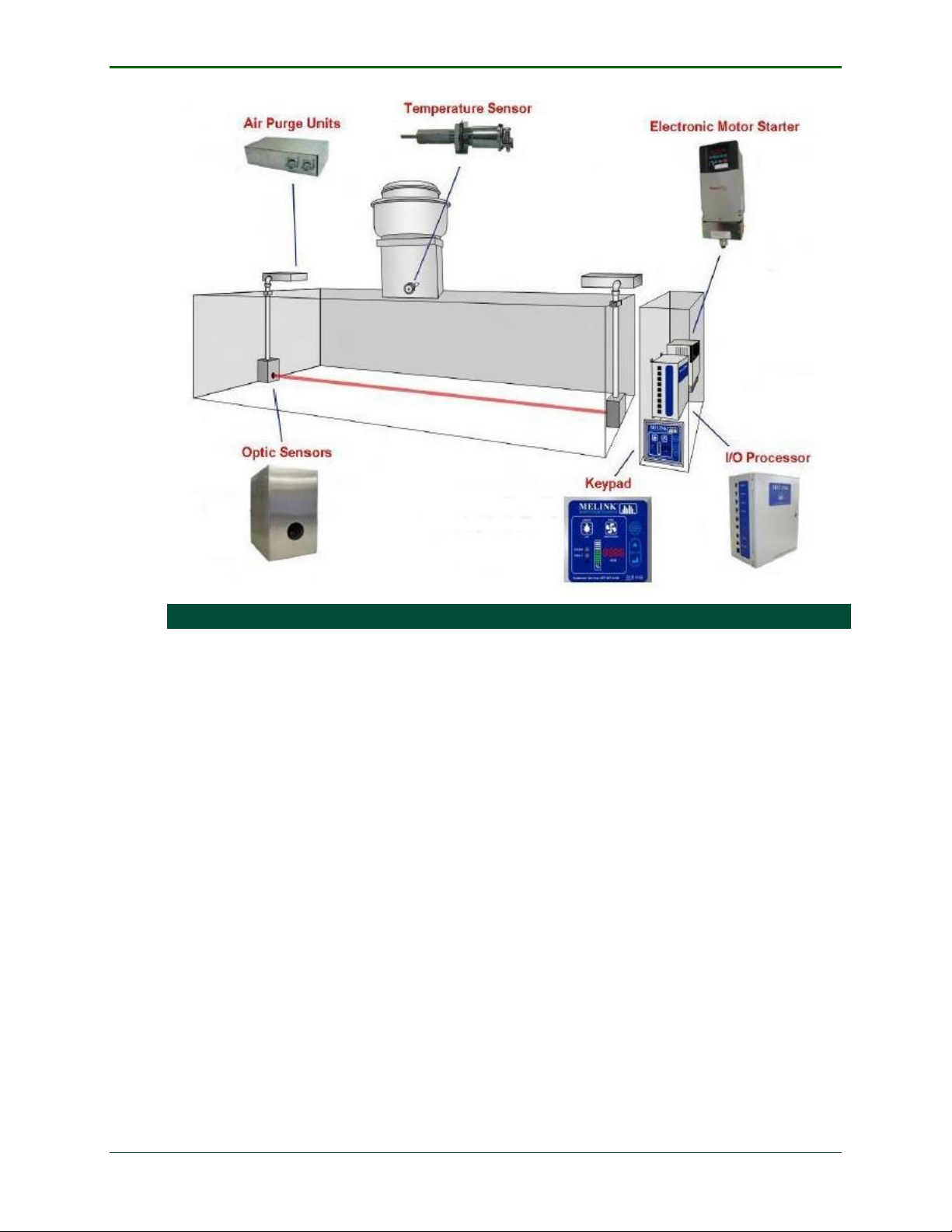

HARDWARE

The Melink Intelli-Hood system consists of 6 pieces of hardw a re as illustrated in

Figure 3.

- I/O Processor receives inputs from the temperature sensor and optic sensor.

With the inputs received from the sensors, the processor controls the output of

the electronic motor starters. The processor also displays current operations of

each hood and is able to be programmed by the keypad.

- Temperature Sensor monitors the exhaust air temperature in the exhaust duct.

A temperature signal is transmitted to the I/O processor that uses the signal to

vary the speed in proportion to actual heat load.

- Optic Sensors monitor the presence of smoke and vapors inside the hood. With

the presence of smoke and/or vapors, a signal is sent to the I/O processor to

ramp fans to full speed to remove it.

- Air Purge Units are miniature blowers that are equipped on both the optical

transmitter and receiver to prevent grease from collecting on the optical sensor

lenses when the kitchen hood exhaust system is operating.

- Electric Motor Starter is a variable frequency drive equipped on each exhaust

and Make-up fan motor. The electric motor starter receives the signal from the

I/O processor then adjusts the motor speed to meet each hood’s needs.

- Keypad allows users to turn on the system and displays current system fan

levels. The keypad also gives the user programming capabilities for the system.

Southern California Edison Page 6

Design & Engineering Services June 2009

Page 14

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

FIGURE 3 MELINK INTELLI-HOOD HARDWARE (COURTESY OF MELINK®)

