5-phase Stepping Motor Driver

GD-5610

Instructions Manual

(For designers' use)

MN03 2 5-1

Please ensure to read and understand this

Instructions Manual before using the product.

Please keep this Instructions Manual at hand

so that it is always available for reference.

GD-5610

Instructions Manual

Introduction

This Instructions Manual describes the safe and proper method of handling

"5-phase Stepping Motor Driver GD-5610" with emphasis on the specifications,

assuming that our readers are engaged in designing of control devices

incorporating stepping motors.

Please ensure to read and understand this Instructions Manual

before using the product.

Please keep this Instructions Manual at hand

so that it is always available for reference.

-2-

GD-5610

Instructions Manual

Descriptions in this manual on safety matters:

This product must be operated and used properly.

Otherwise, or when it is operated and used erroneously, unforeseen accidents

may occur, causing physical injuries or property damages.

Majority of these accidents can be avoided if you are well informed of

hazardous circumstances in advance.

Consequently, this instructions manual describes all the hazardous and

dangerous circumstances and situations which can be foreseen and anticipated

as well as necessary precautions.

All the above descriptions are being titled by the following symbol-marks and

signal-words, namely:

Represents warnings ignorance of which can cause accidents

involving fatal or serious physical injuries, or death.

Represents cautions ignorance of which can cause accidents

involving minor physical injuries or property damages.

WARNING

CAUTION CAUTION

-3-

GD-5610

Instructions Manual

Introduction

Descriptions in this manual on safety matters:

CONTENTS PAGE

1. Safety

1-1. Safety Precautions 6

1-2. Safety Information for Handling 7

Overview

2-1. Characteristics 11

2-2. Product Configuration 11

2-3. Appearance 11

3. Name and Function of Each Section

3-1. Signal I/O Connector(J1) 12

3-2. AC Input/Motor Output Terminal Block(J2, J3) 13

3-3. POWER LED 13

3-4. O.H.A LED 13

3-5.

Operating Section

14

4. Setting

4-1. Setting STEP ANGLE SELECT switch 15

4-2. Setting HOLD CURRENT SELECT switch 16

4-3. Setting DRIVE CURRENT SELECT switch 17

4-4.

Setting HOLD SWITCHING TIME SELECT switch

18

4-5. Setting ROTATE CHARACTERISTIC SELECT switch 18

4-6. Setting MOTOR SELECT switch 18

4-7. Setting PULSE INPUT TYPE SELECT switch 19

5.

Installation

5-1. Conditions for Installation 20

5-2. Mounting Method 21

6. Connection

6-1. Overview of Connection Configuration 22

6-2. Connecting Signal I/O Connector(J1) 23

6-3. Connecting AC Input/Motor Output Terminal Block(J2, J3) 24

6-4. Inputting Power 26

7. Confirmation of Setting and Connection

7-1. Check Points 27

2.

-4-

GD-5610

Instructions Manual

PAGE

8. Maintenance and Check-up

8-1. Maintenance and Check-up 28

8-2. Troubleshooting 29

9. Storing and Disposal

9-1. Storing 30

9-2. Disposal 30

Specifications

10-1. General Specifications 31

10-2. Conforming to Europe standards and UL standards 32

10-3. I/O Signal

(1) Example Circuit Connection 33

(2)

Drive pulse input

(CW,CCW) 34

(3) Motor excitation stop input (M.F) 35

(4) Phase signal output (P.O) 36

(5) Overheat alarm signal output and overheat alarm LED (O.H.A) 37

(6) Step angle switch input (C.S) 38

10-4. Dimensions 39

10-5.

Applicable Motors

40

10-6. Torque Characteristics 41

The main parts which revised by this manual

-5-

GD-5610

Instructions Manual

1.Safety

1-1.Safety Precautions

(1)

This product is not designed or manufactured for application for equipment

requiring high level of reliability such as equipment related to nuclear

energy, aeronautics-related equipment, automobiles, ships, medical appliances

directly handling the human body and equipment that might seriously affect

properties.

(2) Do not use or keep the product in explosive or corrosive environments,

in the presence of flammable gases, locations subjected to splashing water,

fine particles, soot, steam, or exposed to radiation or direct sunshine.

Doing so may cause electric shock, injury or fire.

(3)

This product is designed for use within machinery, so it should be installed

within an enclosure.

Be sure to ground the protective earth terminal of the driver.

(4) Do not transport, move, install the product, perform connections or inspections

when the power is on.

Doing so may cause electric shock, injury or fire.

(5) Only qualified personnel are allowed to transport, move, install the product,

perform connections or inspections.

Failure to do so may cause electric shock, injury or fire.

(6) Do not touch the driver during operation or immediately after stopping.

Doing so may cause burn on the skin due to overheating of the driver.

(7) Ensure to use this product according to the method specified

in the Instructions Manual and within the specifications.

(8) Depending on the operational conditions, the stepping motor may step out when

it is on holding-state or driving-state.

In particular, the load in transport may fall if the motor steps out on the

vertical drive (such as the Z-axis).

Start operation after test run for deliberate confirmation of operation.

(9)

Provide fail-safe measures so that the entire system may operate in a safe

mode even in cases of the external power supply failure, disconnection of the

signal line, or any failure on the driver.

WARNING

CAUTION

-6-

GD-5610

Instructions Manual

1-2.Safety Information for Handling

●Overall:

Do not touch the driver during operation.

Failure to do so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Use only an insulated screwdriver to

adjust or set internal switches.

Failure to do so may cause electric shock.

Do not touch the driver during operation

or immediately after stopping.

Doing so may cause burn on the skin due to

overheating of the driver.

●When connecting the AC Input/Motor Output Terminal Block (J2, J3):

Turn the main power OFF.

Failure to do so may cause electric shock.

Securely ground the protective earth

Failure to do so may cause electric shock.

Do not force the power line or the motor

line to be bent or pulled or pinched.

Doing so may cause electric shock or fire.

WARNING

WARNING

WARNING

CAUTION

WARNING

WARNING

WARNING

-7-

GD-5610

Instructions Manual

Erroneous connection may result

in breakage of the motor or the driver.

Correctly connect the motor wiring.

●When setting up the MOTOR SELECT switch:

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

●When setting up the STEP ANGLE SELECT switch:

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of the motor.

Ensure correct setting.

●When setting up the HOLD CURRENT SELECT switch:

A high setting value may cause burn on the

skin due to overheating of the motor.

Do not select a high value beyond the

required.

●When setting up the DRIVE CURRENT SELECT switch:

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

●When setting up the PULSE INPUT TYPE SELECT switch:

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of the moter.

Ensure correct setting.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

-8-

GD-5610

Instructions Manual

●When inputting the motor excitation stop (M.F) signal:

Deterioration of the holding power with

the motor may cause breakage of machine

or injury.

Check safety before inputting.

●When installing:

Overheating may cause fire.

Mount it on a noncombustible member.

Keep it away from combustibles.

●When inputting power:

Do not contact with a wet hand.

Doing so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Unexpected behavior of the motor may cause

breakage of the machine or injury.

Maintain the state where emergency stop is

enabled at any time.

●When the overheat alarm (O.H.A) signal is output:

Overheating may cause fire.

Stop operation upon output of this signal.

WARNING

WARNING

WARNING

CAUTION

WARNING

CAUTION

-9-

GD-5610

Instructions Manual

●When the overheat alarm (O.H.A) LED comes on

Overheating may cause fire.

Stop operation when this LED comes on.

●When performing maintenance and checking:

Only qualified personnel are allowed to

perform maintenance and checking.

Failure to do so may cause electric shock.

