查询MLX90217供应商

MLX90217

Hall-Effect Cam Sensor

Features and Benefits

■

Rotary Position Gear Tooth Sensor

■

Short Circuit Protection

■

On-chip 10 bit A/D Converter

■

Self-Adjusting Magnetic Range

■

High Speed Operation

■

No Chopper Delay

■

Zero Speed Detection

■

No Rotary Orientation Concerns

Applications

■

Camshaft Sensor

■

Geartooth Sensor

■

Linear Encoder

■

Rotary Encoder

■

Direction Detection*

*See applications example

Ordering Information

Part No. Temperature Suffix Package Code

MLX90217 L (-40

o

C to 150oC) UA (TO-92 flat)

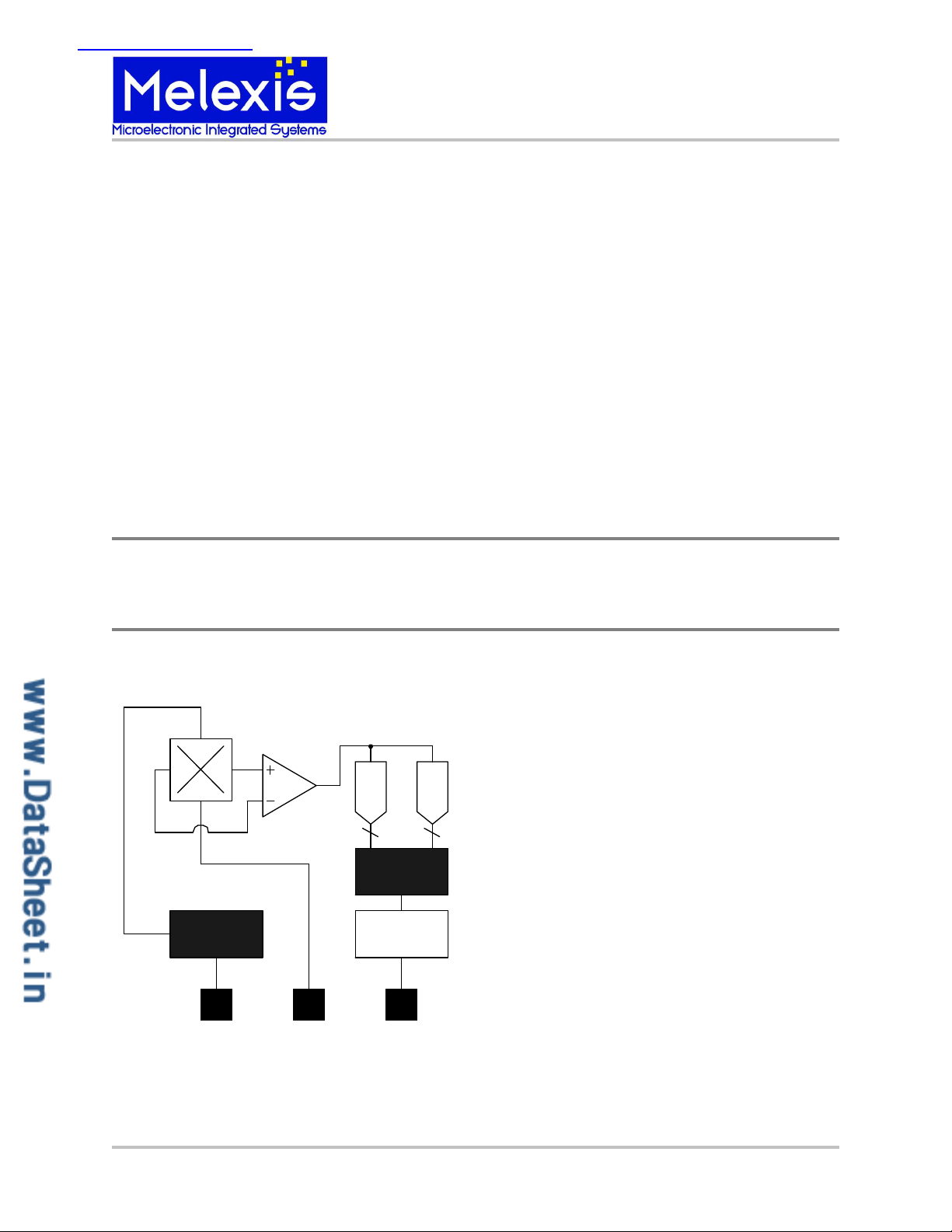

Functional Diagram

Hall

Plate

Amplifier

Voltage

Regulator

1 2 3

Pin 1 - VDD (Supply)

Pin 2 - VSS (Ground)

Pin 3 - Output

Note:

precautions.