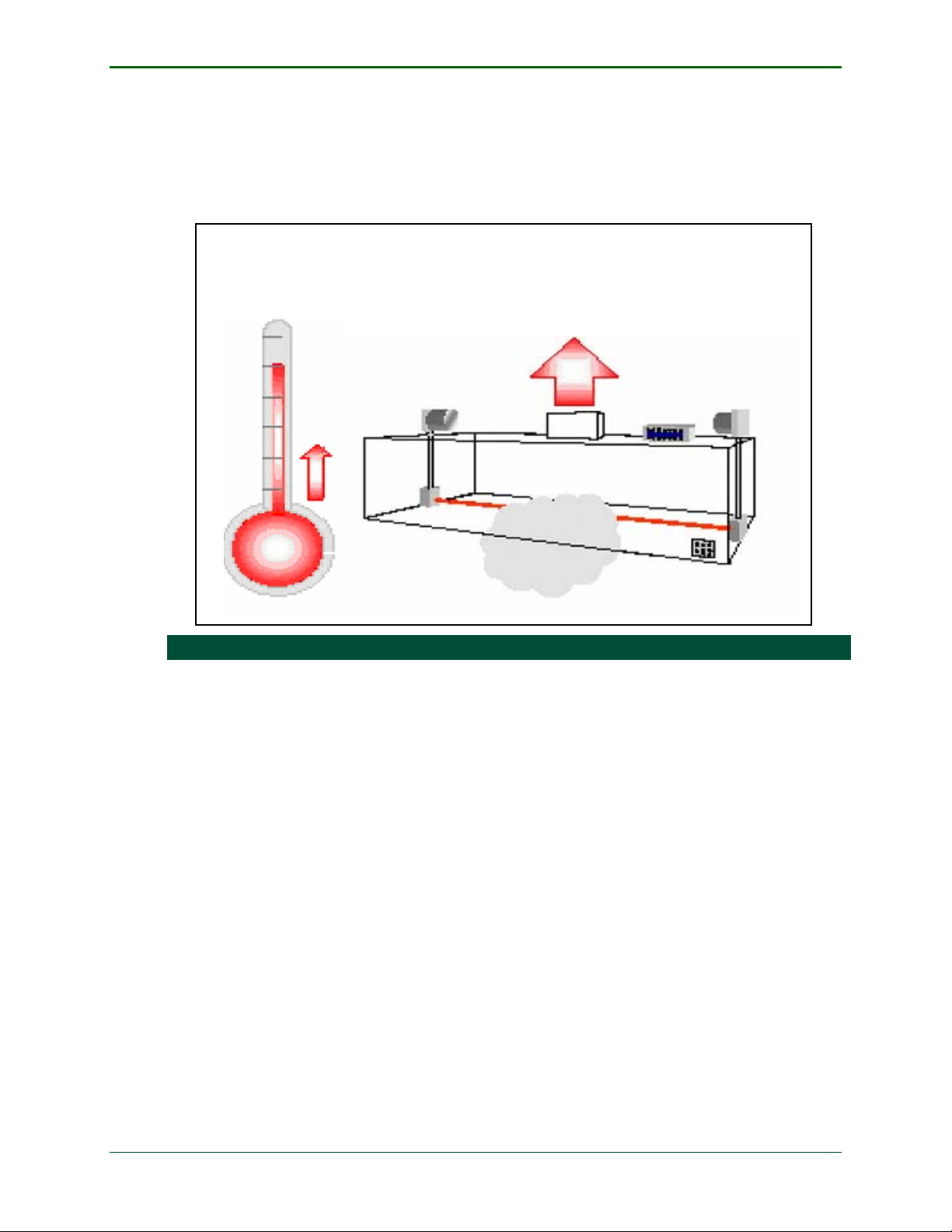

CONTROLS

The Melink Intelli-Hood system I/O processor is the brain for the whole system. The

I/O processor has the ability to control up to 4 exhaust fan motors and its

corresponding MUA units. The I/O processor displays current system fan levels for

each hood it controls on the keypad. The keypad is how different system parameters

are configured, such as electric motor starter speed rate for corresponding

temperature ranges and Infrared (IR) beam strength. The I/O processor receives

exhaust duct temperature signals for each hood from temperature sensors. The

different appliances under the hood produce heat load whether they are in use or on

stand-by. The electric motor starter varies the exhaust fan and MUA motor

depending on the temperature signal received and where it falls in the programmed

temperature parameters as illustrated in Figure 4

receiver and transmitter. The optical sensor is mounted in the bottom center on each

side of the hood. The transmitter transmits a red IR beam across the hood and when

the receiver receives intensities of less than 95% of fu ll input, a signal is sent to the

I/O processor. Usually smoke or vapors from the cookline are the cause of the

obstructions. When the signal is received the I/O processor runs the exhaust and

MUA fans at full speed, regardless of the exhaust ducts temperature, to remove

obstructions to the optical sensor as illustrated in .

. The optical sensor consists of a

Figure 4

Southern California Edison Page 7

Design & Engineering Services June 2009

Page 15

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

The Melink Intelli-Hood different paramete rs are tailored and programmed dependent

on the configuration of the kitchen. Configurations such as hood length, hood type,

hood design, how MUA is introduced, appliance exhaust requirements, and type of

food being cooked play an important role on the different parameters. The

parameters are programmed with kitchen configurations in mind during system

commissioning to achieve optimized performance and energy savings.

Heat and Smoke

FIGURE 4 MELINK INTELLI-HOOD HEAT AND SMOKE DETECTION (COURTESY OF MELINK®)

Southern California Edison Page 8

Design & Engineering Services June 2009

Page 16

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

APPROACH

To evaluate the field performance and demonstrate how the Melink Intelli-Hood DCV system

can reduce energy costs, each customer’s kitchen exhaust and MUA fan motor electrical

usage was monitored. In this evaluation only the exhaust and MUA fan motor energy

savings were measured. Since HVAC savings are weather dependent, cooling load reduction

savings were not accounted for due to the complexity it would bring to this field evaluation.

To determine potential energy savings realized by the Melink Intelli-Hood system at each

site, three phases were completed.

- Phase 1 - Baseline evaluation: After the customer sites were chosen to

participate in the field evaluation, the kitchen configuration was noted. The

different exhaust and MUA fan motors were found and corresponding electrical

service breakers were found. Fan motors name plate data was also recorded. A

Micro Data logger was installed on each exhaust and MUA electrical breaker to

monitor electrical usage of the corresponding fan motor. At sites where the DCV

system was a retrofit, electrical usage was logged. At sites where the DCV

system was already installed, the keypad was used to override the DCV system

before monitoring electrical usage. By overriding the DCV system, the simple

“on” or “off” controls of the kitchen exhaust hood were restored to measure

baseline data for the hood. Since the motors ran constantly at full speed under

the baseline controls of the kitchen hoods, the power draw from each fan motor

was pretty much constant. Baseline data was recorded for about one week at

each site and analyzed.

- Phase 2 - System retrofit or adjustment: After each kitchen exhaust hood

electrical usage was baselined, phase two was initiated. At sites where the simple

“on” or “off” controls strategy was employed, the DCV system hardware was

installed and system parameters were programmed during commissioning. At

sites where the DCV system was already installed, the keypad was used again to

restore the DCV system controls.

- Phase 3 - New system evaluation: After installation or adjustment of the DCV

system, the system was allowed to run for two weeks to ensure proper

performance. The DCV system’s electrical usage was monitored for about six

weeks in the quick-service restaurants and twelve weeks in the hotels.

MONITORING EQUIPMENT

Micro Data Loggers, (MDL) Current Transducers, (CT) and wattnodes were also

installed in the electrical breaker servicing each exhaust and MUA fan motor at all

five sites as shown in Figure 5. The MDL logs power data coming from a wattnode.

The wattnode generates pulses from voltage readings tapped into the circuit and

amperage readings from CTs (generically, Power=voltage x amperage). Electrical

service for each fan motor was either three phase 480v delta or three- phase 208v

wye. When monitoring three phase 480v delta circuits, a WNA-3D-480P wattnode

was used. When monitoring three phase 208v wye-wired circuits, a WNA-3Y-208P

wattnode was used. The wattnode has an accuracy of

scale through 25th harmonic.