Do not contact with a wet hand.

Doing so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Do not replace fuse.

Do not disassemble, repair or modify.

Doing so may cause electric shock, injury

or fire.

WARNING

WARNING

WARNING

WARNING

WARNING

-10-

GD-5610

Instructions Manual

2.Overview

2-1.Characteristics

GD-5610 is a driver for a 5-phase stepping motor with single-phase 100-115V input.

Ten step angles can be selected from angles ranging from a 1/1 division to

a 1/800 division of the basic angle.

HOLD CURRENT and DRIVE CURRENT can be set up.

●

Applicable motors and setting for each motor are given in the table

"10-5. Applicable Motors".

2-2.Product Configuration

The product consists of the main frame and the accessories.

●

GD-5610 One unit

(Complete with terminal block covers)

●

Housing for J1 (51103-1200:Molex) One unit (accessory)

●

Contact for J1 (50351-8100:Molex) 14 contacts (accessories,2 for spares)

2-3.Appearance

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

MOTOR

!

GD-5610

J1

1

12

POWER

OHA

OP2

ON←

OP4

OP5

OP3

OP1

SPI

DRIVE

HOLD

STEP

J3

J2

3

4

5

2

1

1

23L

N

115V~

100V

DHT

RC

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

Model Name

Mounting Section

Model Name

Signal I/O Connector

O.H.A LED(RED)

POWER LED(GREEN)

Operating Section

AC Input

Terminal Block

Motor Output

Terminal Block

2

1

J3

5

4

3

RED/GRY

VIO/BLU

BLK/YLW

WHT/ORN

GRN/BRN

GRN

BLK

BLU

RED

ORN

Protective earth

Terminal Block

Mounting Section

GD-5610

100-115V~

5.9A

1φ50/60Hz

Melec Inc.

MADE IN JAPAN

R

-11-

GD-5610

Instructions Manual

3.Name and Function of Each Section

3-1.Signal I/O Connector(J1)

GD-5610

CW+

J1

●Directs the motor to operate CW.

●Shuts off output current to drive the motor.

●Outputs the signal when internal temperature

of the driver has reached approx. 65℃ or more.

1

Motor excitation stop signal input terminal

Step angle switch signal input terminal

Phase signal output terminal

Overheat alarm signal output terminal

CW drive pulse signal input terminal

●Switches the step angle by 1/20 division.

●Outputs the signal when the motor-excitation

state is the excitation home position.

CW-

CCW+

CCW-

M.F+

M.F-

C.S+

C.S-

2

3

4

5

6

7

8

9

10

11

12

P.O+

O.H.A+

CCW drive pulse signal input terminal

●Directs the motor to operate CCW.

P.O-

O.H.A-

-12-

GD-5610

Instructions Manual

3-2.AC Input/Motor Output Terminal Block(J2,J3)

Do not touch the driver during operation.

Failure to do so may cause electric shock.

GD-5610

3-3.POWER LED

POWER LED (GREEN) comes on upon inputting power.

3-4.O.H.A LED

O.H.A LED(RED)comes on when internal temperature

of the driver has reached approx. 65℃ or more.

Motor output terminal

J2

4

J3

3

2

1

5

GRN

BRN

WHT

ORN

BLK

YLW

RED

GRY

VIO

BLU

3

2

1

100115V~

●Outputs current to drive the motor.

AC input terminal

●Power input terminal.

The power supply is connected.

Protective earth terminal

●Protects against electric shock as connected

to the protective earth terminal of the equipment.

N

L

MOTOR

BLU

RED

ORN

GRN

BLK

WARNING

-13-

GD-5610

Instructions Manual

3-5.Operation Section

Do not touch the driver during operation.

Failure to do so may cause electric shock.

GD-5610

STEP ANGLE

SELECT switch

Selects a step angle.

No.1

Selects HOLD CURRENT.

No.6

No.D

HOLD CURRENT

SELECT switch

DRIVE CURRENT

SELECT switch

Selects DRIVE CURRENT.

OFF

ROTATE CHARACTERISTIC

SELECT switch

Selects a characteristic of motor rotation.

OFF

HOLD SWITCHING TIME

SELECT switch

DRIVE/HOLD CURRENT automatic switching time

is selected.

Factory Setting

PULSE INPUT TYPE CELECT

switch

Selects a pulse input type.

OFF

OP4

OP5

Name of Operation Section

Function

OFF

OFF

OFF

MOTOR SELECT

switch

Extend functions

switch

Please use it with OFF.

Selects the applicable motor.

OP1

OP2

OP3

DRIVE CURRENT SELECT switch (DRIVE I.SEL)

DRIVE

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

HOLD

STEP

HOLD CURRENT SELECT switch (HOLD I.SEL)

STEP ANGLE SELECT switch (STEP SEL)

POWER

OHA

POWER LED(GREEN)

OHA LED(RED)

ON

HOLD SWITCHING TIME SELECT switch (DHT SEL)

ROTATE CHARACTERISTIC SELECT switch (RC SEL)

Extend functions switch

OP4

OP3

OP2

OP1

OP5

SPI

DHT

RC

[1P - 2P]

[1s - 150ms]

[ON - OFF]

PULSE INPUT TYPE SELECT switch (SPI SEL)

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

MOTOR SELECT switch (OP1,OP2)

WARNING

-14-

GD-5610

Instructions Manual

4.Setting

4-1.Setting STEP ANGLE SELECT switch

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of motor.

Ensure correct setting.