Static sensitive device, please observe ESD

ADC

4-Bit

Logic

Protected

Output

ADC

Description

The MLX90217 is a self adjusting digital output

rotary position gear tooth sensor designed for use

in automotive camshaft sensing as well as other

speed sensing applications. It is designed to be

10-Bit

used with a bias magnet south facing the back

(non-marked) side of the IC. The device has an

open collector output which is short circuit

protected.

The MLX90217 is a sophisticated IC featuring an

on-chip 10-bit A/D Converter and logic that acts

as a digital sample and hold circuit. A separate 4bit A/D converter provides a fixed hysteresis. The

90217 does not have a chopper delay. The 90217

uses a single Hall plate which is immune to rotary

alignment problems. The bias magnet can be

from 50 to 400mT.

As the signal is sampled, the logic recognizes an

increasing or decreasing flux density. The output

will turn on (BOP) after the flux has reached its

peak and decreased by an amount equal to the

hysteresis. Similarly the output will turn off (BOP)

after the flux has reached its minimum value and

increased by an amount equal to the hysteresis.

3901090217 Page 1 Jun/04

Rev. 009

MLX90217

Hall-Effect Cam Sensor

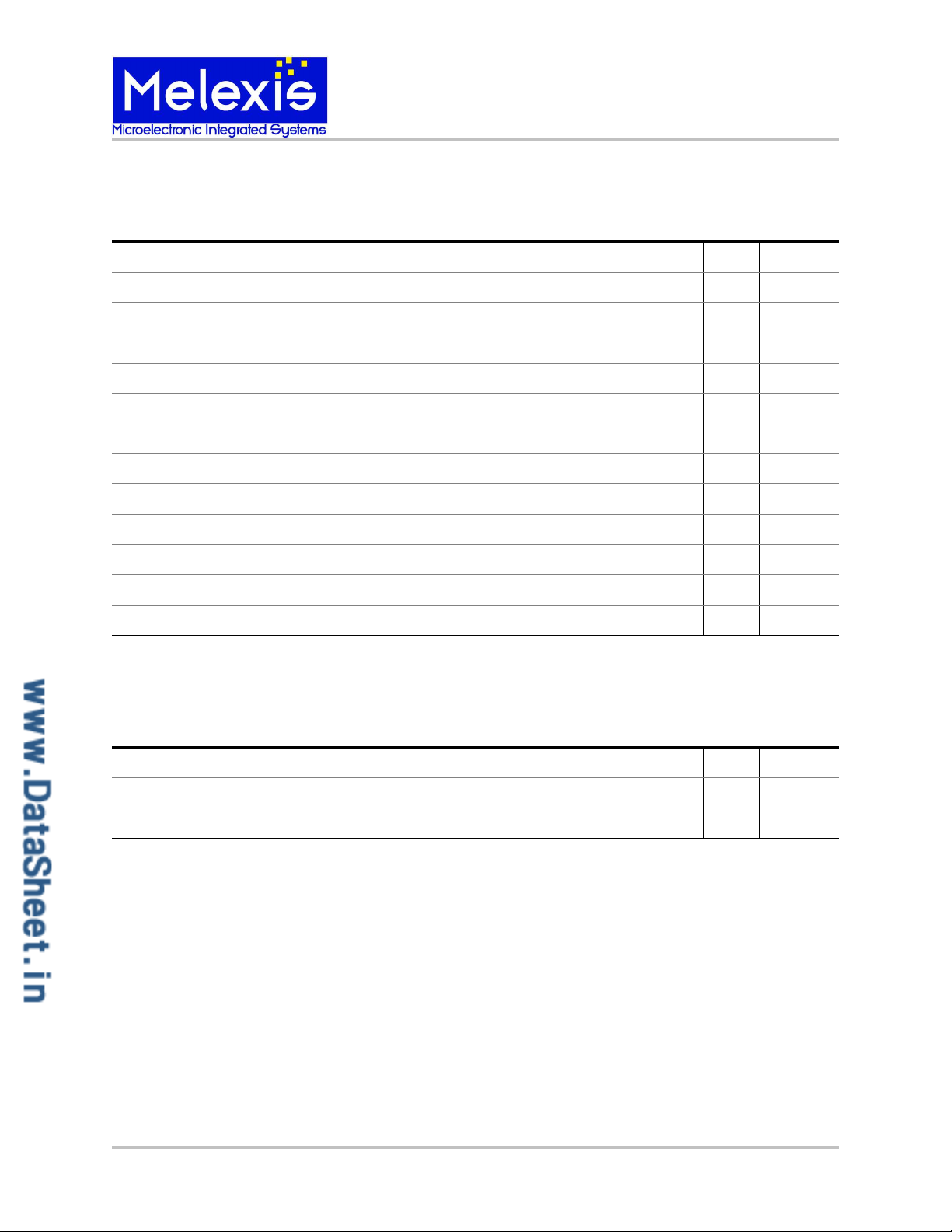

MLX90217 Electrical Specifications

DC Operating Parameters TA = -40oC to 150oC, VDD = 3.5V to 24V (unless otherwise specified).

Parameter

Supply Voltage VDD Operating 3.5

Supply Current IDD VDD = 12V 1.5

Supply Current IDD VDD = 3.5V to 24V 1

Leakage Current I

Output Current I

Output Saturation Voltage V

Output Short Circuit Current I

Output Short Circuit Shutdown T

Clock Frequency f

Output Rise Time tr VDD=12V R1 = 880W C1 = 20pf

Symbol Test Conditions

V

LEAK

Operating -

OUT

VDD = 12V, I

SAT

Fault 50 100 150 mA

FAULT

Fault 100

FAULT

Operating 300 500 800 kHz

CLK

= 3.5V to 24V -

OUT

OUT

= 25mA -

Min Typ Max

-

3.0

-

-

-

-

-

-

24 V

4.5 mA

6 mA

10

25 mA

600 mV

200

400 nS

Units

A

µ

µ

S

Output Fall Time tf VDD=12V R1 = 880W C1 = 20pf

Bandwidth BW Operating -

Thermal Resistance RTH Operating -

-

-

-

400 nS

15 kHz

200

MLX90217 Magnetic Specifications

DC Operating Parameters TA = -40oC to 150oC, VDD = 3.5V to 24V (Unless otherwise specified)

Parameter

Back Bias Range B

Linear Region VDD = 12V 50

Hysteresis B

Notes:

1 mT = 10 Gauss

Symbol Test Conditions

Operating -30

BIAS

VDD = 3.5V to 24V 1.8 3.5 10 mT

hys

Min Typ Max

-

-

400 mT

500 mT

o

C/Watt

Units

3901090217 Page 2 Jun/04

Rev. 009

j

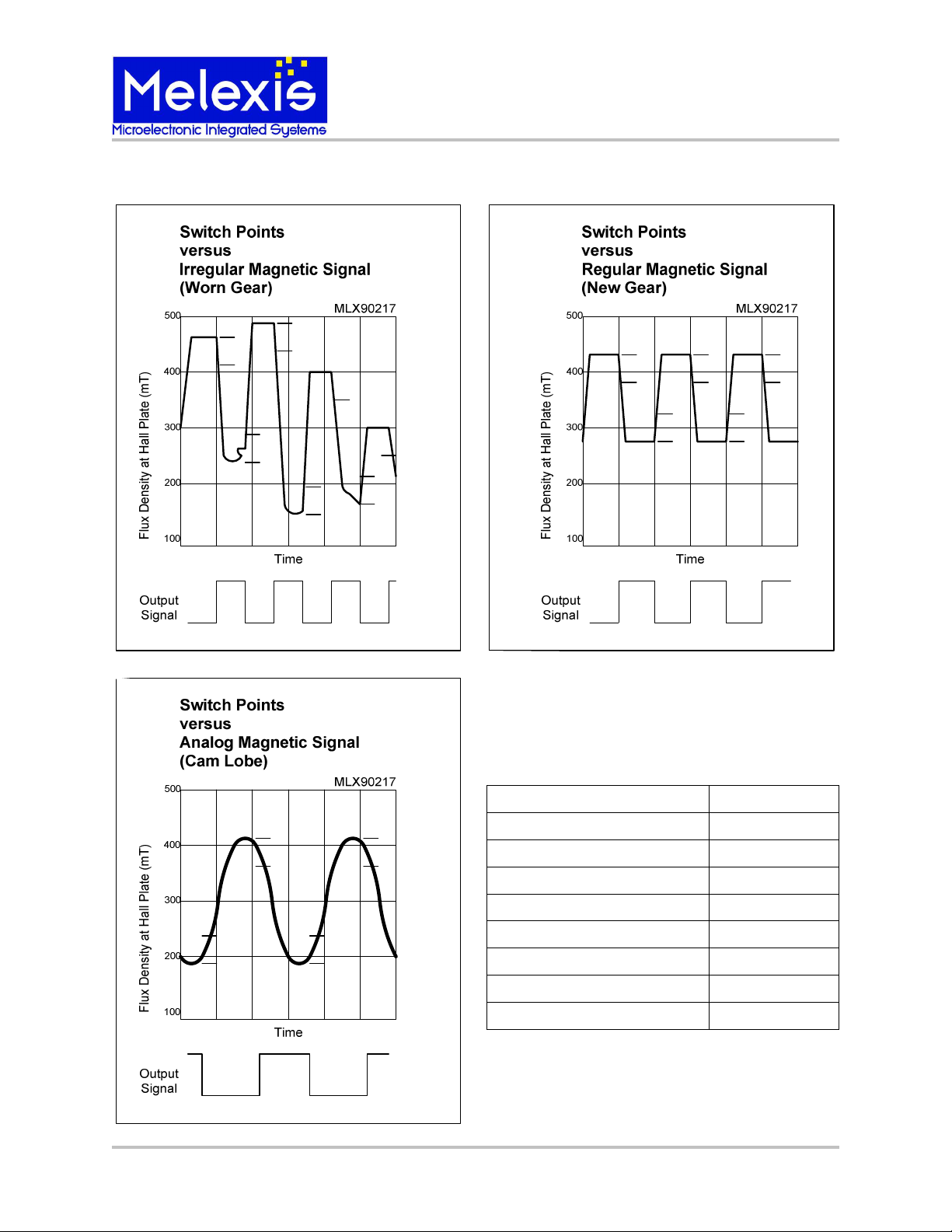

Performance Graphs

MLX90217

Hall-Effect Cam Sensor

Absolute Maximum Ratings

Supply Voltage (Operating), VDD 30V

Supply Current (Fault), IDD 50mA

Output Current (Fault), I

Output Current (Fault), I

Output Voltage, V

Power Dissipation, PD 100mW

Operating Temperature Range, TA - 40°C to 150°C

Storage Temperature Range, TS - 65°C to 150°C

Maximun Junction Temp, TJ 175°C

3901090217 Page 3 Jun/04

Rev. 009

OUT

30mA

OUT

50mA

fault

30V

Application Notes

Maximum dynamic range is 500 mT. The

hysteresis is fixed at 5.0 mT. Best angular

accuracy will be obtained when the magnetic

circuit provides peak magnetic flux at the chip

near the high end of the linear range of 500 mT.

EMC protection using external components are

recommended. Two possibilities are shown on

the following page. Normally the South pole faces

the unbranded side of the device. A North pole

will enable a test sequence used in factory

testing.

Unique Features

The output is reset to the high state at power on

(output driver is off) whatever the field is. The

output only changes after the first min is detected.

The reset state holds no information about the

field. If the supply of the chip is raised slowly, the

reset state is not stable. This has been observed

at 0 field but it should be the same with small and

large fields.