Maximum amperage draw of each fan motor dictated the CT size used for monitoring

CTs used for each of the sites were either 5 or 20 amps.

0.45% of reading + 0.05% of full

Southern California Edison Page 9

Design & Engineering Services June 2009

Page 17

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

each motors electrical full load amps (FLA). The CTs has an accuracy of ±1% at 10%

to 130% of rated current

Power data was measured in 15-second intervals and averaged into 5-minute data

points logged by the MDL. A low sample interval was chosen to provide high

accuracy and resolution for the readings. The compiled 5-minute data was

downloaded monthly. A Fluke 43B power quality analyzer was used to verify data

collected. Spot checks were also administered each time data was downloaded and

the logger was reset.

FIGURE 5 MONITORING EQUIPMENT INSTALLATION

Southern California Edison Page 10

Design & Engineering Services June 2009

Page 18

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

TEST SITE DESCRIPTIONS

The test sites chosen for this field evaluation include two hotel/resorts and three quick- service

restaurants. These market segments were chosen specifically because there was a lack of

energy savings information. The two hotels were also chosen due to their high potential for

energy savings because of the number of commercial kitchen hoods and their corresponding

horse power. The hotels have a large amount and variety of cooking appliances, kitch en

operation hours, number of stories and diverse kitchen use. For these reasons both the Desert

Springs Marriott and the Westin Mission Hills hotels were selected for this study. The quickservice market sector was another area of focus due to the large amount of customer foot

traffic in addition to the lack of savings information on the market sector. The three quickservice restaurants selected all had different types of menus and corresponding appliances. The

selected restaurants include an El Pollo Loco, Panda Express, and a Farmer Boys restaurant.

DESERT SPRINGS MARRIOTT

The Desert Springs Marriott hotel is located in Palm Desert, CA and serves 844 guest

rooms. The hotel stands nine stories high with the kitchen located on the ground

floor. The kitchen operates 24-hours a day, 365 days a year and serves breakfast,

lunch, dinner, room service, and all of the hotels different catering needs. The

kitchen consists of 6 wall-mounted canopy kitchen exhaust hoods. MUA is introduced

into the kitchen by integrated short circuit supply registers within each hood. There

is 21 hp of combined exhaust motor horse power to exhaust a total of 23,914 cfm.

There is 11.5 hp combined MUA motor horse power to make-up 13,804 cfm. The

MUA units replace 57% of exhaust flow from the kitchen. The air handler places

17,923 cfm of conditioned air into the kitchen space, of which 6,100 cfm of the air

comes from outside. All exhaust and MUA fan motors run on 480v service. The

Desert Springs Marriott was one of the customers where energy usage was baselined

before the DCV system was retrofitted to their kitchen exhaust hoods. When the DCV

retrofit system was installed, two systems were installed - System A and System B.

The total cost of the retrofit for the new system including labor was about $28,000.

Southern California Edison Page 11

Design & Engineering Services June 2009

Page 19

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

WESTIN MISSION HILLS

The Westin Mission Hills hotel is located in Rancho Mirage, CA and serves 472 guest

rooms. It has a single-story kitchen that operates 18-hours a day, 365 days per

year. Even though the kitchen only operates 18-hours a day, the kitchen hoods

operate 24-hours a day providing high potential for demand controlled ventilation.

The kitchen serves breakfast, lunch, dinner, room service, and all of the hotels

catering needs. It consists of 3 wall-mounted canopy kitchen exhaust hoods. MUA is

untreated and introduced into the kitchen by an integrated air curtain supply

register, or by ceiling diffusers. There is 14 hp of combined exhaust motor horse

power to exhaust a total of 21,594 cfm. There is 8 hp combined MUA motor horse

power to make-up 14,920 cfm. The MUA units replace 69% of exhaust flow from the

kitchen. The air handler places 12,000 cfm of conditioned air into the kitchen space.

All exhaust and MUA fan motors run on 480v service. The Westin Mission Hills was

one of the customers where energy usage was baselined before the DCV system was

retrofitted into their kitchen exhaust hoods. The total cost of the retrofit for the new

system including labor was about $22,000.

EL POLLO LOCO

El Pollo Loco is a quick-service chicken restaurant located in E l M onte, CA. Store

hours are Monday - Sunday 9:00a.m. to 12:00a.m., and is open 364 days out of the

year. The kitchen is a single-story that serv es flame-grilled chicken and other menu

items. The kitchen consists of a wall-mounted canopy kitchen exhaust hood and a

single-island canopy hood. MUA is evaporative cooled air and introduced into the

kitchen by an integrated perforated perimeter supply register. There is 3 hp of

combined exhaust motor horse power to exhaust a total of 7,760 cfm. There is 3 hp

combined MUA motor horse power to make-up 5,330 cfm. The MUA units replace

69% of exhaust flow from the kitchen. The HVAC system places 5,000 cfm of

conditioned air into the kitchen space. All exhaust and MUA fan motors run on 208v

service. El Pollo Loco is one of the customers where energy usage was baselined

before the DCV system was retrofitted into their kitchen exhaust hoods. The total

cost of the retrofit for the new system including labor was about $15,500.

PANDA EXPRESS

Panda Express is a quick-service Chinese food restaurant located in Quartz Hill, CA .

Store hours are Monday - Thursday 10:30a.m. to 9:30p.m, Friday - Saturday

10:30a.m. to 10:00p.m, and Sunday 11:00a.m. to 9:00p.m. The store is open 365

days out of the year. The kitchen is a single-story that serves a variety of Chinese

food. The kitchen consists of two wall-mounted canopy kitchen exhaust hoods. MUA

is evaporative cooled air and introduced into the kitchen by an integrated perforated

perimeter supply register. There is 4 hp of combined exhaust motor horse power to

exhaust a total of 6,000 cfm. There is 1 hp combined MUA motor horse power to

make-up 4,800 cfm. The MUA units replace 80% of exhaust flow from the kitchen.

The HVAC system places 5,000 cfm of conditioned air into the kitchen space. All

exhaust and MUA fan motors run on 208v service. The Panda Express had the DCV

system previously installed before this field evalua tion. The total new construction

cost for the new system including labor was about $8,000.