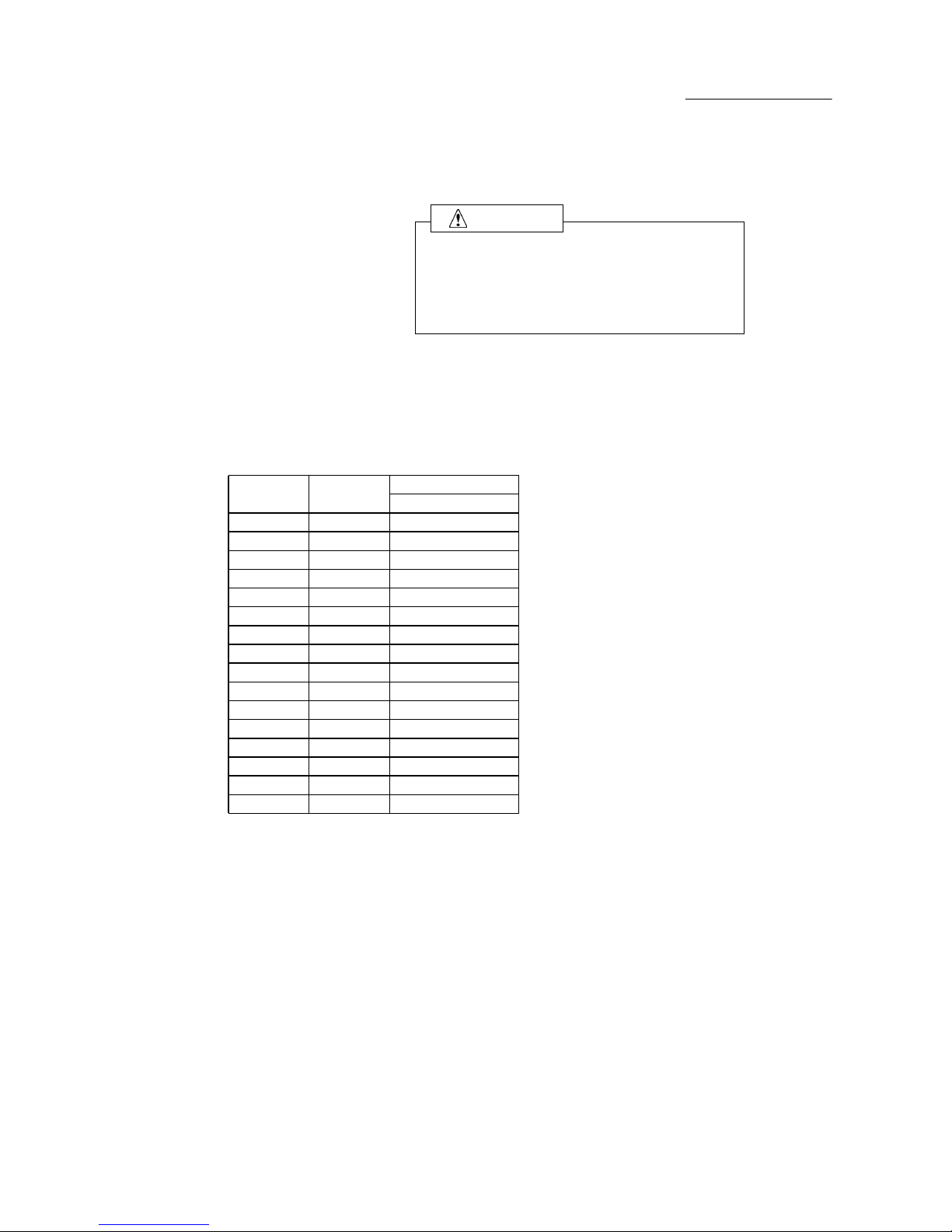

The step angle is set up with the STEP SEL switch.

(1) Set the STEP SEL switch No. to the step angle required.

●

Relationship between the STEP SEL switch No. and the step angle.

(Factory Setting)

●

Driving with two types of step angles are provided by combining

the STEP SEL switch setting and the C.S signal.

0.0018

0.0009

0.036

0.018

0.0072

0.0036

6

7

Switch No.

1234089

1/

Divisions

1/1

1/2

1/4

1/10

1/20

1/4051/800

Step angle(°)

0.72°motor

0.72

0.36

1/100

1/200

1/400

0.18

0.072

1/16

0.045

ABCD----1/8

0.09

1/80

0.009

1/160

0.0045

E

F

CAUTION

-15-

GD-5610

Instructions Manual

4-2.Setting HOLD CURRENT SELECT switch

A high setting value may cause burn on the

skin due to overheating of the motor.

Do not select a high value beyond the

required.

HOLD CURRENT is set up with the HOLD I.SEL switch.

This sets the ratio of HOLD CURRENT to DRIVE CURRENT.

(1) Set the HOLD I.SEL switch No. to the ratio of HOLD CURRENT to

DRIVE CURRENT required.

●

Ratio of HOLD CURRENT

HOLD CURRENT

DRIVE CURRENT

(Factory Setting)

●

HOLD CURRENT changes relative to DRIVE CURRENT setting.

The ratio of HOLD CURRENT set the switch No. to [No.F]:100% represents

the same as the setting for DRIVE CURRENT.

●

The greater the ratio of HOLD CURRENT grows, the more heat the motor

generates when is on holding-state.

9

5055303540

45

52301

8

×100

Switch No.

Ratio of HOLD CURRENT (%)

101520A60B65

Ratio of HOLD CURRENT(%)

=

25

674

E90F

100C70D80

CAUTION

-16-

GD-5610

Instructions Manual

4-3.Setting DRIVE CURRENT SELECT switch

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

DRIVE CURRENT is set up with the DRIVE I.SEL switch.

(1) Set the DRIVE I.SEL switch No. to the setting specified in the table

"10-5. Applicable Motors".

●

Relationship between the DRIVE I.SEL switch and DRIVE CURRENT.

(Factory Setting)

Switch No.

F

2.0

1.8

1.7

1.6

2.1

3.0

1.5

1.4

2.9

2.3

2.4

2.5

2.6

A/phase

2.2

2.7

2.845670123CDE89A

B

CAUTION

-17-

GD-5610

Instructions Manual

4-4.Setting HOLD SWITCHING TIME SELECT switch

DRIVE/HOLD CURRENT automatic switching time is set up

with the DHT SEL switch.

(1) Set the DHT SEL switch.

4-5.Setting ROTATE CHARACTERISTIC SELECT switch

ROTATE CHARACTERISTIC is set up with the RC SEL switch.

(1) Set the RC SEL switch to the specified in the talbe

"10-5. Applicable Motors."

4-6.Setting MOTOR SELECT switch

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

The OP1 and OP2 switches is turned to the setting

corresponding to the motor in use.

(1) Set the OP1 and OP2 switches to the specified in the talbe

"10-5. Applicable Motors."

(Factory Setting)

Hold Switching

Time

DHT SEL1s150ms

ON

OFF

CAUTION

-18-

GD-5610

Instructions Manual

4-7.Setting PULSE INPUT TYPE SELECT switch

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of motor.

Ensure correct setting.

2-pulse input method / 1-pulse input method are

set up by the SPI SEL switch.

(1) Set the SPI SEL switch.

●

When the motor is operated with two pulse signal inputs of CW and CCW,

set the SPI SEL switch to [OFF].

●

When the motor is operated with the pulse signal and direction signal

input, set the SPI SEL switch to [ON].

● In the case that 1-pulse input method is selected, the CCW terminal becomes

direction signal input designating the direction of the motor rotation.

Drive pulse set to the CW terminal(CW+,CW-).

● The input timing is same with 2-pulse input method and 1-pulse input method .

As for input timing, refer to "10-3. (2)Drive pulse input(CW, CCW)"

(Factory Setting)

SPI SEL

Input type

1PULSE (1P)

2PULSE (2P)

ON

OFF

CCW terminal(CCW+,CCW-)

direction set

Photo-coupler OFF: CCW direction

Photo-coupler ON : CW direction

CAUTION

-19-

GD-5610

Instructions Manual

5.Installation

5-1.Conditions for Installation

Mount it on a noncombustible member.

Keep it away from combustibles.

Overheating may cause fire.

(1) Designed for incorporating into equipment used indoors, this product requires

to be installed in the following environment:

●

Area that is free of explosive, corrosive or inflammable gas

●

Indoors (Area not exposed to direct sunshine)

●

Area that ambient temperature and humidity are controlled within the range

set out in the specifications

●

Area protected from dust, salt or iron particles

●

Area not subject to direct vibration or shock

●

Area not subject to splashing water, oil or chemicals

(2) Install the driver at least 10mm away from other equipment.

However, please be installed to a distance of at least 15mm from the

heating element.

●

Please contact us if you are not installed to a distance of at least 15mm

from the heating element.

(3) Considering heat release, control the ambient temperature around the driver

within the specified value.

●

Take measures against accumulation of heat such as allowing generous space

ようにする。

around the driver or installing a fan so that heat release is taken care of.

●

Install the driver securely in contact with metal or other substance with

adequate heat conductivity.

(4) In the case that an overheat alarm signal is output, perform the cooling measure of

the mounting plate is enlarged or compulsion air cooling etc.

Use the driver on the condition that an overheat alarm signal is not output.

(5)

Do not allow standing or placing anything heavy on the product.

WARNING

10mm or more

10mm or more

15mm or more

Driver

10mm or more

Driver

10mm or more

heating

element

-20-

GD-5610

Instructions Manual

5-2.Mounting Method

The following items are required:

●

M-4 screw (8mm or more in length):

4

●

M-4 spring washer:

4

●

M-4 flat washer:

4

(1) Temporarily fix the product at the round hole.