Gear tooth sensors often need to be adjusted

after the module is assembled to align the

magnet with differential Hall plates or orient with

teeth. However the MLX90217 is “self adjusting”

over a wide range of back bias flux eliminating

the need for any trimming in the application. The

magnet may be glued to the back surface (non

branded side) of the IC using a cyanoacrylate

adhesive or suitable epoxy.

MLX90217

Hall-Effect Cam Sensor

3901090217 Page 4 Jun/04

Rev. 009

j

Applications Examples

MLX90217

Hall-Effect Cam Sensor

3901090217 Page 5 Jun/04

Rev. 009

Physical Characteristics

MLX90217

Hall-Effect Cam Sensor

3901090217 Page 6 Jun/04

Rev. 009

j

MLX90217

Hall-Effect Cam Sensor

Reliability Information

This Melexis device is classified and qualified regarding soldering technology, solderability and

moisture sensitivity level, as defined in this specification, according to following test methods:

■ IPC/JEDEC J-STD-020

Moisture/Reflow Sensitivity Classification For Nonhermetic Solid State Surface Mount De-

vices

(classification reflow profiles according to table 5-2)

■ EIA/JEDEC JESD22-A113

Preconditioning of Nonhermetic Surface Mount Devices Prior to Reliability Testing

(reflow profiles according to table 2)

■ CECC00802

Standard Method For The Specification of Surface Mounting Components (SMDs) of

Assessed Quality

■ EIA/JEDEC JESD22-B106

Resistance to soldering temperature for through-hole mounted devices

■ EN60749-15

Resistance to soldering temperature for through-hole mounted devices

■ MIL 883 Method 2003 / EIA/JEDEC JESD22-B102

Solderability

For all soldering technologies deviating from above mentioned standard conditions

(regarding peak temperature, temperature gradient, temperature profile etc) additional classification and qualification tests have to be agreed upon with Melexis.

The application of Wave Soldering for SMD’s is allowed only after consulting Melexis regarding assurance of adhesive strength between device and board.

Based on Melexis commitment to environmental responsibility, European legislation

(Directive on the Restriction of the Use of Certain Hazardous substances, RoHS) and customer

requests, Melexis has installed a Roadmap to qualify their package families for lead free processes also.

Various lead free generic qualifications are running, current results on request.

For more information on manufacturability/solderability see quality page at our website:

http://www.melexis.com/html/pdf/MLXleadfree-statement.pdf

ESD Procautions

Electronic semiconductor products are sensitive to Electro Static Discharge (ESD).

Always observe Electro Static Discharge control procedures whenever handling semiconductor

products.

3901090217 Page 7 Jun/04

Rev. 009

MLX90217

Hall-Effect Cam Sensor

Disclaimer

Devices sold by Melexis are covered by the warranty and patent indemnification provisions appearing in its Term of Sale. Melexis makes no warranty, express, statutory, implied, or by description regarding the information set forth herein or regarding the freedom of the described devices from patent infringement. Melexis reserves the right to change specifications and prices at any time and without notice. Therefore, prior to designing this product into a system, it is necessary to check with

Melexis for current information. This product is intended for use in normal commercial applications.

Applications requiring extended temperature range, unusual environmental requirements, or high

reliability applications, such as military, medical life-support or life-sustaining equipment are specifically not recommended without additional processing by Melexis for each application.

The information furnished by Melexis is believed to be correct and accurate. However, Melexis shall

not be liable to recipient or any third party for any damages, including but not limited to personal injury, property damage, loss of profits, loss of use, interrupt of business or indirect, special incidental

or consequential damages, of any kind, in connection with or arising out of the furnishing, performance or use of the technical data herein. No obligation or liability to recipient or any third party shall

arise or flow out of Melexis’ rendering of technical or other services.

© 2002 Melexis NV. All rights reserved.

For the latest version of this document, go to our website at:

www.melexis.com

Or for additional information contact Melexis Direct:

Europe and Japan: All other locations:

Phone: +32 13 67 04 95 Phone: +1 603 223 2362

E-mail: sales_europe@melexis.com E-mail: sales_usa@melexis.com

3901090217 Page 8 Jun/04

Rev. 009

ISO/TS16949 and ISO14001 Certified

j

Loading...

Loading...