Southern California Edison Page 12

Design & Engineering Services June 2009

Page 20

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

FARMER BOYS

Farmer Boys is a quick-service American restaurant located in Irwindale, CA. Store

hours are Monday - Saturday 6:00a.m. to 10:00p.m, and Sunday 6:00a.m. to

9:00p.m and is open 364 days out of the year. The kitchen is a single-story that

serves breakfast, lunch, and dinner entrees that can be ordered at anytime of the

day. The kitchen consists of two wall-mounted canopy kitchen exhaust hoods and a

single-island canopy hood. There is no dedicated MUA unit for the kitchen. Instead

the HVAC system is introduced into the kitchen by an integrated perforated

perimeter supply register. Since there was not a dedicated MUA unit, the air supply

coming from the integrated perforated perimeter supply registers was not modulated

when the DCV system was installed. There is 2.25 hp of combined exhaust motor

horse power to exhaust a total of 6,500 cfm. The HVAC system places 2,606 cfm of

conditioned air into the kitchen space. The rest of the MUA requirements are taken

from the transfer air of the nearby dining area. All exhaust fan motors run on 208v

service. Farmer Boys had the DCV system previously installed before this field

evaluation. The total new construction cost for the new system including labor was

about $9,000.

Southern California Edison Page 13

Design & Engineering Services June 2009

Page 21

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

RESULTS AND DISCUSSION

After the data was recorded and analyzed, power and energy consumptions were compared

between the kitchen ventilation system “with” and “without” a DCV system. Table 2 lists the

average kW draw, percentage reduction, daily operational values, daily energy

consumption, annual energy consumption, annual savings, percentage energy usage

reduction, and estimated annual operational cost for all hood data at each site. Measured

average kW for the baseline was pretty much a consistent number that fluctuated a little

from the baseline. The measured average kW for new system case was only the average of

the kW when the kitchen hood was on. The average kW for the two cases was used to

calculate the average kW reduction using Equation 1.

EQUATION 1 PERCENTAGE AVERAGE KW REDUCTION

Daily operations were 24-hours for the two hotels since they never turned off their hoods.

For the three quick-service restaurants, the hours of operation for the kitchen exhaust hood

system were estimated. These estimates were determined by using Equation 2. From the

end use monitoring equipment data was downloaded. The data was a reading of demand

draw averaged into a five-minute data point. Demand draw only occurred when the kitchen

exhaust hood system was in operation. Since any demand draw meant the kitchens’

exhaust hood system was in operation, the amount of data points with demand draw that

were counted were the demand occurrences. When all the demand occurrences were

summed they were multiplied by five minutes to give a sum of minutes of operation. The

sum of minutes was then divided by the number of days the data came from to give the

average daily operational hours.

EQUATION 2 AVERAGE DAILY OPERATIONAL HOURS

The daily energy use was then calculated by multiplying t he average kW times the

operational hours to get daily energy consumption. The daily energy consumption was then

multiplied by the number of days the restaurant was open for business to find annual

energy consumption. The difference between the baseline and the new system provided the

savings. The savings were divided by the baseline to get annual energy usage reduction.

The savings were also multiplied by the rate of fifteen cents a kilowatt hour (kWh) to

estimate the technologies’ annual operational savings. This rate was derived from SCE’s

current rate structure, averaged for applicable commercial customers.

Southern California Edison Page 14

Design & Engineering Services June 2009

Page 22

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

The percent reduction for all the sites ranged from 37% to 62% savings. This percentage

was good, but did not translate into large energy savings or dollar savings unless the hours

of operation and horse power were high. The range of savings was also greatly impacted by

the appliances used and the corresponding food being cooked. If the appliance was rated a

medium to heavy duty and had a constant heat load, the savings opportunity decreased

significantly. For example, charbroilers have a constant heat load whether food is in the

process of cooking or not. Appliances rated light to medium usually created heat load when

cooking occurred, resulting in large savings opportunities.

TABLE 2 OVERALL FIELD EVALUATION RESULTS FOR ALL SITES

Overall Results For All Sites

Average demand without DCV

system (kW)

Average demand with DCV

system (kW)

Average kW reduction (%)

Daily Operational Hours

Daily energy usage without

DCV system (kWh/day)

Daily energy usage with DCV

system (kWh/day)

Annual energy usage without

DCV system (kWh/yr)

Annual energy usage with

DCV system (kWh/yr)

Annual energy savings with

DCV system (kWh/yr)

Percentage energy usage

reduction (kWh/yr)

Estimated annual operational

savings (@$0.15 a kWh)

Desert Springs

Marriott

Westin

Mission Hills

El Pollo

Loco

Panda

Express

Farmer

Boys

27.9 12.1 4.7 5.2 2.9

10.7 5.2 2.9 2.0 1.4

61.6% 57.0% 38.3% 61.5% 51.7%

24 24 15.36 13.1 15.83

670 291 72 67 44

257 125 45 26 23

244,500 106,034 26,313 24,620 16,159

93,681 45,595 16,442 9,559 8,276

150,819 60,439 9,871 15,061 7,884

61.7% 57.0% 37.5% 61.2% 48.8%

$22,623 $9,066 $1,481 $2,259 $1,183

DESERT SPRINGS MARRIOTT

The Desert Springs Marriott shows that hotels are a good application for a DCV

system. Table 3 shows the results for all exhaust fans at the Desert Springs Marriott.

The number of hoods, appliances usage, type of appliances, hours of operation, and

horse power affected the DCV systems performance and its corresponding savings

greatly. The number of kitchen hoods and their horse power attributed to the

exhaust fan motor energy consumption of 115,078 kWh a year. After the DCV

system was installed the energy consumption dropped by 69% to 50,757 kWh a

year. The savings are 115,078 kWh a year. The reduction of 69% can be attributed

to the appliances usage. Out of 6 hoods only one cookline was actually on 24 hours

in a day, which was the room service cookline EF 164. The other five cooklines had

appliances either turned off, or were put on a very low setting from10:00 p.m. to

4:00 a.m. the next day. Almost all EFs dropped to a very low state between those

times. EF 159, 161, 162, and 163 all modulated very little throughout the day as

shown in Appendix A, Figure 17 to Figure 20. Those EFs are all batch cooking

Southern California Edison Page 15

Design & Engineering Services June 2009

Page 23

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

cooklines with appliances that were either on or off. When the appliances were off

there was no heat load to exhaust. When the appliances were on the savings were

reduced and were dependent on the appliances duty rating. The appliances range

from light duty to medium duty. The duty of the appliance combined with the limited

activity provided for large savings seen at the site.