(2) Fix the product at the three cutouts.

(3) Fasten the screw in the round hole.

●

Mounting example

Fixing with a screw

Fixing with a screw Fixing with a screw

M-4 screw

M-4 spring washer

M-4 flat washer

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

MOTOR

!

GD-5610

J1

1

12

POWER

OHA

OP2

ON←

OP4

OP5

OP3

OP1

SPI

DRIVE

HOLD

STEP

J3

J2

3

4

5

2

1

1

23L

N

115V~

100V

DHT

RC

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

Fixing with a screw

2

1

J3

5

4

3

RED/GRY

VIO/BLU

BLK/YLW

WHT/ORN

GRN/BRN

GRN

BLK

BLU

RED

ORN

-21-

GD-5610

Instructions Manual

6.Connection

6-1.Overview of Connection Configuration

GD-5610

●

Connect only one motor to one driver.

●

Use twisted pair wire for the CW/CCW input signal line.

●

Provide shielding for the signal line where considerable noise is generated.

●

Use the wire material of the characteristic that is difficult to burn.

●

Provide ferrite core for the motor line if it generates significant noise.

〔Example configuration〕

The metallic enclosure and shielded wires and ferrite core work to shield noise.

CWP

J1

CW+

1

R.GND

User

controller

CCWP

+COM

+COM

R.GND

2

3

4

5

6

7

8

9

10

11

12

C.S

O.H.A

P.O

M.F

CCWP

CWP

CWCCW+

CCWM.F+

M.F-

C.S+

J3

P.O+

O.H.A+

C.S-

J2

1

2

3

5

3

4

1

2

Protective earth

terminal for the

equipment (PE)

(O.75mm2 or more)

Motor

Single-phase 100-115V

N

L

Twisted

pair wire

Single-phase 100-115V

P.O-

O.H.A-

User

controller

Driver

Metal Enclosure

Metal Enclosure

Grounding

Shield

Metal Enclosure

Motor

Ferrite core

Grounding Grounding

-22-

GD-5610

Instructions Manual

6-2.Connecting Signal I/O Connector(J1)

The following items are required:

●

Housing for J1 (51103-1200:Molex): One unit (accessory)

●

Contact for J1 (50351-8100:Molex): 12 contacts (accessories)

●

Manually operated crimping tool

for AWG28-22(57295-5000:Molex): One unit

(1) Crimp the contact to the cable used for wiring.

(2) Insert the contact into the housing.

Make sure that the housing No. and the connector No. on the main frame are

matched before inserting the contacts.

(3) Connect the housing to the connector on the main frame.

●

The contacts for J1 are 12 pieces.

●

When inserting, keep pushing J1 housing into the connector until it is locked.

Also, check if the contacts are not displaced from the housing.

●

In wiring, isolate the J1 signal lines from equipment that may be

さい。

a source of noise, the power line and the motor line.

(Surface on which the contacts are inserted)

Housing for J1

GD-5610

●

Use a signal cable of AWG26(0.15mm2) or more in diameter.

12 11 10 9 8 7 6 5 4 3 2 1

CWP

J1

CW+

R.GND

User

controller

CCWP

+COM

+COM

R.GND

C.S

O.H.A

P.O

M.F

CCWP

CWP

CWCCW+

CCWM.F+

M.F-

C.S+

P.O+

O.H.A+

Step angle

switch input

〈Wiring〉

〈Crimping〉

〈Connection〉〈Insertion〉

Contact Housing

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

C.S-

Overheat alarm

signal output

Phase signal output

Motor excitation

stop input

Drive pulse input

Drive pulse input

P.O-

O.H.A-

-23-

GD-5610

Instructions Manual

6-3.Connecting AC Input/Motor Output Terminal Block(J2,J3)

Turn the main power OFF.

Failure to do so may cause electric shock.

Securely ground the protective earth

Failure to do so may cause electric shock.

Do not force the power line or the motor

line to be bent or pulled or pinched.

Doing so may cause electric shock or fire.

Erroneous connection may result

in breakage of the motor or the driver.

Correctly connect the motor wiring.

The following items are required:

●

Crimping terminal

8

(TMEV1.25-3: Nichifu or the equivalent)

●

Manually operated crimping tool for AWG22-16 One unit

(NH-11: Nichifu or the equivalent)

(1) Turn power of the equipment [OFF].

(2) Crimp the crimping terminals to the cable used for wiring.

(3) Remove the covers of terminal block, then connect.

(4) Fix the terminal block covers after completing connection.

GD-5610

J2

〈Wiring〉〈Connection〉

〈Crimping〉

Crimping terminal

1

2

3

N

L

NEUTRAL

LIVE

Single-phase 100-115V

Protective earth terminal

for the equipment (PE)

100-

115V~

Protective earth

terminal

〔Protective earth terminal ・ AC input terminal〕

WARNING

WARNING

WARNING

CAUTION

-24-

GD-5610

Instructions Manual

●

the protective earth terminal of the equipment (PE).

●

Use a protective earth cable and power cable of AWG18(0.75mm2) or more

in diameter.

GD-5610

GD-5610

●

Color indications for the motor crimping terminals (1~5) represent colors

of the leads of the motor.

●

Use a motor cable of AWG20(0.5mm2) or more diameter.

●

When use a motor cable more than 5m, contact our office.

〔Motor output terminal〕

J3

MOTOR

〈Wiring〉〈Connection〉

〈Crimping〉

Crimping terminal

Motor

Green/Brown

Leads of the motor

1

2

3

4

5

GRN

BRN

WHT

ORN

BLK

YLW

RED

GRY

VIO

BLU

BLU

RED

ORN

GRN

BLK

White/Orange

Black/Yellow

Red/Gray

Violet/Blue

J3

MOTOR

Motor

Red

Orange

Green

Black

Blue

1

2

3

4

5

GRN

BRN

WHT

ORN

BLK

YLW

RED

GRY

VIO

BLU

BLU

RED

ORN

GRN

BLK

〈Wiring〉〈Connection〉

〈Crimping〉

Crimping terminal

Leads of the motor

-25-

GD-5610

Instructions Manual

6-4.Inputting Power

Do not contact with a wet hand.

Doing so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Unexpected behavior of the motor may cause

breakage of the machine or injury.

Maintain the state where emergency stop is

enabled at any time.

(1) Input power (single-phase 100-115V) into the cable connected to No.2

and No.3 terminals of J2.

WARNING

WARNING

CAUTION

-26-

GD-5610

Instructions Manual

7.Confirmation of Setting and Connection

7-1.Check Points

(1)

This product requires different switch setting and motor wiring depending on

the motor used.

Check if the switch setting and the motor wiring are correctly performed.

(2)

(3) Check if the terminal block covers are fixed on J2 and J3.

Setting of PULSE INPUT TYPE

SELECT switch

OFF/ON

Connection of J1

Remarks

Check

Check Points

Switch No.

Setting of STEP ANGLE

SELECT switch

Setting of HOLD SWITCHING TIME

SELECT switch

Setting of DRIVE CURRENT

SELECT switch

Connection of J3

AC input terminal (L,N)

Switch No.

Terminal block cover

Motor output terminal

Terminal block cover

OFF/ON

OFF/ON

Setting of MOTOR SELECT switch

Setting of Extend functions

switch

Setting of HOLD CURRENT

SELECT switch

Connection of J2

OFF/ON

Switch No.

Setting of ROTATE

CHARACTERISTIC SELECT switch

OFF/ON

-27-

GD-5610

Instructions Manual

8.Maintenance and Check-up

8-1.Maintenance and Check-up

Only qualified personnel are allowed to

perform maintenance and checking.