TABLE 3 DESERT SPRINGS MARRIOTT EXHAUST FAN RESULTS

Desert Springs Marriott

Exhaust fan motors

Average demand without DCV

system (kW)

Average demand with DCV

system (kW)

Average kW reduction (%)

Daily Operational Hours

Daily energy usage without

DCV system (kWh/day)

Daily energy usage with DCV

system (kWh/day)

Annual energy usage without

DCV system (kWh/yr)

Annual energy usage with

DCV system (kWh/yr)

Annual energy savings with

DCV system (kWh/yr)

Percentage energy usage

reduction (kWh/yr)

EF 159 EF 160 EF 161 EF 162 EF 163 EF 164

Combined

Data

1.5 6.4 1.9 1.7 2.0 5.5 18.9

0.1 3.8 0.4 0.4 0.3 0.9 5.8

93.5% 41.1% 78.5% 75.9% 86.8% 84.3% 69.4%

24 24 24 24 24 24 24

36 153 45 41 47 133 454

2 90 10 10 6 21 139

13,146 55,966 16,282 14,842 17,165 48,435 165,836

855 32,961 3,501 3,570 2,266 7,604 50,757

12,290 23,005 12,780 11,272 14,899 40,832 115,078

93.5% 41.1% 78.5% 75.9% 86.8% 84.3% 69.4%

Estimated annual operational

savings (@$0.15 a kWh)

Table 4 shows the results from the six MUA units. MUA is introduced to the kitchen

through an integrated short circuit register inside the hood, which can create spillage

of effluent from the kitchen exhaust hood. As a general rule of thumb, only 15%

exhaust cfm should be made up by a short circuit style hoods. Any amount above

15% of the exhaust cfm starts to degrade the hoods ability to capture and contain

effluent. The Desert Springs Marriott was exhausting 57%. Since the percentage was

so high, the MUA units were turned off during the initia l commissioning of the

system. The customer noticed the building pressure was too negative and decided to

turn two of the MUA units back on. The energy savings from turning off four of the

MUA units was 45% or 35,741 kWh. For this study MUA energy savings were

accounted for as part of the savings because the customers can see the impact on

their energy usage and their corresponding bill. The total savings of the new system

was 62% or 150,819 kWh. However, the EF energy savings, as the MUA savings

could have been accomplished without a DCV system.

$1,844 $3,451 $1,917 $1,691 $2,235 $6,125 $17,262

Southern California Edison Page 16

Design & Engineering Services June 2009

Page 24

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

TABLE 4 DESERT SPRINGS MARRIOTT MUA RESULTS

Desert Springs Marriott

MUA

Average demand without

DCV system (kW)

Average demand with

DCV system (kW)

Average kW reduction

(%)

Daily Operational Hours

Daily energy usage

without DCV system

(kWh/day)

Daily energy usage with

DCV system (kWh/day)

Annual energy usage

without DCV system

(kWh/yr)

Annual energy usage

with DCV system

(kWh/yr)

Annual energy savings

with DCV system

(kWh/yr)

Percent energy usage

reduction (kWh/yr)

Estimated annual

operational savings

(@$0.15 a kWh)

MUA 10 MUA 11 MUA 6 MUA 7 MUA 8 MUA 9

Combined

Data

1.0 1.0 0.8 2.1 2.8 1.3 9.0

0.0 0.0 0.0 2.1 2.8 0.0 4.9

100.0% 100.0% 100.0% 0.0% 0.0% 100.0% 45.4%

24 24 24 24 24 24 24

25 24 19 51 67 31 216

0 0 0 51 67 0 118

9,023 8,585 6,920 18,571 24,353 11,213 78,665

0 0 0 18,571 24,353 0 42,924

9,023 8,585 6,920 0 0 11,213 35,741

100.0% 100.0% 100.0% 0.0% 0.0% 100.0% 45.4%

$1,353 $1,288 $1,038 $0 $0 $1,682 $5,361

Figure 6 provides an example of a typical demand profile for exhaust fan EF 160. EF

160 is the kitchens main line, and handles a large amount of short order cooking.

The black solid line represents the baseline case that consistently draws around 6.5

kW. This consistent demand draw is due to the fans simple “on” or “off” control

strategy. The minor variation of the baseline is due to the loading and unloading of

the exhaust fan as effluent is exhausted. The dashed redline represents the new

system case (with DCV installed). As expected, the fan motor demand drops

significantly from 10:00p.m. to 4:00 a.m. Between these hours, the short order food

demands for the hotel are very low, so the kitchen staff turns off or runs the

appliances at the lowest set point under the hood. With the appliances off or at low

settings, there is little, if any, heat produced that needs exhausting. The DCV system

was programmed to decrease fan speed as low as possible when the exhaust

temperature dropped significantly. The dropped fan speed during this period of time

translated into large demand reductions. Between 4:00a.m. to 7:00a.m. a rise in

energy demand occurs as some appliances are turned on and at around 7:30 a.m. all

appliances are fully functional and the energy demand fluctuates depending on the

cooking taking place. This routine occurs about the same time everyday. However, to

account for the variations in appliance shut offs; cooking demand during operational

hours, and special-events catering, an average was taken from the 12 weeks of data.

The average demand draw for EF 160 with the DCV system was 3.8 kW, which is

Southern California Edison Page 17

Design & Engineering Services June 2009

Page 25

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

represented by the dashed green line which gives a visual representation of energy

usage drop from baseline to the new system case. Typical demand profile graphs for

each of the five exhaust fans can be found in Appendix A, Figure 17 to Figure 21.

The other exhaust fans followed the same pattern as EF 160. The only exhaust fan

that didn’t follow the general rule was EF 164. EF 164 was used for room service

orders. The room service cookline has a 24-hour operation and has the opposite

demand profile because the appliances are on the entire day, but the food demand

varies from 7:00a.m. to 1:00a.m. the next day.

FIGURE 6 TYPICAL DEMAND USAGE FOR EF 160 AT DESERT SPRINGS MARRIOTT

WESTIN MISSION HILLS

The Westin Mission Hills is another hotel that demonstrat es why hotels are a good

application for a DCV system. Table 5 shows the results for all the EF and SF unit s

for the Westin Mission Hills. The amount of exhaust fans, appliance usage, type of

appliances, hours of operation, and horse power affected the DCV system

performance and its corresponding savings greatly. The baseline energy consumption

was 106,034 kWh a year. After the DCV system was installed the energy

consumption dropped by 57% to 45,595 kWh a year. The savings are 60,439 kWh a

year. The reduction is mainly due to the limited activity occurring in the two back-toback 30-ft hoods. The hoods are mainly used for batch cooking. EF 7, 8, and 9 all

service both hoods along with SF 2 and 3. Appliances under the hoods are mainly

light to medium duty appliances. These appliances only create a heat load when the

appliances are on. The only exceptions were the two griddles located under EF 8. The

constant heat load from the appliances reduced the savings of just that particular

Southern California Edison Page 18

Design & Engineering Services June 2009

Page 26

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

exhaust fan. EF 10/MUA shows very little savings and modulation during operational

hours due to the constant heat load from the griddle and charbroiler.