Failure to do so may cause electric shock.

Do not contact with a wet hand.

Doing so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Do not replace fuse.

Do not disassemble, repair or modify.

Doing so may cause electric shock, injury

or fire.

(1)

As for a maintenance inspection the engineer of the specialty shall do it.

(2) We recommend that the following check-ups should be performed periodically:

●

Checking for any loosened screws on the terminal block and

contacts on the connectors.

●

Checking for any flaw and crack on the cabling.

(3) In case of failure, return the driver to us and have it repaired.

WARNING

WARNING

WARNING

WARNING

-28-

GD-5610

Instructions Manual

8-2.Troubleshooting

1.

POWER LED does not ・Connection of power supply. ・Wiring error with power supply.

come on. ・Value of power voltage. ・Power voltage failure.

・Driver failure.

2.

The motor is not excited. ・Connection of the motor to ・Wiring error with the motor

(It can be easily

the driver. and the driver.

rotated by hand.)

・ON/OFF status of the M.F

・The M.F signal is input.

signal. ・Driver failure.

3.

The motor does not rotate.

・The same check items as

The motor behaves those under item 2 above.

abnormally. ・Setting of the PULSE INPUT ・Wrong setting for the pulse

The motor steps out. TYPE SELECT switch. input type.

・Connection of the pulse signal. ・Wiring error with the pulse

signal line.

・Voltage and wave form of the ・Pulse signal of wrong

pulse signal. specifications.

・Setting of the DRIVE CURRENT ・DRIVE CURRENT is too low.

SELECT switch.

・Setting of the STEP ANGLE ・Wrong setting for the step

SELECT switch.

angle.

・ON/OFF status of the C.S

・The C.S signal is input.

signal. ・Driver failure.

・Motor failure.

4.

The motor steps out ・Starting pulse speed. ・Starting pulse signal speed is

during acceleration.

too high.

・Acceleration time. ・Acceleration time is too short.

5.

The motor generates ・Setting of the DRIVE CURRENT ・DRIVE CURRENT is higher than

excessive heat.

SELECT switch.

the setting for the applicable

motor.

・Setting of the HOLD CURRENT ・The setting for HOLD CURRENT

SELECT switch.

is too high.

・Setting of the MOTOR SELECT ・Wrong setting for the motor

switch. selection.

6.

Overheat alarm signal ・Ambient temperature around ・Ambient temperature is too high

is output. the driver. (50℃ or more).

Short-circuiting of the motor output terminal may cause the driver to fail.

●

Short-circuiting between the motor output terminal and the earth terminal (PE)

●

Short-circuiting between the motor output terminal and the power line

●

Short-circuiting between the motor output terminal and the motor output terminal

●

Wiring error or snapping of the motor output lines

When the failure phenomenon cannot be remedied, contact our office.

Trouble

Check Item

Assumed Cause

-29-

GD-5610

Instructions Manual

9.Storing and Disposal

9-1.Storing

(1) Keep the product in the following environment:

●

Area that is free of explosive, corrosive or inflammable gas

●

Indoors (Area not exposed to direct sunshine)

●

Area that ambient temperature and humidity are controlled within the range

set out in the specifications

●

Area protected from dust, salt or iron particles

●

Area not subject to direct vibration or shock

●

Area not subject to splashing water, oil or chemicals

(2)

Do not allow standing or placing anything heavy on the product.

9-2.Disposal

(1) Dispose of the product as industrial waste.

-30-

GD-5610

Instructions Manual

10.Specifications

10-1.General Specifications

Single-phase 100-115V(50/60Hz) *1

●Rated power at DRIVE: 〔DRIVE I.SEL ⇒ No.F set up〕*2

AC100V : 5.9A AC115V : 5.9A

●Rated power at HOLD: 〔DRIVE I.SEL ⇒ No.F, HOLD I.SEL ⇒ 40% set up〕

AC100V : 0.5A or less AC115V : 0.5A or less

●DRIVE CURRENT 1.4A/phase~3.0A/phase (16 levels)

●HOLD CURRENT 10%~100% of DRIVE CURRENT (16 levels)

●Drive pulse input

(CW, CCW)

Photo-coupler input

●Motor excitation stop input (M.F) Photo-coupler input

●Step angle switch input

(C.S) Photo-coupler input

●Phase signal output (P.O) O/C output

●Overheat alarm signal output

(O.H.A) O/C output

●DRIVE CURRENT selection

(DRIVE I.SEL)

●HOLD CURRENT selection (HOLD I.SEL)

●STEP ANGLE selection (STEP SEL)

●PULSE INPUT TYPE selection

(SPI SEL)

●HOLD SWITCHING TIME selection

(DHT SEL)

●ROTATE CHARACTERISTIC selection (RC SEL)

●MOTOR selection

(OP1,OP2)

Indoor (Exposure to direct sunshine is not allowed.)

Without any explosive, corrosive or inflammable gas, oil mist, or dust

(At ordinary temperature and humidity)

*1 Input voltage range is single-phase 100-115V±10%.

*2 Power demand varies with rotation speed, a load, etc.

*3 Including screws and terminal blocks.

Atmosphere

Supply Power

(No freezing allowed)

Input Signal

Output Signal

Operating Ambient

Temperature

(No condensation allowed)

0℃ ~ +50℃

80%RH or less

-10℃ ~ +55℃

80%RH or less

H149.5 × W170 × D59 (mm) *3

0.9 kg

500VDC: 100MΩ or more

1500VAC: for one minute

500VDC: 100MΩ or more

Withstanding

Vibration

No abnormality should be found after a vibration test

at 10~55Hz, 0.15mm P-P.

AC terminal - signal terminal

Insulated

Withstanding Voltage

Exterior Dimensions

Weight

Insulation Resistance

Motor output current

(No condensation allowed)

Operating Ambient

Humidity

Storing Temperature

Storing Humidity

1500VAC: for one minute

Function of Operating

Sections

Altitude

Up to 1000m above sea level

(No freezing allowed)

-31-

GD-5610

Instructions Manual

10-2.Conforming to Europe standards and UL standards

This product conducted the validation test of low voltage directive and EMC directive

with TÜV(TÜV Japan) for self-declaration of the CE making.

(1) Safety standards

EN 61800-5-1

UL508C

*1

●Low voltage directive

This product is designed for use as a built-in component.

・Install the product within an enclosure in order to avoid contact with the hand.

・Securely ground the protective earth terminals.

●Installation conditions

Protective class:

Ⅰ

Overvoltage category:

Ⅱ (EN 61800-5-1), Ⅲ (UL508C)

Pollution degree:

Class 2

Protective type: IP10

*1 Warning for UL standards

This product has no provision for motor over temperature protection.

Motor over temperature protection is required in the end use product.

(2) EMC standards

EN 61800-3

●EMC derective

This product conducted EMC measurement with the system configuration for EMC.

・EMC characteristic may vary depending on the configuration of the equipment that

contains the driver or stepping motor. Be sure to conduct EMC measurement with

the product assembled in your equipment.

The metallic enclosure and shielded wires and ferrite core work to shield noise.

Configuration

User

controller

(Protective

classⅡ)

GD-5610

Metal Enclosure

Metal Enclosure

AC input

Transformer with

reinforced insulation

Shield

Metal Enclosure

Motor

Grounding

Ferrite core

GroundingGrounding

-32-

GD-5610

Instructions Manual

10-3.I/O Signal

(1) Example Circuit Connection

GD-5610

●

Power supply for I/O circuit shall be reinforced or double insulation

against hazardous voltage such as 100Vac mains.