TABLE 5 WESTIN MISSION HILLS RESULTS

Westin Mission Hills

Average demand

without DCV system

(kW)

Average demand with

DCV system (kW)

Average kW reduction

(%)

Daily Operational

Hours

Daily energy usage

without DCV system

(kWh/day)

Daily energy usage

with DCV system

(kWh/day)

Annual energy usage

without DCV system

(kWh/yr)

Annual energy usage

with DCV system

(kWh/yr)

Annual energy savings

with DCV system

(kWh/yr)

Percentage energy

usage reduction

(kWh/yr)

Estimated annual

operational savings

(@$0.15 a kWh)

EF 10/

MUA

EF 7 EF 8 EF 9 SF 2 SF 3

Combined

Data

3.8 1.9 2.2 2.2 0.6 1.3 12.1

3.0 0.3 1.0 0.6 0.1 0.1 5.2

20.3% 83.2% 57.3% 71.4% 76.6% 90.9% 57.0%

24 24 24 24 24 24 24

92 46 54 52 14 32 291

73 8 23 15 3 3 125

33,400 16,965 19,614 19,072 5,196 11,787 106,034

6,785 14,117 11,237 13,612 3,979 10,710 60,439

26,616 2,848 8,377 5,460 1,217 1,076 45,595

20.3% 83.2% 57.3% 71.4% 76.6% 90.9% 57.0%

$1,017.70 $2,117.52 $1,685.51 $2,041.79 $596.81 $1,606.54 $9,065.87

Figure 7 gives an example of a typical demand profile for exhaust fan EF 8. EF 8 is

the center EF motor serving the center 10-ft of the back-to-back 30-ft kitchen hood.

The black solid line represents the baseline case. The baseline consistently draws

around 2 kW. The consistent demand draw is due to the fans simple “on” or “off”

control strategy. The EF actually varies a considerable amount. The variation is from

1.7 kW all the way up to 2.0 kW depending on the loading and unloading of the

exhaust fan as effluent is exhausted. The dashed red line represents the new system

case (with DCV installed). As expected, the fan moto r demand drops significantly

throughout the day. The exhaust setup is unique where the exhaust serves a batch

cookline (hood 1 and 2). There also are no barriers between EF 7 and 9 exhaust

registers. Since there are no barriers between the exhaust registers of the 30-ft

kitchen hood, effluent not directly under could be exhausted by EF 8 as it runs at a

higher speed most of the day. The appliances serviced by EF 8 are 2 griddles under

hood 1; a kettle under, and a tilting skillet under hood 2. The griddles are on at all

times, which create a consistent heat load. The consistent heat load keeps the fan at

0.8 kW. As items are cooked on the griddle, or batch cooking occurs on the

Southern California Edison Page 19

Design & Engineering Services June 2009

Page 27

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

kettles/tilting skillet, the fan modulat es depending on exhausting needs. This routine,

occurs about the same time everyday, but to account for the variations of appliance

shut offs, cooking demand during operational hours, and special events catering, an

average was taken from the 12 weeks of data. The average demand draw for EF 8 is

0.95 kW, which is represented by the dashed green line. The dashed green line gives

a visual representation of energy usage drops from the baseline for the new system

case. Typical demand profile graphs for each of the 4 exhaust fans and supply fans

can be found in Appendix A, Figure 25 to Figure 27. The typical demand profile for

the other exhaust fans servicing the 30-ft hoods have a considerably lower demand

draw as the rated appliances are low-duty to medium-duty fans. The particular

appliances serviced by EF 7 and 9 only create heat when cooking is taking place. The

typical demand usage of the supply fans (SF) are also considerably lower since they

modulate dependent on EF 7, 8, and 9 make up air requirements. Typical demand

usage for EF10 / MUA modulation opportunity is a lot lower as the medium to heavy

duty appliances place a high heat load on the DCV system.

FIGURE 7 TYPICAL DEMAND USAGE FOR EF 8 AT THE WESTIN MISSION HILLS

EL POLLO LOCO

El Pollo Loco shows the impact a DCV system has on the quick service restaurant

market segment. Table 6 shows the results for all the EF and MUA units for El Pollo

Loco. The amount of exhaust fans, appliance usage, type of appliances, hours of

operation, and horse power affects the DCV systems performance and savings

greatly. The baseline energy consumption was 26,313 kWh a year. After the DCV

system was installed the energy consumption dropped by 37% to 16,442 kWh a

year. The savings are 9,871 kWh a year. The reduction was mainly due to the

decreased kitchen exhaust demand during the first and last two hours of opening

Southern California Edison Page 20

Design & Engineering Services June 2009

Page 28

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

and closing. EF 1 and 2 serviced the two heavy duty charbroilers that chicken was

cooked on. The charbroilers open flame and constant heat provided little opportunity

for the DCV system to save energy. The bulk of the savings were in the morning and

at night as the charbroilers were at a low setting in preparation for opening and

closing. EF 2 serviced medium duty appliance combination ovens. The combination

ovens only created a heat load when cooking occurred and were rated as medium

duty appliances due to the exiting steam as the ovens’ door opened. Since there was

only one MUA unit, the MUA modulated dependent on all the EF current exhaust

requirements, saving 43.5% of MUA energy usage. The savings for EF 1, 2, and 3

was 33% of the combined exhaust fans energy consumption. The exhaust fans

servicing the charbroilers was the main reason for the lowered the saving s.

TABLE 6 EL POLLO LOCO RESULTS

El Pollo Loco EF 1,2,3 MUA 1

Average demand without DCV system (kW)

Average demand with DCV system (kW)

Average kW reduction (%)

Daily Operational Hours

Daily energy usage without DCV system (kWh/day)

Daily energy usage with DCV system (kWh/day)

Annual energy usage without DCV system (kWh/yr)

Annual energy usage with DCV system (kWh/yr)

Annual energy savings with DCV system (kWh/yr)

Percent energy usage reduction (kWh/yr)

Combined

Data

2.8 1.9 4.7

1.9 1.1 2.9

33.4% 43.5% 37.5%

15.36 15.36 15.36

43 29 72

29 17 45

15,676 10,637 26,313

10,435 6,007 16,442

5,241 4,630 9,871

33.4% 43.5% 37.5%

Estimated annual operational savings (@$0.15 a

kWh)

$786 $694 $1,481

At El Pollo Loco all the exhaust fans were connected on one circuit breaker. Figure 8

gives an example of typical demand usage for EF 1, 2, and 3. EF 1 and 2 are the

exhaust fans servicing the two charbroilers used to cook chicken throughout the day.

EF 3 services the different combination ovens. The black solid line represents the

baseline case. The baseline consistently draws around 3 kW. The consistent demand

draw is due to the fans simple “on” or “off” control strategy. The minor variation of

the baseline is due to the loading and unloading of the exhaust fan as effluent is

exhausted. The dashed red line represents the new system case (with DCV

installed). When the workers arrive at the store around 7:00 a.m., the hoods are

turned on and the chicken is pre-cooked in the combination ovens until 9:00 a.m.

The demand jumps as the store begins to flame grill the chicken once the store

opens at 9:00 a.m. The exhaust modulates very little while chick en is char broiled

throughout the day. The modulation is very minimal due to the chicken and

charbroiler’s large amounts of effluent and heat. The large amount of heat is due to

Southern California Edison Page 21

Design & Engineering Services June 2009

Page 29

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

the charbroiler’s open flames that operate on a high setting during chicken

production. The major demand usage savings are really the two hours before the

store opens and closes due to the charbroiler’s not used, or being turned to the

lowest setting. This routine, occurs about the same time everyday, but to account for

the variations of chicken being cooked and their corresponding exhaust fan

modulation, an average was taken from the 6 weeks of data. The average demand

draw for EF 1, 2, and 3 with the DCV system is 2 kW, which is represented by the

dashed green line. This green line gives a visual representation of energy usage drop

from baseline for the new system case. The new system case average is only when

the exhaust hood is actually on. The typical demand profile graph for MUA can be

found in Appendix A, Figure 32. The MUA fans demand usage almost mirrors the EF

demand usage since most of the MUA is supplying EF 1 and 2.

FIGURE 8 TYPICAL DEMAND USAGE FOR EF 1,2,3 AT EL POLLO LOCO

Southern California Edison Page 22

Design & Engineering Services June 2009

Page 30

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

PANDA EXPRESS

Panda Express shows the impact a DCV system can have on the quick-service

restaurant market segment. Table 7 shows the EF and MUA unit results. The amount

of exhaust fans, appliance usage, type of appliances, hours of operation, and horse

power affected the DCV system performance and its corresponding savings greatly.

The baseline energy consumption is 24,620 kWh a year. After the DCV system was

installed the energy consumption dropped by 61% to 9,559 kWh a year. The savings

are 15,061 kWh a year. EF 1 and 2, and MUA service the three heavy-duty rated

woks that cook the different menu items. The woks heat load occurs only when

cooking. When cooking does occur, exhaust demand is high. The opportunity for

modulation is very high in both of the kitchen exhaust hoods since cooking does not

occur at all times. Most of the menu items were cooked on EF 1, resulting in 50%

savings of the exhaust fans energy consumption. EF 2/ MUA savings are a little

higher at 66% of the exhaust and MUA fans energy consumption. The combination of

EF 2 cookline being the secondary wok used for cooking and a single MUA unit

resulted in a little higher percentage of savings.

TABLE 7 PANDA EXPRESS RESULTS

Panda Express EF 1

Average demand without DCV system (kW)

Average demand with DCV system (kW)

Average kW reduction (%)

Daily Operational Hours

Daily energy usage without DCV system (kWh/day)

Daily energy usage with DCV system (kWh/day)

Annual energy usage without DCV system (kWh/yr)

Annual energy usage with DCV system (kWh/yr)

Annual energy savings with DCV system (kWh/yr)

Percent energy usage reduction (kWh/yr)

EF

2/MUA

Combined

Data

1.5 3.6 5.1

0.8 1.2 2.0

50.2% 65.8% 61.2%

13.10 13.10 13.10

20 47 67

10 16 26

7,353 17,267 24,620

3,660 5,898 9,559

3,693 11,368 15,061

50.2% 65.8% 61.2%

Estimated annual operational savings (@$0.15 a kWh)

$554 $1,705 $2,259

Figure 10 gives an example of typical demand usage for EF 1. Under the hood are 3

woks. The black solid line represents the baseline case. The baseline consistently

draws around 1.6 kW. The consistent demand draw is due to the fans simple “on” or

“off” control strategy. The minor variations of the baseline are due to the loading and

unloading of the exhaust fan as effluent is exhausted. The dashed red line represents

the new system case (with DCV installed). The new system demand usage has

Southern California Edison Page 23

Design & Engineering Services June 2009

Page 31

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

jagged modulations with a range of 0.6 to 1.4 kW daily at the Panda Express. The

jagged modulation is due to the woks. The wok is a heavy-duty appliance that

creates heavy heat. This type of appliance also does not produce a constant heat.

Instead woks are only turned on when needed to refill the different entrees in the

steam tables. So, as the food is cooked there is a quick demand for exhaust. When

not needed, the appliance is turned off and the exhaust demand drops immediately.

The different peaks are dependent on how many woks are used at a time. Towards

the end of the night, between 8:00 p.m. to 10:00 p.m., the need to cook drops

significantly and spot cooking occurs, as needed. The lowered cook demand drops

the exhaust even more. The typical demand profile occurs about the same time

everyday, but to account for the variations of fan modulation, an average was taken

from the 6 weeks of data. The average demand draw for EF 1, with the DCV system,

is 0.78 kW, which is represented by the dashed green line. This line gives a visual

representation of energy usage drop from baseline for the new system case. The new

system case average was only when the exhaust hood was actually turned on.

Typical demand usage graphs for EF 2/MUA can be found in Appendix A, Figure 35.

The EF2/MUA fans demand usage almost mirrored the EF 1 demand usage since the

main appliances under the hood were woks and the MUA met both of the hoods MUA

requirements.

FIGURE 9 TYPICAL DEMAND USAGE FOR EF 1 AT PANDA EXPRESS

Southern California Edison Page 24

Design & Engineering Services June 2009

Page 32

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

FARMER BOYS

Farmer Boys also shows the impact a DCV system can have on the quick-service

restaurant market segment. Table 8 shows all the EF unit results for Farmer Boys.

The amount of exhaust fans, appliance usage, type of appliances, hours of operation,

and horse power greatly affected the DCV system and its corresponding savings .