Proving SELV≦60Vdc power supply circuit is necessary.

Example connection

of the user controller

CW+

5

CWP

CW-

6

3

12

11

4

1

2

9

10

CWP

CCW+CCWP

CCW-CCWP

+24V

M.F++COM

M.F-M.F

C.S

C.S++COM

C.S-

R.GND

7

8

+Vo

R

P.O

P.O+

R.GND

R

O.H.A O.H.A+

-Vo

(J1)

GND

GND

26LS31

Y

Z

26LS31

Y

Z

160Ω

160Ω

1.3kΩ

1.3kΩ

Photo-coupler

+24V

Photo-coupler

Photo-coupler

Photo-coupler

Photo-coupler

Photo-coupler

Photo-coupler

Photo-coupler

P.O-

O.H.A-

-33-

GD-5610

Instructions Manual

(2)

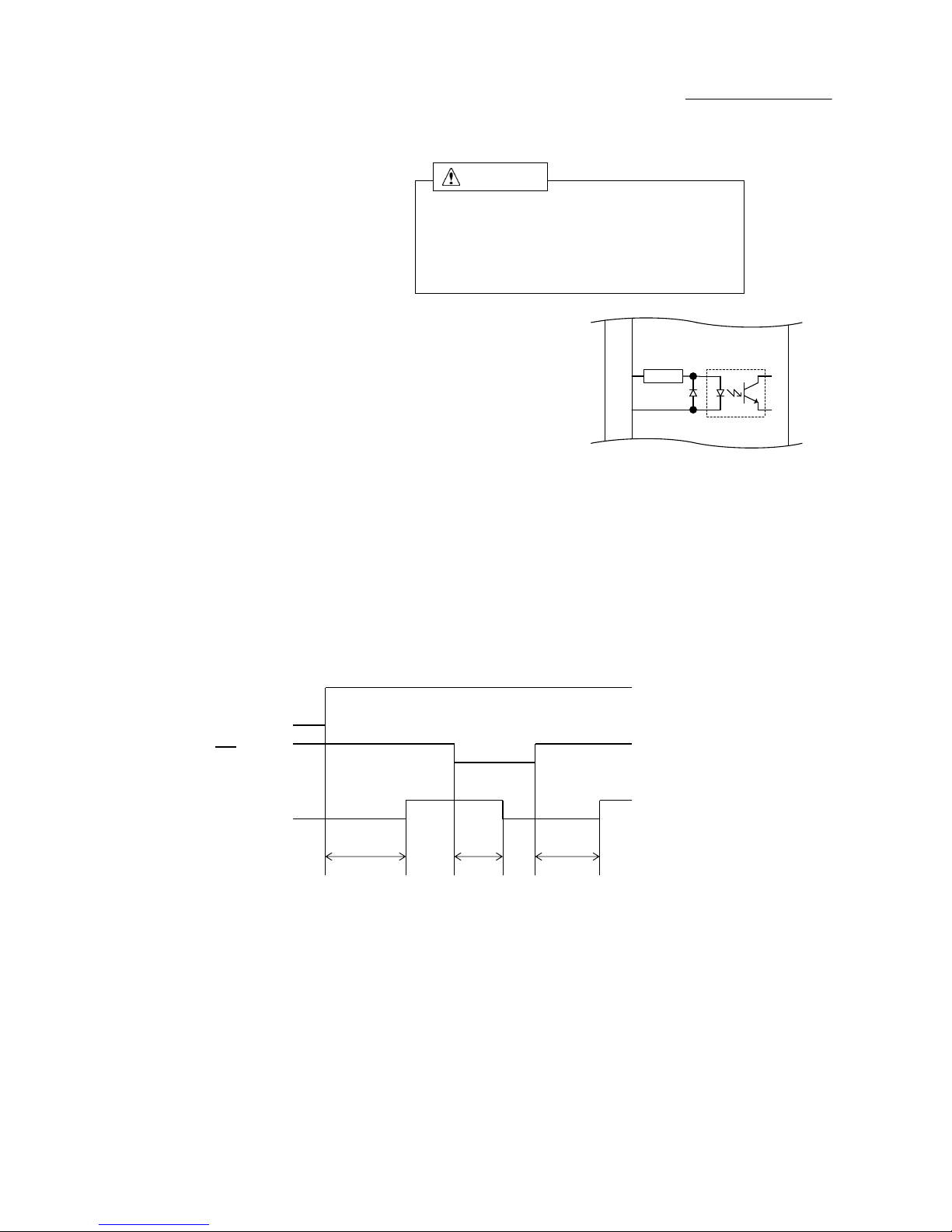

Drive pulse input(CW, CCW)

① Operating current range : 9mA~27mA

The photo-coupler turns on with GD-5610

inter-terminal voltage of 3.1 V~5.5 V.

(Photo-coupler diode VF≒ 1.6 V)

② Timing chart

[To the line driver 26LS31]

t1≧0.5μs, t2≧0.5μs, tf,tr≦1μs

t3≧1μs, t4>1μs

Maximum response frequency : 1MHz

(Duty 50%)

●

The shaded area ( ) indicates light emission from the photo-coupler,

and the motor is driven at the rising edge ( ).

"t4" greatly varies according to the inertial moment including that of the motor.

③ Automatic switching for DRIVE/HOLD

DRIVE

HOLD HOLD

t1

t1≒150ms (HOLD SWITCHING TIME SELECT switch : OFF)

t1≒1s (HOLD SWITCHING TIME SELECT switch : ON)

●

Inputting drive pulse causes the current output to the motor to change from

HOLD CURRENT to DRIVE CURRENT, which returns to HOLD CURRENT in "t1".

DRIVE CURRENT continues if pulse is input on driving-state.

④ Direction of rotation

CCW

CW(Clockwise)

CWP

CCWP

Motor

current

CW+ (CCW+)

26LS31

Y

Z

CW- (CCW-)

CWP

90%

10%

t1 t2

tf tr

t3 t4

CCWP

CW-

CCW+

CCW-

CW+

3

4

1

2

(J1)