The baseline energy consumption was 16,159 kWh a year. After the DCV system was

installed, the energy consumption dropped by 48.8% to 7,884 kWh a year. The

savings are 8,276 kWh a year. EF 1 serviced four fryers rated as medium-duty

appliances. The fryers produced a constant heat load throughout the day. As food

was fried, effluent was exhausted. EF 1 modulated dependent on the fryers use

throughout the day. The varying exhaust demand as fries are cooked, resulted in a

55.4% savings of exhaust fan energy consumption. EF 2 had an 82% savings, which

was the largest savings due to its limited use. The cookline serviced by EF 2 is only

used for very high kitchen demands. When the EF 3 cookline is unable to meet the

kitchens cooking demands, the EF 2 cookline is used. EF 3 is th e main cookline. The

cookline has a heavy-duty rated charbroiler and a medium-duty rated griddle

appliance under the hood. Both create constant heat during hours of operation.

When business is slower the charbroilers are at the lowest setting. Modulation occurs

during the slower times of the day. The main cookline is in operation consistently,

which resulted in only a 20.7% savings for the exhaust hood.

TABLE 8 FARMER BOYS RESULTS

Farmer Boys EF 1 EF 2 EF 3

Average demand without

DCV system (kW)

Average demand with DCV

system (kW)

Average kW reduction (%)

Daily Operational Hours

Daily energy usage without

DCV system (kWh/day)

Daily energy usage with

DCV system (kWh/day)

Annual energy usage

without DCV system

(kWh/yr)

Annual energy usage with

DCV system (kWh/yr)

Annual energy savings with

DCV system (kWh/yr)

Percent energy usage

reduction (kWh/yr)

Estimated annual

operational savings

(@$0.15 a kWh)

Combined

Data

1.0 0.7 1.1 2.8

0.4 0.1 0.9 1.4

55.4% 82.0% 20.7% 48.8%

15.8 15.8 15.8 15.8

16 12 17 44

7 2 14 23

5,658 4,205 6,296 16,159

2,525 756 4,994 8,276

3,133 3,449 1,302 7,884

55.4% 82.0% 20.7% 48.8%

$469 $517 $195 $1,183

Southern California Edison Page 25

Design & Engineering Services June 2009

Page 33

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

Figure 10 gives an example of a typical demand profile for EF 3. The black solid line

represents the baseline case and consistently draws around 1.1 kW. The consistent

draw is due to the fans simple “on” or “off” control strategy. The minor variation of

the baseline is due to the loading and unloading of the exhaust fan as effluent is

exhausted. The dashed red line represents the new system case (with DCV

installed). The new system demand does not modulate too much. The main demand

savings are attributed to the charbroiler’s very low setting early in the morning and

later at night when business is slow. The griddle keeps a constant temperature

throughout the day when its settings are on high. The main line cooks constantly so

the opportunity for savings is not as high. The typical demand profile, displayed

below, occurs about the same time everyday for EF 3, but to account for the

variations of fan modulation, an average was taken from the 6 weeks of data. The

average demand draw for EF 3 with the DCV system is 0.85 kW, which is

represented by the dashed green line. This green line gives a visual representation of

energy usage drops from baseline for the new system case. The new system case

average is only when the exhaust hood is actually on. Typical demand usage graphs

for EF 1 and 2 can be found in Appendix E – Farmer Boys, Figure 39 to Figure 40.

The EF 1 fan’s demand usage modulates about the same as fries are cooked

throughout the day. EF 2 is at the lowest setting due to limited use.

FIGURE 10 TYPICAL DEMAND USAGE FRO EF 1 AT FARMER BOYS

Southern California Edison Page 26

Design & Engineering Services June 2009

Page 34

Demand Control Ventilation for Commercial Kitchen Hoods ET 07.10

CONCLUSIONS

The Melink Intelli-Hood DCV system was shown to significantly reduce the energy

consumption and electrical demand associated with operating a commercial kitchen exhaust

hood. The savings results can realize a 37-62% energy savings over current commercial

kitchen hoods energy usage. The DCV system was most effective in the hotel market sector

due to the amount of hoods, amount of HP servicing the hotel, and the hours of operations.

In hotels - kitchens are sized for peak food preparation which is defined as the maximum

food preparation at any given time in a hotels’ kitchen. The hotel kitchen sizing also means

there are multiple hoods and higher amounts of HP needed to meet the kitchen’s maximum

food preparation. Since “maximum” food preparation rarely happens, the hotel market

sector has a high potential for savings. Most of the time there is limited kitchen use

occurring in a given day, allowing a DCV system to save energy by running at minimal

exhaust settings. In the quick-service restaurant market sector there was a large

percentage energy drop at each site, but a significantly lower energy savings. The lower

energy savings were attributed to the lower hp motors, operational time, appliance usage,

and the amount of hoods in the quick-service restaurant sector. In addition to energy

savings, with the installation of a DCV system, there was the added benefit of noise

reduction from the kitchens’ exhaust hood system.

This evaluation also demonstrated that the performance of the DCV system was highly

impacted by the different appliance types and their controls. Appliance types ranged from

light duty to extra heavy duty. The opportunity for energy savings decreased as the

appliances duty rating got closer to extra heavy duty rated appliances. The higher the rated

duty, the higher heat load and more effluent the appliance created during cooking. The

opportunity for savings also decreased when the appliances controls created a constant heat

load when either in use or not in use. Appliances that only produce heat when cooking gave

a large opportunity for savings.

RECOMMENDATIONS

In this field evaluation HVAC energy savings were not accounted for. The lowered

kitchen air exhaust can impact HVAC load requirements as less conditioned air is

exhausted in the kitchen space. A study should be initiat ed to evaluate the DCV

systems’ impact on HVAC systems. Since HVAC systems are weather-dependent, it is

further recommended that simulation studies should be performed to evaluate DCV

system impacts on HVAC systems.

Southern California Edison Page 27

Design & Engineering Services June 2009

Page 35

Demand Control Ventilation for Commercial Kitchen Hoods

APPENDIX A – DESERT SPRINGS MARRIOTT

KITCHEN HOOD DESCRIPTION

Hood 1 of system A is a 13-ft 6-in wall-mounted canopy hood. The exhaust fan

motor is labeled as EF 159 and has a rated horse power of 2 hp. The MUA fan motor

is labeled MUA 6 and has a rated horse power of 1 hp. The appliances under the

hood from left to right as shown in include a deck oven, and a 4-burner

range with oven. This cookline is known as the bakery and provides the majority of

deserts and pastries.

Figure 11

FIGURE 11 DESERT SPRINGS MARRIOTT HOOD 1 SYSTEM A

Hood 2 of system A is a 12-ft wall-mounted canopy hood. The exhaust fan motor is

labeled as EF 163 and has a rated horse power of 2 hp. The MUA fan motor is labeled

MUA 10 and has a rated horse power of 1.5 hp. The appliances under the hood from

left to right as shown in Figure 12 include two 6-burner ranges with ovens. This

cookline is known as the cold prep line and is used for batch cooking and when extra