Photo-coupler

160Ω

160Ω

Photo-coupler

-34-

GD-5610

Instructions Manual

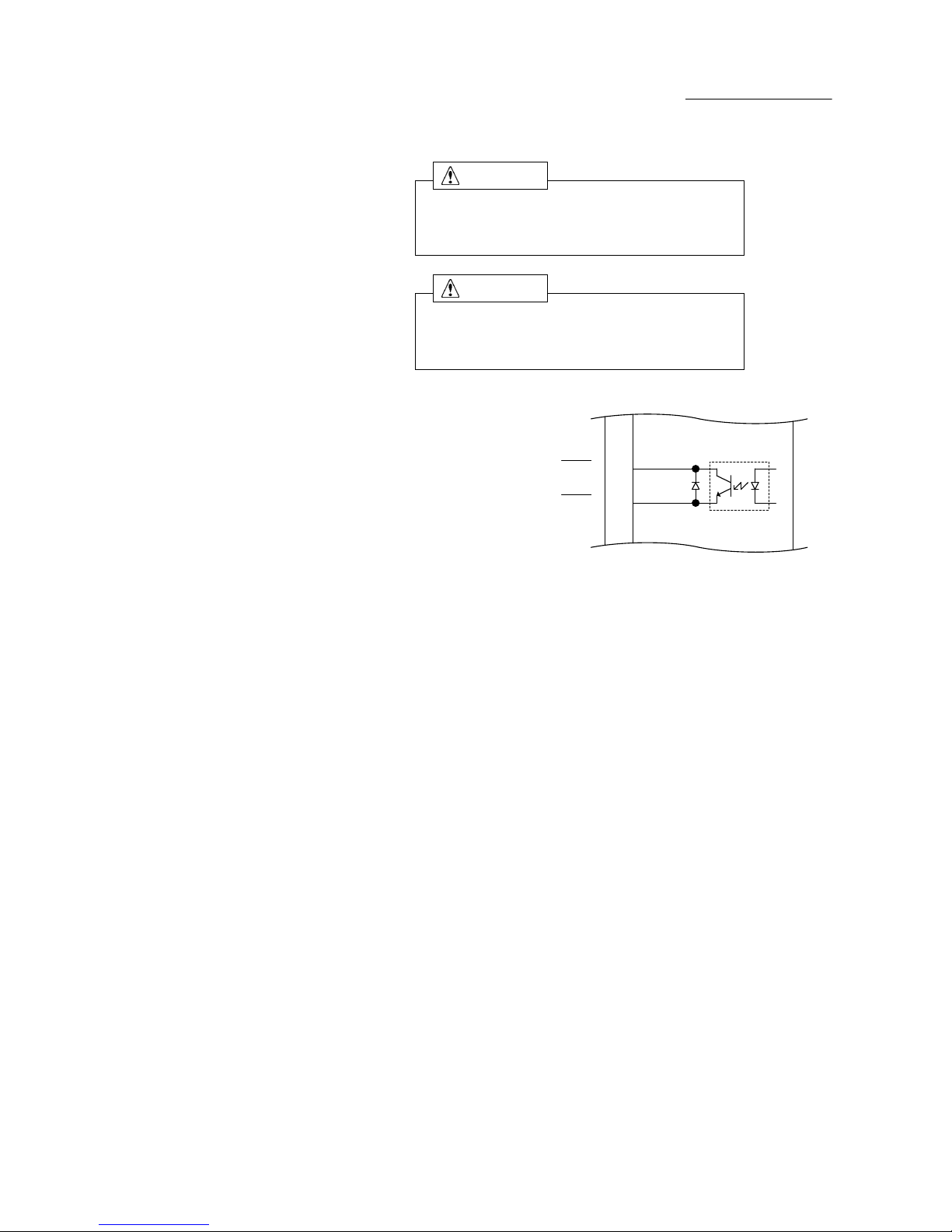

(3) Motor excitation stop input(M.F)

Deterioration of the holding power with

the motor may cause breakage of the machine

or injury.

Check safety before inputting.

① Operating current range : 2.6mA~19.5mA GD-5610

The photo-coupler turns on with

inter-terminal voltage of 4.5V~26.4V.

(Photo-coupler diode VF≒ 1.1 V)

●

Motor output current is shut off with the photo-coupler ON.

At this time, motor torque changes to detent torque.

●

When this signal is input, motor torque may be lost, resulting in failure to

retain the load transported.

In particular, this risk is high with the vertical drive (such as the Z-axis).

② Timing chart

Supply

power

M.F

t1 t2

t1≦1.5s (t1:Time required for the motor to be enabled.)

t2≦5ms (t2:Time required for the motor output current to be shut off.)

t3≦100ms (t3:Time required for the motor to be enabled.)

t3

Motor

excitation

OFFONOFFONON

ON

5

6

M.F+

M.F-

(J1)

Photo-coupler

1.3kΩ

CAUTION

-35-

GD-5610

Instructions Manual

(4) Phase signal output(P.O)

① Output current

a.

IC≦6mA, VCE<2V

b.

IC≦2mA, VCE(sat)<0.6V GD-5610

VCEO≦30V

●

In case of the excitation home position, the signal is output.

(photo-coupler ON)

●

In case of simultaneously using P.O signal and C.S signal,

input C.S signal while P.O signal is being output to switch the step angle.

Otherwise, P.O signal may not be output.

② Timing chart

●

P.O output timing (for 1/1 STEP)

CWP

CCWP

P.O

7.2°

(For a motor with the basic angle of 0.72°)

●

P.O output time

1/1 STEP: once in 10 pulses 1/8 STEP: once in 80 pulses

1/2 STEP: once in 20 pulses 1/16 STEP: once in 160 pulses

1/4 STEP: once in 40 pulses 1/80 STEP: once in 800 pulses

1/10 STEP: once in 100 pulses 1/160 STEP: once in 1600 pulses

1/20 STEP: once in 200 pulses

1/40 STEP: once in 400 pulses

1/100 STEP: once in 1000 pulses

1/200 STEP: once in 2000 pulses

1/400 STEP: once in 4000 pulses

1/800 STEP: once in 8000 pulses

5678123410901

2

7

8

P.O+

(J1)

Photo-coupler

P.O-

-36-

GD-5610

Instructions Manual

(5) Overheat alarm signal output(O.H.A)

Overheating may cause fire.

Stop operation upon output of this signal.

Overheating may cause fire.

Stop operation when this LED comes on.

① Output current

a.

IC≦6mA, VCE<2V

b.

IC≦2mA, VCE(sat)<0.6V GD-5610

VCEO≦30V

●

Use overheat alarm signal output(O.H.A)without fail.

●

In case of internal temperature of the driver reaches approx. 65℃ or more,

this signal is output (photo-coupler ON) and O.H.A LED comes on.

At this time the motor output current is not blocked.

●

When this signal is output, stop operation and check if there is any

abnormality occurring with the motor and the driver.

●

Perform the cooling measure of the mounting plate is enlarged or

compulsion air cooling, for example, if this signal is output

while no abnormality is detected.

●

Continuous operation is possible unless this signal is output.

9

10

O.H.A+

(J1)

Photo-coupler

O.H.A-

WARNING

WARNING

-37-

GD-5610

Instructions Manual

(6)

Step angle switch input(C.S)

① Operating current range : 2.6mA~19.5mA

The photo-coupler turns on with GD-5610

inter-terminal voltage of 4.5V~26.4V.

(Photo-coupler diode VF≒ 1.1 V)

●

Step angle division is switched to 1/20 divisions with the photo-coupler ON.

The setting for the STEP ANGLE SELECT switch is ignored.

●

No displacement occurs even if the step angle is switched by the C.S signal.

② Timing chart

Number of divisions 1/20divisions Number of divisions

of STEP SEL switch of STEP SEL switch

ON OFF

C.S

t1≧30ms

t2≧ 1ms

●

Switching the step angle by the C.S signal requires time t1 and t2 before

and after inputting drive pulse.

③ STEP ANGLE SELECT switch and C.S signal

〔When the C.S signal is input〕

1/20 (0.036°)

8

2

1/2

1/4

1/10

0.0009

1/400

1/800

0.0018

9

1/20

1/40

1/10056

0.36

1

0.18

0.0036

0.018

0.0072

0.036

0.072

7

1/200

CWP

CCWP

t1t2t1

0.72

1/

Divisions

Switch No.

t2

A--34

0

1/1

Step angle(°)

0.72°motor

B--

C

1/8

0.09

F

1/160

0.0045

D

1/16

0.045

E

1/80

0.009

11

12

C.S+

C.S-

(J1)

Photo-coupler

1.3kΩ

-38-

GD-5610

Instructions Manual

10-4.Dimensions

(Unit:mm)

149.5

135 (14.5)

142

14

14

170

(5) 160 (5)

(59)

7.62

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

MOTOR

!

GD-5610

J1

1

12

POWER

OHA

OP2

ON←

OP4

OP5

OP3

OP1

SPI

DRIVE

HOLD

STEP

J3

J2

3

4

5

2

1

1

23L

N

115V~

100V

DHT

RC

(3)

16.5 20 16.5

53

(59)

(3)

37

20

16

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

R2.254.5

2

1

J3

5

4

3

RED/GRY

VIO/BLU

BLK/YLW

WHT/ORN

GRN/BRN

GRN

BLK

BLU

RED

ORN

GD-5610

100-115V~

5.9A

1φ50/60Hz

Melec Inc.

MADE IN JAPAN

R

-39-

GD-5610

Instructions Manual

㸯㸮㸫㸳㸬$SSOLFDEOH0RWRUV

R1

ە

GD-5610 can drive a 5-phase stepping motors of 2.4 - 2.8A/phase.

PKP564FN24A(B)2

PKP566FN24A(B)2

PKP569FN24A(B)2

PKP564N28A(B)2

PKP566N28A(B)2

PKP568N28A(B)2

PK569H-A(B)

PK596H-A(B)

PK599H-A(B)

SF5601-9251

SF5602-9251

SF5603-9251

( ) : Both axes

ە

When use a non-applicable motor, contact our office.

Fig.12

0.72 2.8

D

OFF

OFF

OFF

Fig.10

Fig.11

ڧPP

0.72 2.8

D

ڧPP

2.8

2.8

D

Basic

Angle

r

Current

(A/phase)

0.72

0.72

OP1

switch

OP2

switch

0.72 2.4

Basic

Angle

r

Current

(A/phase)

D

ڧPP

ORIENTAL MOTOR CO., LTD.

DRIVE

I.SEL

switch

RC SEL

switch

9

Torque Data

Fig. No.

Fig.1

Fig.2

Fig.3

Fig.4

ON

OFF

OFF

OFF

OFF

OFF Fig.5

Fig.6

OP1

switch

OFF

OFF

OFF

OFF

ON

ON

OP2

switch

Torque Data

Fig. No.

ڧPP

ڧPP

Fig.7

Fig.8

Fig.9

DRIVE

I.SEL

switch

SANYO DENKI CO., LTD.

RC SEL

switch

-40-

GD-5610

Instructions Manual

10-6.Torque Characteristics

(1)

Representations in the torque characteristics table are made in terms of the

motor rotation speed (s-1) vs. torque (N・m).

Motor rotation speed (s-1) and drive pulse frequency (Hz) are converted as follows:

360°

Step angle

●

Maximum value of the rotation speed is 60s-1 at 0.72゜ motor.

(2) The Maximum Starting Pulse Rate is represented as "fs" by the value at zero

inertial load.

(3) Upon operation, provide adequate allowance for torque.

(4)

The stepping motor may attain high temperature, depending on the operational

conditions.

Use the stepping motor according to the Instructions Manual produced

by motormakers.

×=Drive pulse input frequency(Hz)

-1

)

-41-

GD-5610

Instructions Manual

R1

Fig.1

OP1,OP2 = ON,ON

AC100V

1.0

0.8

0.6

0.4

0.2

HOLD 40㸣 = 0.30N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s )

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

PKP564FN24A(B)2

2.4A/PHASE

GD-5610

DRIVE I.SEL = No.9(2.4A/PHASE)

Fig.2

OP1,OP2 = ON,ON

AC100V

2.0

1.6

1.2

0.8

0.4

HOLD 40㸣 = 0.53N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s

)

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

PKP566FN24A(B)2

2.4A/PHASE

GD-5610

DRIVE I.SEL = No.9(2.4A/PHASE)

Fig.3

OP1,OP2 = ON,ON

AC100V

2.5

2.0

1.5

1.0

0.5

HOLD 40㸣 = 0.94N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s

)

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

PKP569FN24A(B)2

2.4A/PHASE

GD-5610

DRIVE I.SEL = No.9(2.4A/PHASE)

Fig.4

OP1,OP2 = OFF,OFF

AC100V

1.0

0.8

0.6

0.4

0.2

HOLD 40㸣 = 0.18N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s

)

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

PKP564N28A(B)2

2.8A/PHASE

GD-5610

DRIVE I.SEL = No.D(2.8A/PHASE)

Fig.5

OP1,OP2 = OFF,OFF

AC100V

2.0

1.6

1.2

0.8

0.4

HOLD 40㸣 = 0.33N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s )

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

PKP566N28A(B)2

2.8A/PHASE

GD-5610

DRIVE I.SEL = No.D(2.8A/PHASE)

Fig.6

OP1,OP2 = OFF,OFF

AC100V

2.5

2.0

1.5

1.0

0.5

HOLD 40㸣 = 0.61N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s )

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

PKP568N28A(B)2

2.8A/PHASE

GD-5610

DRIVE I.SEL = No.D(2.8A/PHASE)

-42-

GD-5610

Instructions Manual

R1

Fig.7

OP1,OP2 = OFF,OFF

AC100V

2.5

2.0

1.5

1.0

0.5

HOLD 40㸣 = 0.81N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s

)

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

PK569H-A(B)

2.8A/PHASE

GD-5610

DRIVE I.SEL = NO.D(2.8A/PHASE)

Fig.8

OP1,OP2 = OFF,OFF

AC100V

5.0

4.0

3.0

2.0

1.0

HOLD 40㸣 = 1.01N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s

)

-1

RC SEL = ON

PULLOUT TORQUE

INPUT CURRENT

fs

PK596H-A(B)

2.8A/PHASE

GD-5610

DRIVE I.SEL = No.D(2.8A/PHASE)

Fig.9

OP1,OP2 = OFF,OFF

AC100V

5.0

4.0

3.0

2.0

1.0

HOLD 40㸣 = 1.97N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s )

-1

RC SEL = ON

PULLOUT TORQUE

INPUT CURRENT

fs

PK599H-A(B)

2.8A/PHASE

GD-5610

DRIVE I.SEL = No.D(2.8A/PHASE)

Fig.10

OP1,OP2 = OFF,OFF

AC100V

1.0

0.8

0.6

0.4

0.2

HOLD 40㸣 = 0.25N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s )

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

SF5601-9251

2.8A/PHASE

GD-5610

DRIVE I.SEL = No.D(2.8A/PHASE)

Fig.11

OP1,OP2 = OFF,OFF

AC100V

2.0

1.6

1.2

0.8

0.4

HOLD 40㸣 = 0.40N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s

)

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

SF5602-9251

2.8A/PHASE

GD-5610

DRIVE I.SEL = NO.D(2.8A/PHASE)

Fig.12

OP1,OP2 = OFF,OFF

AC100V

2.5

2.0

1.5

1.0

0.5

HOLD 40㸣 = 0.74N࣭m

2

4

6

8

10

TORQUE(N࣭m)

INPUT CURRENT(A)

0.02 0.1 1 10 100

(s

)

-1

RC SEL = OFF

PULLOUT TORQUE

INPUT CURRENT

fs

SF5603-9251

2.8A/PHASE

GD-5610

DRIVE I.SEL = No.D(2.8A/PHASE)

-43-

GD-5610

Instructions Manual

The main parts which revised by this manual

࠙5ࠚ

Addition of the motors.

Parts Content

P40,P42,P43

-44-

Technical Service

TEL.(042)664-5382 FAX.(042)666-5664

E-mail s-support@melec-inc.com

Sales and Service

TEL.(042)664-5384 FAX.(042)666-2031

URL:http://www.melec-inc.com

Melec Inc. Control equipment marketing department

516-10,Higashiasakawa-cho,Hachioji-shi,Tokyo 193-0834,Japan

This Operating Manual is subject to change without prior notice

for the purpose of product improvement.

C1703

Loading...

Loading...